A method for manufacturing a rigid-flex circuit board with a flexible board on the outer layer

A technology of rigid-flexible combination and manufacturing method, which is applied in the secondary processing of printed circuits, coating non-metallic protective layers, and assembling printed circuits with electrical components, which can solve the problem of burrs, asymmetric structures, and difficult graphics on flexible boards. Transfer and other problems to achieve the effect of improving soft board burrs and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

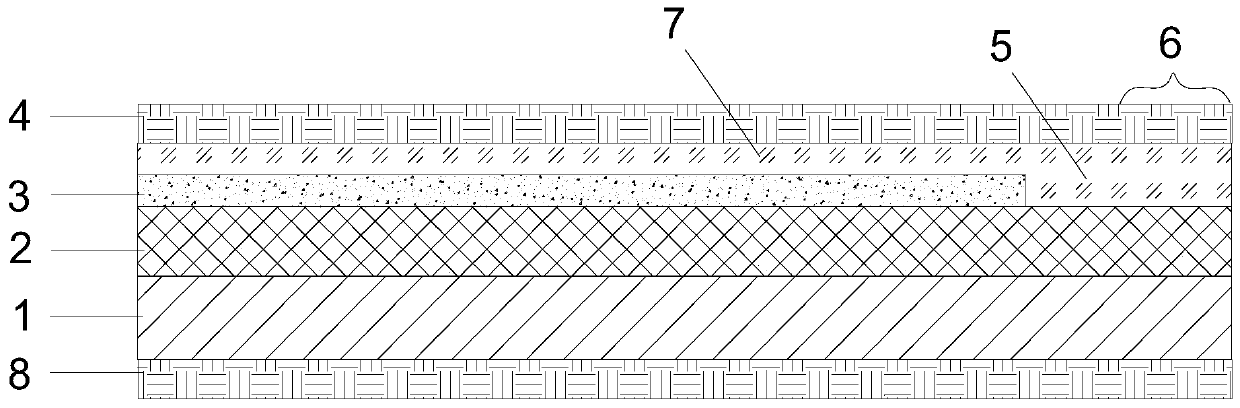

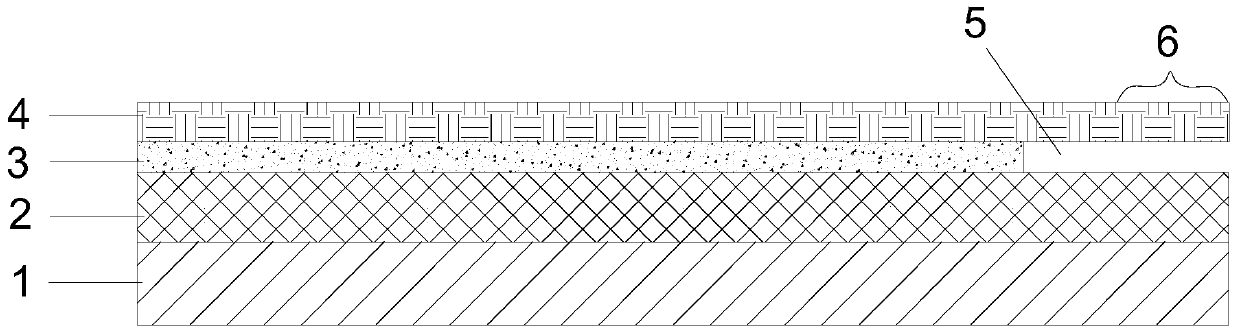

[0020] Such as figure 1 The shown rigid-flex circuit board includes a rigid board 1 and a flexible board 2 pressed on the surface of the rigid board 1 .

[0021] The method for manufacturing a rigid-flex circuit board includes the following steps in sequence: making a flexible board, making a rigid board, making an adhesive (PP with low fluidity), laminating a flexible board and a rigid board, making outer graphics, soldering, Mechanical forming.

[0022] The method of mechanical forming is as follows: the surface of the outer flexible board 2 is coated with solder resist ink, and the solder resist ink covers the surface of the flexible board 2, including the circuit copper layer 3 area and the non-circuit copper layer area 5, and the circuit copper layer on the surface of the flexible board The thickness of layer 3 is 35 μm; then bake the circuit board coated with solder resist ink at 150°C for 60 minutes, so that the solder resist ink forms a rigid film 7 with a film hardn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com