Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve maintenance ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seed coatings, coating compositions and methods for use

InactiveUS20120220454A1Promote seedling establishmentEasy to keepBiocideDead plant preservationCoatingFood science

Coating compositions and methods of use, allowing for improved water and / or nutrient usage by seeds, plants, shrubs, and vegetation, among others, are disclosed.

Owner:RHODIA OPERATIONS SAS

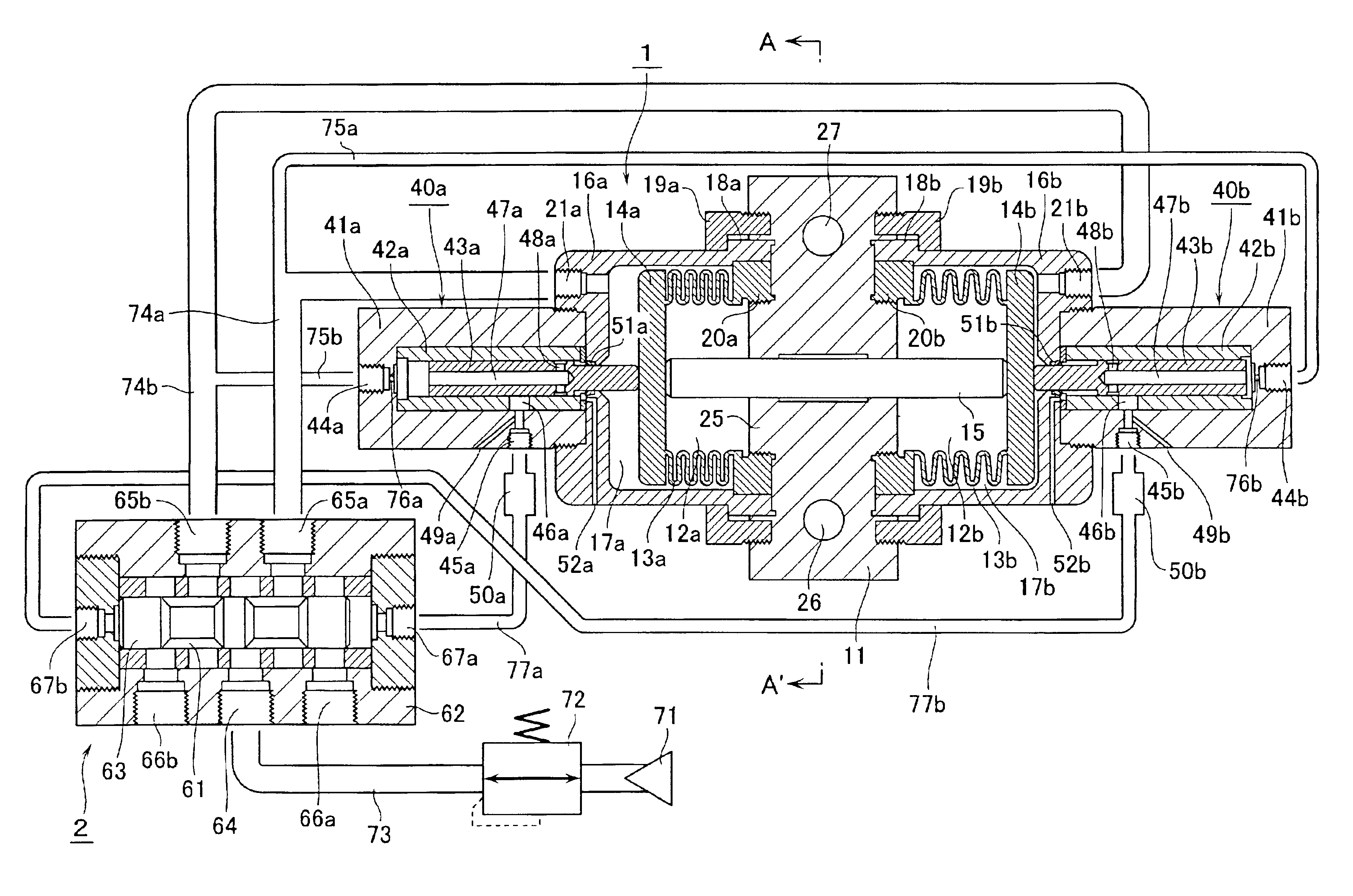

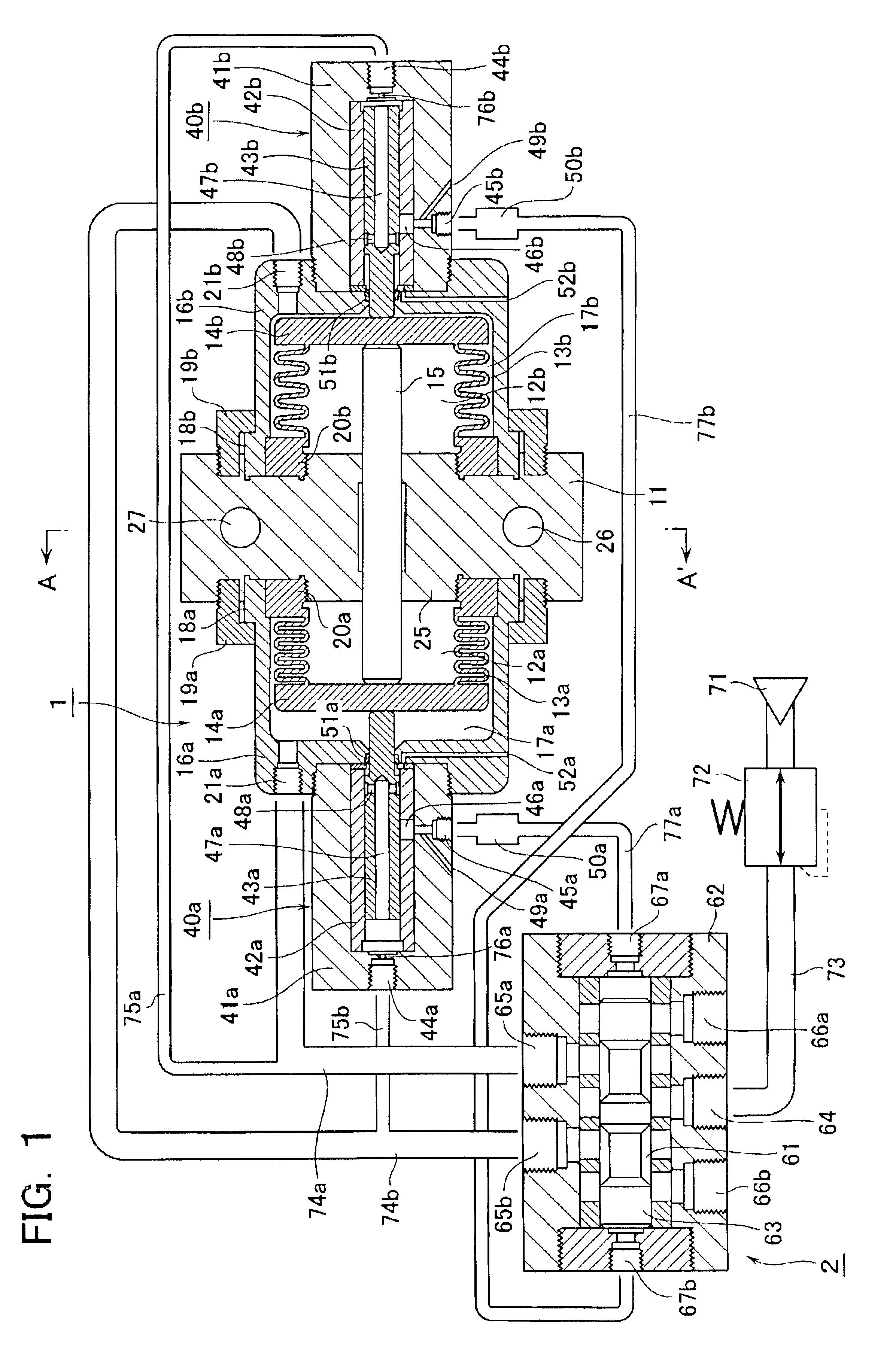

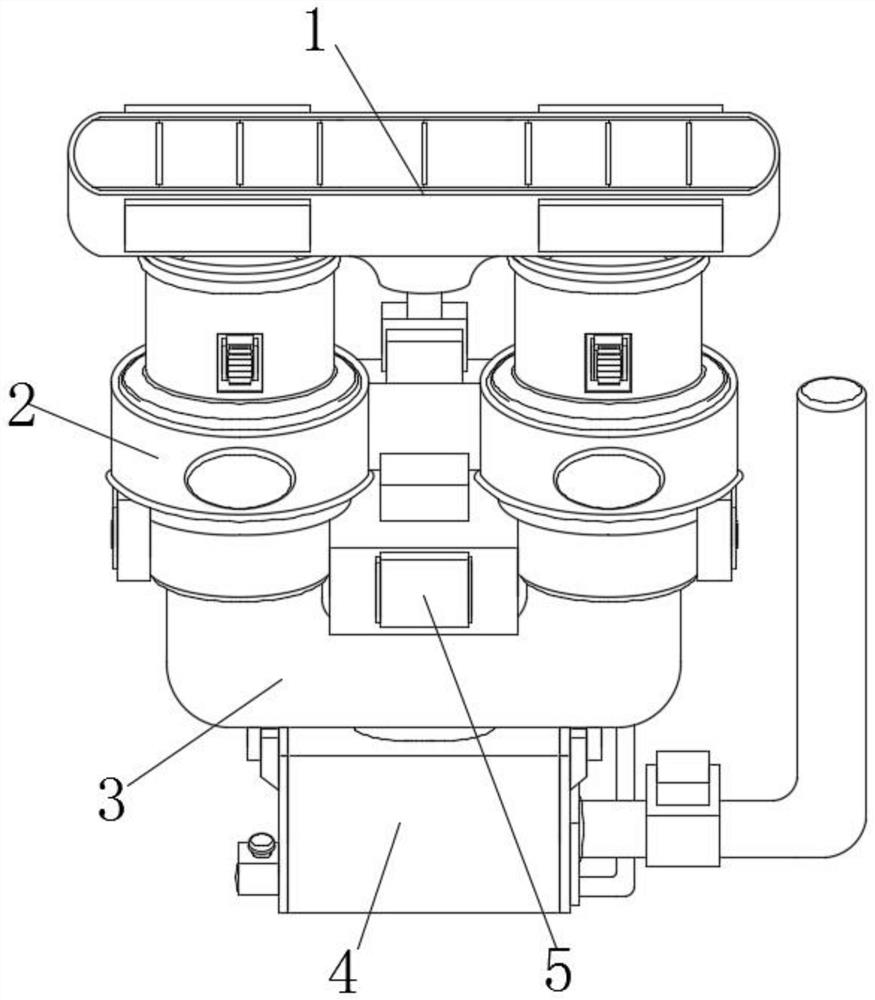

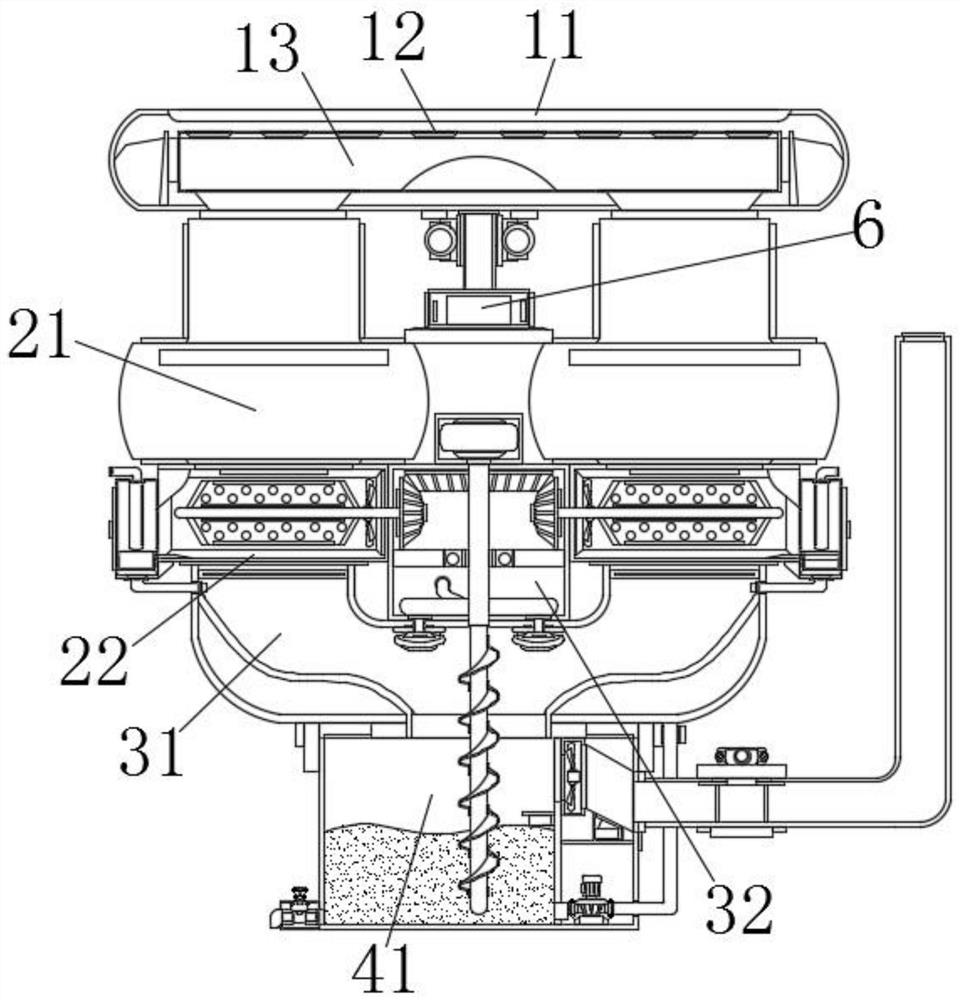

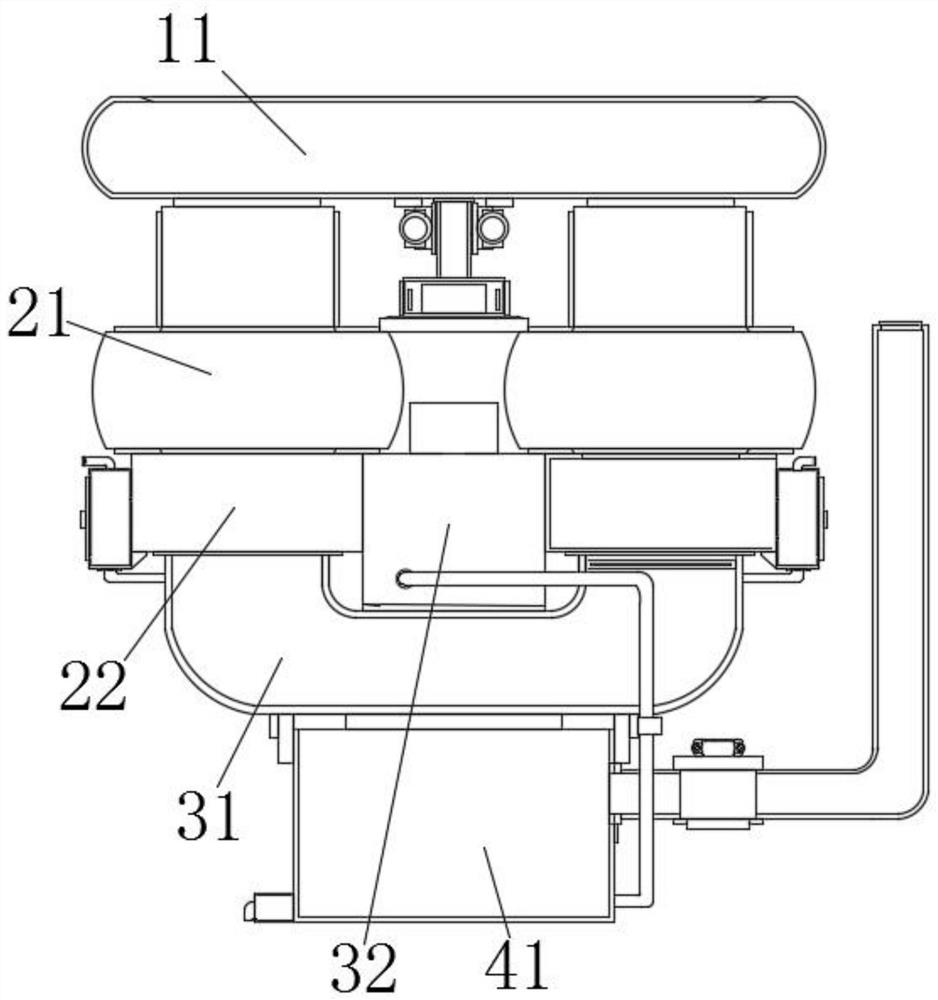

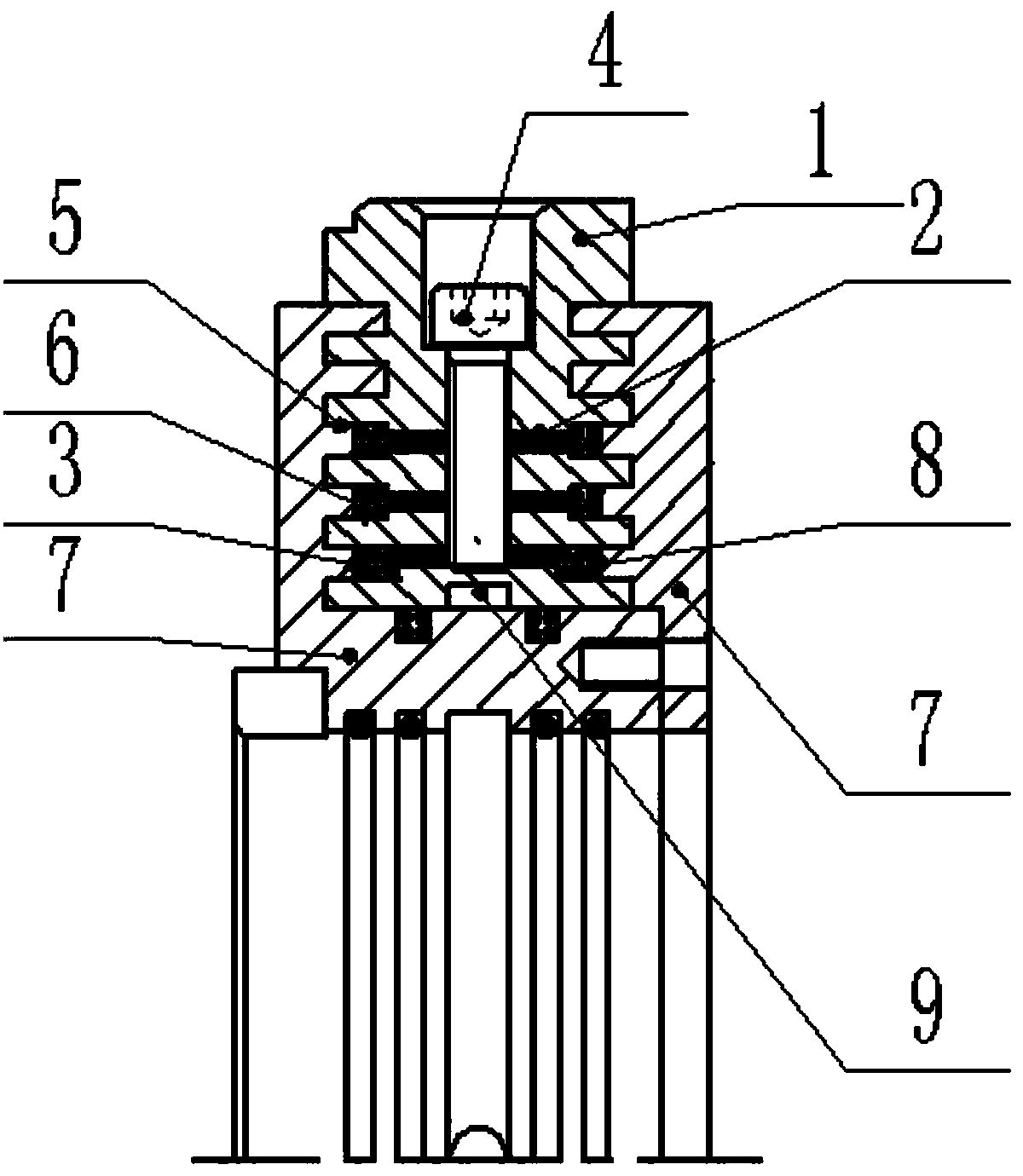

Pump system using a control fluid to drive a switching valve mechanism for an actuating fluid

InactiveUS6874997B2Good compatibilityImprove maintenance abilityLiquid surface applicatorsValve drivesEngineeringAir chamber

There is provided a pump system excellent in a maintenance ability and compatibility. The pump system comprises a pump (1) for transferring a liquid by alternately supplying air to air chambers (17a, 17b) to extend and contract a pair of bellows (13a, 13b) linked to a shaft (15). It also comprises a switching valve mechanism (2) for switching the air supplied to the pump (1). Switching mechanisms (40a, 40b) are employed to switch the pilot air for controlling the switching operation of the switching valve mechanism (2). The switching mechanisms are detachably attached to cases (16a, 16b) of the pump (1) from outside.

Owner:IWAKI

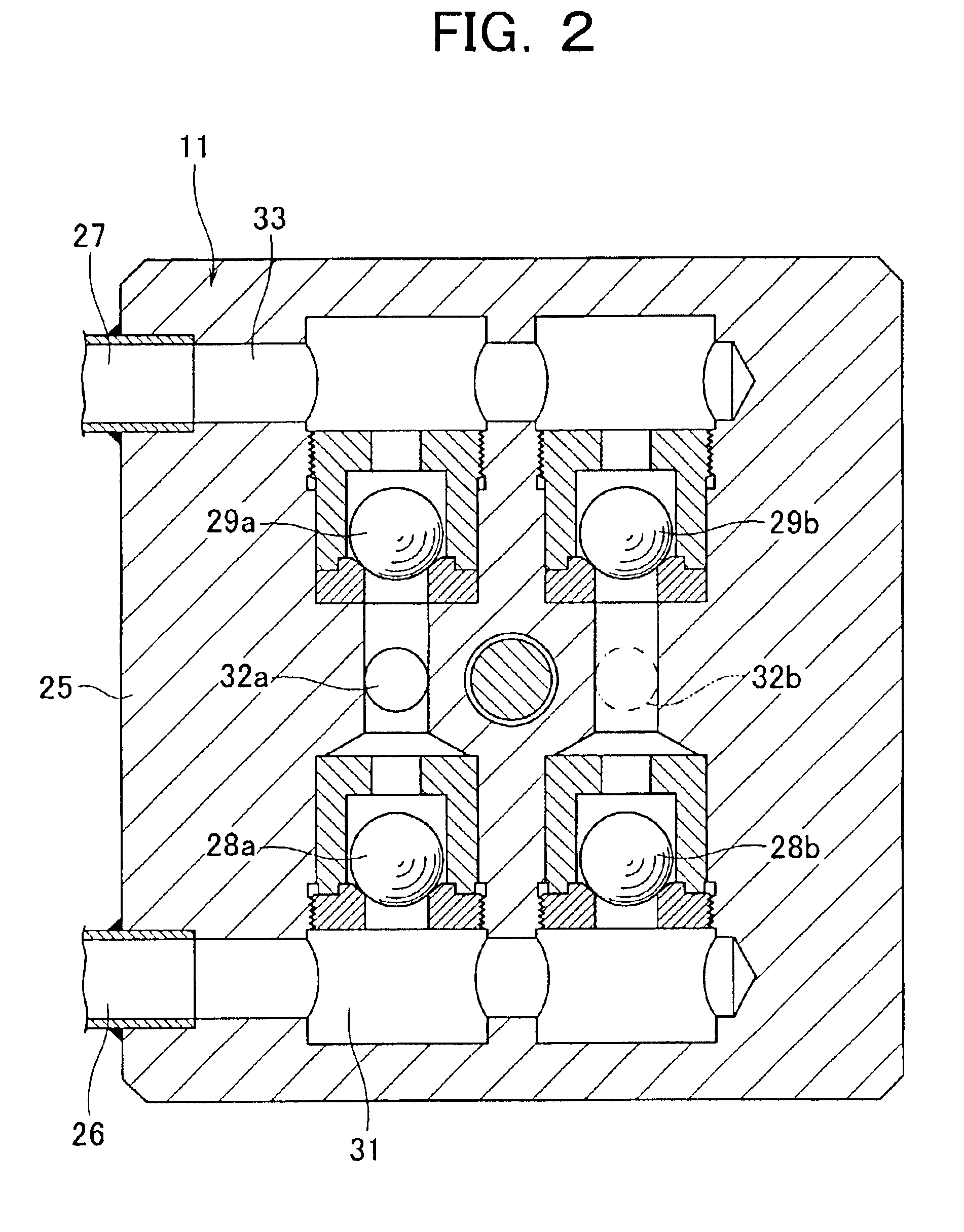

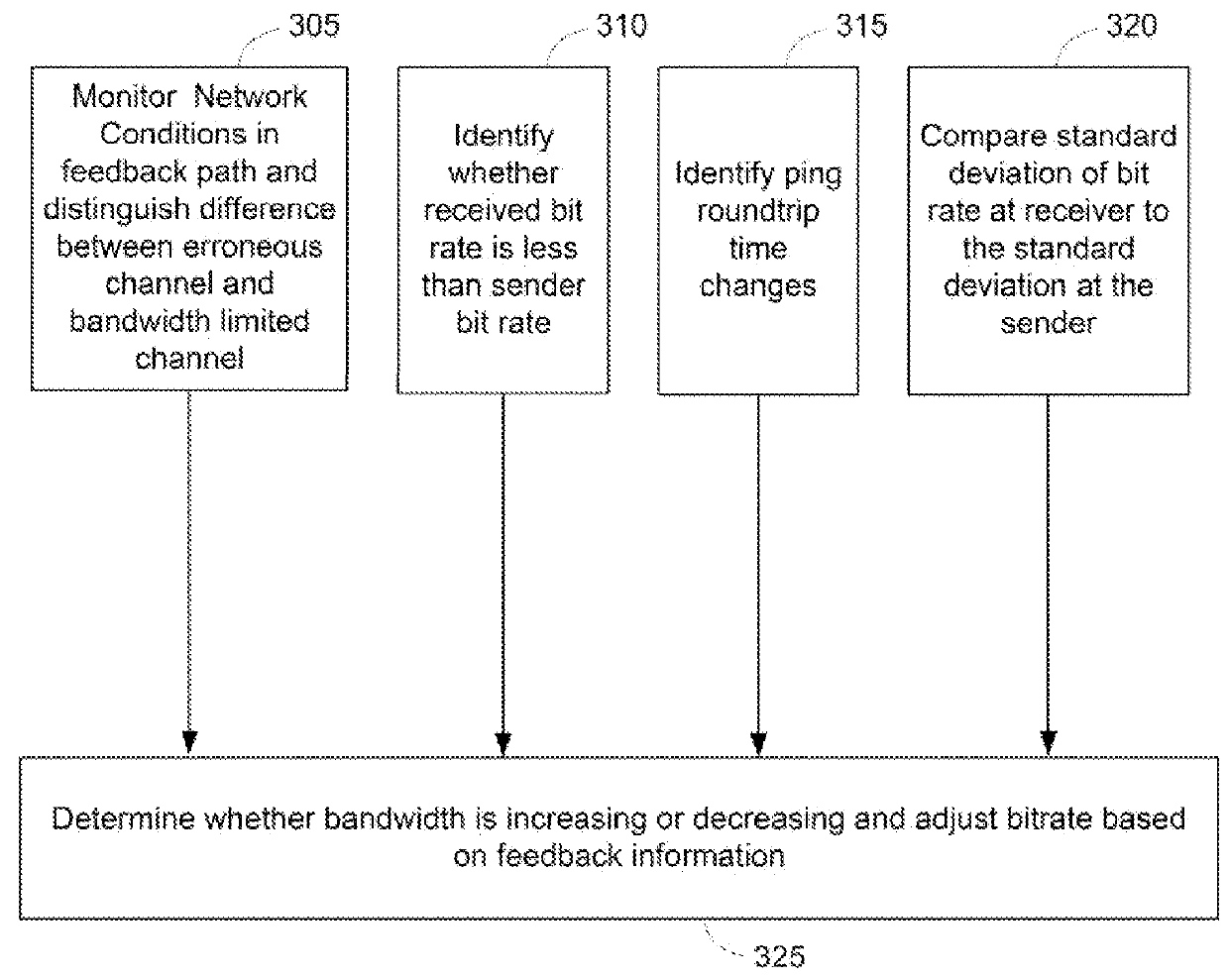

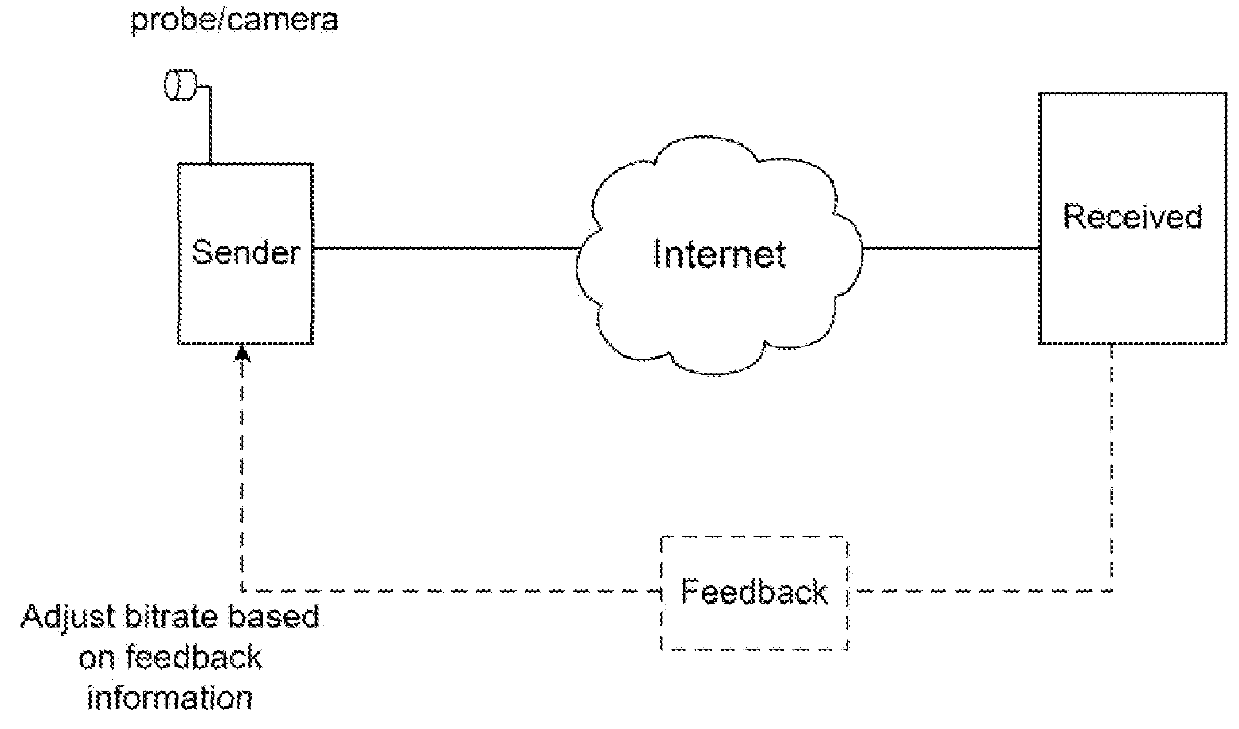

Video enhancements for live sharing of medical images

InactiveUS20160055305A1Improve maintenance abilityMeet cutting requirementsTelevision conference systemsTelemedicineReal time analysisNetwork conditions

In a telemedicine application there is live sharing of a video stream of medical images from a first site to a second site as well as a two-way conferencing capability. Live streaming of medical images in a live interactive session imposes many limitations on the video streaming process not found in conventional video conferencing. The network conditions are heterogeneous and low latency is required to support: 1) live streaming of medical images to a remote site and 2) supporting two-way conferencing in which a doctor or clinician at the remote site can provide real-time analysis or guidance on how to adjust a location of an imaging device. A suite of video enhancements is disclosed to improve the capability to sustain live video streaming of medical images in a telemedicine environment including a two-way conference between doctors or clinicians.

Owner:EAGLEYEMED

Fluorine-containing rubber composition

InactiveUS6503986B1Enhanced radiationHigh transparencyOther chemical processesSemiconductor/solid-state device detailsPolymer scienceMulti segment

To provide a fluorine-containing rubber composition comprising (a-1) a non-perfluoro fluorine-containing rubber and (b-1) a fluorine-containing multi-segment polymer comprising an elastomeric fluorine-containing polymer chain segment and non-elastomeric fluorine-containing polymer chain segment, in which structural units of each of the elastomeric fluorine-containing polymer chain segment and the non-elastomeric fluorine-containing polymer chain segment comprise not less than 90% by mole of a perhalo olefin unit. The fluorine-containing rubber composition is capable of providing a clean sealing material for semi-conductor production apparatuses without using a filler.

Owner:DAIKIN IND LTD

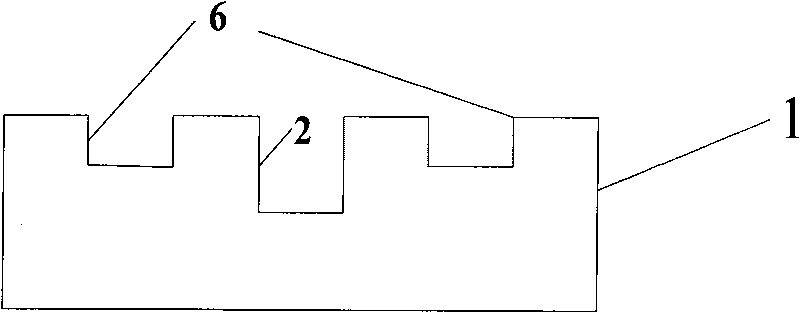

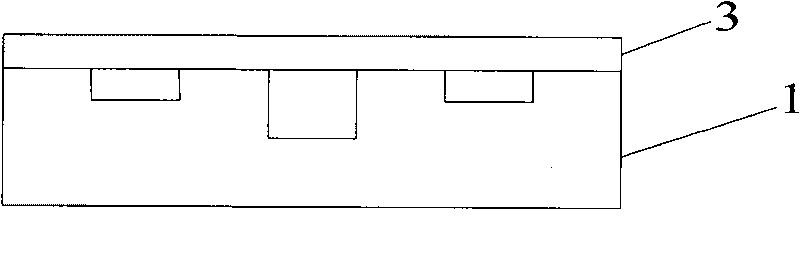

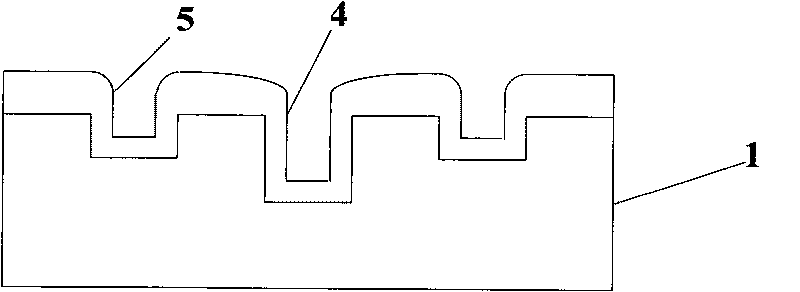

MEMS wafer level vacuum packaging process

ActiveCN101723308AIncreased vacuum holding capacitySolve the flatnessDecorative surface effectsChemical vapor deposition coatingEngineeringPressure difference

The invention discloses an MEMS glass microcavity vacuum packaging process with long vacuum maintaining time, which comprises the following steps of: firstly, etching a deep packaging groove on a Si wafer by using an Si microprocessing process and etching a relatively shallower annular vacuum buffer groove at the periphery of the deep packaging groove; then bonding the Si wafer etched with the microgroove and a glass wafer so that the glass wafer and the specific pattern form a packaging cavity; heating and preserving the temperature of the bonded wafer at atmosphere pressure and leading softened glass to flow into the packaging cavity by a pressure difference inside and outside the cavity so as to form a microcavity structure corresponding to the microcavity pattern structure; cooling and annealing and removing stress of the wafer at normal pressure; then corroding to remove the Si wafer; and carry out anode bonding on the Si wafer and the glass wafer at the atmosphere of 1Pa-10Pa to form the integral vacuum packaging. The invention improves the maintaining capability of vacuum degree in the packaging cavity by manufacturing the annular vacuum buffer cavity at the periphery of the packaging cavity.

Owner:SOUTHEAST UNIV

Biopolymer-based seed coatings compositions and methods for use

ActiveUS20190150354A1Promote seedling establishmentEasy to keepAmylose/amylopectin coatingsDextran coatingsCross-linkCellulose

A seed or seedling is coated with a cross-linked biopolymer and, optionally, a second binder selected from underivatized guar, cationic hydroxypropyl guar, polyacrylamide, poly(methacrylic acid), poly(acrylic acid), polyacrylate, poly(ethylene glycol), polyethyleneoxide, polyamide, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, underivatized starch, cationic starch, corn starch, wheat starch, rice starch, potato starch, tapioca, waxy maize, sorghum, waxy sarghum, sago, dextrin, chitin, chitosan, xanthan gum, carageenan gum, gum karaya, gum arabic, pectin, cellulose, hydroxycellulose, hydroxyalkyl cellulose, hydroxyethyl cellulose, carboxymethylhydroxyethyl cellulose, or hydroxypropyl cellulose. The seed coating composition is characterized by a dust value, as measured using a Heubach dustmeter device, which is lower by at least 30% as compared to an analogous composition that does not contain the crosslinked biopolymer.

Owner:RHODIA OPERATIONS SAS

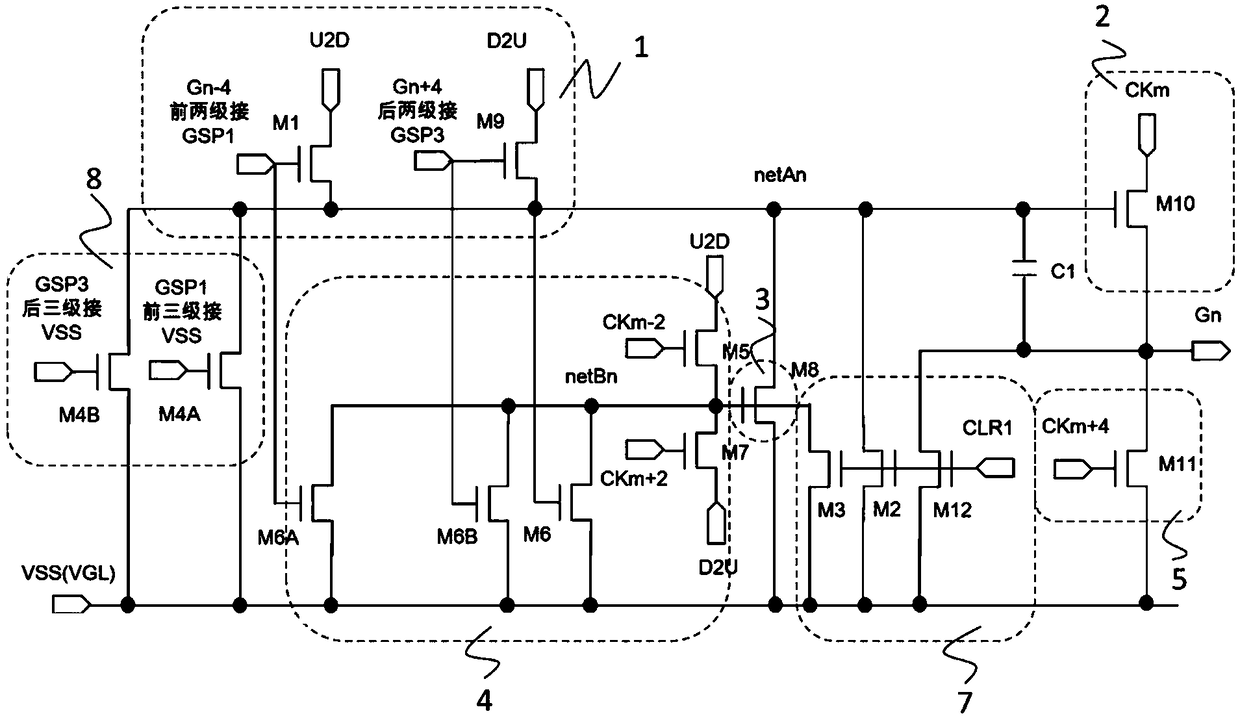

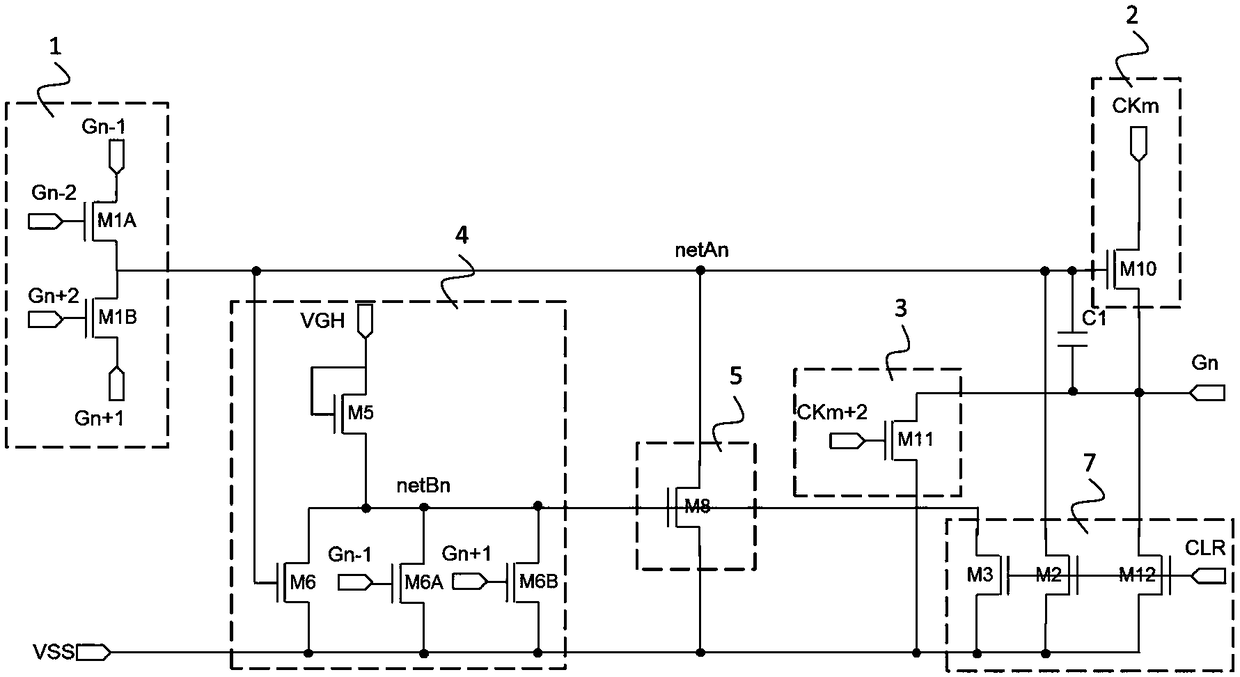

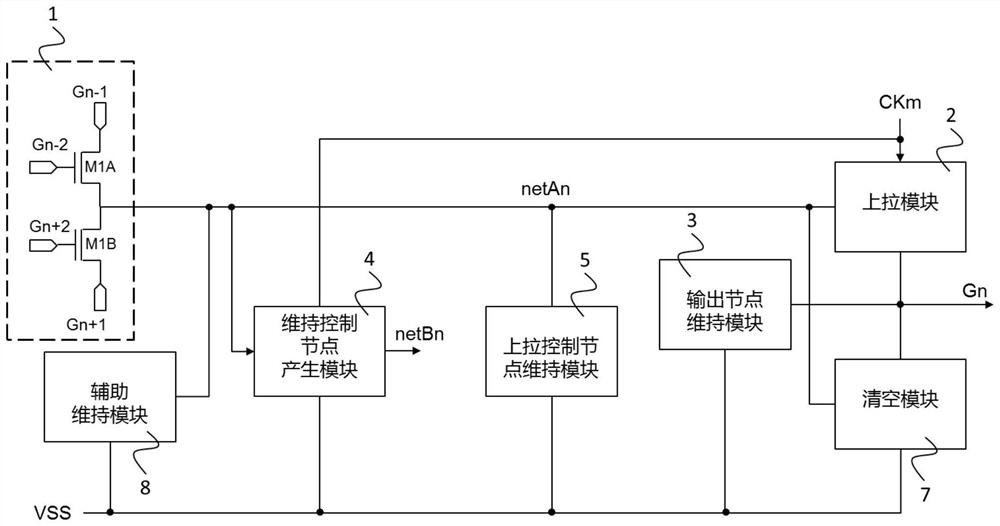

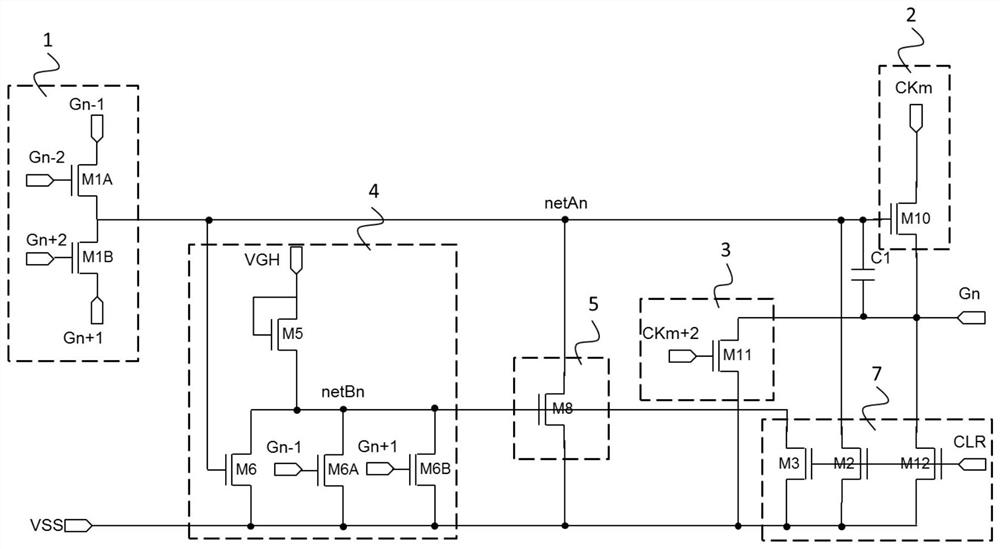

Gate scanning driving circuit

ActiveCN108154856AAvoid functional failureReduce in quantityStatic indicating devicesComputer moduleEngineering

The invention discloses a gate scanning driving circuit. The gate scanning driving circuit comprises N (N is larger than 4 and is a positive integer) driving circuit units; a nth (n is larger than orequal to 1 and smaller than or equal to N, and is a positive integer) driving circuit unit comprises a pull-up control module, a pull-up module, an output-node maintaining module, a maintaining-control-node generating module and a pull-up control node maintaining module; the pull-up control module of the nth driving circuit unit comprises two thin film transistors, one thin film transistor is subjected to precharging of forward-and-reverse scanning controlling with scanning signals of a (n-1)th driving circuit unit and a (n-2)th driving circuit, and the other thin film transistor is subjectedto precharging of forward-and-reverse scanning controlling with scanning signals of a (n+1)th driving circuit unit and a (n+2)th driving circuit. Bias stress and threshold voltage shift of the thin film transistors are reduced, and the stability of the circuit is enhanced.

Owner:NANJING CEC PANDA LCD TECH

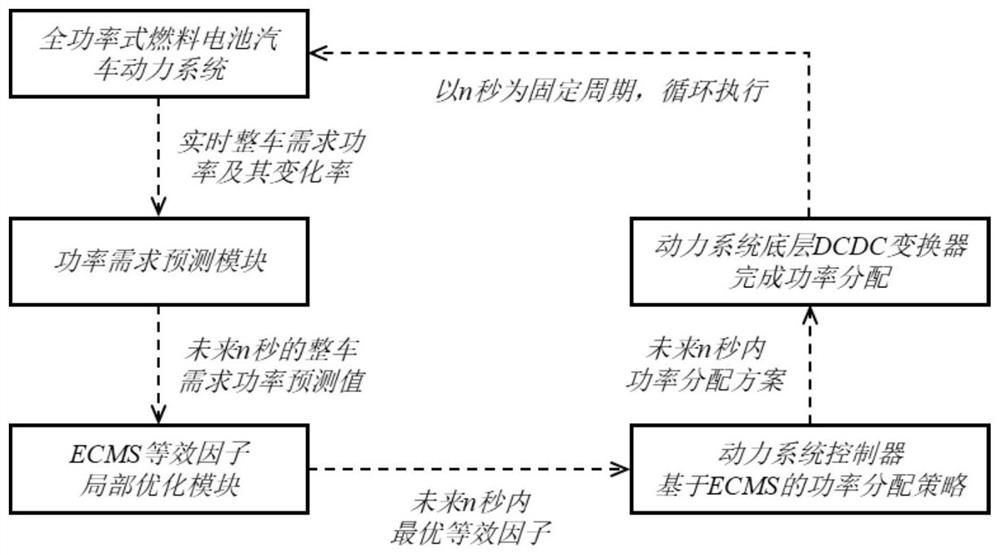

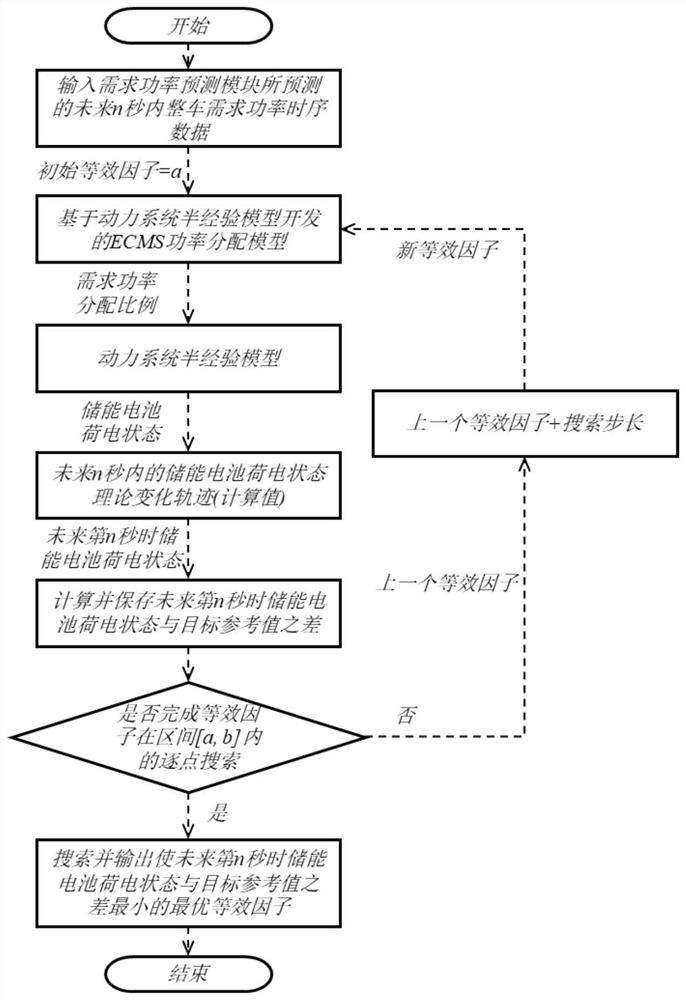

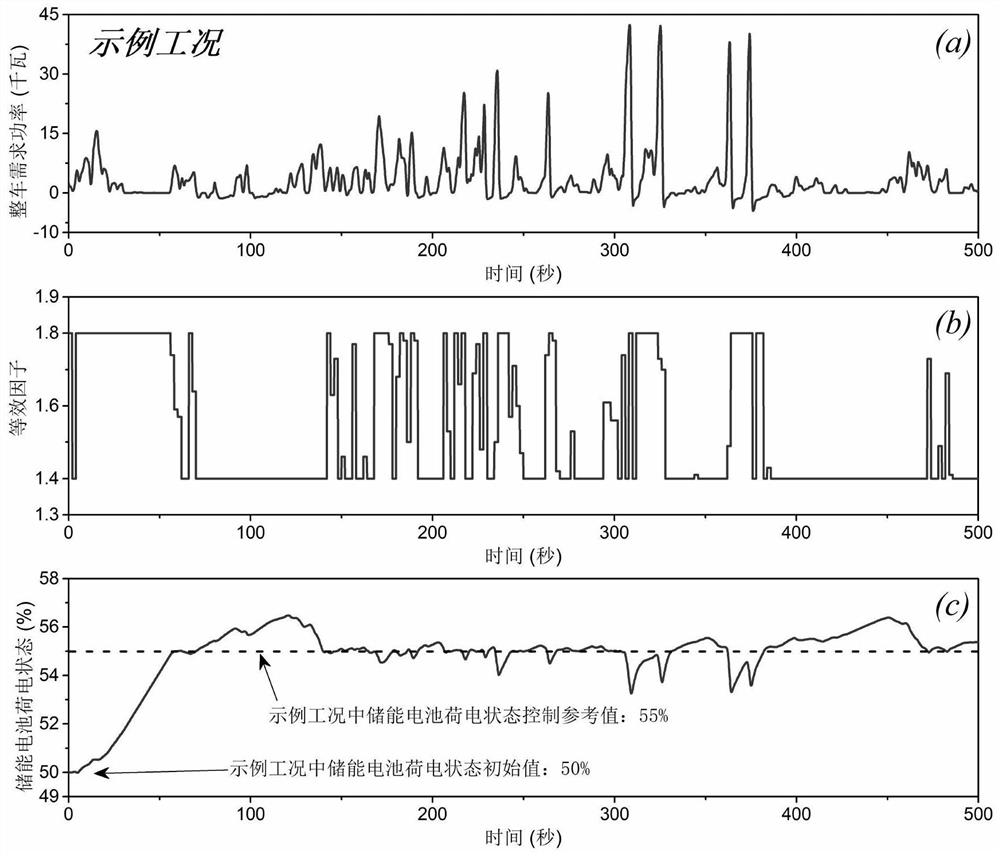

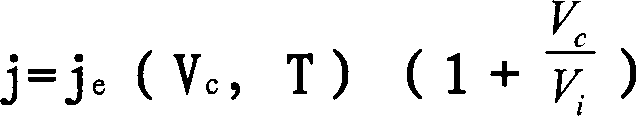

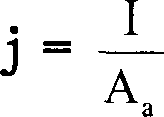

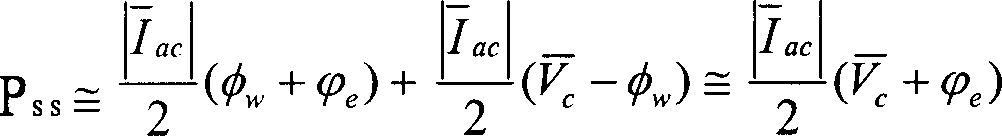

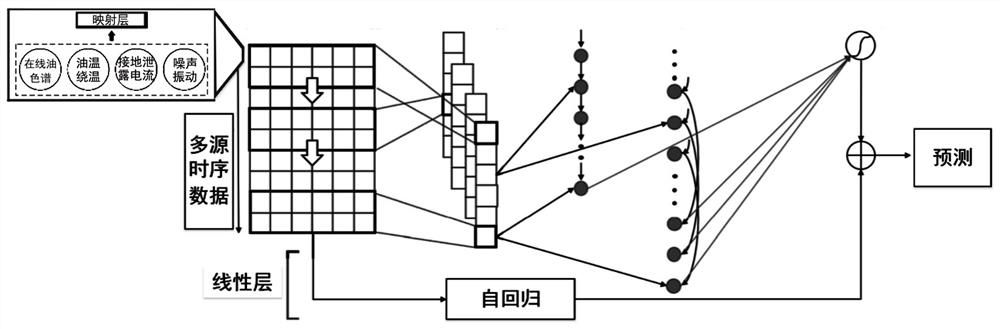

Self-adaptive equivalent consumption minimization energy management method for fuel cell vehicle

ActiveCN112140942AImprove maintenance abilityImprove robustnessBattery/fuel cell control arrangementTransportation hydrogen technologyEnergy technologyNew energy

The invention relates to a self-adaptive equivalent consumption minimization energy management method for a fuel cell vehicle, and belongs to the technical field of new energy. A mode of periodicallyupdating equivalent factors in an equivalent consumption minimization energy management strategy is adopted, and it is guaranteed that the updated equivalent factors are used for power distribution sothat the charge state of an energy storage cell can change in the direction of converging to a target reference value at the fastest speed in short-term future time; required power time series data of the vehicle in a short-term future time range is predicted by adopting an intelligent algorithm, and the predicted required power data is applied to local optimization to determine a short-term optimal equivalent factor; and on the basis of the equivalent consumption minimization strategy, the equivalent factors are adaptively adjusted by a local optimization method, so that maintenance capability of the charge state of the energy storage cell is improved, and the fuel economy of a power system is guaranteed to the greatest extent. The approximately optimal fuel economy of the power system is guaranteed through the approximately optimal power distribution proportion of the equivalent hydrogen consumption.

Owner:CHONGQING UNIV

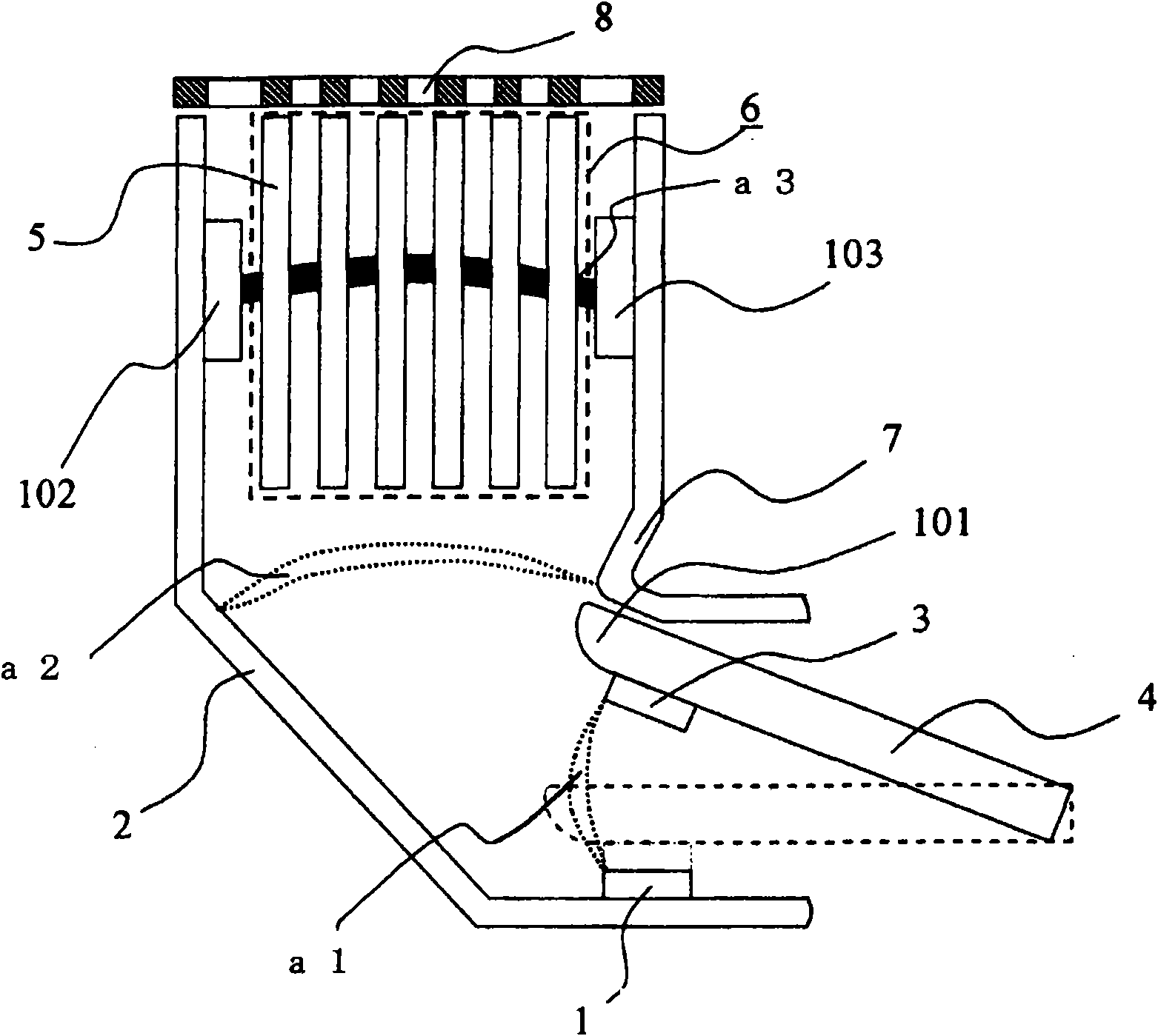

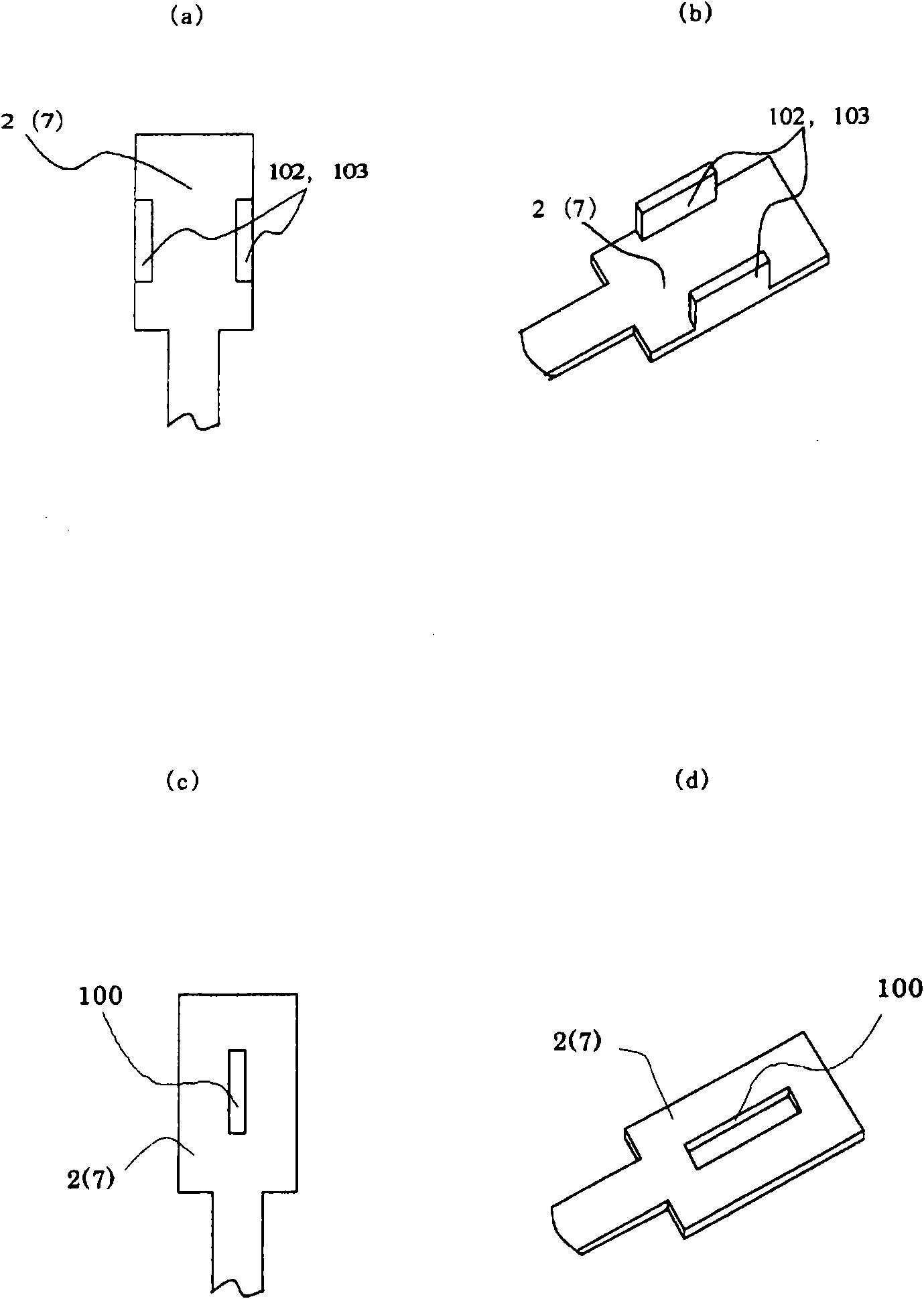

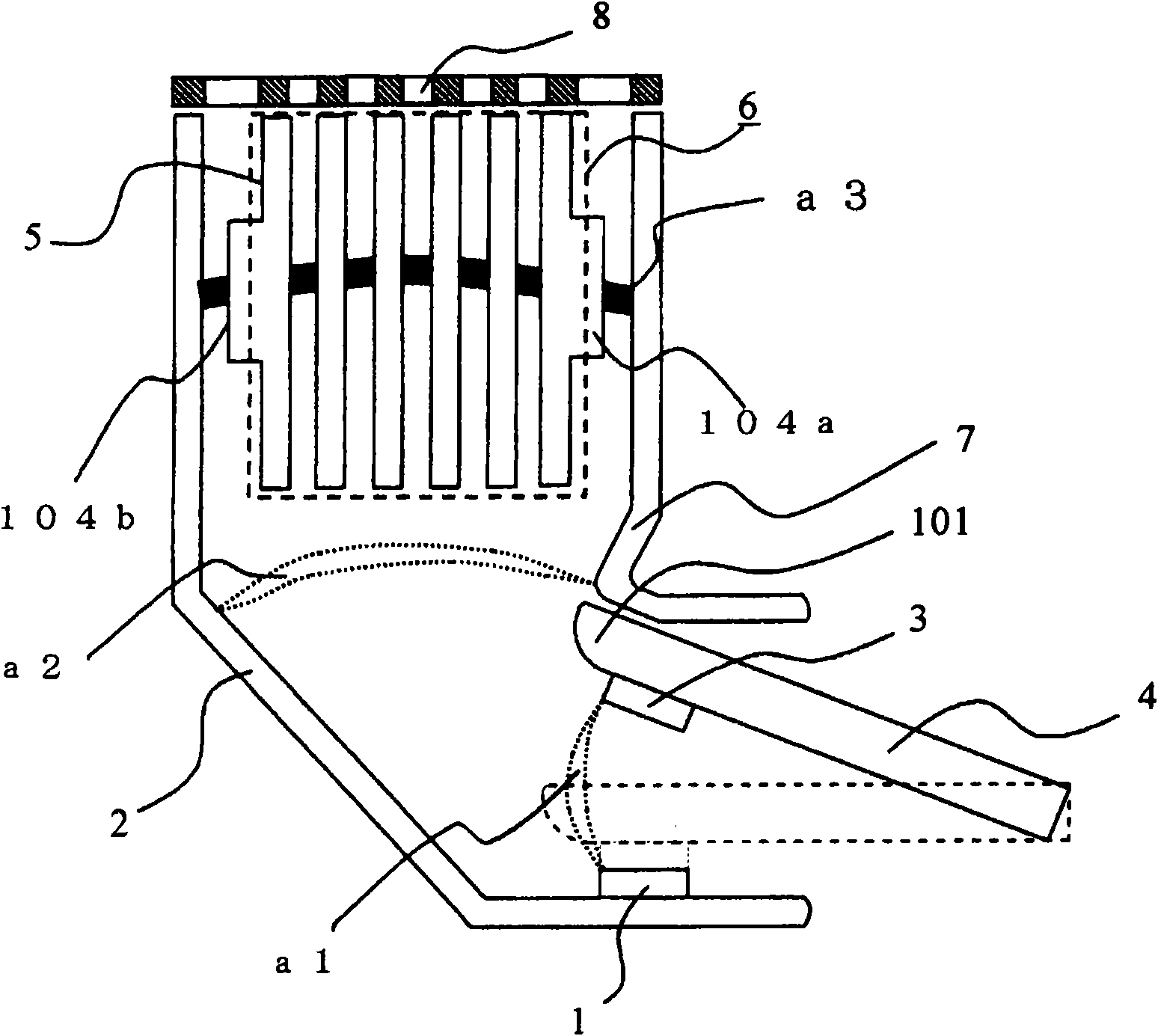

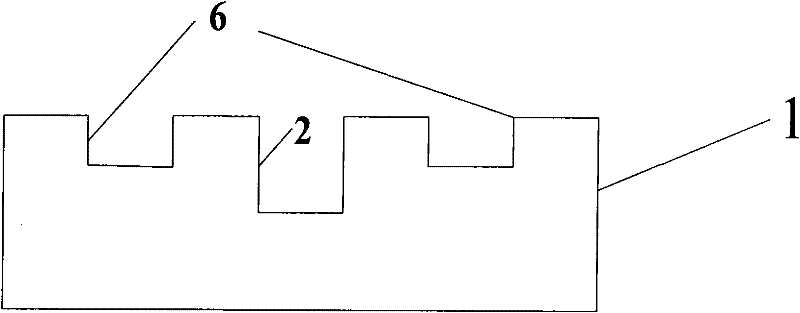

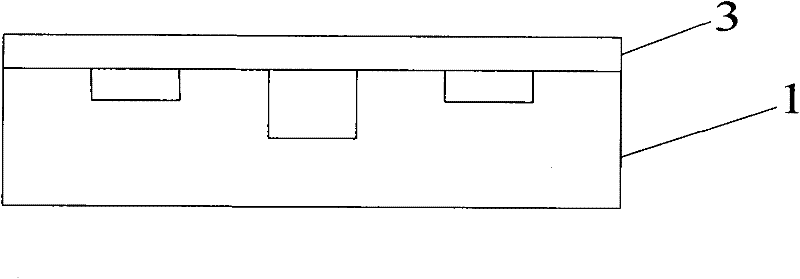

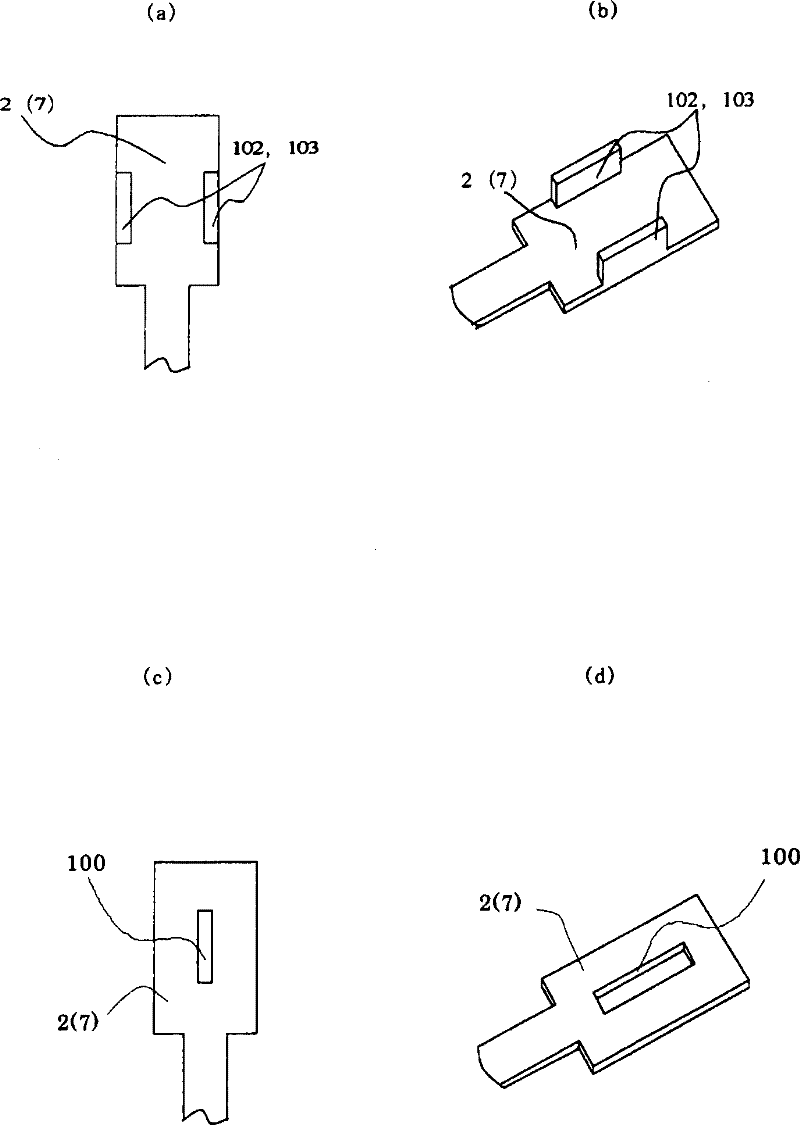

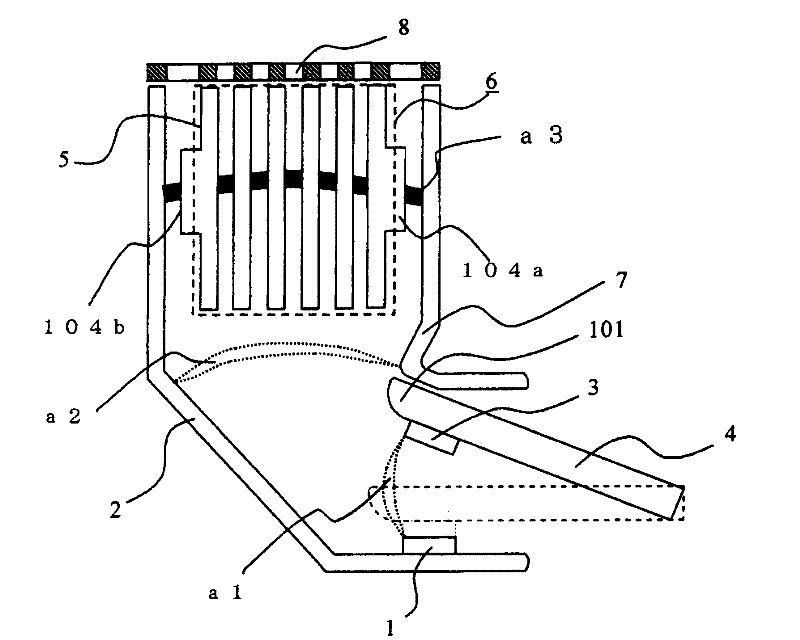

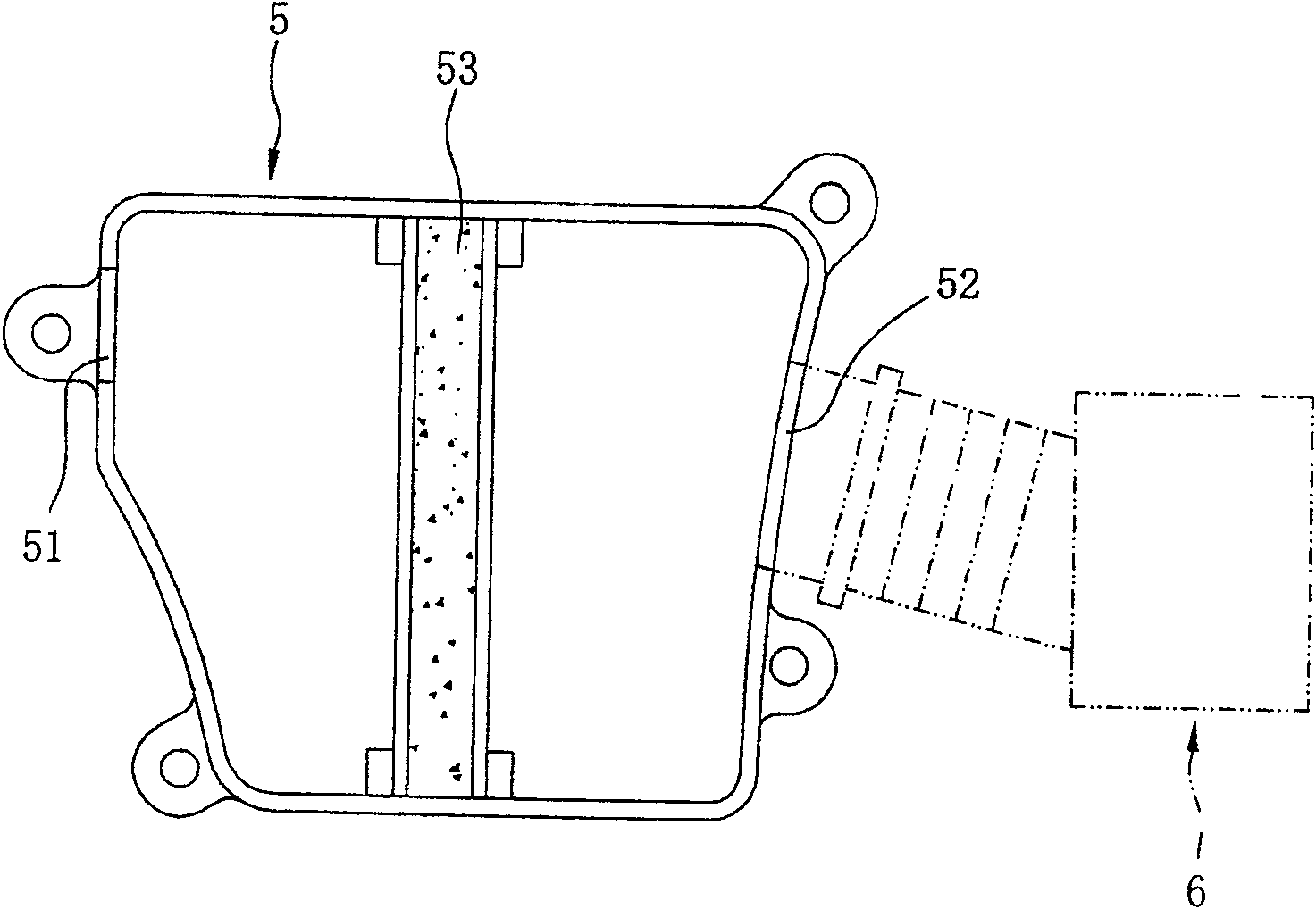

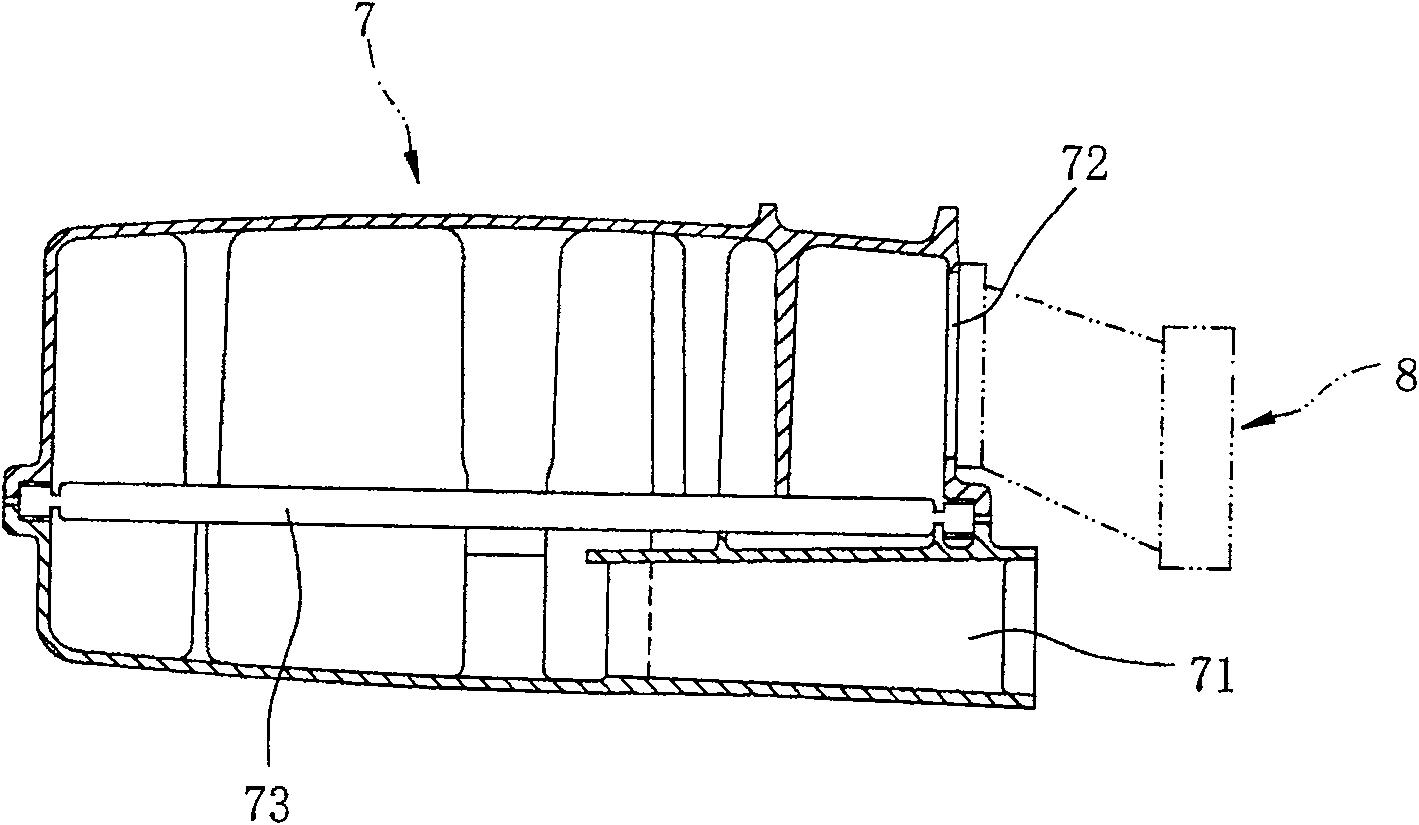

Circuit breaker

InactiveCN101625934AReduce the burden onMiniaturizationElectric switchesCircuit-breaking switch detailsElectrical conductorEngineering

The present invention provides a circuit breaker which comprises a fixed contact point (1), a movable contact point (3) contacted or separated from the fixed contact point (1), an extinguishing arc mechanism (6), an arc movable conductor (2) located on a side of the fixed contact point for leading the arc to the extinguishing arc mechanism (6), and an arc movable conductor (7) located on a side of the movable contact point. The extinguishing arc mechanism (6) is formed by arranging a plurality of extinguishing arc plates (5), the extinguishing arc plates (5) switch and extinguishing arc generated between the fixed contact point (1) and the movable contact point (3) when the movable contact point (3) is separated, the arc movable conducts (2, 7) are opposite to the extinguishing arc plates by spacing preset clearance respectively. An electric field intensification part is arranged on any one or both side of the relative face of the arc movable conducts (2, 7) and the extinguishing arc plate (5) on external side.

Owner:MITSUBISHI ELECTRIC CORP

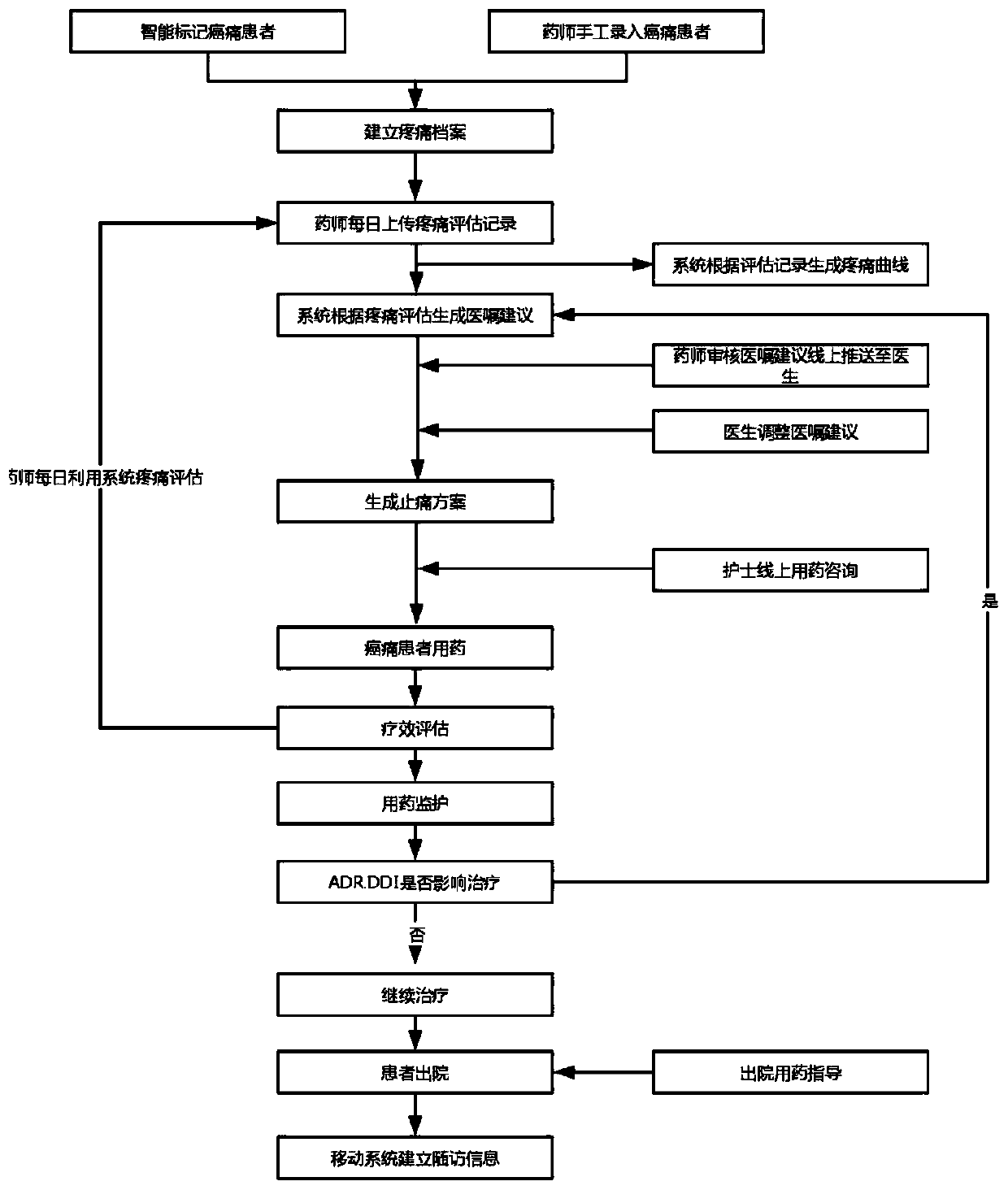

Cancer pain treatment management system

InactiveCN111354428AImprove efficiencyReduce the delay in communicating with each otherMedical communicationDrug and medicationsOnline evaluationMedical staff

The invention provides a cancer pain treatment management system, which relates to the technical field of medical instruments, and comprises a patient basic information module, a patient grouping information module, a pain evaluation module, a treatment monitoring module, a hospital leaving education and follow-up visit module and a treatment management log module. The system intelligently marks cancer pain patients according to patient information to realize quick grouping; medical staff perform online evaluation on the patient every day to generate a pain curve; the system generates pain medical advice suggestions according to the pain curves, the pain medical advice suggestions are submitted to doctors online after being audited by pharmacists, and the doctors can select acceptance or rejection to obtain pain relieving schemes. After the patient leaves the hospital, the system periodically pushes a follow-up visit table to the patient leaving the hospital and gives medication guidance according to the filled follow-up visit table. According to the system, the functions of automatic screening and marking of pain patients, online pain assessment, intelligent pushing of medical advices for pain, online communication, regular and automatic pushing of out-of-hospital follow-up visit tables, storage and retrieval of past treatment files and the like can be achieved at the same time, a large amount of time can be saved for medical workers, and the working efficiency is improved.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

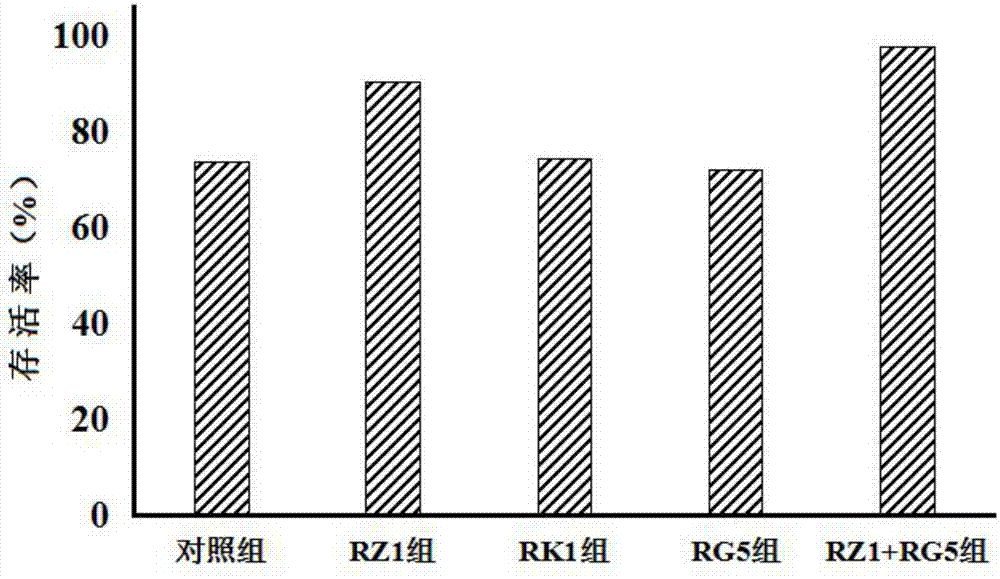

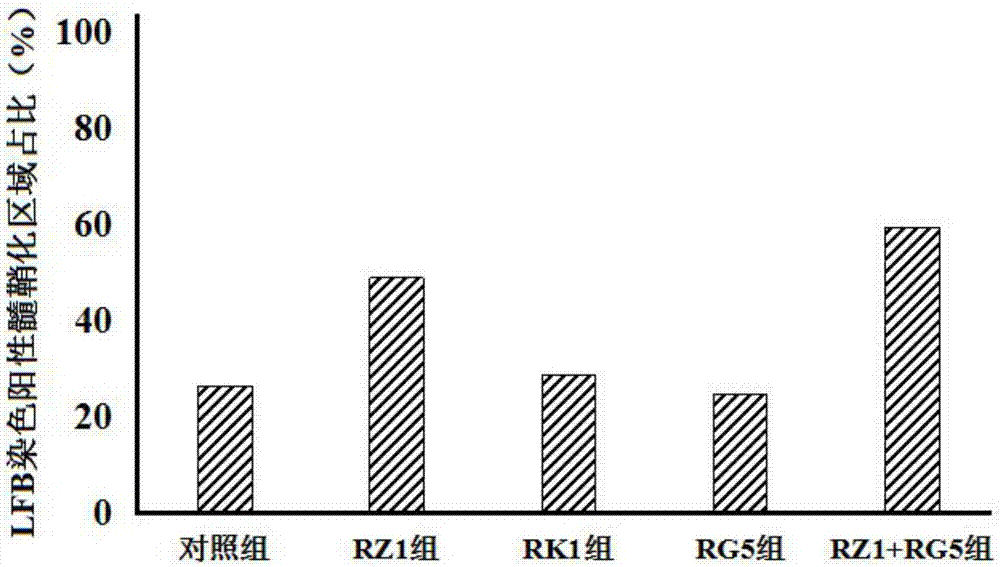

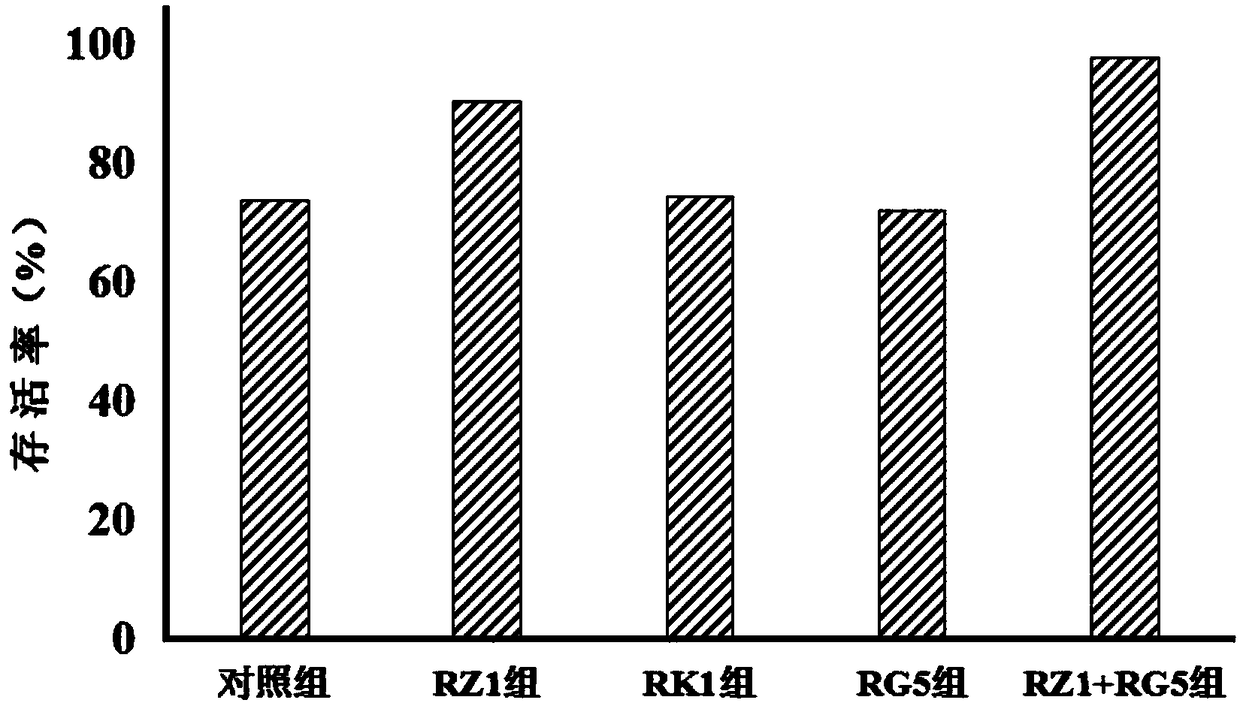

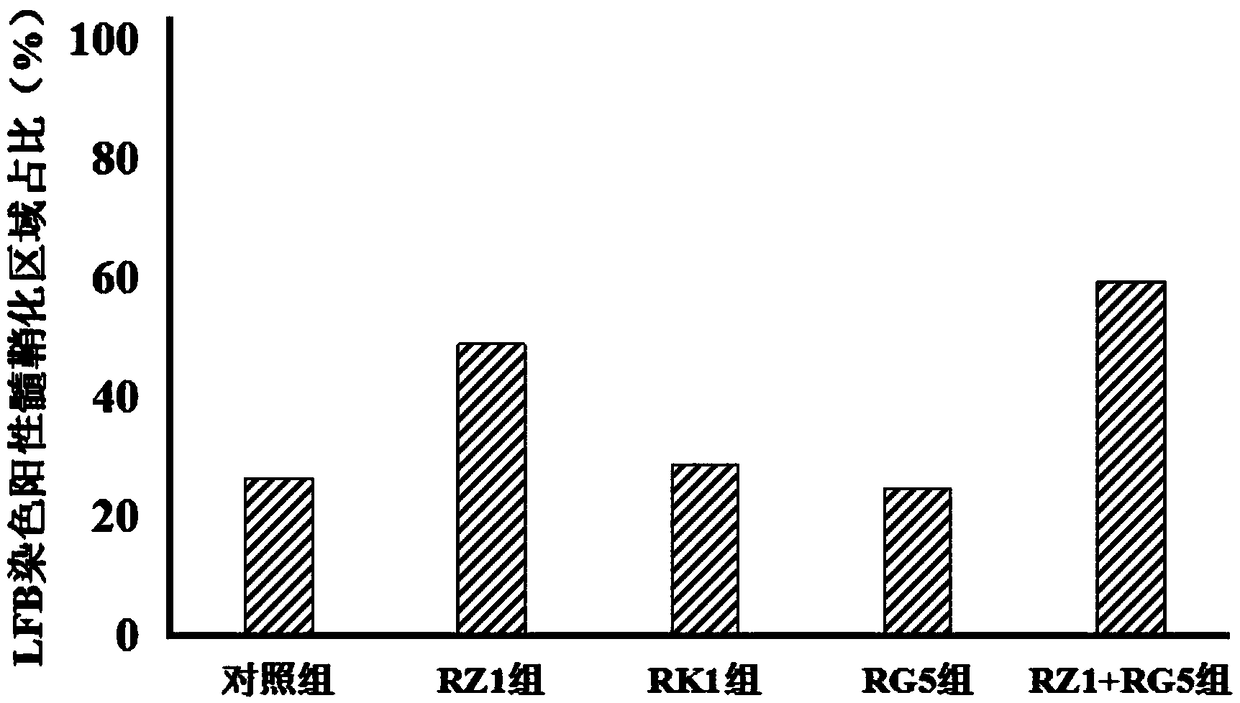

Storage liquid for mesenchymal stem cells

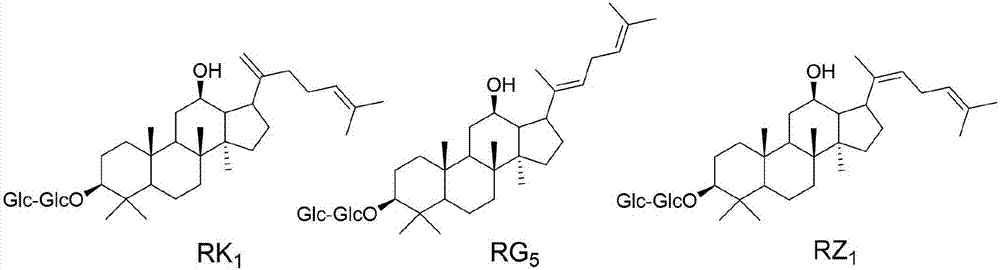

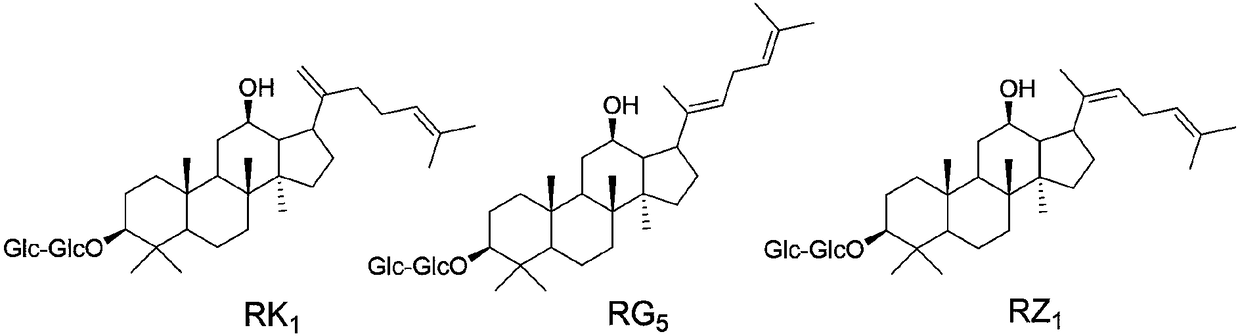

The invention relates to storage liquid for mesenchymal stem cells. The storage liquid is characterized in that a solution is 0.9% normal saline and the solution further contains effective-concentration ginsenoside RZ1. The storage liquid has the advantages that the survival rate of the mesenchymal stem cells can be maintained to the maximum degree, the survival rate lower percentage after 12 hours of storage can be controlled to be within 10%, and the storage liquid evidently better than the 0.9% normal saline which does not contain the ginsenoside RZ1; in addition, if effective-concentration ginsenoside RG5 is also added, the survival rate lower percentage after 12 hours of storage can be controlled to be within 5%; accordingly, the ginsenoside RZ1 can be used for preparing the storage liquid for the mesenchymal stem cells, and the ginsenoside RG5 can further enhance the maintaining effect of the ginsenoside RZ1 on the survival rate of the mesenchymal stem cells.

Owner:恩大细胞基因工程有限公司

Slotted electrode for high intensity discharge lamp

InactiveCN1835183AImprove maintenance abilityReduce the temperatureGas discharge lamp detailsMean free pathGas composition

Operation of an HID lamp may be improved by forming a glow generating recess on an exterior side the electrode. The lamp may be of standard construction with a light transmissive lamp envelope having a wall defining an enclosed volume. At least one electrode assembly is extended in a sealed fashion from the exterior of the lamp through the lamp envelope wall to be exposed at an inner end of the electrode assembly to the enclosed volume. A metal halide lamp fill is enclosed with an inert fill gas. The inner end of the electrode is formed with a recess having a least spanning dimension S and a recess depth of D where S is greater the electron ionization mean free path but less than twice the cathode fall plus negative glow distances, throughout the glow discharge phase of starting, for the chosen fill gas composition and pressure (cold).

Owner:OSRAM SYLVANIA INC

Mining wind speed sensor and correction method thereof

InactiveCN110907659AInstallation suspension position is not restrictedOptimize locationTesting/calibration of speed/acceleration/shock measurement devicesFluid speed measurementAir velocityMechanical engineering

The invention discloses a mining wind speed sensor and a correction method thereof. The sensor comprises a mounting barrel, a wind speed sensor main body is arranged in the mounting cylinder; a rotating rod is arranged on the lower end surface of the wind speed sensor main body; a first mounting plate is arranged at the lower end of the rotating rod; a wind cup part is arranged on the first mounting plate. In the mining wind speed sensor and the correction method thereof, a reinforcing rib, a locking nut, a correction box and the like are arranged; the mounting and hanging positions of the mining wind speed sensor are not limited; the wind speed sensor can be conveniently corrected; the measuring accuracy effect is improved, the problems in the prior art that the support is simple in structure, it cannot guarantee that the installation and suspension positions of the wind speed sensor are not limited, and the sensor needs to be corrected to improve the measurement precision, is disassembled and maintained at present, is sent to a laboratory for correction, and is very troublesome in practice are solved.

Owner:NORTH CHINA INST OF SCI & TECH

High-efficiency slow-release sterilizing composite material for lobster pond

InactiveCN107683863AImprove release efficiencyWell mixedBiocideDead animal preservationSodium acetateBenzoic acid

The invention discloses a high-efficiency slow-release sterilizing composite material for a lobster pond. The high-efficiency slow-release sterilizing composite material comprises the following raw materials of modified filler A, modified filler B, methylisothiazolinone, glutaraldehyde, sorbate, benzoic acid, fixative, benzalkonium bromide, starch, isobutyraldehyde, benzoate, chlorhexidine acetate, sodium acetate, disodium ethylene diamine tetraacetic acid, sodium polyacrylate, hexadecyl dimethyl ethyl ammonium bromide, linoleic acid glycerides, propylene glycol, fatty alcohol-polyoxyethyleneether, sodium chloride, polyethylene glycol, oxalic acid, asarone, beta-sitosterol, sodium humate, fulvic acid, photosynthetic bacteria and deionized water. The high-efficiency slow-release sterilizing composite material has the advantages that the composite material is used for sterilizing the lobster pond, and the excellent slow-release property of bactericide is realized; after the composite material is applied to the pond, the rich inorganic growth auxin is provided for the vegetation at the bottom part of the pond; while the high-efficiency and high-quality sterilizing is guaranteed, themaintaining ability of an ecological system in the pond is improved.

Owner:宿松县辉煌家庭农场

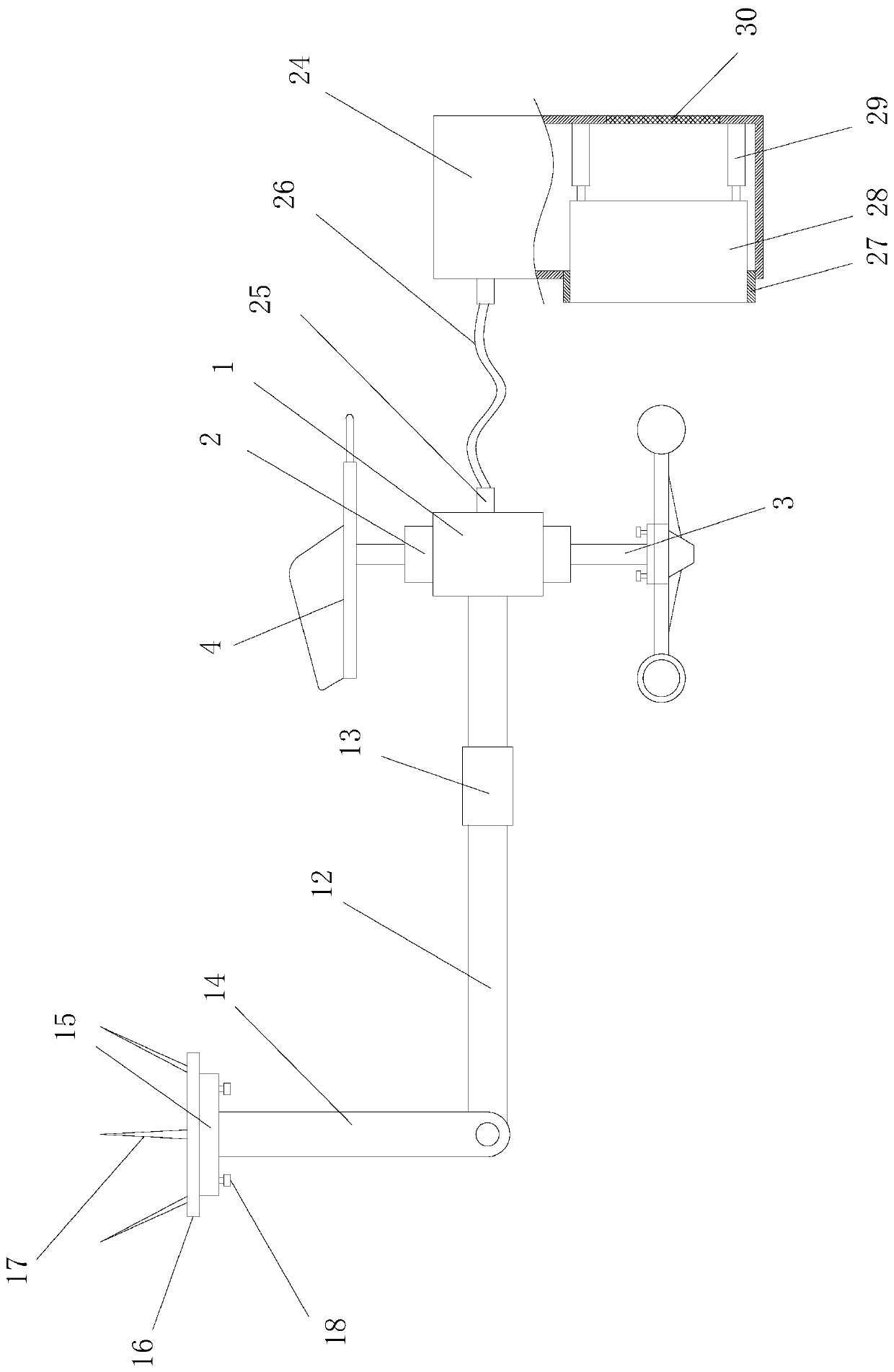

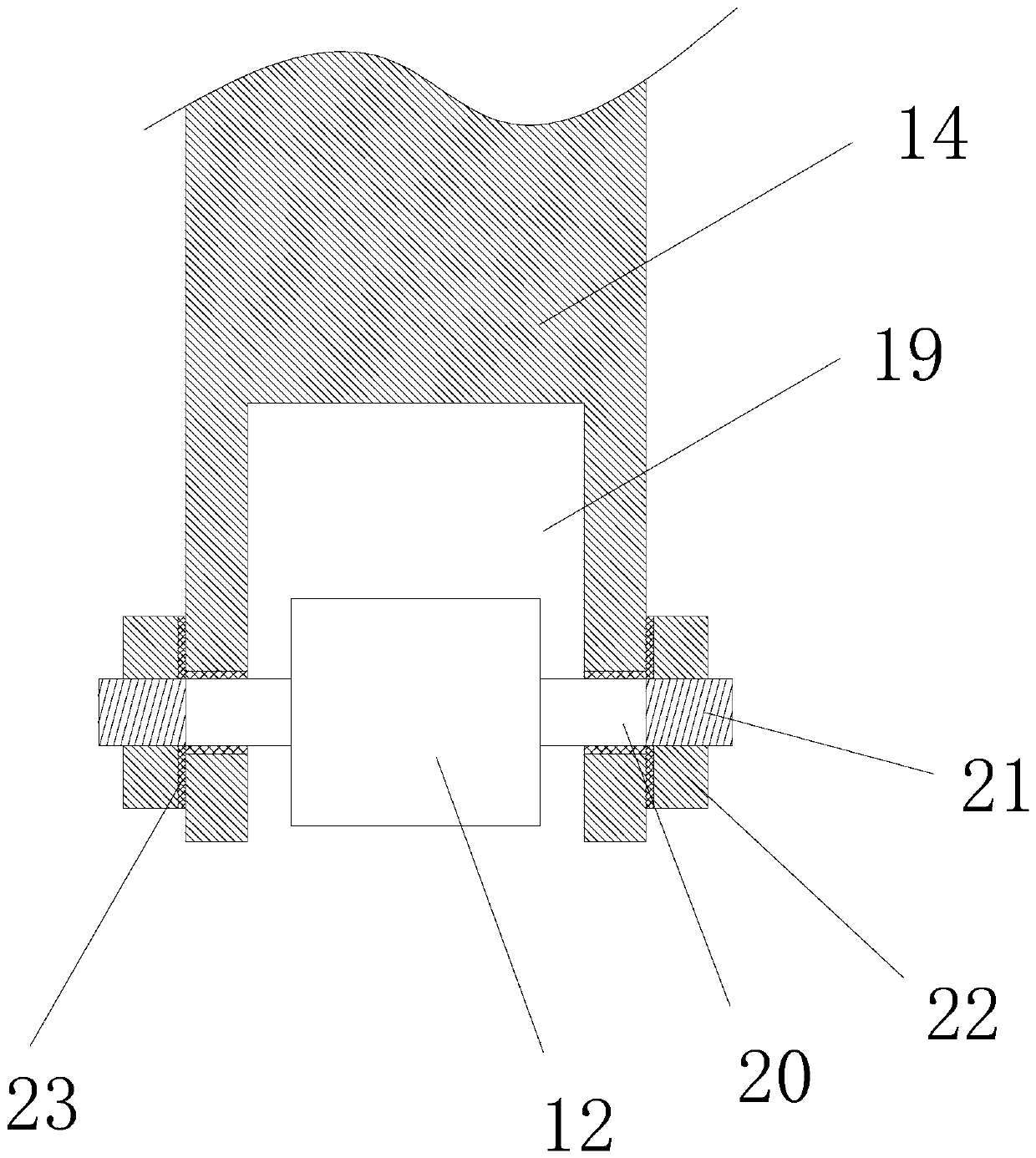

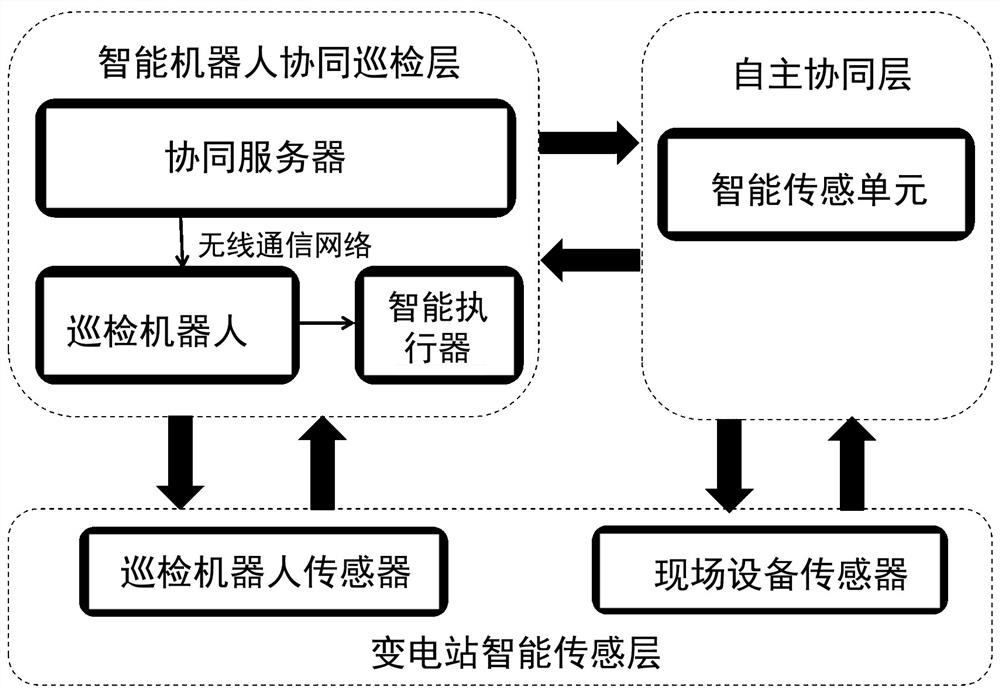

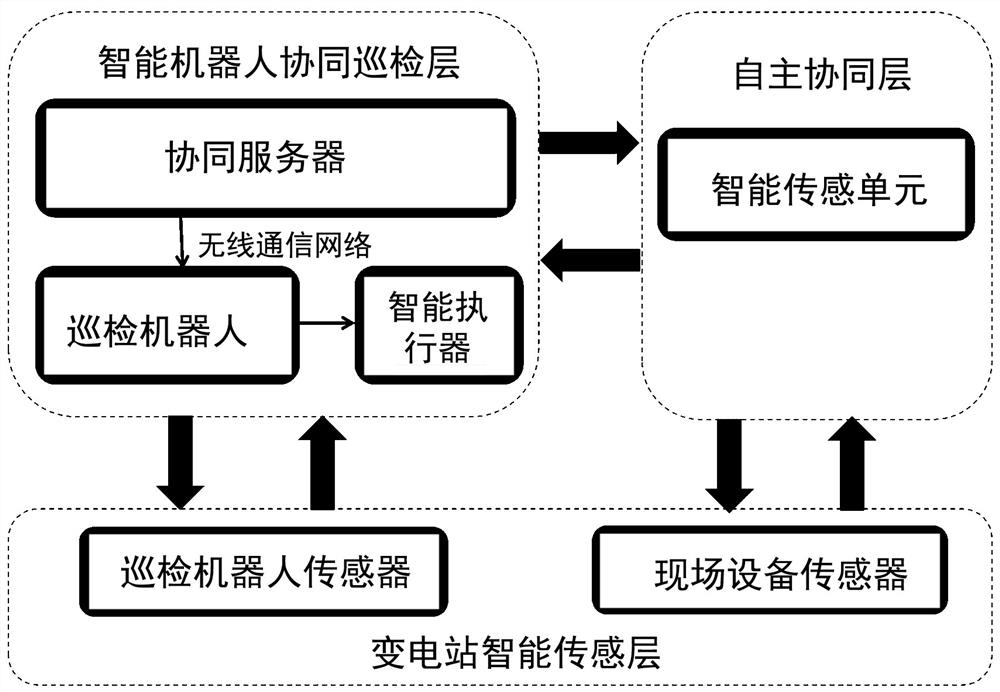

Transformer substation robot intelligent inspection system and method based on active cooperation of intelligent sensor

PendingCN114069838AImprove timelinessImprove maintenance abilityCircuit arrangementsParticular environment based servicesSmart transducerSource data

The invention provides a transformer substation robot intelligent inspection system and method based on intelligent sensor active cooperation. The inspection system comprises an intelligent robot cooperation inspection layer, an autonomous cooperation layer and a transformer substation intelligent sensing layer which form a three-layer intelligent inspection architecture. In the inspection system, the inspection robot performs autonomous path planning to complete image data acquisition, the intelligent sensor senses the state of the detected equipment and performs data preprocessing and analysis, and the inspection robot and the intelligent sensor perform active cooperation through a near field communication mechanism and an intelligent actuator. And a cooperative server performs complex scene identification based on the inspection robot sensing data, and performs multi-source data fusion analysis on the inspection robot sensing data and the intelligent sensor sensing data. The timeliness of inspection tour is remarkably improved, the personnel safety risk in the operation process is avoided, manual intervention in the inspection tour process is reduced, and it is guaranteed that the power transformation inspection tour task is smoothly carried out.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +4

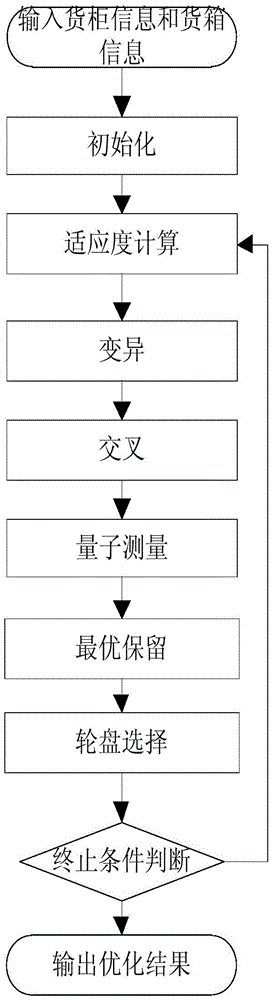

Three-dimensional cargo loading layout optimization method and system based on quantum genetic algorithm

ActiveCN103473464BIncrease diversityAccurate 3D layout optimization resultsSpecial data processing applicationsLogistics managementAlgorithm

Owner:SICHUAN AEROSPACE SYST ENG INST

A kind of bone marrow mesenchymal stem cell storage solution

The invention relates to storage liquid for mesenchymal stem cells. The storage liquid is characterized in that a solution is 0.9% normal saline and the solution further contains effective-concentration ginsenoside RZ1. The storage liquid has the advantages that the survival rate of the mesenchymal stem cells can be maintained to the maximum degree, the survival rate lower percentage after 12 hours of storage can be controlled to be within 10%, and the storage liquid evidently better than the 0.9% normal saline which does not contain the ginsenoside RZ1; in addition, if effective-concentration ginsenoside RG5 is also added, the survival rate lower percentage after 12 hours of storage can be controlled to be within 5%; accordingly, the ginsenoside RZ1 can be used for preparing the storage liquid for the mesenchymal stem cells, and the ginsenoside RG5 can further enhance the maintaining effect of the ginsenoside RZ1 on the survival rate of the mesenchymal stem cells.

Owner:恩大细胞基因工程有限公司

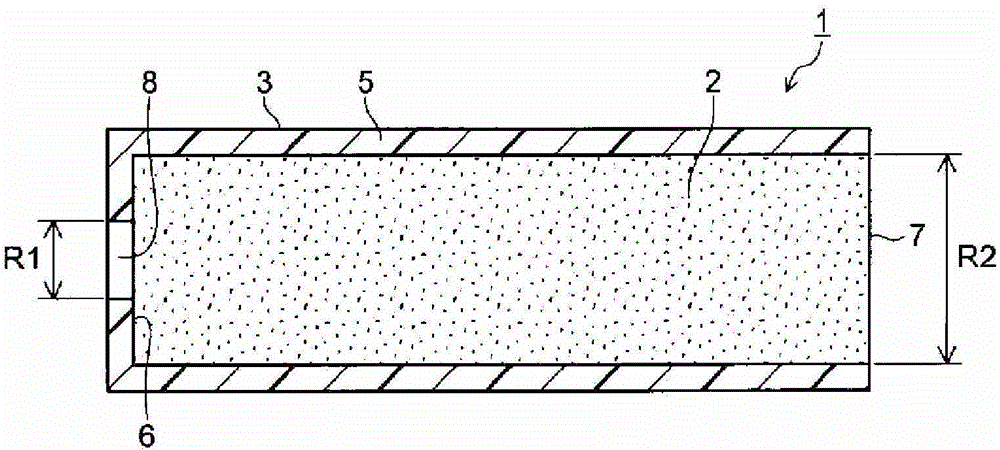

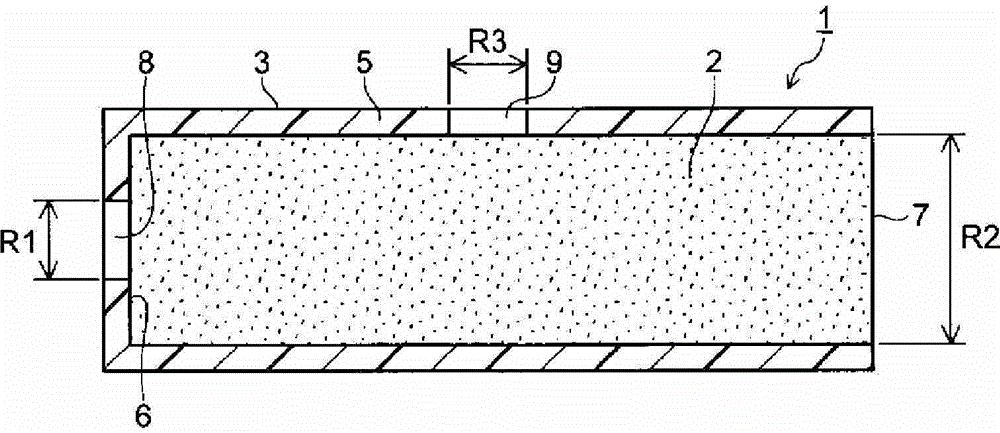

Antenna component and method for producing same

ActiveCN102742076BImprove maintenance abilityImprove the winding effectLoop antennas with ferromagnetic coreInductances/transformers/magnets manufactureBiomedical engineeringWrap around

Disclosed is an antenna component (1) equipped with: a hollow component (3); a magnetic core material (2) inserted into the hollow component (3); and a coil wrapped around the perimeter of the hollow component (3). The hollow component (3) has: a tubular section (5) having an internal measurement of R2; a partition section (6) provided to one end of the tubular section (5); and an opening section (7) provided to the other end of the tubular section (5). A hole (8) having a size (R1) that satisfies 0.05 mm = R1 = 0.5 mm and R1 < R2 is provided to the partition section (6).

Owner:KK TOSHIBA +1

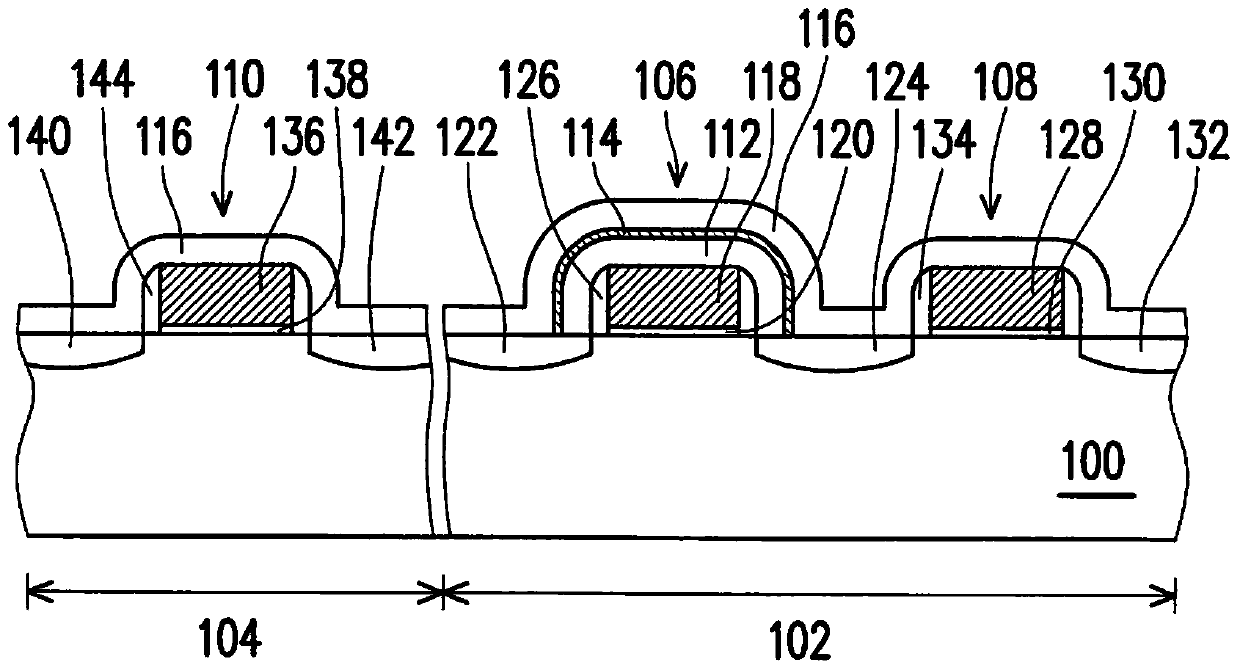

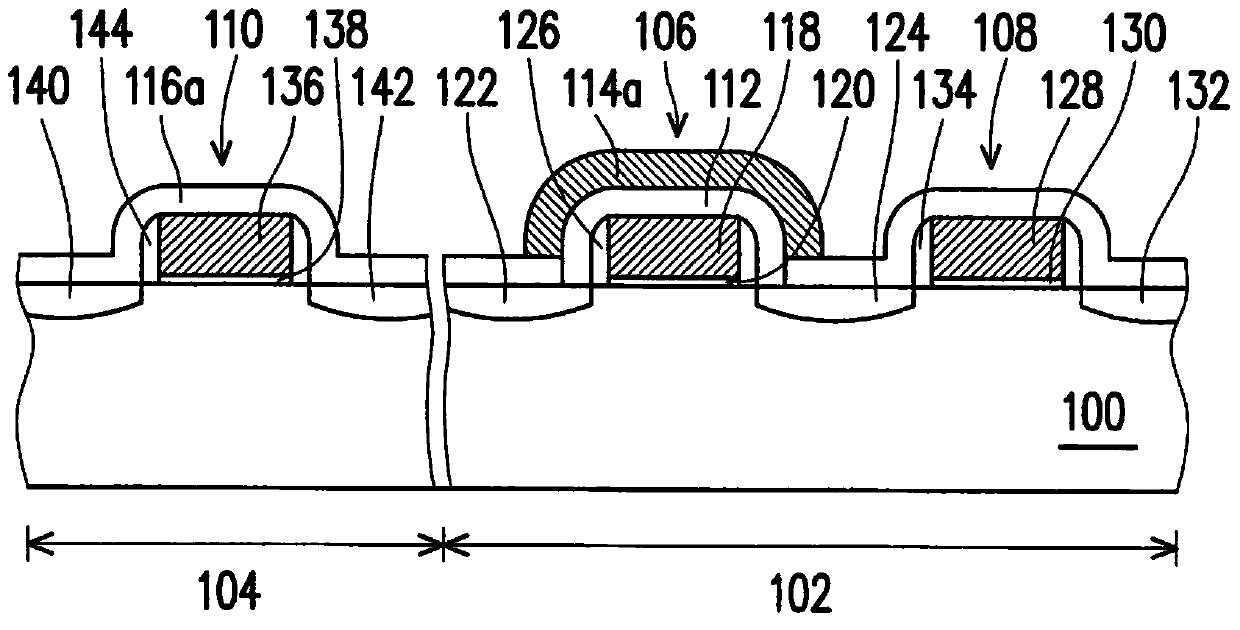

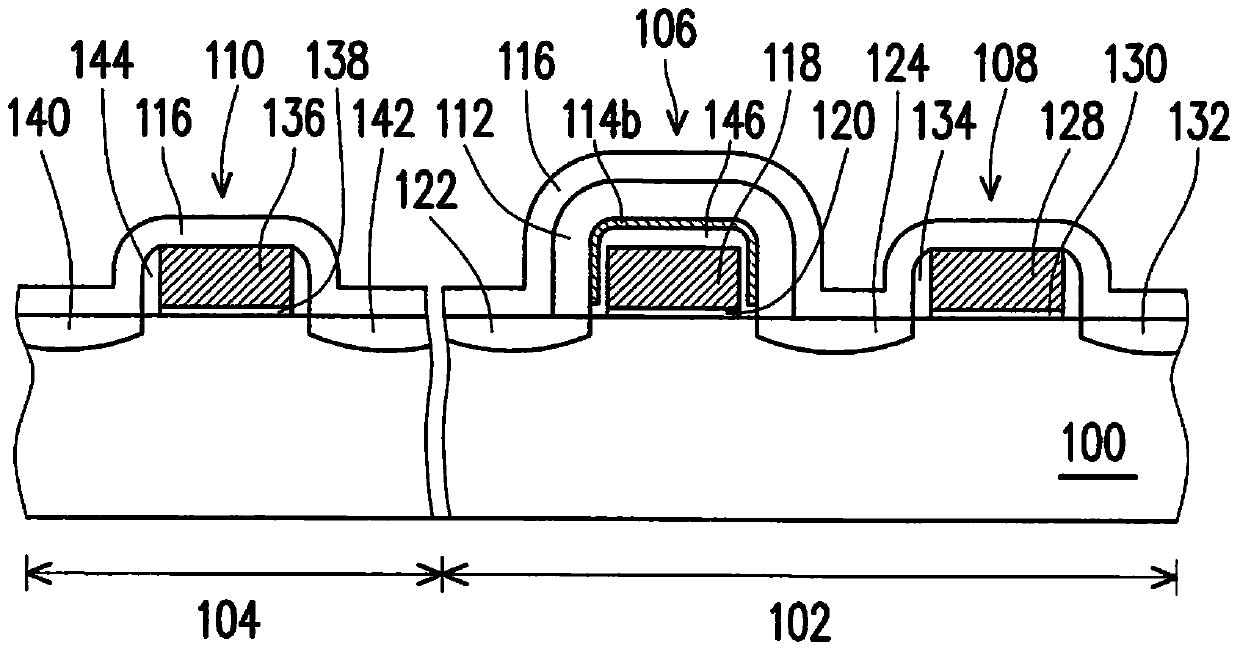

non-volatile memory

ActiveCN105633086BImprove maintenance abilityReduce lossesSolid-state devicesSemiconductor devicesEmbedded systemNon-volatile memory

The invention discloses a non-volatile memory, which is arranged on a substrate including a peripheral circuit area and a memory unit area. Non-volatile memory includes floating gate transistors, transistors, self-aligned barrier layers, stretch layers, and contact etch stop layers. The floating gate transistor is provided in the memory cell area. The transistor is provided in the peripheral circuit area. The self-aligned barrier layer is disposed on the floating gate of the floating gate transistor. The stretch layer is only provided on the floating gate. A contact etch stop layer covers the entire transistor.

Owner:EMEMORY TECH INC

Built-in intelligent temperature control equipment of gravure electronic engraving machine

ActiveCN113879032AAbsorb evenlyEnhance decomposition and cooling effectModel makingEngravingTemperature controlEngineering

The invention discloses built-in intelligent temperature control equipment of a gravure electronic engraving machine. The equipment comprises an air guide and flow division mechanism, an air suction guide mechanism, a heat dissipation temperature control system and a water circulation cooling mechanism, wherein the air guide and flow division mechanism comprises an air inlet, through holes and a flow division pipe, the flow division pipe is located at the bottom of the interior of the air inlet, the through holes are evenly formed in the top of the flow division pipe, and a temperature monitor is fixedly connected to the middle position of the bottom of the air inlet. According to the equipment, an absorption type heat dissipation and emission system arranged in the electronic engraving machine is formed through communication and cooperation of the air guide and flow division mechanism, the air suction guide mechanism and the heat dissipation temperature control system, so that the temperature control equipment can rapidly absorb hot air flow in a machine body and disperse the air flow for cooling during absorption, the heat source in the air is decomposed and then flows back to the machine body to form air flow circulation, and the maintenance and stability of the constant temperature in the machine body can both be improved.

Owner:深圳市国匠数控科技有限公司

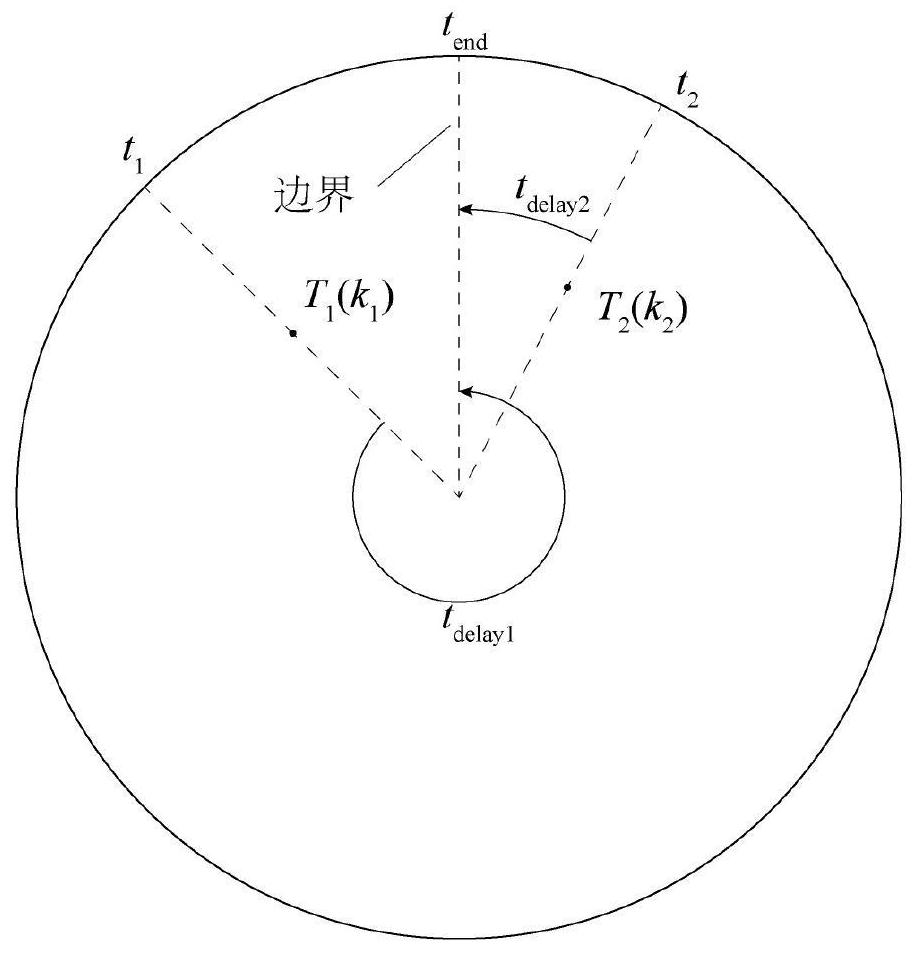

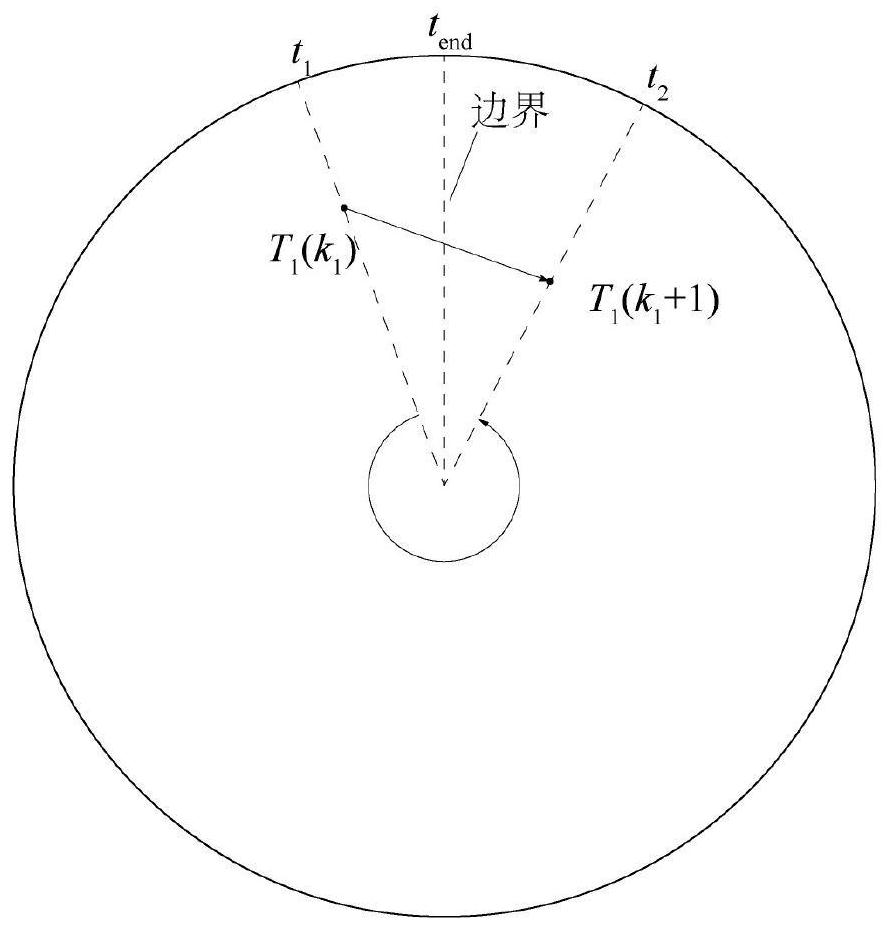

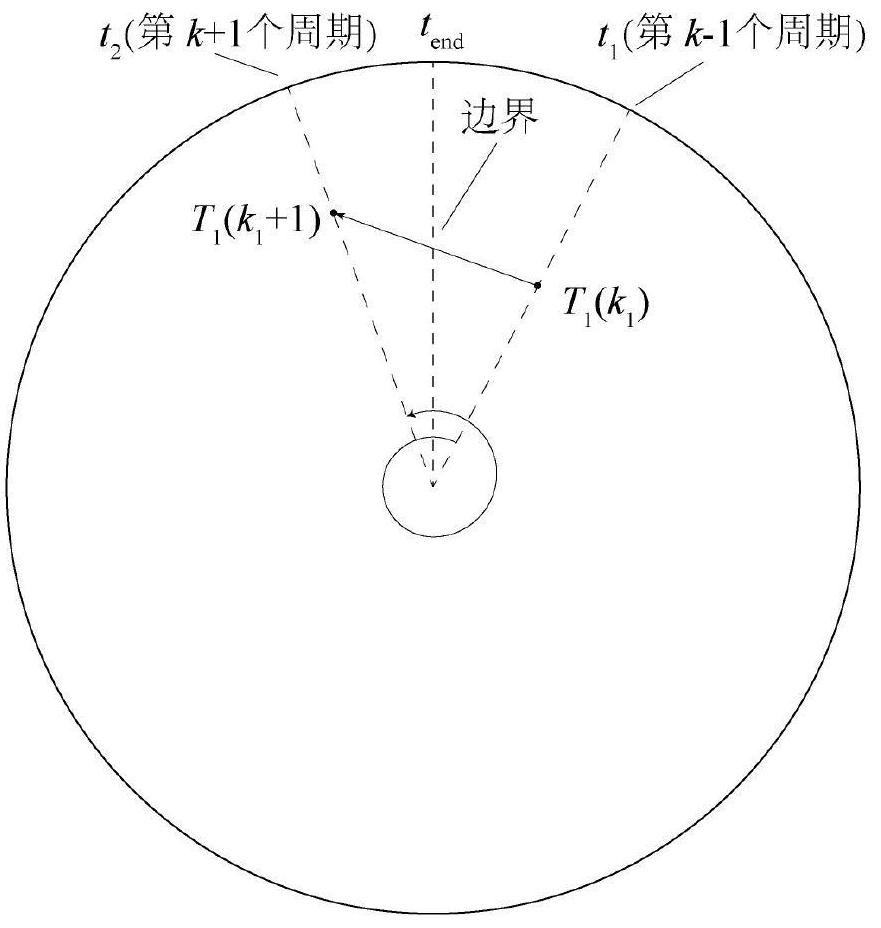

TWS radar multi-target continuous tracking method

ActiveCN113406618AImprove maintenance abilityReduce Tracking LatencyRadio wave reradiation/reflectionRadarEngineering

The invention relates to a TWS radar multi-target continuous tracking method, wherein the method comprises the steps: for each observation received by a TWS radar, selecting observations acquired before the current moment to form a first preselected observation set; establishing a track according to the first preselected observation set, filtering in combination with the state of a track, and calculating prediction estimation of the next updated track and a corresponding gate time interval; for each existing track, determining an acquisition time interval according to a gate time interval at the end moment of the gate time interval corresponding to the current track in each update, acquiring observation in the acquisition time interval, and forming a second preselected observation set; and at the end moment of the acquisition time interval, updating the state of the current track by using the second pre-selected observation set, filtering in combination with the state of the track, and calculating the prediction estimation of the next updated track and the corresponding gate time interval. According to the invention, TWS radar low-delay tracking can be realized, and the problem of track fracture caused by boundary scanning is solved.

Owner:HARBIN INST OF TECH

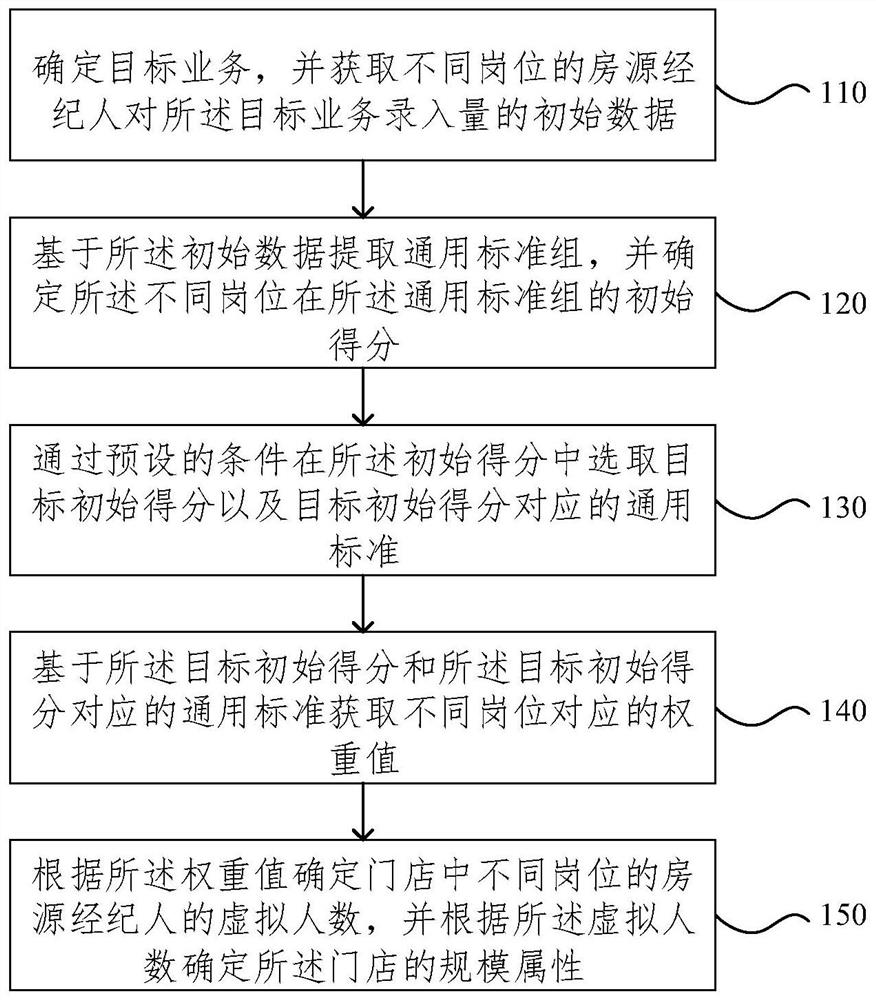

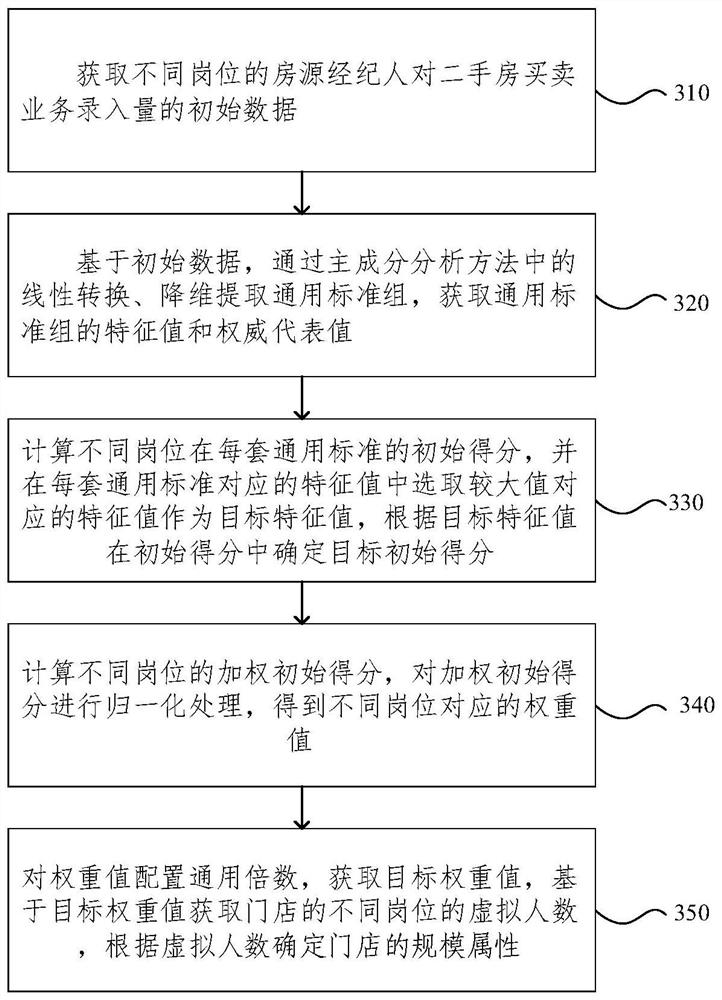

Store scale attribute determination method and device and matching method and device

PendingCN114462774AImprove maintenance abilityMatch actual abilityResourcesMarket data gatheringData ingestionData mining

The invention provides a store scale attribute determination method and device, and a matching method and device, and the method comprises the steps: determining a target business, and obtaining the initial data of the input amount of the target business by housing resource brokers at different posts; a general standard group is extracted based on the initial data, initial scores of different posts in the general standard group are determined, and the general standard group at least comprises one set of general standards; selecting a target initial score and a general standard corresponding to the target initial score from the initial scores through a preset condition; obtaining weight values corresponding to different posts based on the target initial score and a general standard corresponding to the target initial score; and according to the weight value, determining the virtual number of housing resource brokers at different posts in the store, and according to the virtual number of the housing resource brokers, determining the scale attribute of the store. The method achieves the matching of the determined scale attribute of the store and the actual capability of the store, and improves the maintenance capability of the store.

Owner:贝壳找房网(北京)信息技术有限公司

MEMS wafer level vacuum packaging process

ActiveCN101723308BImprove maintenance abilityQuality improvementDecorative surface effectsChemical vapor deposition coatingPressure differenceAnodic bonding

The invention discloses an MEMS glass microcavity vacuum packaging process with long vacuum maintaining time, which comprises the following steps of: firstly, etching a deep packaging groove on a Si wafer by using an Si microprocessing process and etching a relatively shallower annular vacuum buffer groove at the periphery of the deep packaging groove; then bonding the Si wafer etched with the microgroove and a glass wafer so that the glass wafer and the specific pattern form a packaging cavity; heating and preserving the temperature of the bonded wafer at atmosphere pressure and leading softened glass to flow into the packaging cavity by a pressure difference inside and outside the cavity so as to form a microcavity structure corresponding to the microcavity pattern structure; cooling and annealing and removing stress of the wafer at normal pressure; then corroding to remove the Si wafer; and carry out anode bonding on the Si wafer and the glass wafer at the atmosphere of 1Pa-10Pa toform the integral vacuum packaging. The invention improves the maintaining capability of vacuum degree in the packaging cavity by manufacturing the annular vacuum buffer cavity at the periphery of the packaging cavity.

Owner:SOUTHEAST UNIV

Automated coil bending process

ActiveCN110722058BFulfil requirementsAvoid the risk of crushing into bend anglesMechanical engineeringEnergy consumption

The invention relates to the technical field of electronic equipment production, and discloses an automatic material rolling bending technology. The automatic material rolling bending technology comprises the following steps that foam is punched, a height cushioning strip is obtained, meanwhile, a pc board with the thickness being 1.5 mm is tailored, a preliminary bent product is manufactured, theposition distance between punched holes is preset according to the width of the bent product, an assembled material strip is flatly placed in a mother and son bending die to be bent, and finally, thecompleted product is taken out to be machined and ground. According to the automatic material rolling bending technology, the height cushioning strip exceeds the product in the height direction and is attached to the two sides of the material strip, accordingly, after product rolling, only the height cushioning strip can make contact with each circle, the bent product is in an overhead state, therisk of bending angle pressing can be avoided, and the maintaining effect after product material rolling is improved; and meanwhile, the height cushioning strip belongs to bonding connection, and after the height cushioning strip is used, the material strip connected with the height cushioning strip can be repeatedly used, cost can be better saved, and the effect of energy consumption reducing through the technology is improved.

Owner:SUZHOU KECHUAN ELECTRONICS TECH

Circuit breaker

InactiveCN101625934BImprove maintenance abilityEasy to driveElectric switchesCircuit-breaking switch detailsElectrical conductorEngineering

The present invention provides a circuit breaker which comprises a fixed contact point (1), a movable contact point (3) contacted or separated from the fixed contact point (1), an extinguishing arc mechanism (6), an arc movable conductor (2) located on a side of the fixed contact point for leading the arc to the extinguishing arc mechanism (6), and an arc movable conductor (7) located on a side of the movable contact point. The extinguishing arc mechanism (6) is formed by arranging a plurality of extinguishing arc plates (5), the extinguishing arc plates (5) switch and extinguishing arc generated between the fixed contact point (1) and the movable contact point (3) when the movable contact point (3) is separated, the arc movable conducts (2, 7) are opposite to the extinguishing arc platesby spacing preset clearance respectively. An electric field intensification part is arranged on any one or both side of the relative face of the arc movable conducts (2, 7) and the extinguishing arc plate (5) on external side.

Owner:MITSUBISHI ELECTRIC CORP

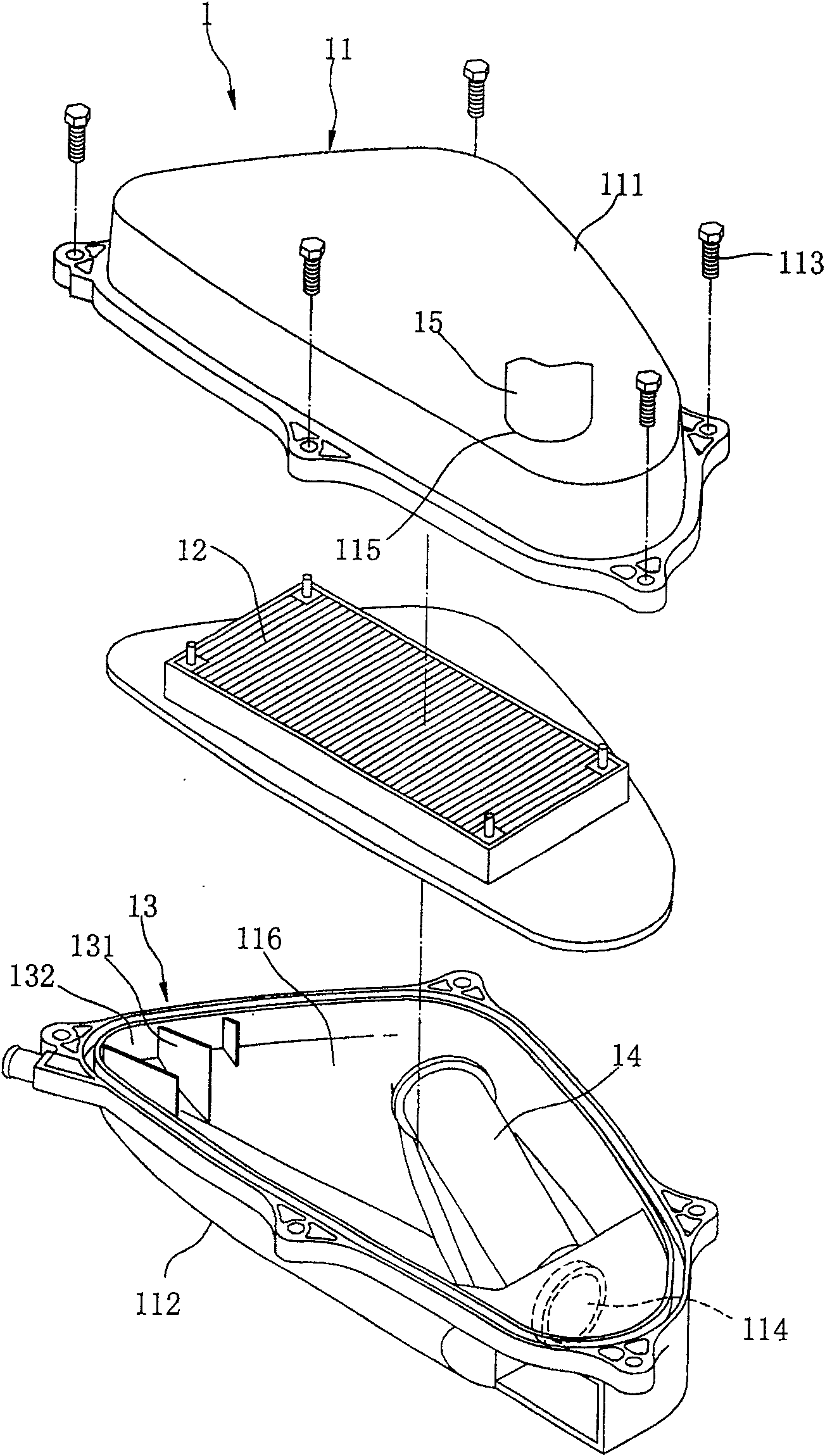

Air purifier of vehicle

ActiveCN100540879CExtended service lifeReduce consumptionMachines/enginesAir cleaners for fuelNetwork structureEddy current

An air filter for a vehicle, an air flow channel is formed between the air intake side and the air outlet side of the air filter, the filter screen is arranged between the air intake side and the air outlet side, and the The air channel between the nets is provided with a flow rate reduction structure, which can reduce the flow rate of the air entering the air filter and generate a vortex, so that the dust in the air can stay in the flow rate reduction structure, so it can reduce dust. The amount of adhesion on the filter screen can prolong the service life of the filter screen, reduce the frequency of filter screen replacement, and help extend the life of the engine and maintain performance.

Owner:YAMAHA MOTOR CO LTD

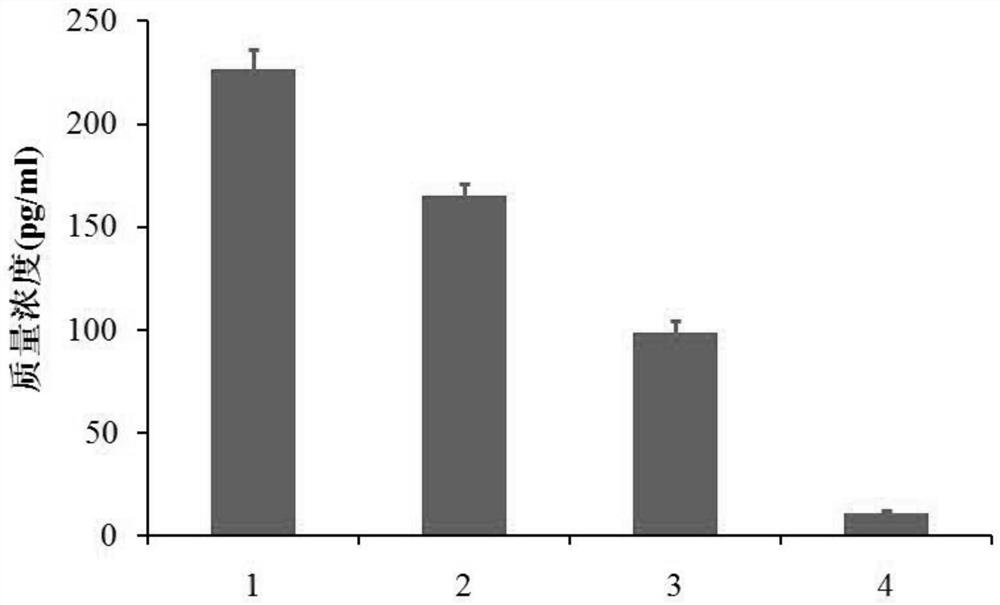

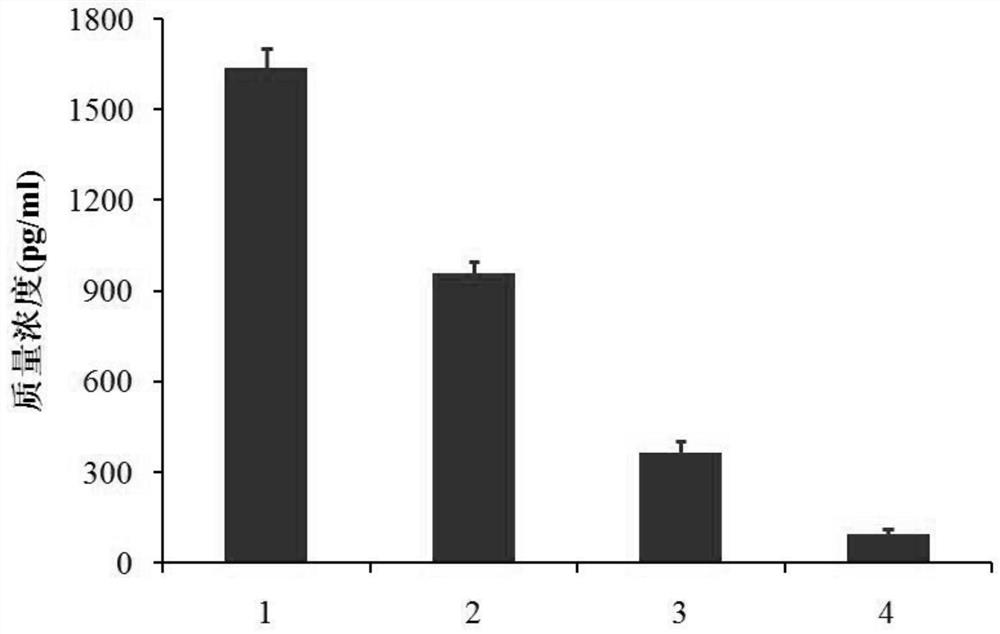

A kind of cationic liposome bird flu vaccine and preparation method thereof

ActiveCN112336855BReduce adverse reactionsImprove presentation abilitySsRNA viruses negative-senseViral antigen ingredientsAntigenLipofectamine

The application discloses a preparation method of cationic liposome avian influenza vaccine. This method is based on the vaccine prepared by cationic liposomes loaded with octadecylamine, which can significantly improve the ability of antigen-presenting cells to present antigens, trigger CD4+ and CD8+ T cell responses, induce a strong inflammatory response, and improve memory T cells. Induction and increase its maintenance ability, the particle size of the vaccine is about 450nm, the encapsulation rate of the vaccine is above 50%, and under certain antigen concentrations, the encapsulation rate exceeds 70%. With the increase of the antigen concentration, the encapsulation rate The sealing rate is gradually increasing.

Owner:江苏飞阳益科生物科技有限公司

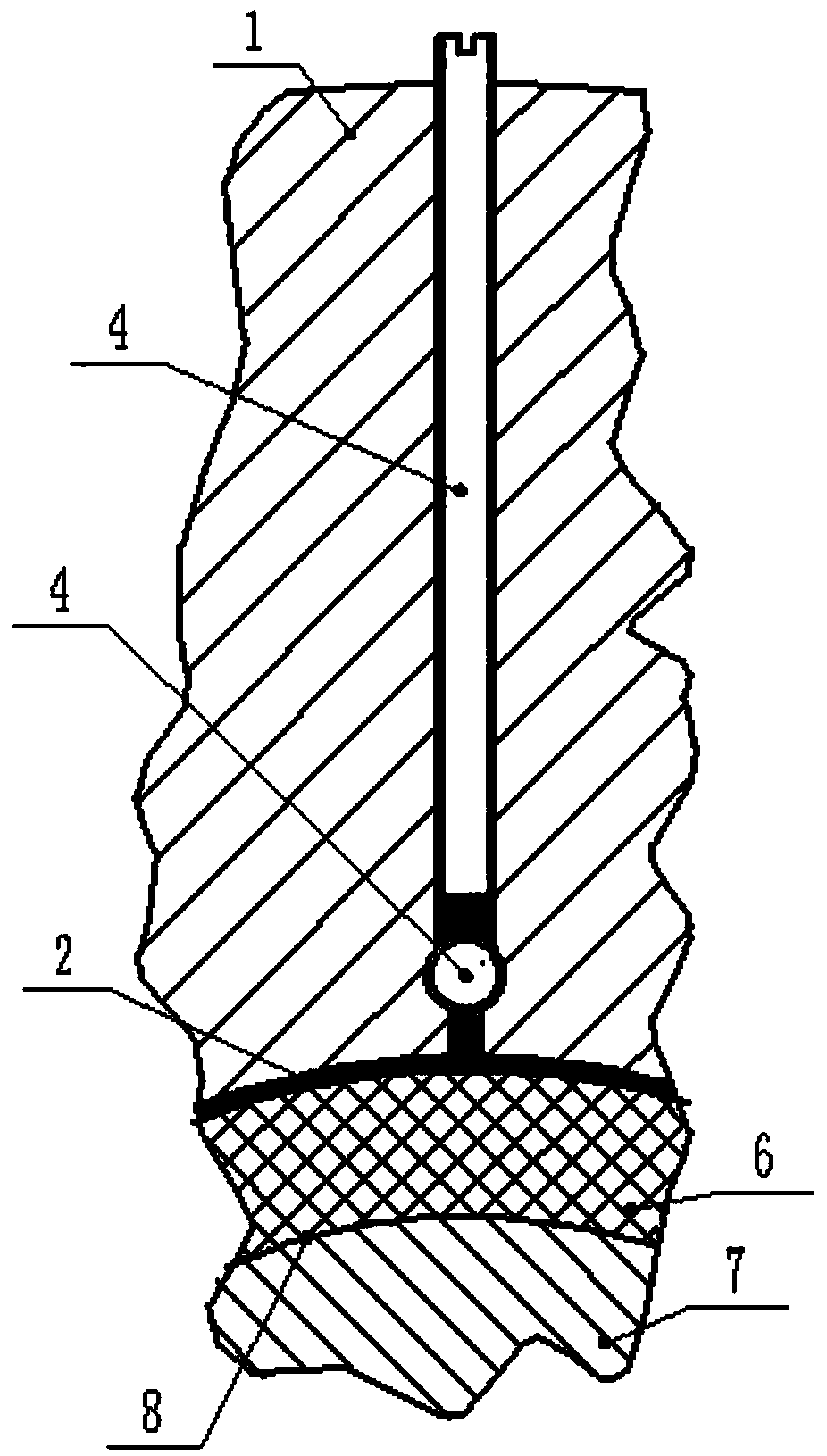

Contact type labyrinth seal

PendingCN108071807AImprove the blocking effectIncreased continuous blocking powerEngine sealsElastic componentContact type

The invention belongs to sealing equipment, and discloses a contact type labyrinth seal. Transition matching sections with work resistance allowed by the labyrinth seal are additionally arranged in alabyrinth channel of the labyrinth seal. Transition fit is formed by utilizing the characteristic of elastic sealing filler adaptive shaping. An elastic component is additionally arranged or the method that the additionally-arranged space communicating with various sealing filler positions is filled with pressure applying media is utilized, and accordingly sealing filler pressure application and running abrasion compensation can be conducted. Even though the scheme disobeys the labyrinth non-contact concept, a labyrinth is further intensified so as to increase the continuous blocking force, and the gradual type leakage preventing blocking action is achieved. The transition fit maintaining capability can be improved through the elastic sealing filler, the elastic component and pressure applying medium filling, and accordingly the labyrinth blocking effect can be improved in a limited manner. The scheme is unique in concept, the structure is simple, the effect is clear, actions are obvious, and the contact type labyrinth seal is suitable for popularization and application.

Owner:许建中

Biopolymer-based seed coatings compositions and methods for use

ActiveUS11284558B2Easy to keepImprove maintenance abilityAmylose/amylopectin coatingsDextran coatingsPolyethylene oxidePotato starch

A seed or seedling is coated with a cross-linked biopolymer and, optionally, a second binder selected from underivatized guar, cationic hydroxypropyl guar, polyacrylamide, poly(methacrylic acid), poly(acrylic acid), polyacrylate, poly(ethylene glycol), polyethyleneoxide, polyamide, hydroxypropyl guar, carboxymethyl guar, carboxymethylhydroxypropyl guar, underivatized starch, cationic starch, corn starch, wheat starch, rice starch, potato starch, tapioca, waxy maize, sorghum, waxy sarghum, sago, dextrin, chitin, chitosan, xanthan gum, carageenan gum, gum karaya, gum arabic, pectin, cellulose, hydroxycellulose, hydroxyalkyl cellulose, hydroxyethyl cellulose, carboxymethylhydroxyethyl cellulose, or hydroxypropyl cellulose. The seed coating composition is characterized by a dust value, as measured using a Heubach dustmeter device, which is lower by at least 30% as compared to an analogous composition that does not contain the crosslinked biopolymer.

Owner:SPECIALTY OPERATIONS FRANCE

Gate scan drive circuit

ActiveCN108154856BAvoid functional failureReduce in quantityStatic indicating devicesHemt circuitsBias stress

Owner:NANJING CEC PANDA LCD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com