Motorcycle Windshield Assembly

a technology for windshields and motorbikes, applied in the direction of roofs, cycle equipment, transportation and packaging, etc., can solve the problems of not being able to provide the shielding effect needed, the windshield b>40/b> cannot be adjusted, etc., and achieves the effect of easy raising, lowering, or tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

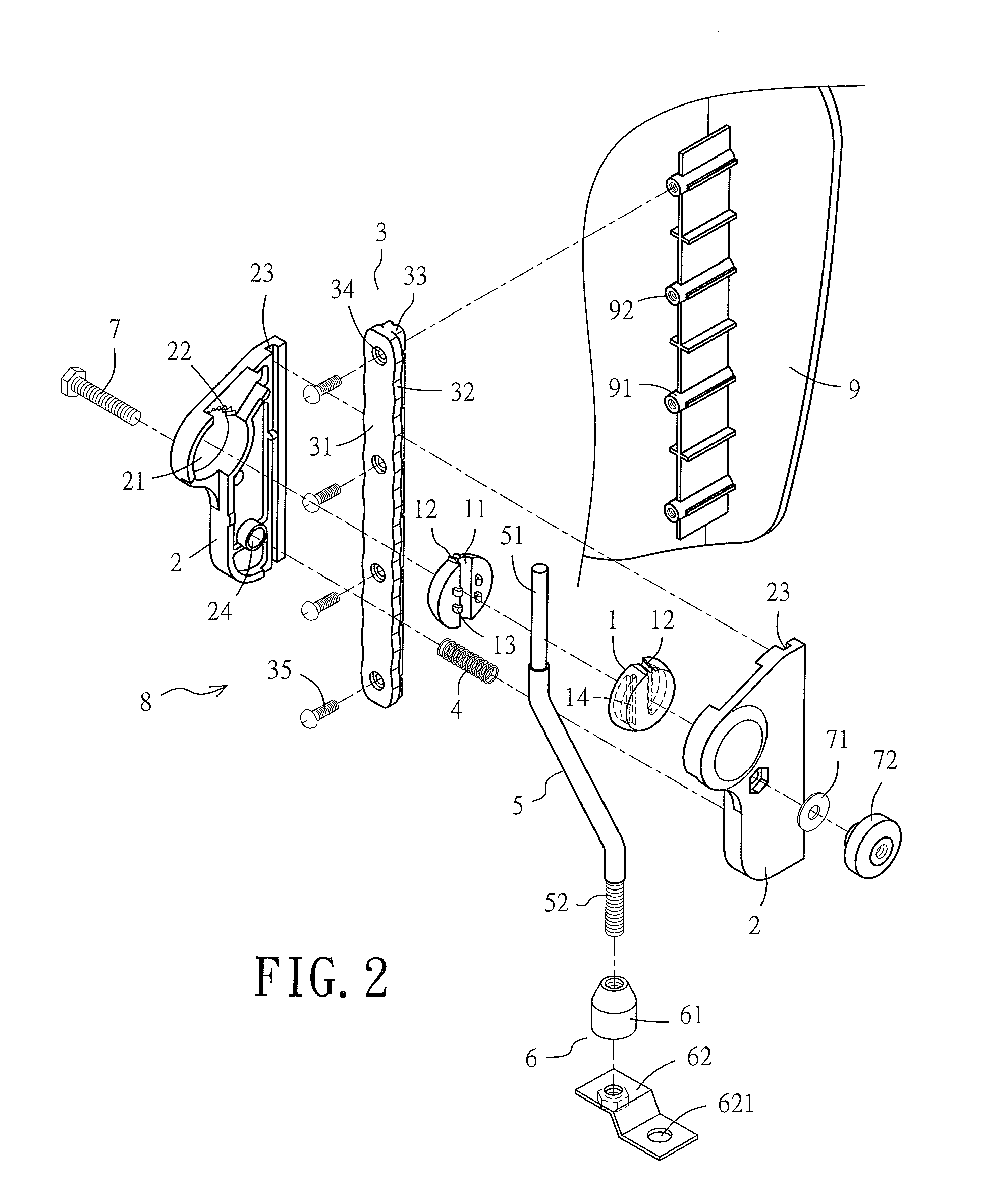

[0021]Referring to FIG. 2, a motorcycle windshield assembly according to an embodiment of the present invention includes two frame units 8 coupled bilaterally to a windshield 9. Each frame unit 8 includes a pair of corresponding adjusting elements 1, a pair of corresponding left and right covers 2, a sliding element 3, a resilient element 4, an installation rod 5, an adapter plate 6, a threaded fastener 7, a washer 71, and a screw nut 72.

[0022]Each adjusting element 1 is formed of a tough plastic and has an inner side concavely provided with a groove 11. Each adjusting element 1 further has a lateral side peripherally formed with teeth 12. One of each pair of the adjusting elements 1 is protrudingly provided with hooks 13 that are arranged on two sides of the groove 11. The other of each pair of the adjusting elements 1 is formed with recesses 14 corresponding in position to the hooks 13 of the corresponding adjusting element 1 so that the two corresponding adjusting elements 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com