Method for overcoming cutting burrs of flexible substrate

A flexible substrate and burr technology, applied in nonlinear optics, optics, instruments, etc., can solve problems such as product yield decline, ODF impact, high burr, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

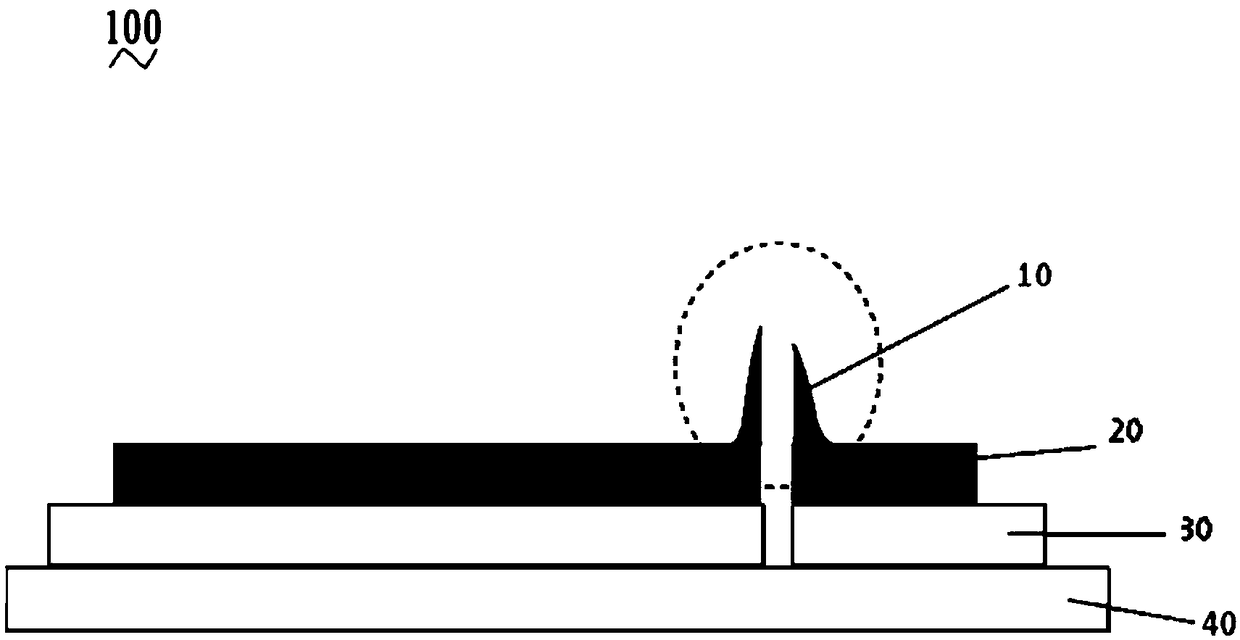

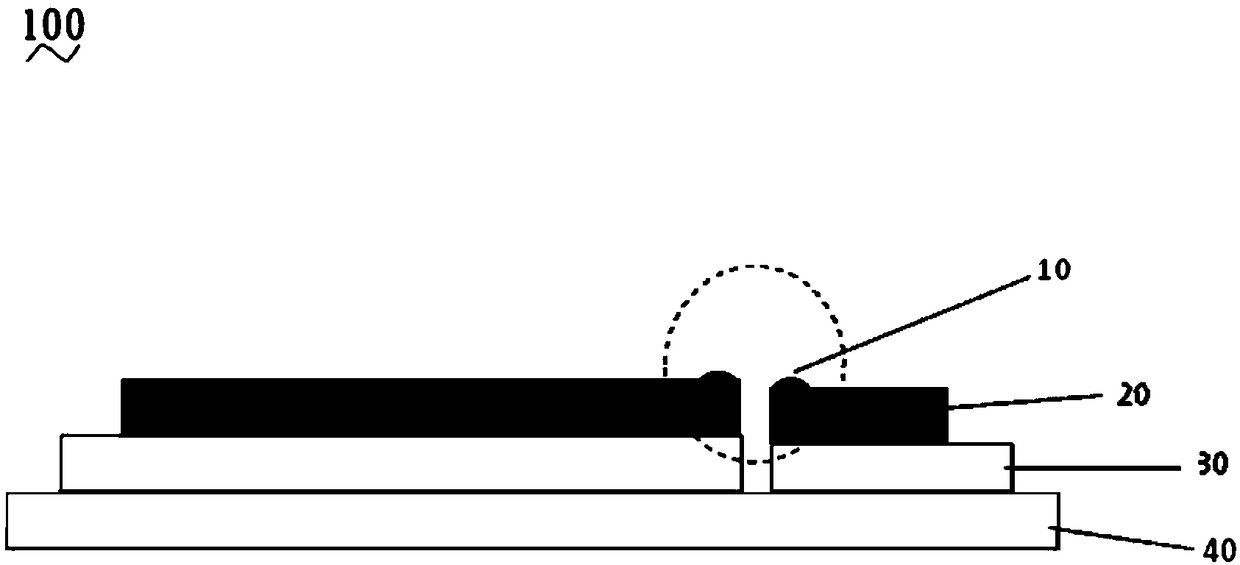

[0034] The flexible substrate 100 of this embodiment is a CF substrate. After the flexible substrate 100 is pre-cut and before the burrs are not improved, its structure is as follows: figure 1 As shown, the flexible substrate 100 includes a substrate 40 , a flexible substrate 30 and an insulating layer 20 . The substrate 40 and the insulating layer 20 are respectively attached to two sides of the flexible substrate 30 . The insulating layer 20 is made of epoxy resin. The pre-cutting is to cut the flexible substrate 30 and the insulating layer 20 , forming a cut at the cutting place, and the insulating layer produces a burr 10 at the cut after cutting. The polishing disk of this embodiment is a nylon polishing wheel with a diameter of 50 mm, and the particle size of the nylon polishing wheel is 400 mesh.

[0035] Using a polishing method to improve the above-mentioned cutting burrs on the flexible substrate includes the following steps:

[0036] The rotating speed of the polis...

Embodiment 2

[0040] The flexible substrate in this embodiment is a CF substrate. After the flexible substrate is pre-cut and before the burrs are not improved, the flexible substrate includes a base material, a flexible underlayment and an insulating layer. The base material and the insulating layer are respectively attached to both sides of the flexible underlayment. , The insulating layer is made of epoxy resin material. The pre-cutting is to cut the flexible substrate and the insulation layer, and the cutting place forms a cutout, and after cutting, the insulation layer produces burrs at the cutout place. The polishing disk of this embodiment is a nylon polishing wheel with a diameter of 100mm, and the particle size of the nylon polishing wheel is 320 mesh.

[0041] Using a polishing method to improve cutting burrs on flexible substrates includes the following steps:

[0042] The rotational speed of the polishing disc is set to 71 r / min, the humidity of the controlled environment is 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com