Preparation method for copper substrate for vertical LED (light-emitting diode) chips

An LED chip, vertical structure technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost, complicated preliminary preparation, hinder the industrialization of vertical structure LED, etc., to improve the yield and overcome a large number of copper adhesion. , the effect of low cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the copper substrate for the vertical structure LED chip of the present embodiment comprises the following steps:

[0037] The preparation method for the copper base plate of vertical structure LED chip is characterized in that, comprises the following steps:

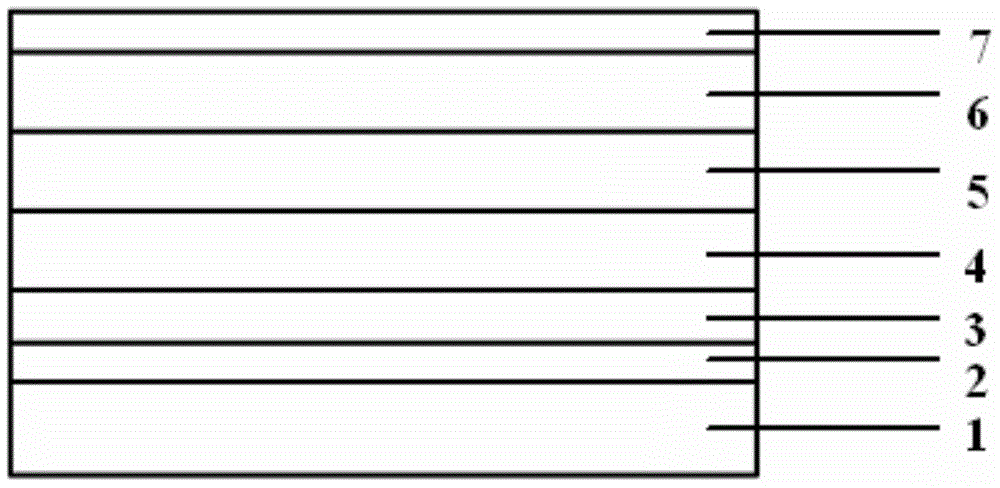

[0038] 1) Evaporate a P-type metal electrode layer on the surface of the GaN epitaxial wafer, the metal in the P-type metal electrode layer is Cr or Pt, and then plate a P-type metal electrode layer on the P-type metal electrode layer by using photolithography or evaporation technology. layer Au to obtain the first substrate; the thickness of the Cr or Pt is 30-50nm, and the thickness of the Au is 800-1000nm.

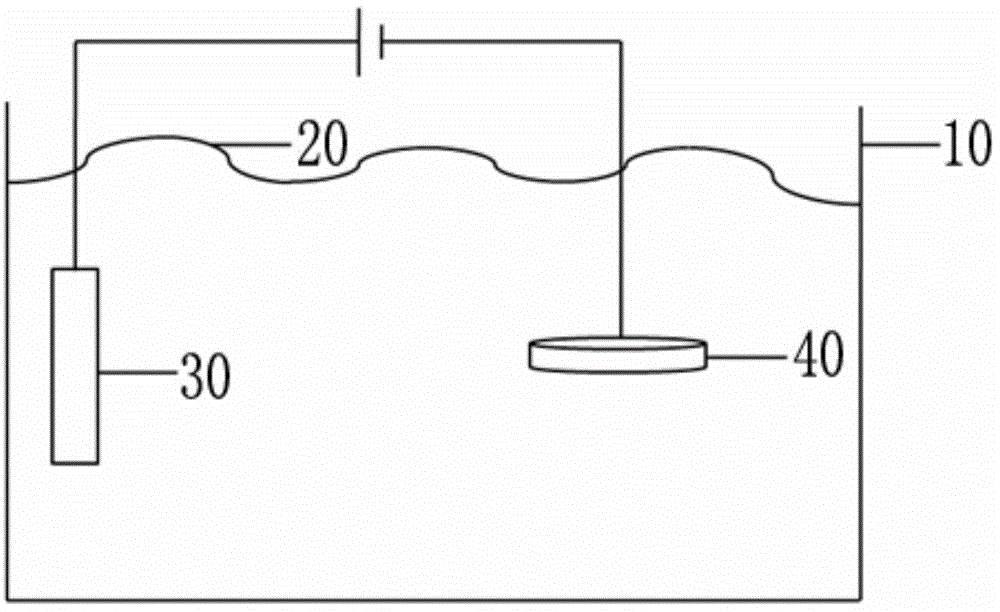

[0039] 2) The first substrate is cleaned, and after the degreasing effect is achieved, the concentration is 10% H 2 SO 4 Surface activation was performed for 1 min; the specific process of cleaning was 1.5, 1.5, and 1 min with acetone, ethanol, and deionized water, respectively....

Embodiment 2

[0051] The preparation method for the copper substrate of the vertical structure LED chip described in this embodiment comprises the following steps:

[0052] 1) Evaporate a P-type metal electrode layer on the surface of the GaN epitaxial wafer, the metal in the P-type metal electrode layer is Cr or Pt, and then plate a P-type metal electrode layer on the P-type metal electrode layer by using photolithography or evaporation technology. layer Au to obtain the first substrate; the thickness of the Cr or Pt is 30nm, and the thickness of the Au is 1000nm.

[0053] 2) The first substrate is cleaned, and after the degreasing effect is achieved, the concentration is 10% H 2 SO 4 Surface activation was performed for 1 min; the specific process of cleaning was 1.5, 1.5, and 1 min with acetone, ethanol, and deionized water, respectively.

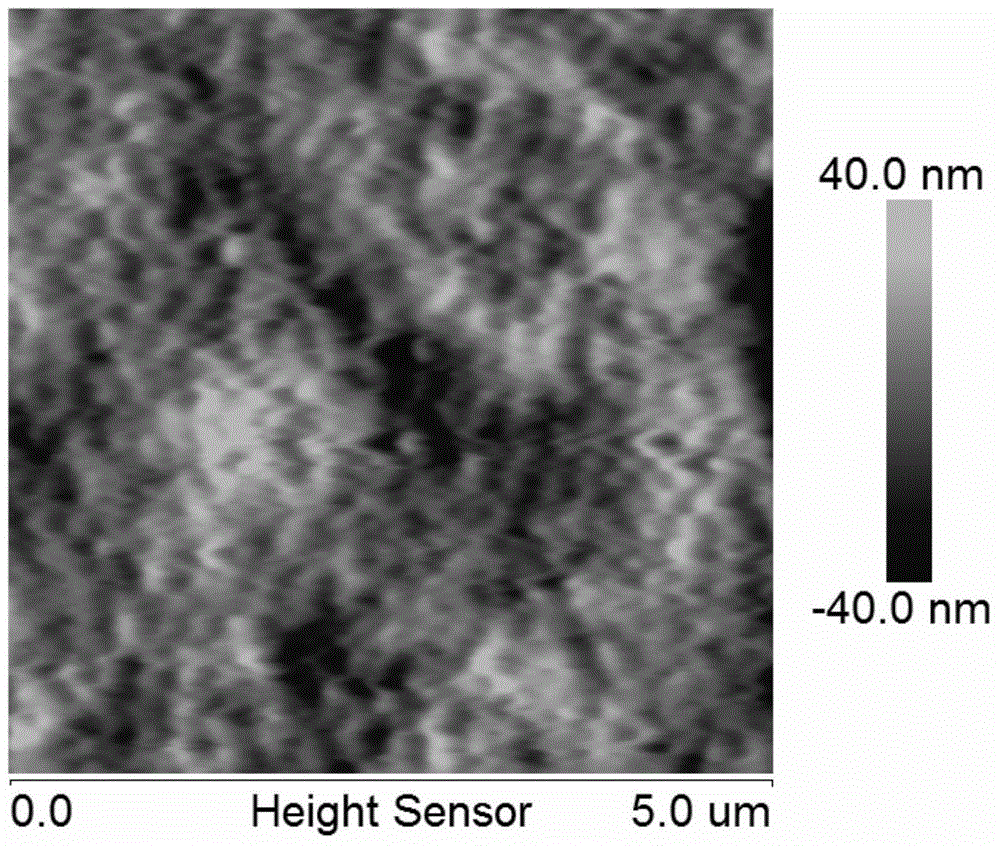

[0054] 3) Blacken the phosphorus copper anode containing 0.04wt% phosphorus for 3 hours, and then clean it; the cleaning solution used in the clean...

Embodiment 3

[0062] The preparation method for the copper substrate of the vertical structure LED chip described in this embodiment comprises the following steps:

[0063] 1) Evaporate a P-type metal electrode layer on the surface of the GaN epitaxial wafer, the metal in the P-type metal electrode layer is Cr or Pt, and then plate a P-type metal electrode layer on the P-type metal electrode layer by using photolithography or evaporation technology. layer Au to obtain the first substrate; the thickness of the Cr or Pt is 50nm, and the thickness of the Au is 900nm.

[0064] 2) The first substrate is cleaned, and after the degreasing effect is achieved, the concentration is 10% H 2 SO 4 Surface activation was performed for 1 min; the specific process of cleaning was 1.5, 1.5, and 1 min with acetone, ethanol, and deionized water, respectively.

[0065] 3) Blacken the phosphorus copper anode containing 0.065wt% phosphorus for 5h, and then clean it; the cleaning solution used in the cleaning p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com