Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

557results about How to "Easy to tilt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

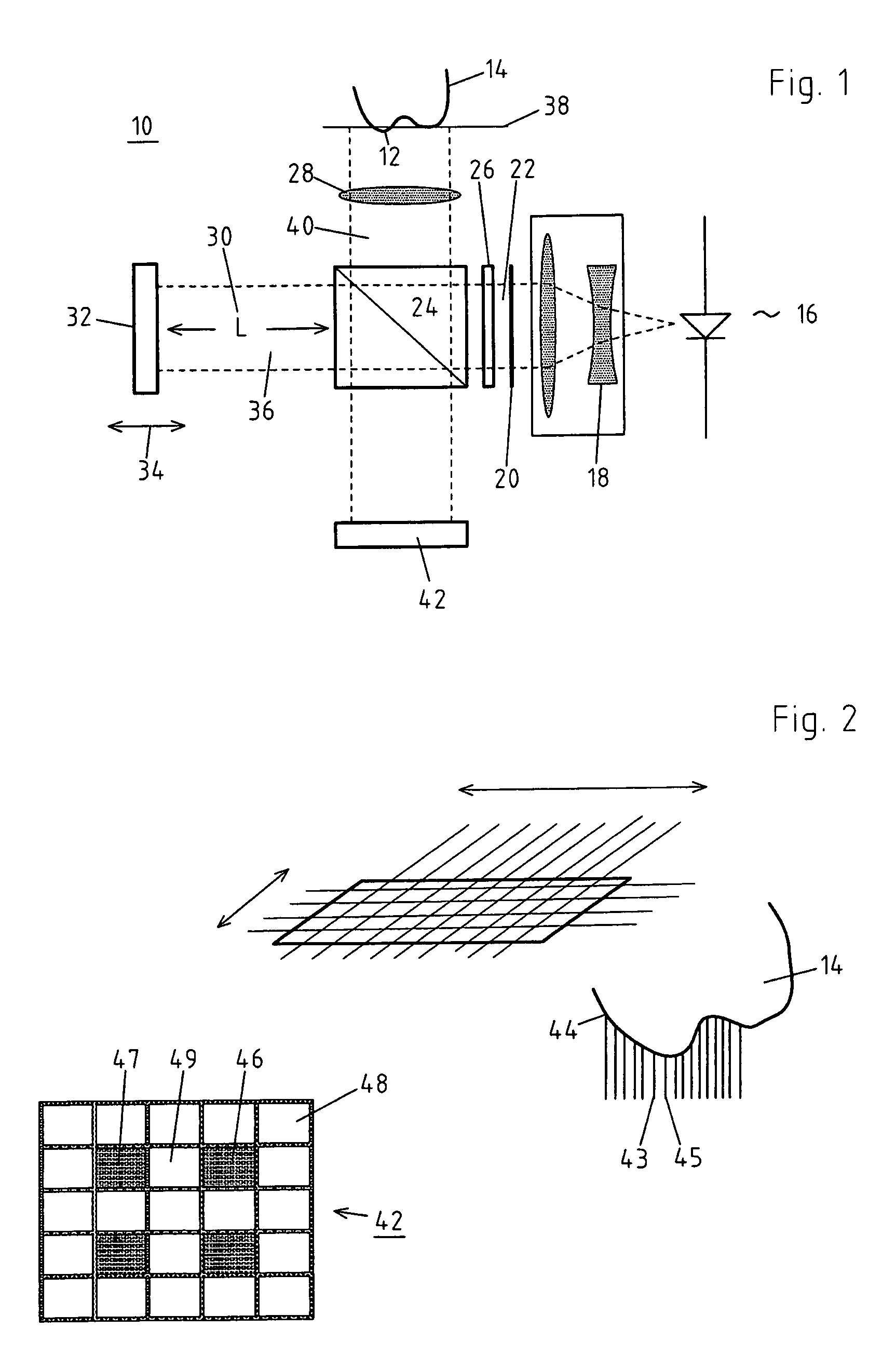

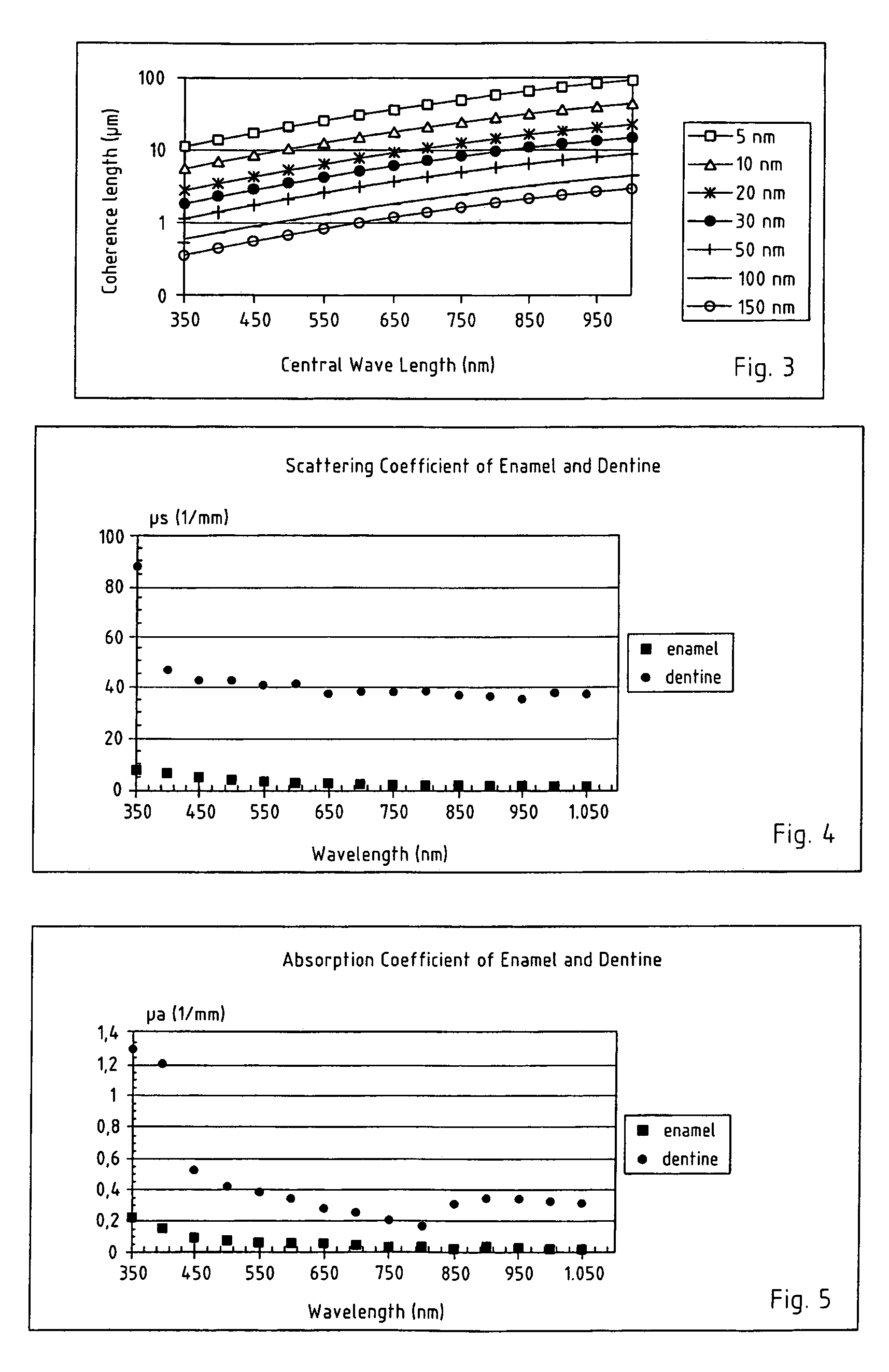

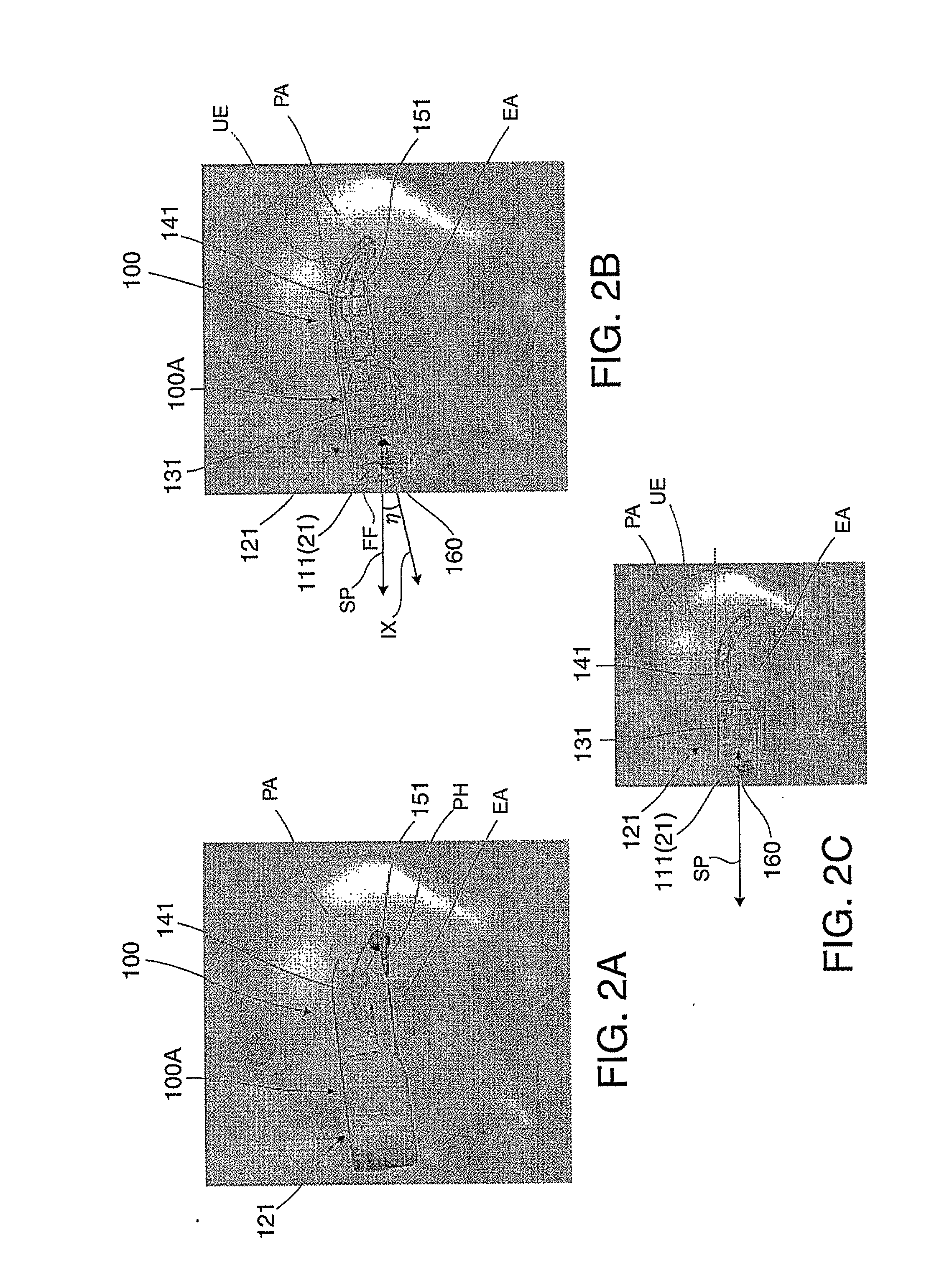

Method and device for detecting the contour data and/or optical characteristics of a three-dimensional semi-transparent object

ActiveUS7872760B2Improve signal-disturb signal ratioHigh resolutionImpression capsRadiation pyrometryOptical propertyLight beam

A method and device for detecting the contour data and / or optical characteristics of an object, such as a tooth or a tooth restoration, based on an interference and / or autocorrelation measurement using an image sensor. To permit an exact surface detection in addition to a determination of the optical characteristics of the object, individual light beams strike the object, which are located at a distance from one another in such a way that no impact of reflected individual light beams takes place on immediately adjacent pixels of the image sensor.

Owner:DEGUDENT

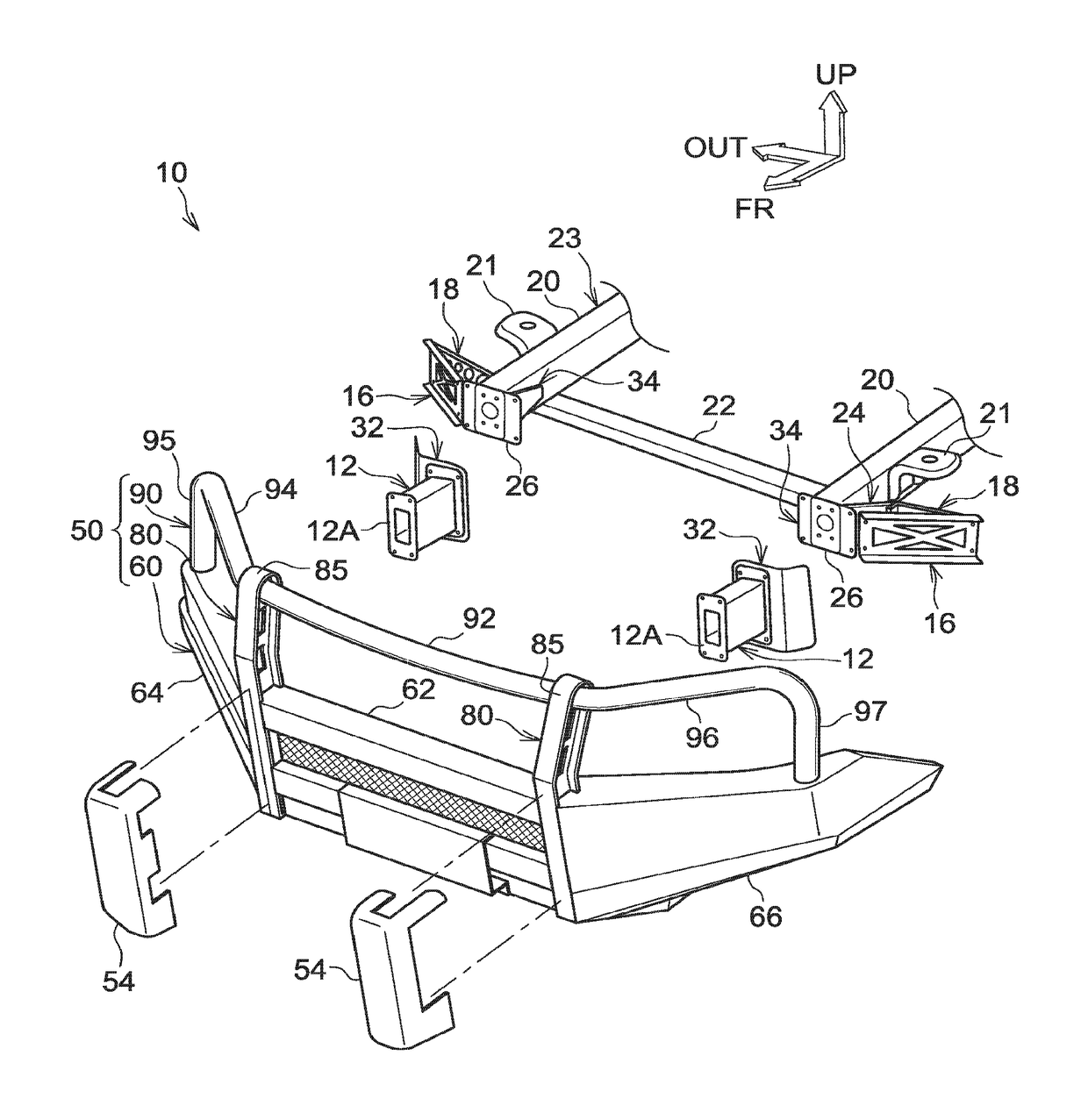

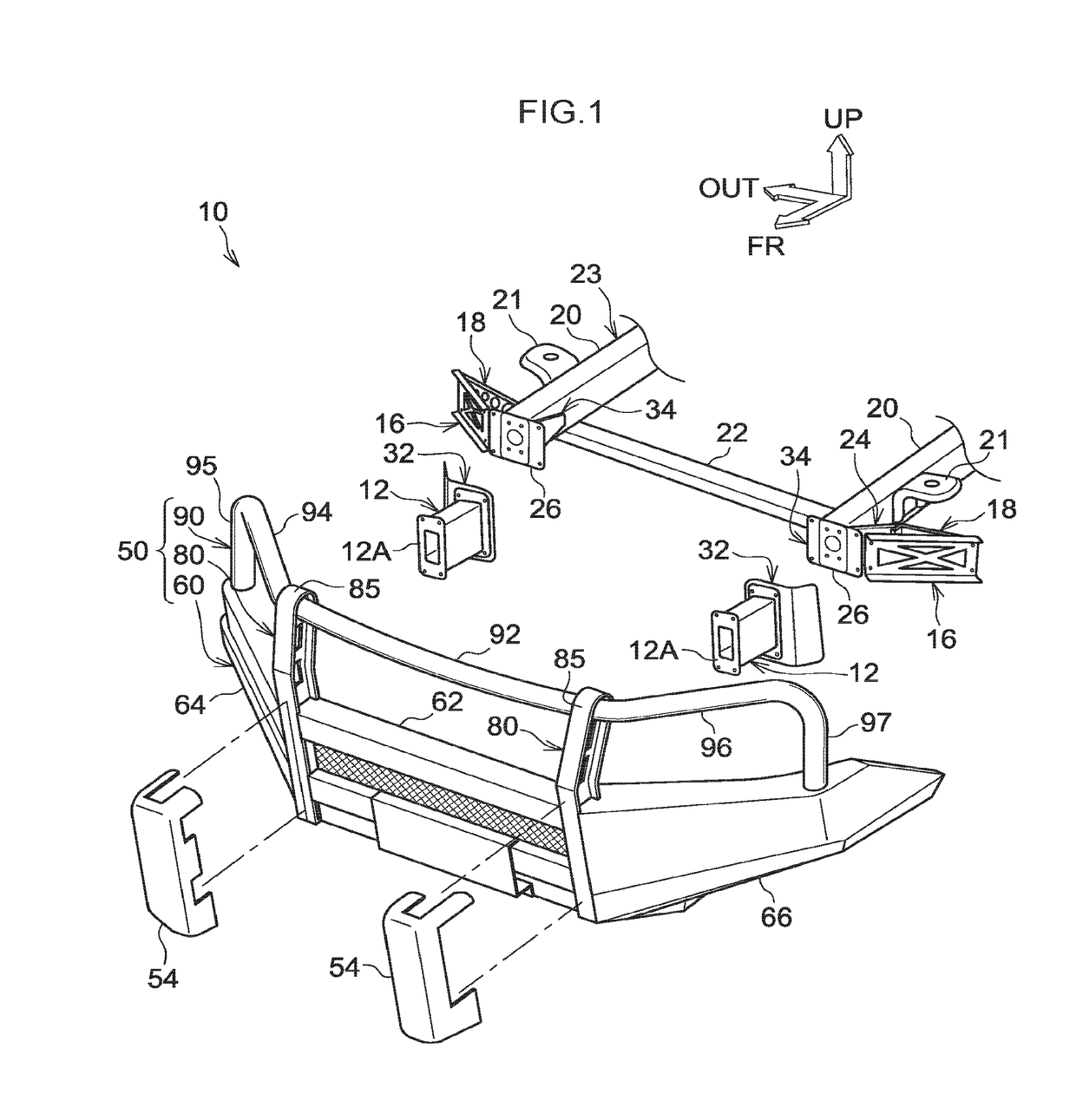

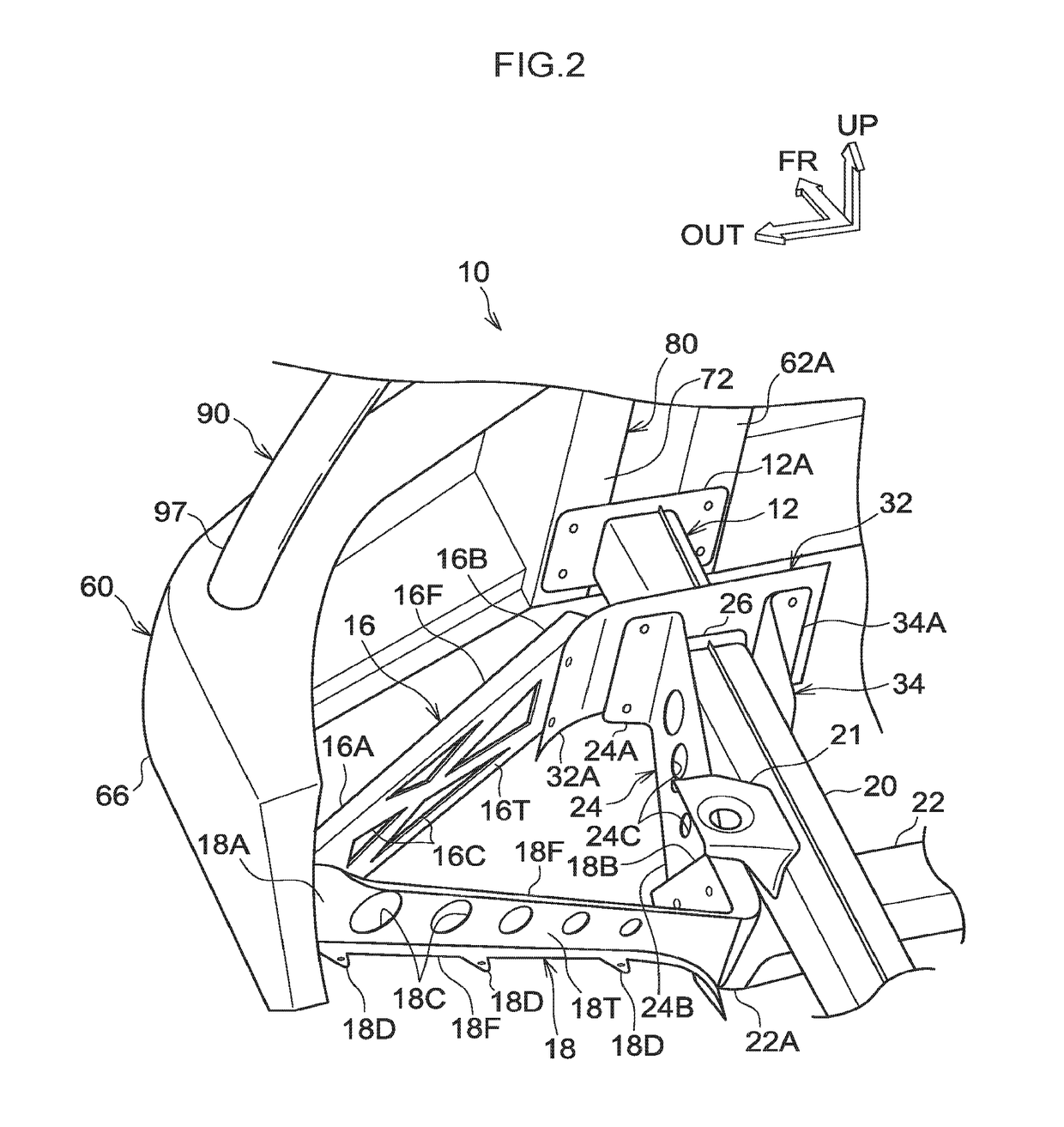

Vehicle front portion structure

ActiveUS20170088076A1Increased durabilityIncrease stiffnessSuperstructure subunitsBumpersEngineeringMechanical engineering

A vehicle front portion structure includes a front side member, a bumper portion, a bumper guard and an up-and-down extension portion. The front side member extends in a vehicle front-and-rear direction. The bumper portion is provided at the vehicle front side of the front side member and extends in the vehicle width direction. The bumper guard is formed in a pipe shape, and is provided at the vehicle upper side of the bumper portion. The up-and-down extension portion extends in a vehicle up-and-down direction. A lower portion of the up-and-down extension portion is joined to the bumper portion and is attached to the front side member via a crush box. An upper portion of the up-and-down extension portion protrudes upward of the bumper portion and is connected to the bumper guard.

Owner:TOYOTA JIDOSHA KK

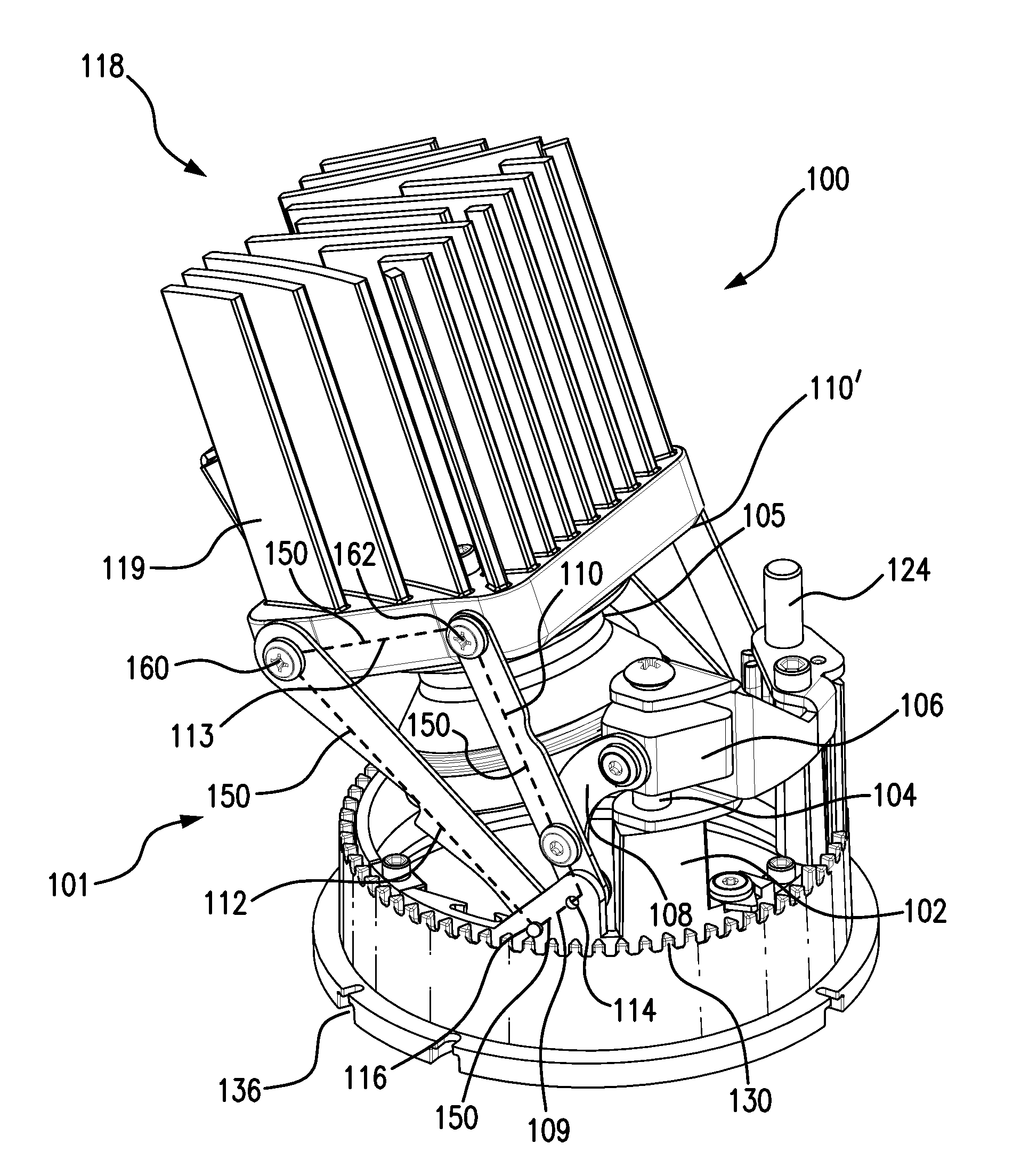

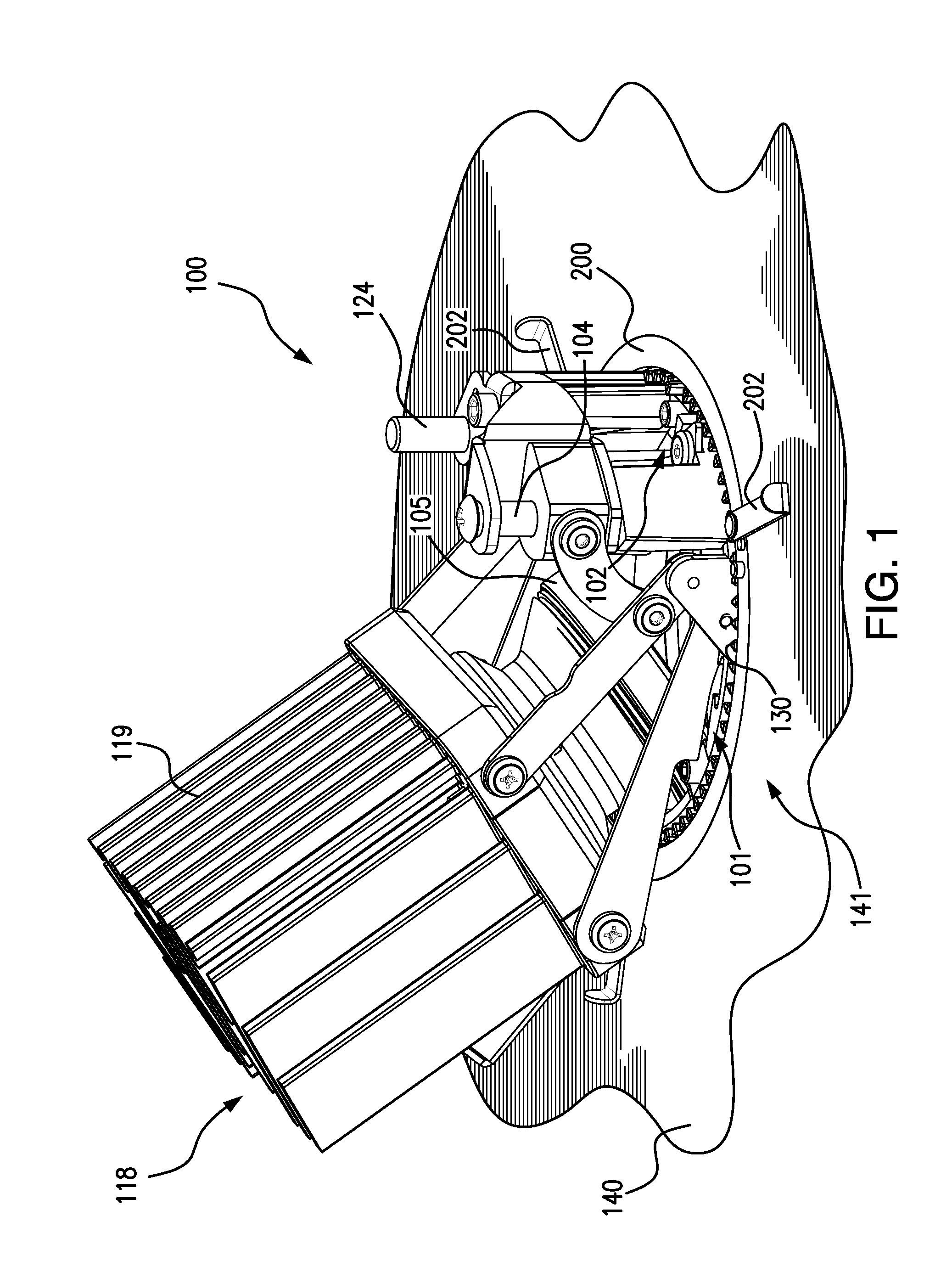

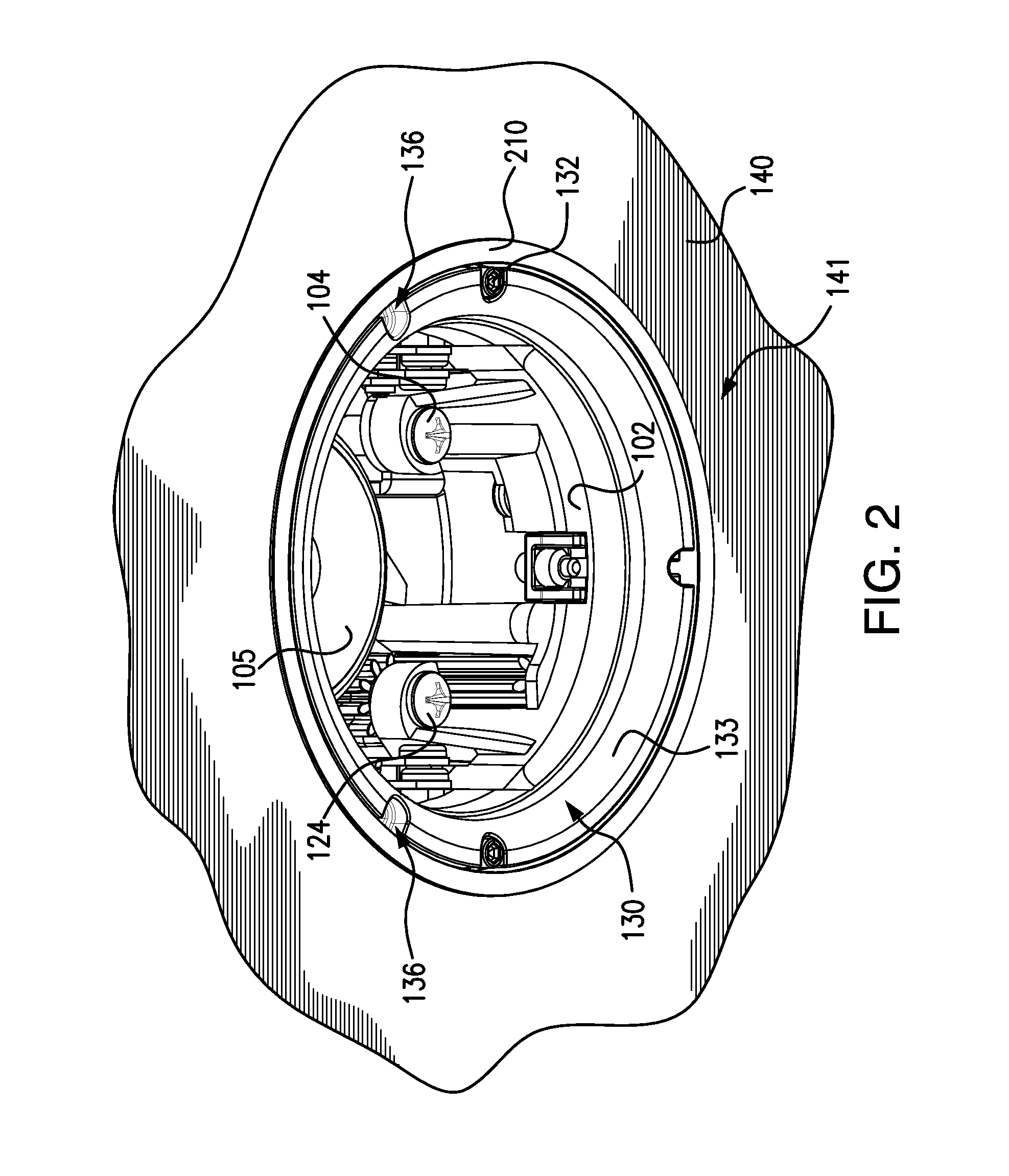

Recessed luminaire adjustment mechanism

ActiveUS20150241039A1Convenient aiming of light beamEasy to lockLighting support devicesFixed installationLight beamEngineering

An adjustment mechanism for directional recessed luminaires includes a tilt adjustment screw 104 and rotation adjustment screw 124 supported in adjacent positions on a bearing ring 102, the screws being oriented vertically and conveniently accessible through an open center of the bearing ring. Follower 106 travels vertically on the tilt adjustment screw when rotated. Drive link 108 connected to both the follower and a four bar linkage (110), transfers force from the follower to the linkage when the tilt screw is rotated. The linkage pivots about anchor points 114,116 and is pivotally connected to lamp carrier frame 118 supporting light source 105. When the tilt adjustment screw is rotated, light source moves along a path (FIG. 6, 7) to aim the light beam. After aiming, the mechanism locks the light source into place. The mechanism is compact and the adjustment screws are easily accessible from beneath the mechanism.

Owner:ABL IP HLDG

Monitor

InactiveUS20050248912A1Smoothly and easily tiltEasy to tiltDigital data processing detailsMowersHinge angleEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

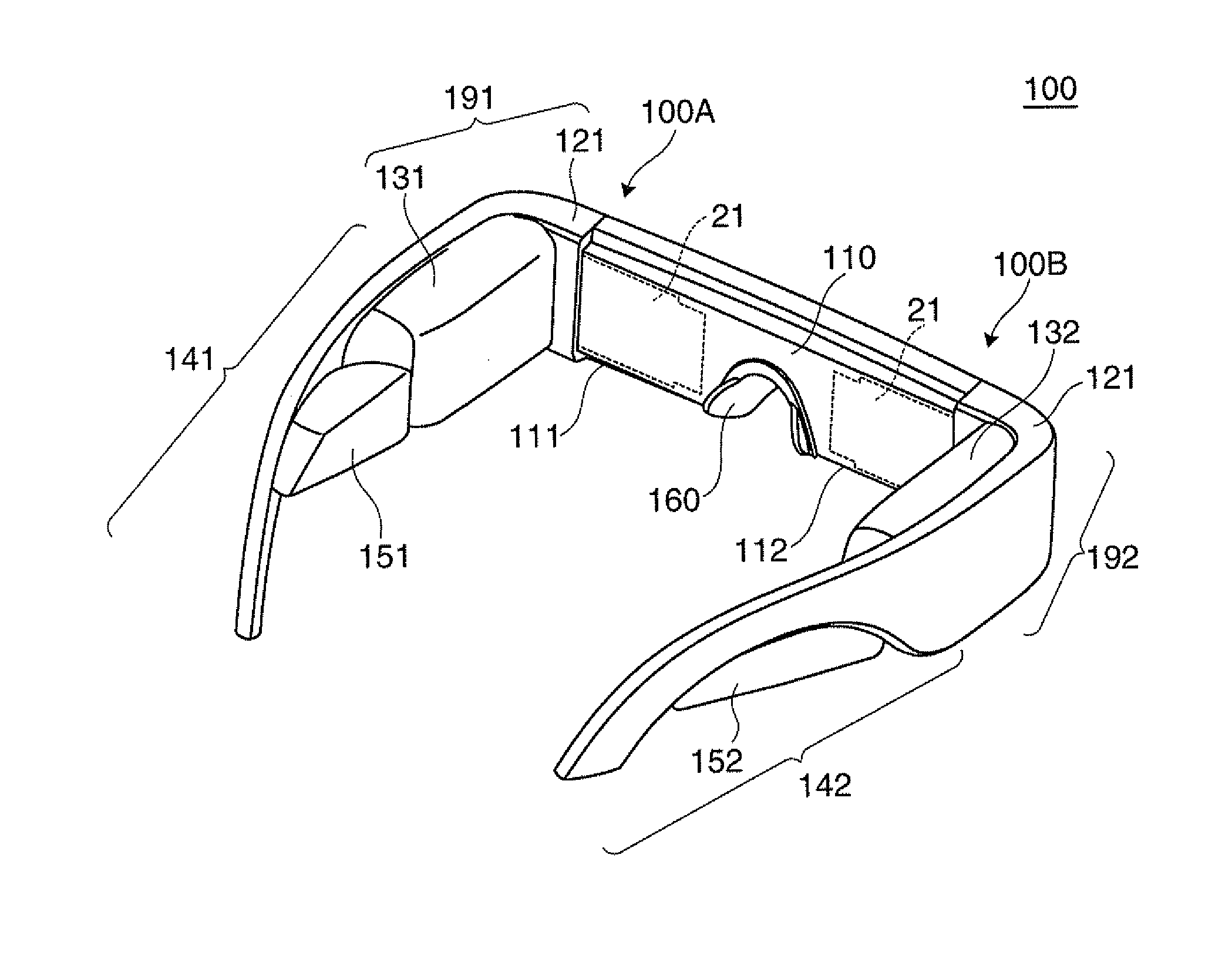

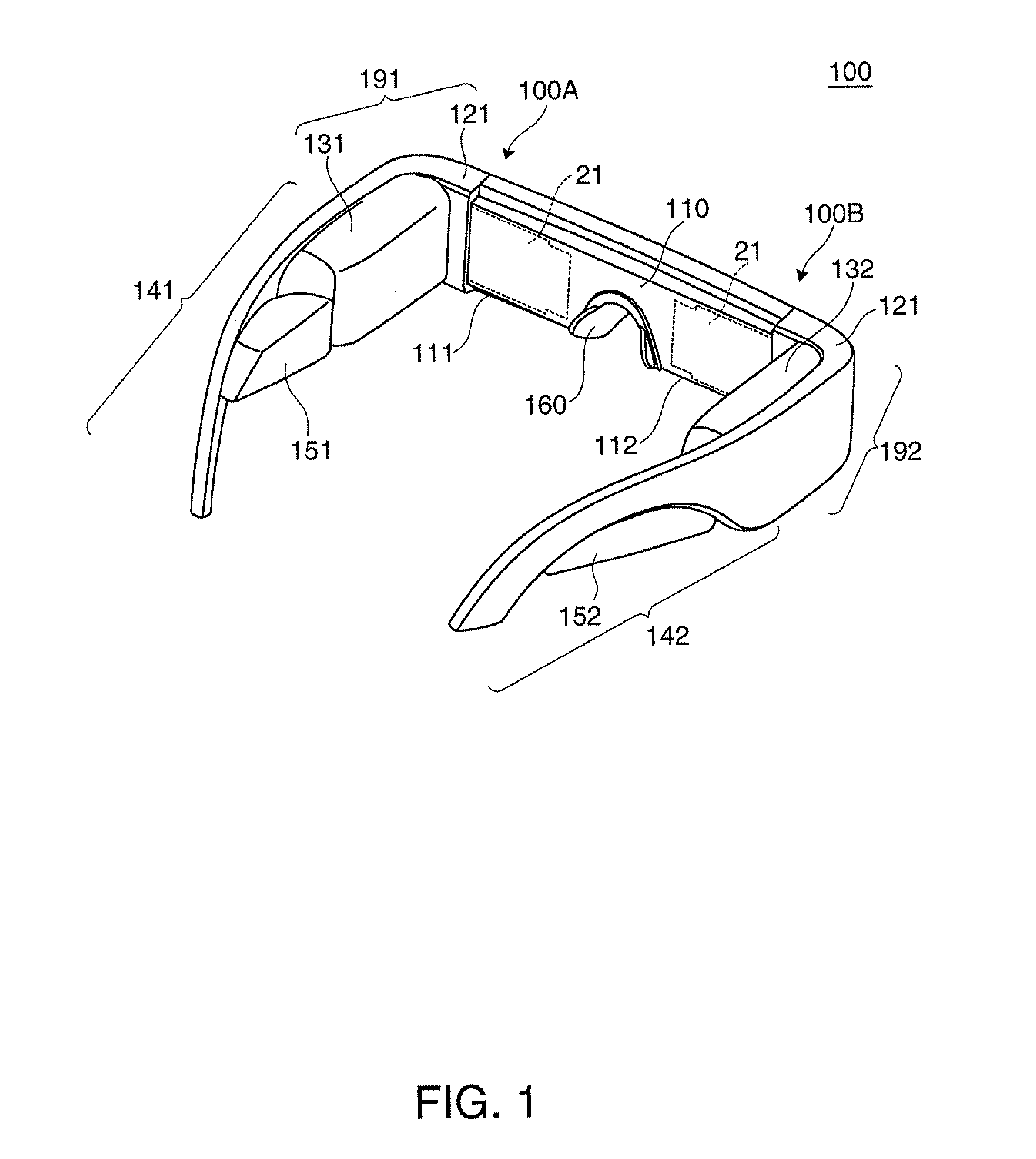

Virtual image display device and manufacturing method of virtual image display device

ActiveUS20130088415A1Relieve pressureSuppress stressCathode-ray tube indicatorsOptical elementsOptical axisDisplay device

In a virtual image display device, direction adjustment of an image optical axis, i.e., angle adjustment of a direction of eyes of an observer can be performed by providing a cushion member or adjusting an amount of shift between an image display unit and a projection system, and thereby, strain on eyes of an observer in use may be reduced. Even when the virtual image display device is used over a long period, for example, stress on the observer may be suppressed.

Owner:SEIKO EPSON CORP

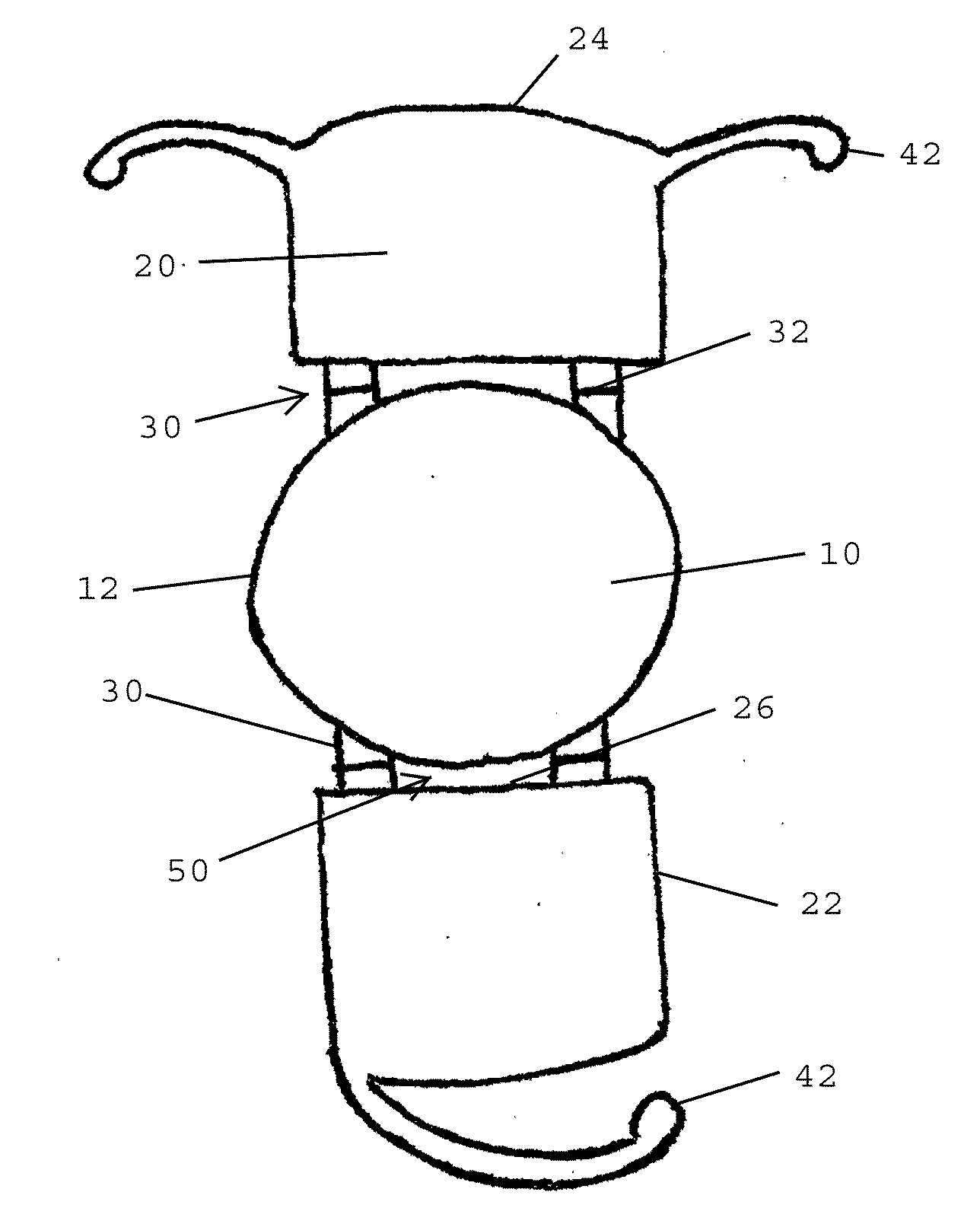

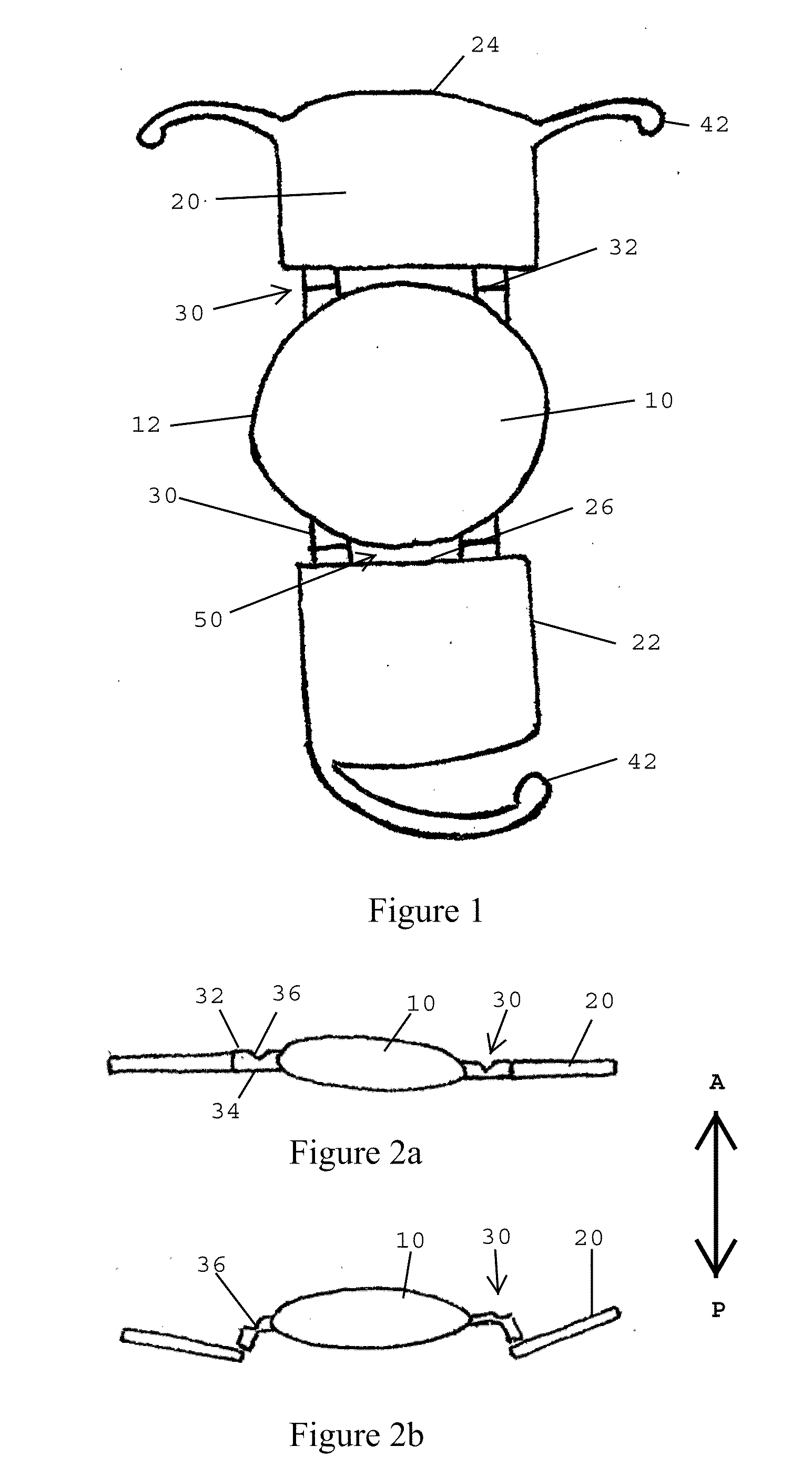

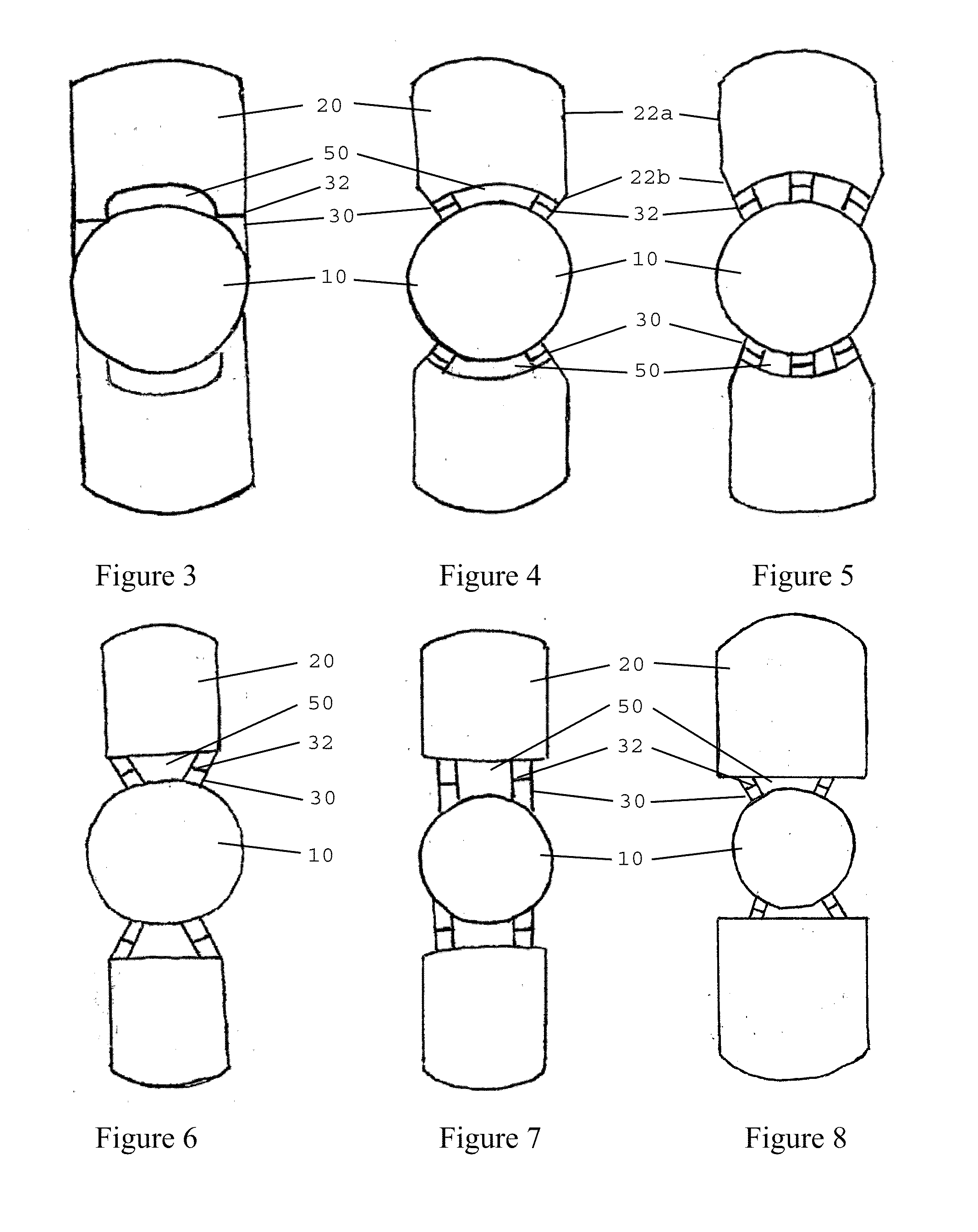

Tilt Stabilizing Accommodating Intraocular Lens

An intraocular lens for insertion into a capsular bag of an eye. A plurality of flexible connecting members couples a lens optic to a pair of opposing of plate haptics. The coupling members stabilize the optic with respect to the haptics. The coupling members are spaced apart straps having grooves that increase lens response to changes in vitreous pressure.

Owner:CUMMING JAMES STUART

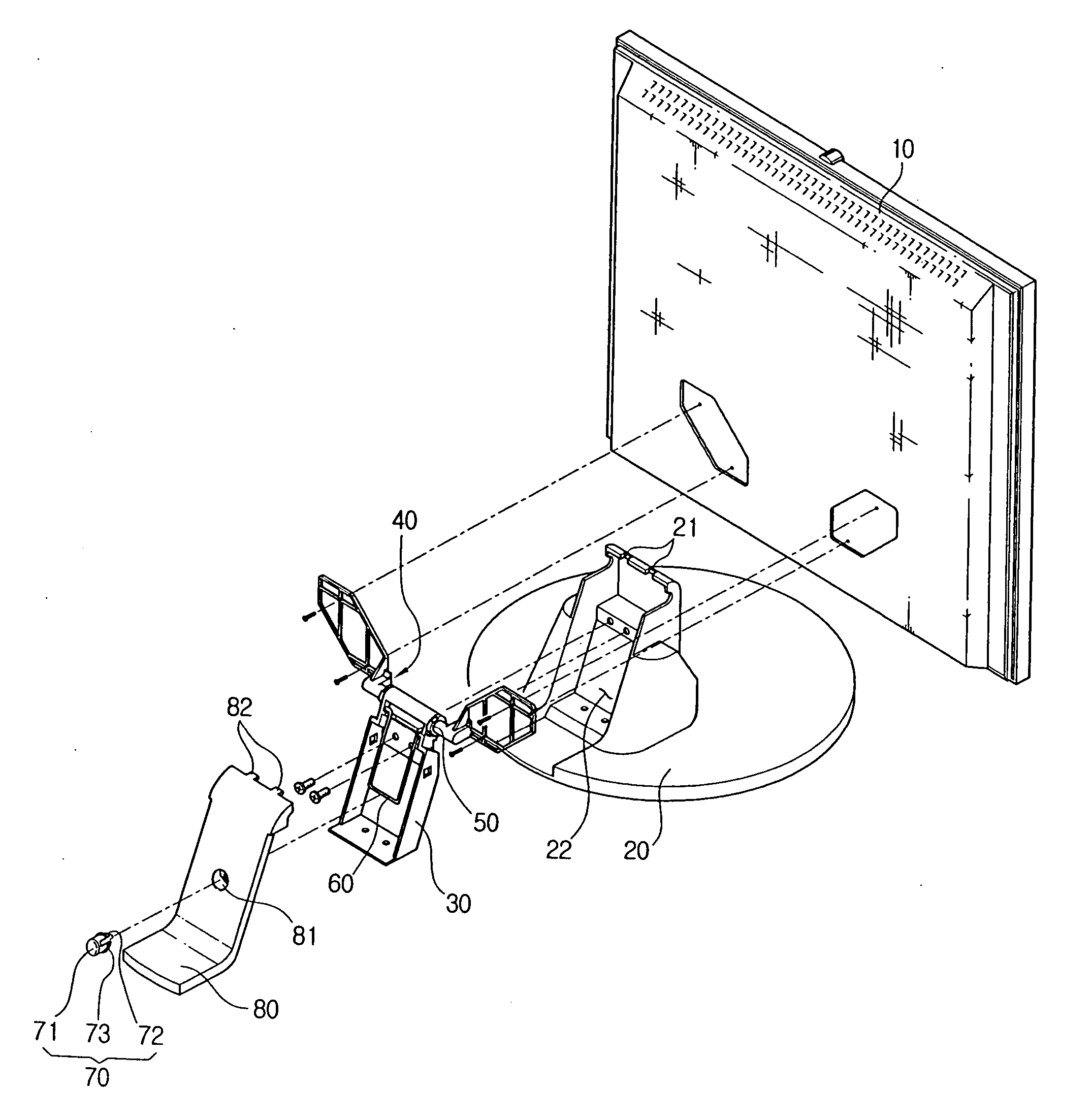

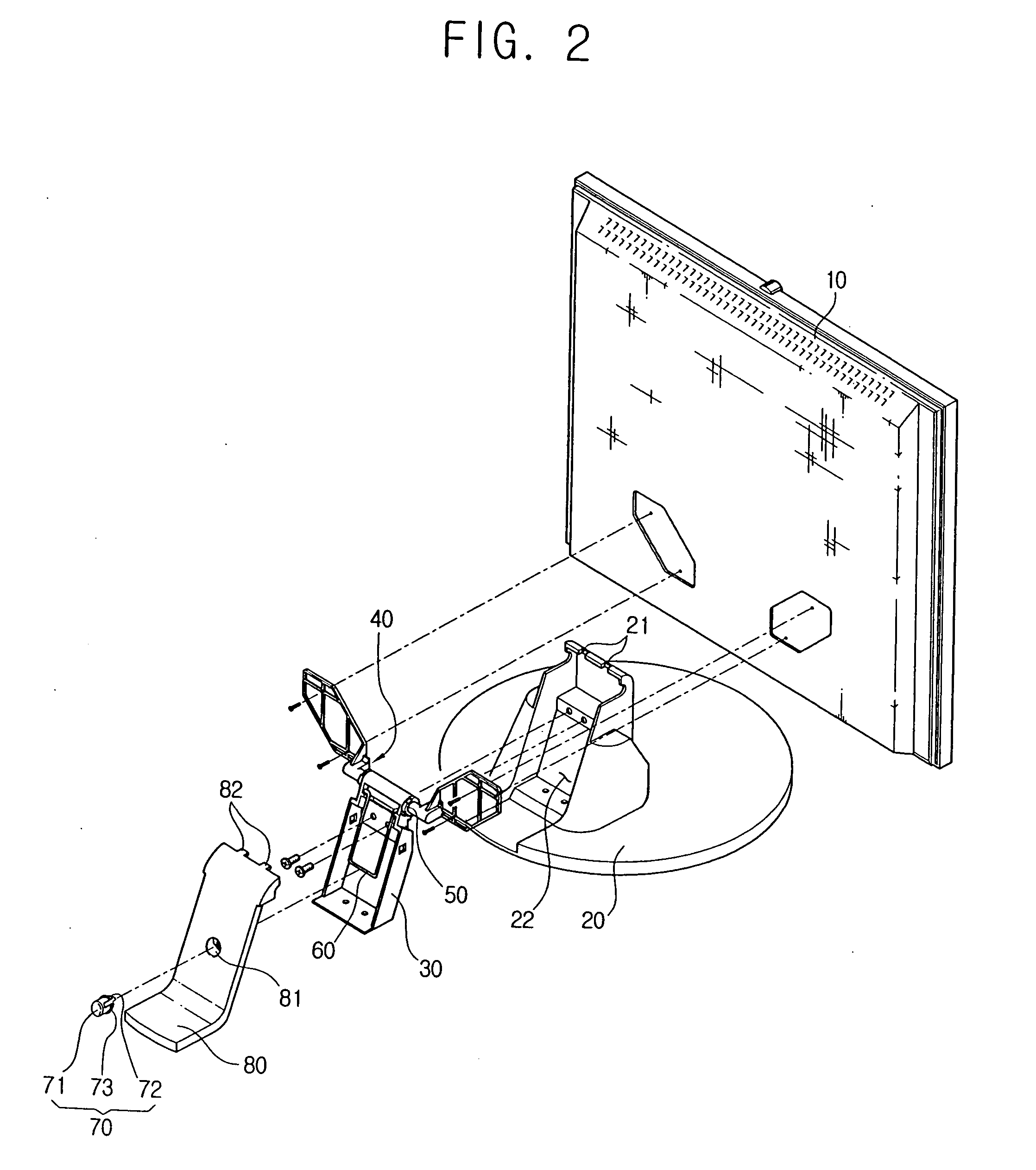

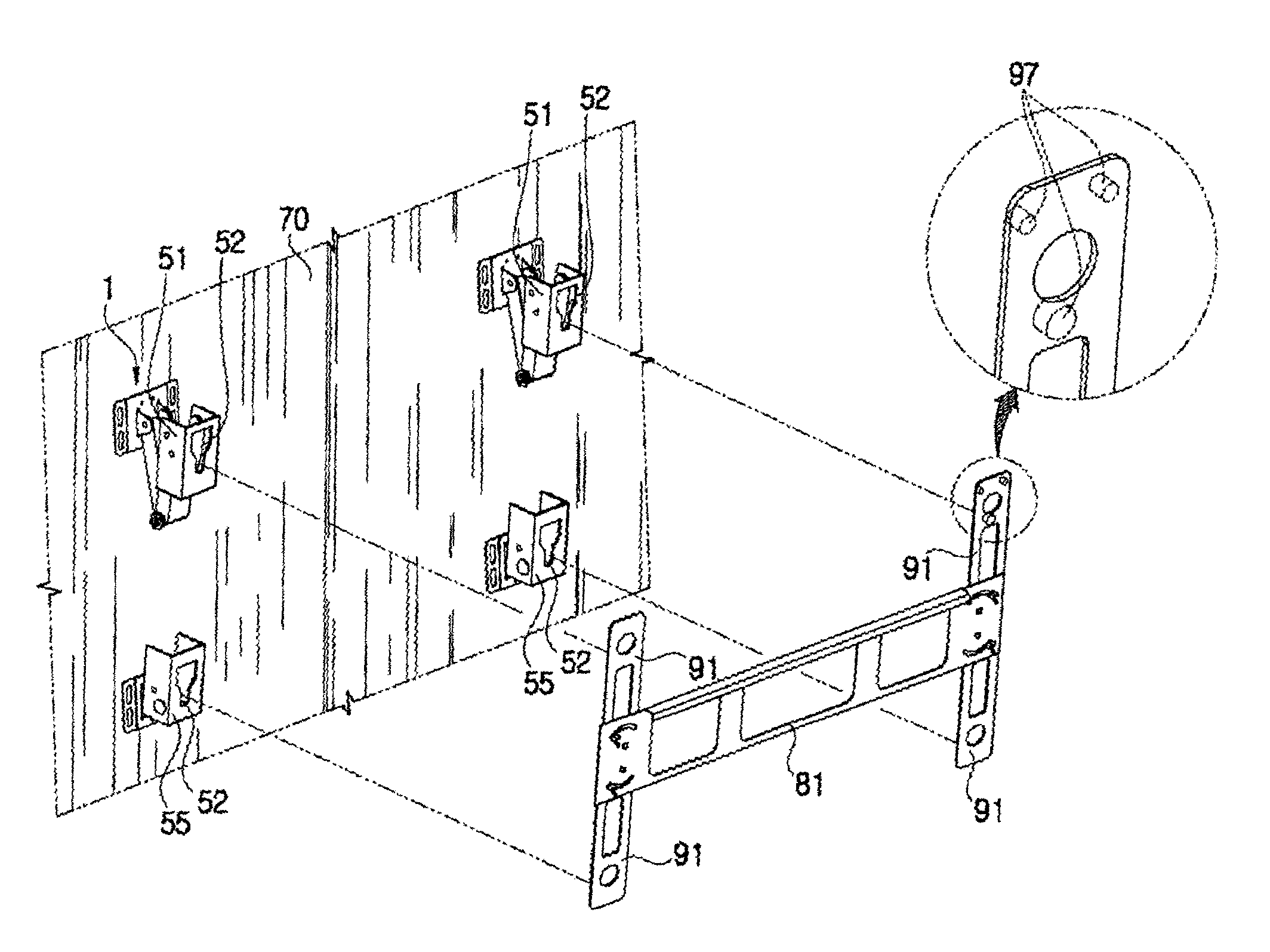

Installation equipment for display main body and jig for installation equipment

InactiveUS7097143B2Simple structureEasy to installTelevision system detailsDigital data processing detailsDisplay deviceEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Chimeric antigen receptor dendritic cell (car-dc) for treatment of cancer

InactiveUS20170151281A1High proliferation rateIncrease productionPolypeptide with localisation/targeting motifPeptide/protein ingredientsIntracellular signallingDendritic cell

The current invention provides monocytic cells transfected with chimeric antigen receptor (CAR) to selectively home to tumors and upon homing differentiate into dendritic cells capable of activating immunity which is inhibitory to said tumor. In one embodiment of the invention, monocytic cells are transfected with a construct encoding an antigen binding domain, a transcellular or structural domain, and an intracellular signaling domain. In one specific aspect of the invention, the antigen binding domain interacts with sufficient affinity to a tumor antigen, capable of triggering said intracellular domain to induce an activation signal to induce monocyte differentiation into DC.

Owner:MYELOID THERAPEUTICS INC

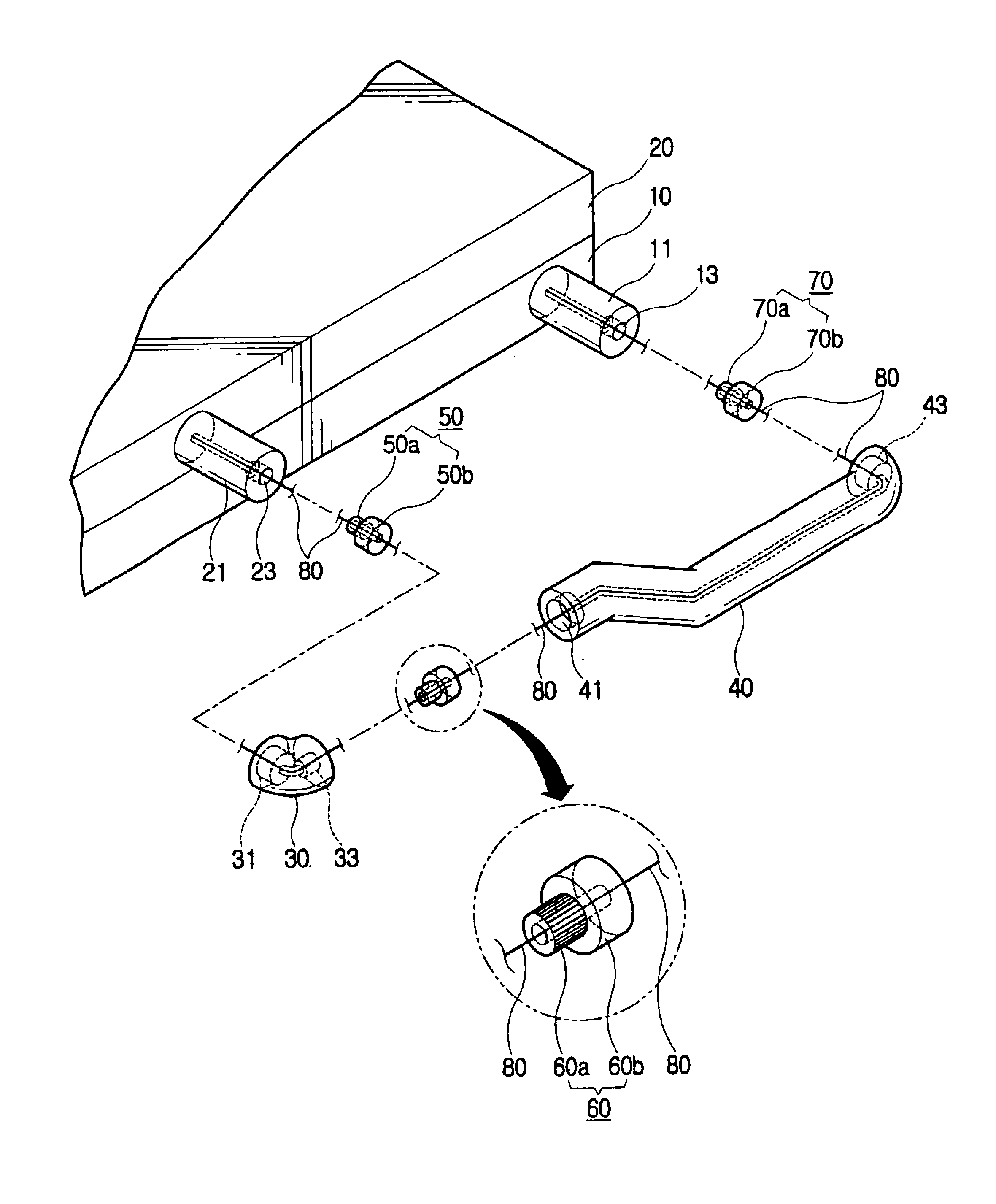

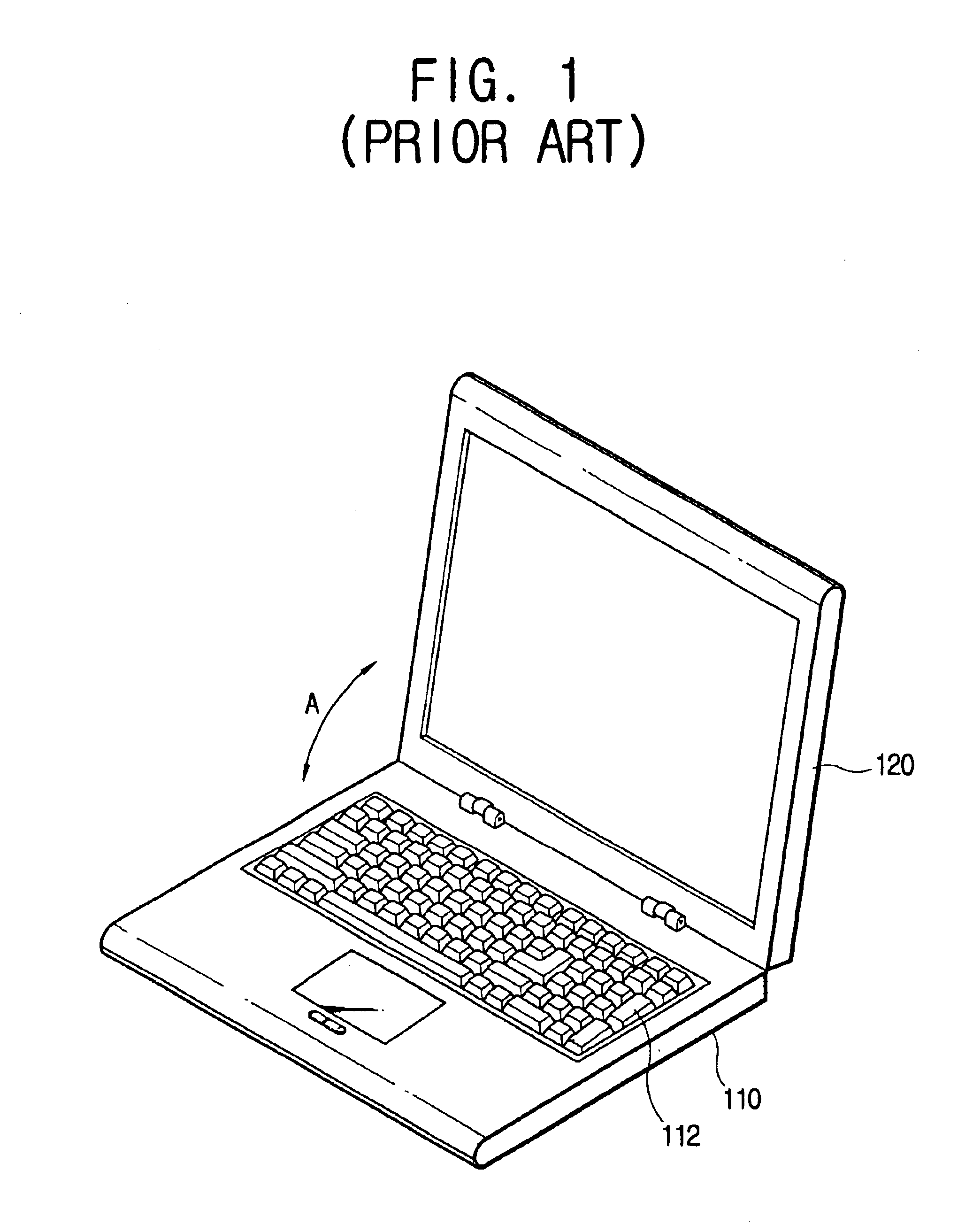

Portable computer

InactiveUS6963485B2Easy to tiltMachine supportsDetails for portable computersDisplay deviceEngineering

A portable computer having a main body and a monitor coupled to the main body, by way of a pivoting link having a first end rotatably combined to the monitor so as to tilt and swivel the monitor relative to the main body, and a second end rotatably combined to the main body so as to pivot the monitor relative to the main body. With this configuration, the present invention provides a portable computer in which the monitor can be tilted, swiveled and pivoted relative to the main body, thereby allowing a user to view the monitor from various angles without moving the whole portable computer.

Owner:SAMSUNG ELECTRONICS CO LTD

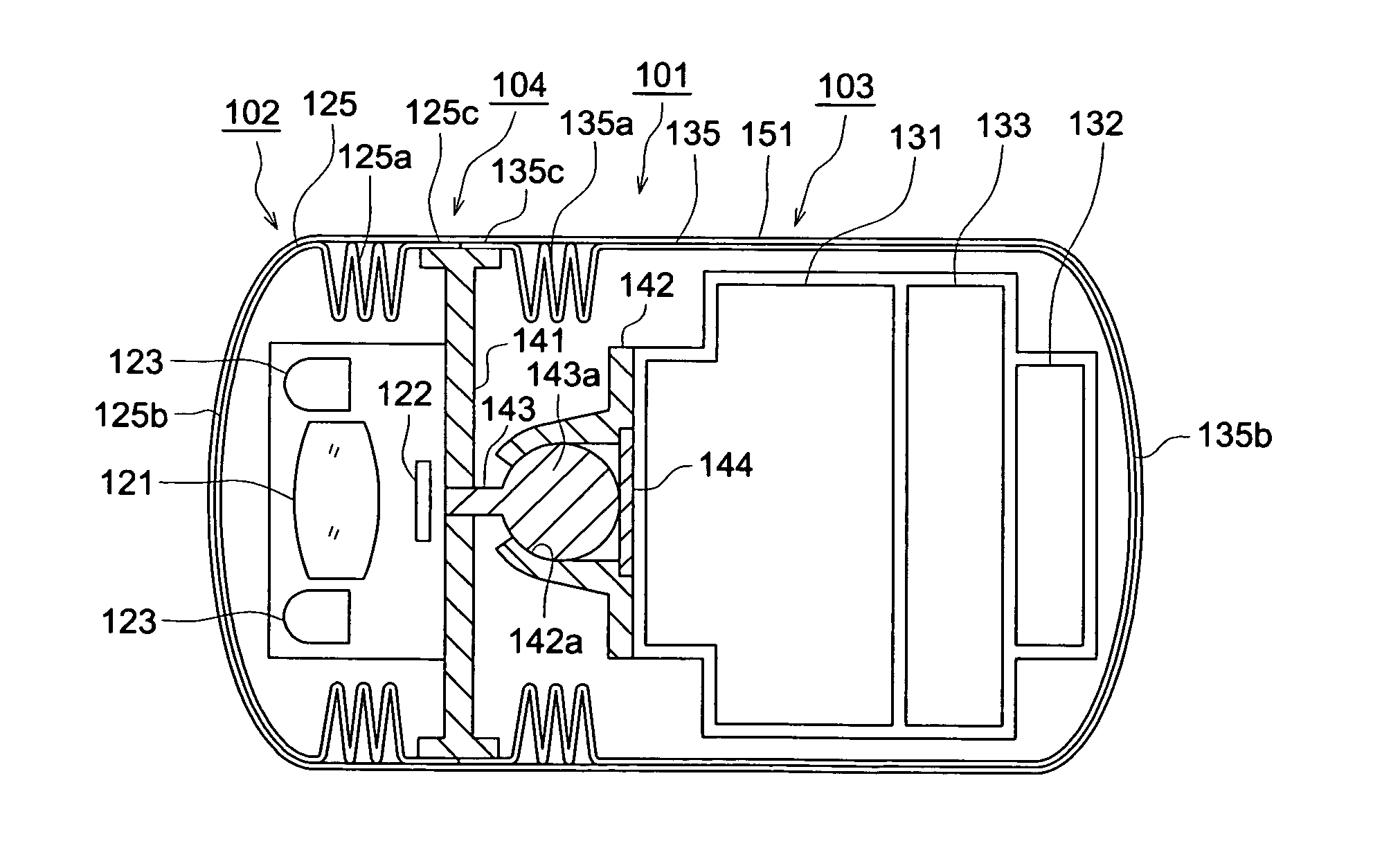

Capsule type medical device

InactiveUS20070100200A1Reduce riskSmall bowel is decreasedSurgeryEndoscopesMedical deviceBiomedical engineering

A capsule type medical device to conduct an operation in an internal organic portion of a body, is provided with a capsule body to move in the internal organic portion; and an operating member incorporated in the capsule body and to conduct the operation in the internal organic portion. The capsule body includes a bellow section formed on a peripheral surface of the capsule body such that the bellow section stretches or contracts in a longitudinal direction of the capsule body.

Owner:KONICA MINOLTA PHOTO IMAGING

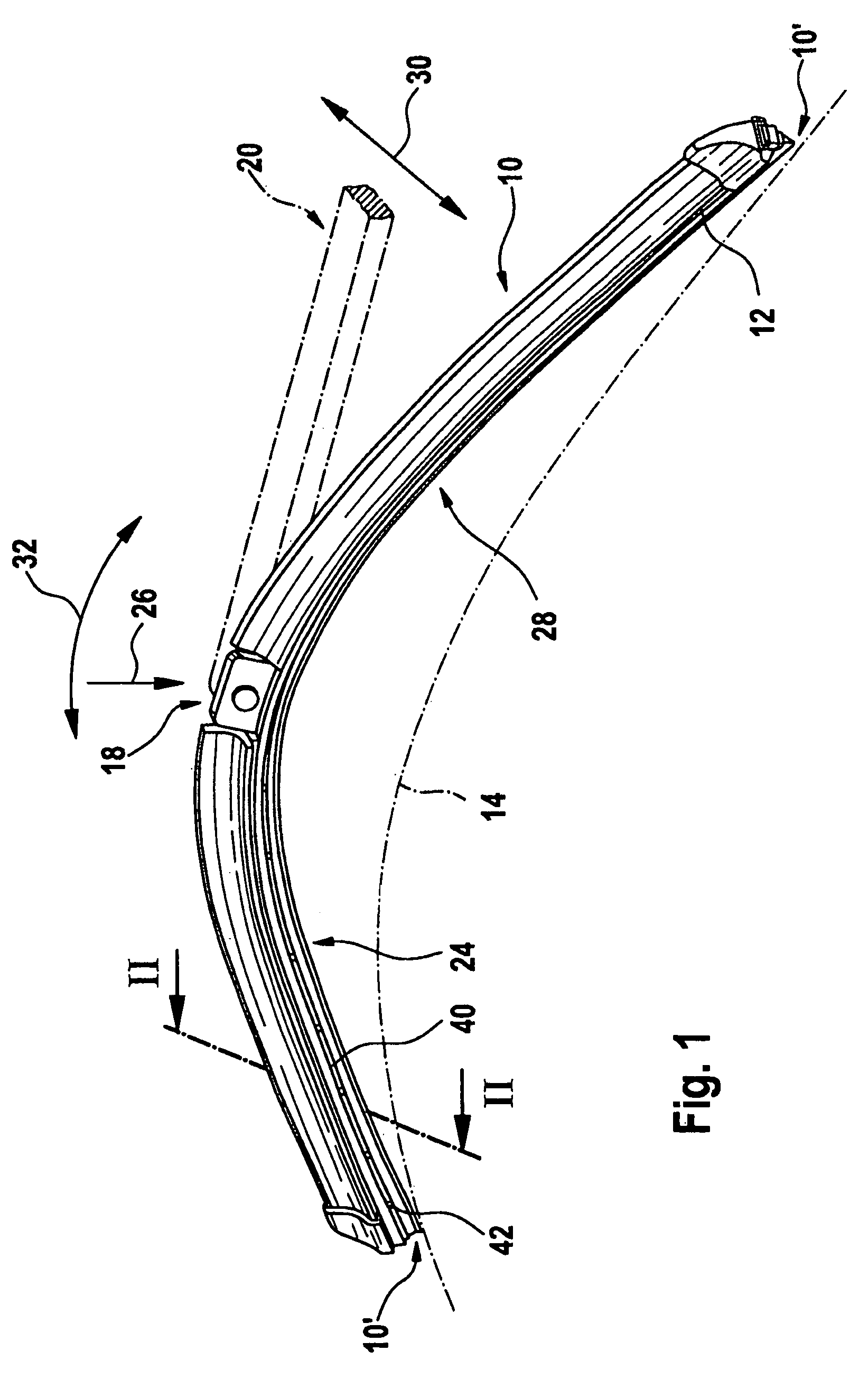

Wiper blade

ActiveUS7836542B2Dampen folding processEasy to tiltWindow cleanersVehicle cleaningAerospace engineering

Owner:ROBERT BOSCH GMBH +1

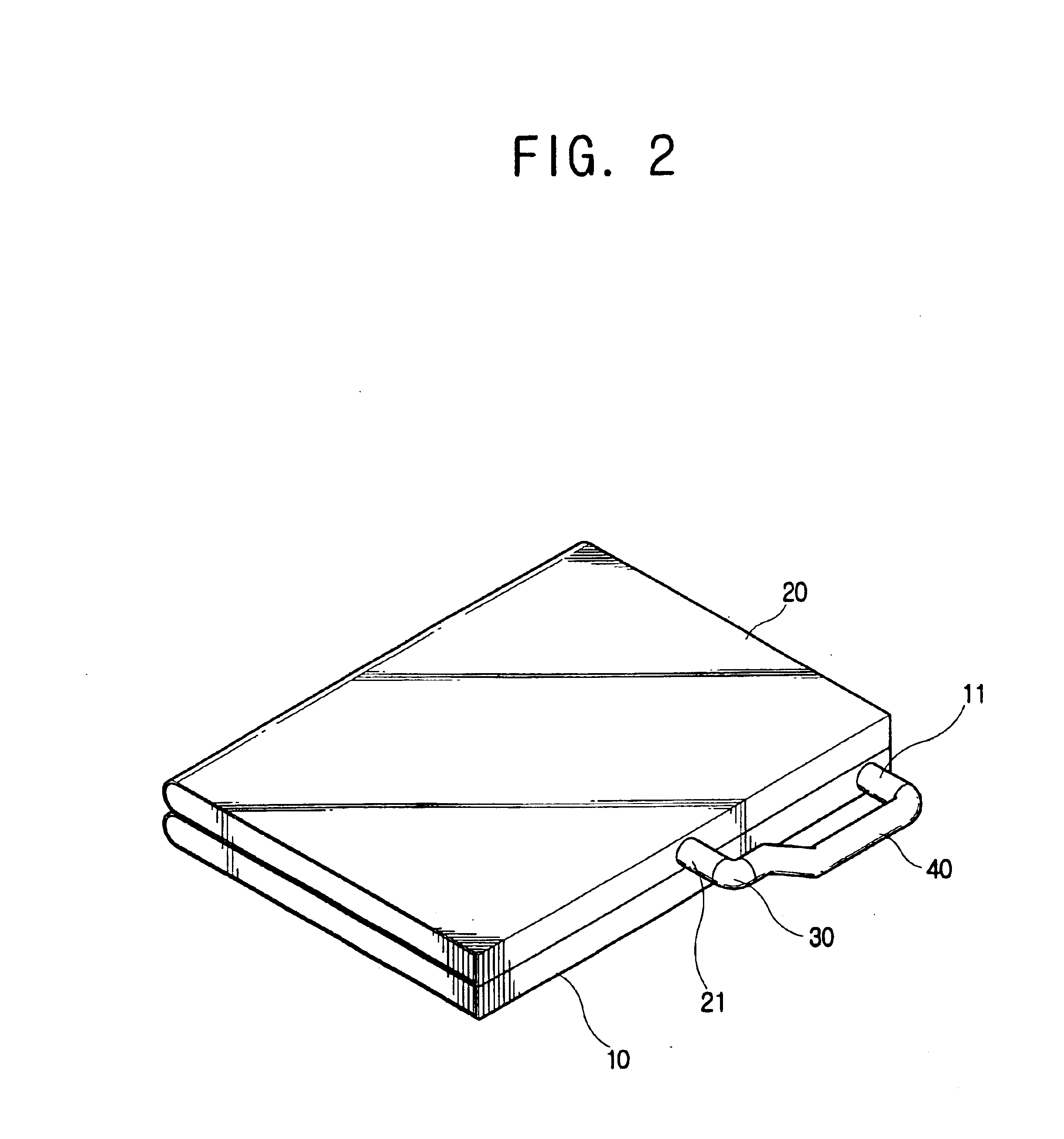

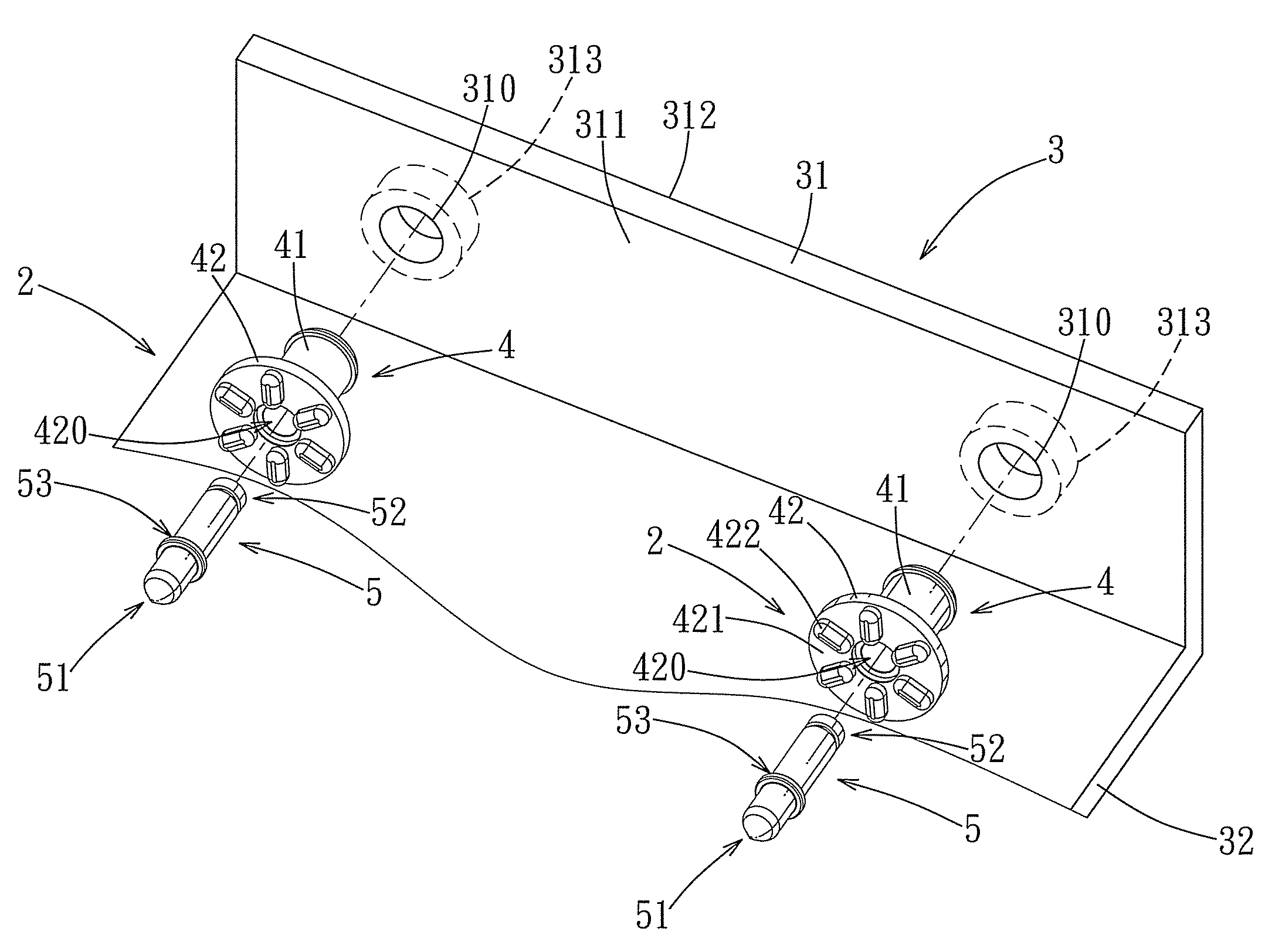

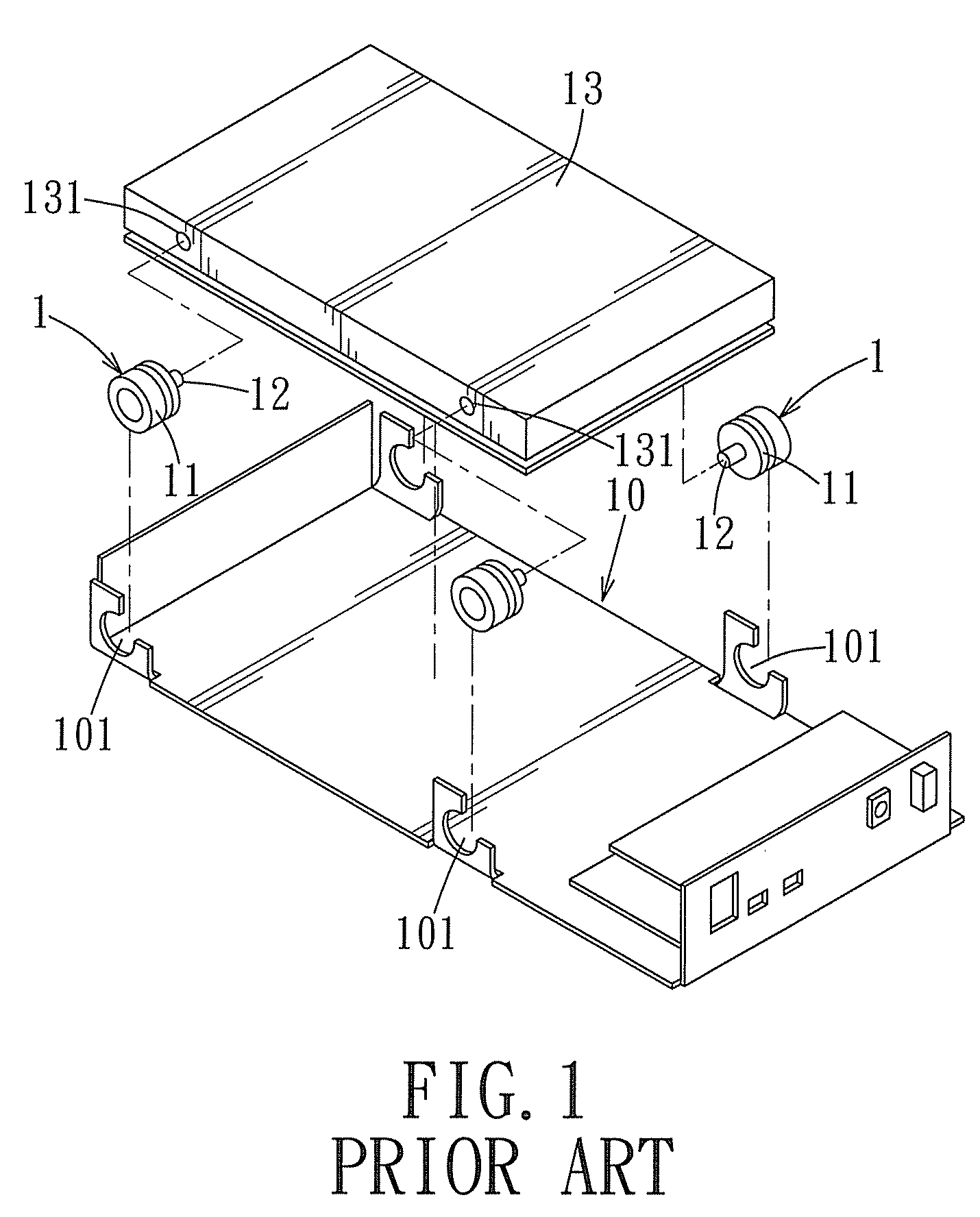

Shockproofing module and assembly of the shockproofing module and an electronic device carrier case

InactiveUS20100039766A1Improve stabilityAvoid leaningNon-rotating vibration suppressionDigital data processing detailsEngineeringMechanical engineering

An assembly of a shockproofing module and an electronic device carrier case includes an electronic device carrier case and a plurality of shockproofing modules. The electronic device carrier case has two side walls spaced apart from each other, and each of the side walls is formed with at least one hole. Each shockproofing module is disposed at a respective one of the holes in the side walls, and includes a shockproofing washer and a pin component. The shockproofing washer is disposed at the respective one of the holes in the side walls, and the pin component is extended into the shockproofing washer and causes a part of the shockproofing washer to expand in radial directions, thereby enabling the shockproofing washer to engage tightly the side wall and avoiding tilting of the pin component, thus enhancing the stability of the shockproofing modules disposed at the side walls.

Owner:WISTRON CORP

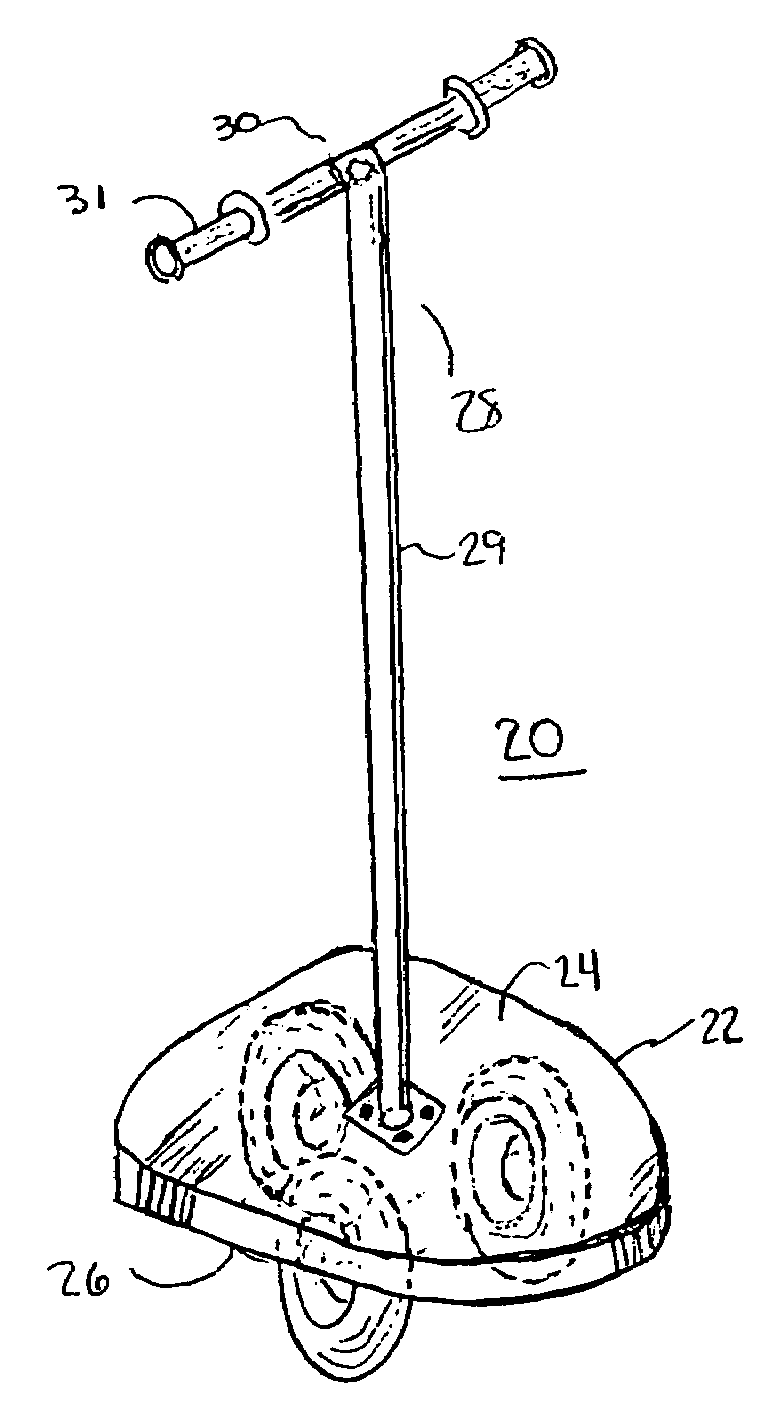

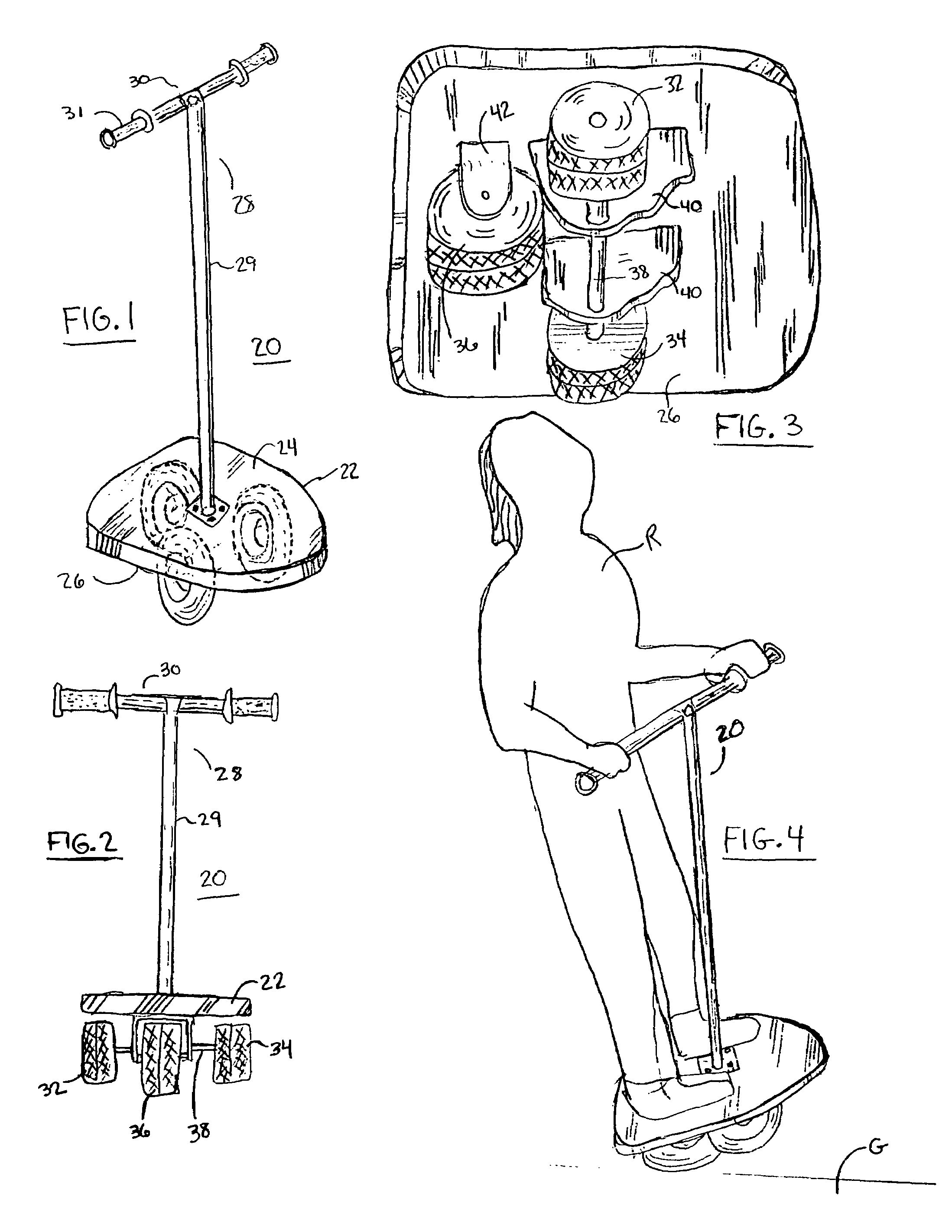

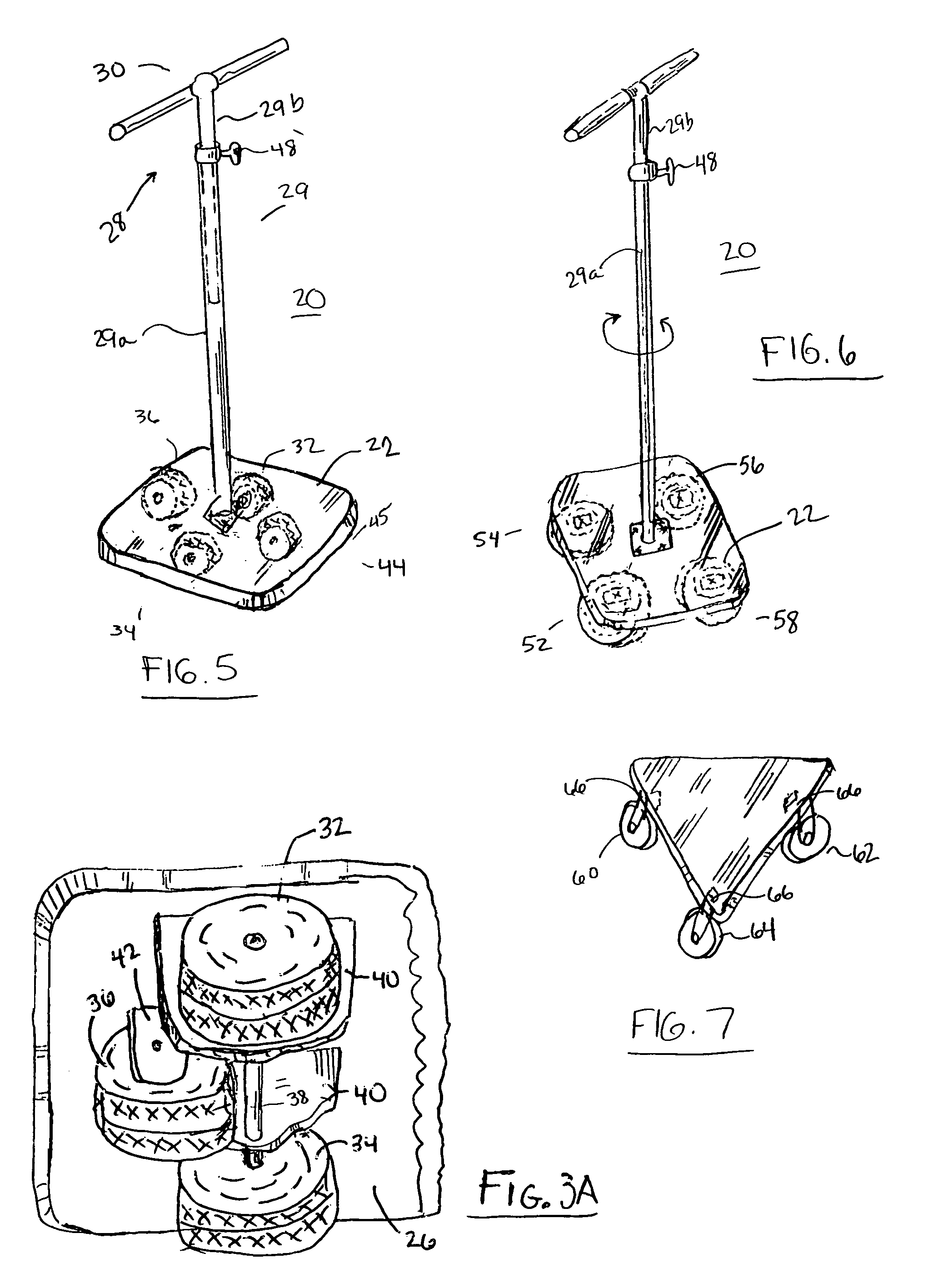

Recreational wheelie vehicle

ActiveUS7226062B1Improve securityOverall controllabilityWheel based transmissionFrictional rollers based transmissionEngineeringWheelie

An amusement-type vehicle is provided particularly for doing so-called wheelies having a short wheel base upon a platform-type base with at least two side by side wheels forwardly and one wheel rearwardly upon which wheelies are performed and having a central handle by which the vehicle may be controlled.

Owner:STEFANO NICK

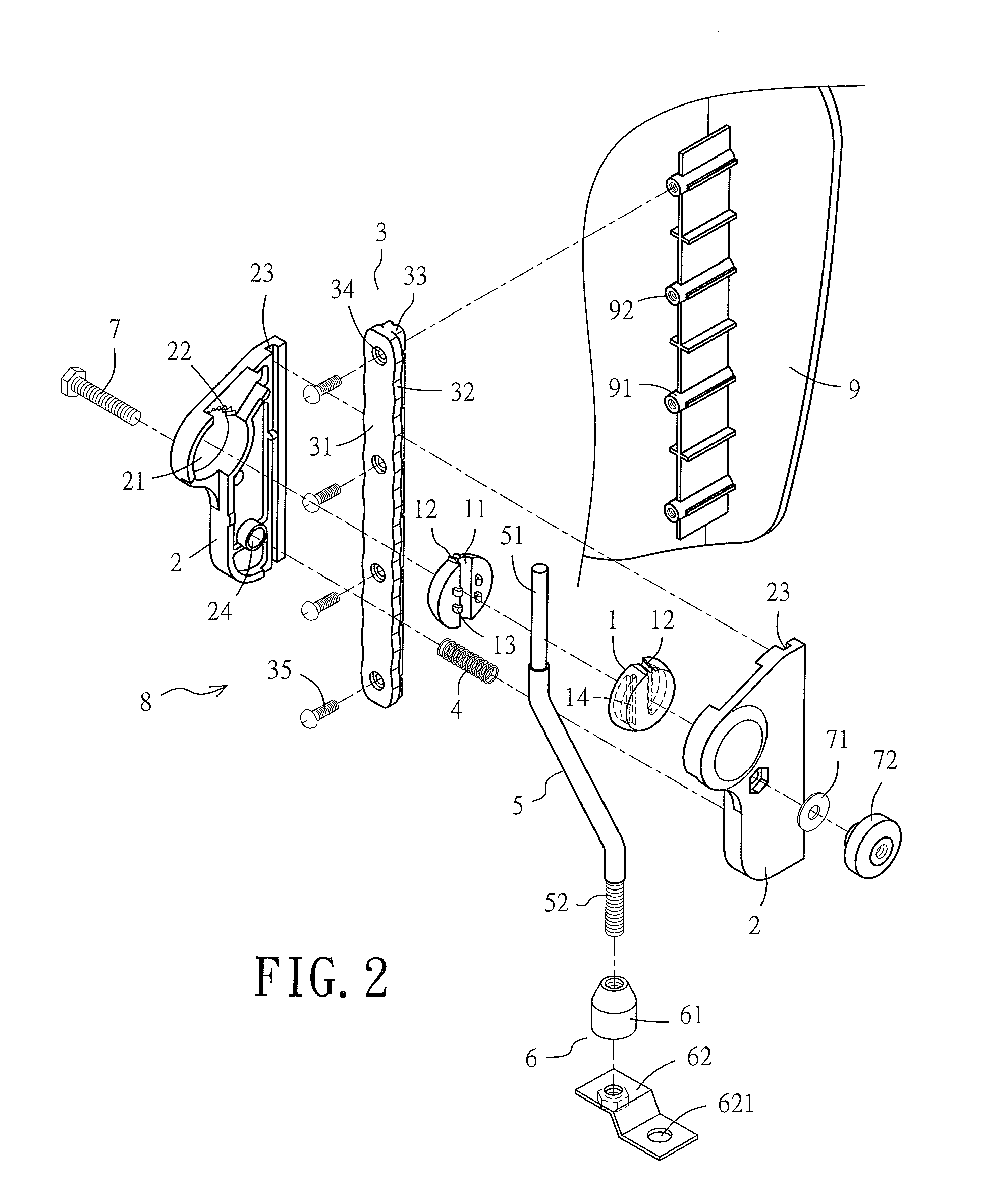

Motorcycle Windshield Assembly

A motorcycle windshield assembly includes two frame units coupled to a windshield. Each frame unit includes a pair of corresponding adjusting elements jointly enclosing an end of an installation rod. Each pair of the adjusting elements are fitted into receiving spaces of a corresponding pair of left and right covers such that teeth formed on each pair of the adjusting elements mesh with teeth formed in the corresponding pair of left and right covers. Each pair of the left and right covers have a side provided with guide grooves for receiving a sliding element coupled to the windshield. Thus, the windshield coupled to the frame units can be conveniently raised, lowered, or tilted to provide the desired shielding effect. The motorcycle windshield assembly is flexibly adjustable in height and tilt angle and is collapsible when not in use.

Owner:YUAN HWEN CADTOOL INDAL

Tiltable rooftop cargo carrier for a vehicle

A vehicle cargo carrier including a cargo platform for placement of cargo thereon, the platform supported by a lower support base affixed atop a vehicle which allows the platform to be manually drawn laterally outward and then to be pivoted from generally horizontal into a tilt along side the vehicle for easier reach. Low-friction plastic strips mounted on surfaces of the cargo carrier provide low friction sliding of the platform on the support base. Low-friction lateral guidance plastic strips extending into the area of pivot studs maintain lateral alignment when the cargo platform is tilted relative to the support base. The pivot studs on which the platform tilts are intermediately or non-edgewardly positioned of the platform to allow placement of cargo on the cargo platform on each side of the pivotal axis so that the weight of the cargo is distributed to aid the user in tilting the platform back toward horizontal. Tilt-stops, preferably adjustable, are applied between the ends of the support base and the underside of the platform to prevent the tilted platform from striking the vehicle and to set a predetermined maximum tilt angle. Manually de-latchable latches are mounted on the cargo carrier to engage between the platform and support base for holding the platform in a retracted position allowing driving of the vehicle.

Owner:FERGUSON ALAN C

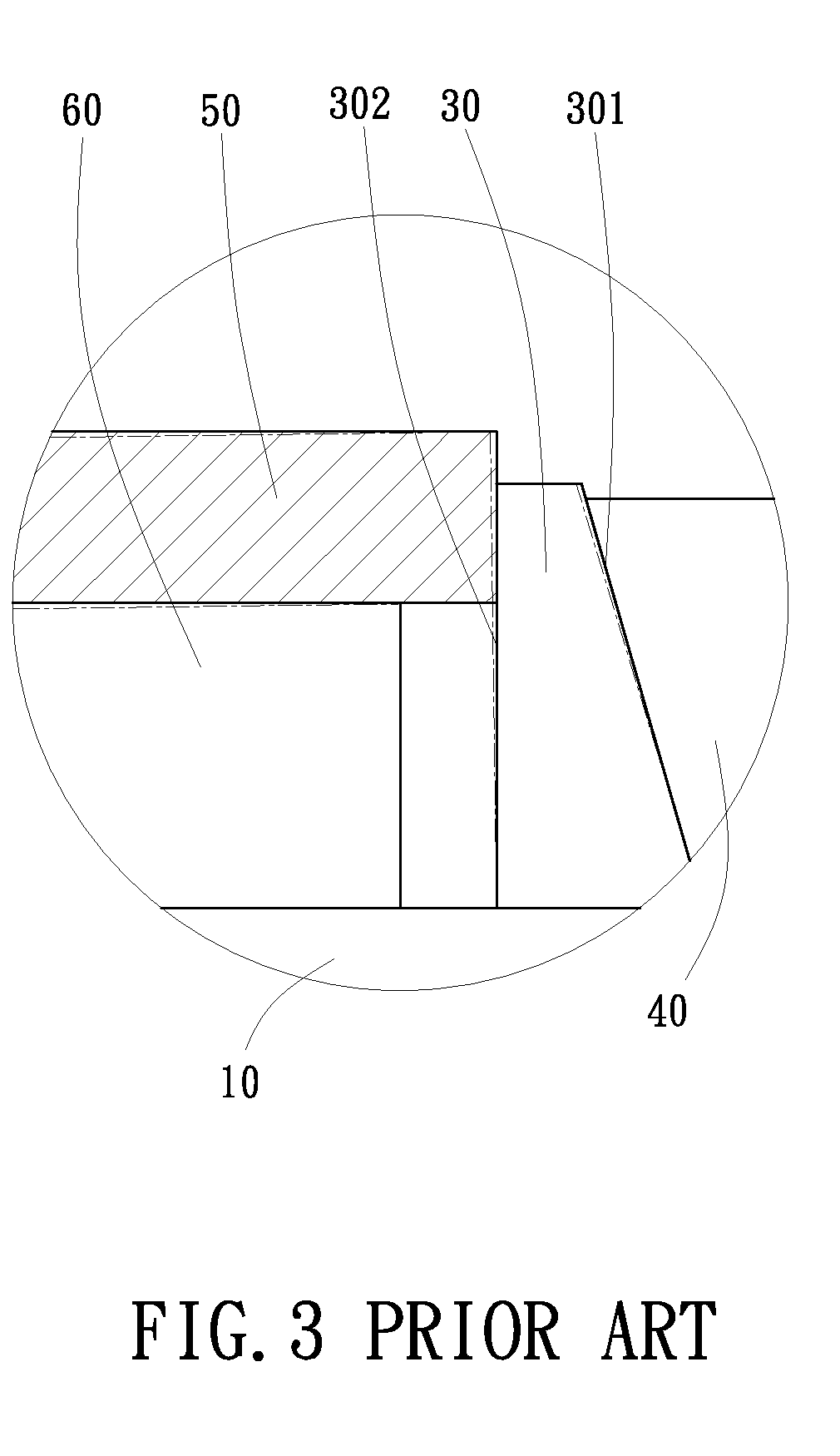

Machining process of half-pore plate

InactiveCN102427667AImprove protectionIt is not easy to cause the copper skin on the hole wall to liftPrinted element electric connection formationEngineeringCopper

The invention belongs to the technical field of printed circuit boards (PCBs), in particular discloses a machining process of a half-pore plate, which mainly adopts a wet film pore plugging method and specifically comprises the steps of: manufacturing a pore plugging template, carrying out wet film pore plugging, baking the board, routing, retreating a film, etching and the like. Through pore plugging, ink and the half-pore plate can form an integer, pore copper on the pore wall is placed between the ink and a board pore plate body, thus the pore copper can be better protected in a routing process so that the pore copper is not easy to generate pore wall copper skin tilting and flash residual, even if less quantity of copper skin tilting and flash residual is generated, the copper tilting and the flash residual can be removed through etching. Therefore, by adopting the invention, the pore wall copper skin tilting and the flash residual of a semi-metallization groove or pore can be effectively improved.

Owner:金悦通电子(翁源)有限公司

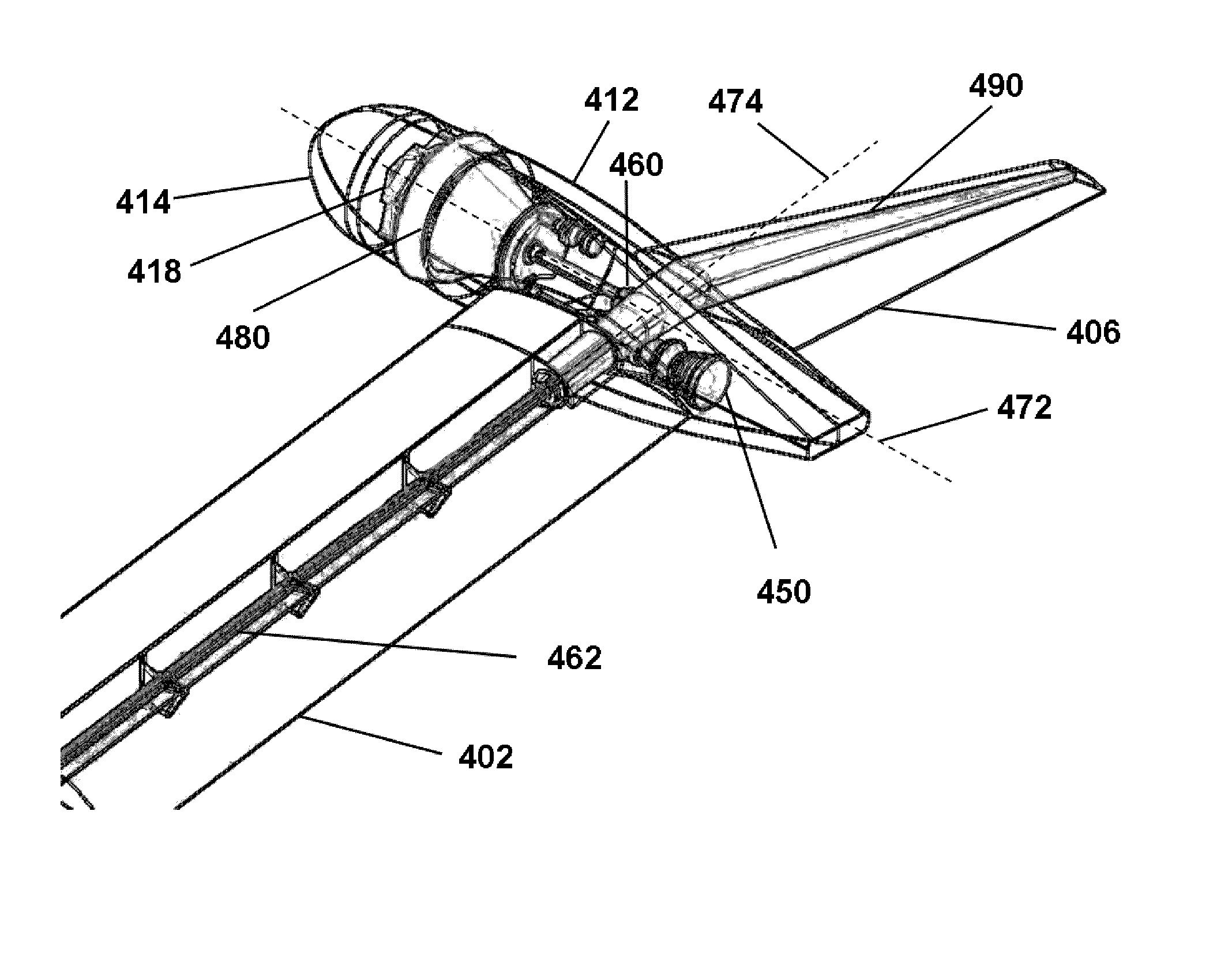

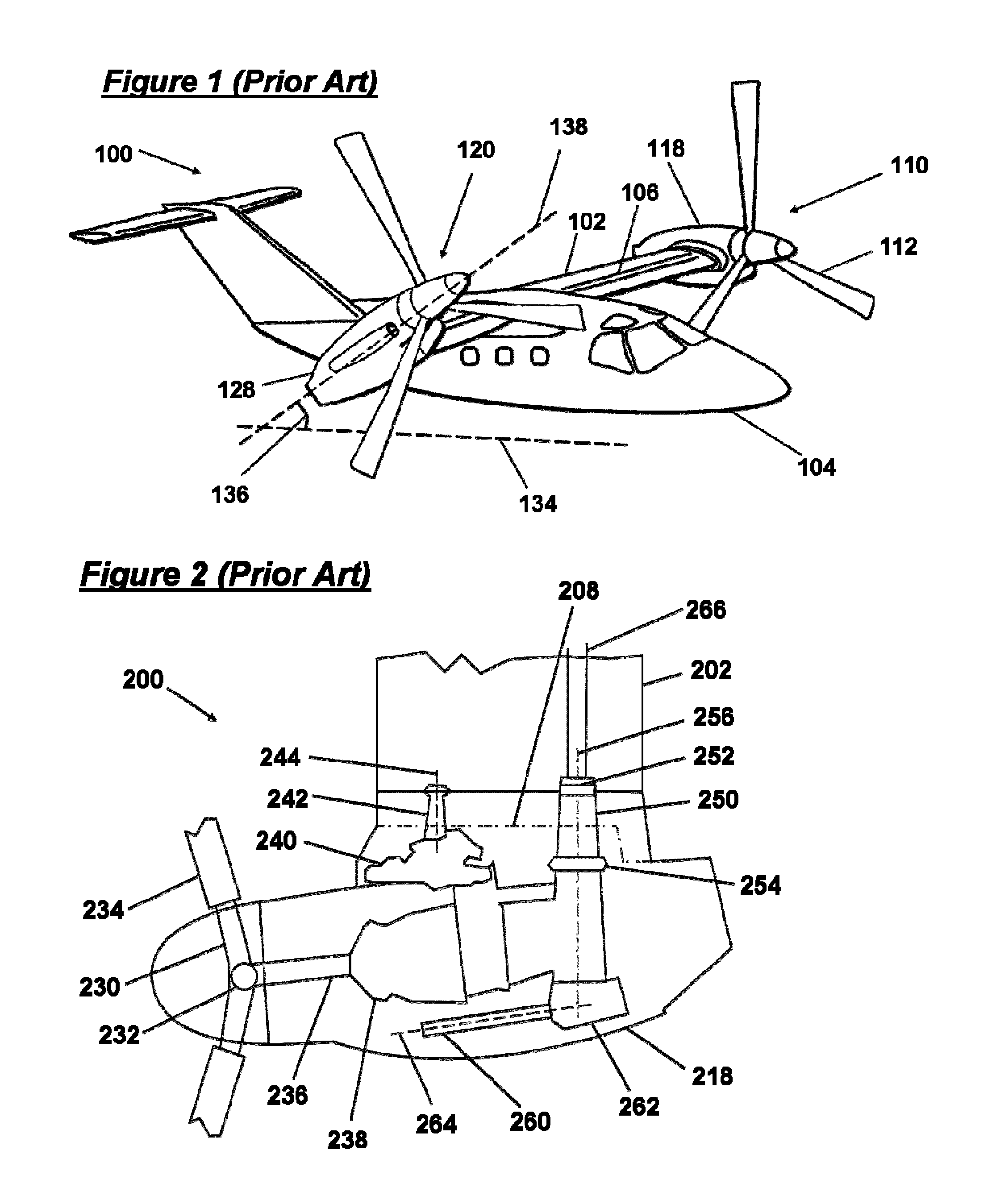

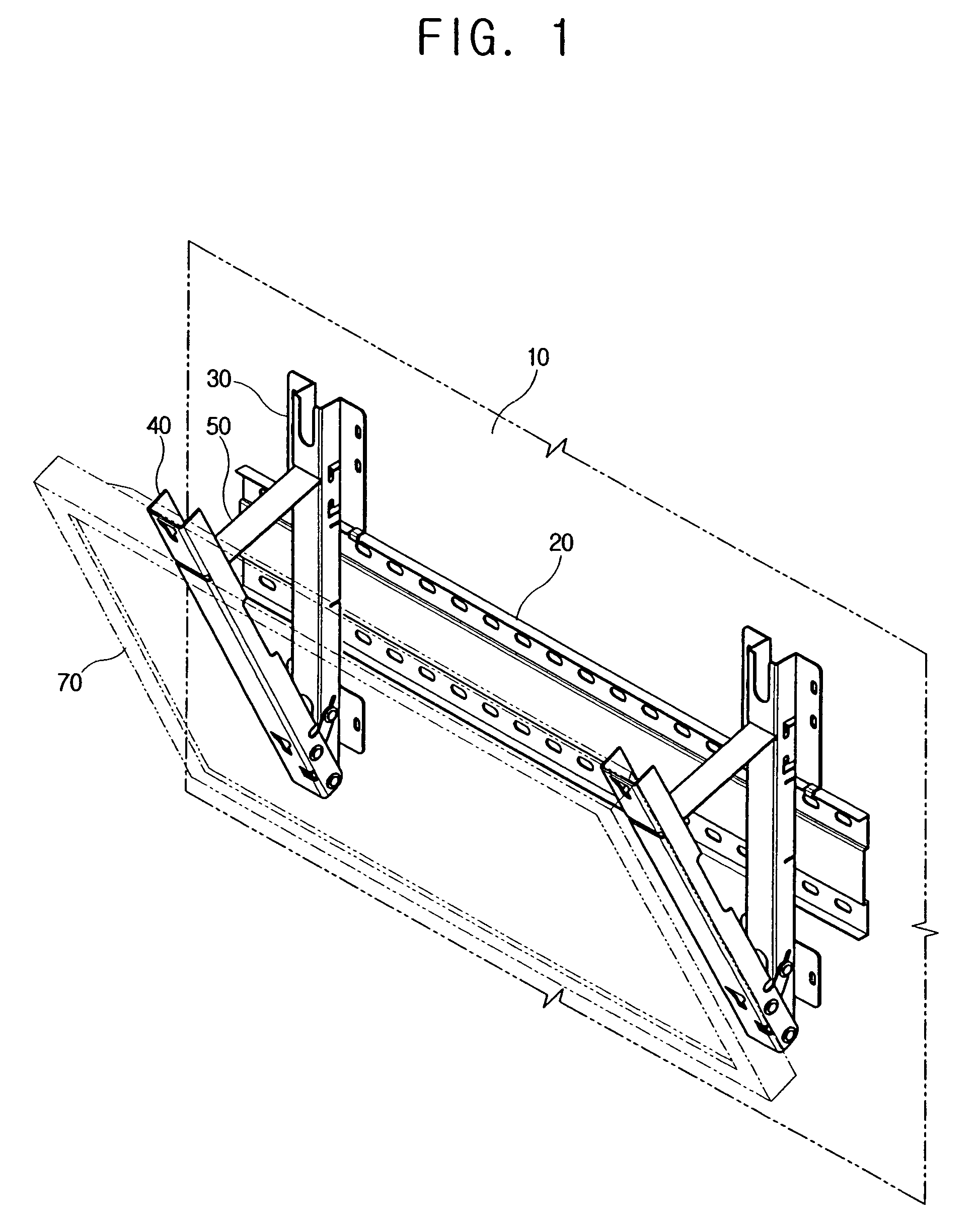

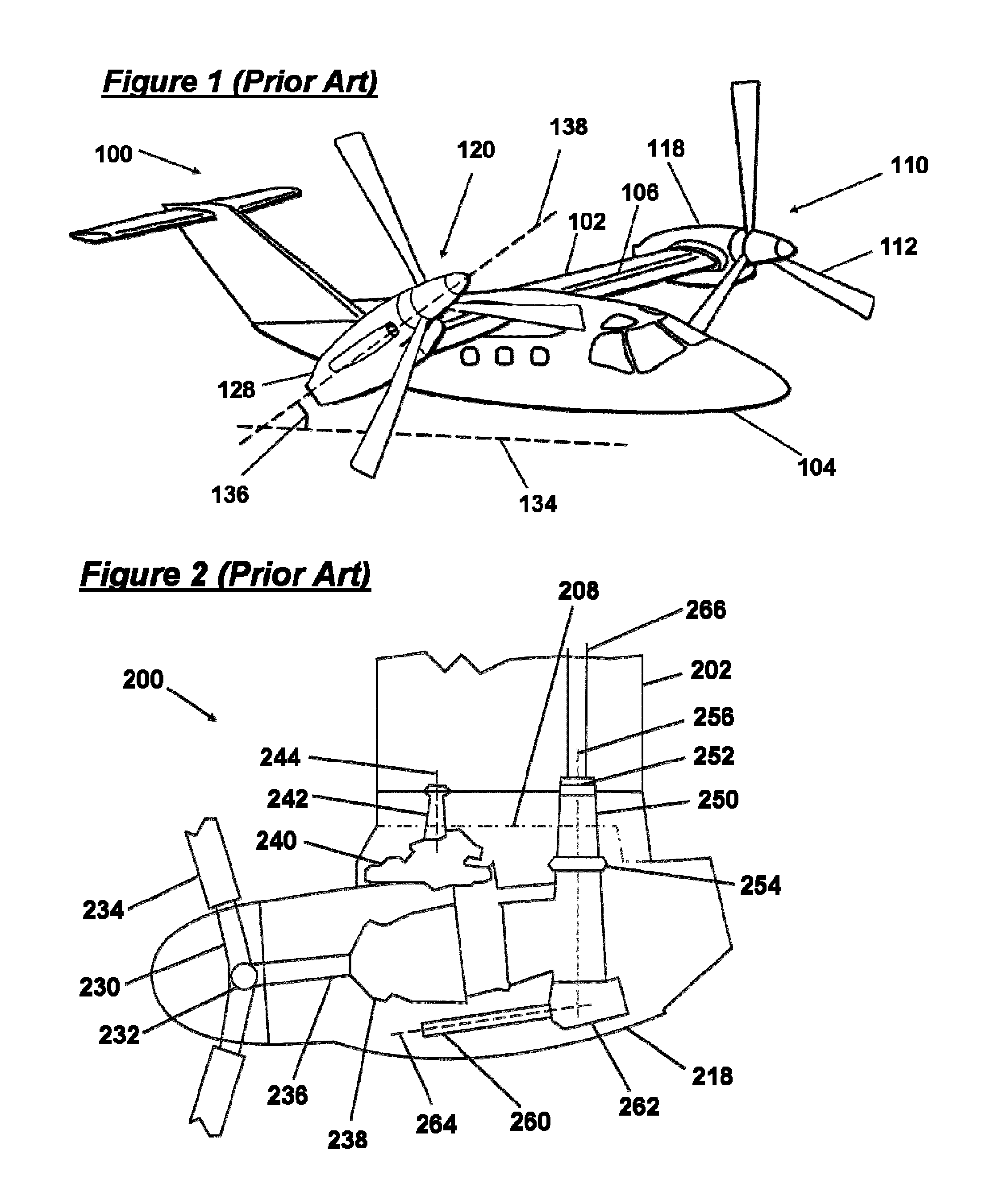

Combination Spar and Trunnion Structure for a Tilt Rotor Aircraft

An aircraft is equipped with a spinnion coupling an inboard wing to a tilting nacelle. The spinnion is advantageously configured to extend across the nacelle from an inboard junction to an outboard junction, and terminates inside the inboard wing. This provides an efficient lightweight structure to support a nacelle and facilitate tilting of the nacelle. The spinnion, which can be configured to be at least partially disposed within the inboard wing, is advantageously concentric with the tilting axis in order to facilitate tilting of a nacelle. A cross-wing driveshaft can be included, disposed at least partly within the inboard wing, and can advantageously be configured to terminate inside the spinnion at a junction with a miter gearbox. The miter gearbox can be disposed at least partly within the spinnion but more preferably lies entirely within the spinnion, and functions to transfer power from an input shaft to the cross-wing driveshaft.

Owner:KAREM ABE

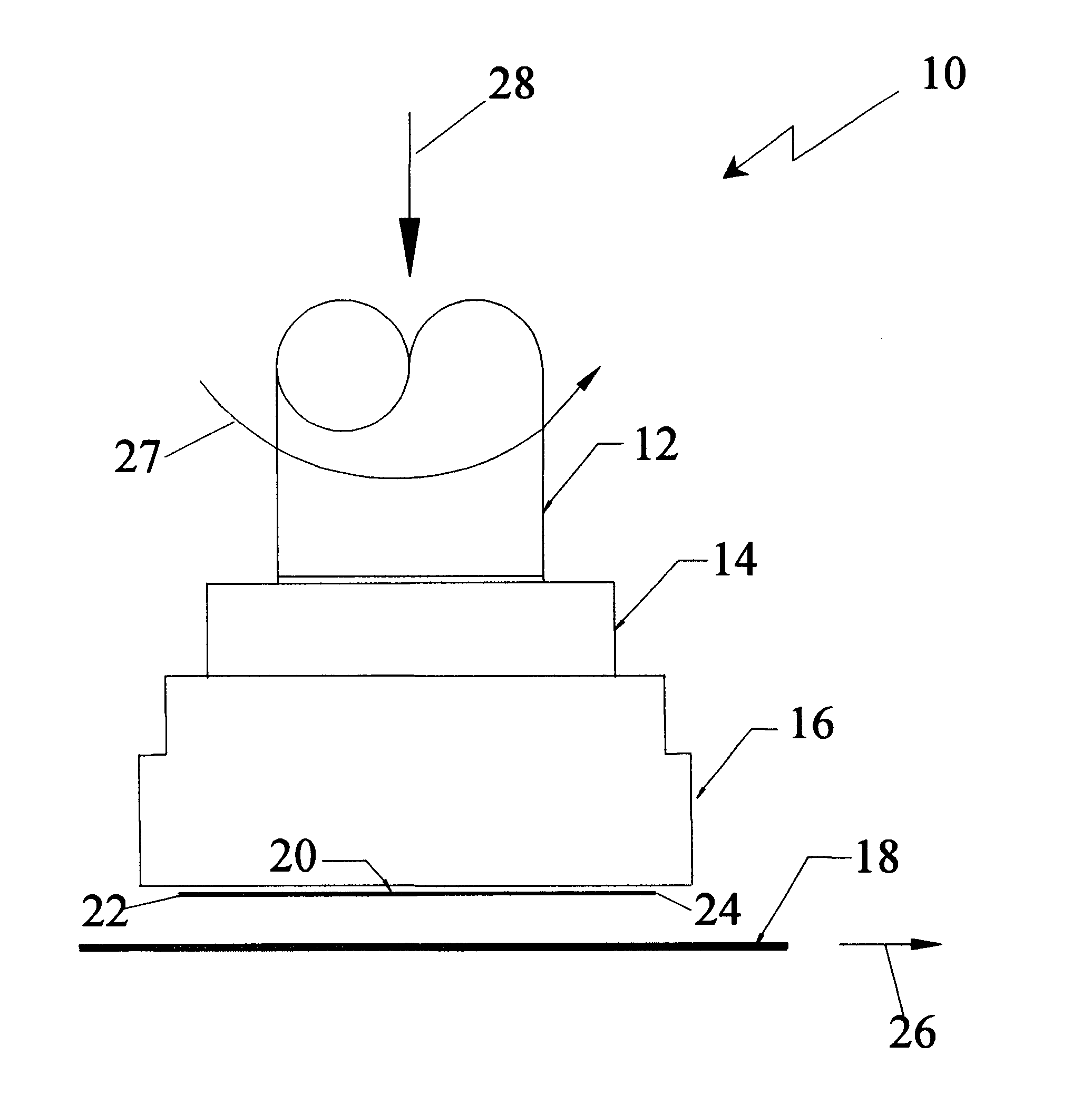

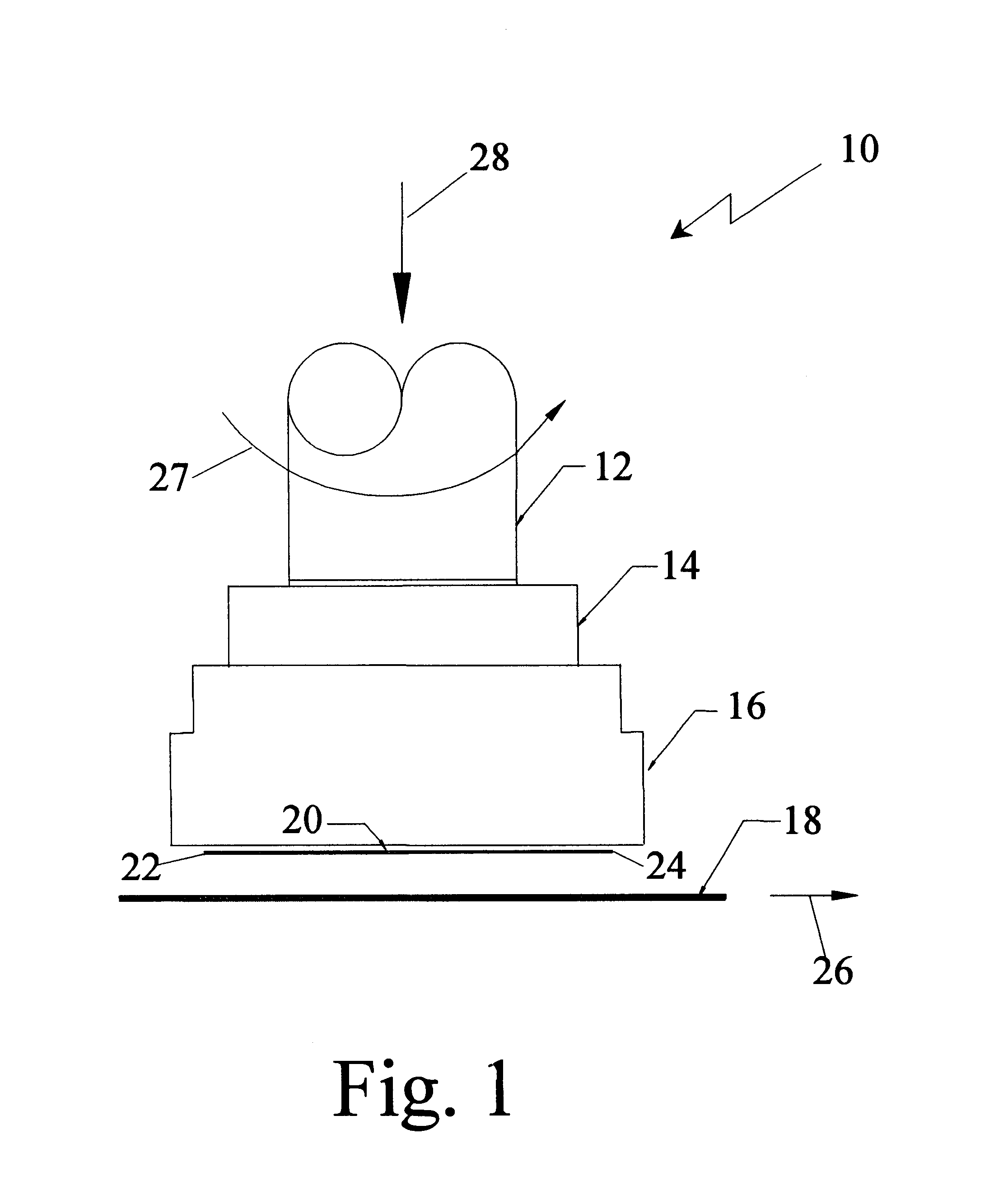

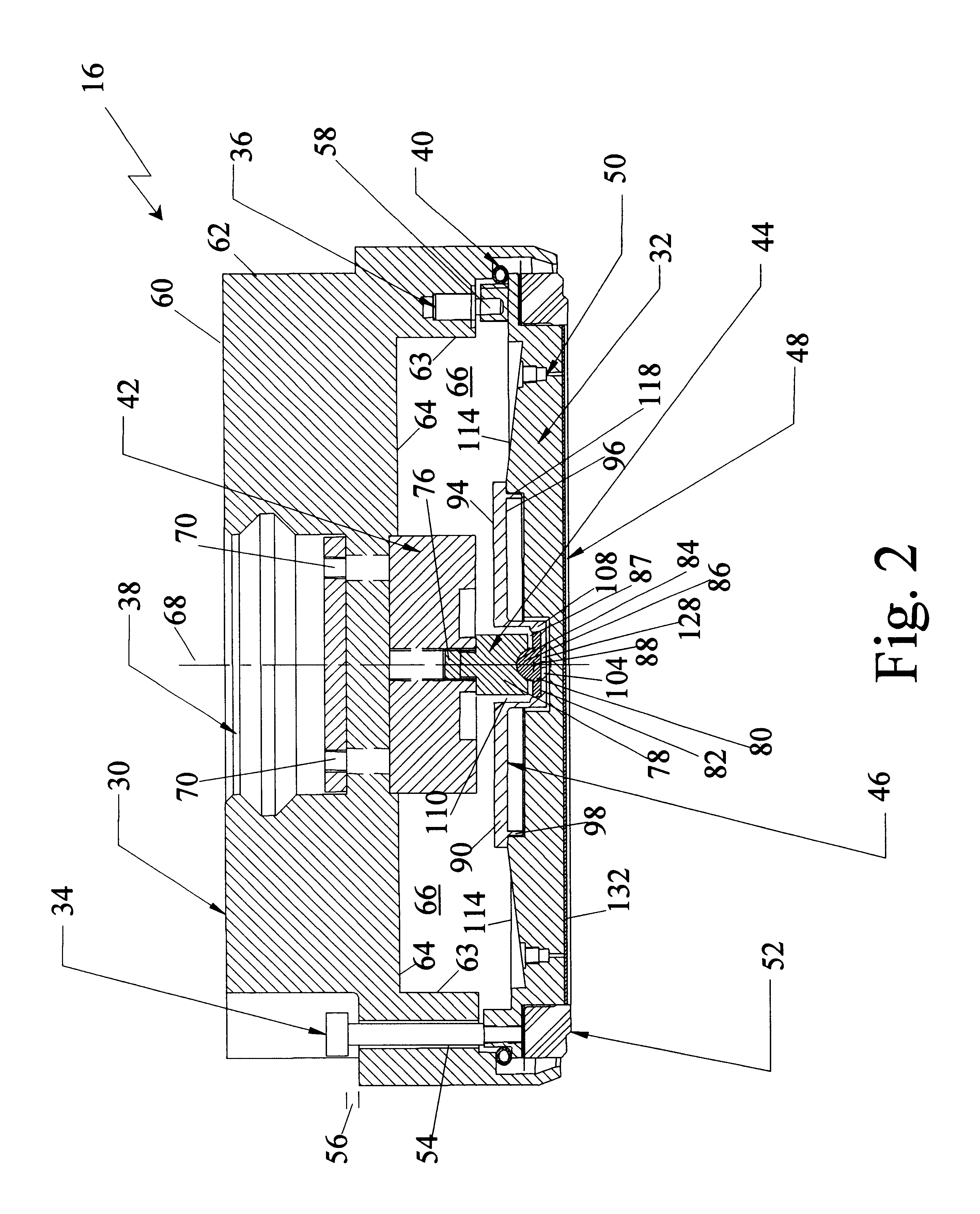

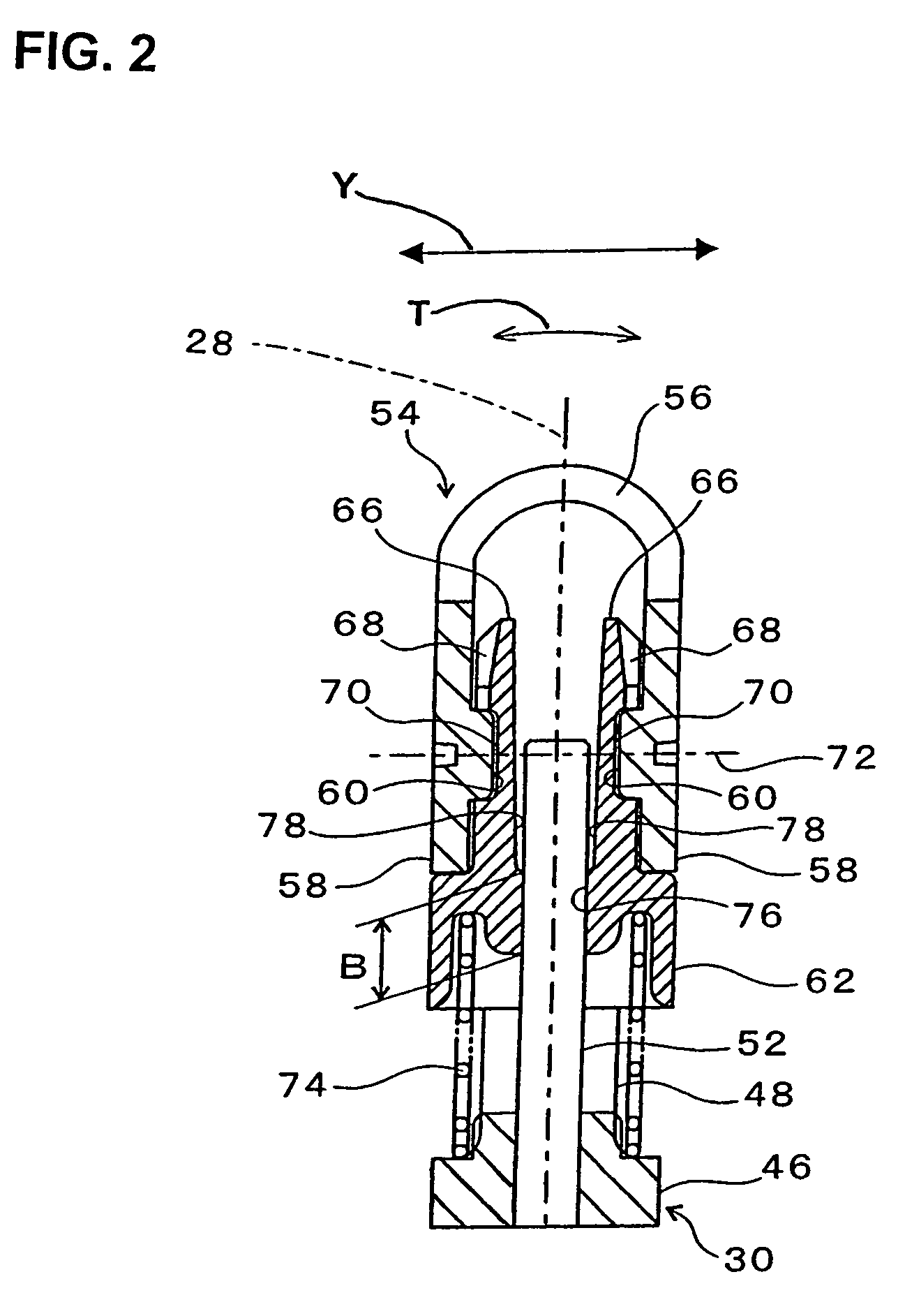

Polishing head assembly

InactiveUS6755723B1Optimize tilt and deformationEasy to tiltPolishing machinesRevolution surface grinding machinesEngineering

A polishing head assembly for retaining an object that is subject to polishing with a polishing pad is disclosed. The polishing head assembly comprises a head retainer assembly movably coupled to a wafer carrier head. The head retainer assembly includes a gimbal post and a load suspension plate. The gimbal post and the load suspension plate are operable to transfer a loading force to the wafer carrier head during polishing. The gimbal post also provides gimballing to optimize the position of the object in parallel with the polishing pad. In addition, the load suspension plate provides distribution of the loading force to optimize the flatness of the object during polishing.

Owner:APPLIED MATERIALS INC

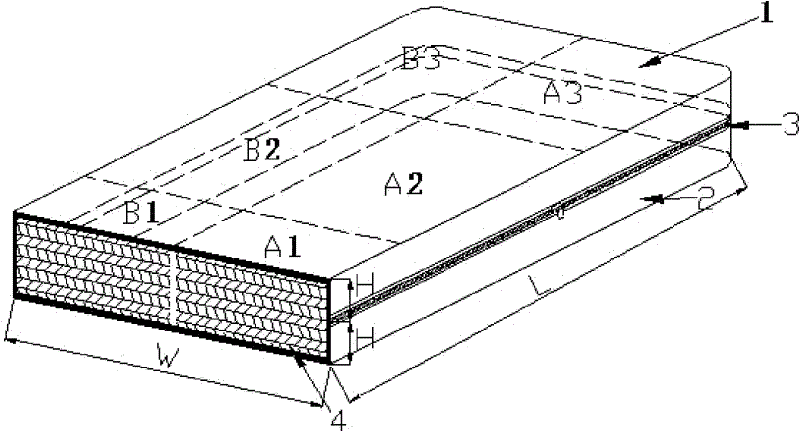

Warp knitted spacer fabric mattress and making method thereof

InactiveCN102613836AEasy to cleanEasy to assemble and disassembleStuffed mattressesSpring mattressesHuman bodySurface layer

The invention relates to the bedding field, and especially relates to a warp knitted spacer fabric mattress and a making method thereof. The mattress comprises an adjustable mattress inner liner and a stereo mattress sleeve, the mattress sleeve is obtained by sewing an upper surface layer, a lower surface layer and a side wall, and at least the upper surface layer and the side wall are warp knitted spacer fabrics; and the mattress inner liner is adjustable and comprises at least two independent inner liner bodies with different supporting strengths arranged in the mattress sleeve, each of the inner liner bodies has a multilayer structure, and at least the top layer is a wrap knitted spacer fabric, so the inner liner bodies and all the layers for forming the inner liner bodies can be reasonably combined and arranged according to ergonomic requirements to adapt to requirements of parameters of the supporting of different positions of a human body, different heights, different body weights and the like. The application of the warp knitted spacer fabric to the mattress sleeve in the invention makes the mattress sleeve have the advantages of elasticity, permeability, ergonomic conforming, bacterial growing inhibition and the like of the warp knitted spacer fabric and simultaneously have the characteristics of dismounting and mounting convenience and cleaning convenience of the mattress sleeve.

Owner:福建福联精编有限公司

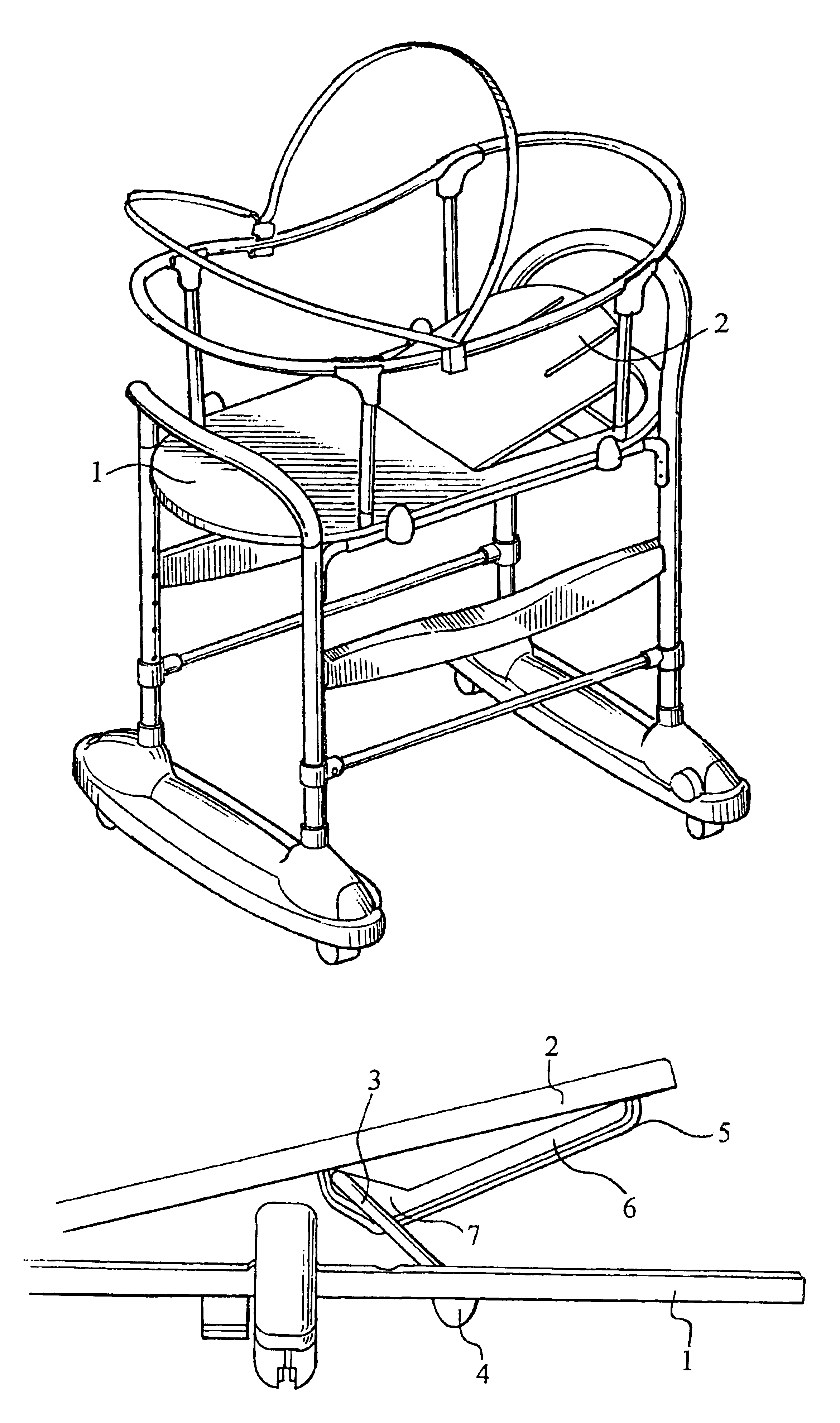

Inclination adjusting means for backrest of bassinet

An inclination adjusting means for the backrest of a bassinet is provided, which comprises a bedplate, a backrest, a supporting rod and a band. The bedplate and the backrest are integrally formed in one component and are connected together via plastic hinges. The supporting rod is pivotally connected to the bedplate with a centrally-protruding portion passing through the sliding slot of the backrest. The band is tied in the middle of the centrally-protruding portion of the supporting rod and the free end of the band is suspended and drooped out of the backrest so that a user can easily draw out the band from the rear of the backrest.When a user intends to raise the backrest, he / she can lift the backrest with his finger passing through a semicircular hole provided on the rear portion of the backrest so that the protruding portion of the supporting rod 3 can slide to the lowest point along a slopping slot. Then, when the user releases his finger, the supporting rod will be directed to engage in the front portion of the sliding slot due to its weight. According, the inclination of the backrest is well defined by the supporting rod. When the user intends to level the backrest, he only needs to hold the backrest with his finger hooking the semicircular hole on the backrest and draw the band toward the rear of the backrest with the other hand so that the backrest enters the front portion of the slopping slot to complete the leveling of the backrest.

Owner:WONDERLAND NURSERYGOODS CO LTD

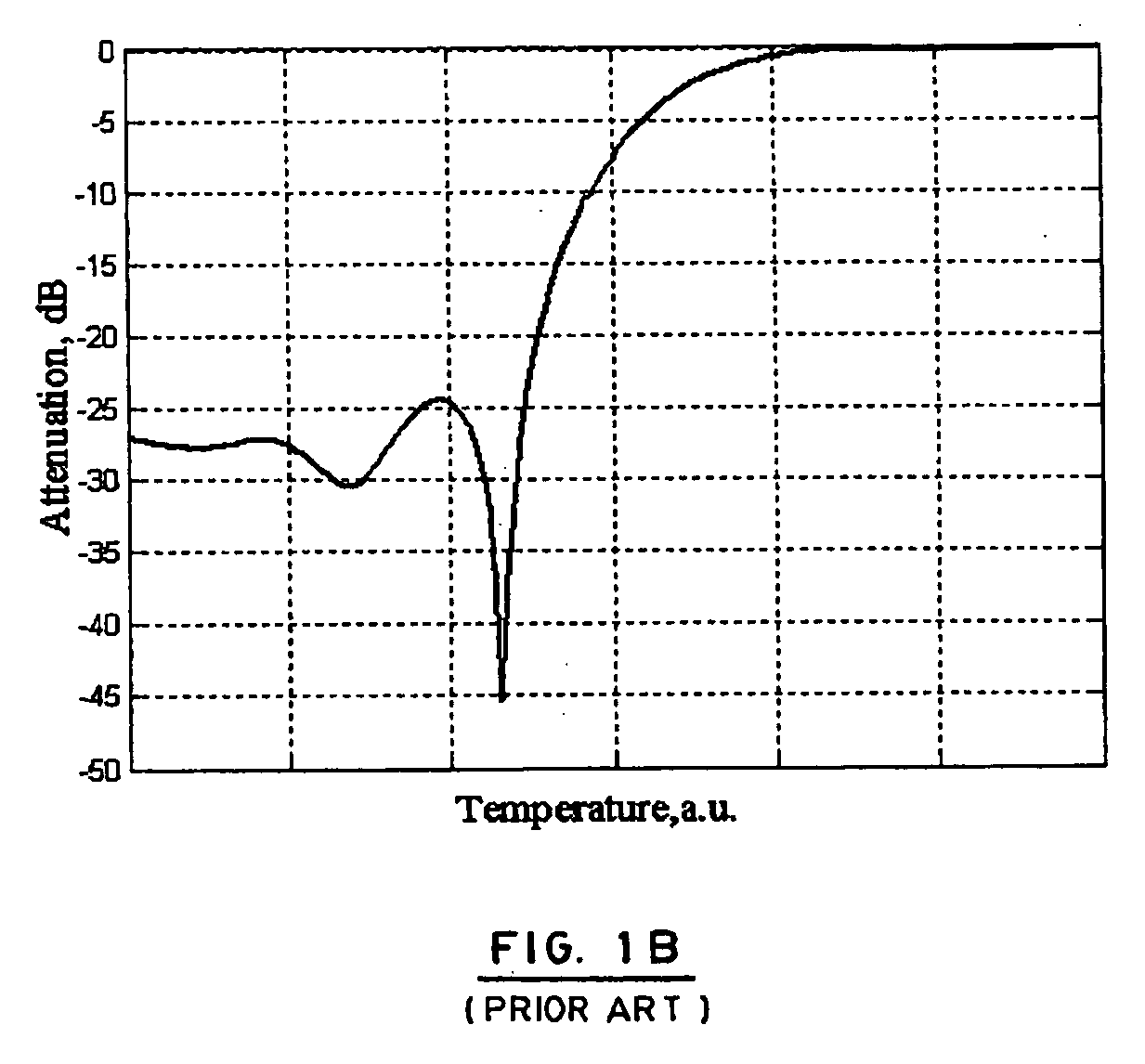

Optical device and method for the spectrally-designed attenuation of a multi-wavelength light signal

InactiveUS20060062518A1Easy to tiltEasy to controlNanoinformaticsNanoopticsUltrasound attenuationOptical property

A device and method for the spectrally-designed and controlled attenuation of a light signal, including an attenuation structure which may be placed in the proximity of a waveguide's core and which comprises a base material system containing non-uniformities having optical properties that are different from those of the host. These non-uniformities may have various natures, geometrical forms and sizes and may be created, doped or otherwise introduced in the base material system to obtain externally controllable optical properties of the whole composite material providing a broadband spectral performance.

Owner:UNIV LAVAL

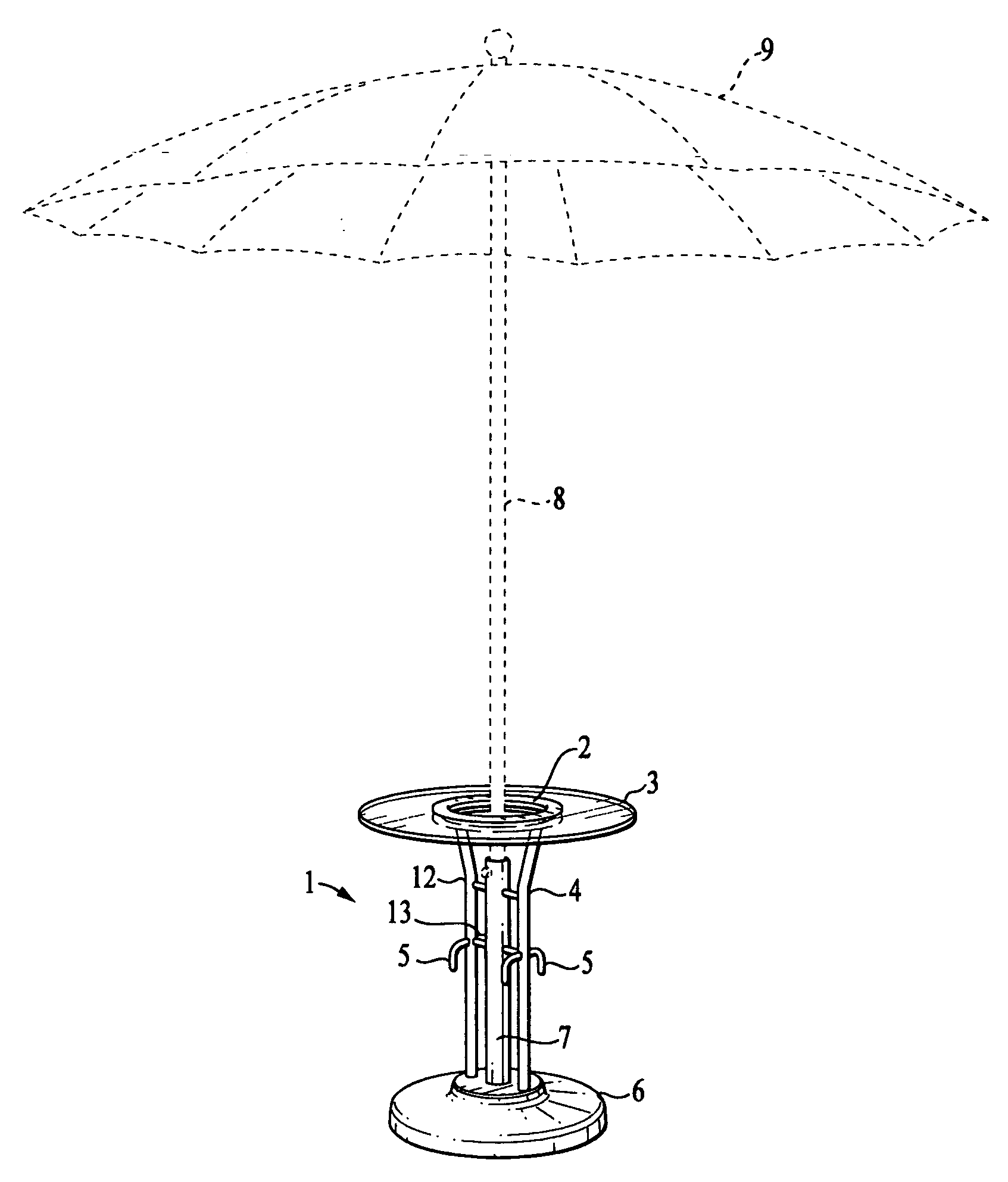

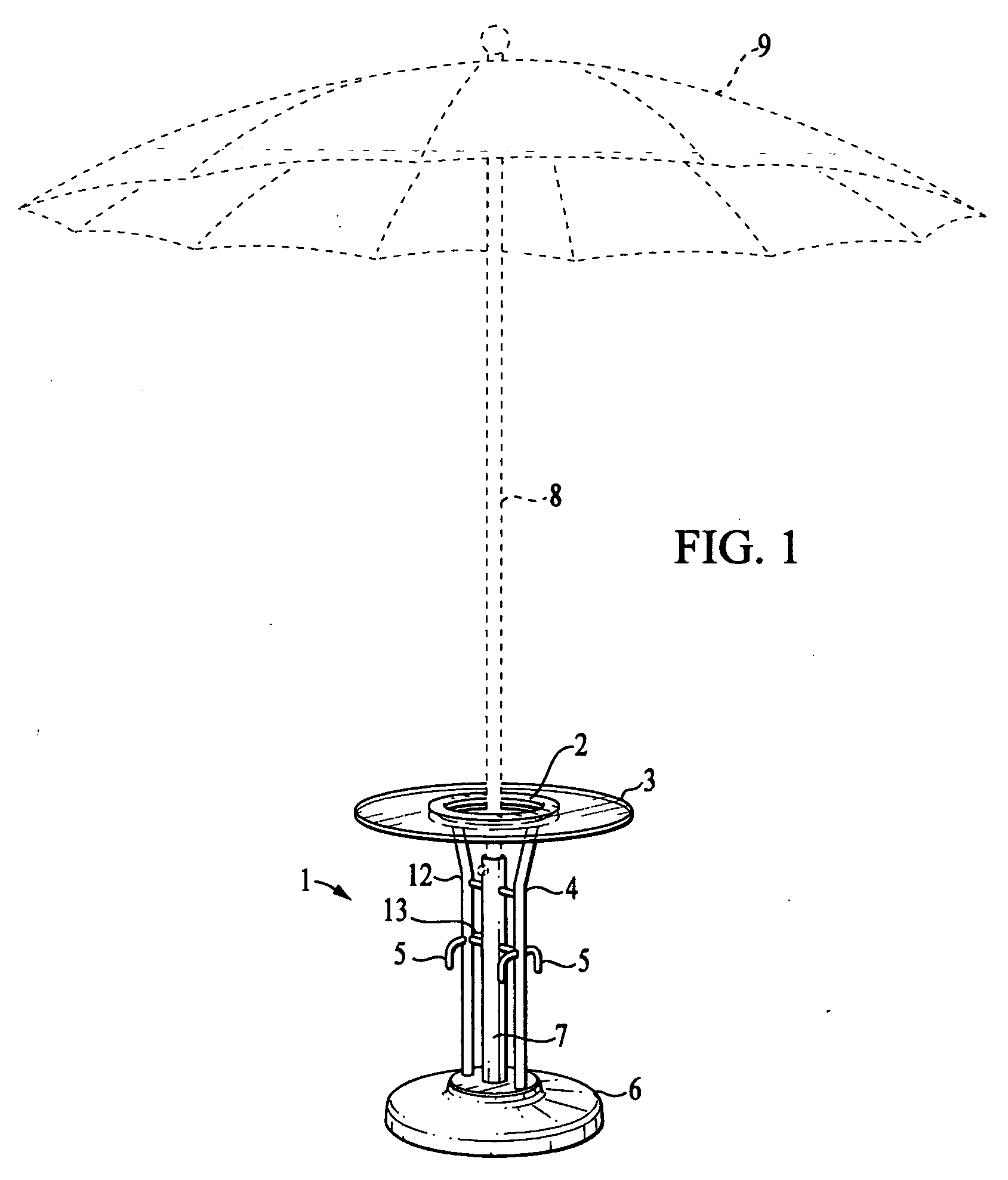

Umbrella table with oversized opening for umbrella pole

Owner:BROWN JORDAN INT

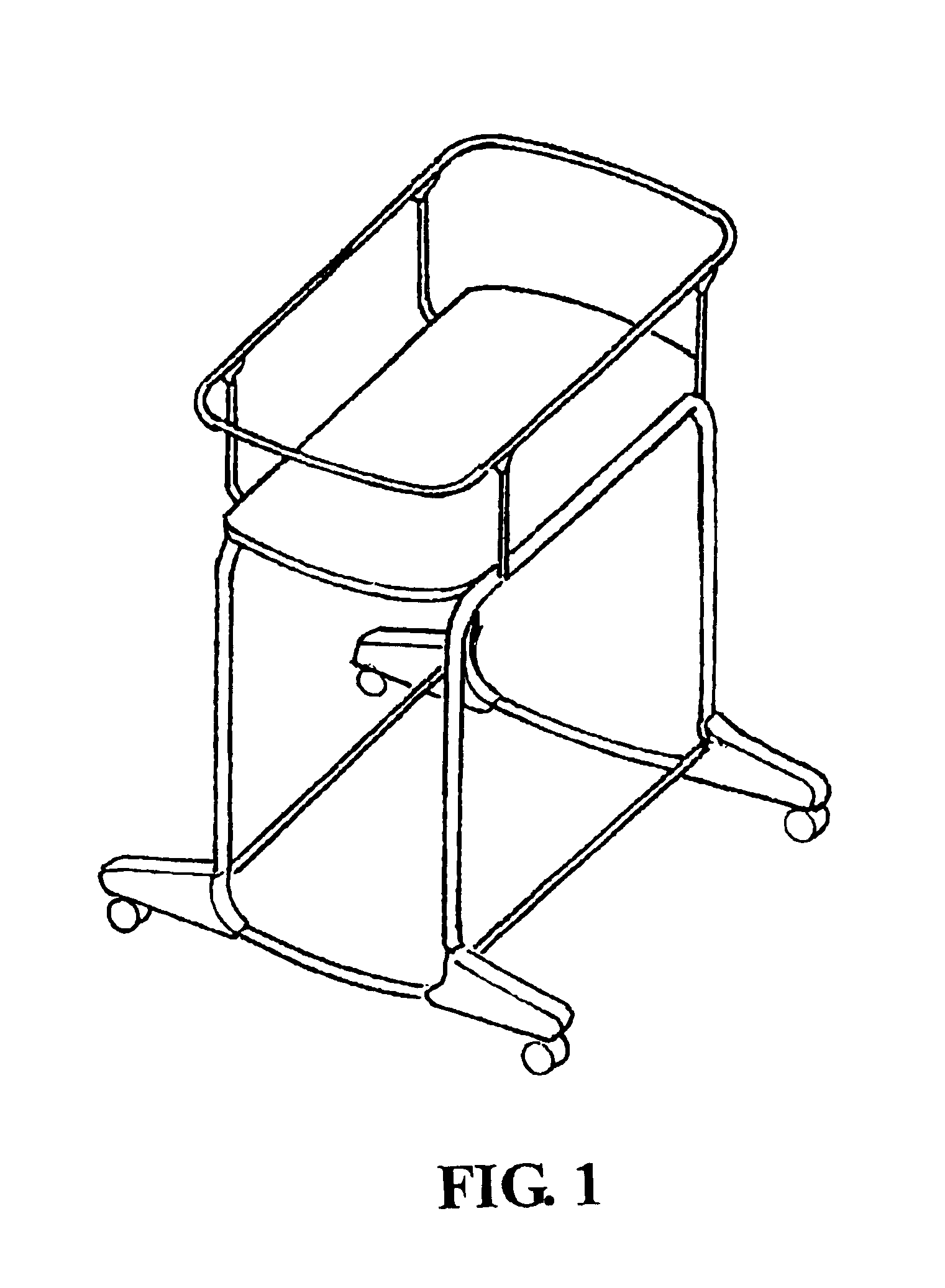

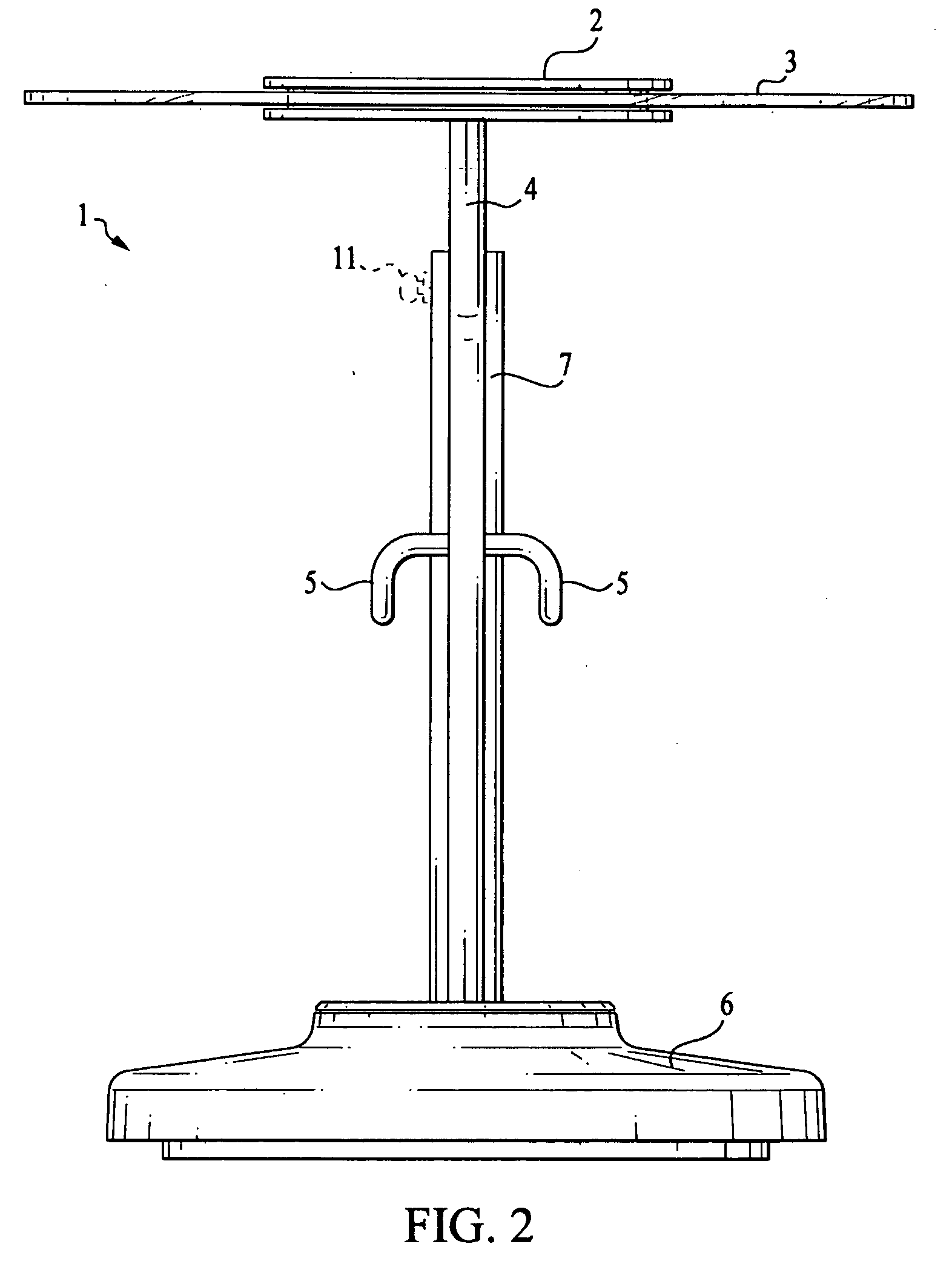

Vanity cart with mirror

InactiveUS20090295110A1Easy to tiltEasily wheeledCarriage/perambulator accessoriesChestsElectricityCleansers skin

A lightweight vanity cart with a mirror mounted on the top that can pivot from a closed to an open position. The mirror can be illuminated with a light strip. The vanity cart provides receptacles, drawers and racks for organizing and storing hair styling tools and personal care items, including cosmetics, hair styling products, lotions, cleansers, applicators, brushes, etc. The vanity cart, which is mounted on wheels, is easily moved from place to place. It provides electrical receptacles for plugging in the cords of electrical styling tools. A master power cord, which supplies electricity to the receptacles, is plugged into a wall receptacle.

Owner:SLEEKA VI INTL

Micro-adjustable parallel bench vise

InactiveUS8181949B2Precise clampingDrawback can be obviatedPositioning apparatusVicesEngineeringMechanical engineering

A micro-adjustable parallel bench vise includes a slide holder having a top dovetail rail, a vise body having a bottom dovetail groove coupled to the dovetail rail of the slide holder and holding a fixed jaw member, a screw holder slidably mounted in the top side of the vise body, a screw rod threaded into the screw holder and rotatable to move the screw holder relative to the vise body. When multiple vise bodies are mounted on the slide holder in parallel, they are micro-adjustable to hold a workpiece or multiple workpieces precisely in position.

Owner:HUNG YI PO

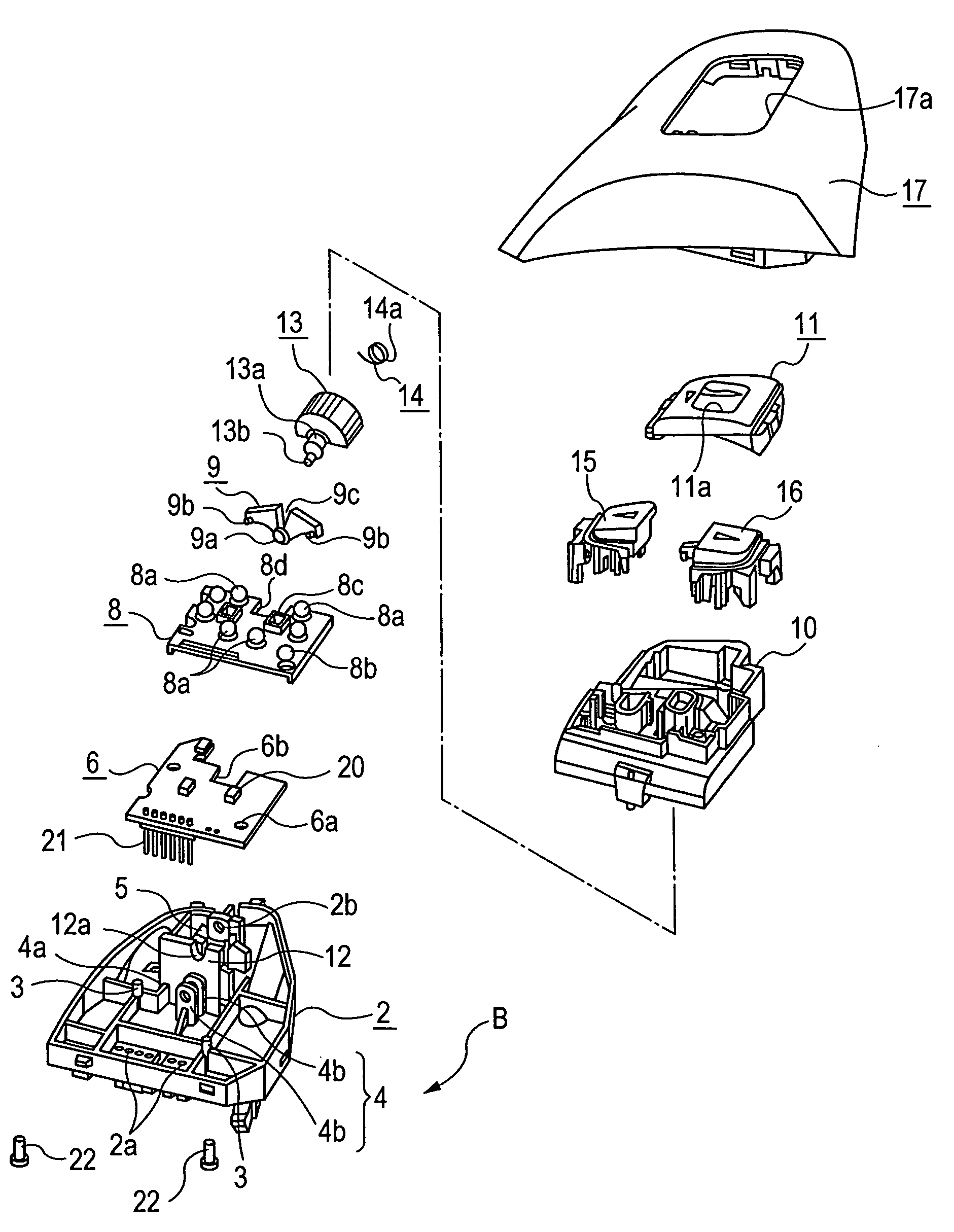

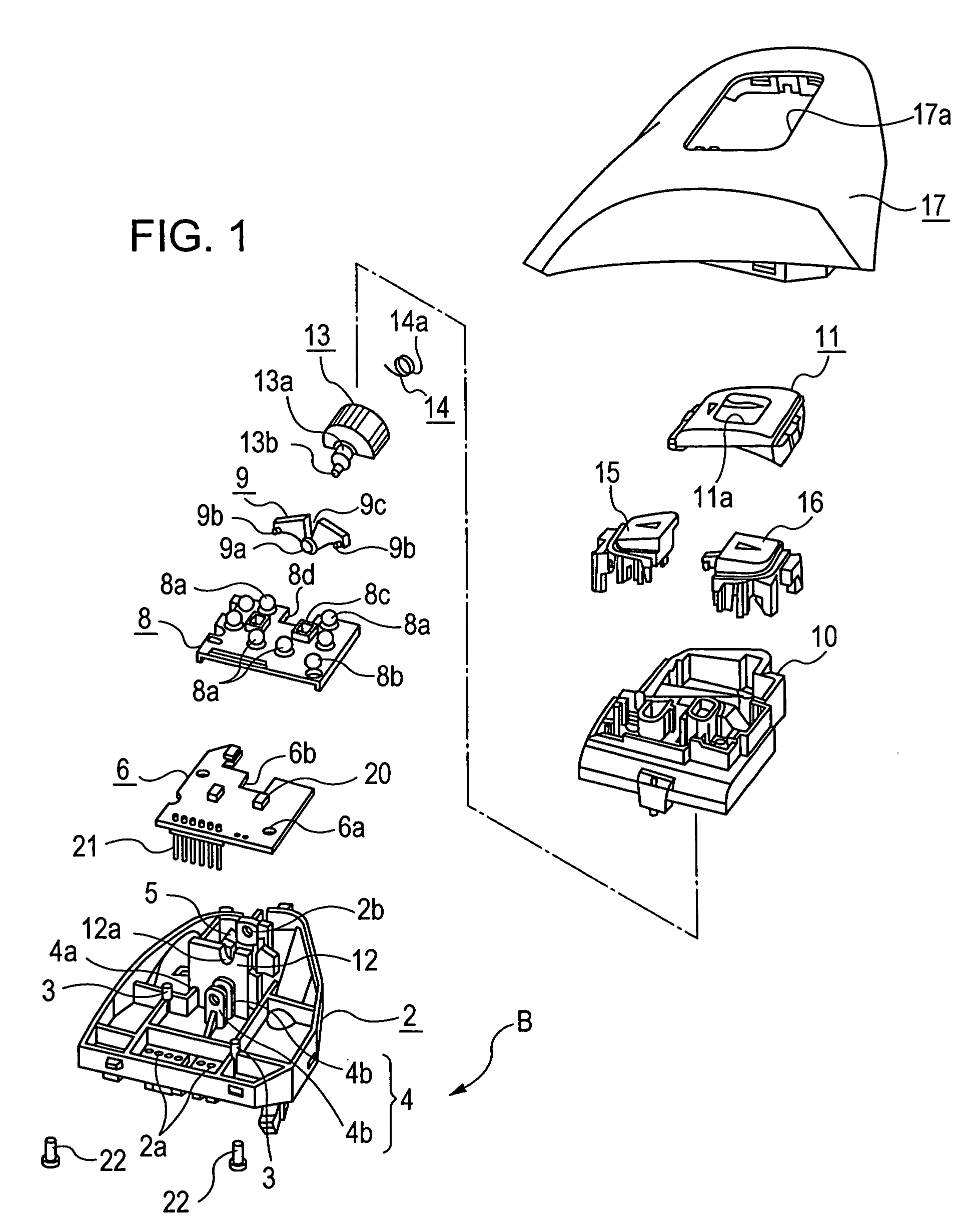

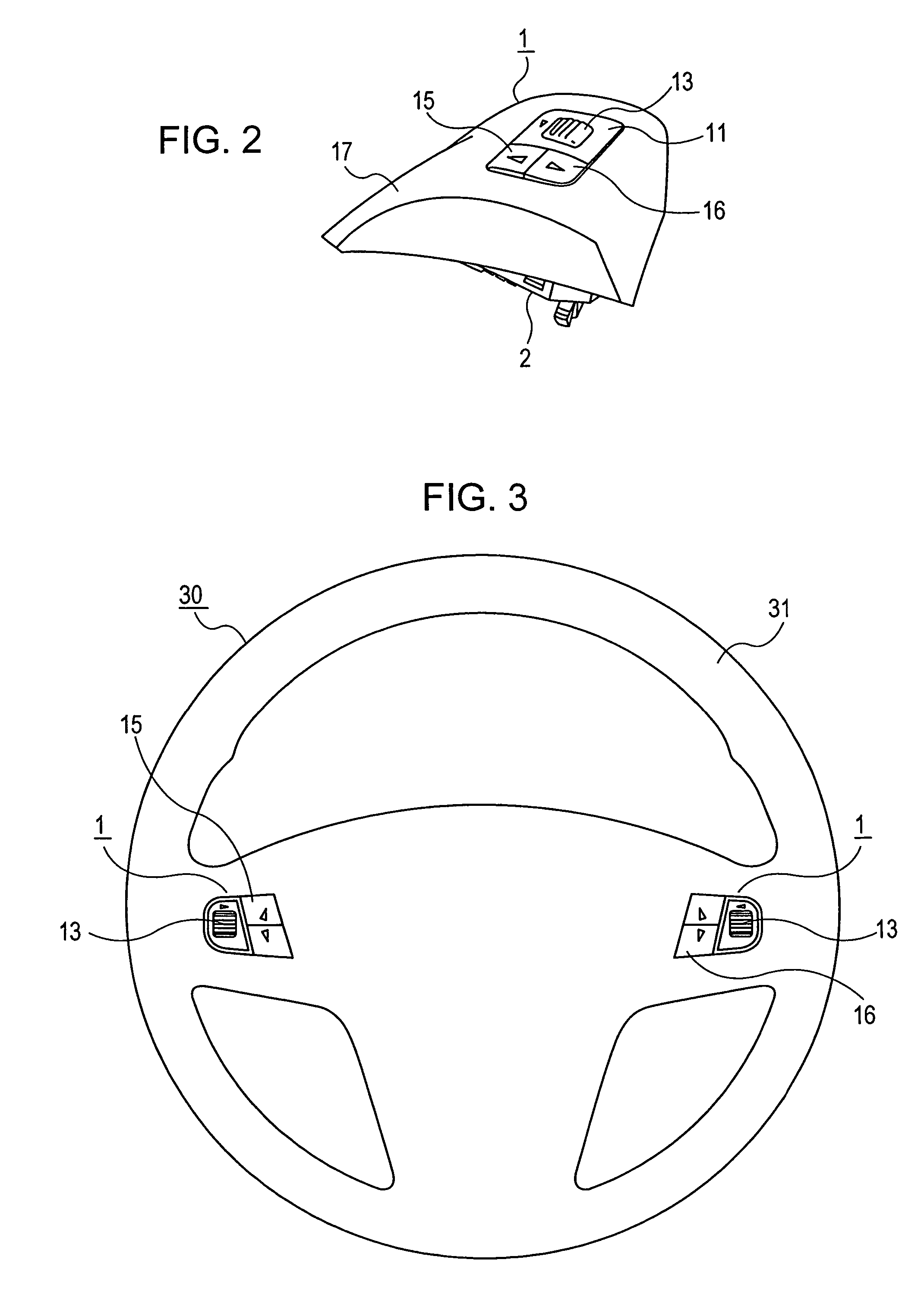

Switch device and steering switch apparatus equipped with the switch device

InactiveUS7439459B2Reduce the overall heightLow-profile structureEmergency actuatorsContact driving mechanismsCoil springEngineering

Owner:ALPS ALPINE CO LTD

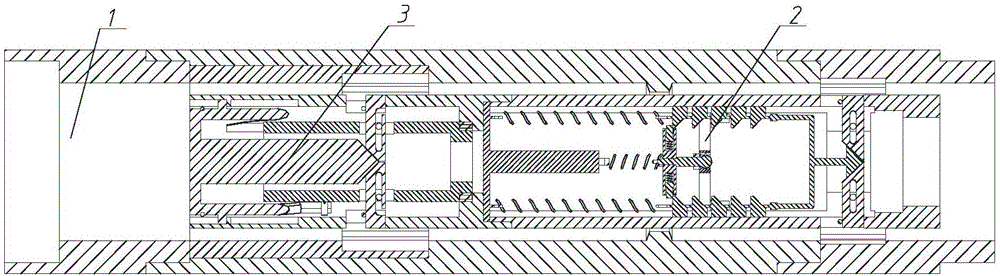

Downhole full-bore infinite sliding-pin slide bushing switch

ActiveCN106761640AAvoid wear and tearEasy to replaceFluid removalWell/borehole valve arrangementsMechanical engineeringEngineering

The invention discloses a downhole full-bore infinite sliding-pin slide bushing switch and solves the problems of inconvenience in maintenance and the like due to the fact that the conventional fracturing slide bushing needs to be wholly lowered into downhole. The downhole full-bore infinite sliding-pin slide bushing switch specifically comprises a main slide bushing body and a tenon block mechanism, wherein the tenon block mechanism comprises a tenon block recognition mechanism and a tenon block switch mechanism, during use, the main slide bushing body is lowered into the downhole, and the tenon block mechanism is lowered for recognizing a fracture layer when a fracture channel needs to be opened or closed. The slide bushing switch has high recognition degree for different fracture layers, parts are convenient and simple to replace and maintain, and the working stability and accuracy are enhanced greatly.

Owner:黑龙江赛恩思科技信息咨询服务有限公司

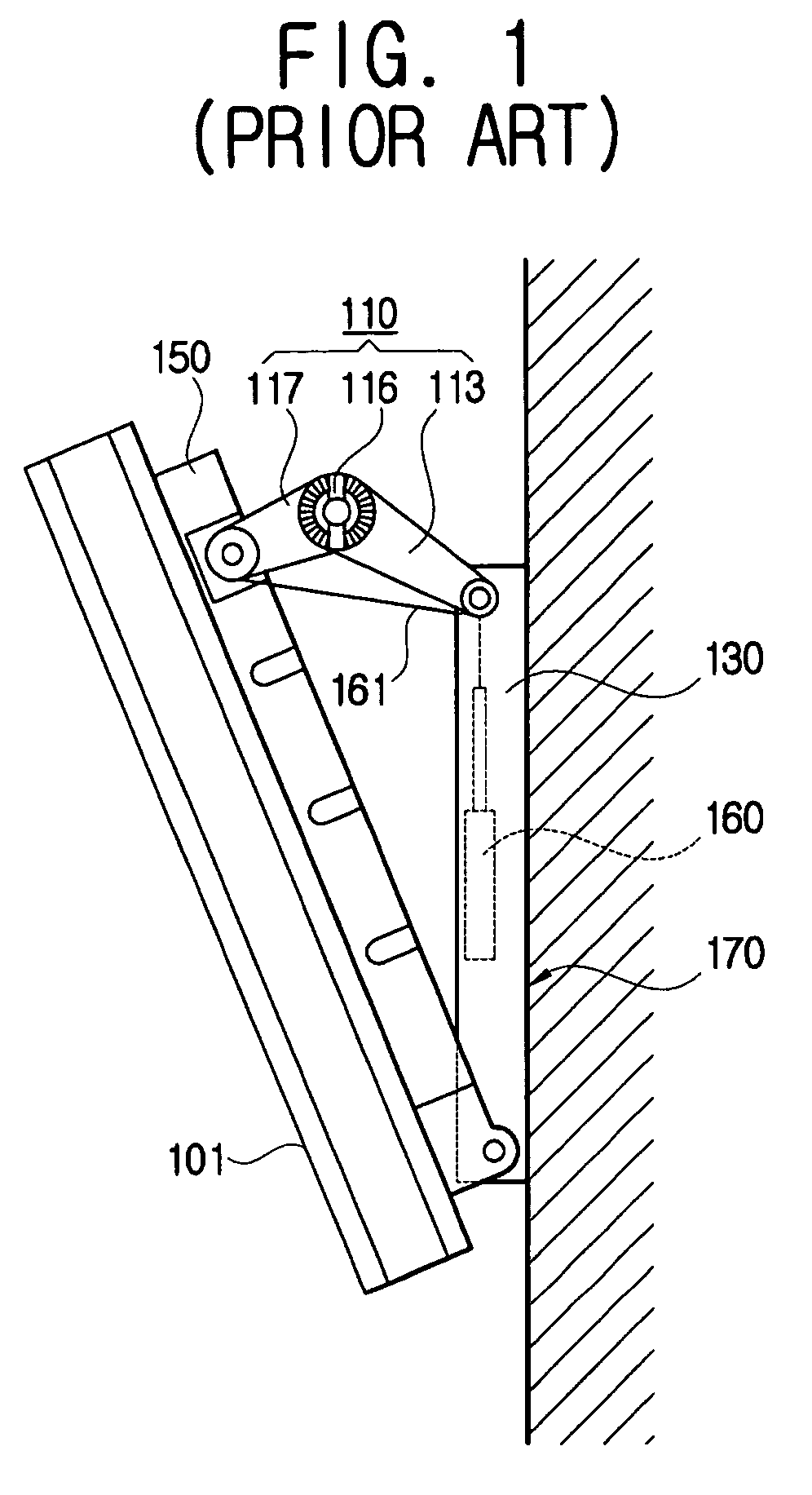

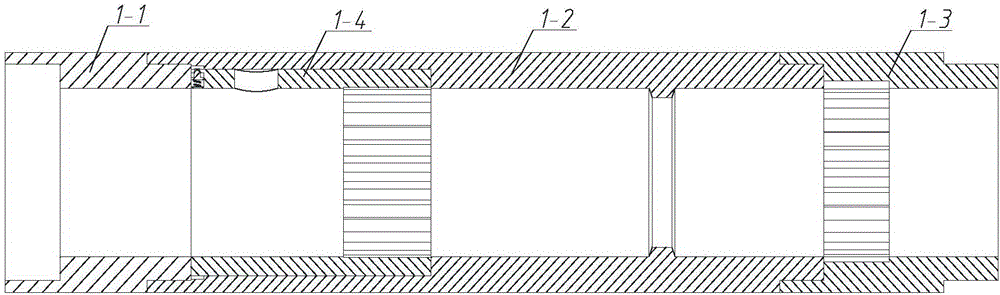

Wall mount usable with display apparatus

InactiveUS7494099B2Easy to tiltSimple structureTelevision system detailsStands/trestlesEngineeringMechanical engineering

A wall mount usable with a display apparatus to mount the display apparatus on a wall, includes a base to attach to the wall, a supporting bracket supported by the base, a rotating bracket tiltably coupled to the supporting bracket and on which the display apparatus is mounted, and an elastic member provided between the supporting bracket and the rotating bracket to expand or contract according to rotation of the rotating bracket to adjust a tilt angle of the rotating bracket. Thus, the wall mount easily tilts the display apparatus through a simplified tilting structure.

Owner:SAMSUNG ELECTRONICS CO LTD

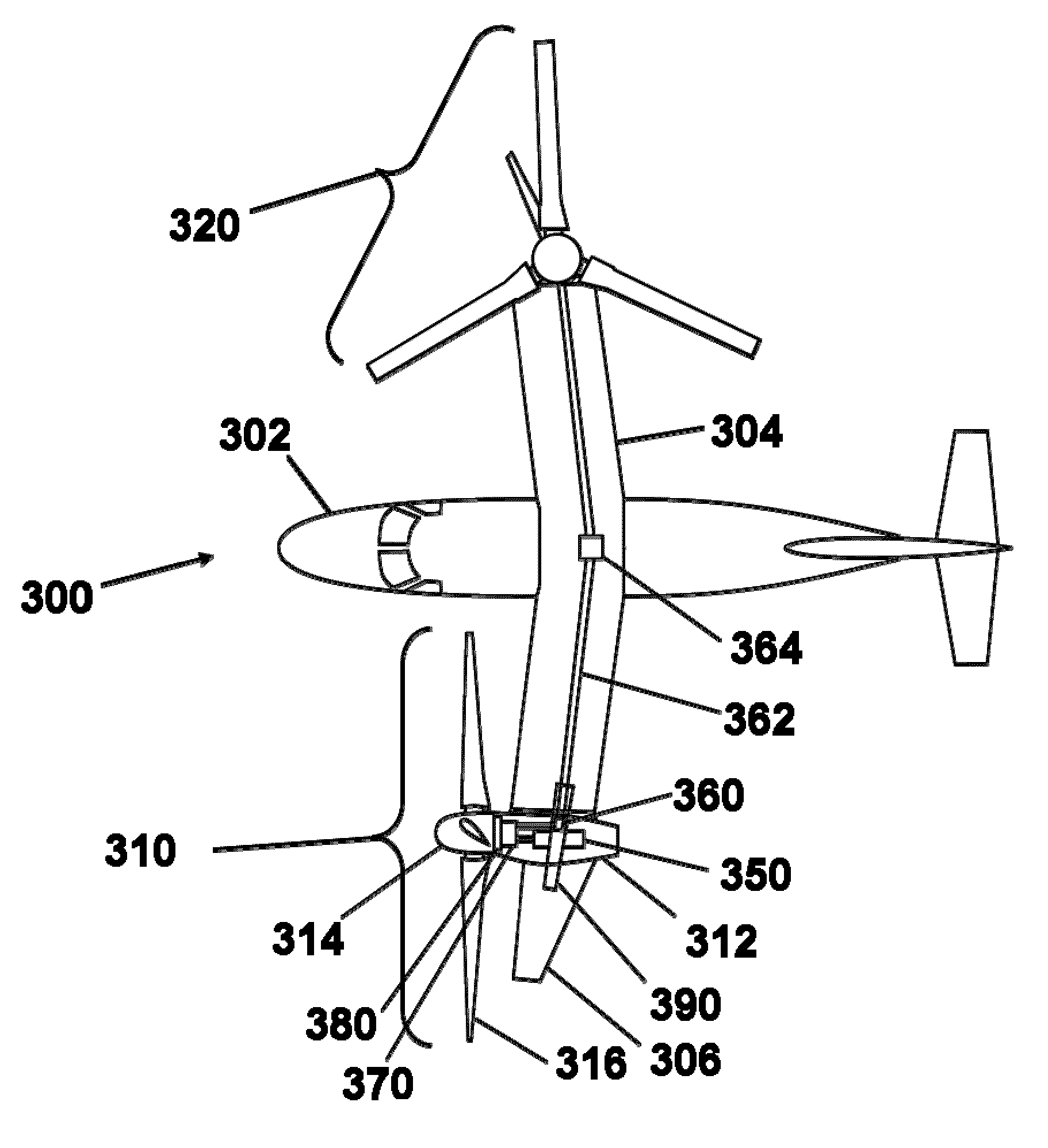

Combination spar and trunnion structure for a tilt rotor aircraft

An aircraft is equipped with a spinnion coupling an inboard wing to a tilting nacelle. The spinnion is advantageously configured to extend across the nacelle from an inboard junction to an outboard junction, and terminates inside the inboard wing. This provides an efficient lightweight structure to support a nacelle and facilitate tilting of the nacelle. The spinnion, which can be configured to be at least partially disposed within the inboard wing, is advantageously concentric with the tilting axis in order to facilitate tilting of a nacelle. A cross-wing driveshaft can be included, disposed at least partly within the inboard wing, and can advantageously be configured to terminate inside the spinnion at a junction with a miter gearbox. The miter gearbox can be disposed at least partly within the spinnion but more preferably lies entirely within the spinnion, and functions to transfer power from an input shaft to the cross-wing driveshaft.

Owner:KAREM ABE

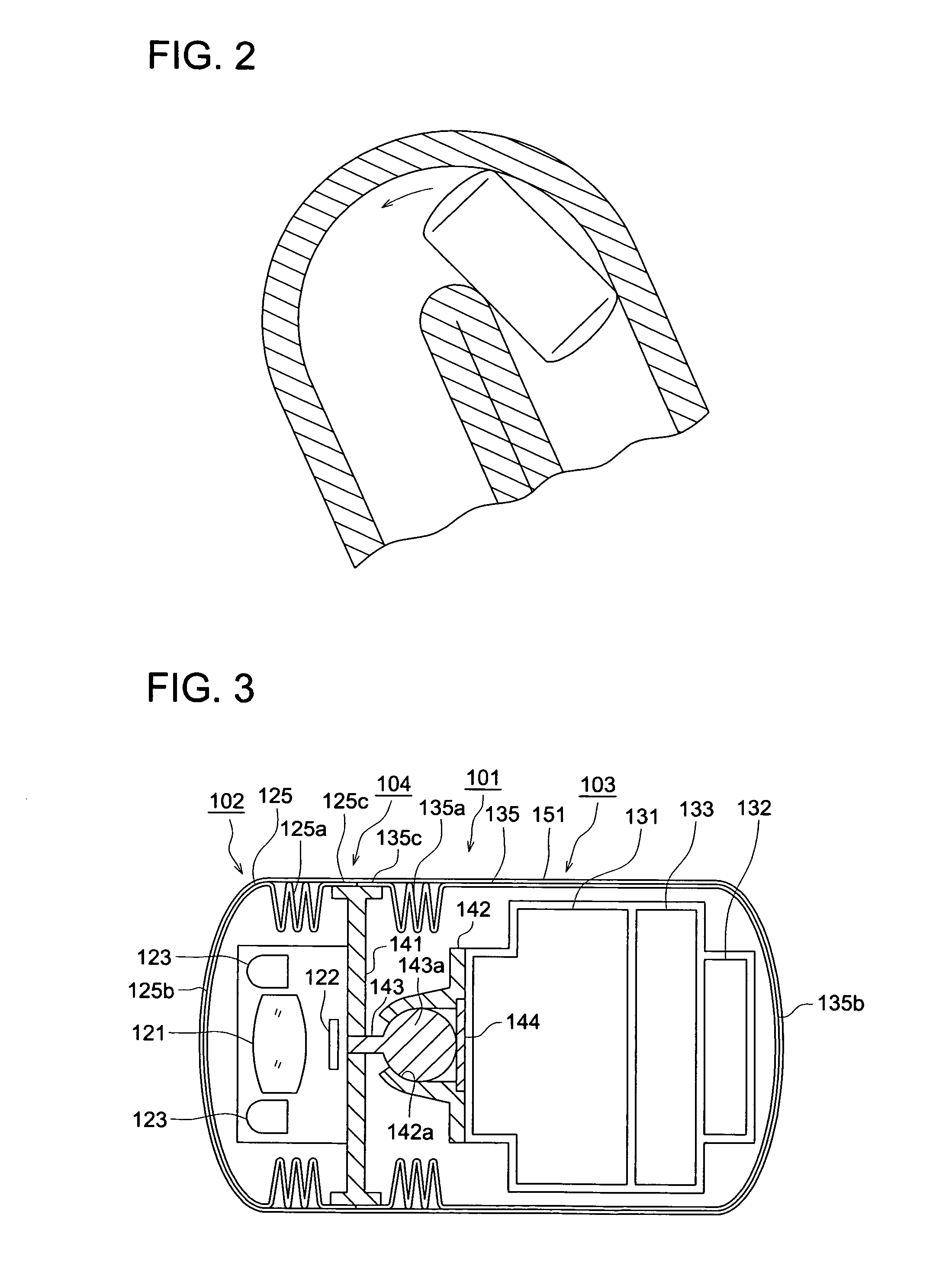

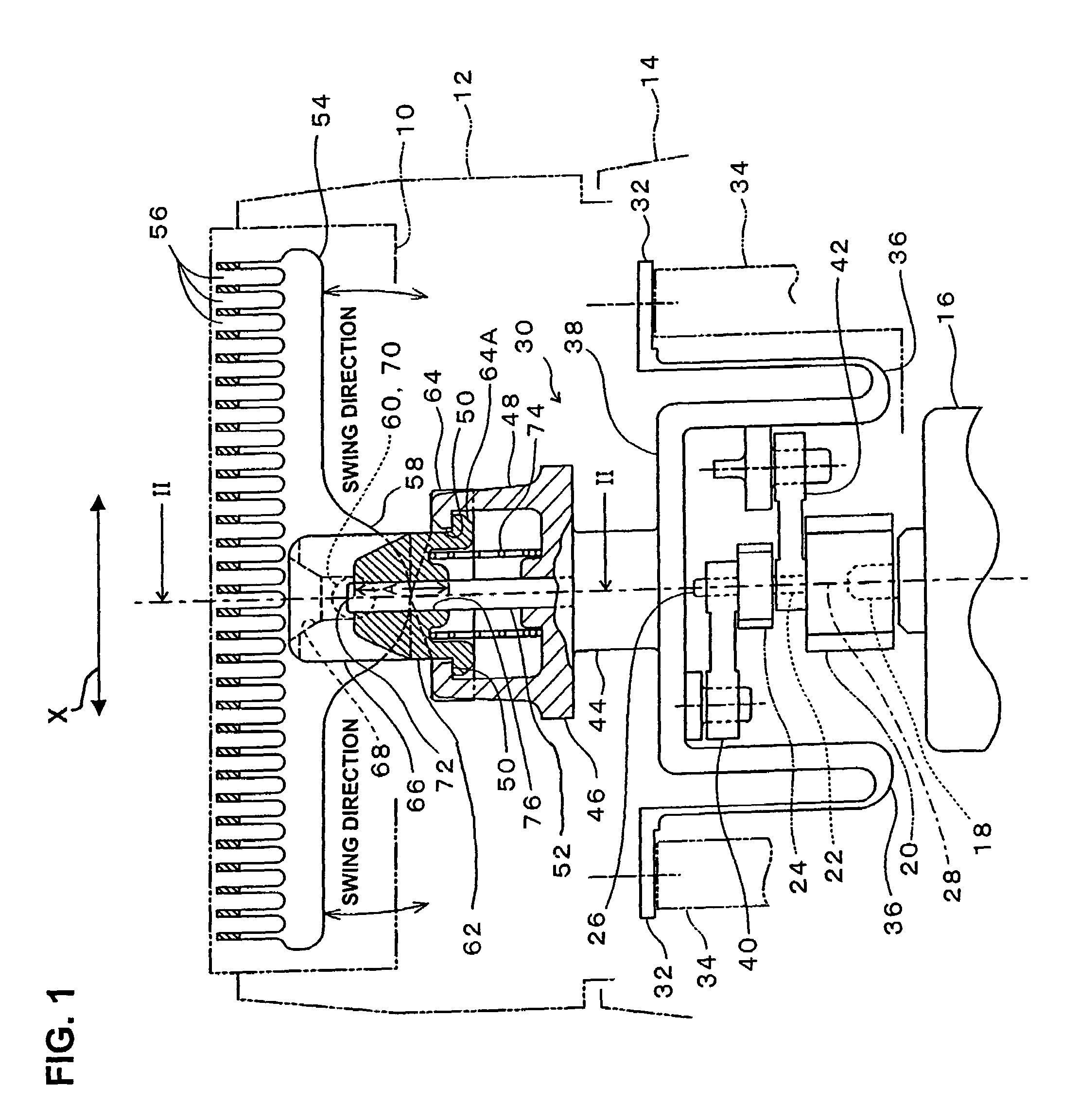

Reciprocating-type electric shaver

A reciprocating-type electric shaver including an outer cutter having an inverted U shape as seen from a side thereof and an inner cutter making a reciprocating motion while making sliding contact with an inside surface of outer cutter, and further including: an oscillator making a reciprocating motion by a motor installed inside the main body of the shaver; a central shaft provided in an upright position on the oscillator and rises toward the inside of the outer cutter; an inner cutter holder disposed in a slidable manner on the central shaft so that the inner cutter holder holds the inner cutter thereon and the inner cutter swings about a straight line that is perpendicular to the reciprocating direction of the inner cutter; and a spring compressedly installed between the oscillator and the inner cutter holder.

Owner:IZUMI PROD CO

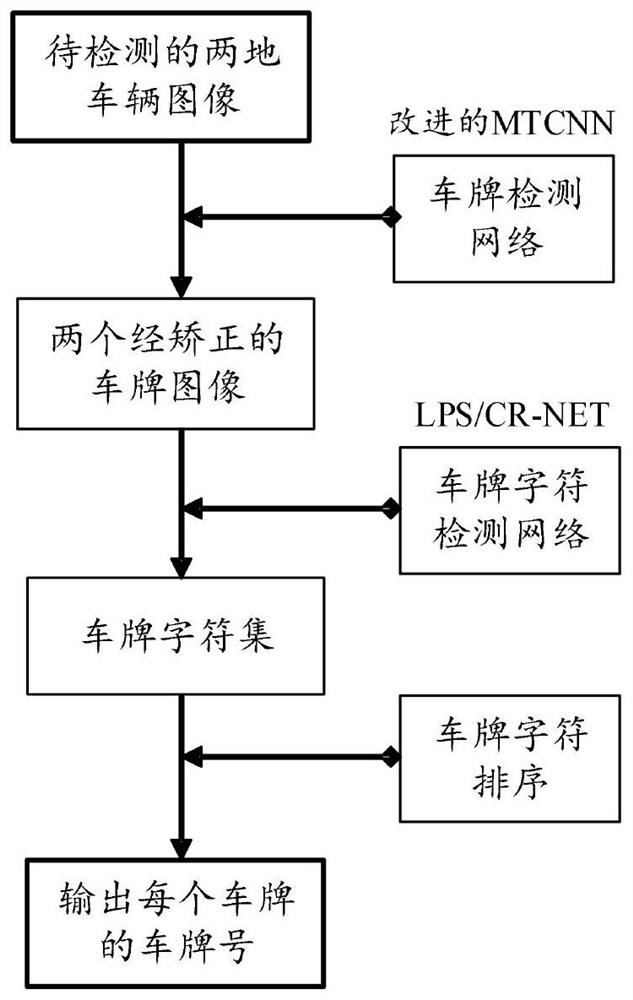

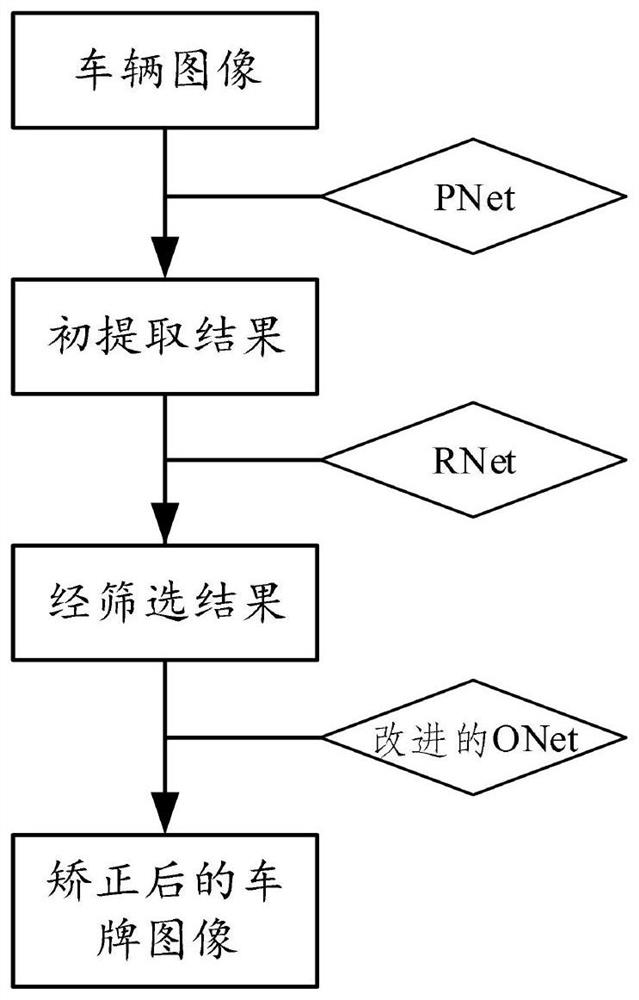

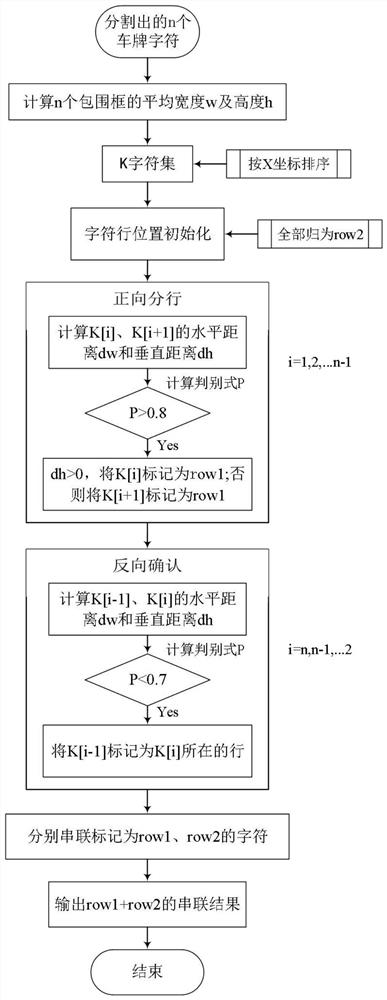

Two-place double-license-plate detection and recognition method and system based on deep learning

ActiveCN111666938AEasy to tiltGood conditionCharacter and pattern recognitionNeural architecturesPattern recognitionAlgorithm

The invention provides a two-place double-license-plate detection and recognition method and system based on deep learning, and the two-place double-license-plate detection and recognition method comprises the steps: constructing a vehicle data set with license plate marks, and carrying out the sample marking; training an improved MTCNN license plate detector, positioning coordinates of a licenseplate area and four corners of a license plate in the image by using the trained license plate detector, and correcting the license plate area by using the coordinates of the four corners of the license plate; training a license plate character detector, and detecting bounding boxes and categories of all characters in the license plate; and sorting the license plate character detection results, and outputting a serial license plate character sequence. The two-place double-license-plate detection and recognition method is mainly used for license plate detection and recognition of vehicles in two places in a complex scene, and the used networks are light networks, and the license plate detection and recognition accuracy can be improved while the time consumed for license plate detection andrecognition is effectively shortened. In addition, four angular point coordinates of the license plate are adopted for license plate correction, and the inclination and distortion conditions of the license plate are effectively improved, and the license plate recognition effect is improved.

Owner:ZHUHAI DAHENGQIN TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com