Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve glitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

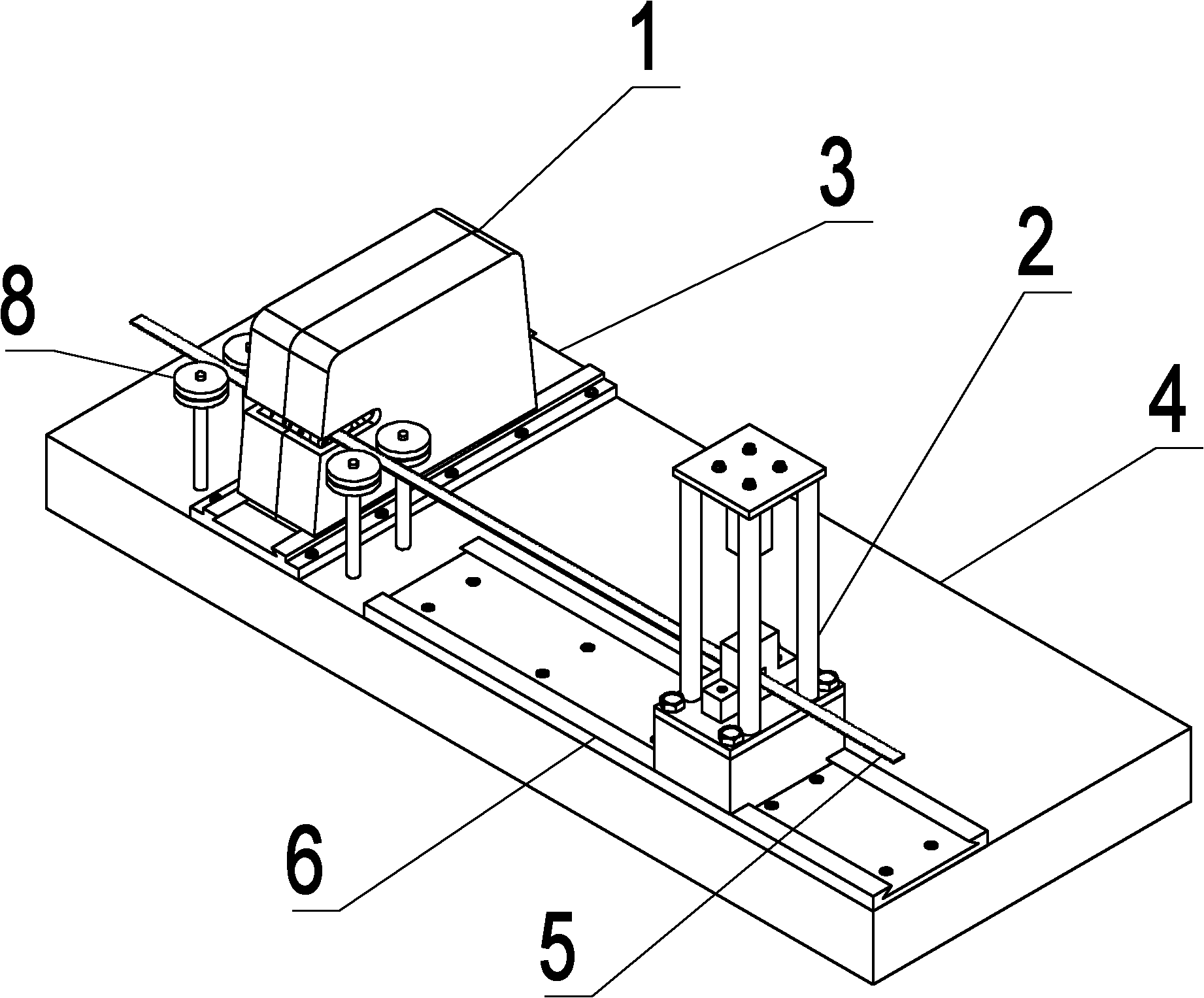

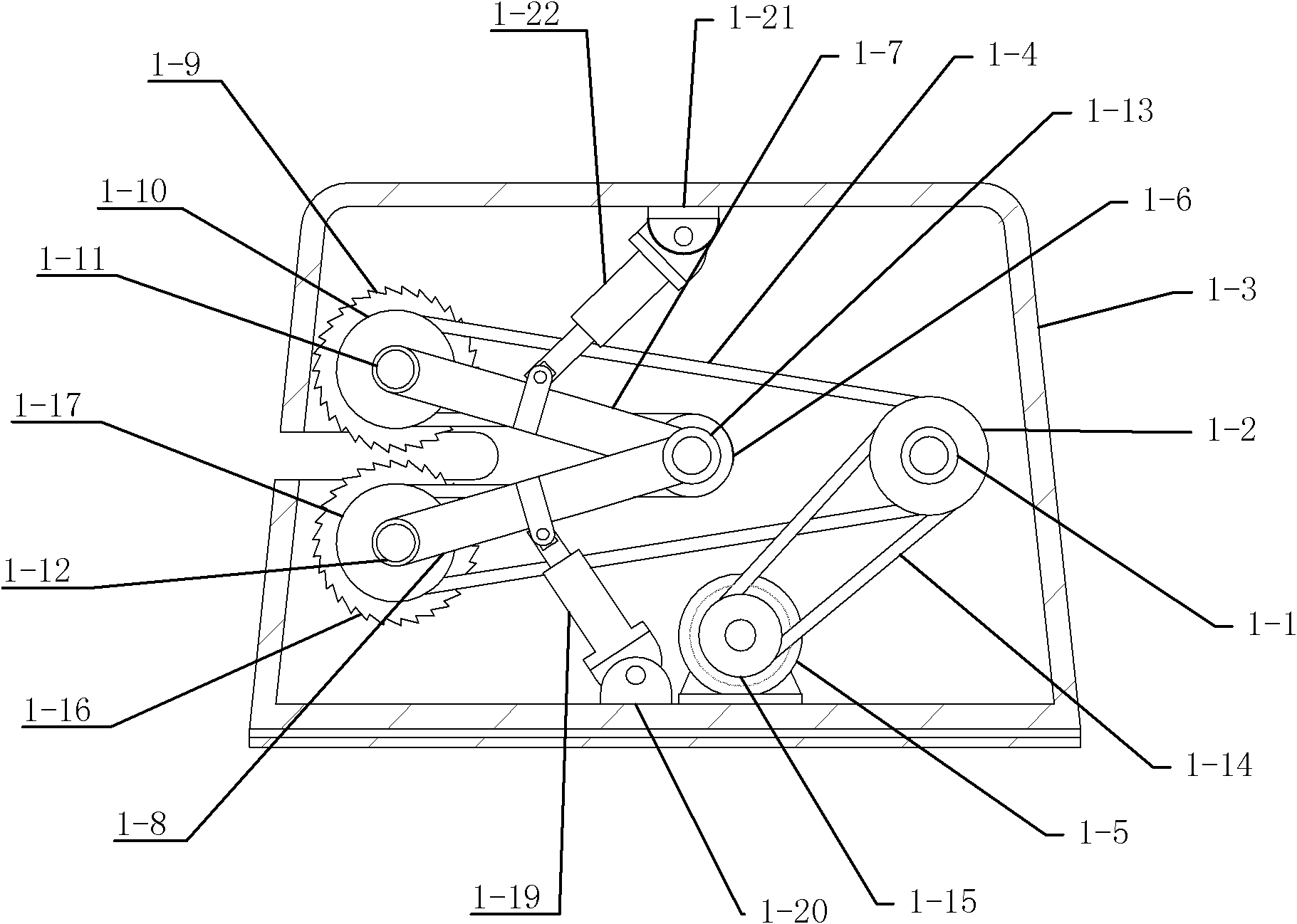

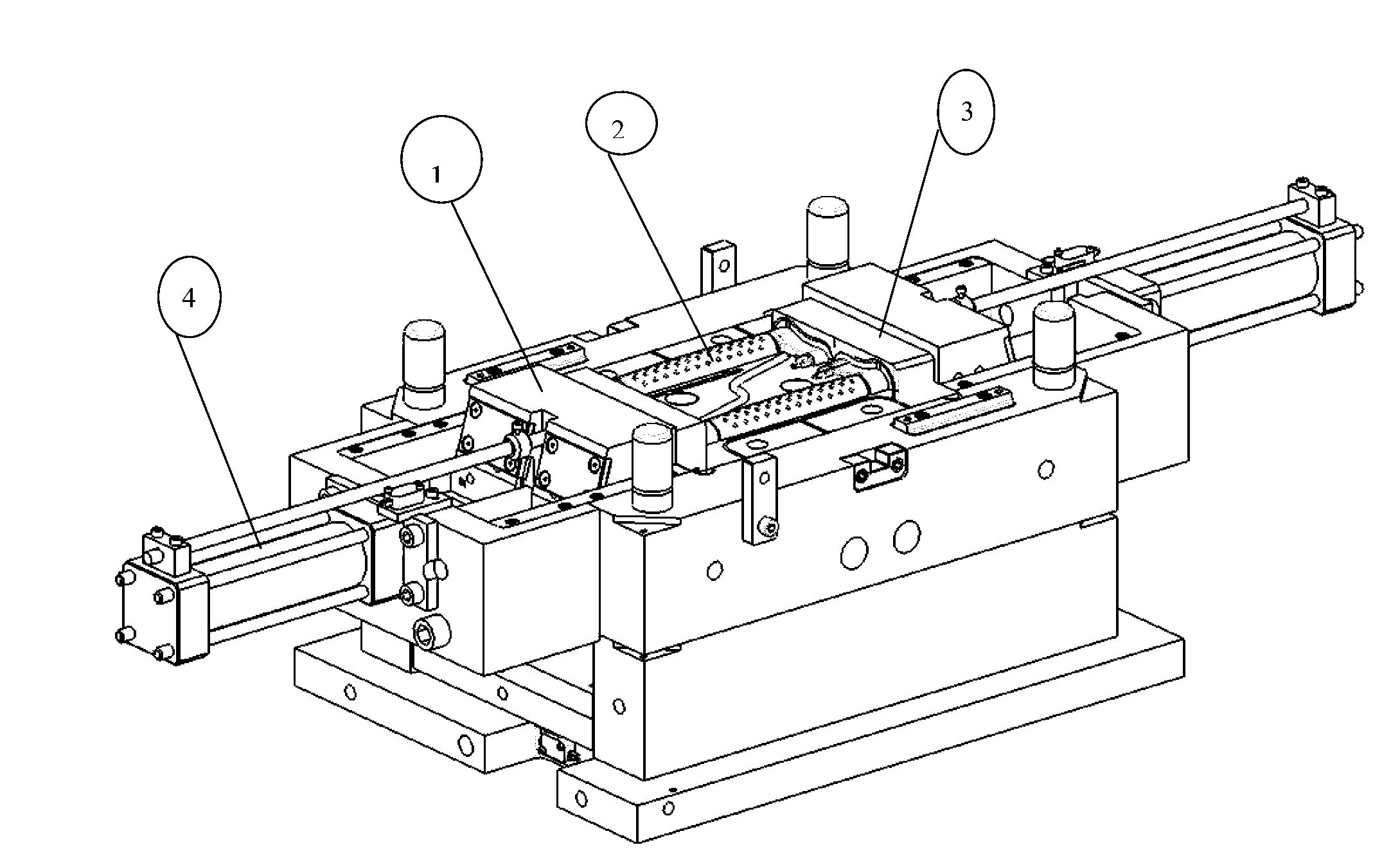

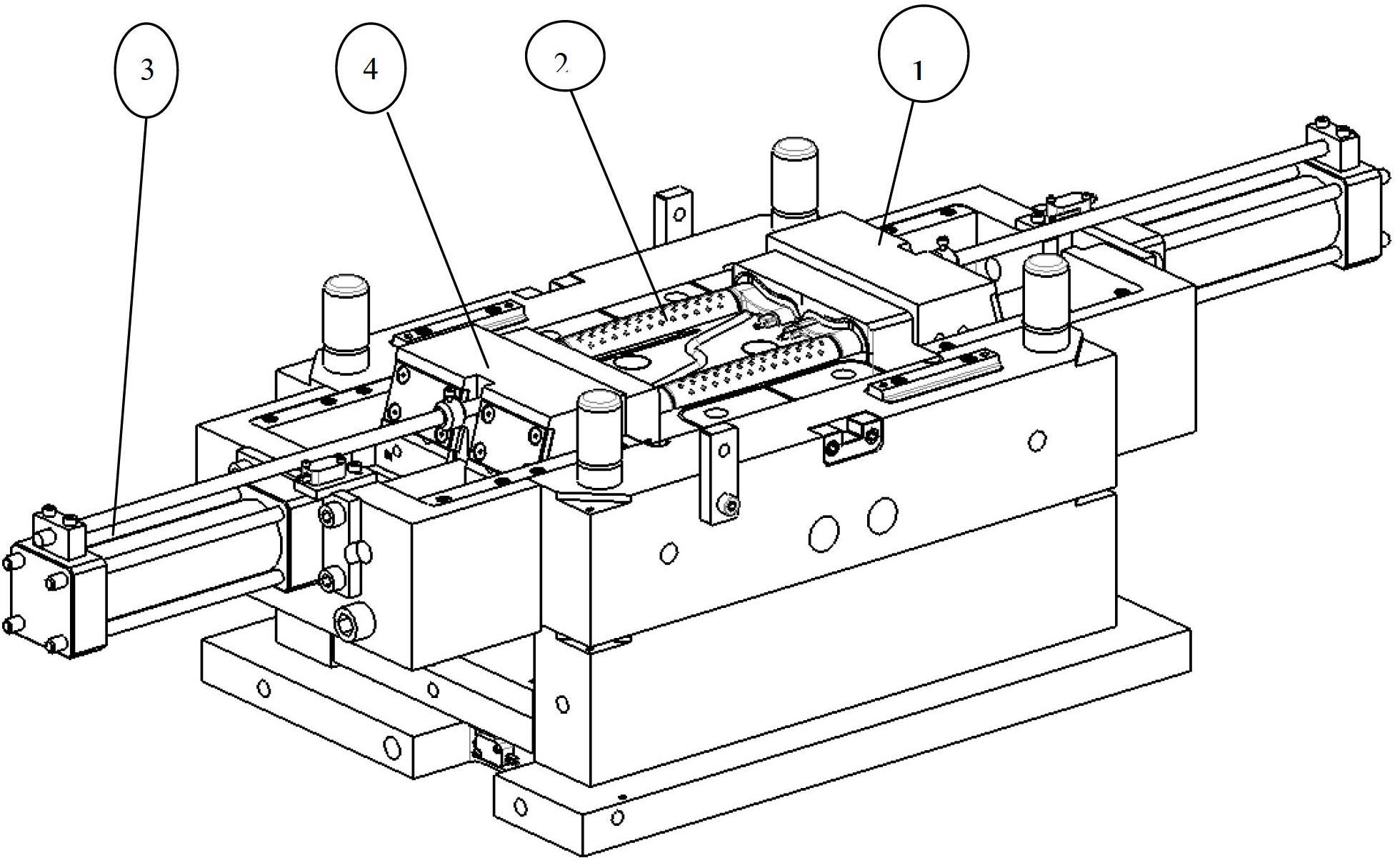

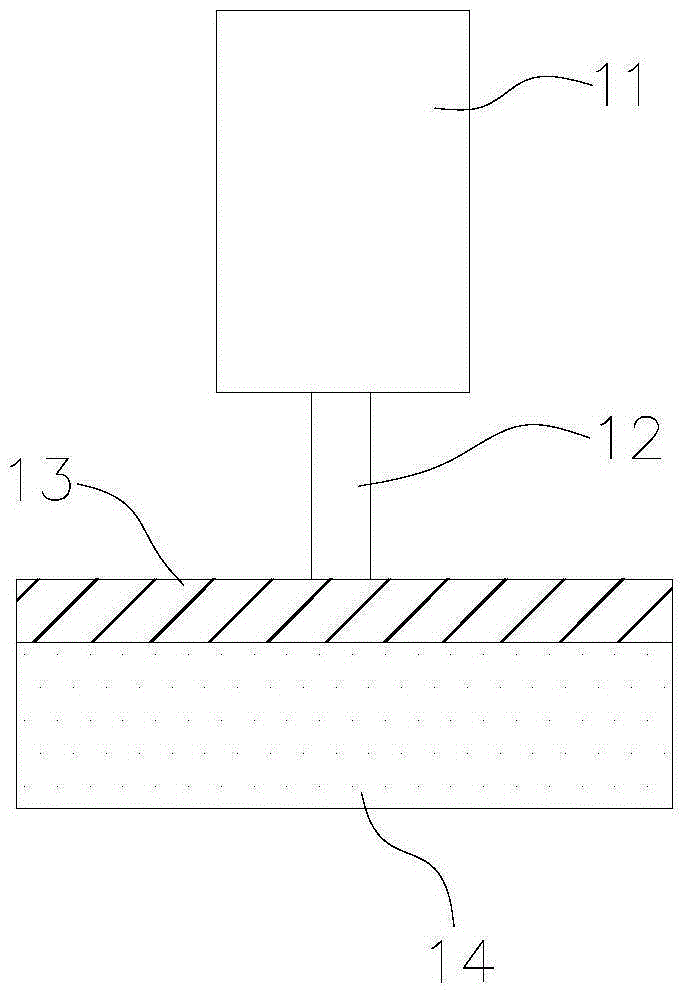

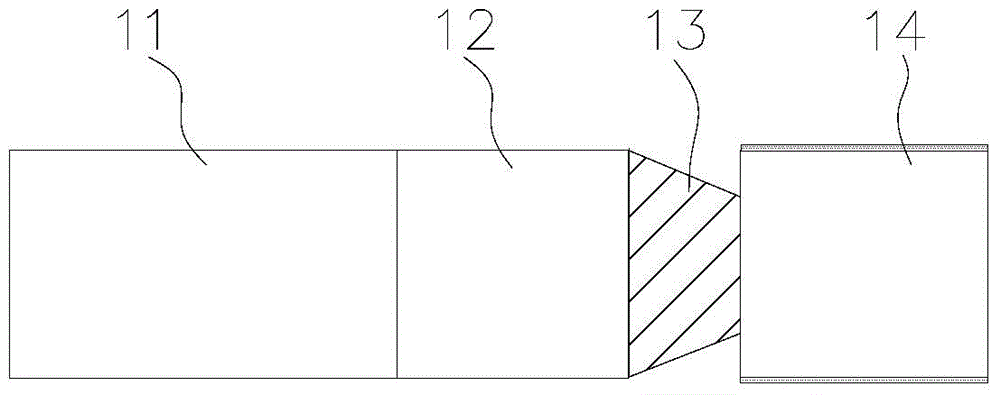

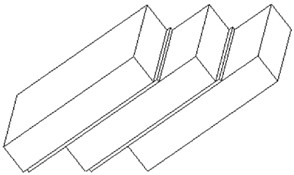

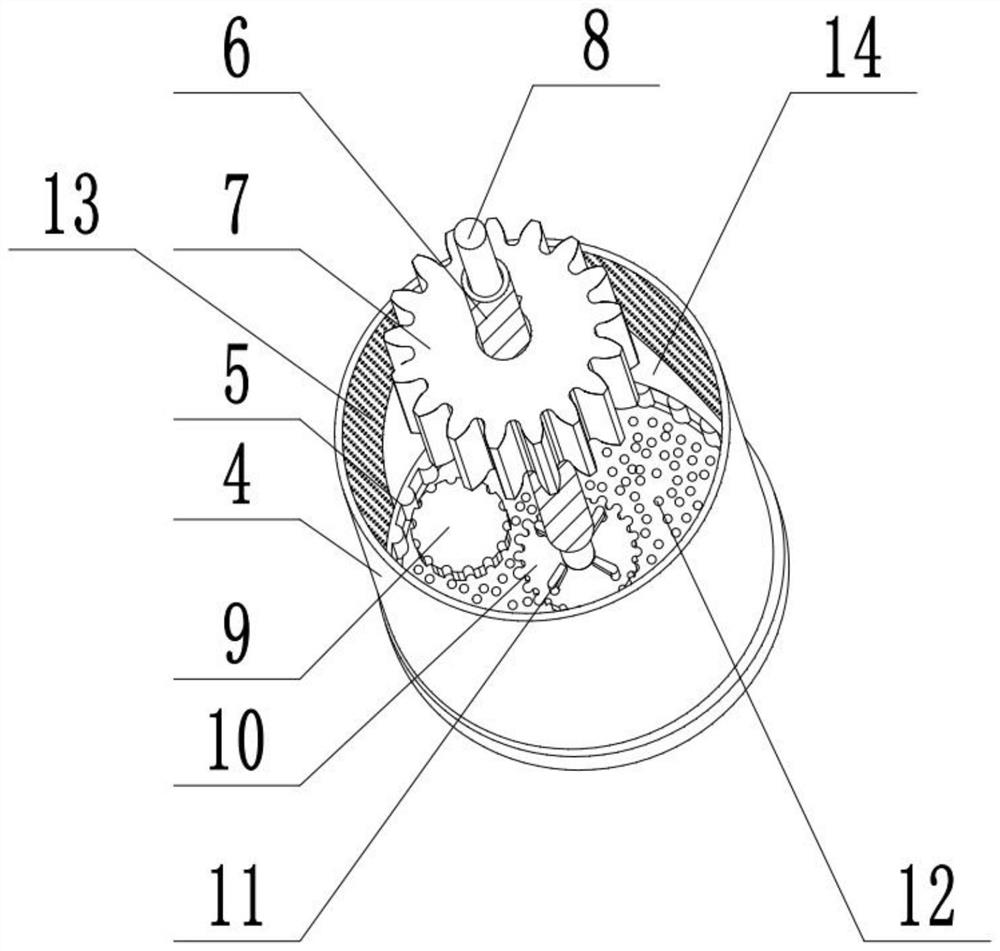

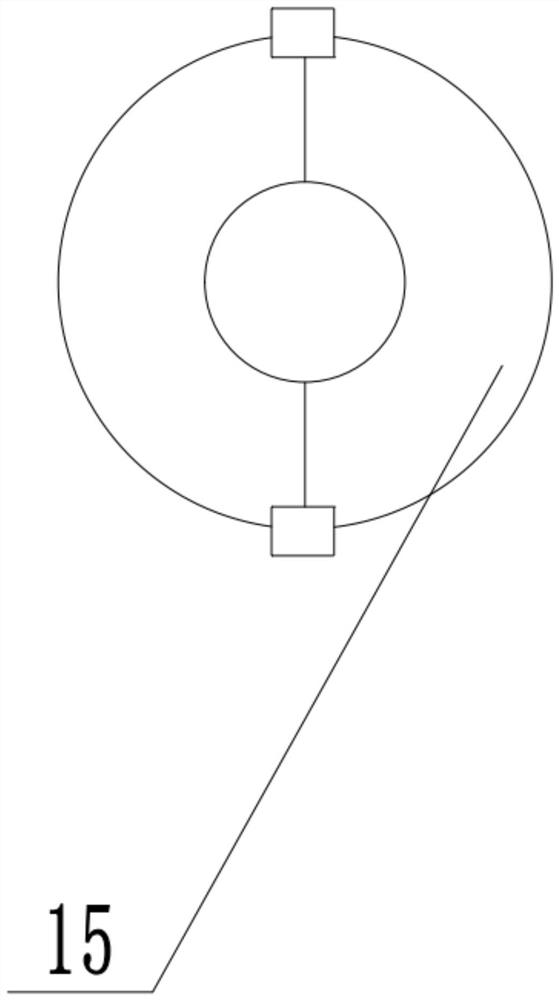

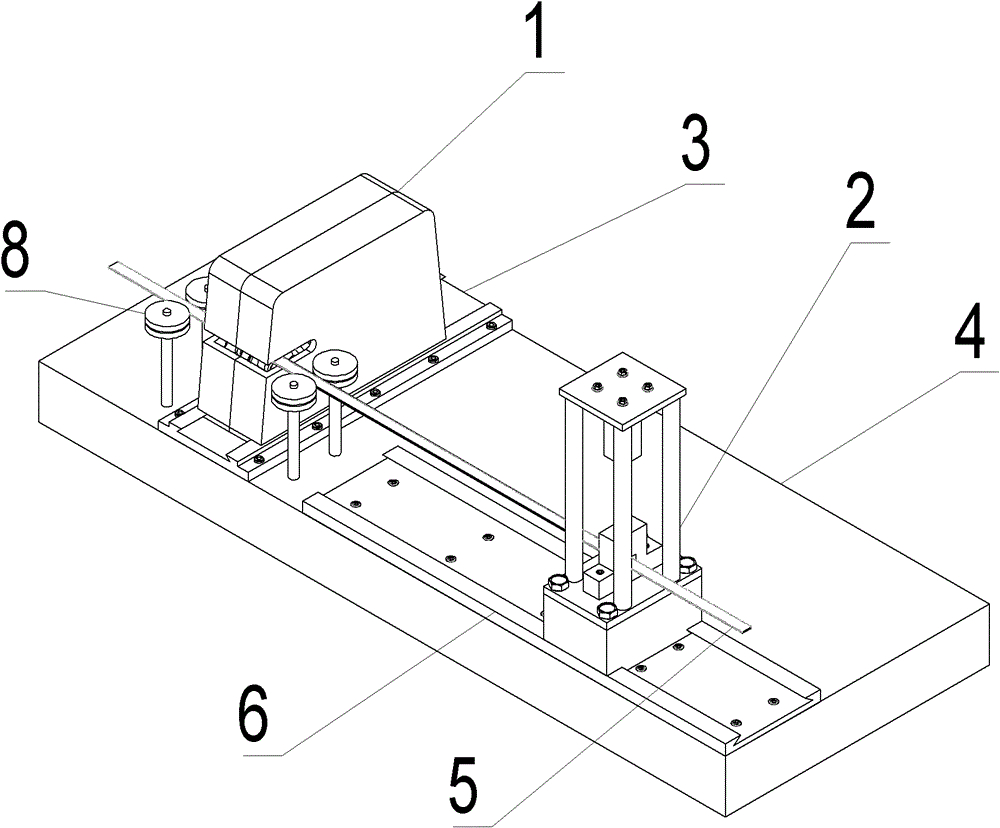

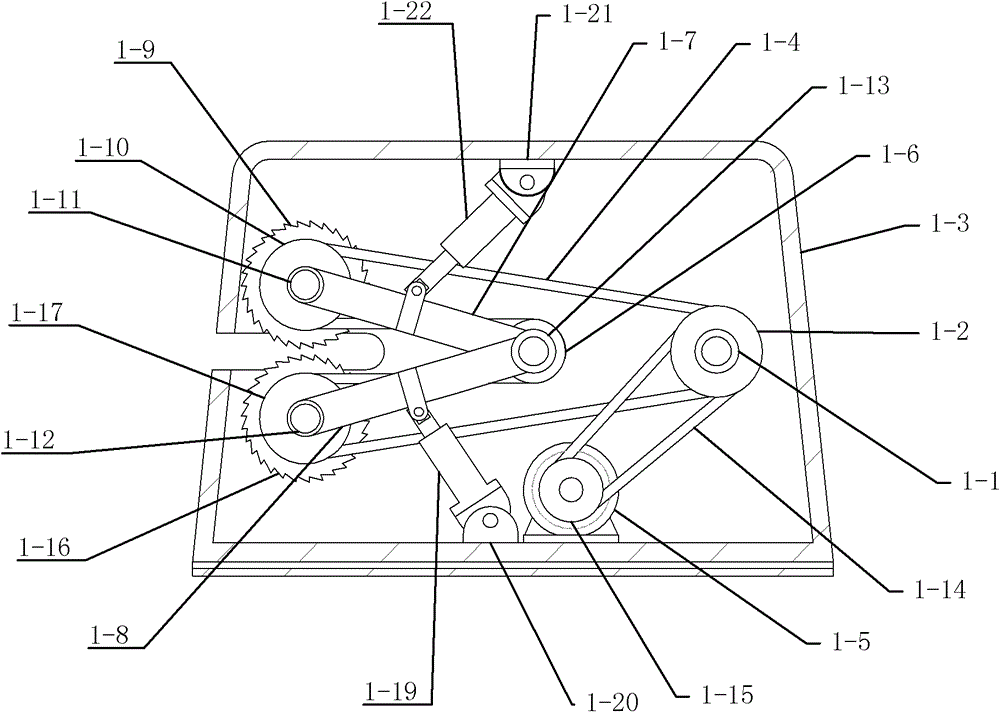

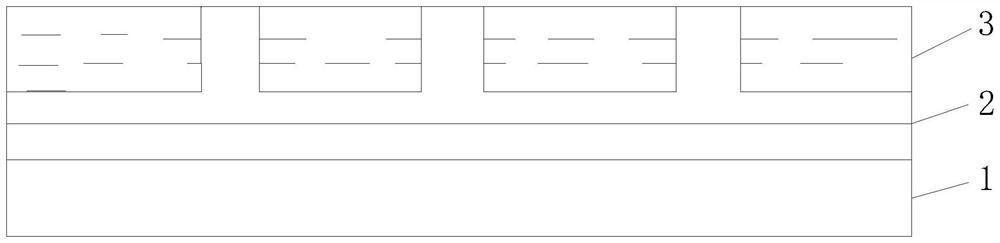

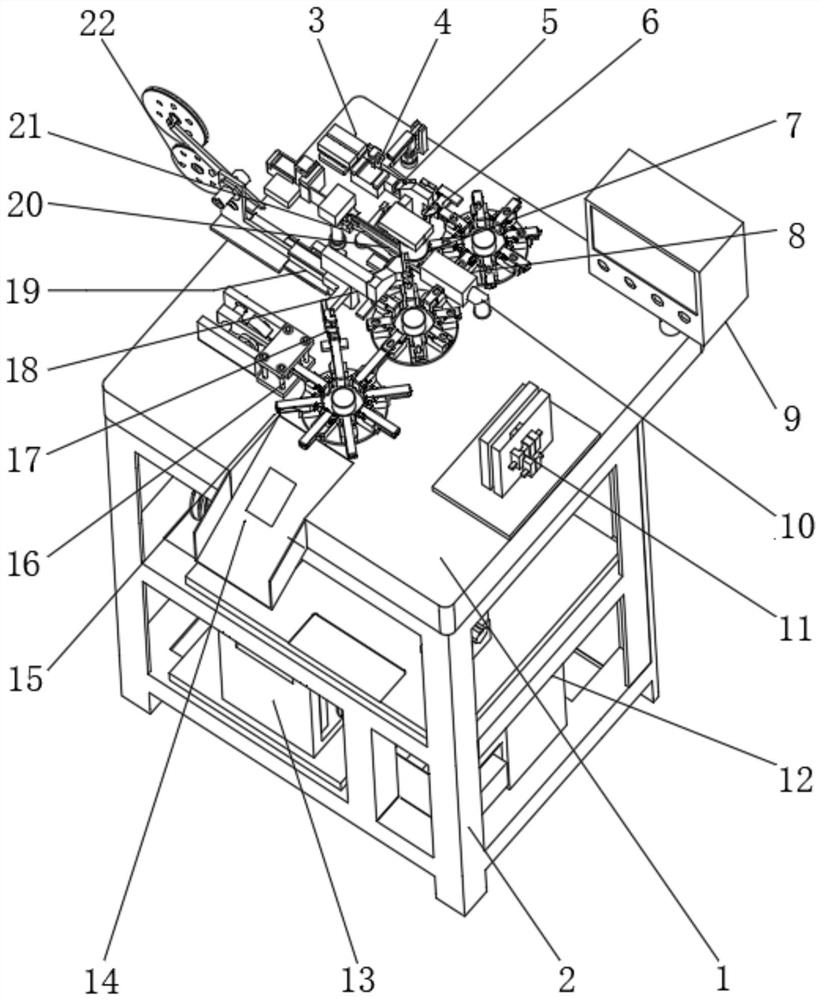

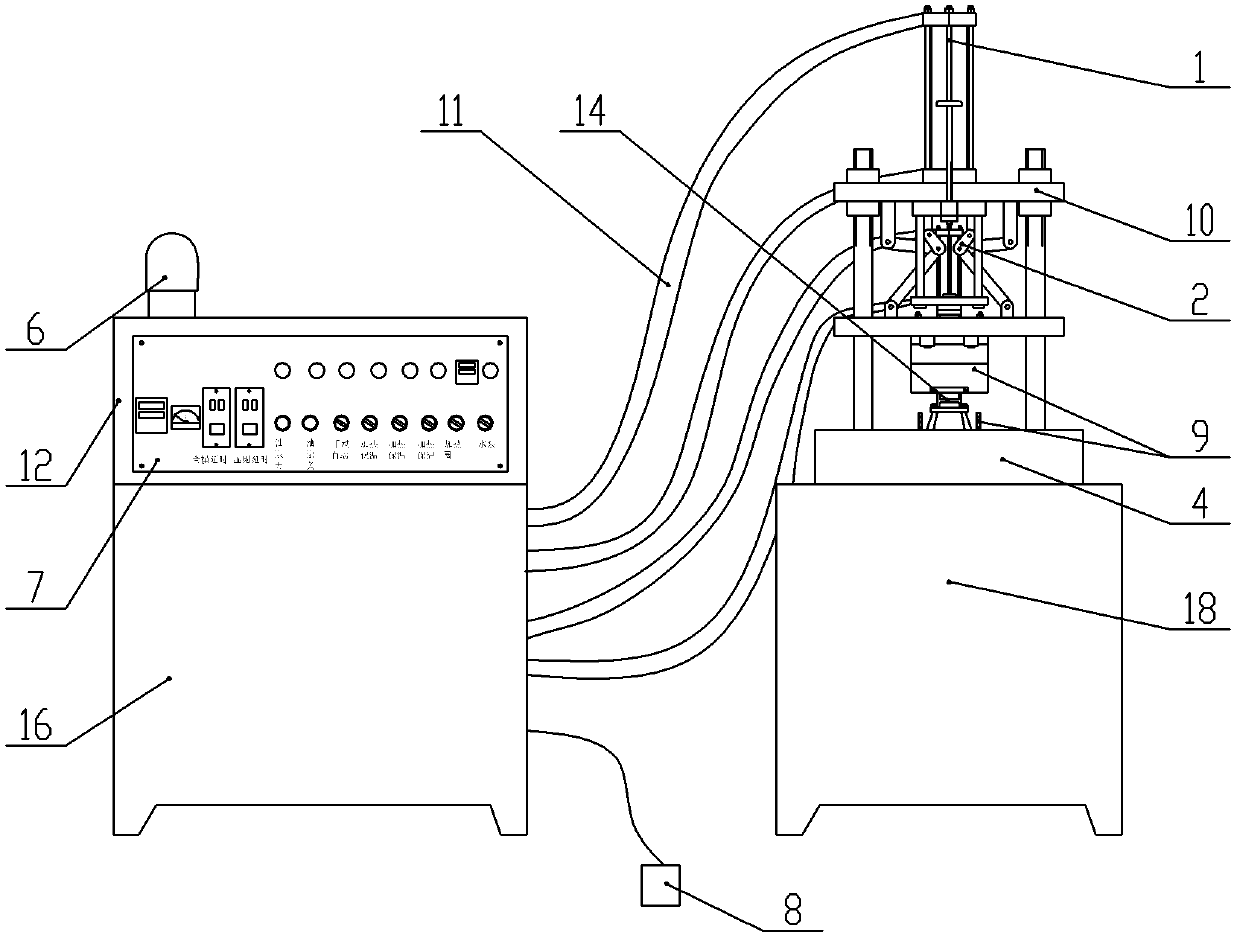

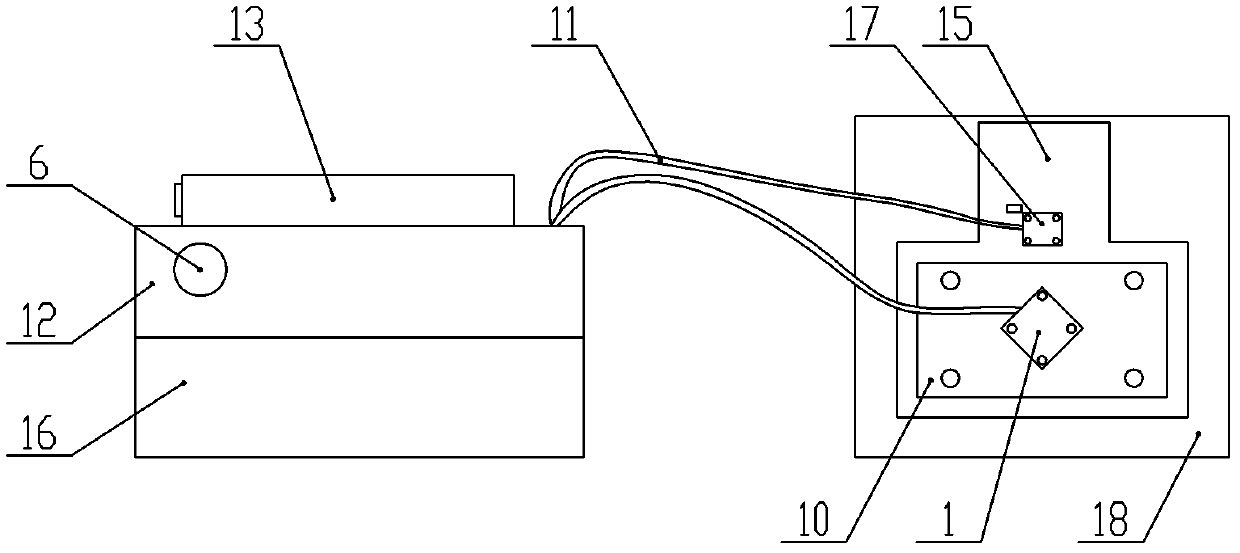

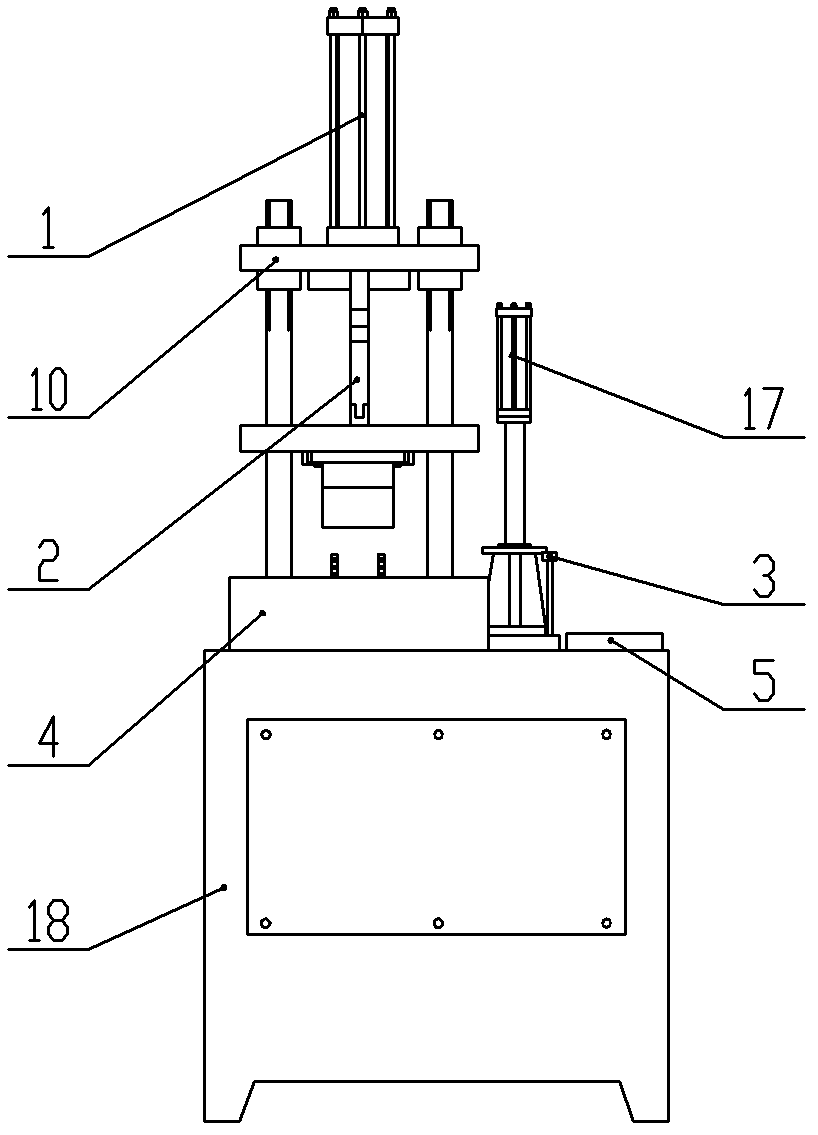

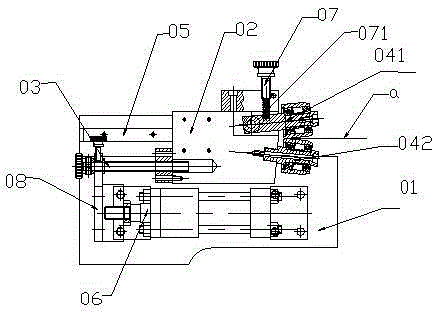

Device for cutting off flat tube of heat exchanger

ActiveCN102009349AReduce throttling lossIncrease productivityOther manufacturing equipments/toolsPlate heat exchangerMilling cutter

The invention provides a device for cutting off a flat tube of a heat exchanger, which comprises a machine base, a milling mechanism capable of transversely sliding along the machine base and a die-cutting mechanism capable of longitudinally sliding along the machine base, wherein the flat tube which is longitudinally conveyed along the machine base is arranged in the milling mechanism and the die-cutting mechanism by penetration, a milling cutter for milling the flat tube and forming a milling cut is arranged on the milling mechanism, and a die cutter which can detect the position of the milling cut and perform die-cutting is arranged on the die-cutting mechanism. The device has the advantages that the device for cutting off the flat tube of the heat exchanger can avoid the deformation and the shrinkage of the cut-off end surfaces of the flat tube, lead the flow of refrigerant to be smooth and improve the heat exchange efficiency of the heat exchanger.

Owner:浙江兰通空调设备有限公司

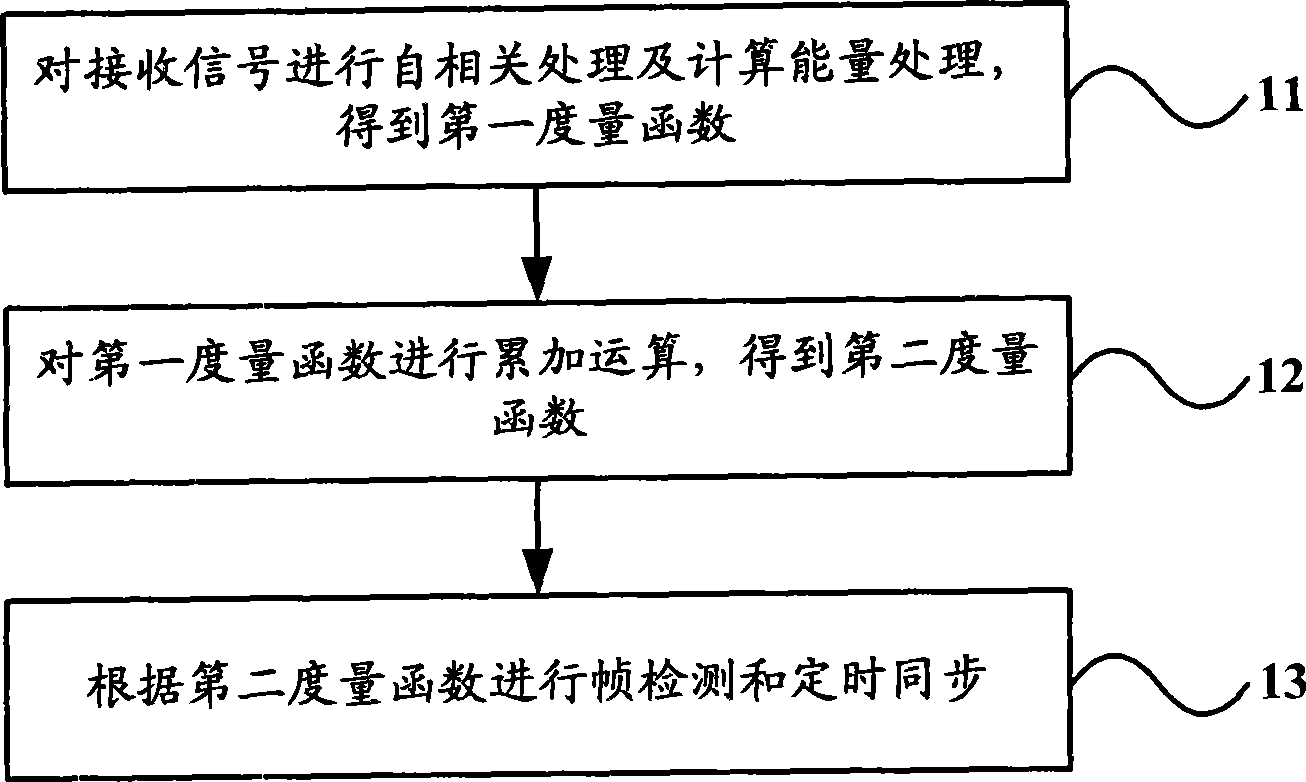

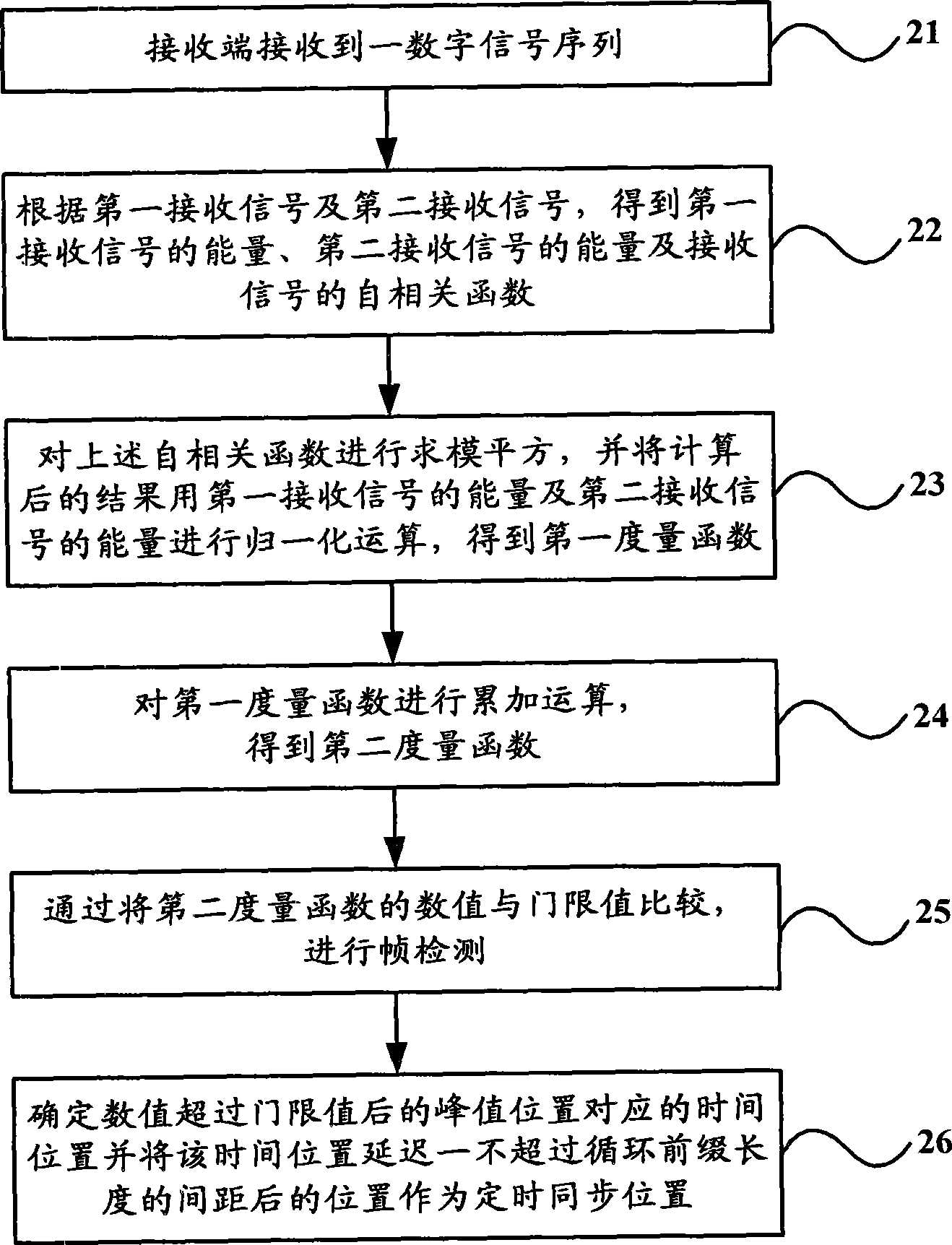

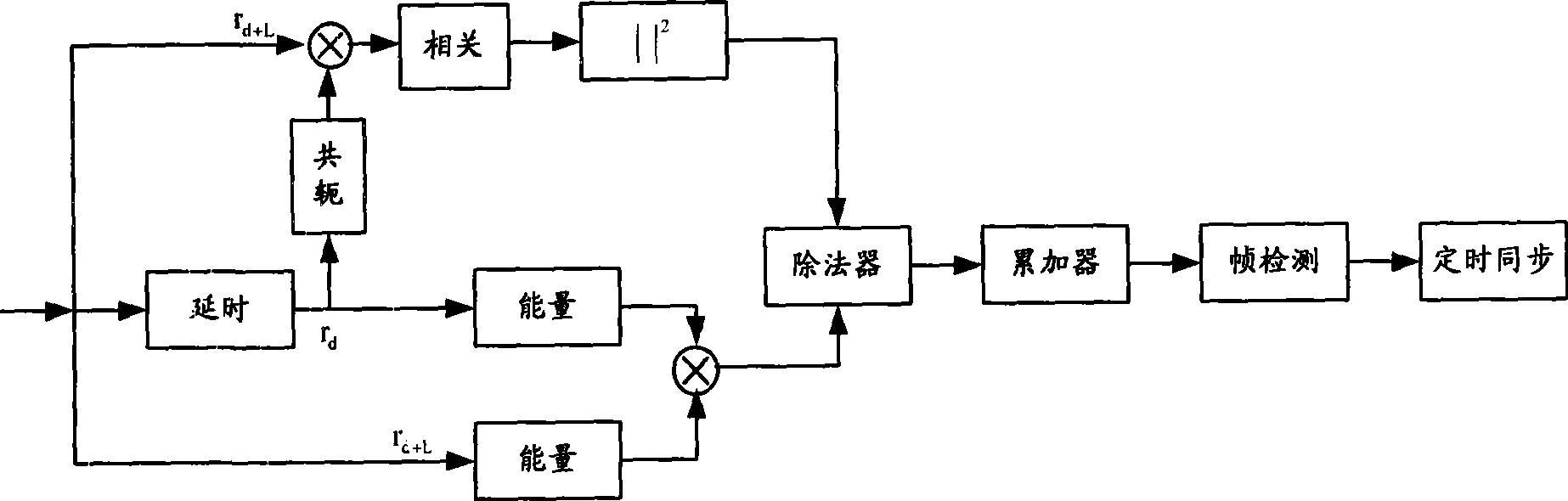

Time synchronization method and apparatus

InactiveCN101442360AImprove glitchImprove accuracyData switching by path configurationRadio transmission for post communicationComputer scienceFalse alarm

The embodiment of the invention relates to a time synchronization method and a time synchronization device. The time synchronization method comprises the following steps: a first metric function which characterizes the autocorrelation degree of a received signal is received according to an autocorrelation function of the received signal; the first metric function is subject to accumulated operation to obtain a second metric function; the frame detection and the timing synchronization are performed according to the second metric function; and the time synchronization device comprises a processing module used for obtaining the first metric function, an accumulation module used for performing accumulated operation on the first metric function to obtain the second metric function, and a frame detection and timing synchronization module used for performing the frame detection and the timing synchronization according to the second metric function. The time synchronization method and the time synchronization device can improve the accuracy of the frame detection and the timing synchronization, and reduce the false-alarm probability of the frame detection.

Owner:HUAWEI TECH CO LTD

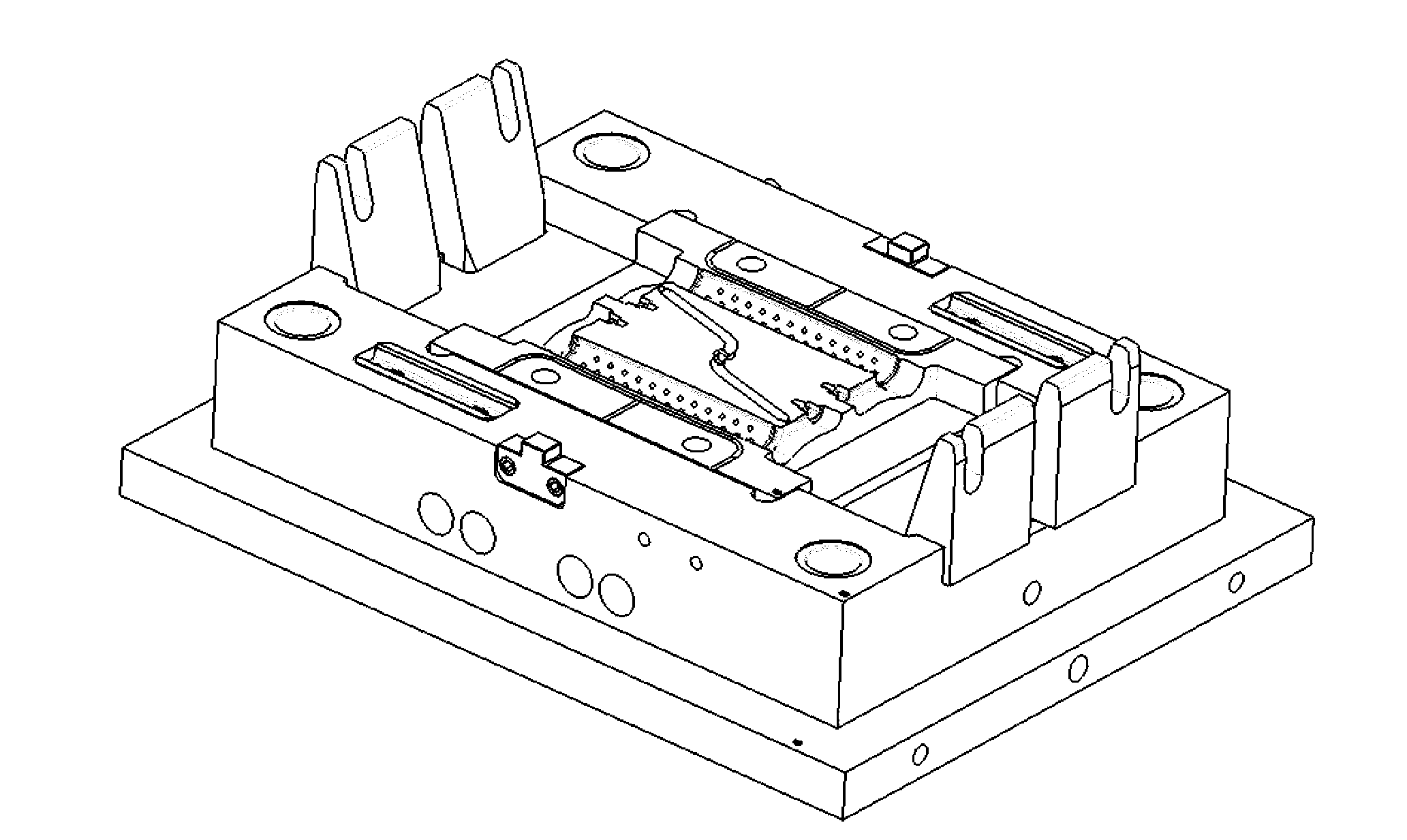

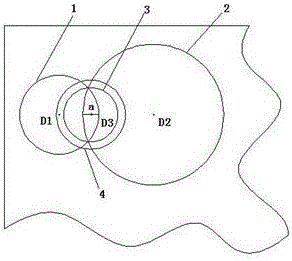

Deformation reducing and uniformly cooling injection mold for long and thin handles and production process

InactiveCN102700070APre-existing process conditionsCurrent situationEngineeringMechanical engineering

The invention relates to a deformation reducing and uniformly cooling injection mold for long and thin handles and a production process. The mold comprises a movable mold, a first side slide block forming mechanism (1), oil cylinder core pulling mechanisms (3) and a second side slide block forming mechanism (4), and is characterized in that the first side slide block forming mechanism (1) and the second side slide block forming mechanism (4) are symmetrically arranged at two sides of the movable mold, the oil cylinder core pulling mechanisms (3) are arranged on respective outer sides of the first side slide block forming mechanism (1) and the second side slide block forming mechanism (4), and a product (2) is arranged between the first side slide block forming mechanism (1) and the second side slide block forming mechanism (4). The deformation reducing and uniformly cooling injection mold for the long and thin handles disclosed by the invention has a stable performance, a uniformly cooling system for movable and fixed molds reduces the forming cycle, the quality of the product can be better guaranteed, and the production efficiency is improved.

Owner:KUSN TUOAN PLASTIC PRODS

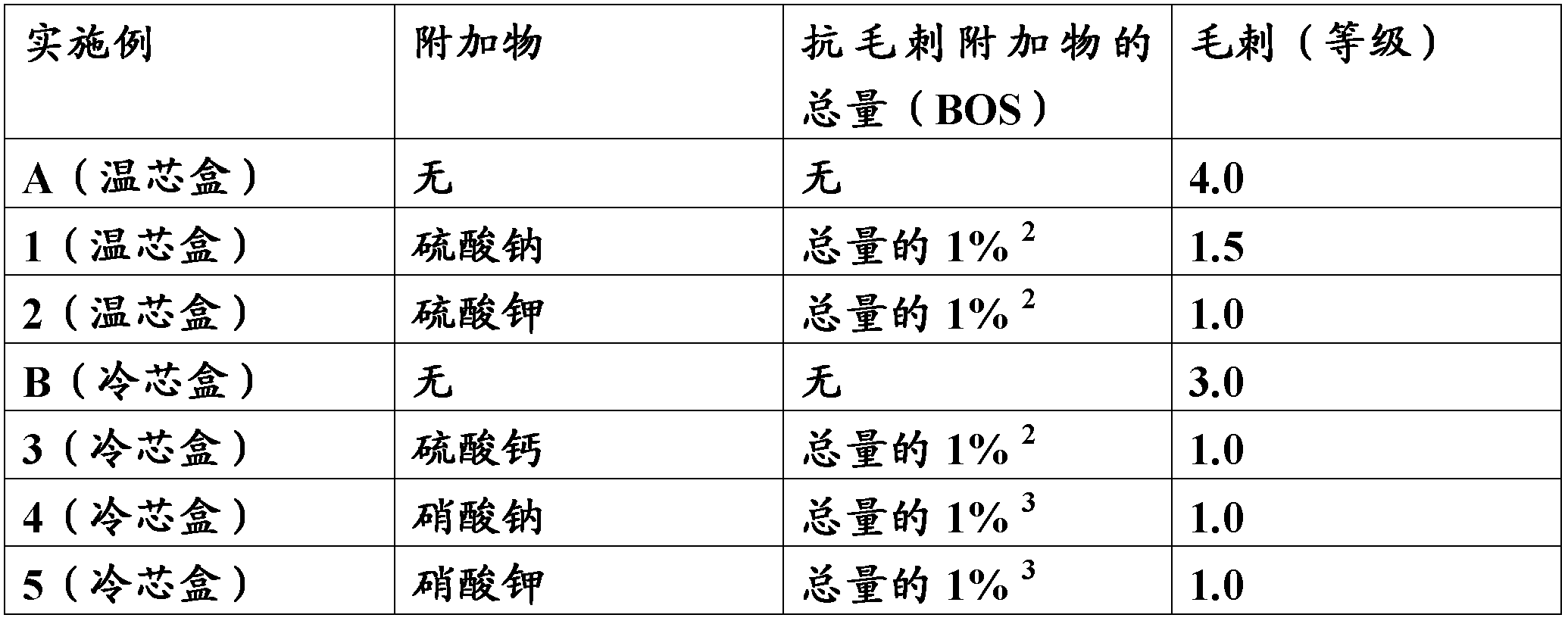

Burr preventive forming method for splayed holes of PCB (printed circuit boards)

InactiveCN106455331ASimple structureGuaranteed appearancePrinted circuit manufactureEngineeringRaw material

Owner:GUANGDONG KINGSHINE ELECTRONICS TECH CO LTD

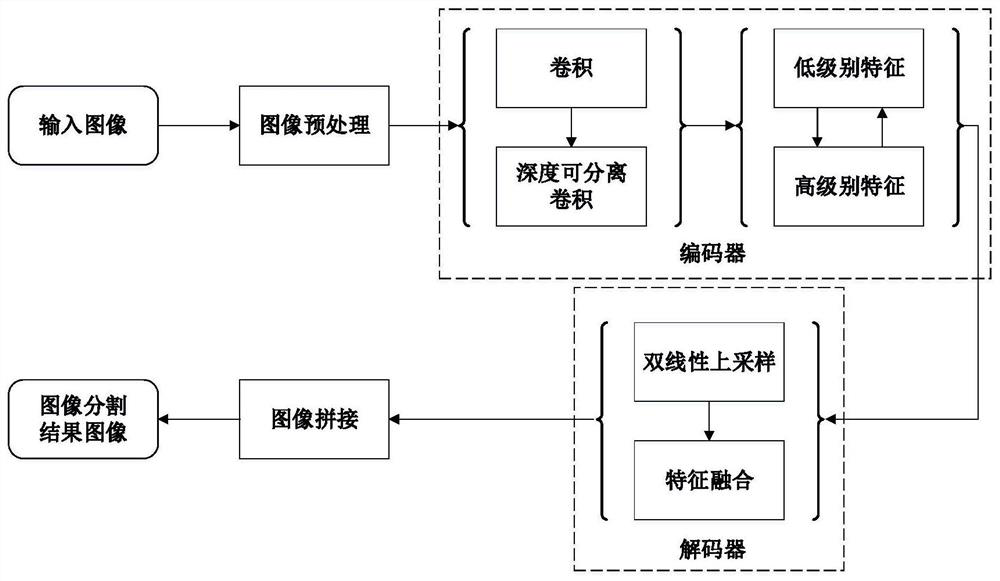

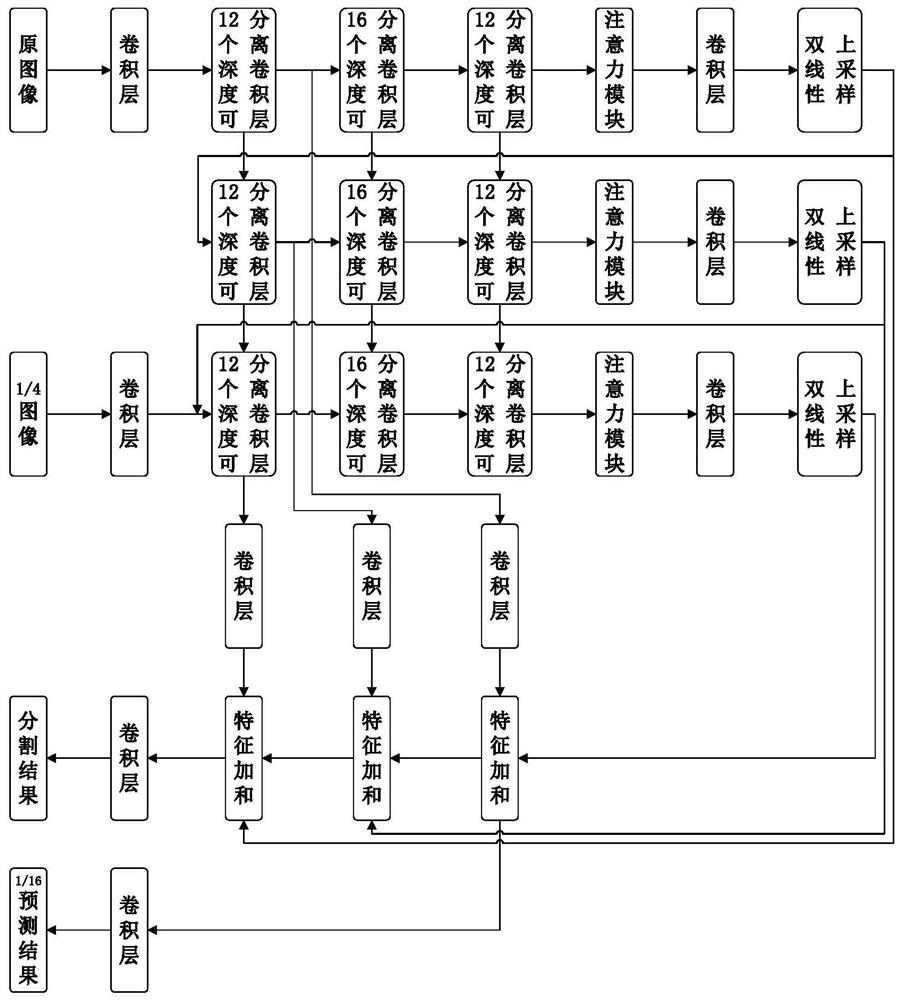

Image segmentation method and system based on multi-branch feature fusion

ActiveCN113205519AImprove accuracyReduce lossImage enhancementImage analysisStochastic gradient descentEngineering

The invention discloses an image segmentation method and system based on multi-branch feature fusion, and the method comprises the steps of building three lightweight sub-networks based on Xception, carrying out the channel reduction operation and quadruple bilinear up-sampling of the output of the three sub-networks, obtaining the high-level feature output of the three sub-networks, then connecting the first advanced feature output and the second advanced feature output in parallel to a second feature extraction module and a third feature extraction module, and building an encoder of an image segmentation model; respectively carrying out channel reduction operation on the outputs of the three feature extraction sub-networks to obtain low-level features and high-level features, and constructing a decoder for completing an image segmentation model; constructing a loss function by using the two prediction images with different sizes; and performing optimization training on the loss function by using a stochastic gradient descent optimizer to obtain a trained image segmentation model, and completing an image segmentation task by using the trained image segmentation model. According to the invention, the segmentation accuracy is improved; the image segmentation speed is accelerated; and the detail part of the segmentation result image is improved.

Owner:XIDIAN UNIV

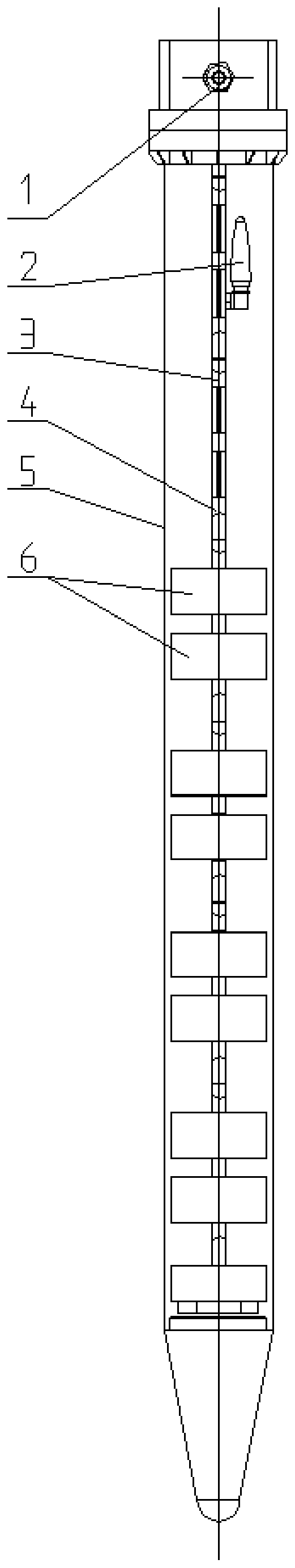

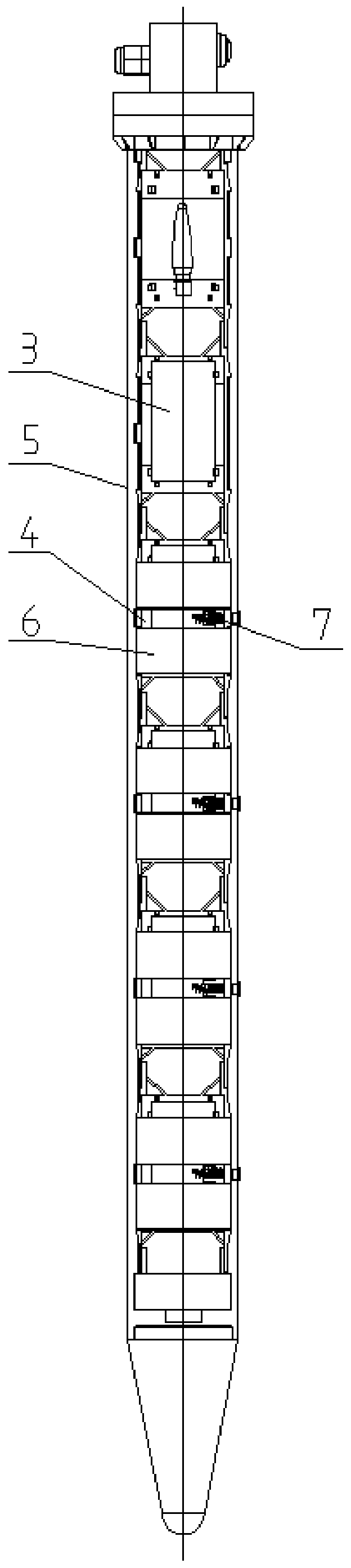

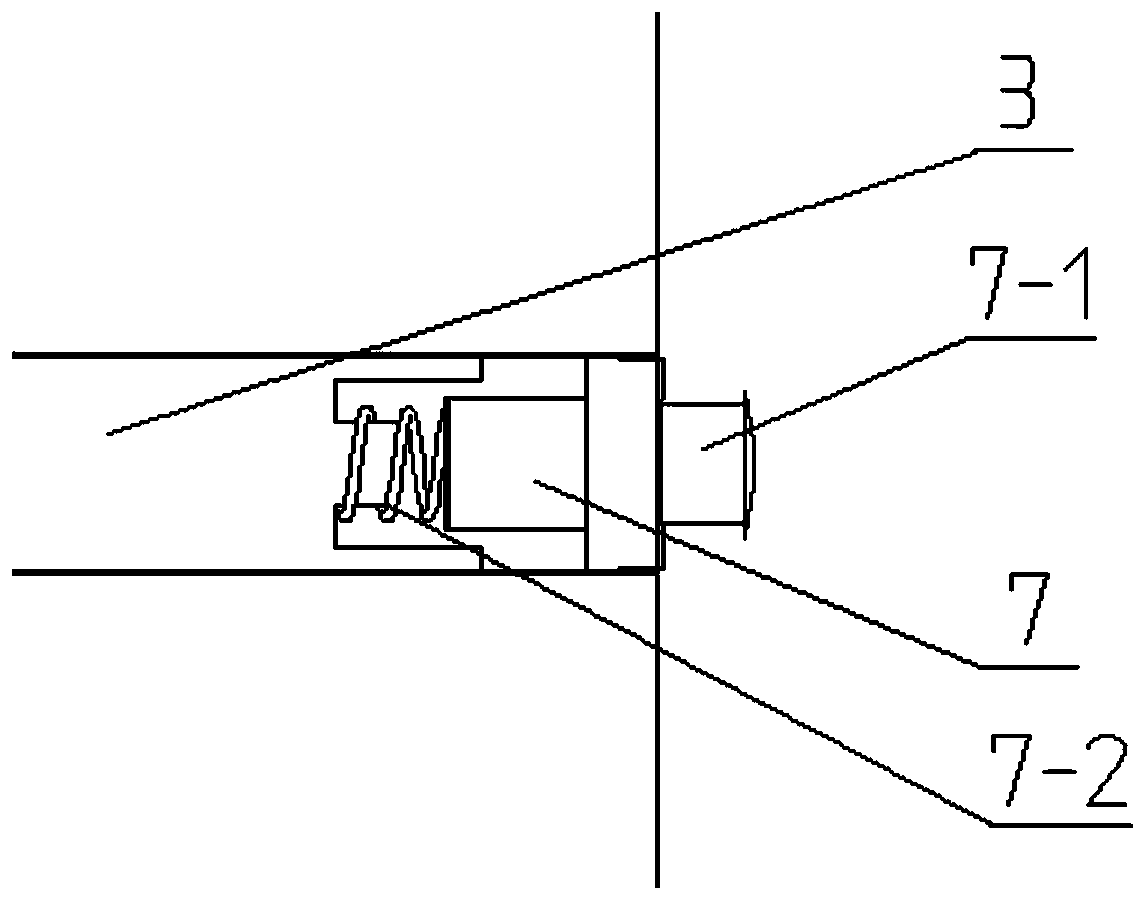

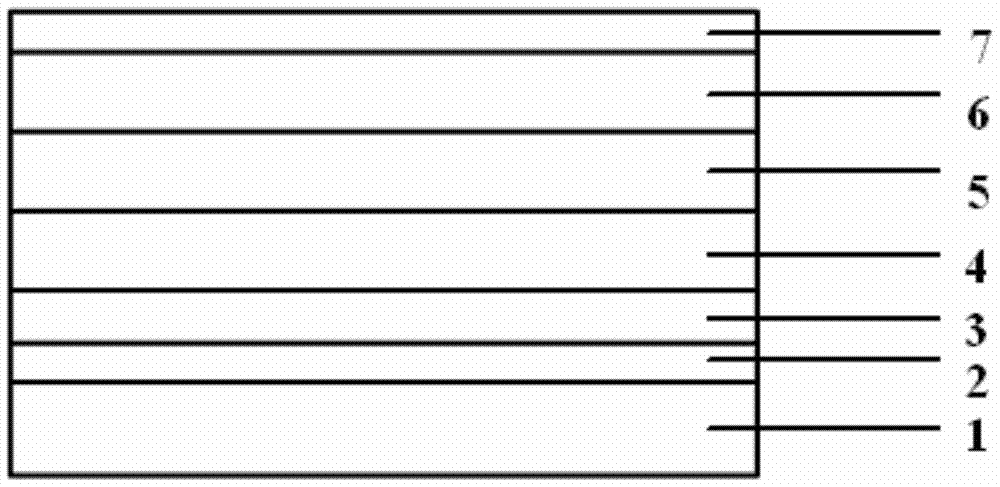

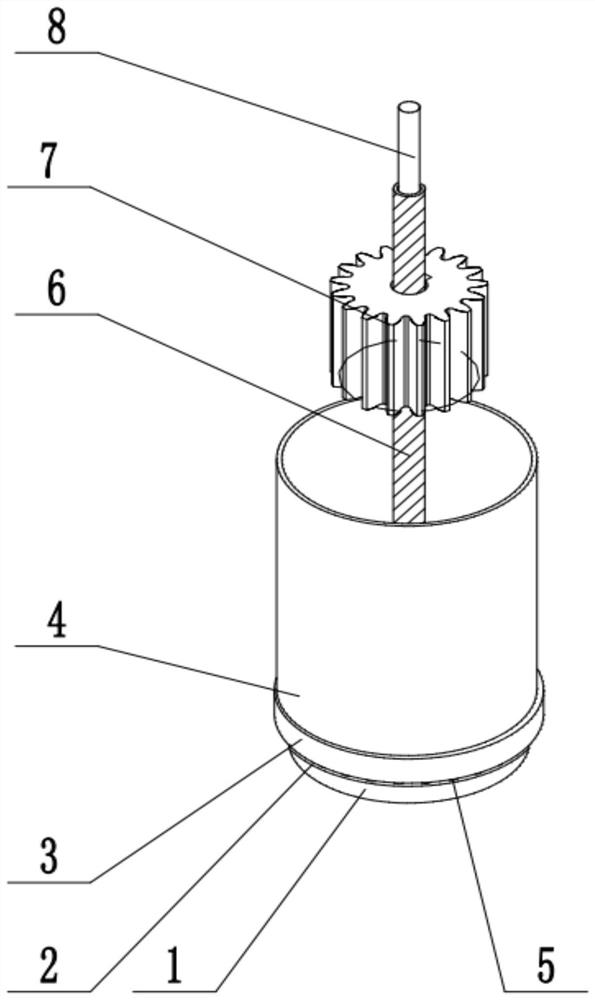

Capacitive multi-layer soil moisture detecting device

InactiveCN110220949ADetect temperature and humiditySimple structureEarth material testingThermometer applicationsCapacitanceEngineering

The invention relates to a capacitive multi-layer soil moisture detecting device. The capacitive multi-layer soil moisture detecting device comprises a shell, a bracket is arranged inside the shell, and a plurality of humidity sensitive capacitors are arranged on the bracket; and a capacitive soil moisture switching circuit is further arranged inside the shell, and the humidity sensitive capacitors are connected with the capacitive soil moisture switching circuit. The capacitive multi-layer soil moisture detecting device is embedded in soil, and the temperature and humidity of the multi-layersoil are detected in real time according to the output pulse frequency.

Owner:威海精讯畅通电子科技有限公司

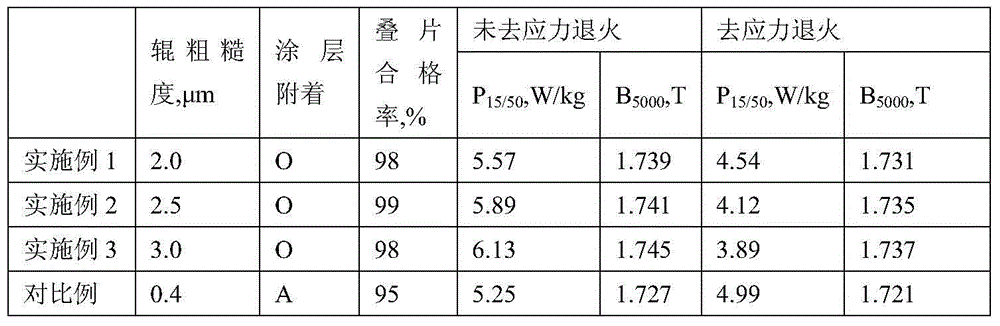

Production method for semi-processed electrical steel

The invention discloses a production method for semi-processed electrical steel. The production method comprises the steps of molten iron desulphurization, converter smelting, RH refining, continuous casting, hot rolling, acid pickling, cold rolling, continuous annealing furnace annealing, stretching and flattening, coating manufacturing, performance examining and packaging. Specifically, molten steel is cast into blanks in a continuous casting mode and the blanks are hot-rolled to 2.0-2.5 mm; the blanks are cold-rolled to 0.6-0.5 mm after being subjected to acid pickling, and the reduction rate is 60-90%; continuous furnace annealing is carried out after cold rolling and the N2 and H2 atmosphere is adopted for protection, wherein N2 accounts for 30-80% in the N2 and H2 atmosphere and the balance is H2; the soaking zone temperature of an annealing furnace ranges from 600 DEG C to 800 DEG C and is preserved for 30-80 seconds; the thickness of products subjected to stretching and flattening ranges from 0.6mm to 0.4mm, the reduction rate is 6-15%, the roughness Ra of a flattening roller on a flattening machine ranges from 2.0 micrometers to 3.0 micrometers and the tension is controlled within 2-5 KN.

Owner:ANGANG STEEL CO LTD

Method for preventing golden finger lead on printed circuit board (PCB) from generating burrs and tilting

ActiveCN105188261AEasy to tiltPromote sheddingPrinted circuit aspectsElectrical connection printed elementsResistEngineering

The invention relates to the technical field of circuit board production, in particular to a method for preventing a golden finger lead on a printed circuit board (PCB) from generating burrs and tilting. One end, which is connected with a golden finger, of the golden finger lead is designed into a trumpet shape; and the connected part of the golden finger lead and the golden finger is relatively wide, so that the problem that the golden finger lead tilts and falls off when a bevel edge is fabricated is solved. The width of the golden finger lead is set to be 0.25+ / -0.025mm, so that the problem that the burrs are generated on the golden finger lead can be solved; and the quality of a product is ensured. A bevel edge area is set into an oil coating area and an oilless area; the area of the golden finger lead covered by a solder resist ink is increased;and the adhesive force of the golden finger lead on the board can be increased, so that the problem that the golden finger lead tilts and falls off is further solved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

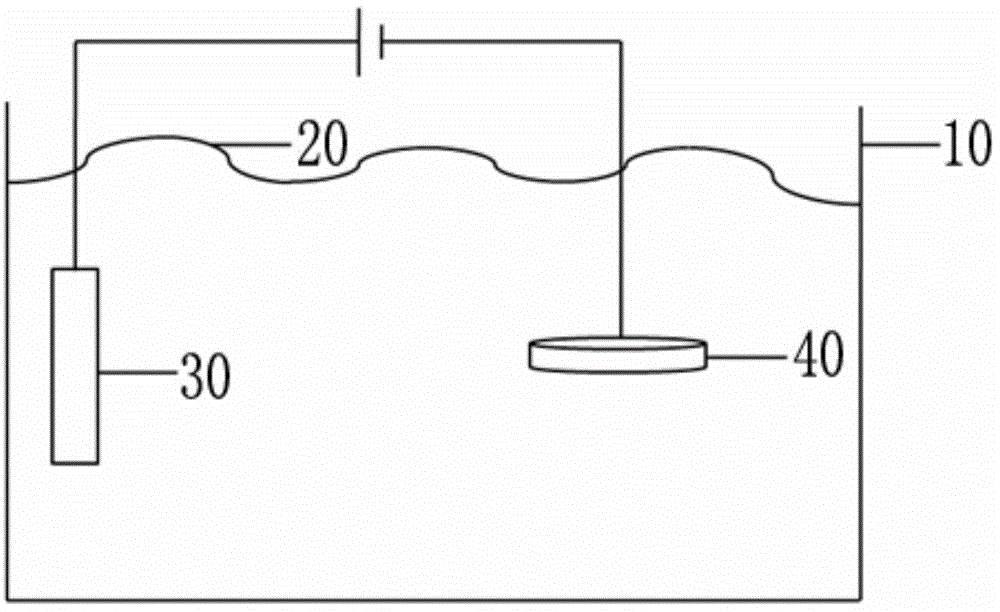

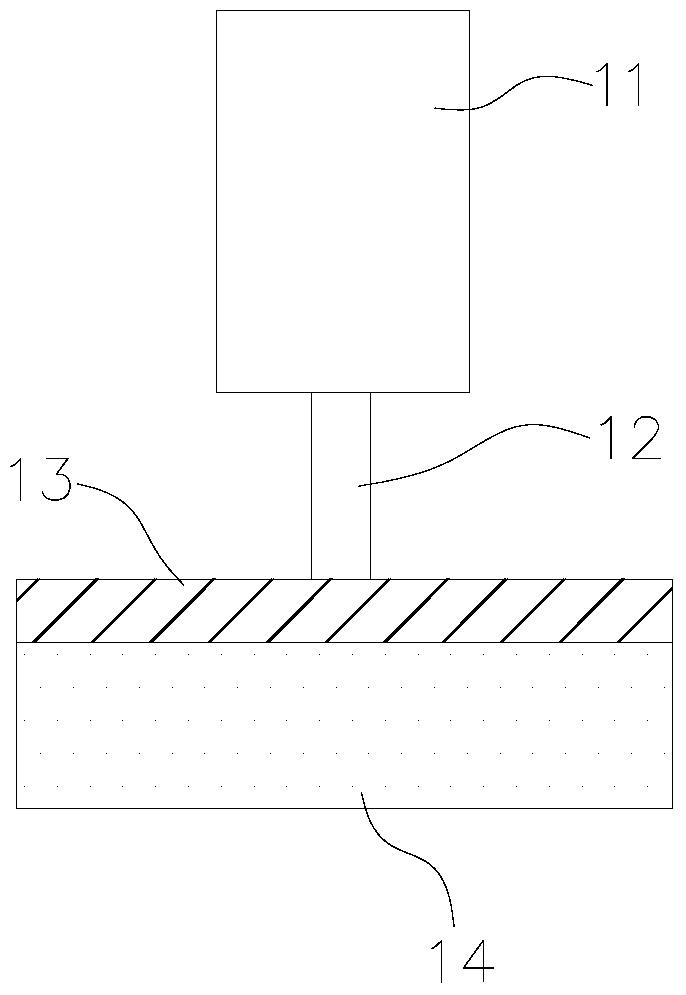

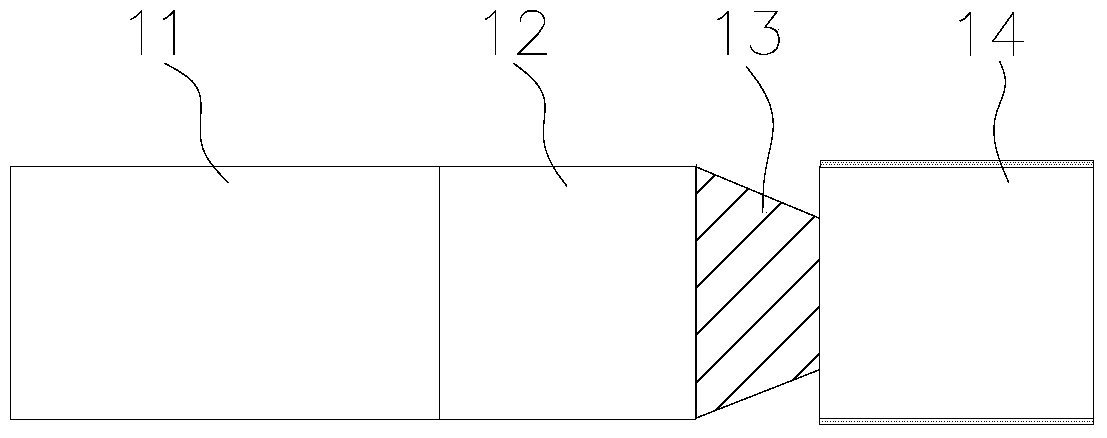

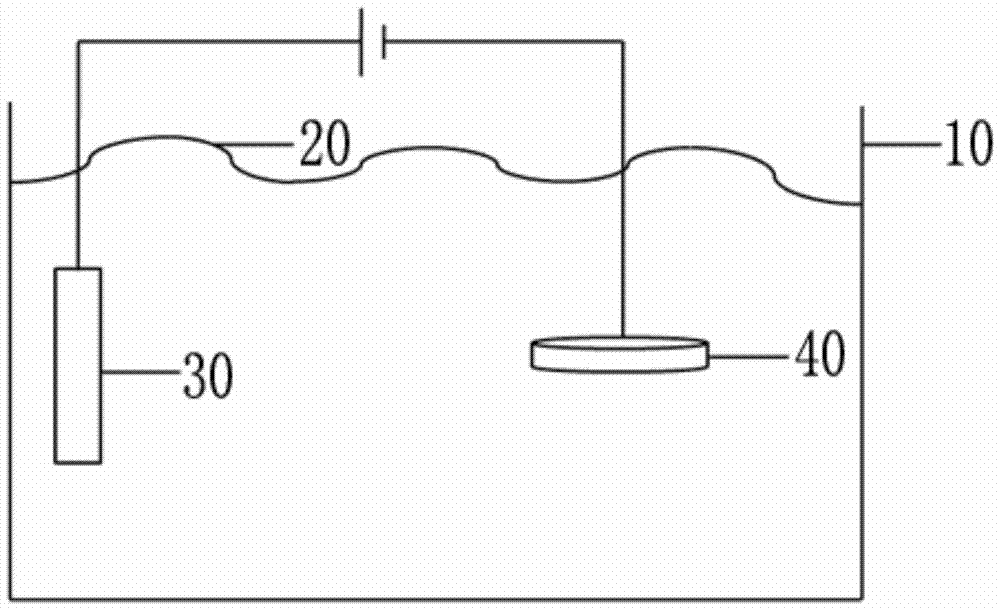

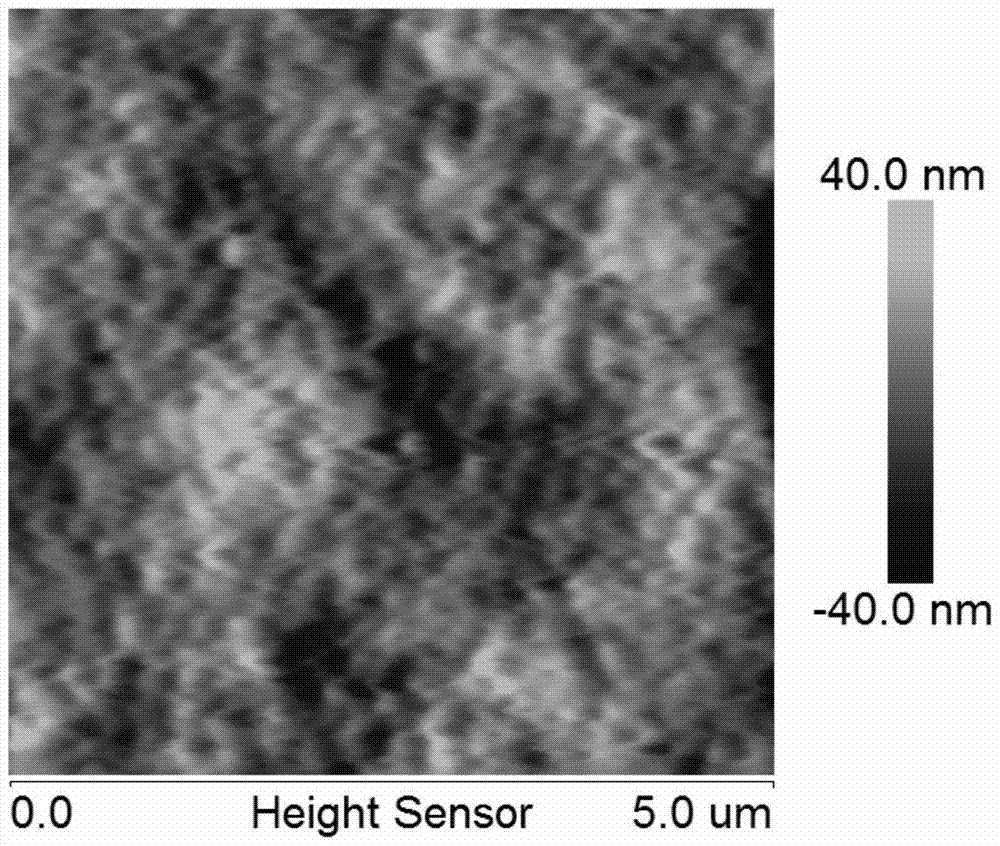

Preparation method for copper substrate for vertical LED (light-emitting diode) chips

ActiveCN104638096ASolve efficiency problemsSolve the problem of longevitySemiconductor devicesCopper platingBiological activation

The invention provides a preparation method for a copper substrate for vertical LED (light-emitting diode) chips, which includes the following steps: (1) a P-type metal electrode layer is deposited on the surface of an epitaxial wafer, a layer of Au is then plated on the P-type metal electrode layer, and thereby a first substrate is obtained; (2) the first substrate is cleaned, and after a degreasing effect is achieved, H2SO4 is used for surface activation; (3) a phosphorized copper anode is blackened, and is then cleaned; (4) the first substrate treated in step 2 and the phosphorized copper anode treated in step 3 are put into copper plating solution and electroplated, so that an electroplated sample is obtained; (5) the electroplated sample is cleaned in order to remove residual copper plating solution, so that the copper substrate is obtained. The preparation method has the characteristics of simple process and low preparation cost, moreover, the copper substrate prepared by the method has the characteristics of no burrs, good surface uniformity, good smoothness, low roughness and good thermal and electric conductivities, and thereby a chip which is prepared by adopting the copper substrate has high light extraction efficiency.

Owner:广州市众拓光电科技有限公司

A method for preventing burrs and warping of gold fingers on pcb

ActiveCN105188261BImprove glitchJoint widthPrinted circuit aspectsElectrical connection printed elementsResistEngineering

The invention relates to the technical field of circuit board production, in particular to a method for preventing burrs and warping of golden fingers on a PCB. In the present invention, the end connecting the gold finger line and the gold finger is designed in a trumpet shape, so that the joint between the gold finger line and the gold finger is wider, thereby improving the problem of the gold finger line warping and falling off when making the hypotenuse. Setting the line width of the gold finger line to 0.25±0.025mm can improve the problem of burrs on the gold finger line and ensure the quality of the product. The hypotenuse area is set as the oil-covered area and the oil-free area, which increases the area covered by the solder resist ink on the gold finger guide line, which can increase the adhesion of the gold finger guide line on the board surface, thereby further improving the problem of the gold finger guide line warping and falling off .

Owner:JIANGMEN SUNTAK CIRCUIT TECH

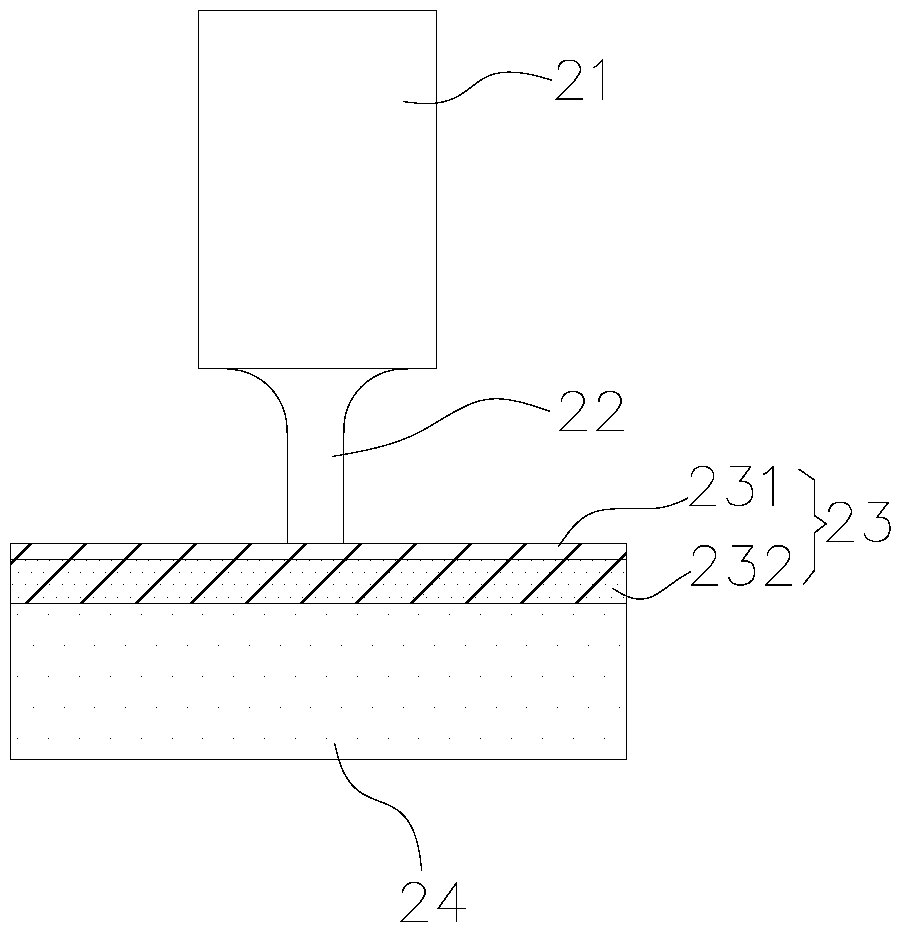

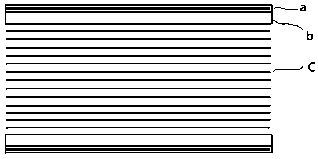

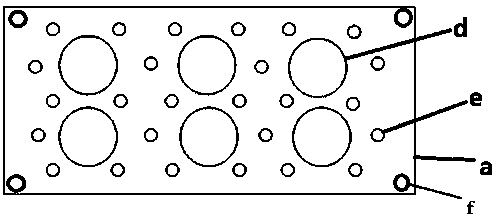

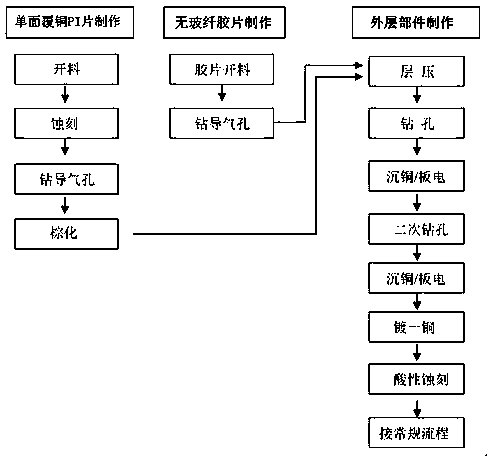

Rigid fiberglass-free photoelectric printed board and machining method thereof

PendingCN109526138AReduce residual air bubbles between layersReduce the difficulty of lamination processLamination ancillary operationsSynthetic resin layered productsEngineeringAir bubble

The invention relates to a rigid fiberglass-free photoelectric printed board which can meet the low-reflection machining requirements of a fiberglass-free photoelectric product. The rigid fiberglass-free photoelectric printed board comprises a first PI sheet, N fiberglass-free films and a second PI sheet which are stacked. A single surface of each of the two PI sheets is coated with copper. The two PI sheets and the fiberglass-free films are pre-drilled to form air guiding holes. The method can reduce the residual air bubbles between layers during pressing, reduces the difficulty of laminationprocess and improves the yield.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

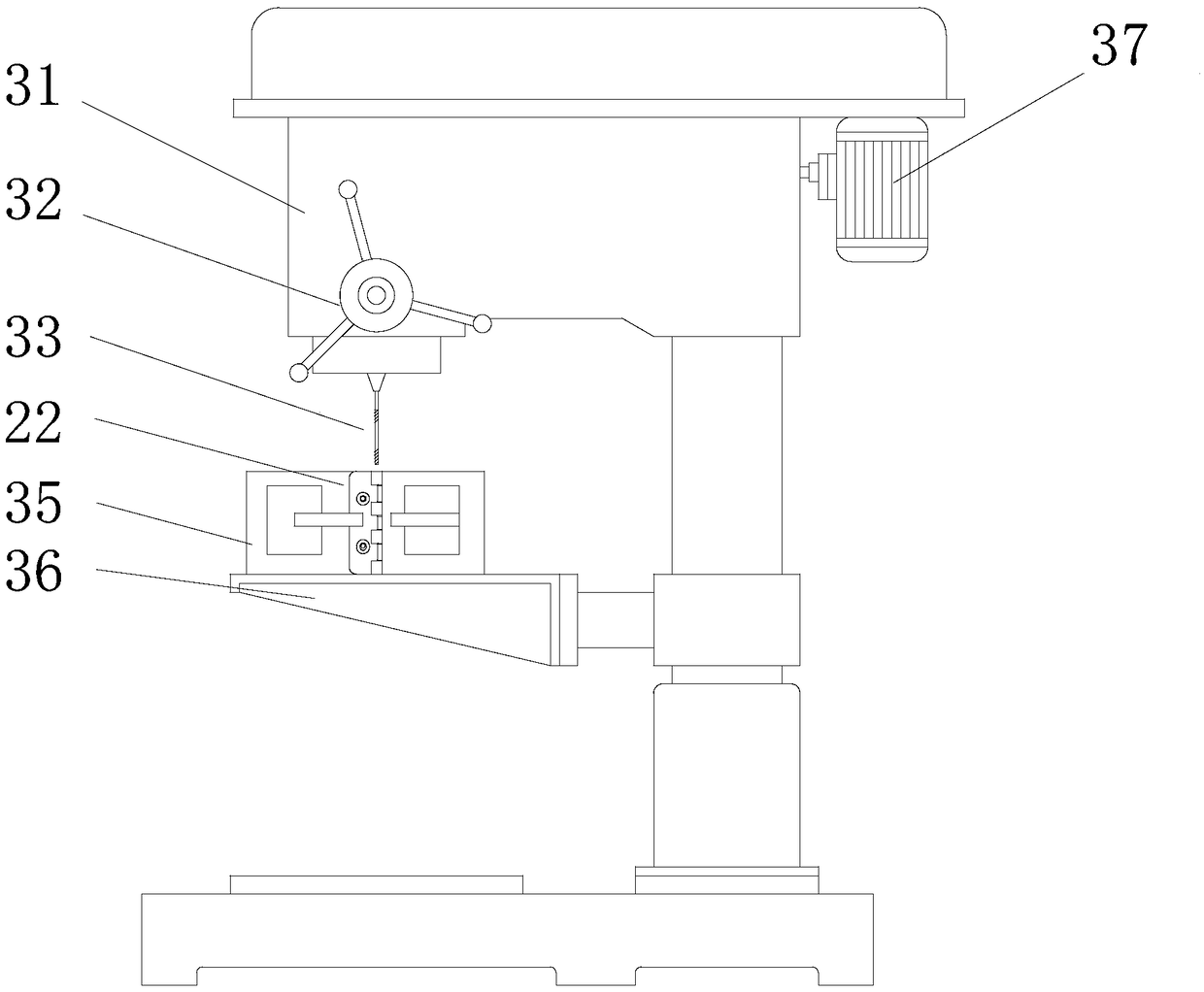

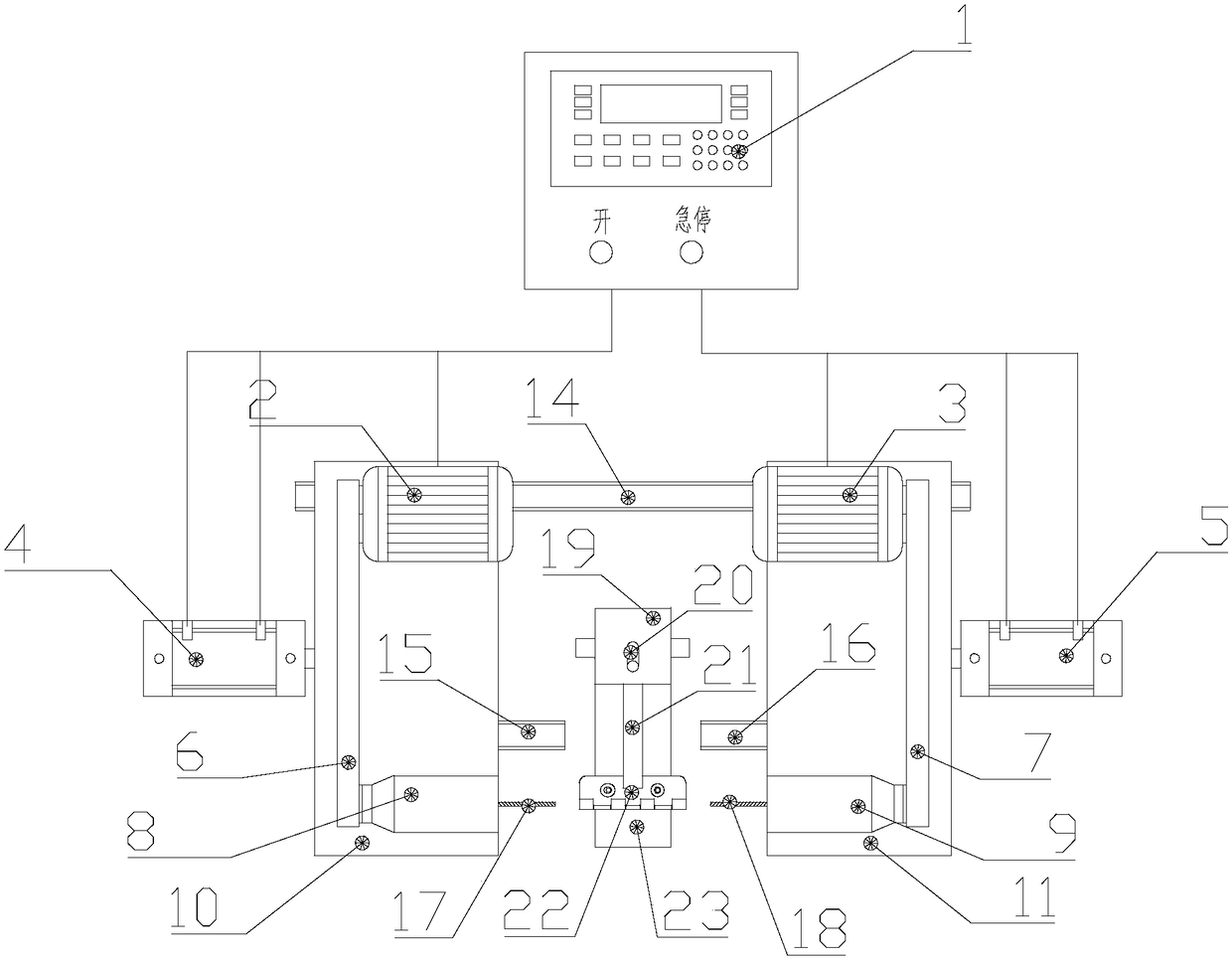

Double-head drilling machine

InactiveCN108856792AUniform horizontal motionExtend your lifeBoring/drilling machinesSemi automaticEngineering

The invention discloses a double-head drilling machine, which comprises a system control box, a first motor, a first drill bit and the like, wherein the first motor and a second motor are respectivelyfixedly arranged at the two ends of a first guide rail, and one end of a first belt is connected with the first motor; the other end of the first belt is connected with a first chuck, and the upper parts of a first bottom plate and a second bottom plate are respectively connected with the two ends of the first guide rail; the first drill bit and the first chuck are fixed and positioned below thefirst guide rail, and a third cylinder and a third bottom plate are fixed and positioned below the first guide rail and the like. Th double-head drilling machine disclosed by the invention has the advantages of reasonable design, simple structure, convenient use, improved stability, structure and safety, semi-automatic control, uniform horizontal movement of the drill bit, concentric four holes, convenient setting of parameters, intuitive interface, reduction in mechanical damage of parts and burrs on drilling edge, greatly improved drilling effect and concentricity, prolonged life of the drill bit, simple whole operation, convenient clamping, reduction in operation time and reduction in labor cost.

Owner:上海华旻机械制造有限公司

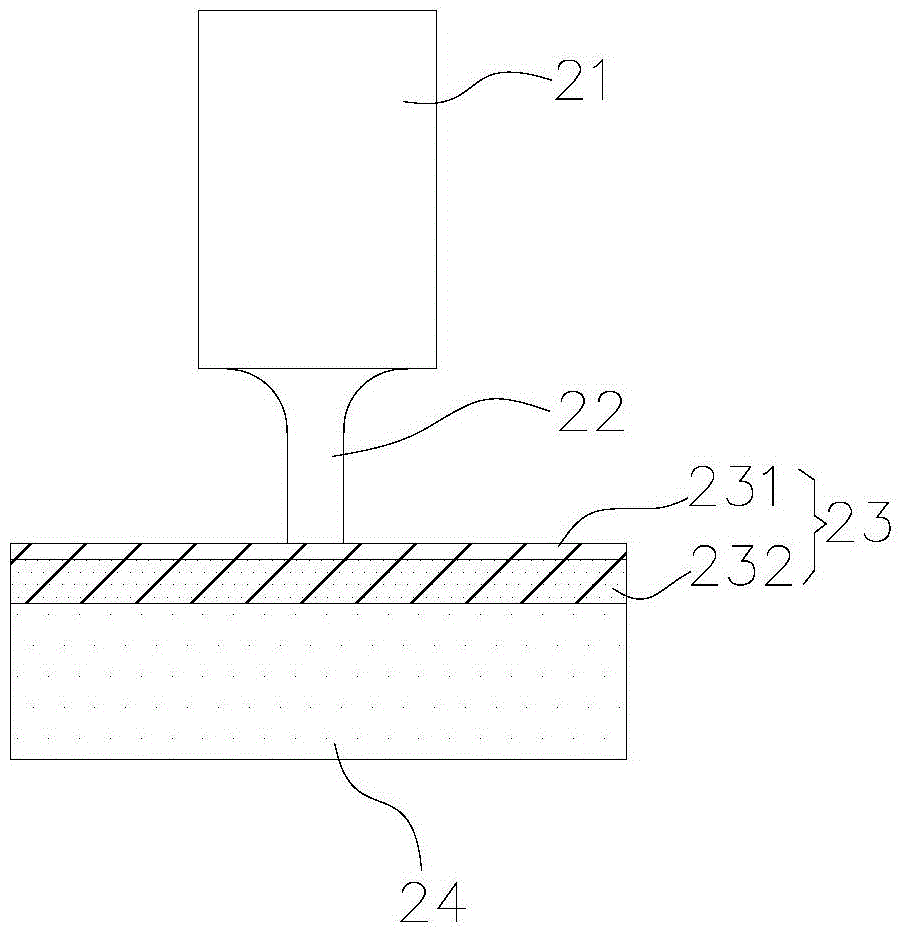

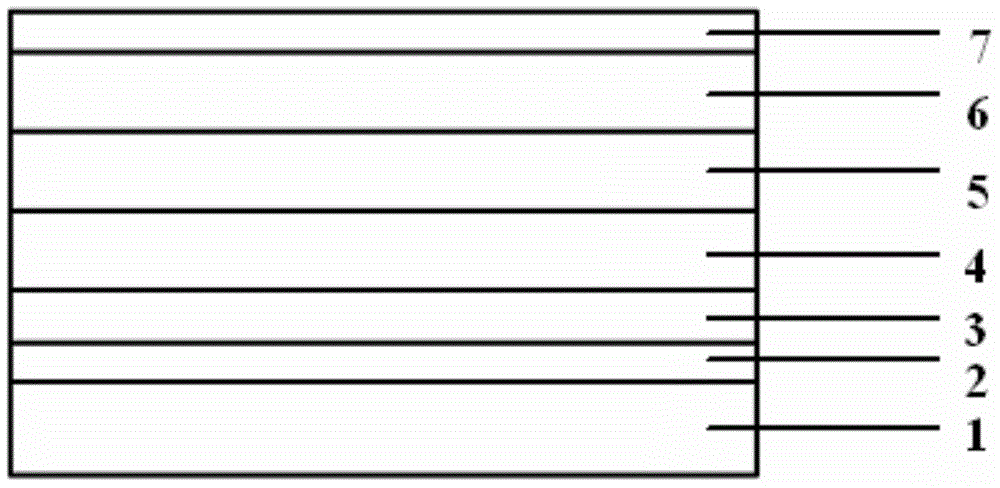

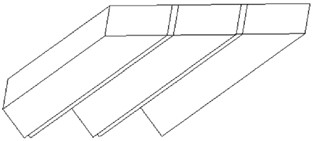

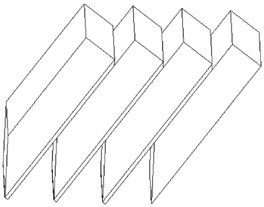

A thin-thick interval lamination method for microstructure mold

The invention relates to the technical field of die manufacturing and provides a microstructure die manufacturing method with thick sheets and thin sheets being alternately stacked. By means of the microstructure die manufacturing method with the thick sheets and the thin sheets being alternately stacked, the straightness in the edge direction of metal sheets can be improved, so that the fit degree between the metal sheets can be improved, and the rigidity of the metal sheets can be improved; according to the processing manner, two-time inclined splicing machining is adopted, so that the toolsetting problem in the edge direction of the metal sheets is solved, and the machining difficulty is lowered.

Owner:福建跃发光新材料股份有限公司

A method for manufacturing a rigid-flex circuit board with a flexible board on the outer layer

ActiveCN104869761BHas hardnessHigh hardnessPrinted circuit assemblingNon-metallic protective coating applicationScreen printingResist

The invention discloses a method for manufacturing a rigid-flex circuit board with a flexible board on the outer layer. The manufacturing method includes making flexible boards, making rigid boards, laminating flexible boards and rigid boards, making outer layers of graphics, soldering, and mechanical forming; the method of mechanical forming includes in sequence: The surface of the molding part is coated with ink; the circuit board is baked to make the ink form a rigid film; the surface of the flexible board is covered with a cover plate; The present invention covers and fills the flexible board that needs to be formed with silk screen solder resist ink, and solves the gap problem caused by the copper layer thickness difference between the copper layer area and the molding area on the surface of the flexible board; in addition, the solder resist ink has a certain hardness after solidification , can improve the hardness of the flexible board, and then use the cover plate and backing plate to cover both sides of the rigid-flexible circuit board, and shape it with a double-edged milling cutter, which can completely improve the problem of soft board burrs during molding.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

A kind of preparation method for the copper substrate of vertical structure led chip

ActiveCN104638096BSolve efficiency problemsSolve the problem of longevitySemiconductor devicesCopper platingLight-emitting diode

The invention provides a preparation method for a copper substrate for vertical LED (light-emitting diode) chips, which includes the following steps: (1) a P-type metal electrode layer is deposited on the surface of an epitaxial wafer, a layer of Au is then plated on the P-type metal electrode layer, and thereby a first substrate is obtained; (2) the first substrate is cleaned, and after a degreasing effect is achieved, H2SO4 is used for surface activation; (3) a phosphorized copper anode is blackened, and is then cleaned; (4) the first substrate treated in step 2 and the phosphorized copper anode treated in step 3 are put into copper plating solution and electroplated, so that an electroplated sample is obtained; (5) the electroplated sample is cleaned in order to remove residual copper plating solution, so that the copper substrate is obtained. The preparation method has the characteristics of simple process and low preparation cost, moreover, the copper substrate prepared by the method has the characteristics of no burrs, good surface uniformity, good smoothness, low roughness and good thermal and electric conductivities, and thereby a chip which is prepared by adopting the copper substrate has high light extraction efficiency.

Owner:广州市众拓光电科技有限公司

Deburring device for automobile part machining

ActiveCN114714189AGroove effectGood deburringEdge grinding machinesGrinding carriagesCircular discBristle

The invention relates to the technical field of deburring, in particular to a deburring device for automobile part machining, which comprises a bottom plate, an annular sliding groove is formed in the side wall of the bottom plate, a first disc brush for deburring a gear key groove is arranged on the bottom plate, and bristles of the first disc brush are vertically upward. First rotating teeth and second rotating teeth meshed with the first rotating teeth are arranged on the bottom plate, a rotating cylinder is arranged on the bottom plate, connecting teeth meshed with the second rotating teeth are arranged at the bottom of the rotating cylinder, the bottoms of the connecting teeth make contact with the annular sliding groove, and a connecting rod is fixedly connected to the first rotating teeth. The connecting rod is detachably connected with a brush rod and a fixing plate used for fixing a deburring workpiece, the bristles can penetrate through a gear groove of the deburring workpiece, the inner wall of the rotating cylinder is provided with a brush pad used for removing the deburring workpiece, and the upper end face of the first rotating tooth is provided with a plurality of springs capable of making contact with the brush rod. The gear deburring device solves the problem that the deburring effect of a traditional gear deburring device on a gear key groove is not obvious.

Owner:重庆乐迪龙鑫科技股份有限公司

Device for cutting off flat tube of heat exchanger

ActiveCN102009349BReduce throttling lossIncrease productivityOther manufacturing equipments/toolsMilling cutterEngineering

The invention provides a device for cutting off a flat tube of a heat exchanger, which comprises a machine base, a milling mechanism capable of transversely sliding along the machine base and a die-cutting mechanism capable of longitudinally sliding along the machine base, wherein the flat tube which is longitudinally conveyed along the machine base is arranged in the milling mechanism and the die-cutting mechanism by penetration, a milling cutter for milling the flat tube and forming a milling cut is arranged on the milling mechanism, and a die cutter which can detect the position of the milling cut and perform die-cutting is arranged on the die-cutting mechanism. The device has the advantages that the device for cutting off the flat tube of the heat exchanger can avoid the deformation and the shrinkage of the cut-off end surfaces of the flat tube, lead the flow of refrigerant to be smooth and improve the heat exchange efficiency of the heat exchanger.

Owner:浙江兰通空调设备有限公司

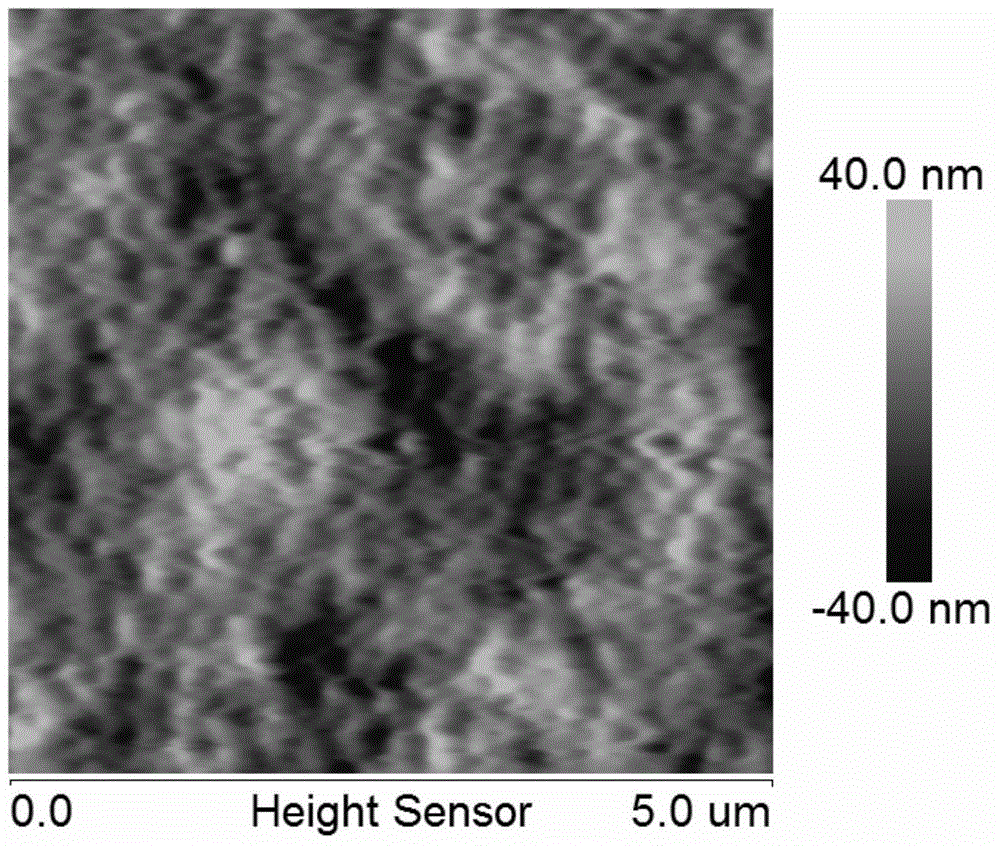

Method for overcoming cutting burrs of flexible substrate

The invention relates to a method for overcoming cutting burrs of a flexible substrate, and the method is used to reduce or eliminate burrs generated in a cutting port after pre-cutting of the flexible substrate by polishing. It is verified that a lot of burns are formed in the cutting port in one side surface of the flexible substrate after precutting, the burrs can be treated by polishing, the burrs can be lowered or even eliminated, the flexible substrate can satisfy the requirement for flat surface of the substrate in subsequent procedures, the yield of the flexible substrate as well as subsequent procedures is improved greatly, and the production benefit is improved.

Owner:TRULY SEMICON

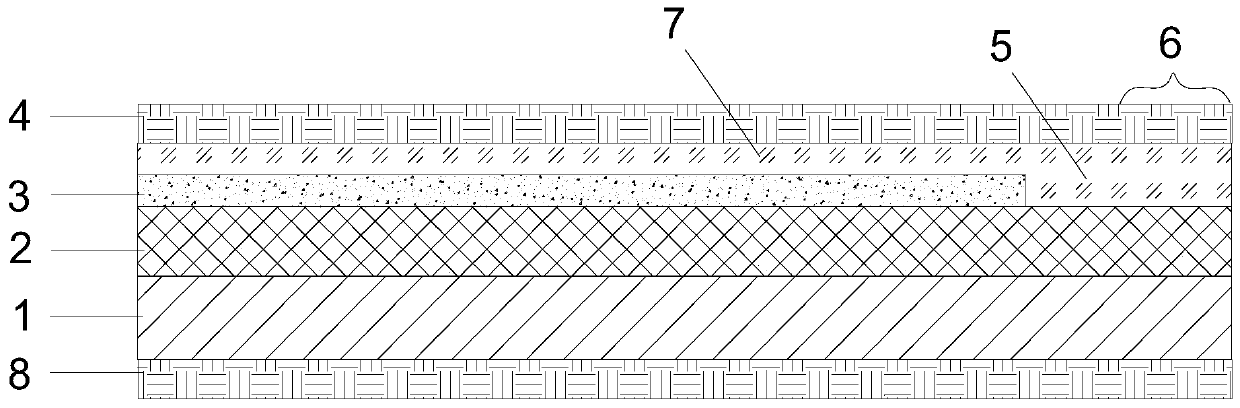

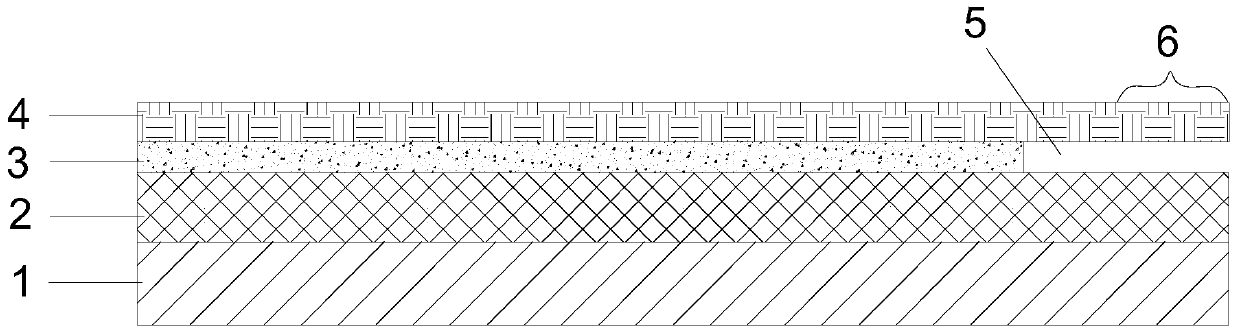

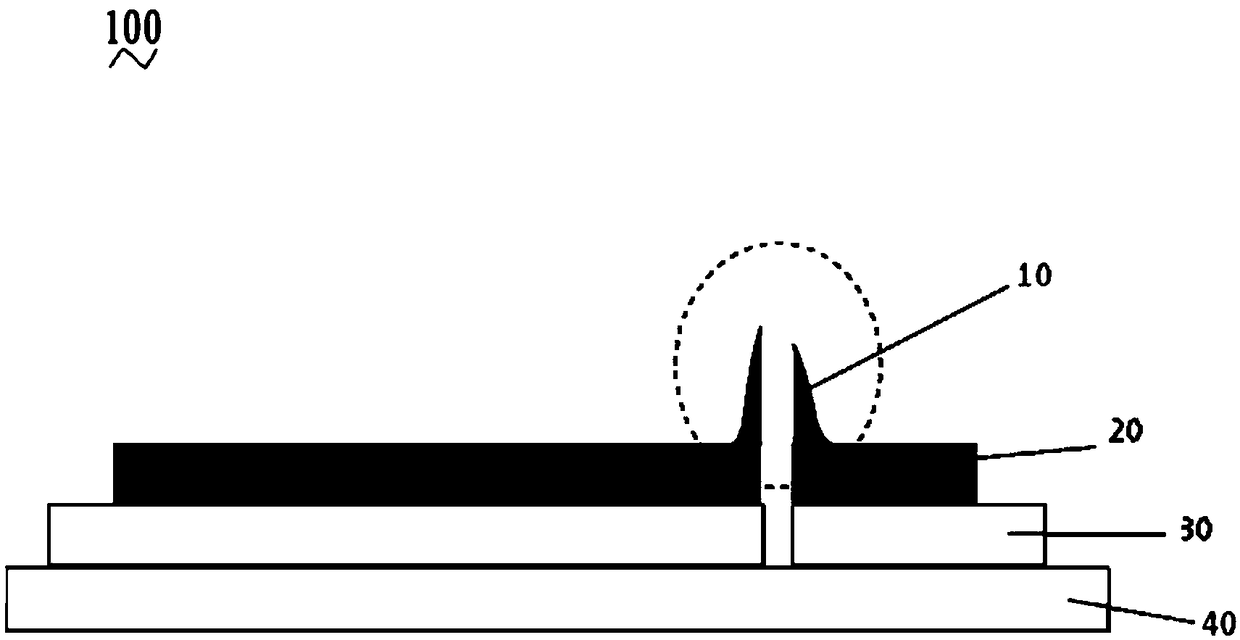

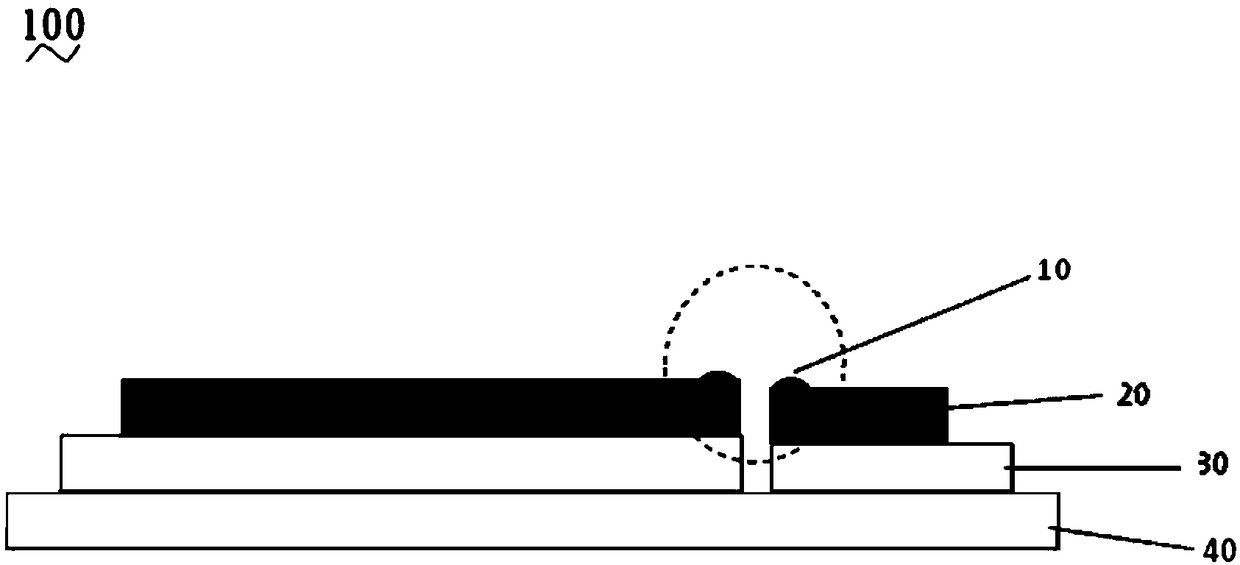

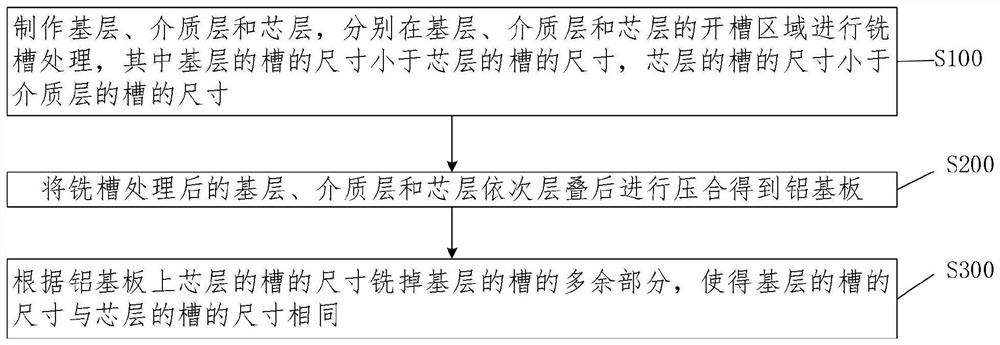

Blind-hole type multi-layer mixed-pressed aluminum substrate preparation process and multi-layer mixed-pressed aluminum substrate

ActiveCN113038709BReduce contact surfaceGuaranteed Alignment AccuracyCircuit laminationMilling cutterAluminum substrate

The invention discloses a blind-hole type multi-layer mixed-pressed aluminum substrate preparation process, which includes making a base layer, a medium layer and a core layer, and performing milling treatment on the slotting areas of the base layer, medium layer and core layer respectively, wherein the grooves of the base layer The size of the groove is smaller than the size of the core layer, and the size of the groove of the core layer is smaller than the size of the groove of the medium layer; the base layer, the medium layer and the core layer after the milling groove treatment are stacked in sequence and pressed to obtain the aluminum substrate; according to the aluminum Dimensions of the grooves of the core layer on the substrate The excess part of the grooves of the base layer is milled away so that the dimensions of the grooves of the base layer are the same as the dimensions of the grooves of the core layer. After the lamination of the present invention, it is only necessary to mill off the redundant part of the groove of the base layer relative to the groove of the core layer, so that the size of the groove of the base layer is the same as that of the core layer, so that the alignment accuracy between layers can be ensured, and the gap between layers can be significantly improved. The problem of offset, and because the area that needs to be milled off the base layer after lamination is small, the contact surface between the milling cutter and the base layer is small, which can significantly improve the problem of milling surface burrs.

Owner:FREEWON CHINA CO LTD

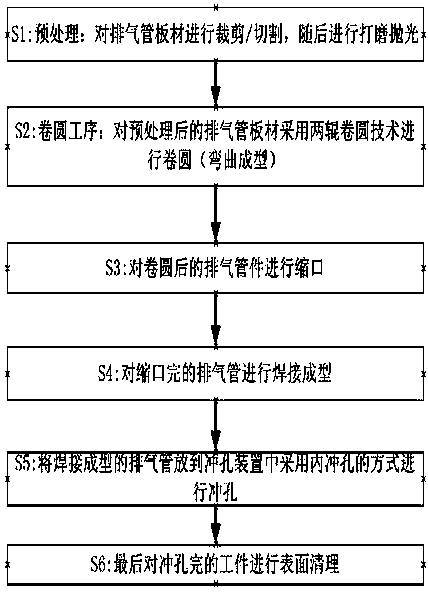

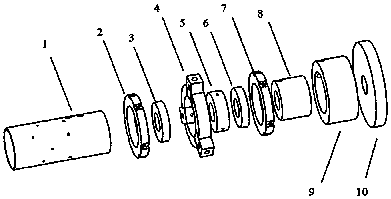

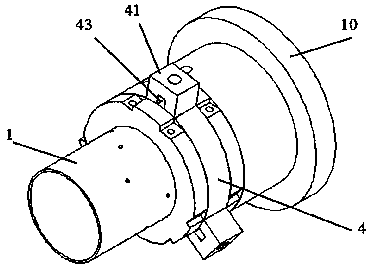

A production process for automobile exhaust pipes formed first and then punched

ActiveCN106181267BImprove glitchInhibit local deformation phenomenonPerforating toolsExhaust apparatusPunchingEngineering

The invention discloses a production process of an automobile exhaust pipe punched after being molded. The production process is characterized by comprising the steps of S1, pretreating: clipping / cutting an exhaust pipe plate, and then, polishing; S2, circle rolling: carrying out circle rolling on the treated exhaust pipe plate by using a two-roller circle rolling technology; S3, necking the circle-rolled exhaust pipe fitting; S4, welding and molding the necked exhaust pipe; S5, placing the welded and molded exhaust pipe into a punching device to punch in an internal punching way; and S6, finally, clearing the surface of the punched exhaust pipe workpiece. The problem that burrs appear at the edges of holes is effectively solved, meanwhile, the local deformation phenomenon in the punching process can be inhibited, and the technical effects of increasing the production efficiency and reducing the production cost are achieved.

Owner:南通钢安机械制造有限公司

Lead butt welding machine

PendingCN114589511AImprove utilizationImprove efficiencyFinal product manufactureOther manufacturing equipments/toolsCapacitanceButt welding

The invention relates to the technical field of capacitor production equipment, and discloses a lead butt welding machine which solves the problem that at present, equipment in the industry is low in speed, the lead butt welding machine comprises a workbench, a material lead straightening mechanism is installed at the position, close to the right side, of the top of the workbench, and a lead feeding mechanism is installed on the front face of the material lead straightening mechanism; according to the invention, through the cooperation of the material lead straightening mechanism and the lead feeding mechanism and the cooperation of the lead transferring mechanism and the lead cutting mechanism, the lead can be processed, the aluminum bar can be fed through the molding material feeding mechanism, and the lead and the aluminum bar can be in butt joint through the lead transferring mechanism and the cathode power supply mechanism; therefore, the utilization rate and the efficiency of equipment can be greatly improved, the average production speed per minute is greatly improved compared with that of traditional equipment according to the size and the model of products and the speed of forming equipment, and the number of produced products is greatly increased.

Owner:青岛海润利得电子科技有限公司

Mould-casting machine for inhaul cable connector

Owner:WUXI HUAFENG CAR & MOTOR FITTINGS

Efficient treatment method for improving drilling quality

PendingCN113891563AReduce or avoid the generation ofPrevention ofPrinted circuit manufactureGrindingDrill hole

The invention provides an efficient treatment method for improving drilling quality. The efficient treatment method comprises the following steps: A, designing a large-hole drilling belt or a long-groove drilling belt; B, controlling a base copper over 1.5 oz plate; and C, setting parameters of the grinding plate. The large hole drilling belt design comprises the steps that: A1, the diameter phi of a drilling hole is set, when the diameter phi is larger than or equal to 1.8 mm and smaller than 3.0 mm, four force unloading holes are formed, the hole distance is larger than or equal to 0.15 mm, and the diameter phi of the force unloading holes is 0.5-1.5 mm; A2, the hole diameter of a drill hole is set as phi, when phi is greater than or equal to 3.0 mm and less than or equal to 6.5 mm,four unloading forces are firstly drilled in the center, and then a large hole is drilled; A3, the hole diameter of the drill hole is set to be phi, and when the hole diameter is larger than 6.5 mm, a small hole reaming mode is adopted; and a G84 format reaming mode is adopted. According to the invention, through the design of the drilling belt, the generation of drilling burrs can be effectively reduced or avoided, and the generation of the drilling burrs is prevented from the source; the bottom copper 1.5 oz plate is managed and controlled in a differentiated manner, so that the process can be simplified and the efficiency can be improved on the premise of ensuring the quality; and through copper deposition plate grinding and setting of grinding plate parameters, hole burrs are obviously improved, and the undesirable condition of burrs is not found.

Owner:奥士康精密电路(惠州)有限公司

Aluminum strip edge roller device

Owner:镇江市宏业科技有限公司

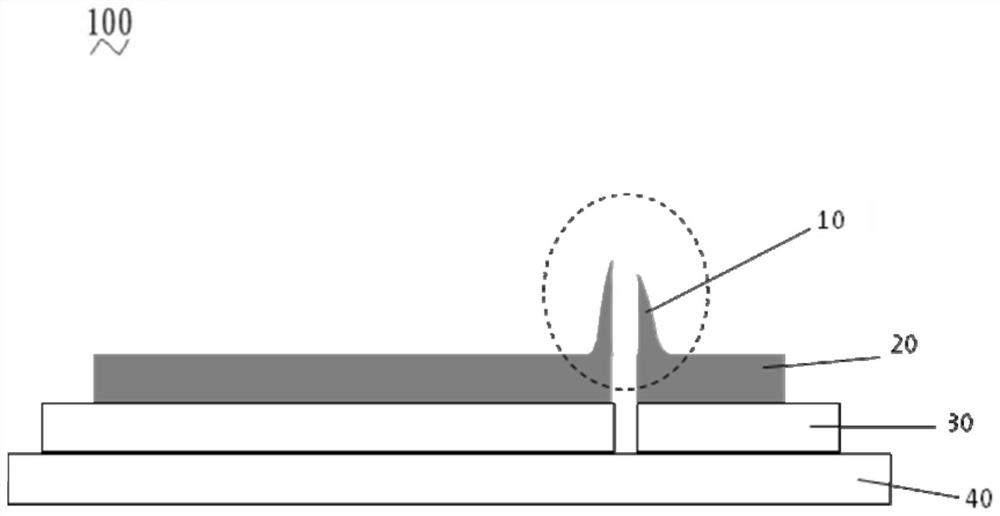

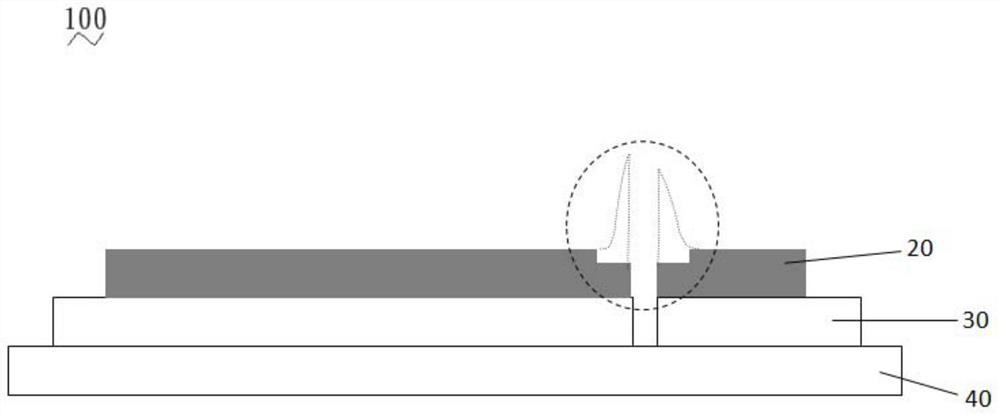

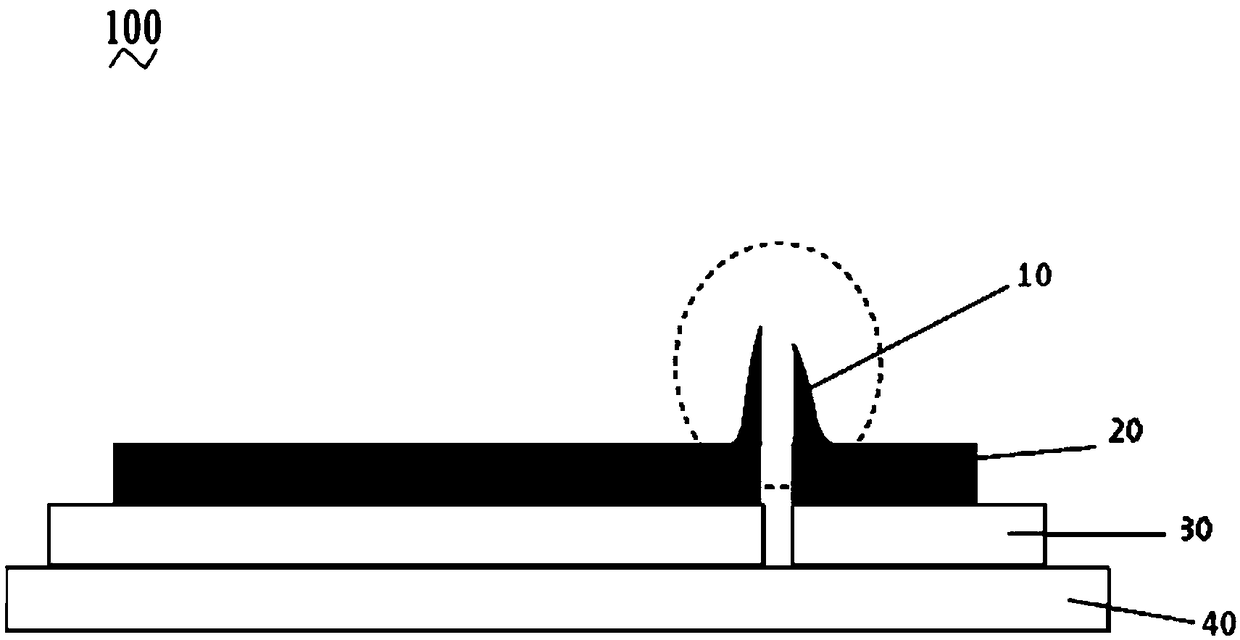

Methods for improving burrs on flexible substrates

ActiveCN109343262BImprove glitchThe follow-up process is smoothNon-linear opticsMechanical engineeringDry etching

The invention relates to a method for improving the burr of a flexible substrate, which is used for reducing or eliminating the burr generated at the cutting edge after the flexible substrate is pre-cut, and adopts dry etching to reduce or eliminate the burr. After verification, it is found that after pre-cutting, one side of the flexible substrate will form a burr at the cutting edge, and the burr can be processed by a dry etching process to reduce the height of the burr, or even eliminate the burr, so that the flexible substrate can meet the requirements of subsequent The requirement of smooth board surface in the process greatly improves the yield rate of flexible substrates and the yield rate of subsequent processes, thereby improving production efficiency.

Owner:TRULY SEMICON

Method of Improving Burr Condition on Flexible Substrate

ActiveCN109343262AImprove glitchThe follow-up process is smoothNon-linear opticsEngineeringDry etching

The invention relates to a method for improving burr condition on flexible substrates, which is used for reducing or eliminating burrs at the cutting edge after pre-cutting of flexible substrates, andadopting dry etching to reduce or eliminate the burrs. After verification, it is found that after pre-cutting, one side of a flexible substrate will form burrs at the cutting edge. The burrs can be treated by dry etching process to reduce the height of the burrs or even eliminate the burrs, so that the flexible substrate can meet the requirements of flat surface in the subsequent process, and toa large extent improve the yield of flexible substrates and the yield of the subsequent process, thus improves the production efficiency.

Owner:TRULY SEMICON

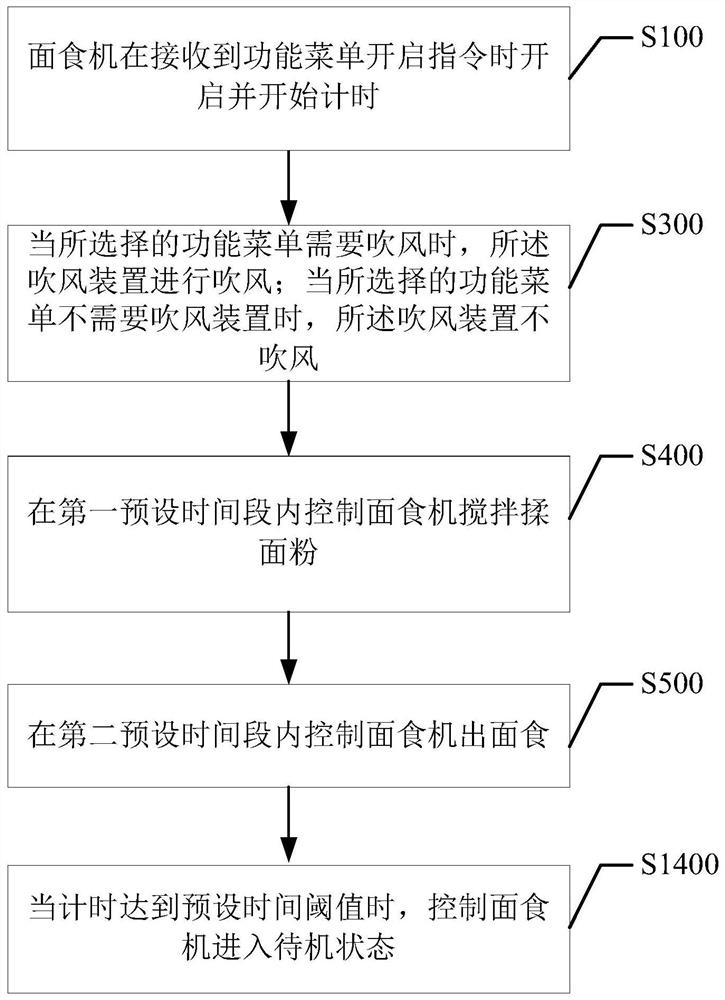

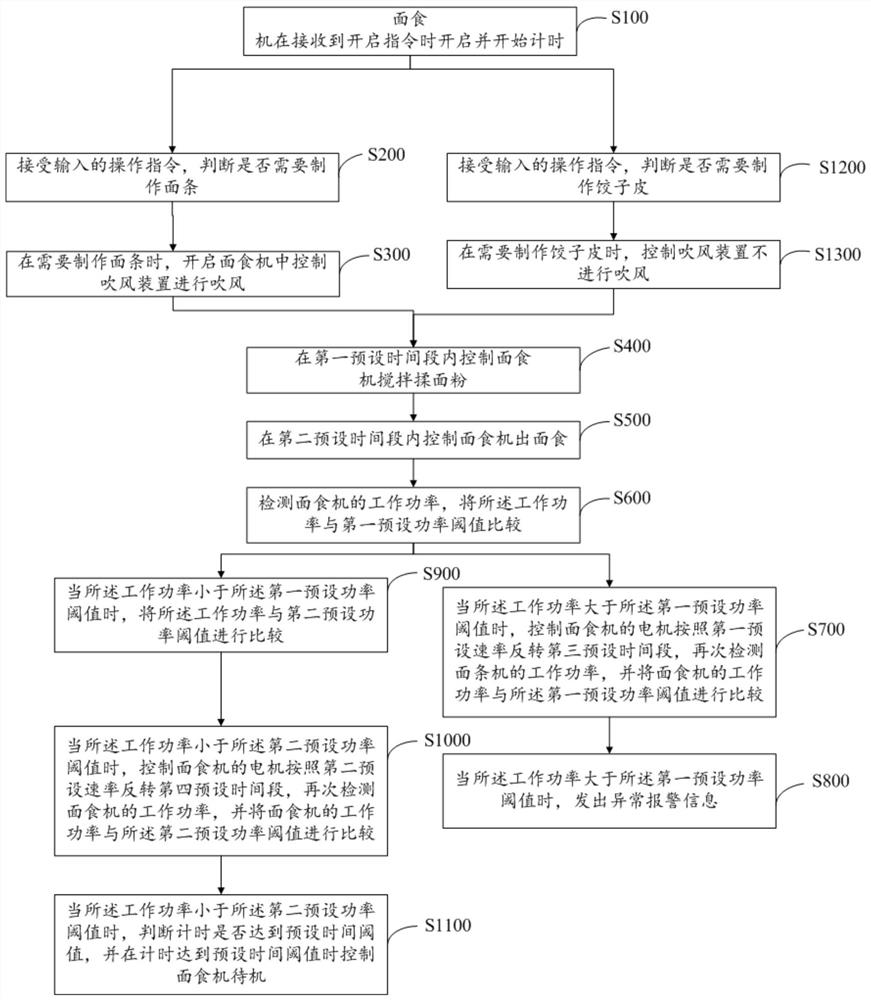

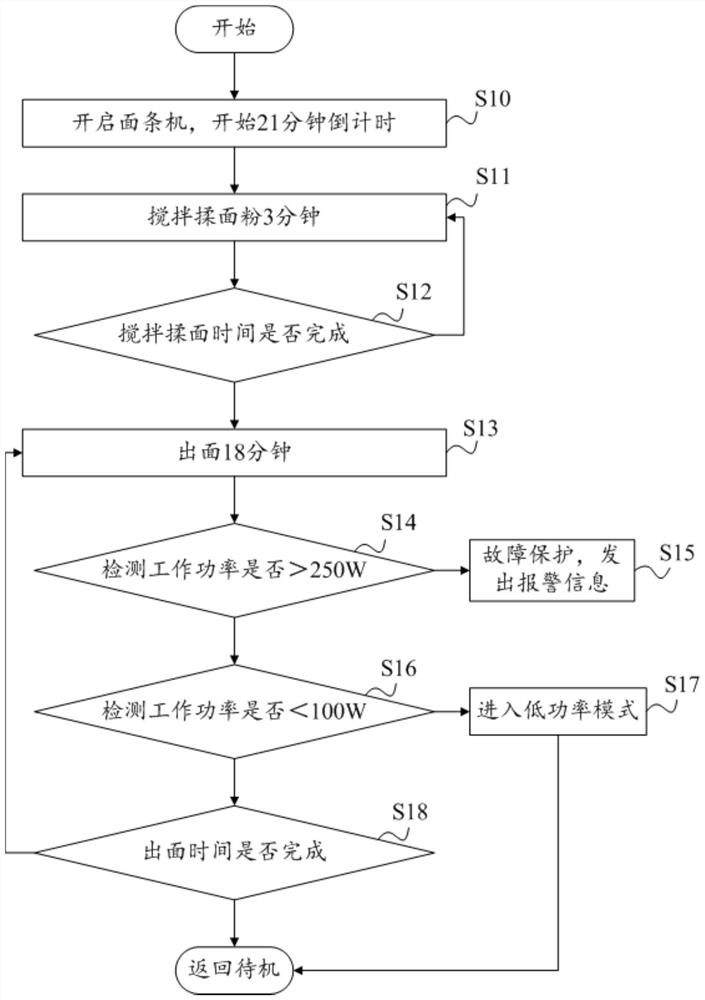

Control method, device, storage medium of pasta machine and pasta machine

ActiveCN109699698BEvenly distributed humidityImprove glitchMixing/kneading with vertically-mounted toolsDough extruding machinesProcess engineeringMechanical engineering

The invention discloses a control method, device, storage medium and pasta machine for a pasta machine. The pasta machine includes a blower and at least two function menus. Start timing; when the selected function menu needs blowing, the blowing device blows; when the selected function menu does not need the blowing device, the blowing device does not blow; control the pasta machine to stir and knead the flour in the first preset time period; 2. Control the pasta machine to produce pasta within the preset time period; when the timing reaches the preset time threshold, control the pasta machine to enter the standby state. The technical scheme of the invention can reduce the burrs on the noodles.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

A kind of output circuit and electronic device

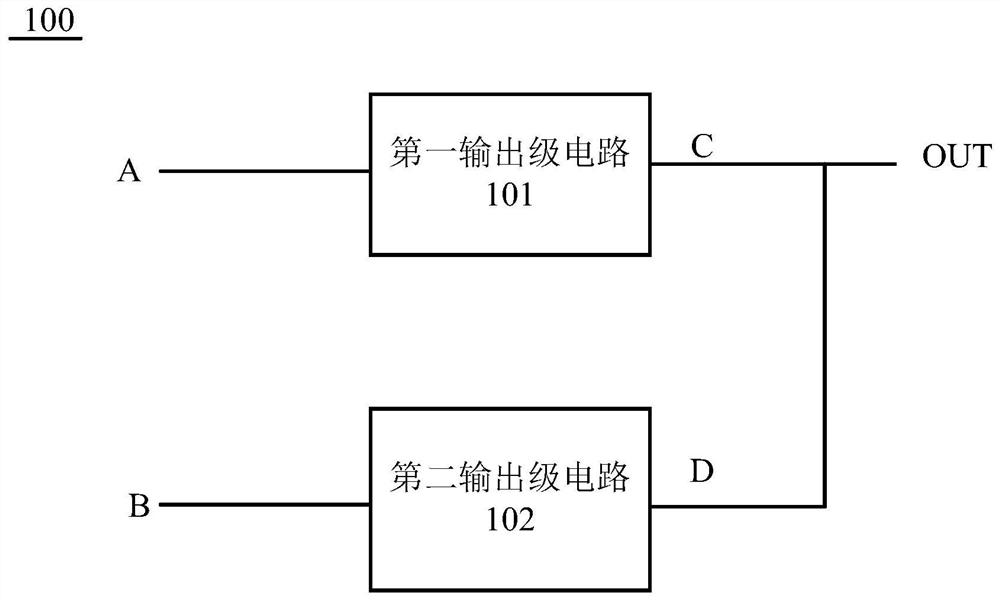

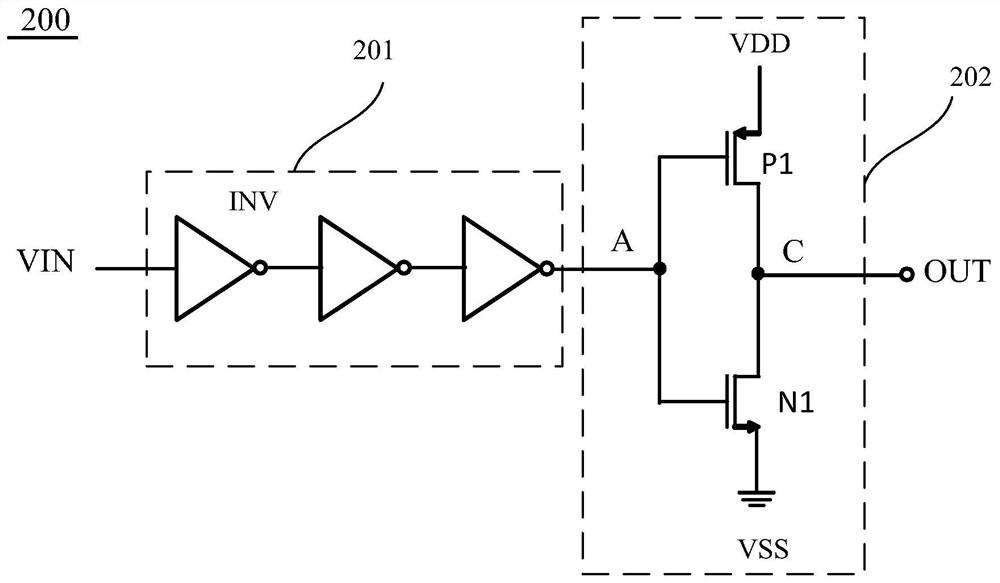

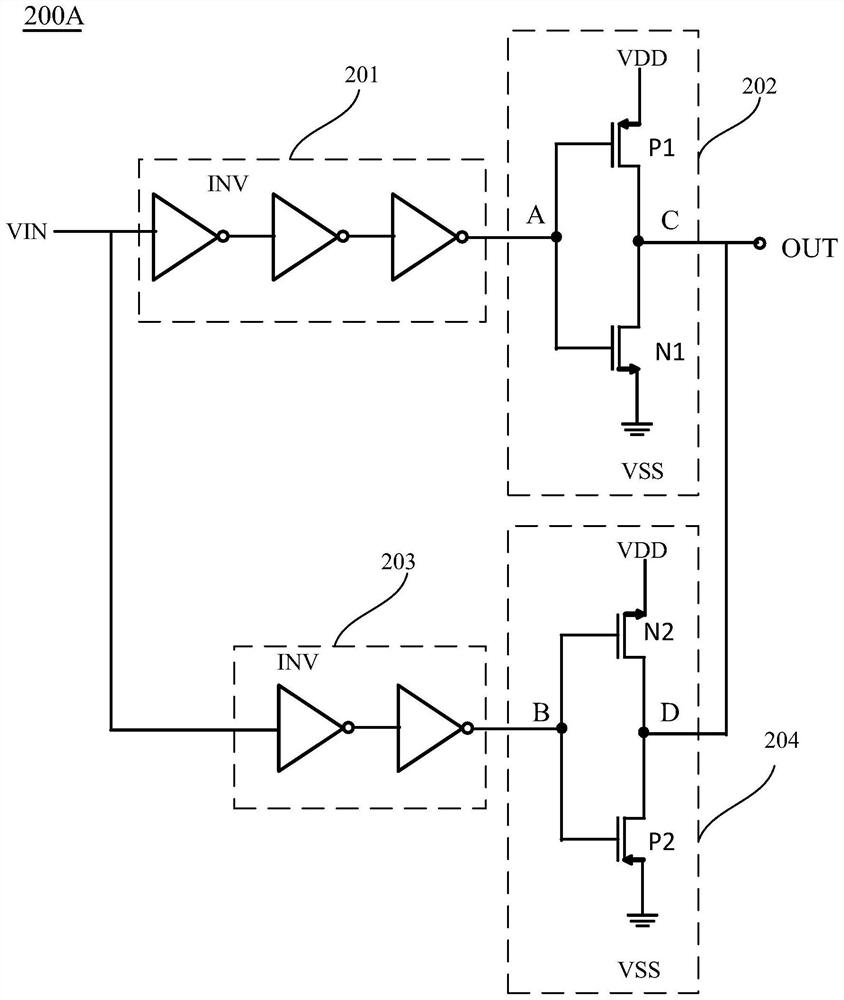

ActiveCN108964651BImprove glitchVoltage/current interference eliminationCapacitanceSoftware engineering

The invention provides an output circuit and an electronic device. The output circuit includes: a first output stage circuit, the first output stage circuit has a first input terminal and a first output terminal, the first input terminal is used to connect with the first input signal, and the first output terminal Connected to the output end of the output circuit, a first coupling capacitor is formed between the first input end and the first output end; a second output stage circuit, the second output stage circuit has a second input end and a second output terminal, the second input terminal is used to connect with the second input signal, the second output terminal is connected to the output terminal of the output circuit, the second input terminal and the second output terminal A second coupling capacitance is formed therebetween; wherein, the first coupling capacitance and the second coupling capacitance have opposite coupling effects. The output circuit can improve the burr at the output end and reduce the influence of the burr on the circuit. The electronic device has similar advantages.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com