Rigid fiberglass-free photoelectric printed board and machining method thereof

A printed board and glass fiber technology, applied in the field of PCB manufacturing, can solve the problems of difficult exhaust, easy generation of air bubbles, signal interference, etc., to reduce the difficulty of lamination process, reduce the residual air bubbles between layers, and improve the burr in the hole. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

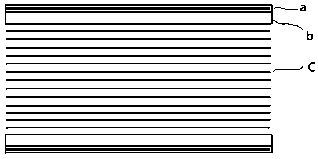

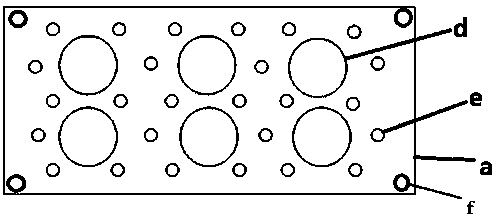

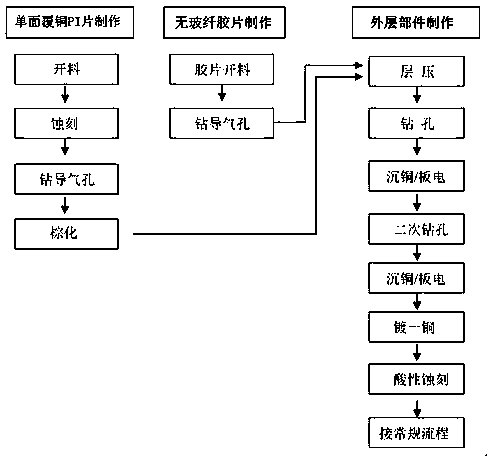

[0029] like Figure 1-2 As shown in , a rigid non-glass fiber photoelectric printed board provided by an embodiment of the present invention includes a first PI sheet b, 13 glass fiber-free films c and a second PI sheet that are stacked. The end faces of the first PI sheet a and the second PI sheet away from the non-glass fiber film are coated with a copper foil layer a. The first PI sheet a, the non-glass fiber film c and the second PI sheet pass through up and down to form an air guide hole e for air guide, and the air guide hole is arranged in a non-graphic area. The first PI sheet, the N glass-free films and the second PI sheet are connected up and down to form a metallized through hole d, and the through hole d is arranged in the pattern area. The edges of the first PI sheet b, the non-glass fiber film c and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com