Blind-hole type multi-layer mixed-pressed aluminum substrate preparation process and multi-layer mixed-pressed aluminum substrate

A preparation process, a technology for aluminum substrates, applied in circuit lamination, printed circuit manufacturing, printed circuits, etc., can solve the problems of easy slot deviation, affecting product quality, burrs on the surface of milling slots, etc., to improve the interlayer deviation. The effect of removing and improving the surface burr of the milling groove and ensuring the accuracy of the interlayer alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

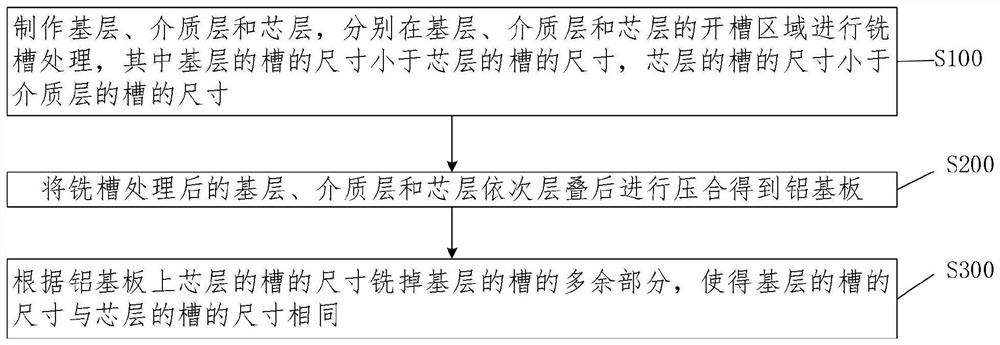

[0030] Embodiment 1~3: figure 1 It shows a schematic flow chart of the preparation process of the blind-hole type multi-layer mixed-pressed aluminum substrate of the present invention.

[0031] Such as figure 1 As shown, the present invention provides a process for preparing a blind-hole multi-layer mixed-pressed aluminum substrate, the method comprising the following steps:

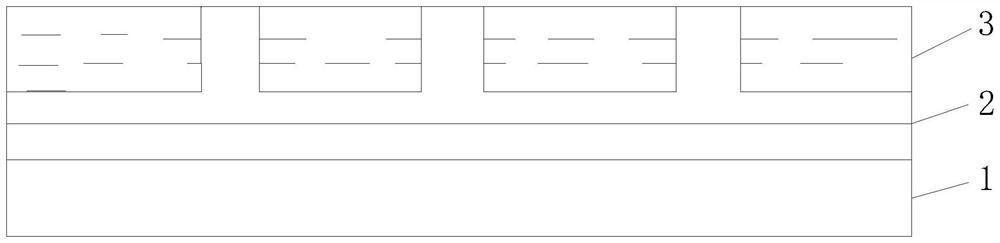

[0032] S100: making the base layer 1, the dielectric layer 2 and the core layer 3, and milling grooves in the grooved areas of the base layer 1, the dielectric layer 2, and the core layer 3 respectively, wherein the size of the groove of the base layer 1 is smaller than the size of the groove of the core layer 3 , and the size of the grooves in the core layer 3 is smaller than the size of the grooves in the dielectric layer 2 .

[0033] Exemplarily, the base layer 1 is an aluminum plate, and a 95% pure aluminum base material is used to make the aluminum plate. The thickness of the aluminum plate can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com