Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "High sulfonation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

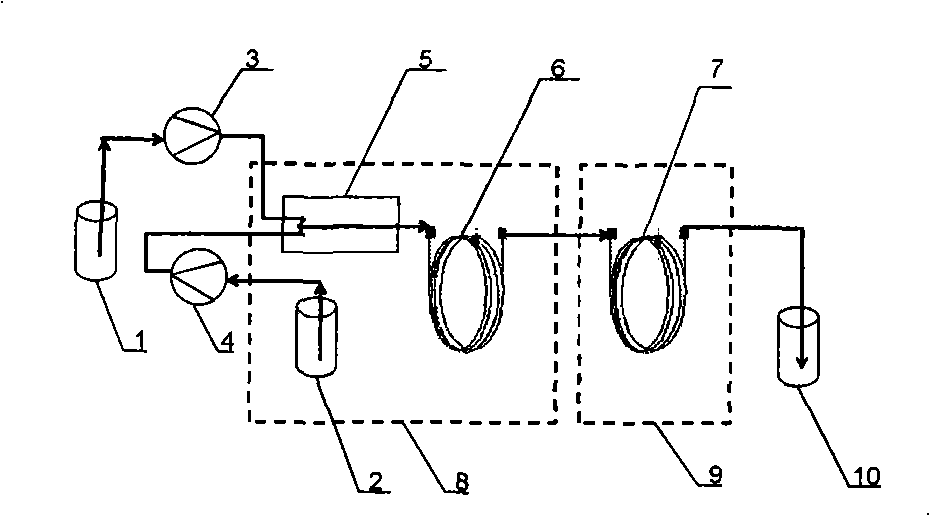

Method of preparing alpha-sulphonic acid fatty acid ester

InactiveCN101508660AImprove securityRelaxed reaction conditionsSulfonic acid preparationState of artReaction temperature

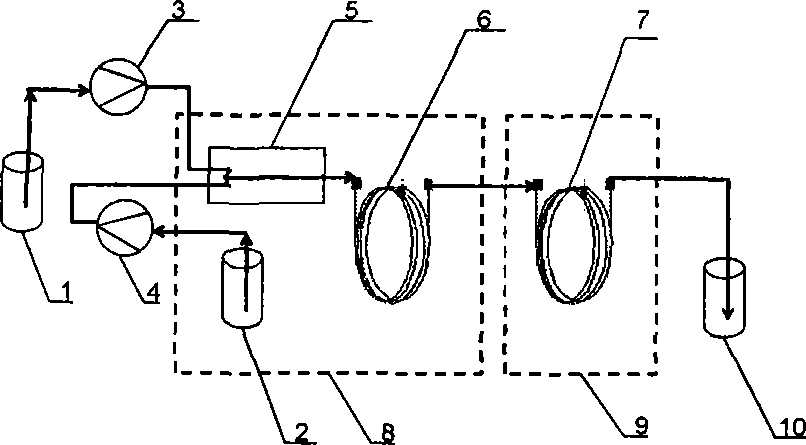

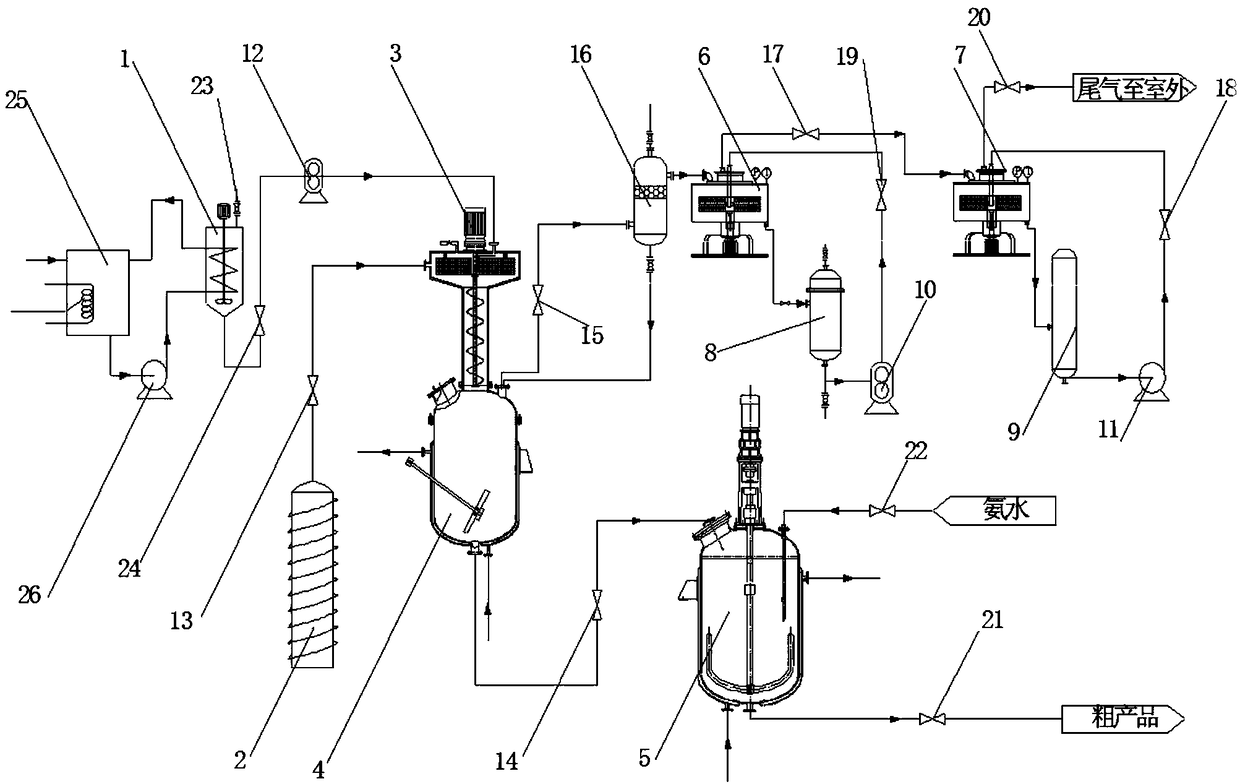

The invention relates to a method for preparing alpha-sulfonic fatty acid ester by sulfonating fatty acid ester, comprising the following steps: injecting the fatty acid ester and a sulfonating agent into a micro-structural reactor (5) and a reactor (6) inside diameter of which is a micro passage respectively, mixing and sulfonating the fatty acid ester and the sulfonating agent, controlling the reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 1ms to 1s in the micro-structural reactor (5) and stay for 0.5 to 30 minutes in the micro-passage reactor (6); and then injecting the reaction materials into a micro-passage reactor (7), aging the reaction materials at a reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 0.5 to 30 minutes in the micro-passage reactor to obtain the alpha-sulfonic fatty acid ester. In the method, the novel micro-structural reactor is adopted, the defect of difficult control due to strong reaction heat release in the prior art is overcome, the materials can be mixed evenly, the released reaction heat can be removed in time, the reaction time can be controlled accurately, and the method has the advantages of good sulfonating efficiency, simple and safe operation and good product quality.

Owner:NANJING UNIV OF TECH

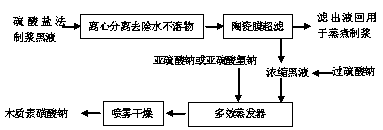

Resource treatment method of wood pulp black liquor obtained by sulfate method

ActiveCN109179845ALow viscositySave on enrichment costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationLiquid wasteUltrafiltration

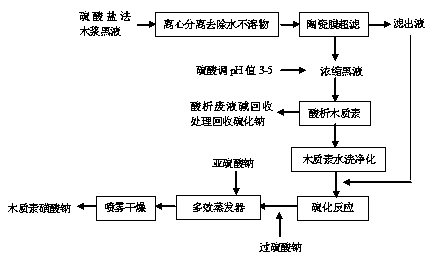

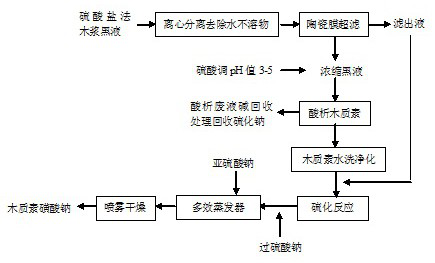

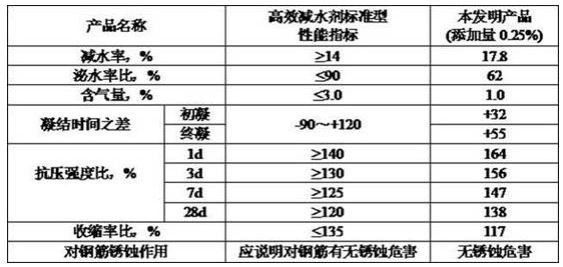

The invention discloses a resource treatment method of a wood pulp black liquor obtained by a sulfate method and belongs to the fields of pulping and papermaking, environmental protection and comprehensive utilization of resources. The resource treatment method comprises: carrying out centrifugation on a digestion black liquor obtained by the sulfate method wood pulp papermaking to separate waterinsoluble matters, filtering the digestion black liquor through a ceramic ultrafiltration membrane, recycling the filtrate, adjusting pH of the concentrated black liquor to precipitate lignin at pH less than 7 and carrying out separation purification on the lignin, washing purification, sulfurization reaction, evaporation concentration, simultaneous sulfonation modification, and spray drying to obtain sodium lignosulfonate. Sodium sulfide in the acid precipitation waste liquid is recovered and treated through an alkali recovery process and is used for digestion pulping. The sodium lignosulfonate product obtained by the method has high purity and good quality, can be used as a concrete water reducing agent and has performance indexes meeting the standard requirements of the concrete high-efficiency water reducing agent.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Preparation of polystyrolsulfon acid and application

InactiveCN104209143ALow priceEasy to separateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolystyreneDissolution

The invention relates to synthesis of polystyrolsulfon acid and its application. Recovered polystyrene is used as a raw material and is purified by ethyl acetate dissolution; and fuming sulphuric acid is used for sulfonation so as to prepare polystyrolsulfon acid which is used as a catalyst to be applied in catalyzing an esterification reaction between polyol and carboxylic acid. Research results show that, in comparison with benzenesulfonic acid, the catalyst has advantages of low production cost, high esterification rate, convenient recovery, simple product aftertreatment technology, high viscosity index of an esterification product and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

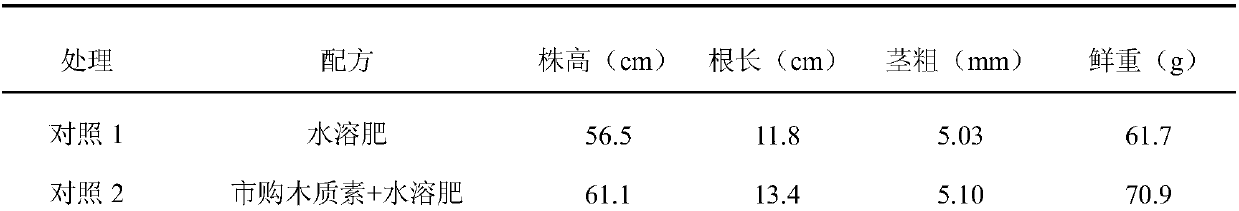

Controlled-release fertilizer as well as preparation method and application thereof

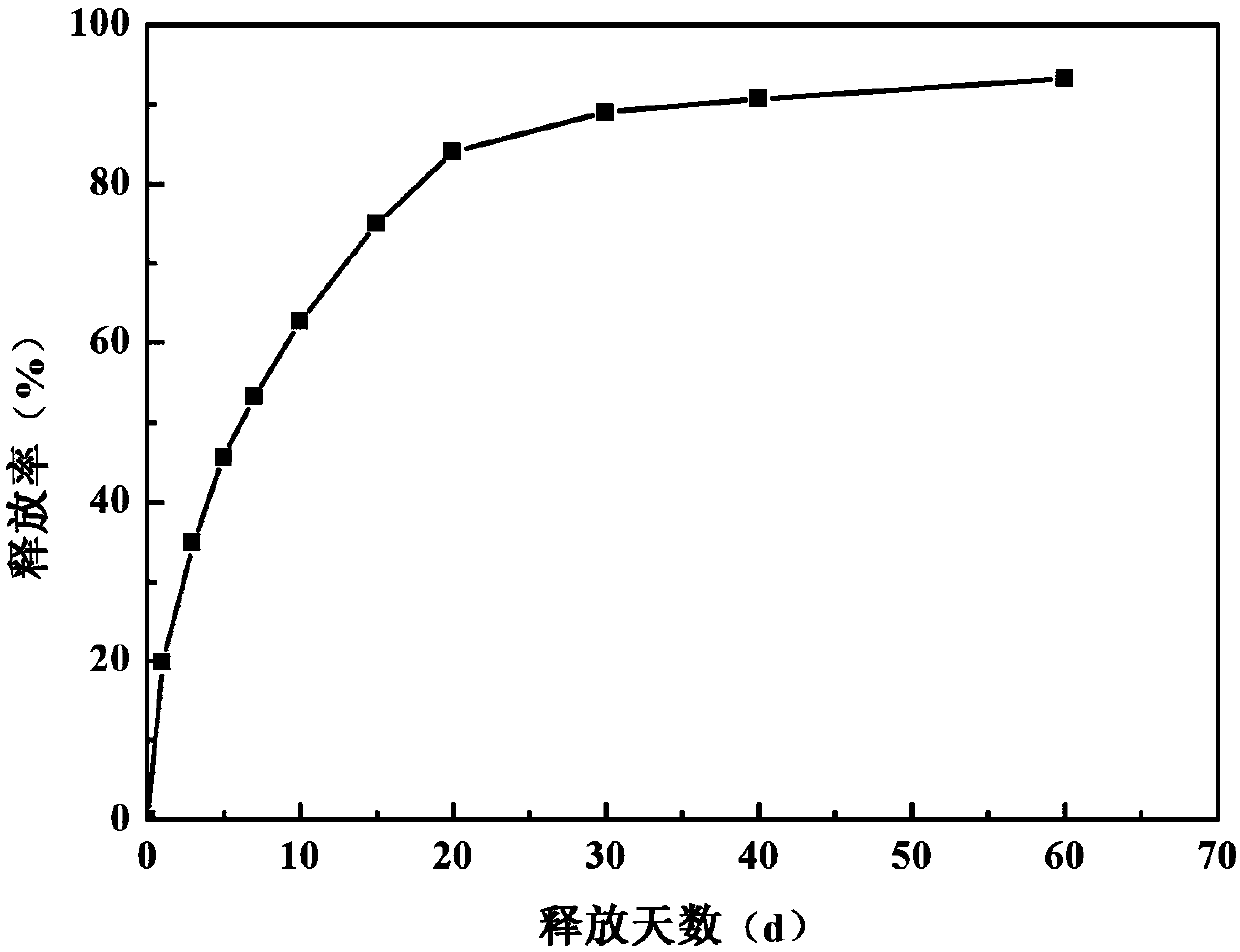

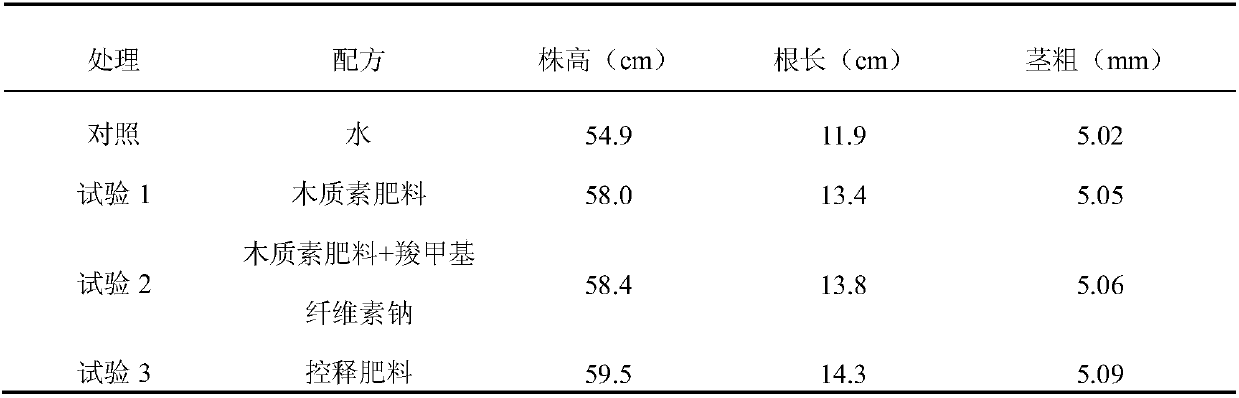

InactiveCN107827548AGood effectEasy to separateOrganic fertilisersAmmonium salt fertilisersCelluloseCopper salt

The invention relates to controlled-release fertilizer as well as a preparation method and application thereof. The controlled-release fertilizer is prepared by taking straw powder as a raw material,carrying out sulfonation treatment under the existence of sulfite, a buffer agent, anthraquinone and copper salt, then carrying out alkalization treatment by sodium hydroxide and finally carrying outchloroacetic acid treatment. The invention also provides the preparation method and the application of the controlled-release fertilizer. In the controlled-release fertilizer provided by the invention, the molecular weight of lignin is small, the sulfonating rate is high, and the lignin and cellulose in plant straw are fully utilized; the controlled-release fertilizer can be applied by adding water or be applied as base fertilizer or topdressed fertilizer, a slow release effect is good, and release of nutrients can be effectively controlled.

Owner:KINGENTA ECOLOGICAL ENG GRP +2

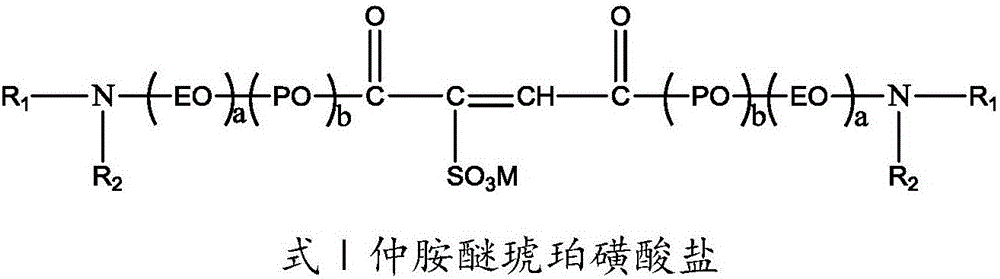

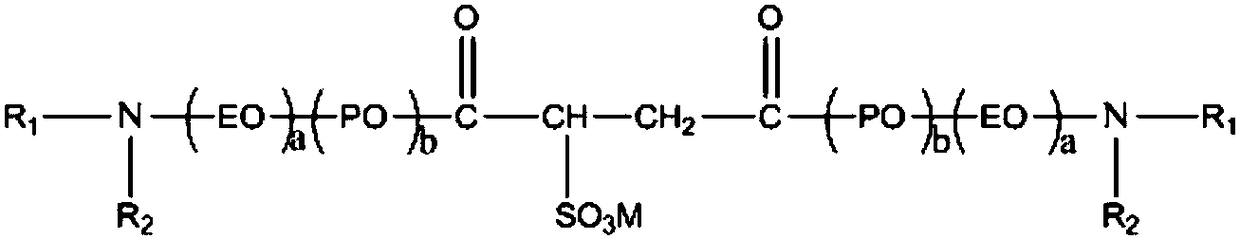

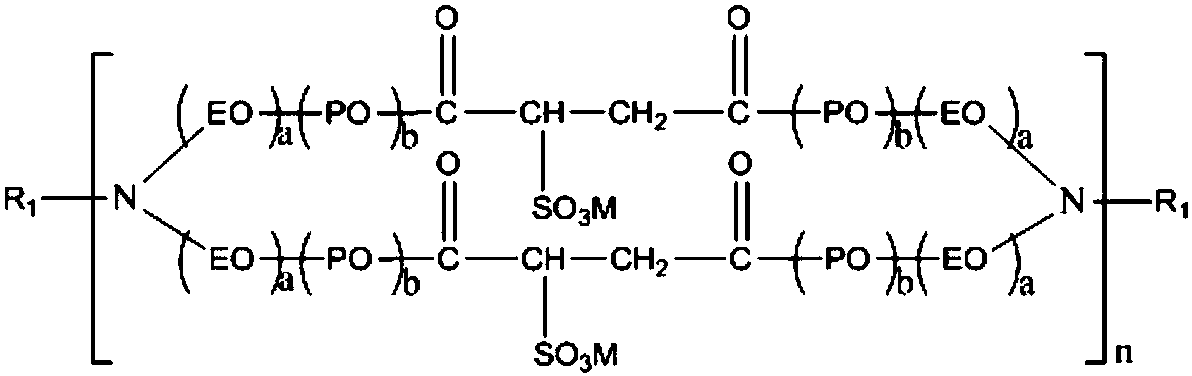

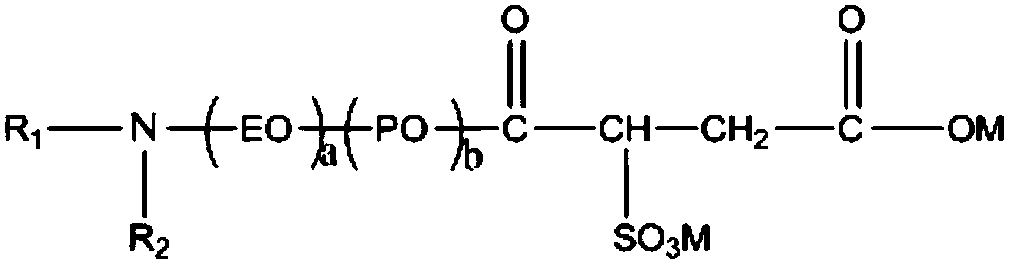

Gemini alkyl amine ether sulfosuccinate salt surfactants and preparation method thereof

ActiveCN106076190AReduce decompositionReduce salt contentTransportation and packagingSulfonic acids salts preparationEtherMaleic anhydride

The invention relates to gemini alkyl amine ether sulfosuccinate salt surfactants with chemical structural formulas I, II, III and IV, and in the formulas, R1 and R2 are respectively selected from C4-C22 linear or branched saturated or unsaturated alkyls, a=1-100, b=1-100, n=1-10, and a, b and n are all integer, and M is one or more of Li<+>, Na<+>, K<+> and NH<4+>. The preparation method of the surfactants comprises performing monoesterification or diesterification on a secondary amine ether, a primary amine ether and polyamine ether with maleic anhydride, and then performing sulfonation to obtain the corresponding gemini alkyl amine ether sulfosuccinate salt, and adjusting the performance of the finally-obtained Gemini surfactants from the molecular structure, such as the amine ether alkyls, EO, PO addition number and quantity of amine ether functional group. The preparation method is simple, easy to operate and small in environment hazards.

Owner:山东转化科技有限公司

Low-fluorescence sulfonating asphalt for blocking agent for drilling liquid

InactiveCN108410437AHigh sodium sulfonate contentHigh sodium contentWorking-up pitch/asphalt/bitumen by chemical meansDrilling compositionFluorescenceSolvent

The invention provides a low-fluorescence sulfonating asphalt for a blocking agent for a drilling liquid. The high-temperature and high-pressure filter loss is 3.8 to 5.6ml / 30min, the content of water-soluble matter is 79.4 to 87.6%, and the content of sodium sulfonate is 15.6 to 18.8%. The low-fluorescence sulfonating asphalt for the blocking agent for the drilling liquid is prepared by a methodwith the following steps of dispersing silica gel powder into petroleum ether, slowly adding chlorosulfonic acid, and stirring, so as to obtain a sulfonating agent; mixing the low-fluorescence asphaltand a solvent to obtain a reaction raw material, and sulfonating the reaction raw material by a sulfonating agent for 3 to 5h; neutralizing a product after sulfonating reaction and a sodium hydroxidewater solution to react until the pH (potential of hydrogen) value is 8 to 9; distilling and drying the product after neutralizing reaction, so as to obtain the low-fluorescence sulfonating asphalt for the blocking agent for the drilling liquid, wherein the solvent contains C6-C12 sodium alkyl benzene sulfonate and petroleum ether. The low-fluorescence sulfonating asphalt for the blocking agent for the drilling liquid has the advantages that the content of water-soluble matter is high, the sulfonating rate is high, and the high-temperature and high-pressure filter effect is good; the preparation method adopts mild reaction conditions, and is suitable for large-scale industrialized production.

Owner:TIANJIN DAGANG BOZHONG OIL ADDITIVES

Lignin fertilizer and preparation method and application

InactiveCN107935676APlay a role in antibacterialLow priceAmmonium salt fertilisersOrganic fertilisersWater solubleSulfite

The invention relates to a lignin fertilizer and a preparation method and application. The lignin fertilizer takes straw as a raw material, and straw together with sulfite, a buffering agent, anthraquinone and copper salt undergoes a one-step reaction to prepare a liquid fertilizer. The content of lignin is 1.5-3.5% according to a mass ratio, and the weight average molecular weight of lignin is 2000-5000. The invention further provides a preparation method and application of the lignin fertilizer. Lignin in plant straw is fully applied at a high value. The lignin is small in molecular weight,high in sulfonation rate, good in sulfonation and beneficial for crop absorption. The preparation step is simplified, and the lignin fertilizer is obtained through a one-step charging reaction.

Owner:KINGENTA ECOLOGICAL ENG GRP +1

Sulfonated leather greasing agent containing fatty acid low-carbon ester and preparation method thereof

The invention discloses a sulfonated leather greasing agent containing fatty acid low-carbon ester. The sulfonated leather greasing agent containing fatty acid low-carbon ester disclosed by the invention is prepared by comprising the following steps: sulfonating by taking saturated fatty acid low-carbon ester as the raw material so as to obtain sulfonated fatty acid low-carbon ester, adding grease or modified grease, uniformly mixing, putting in an aging tank to age, decolourizing, and finally, adjusting pH of the decolourized sulfonated fatty acid low-carbon ester to be 4-8 so as to obtain the leather greasing agent. The invention further discloses a preparation method of the leather greasing agent. Because of being a liquid product, the leather greasing agent disclosed by the invention is convenient for down-stream customers to use; furthermore, the leather greasing agent is steady in property and has good fillibility; and thus, leather is plump and soft in hand feeling and smooth in surface.

Owner:广州浪奇日用品有限公司 +1

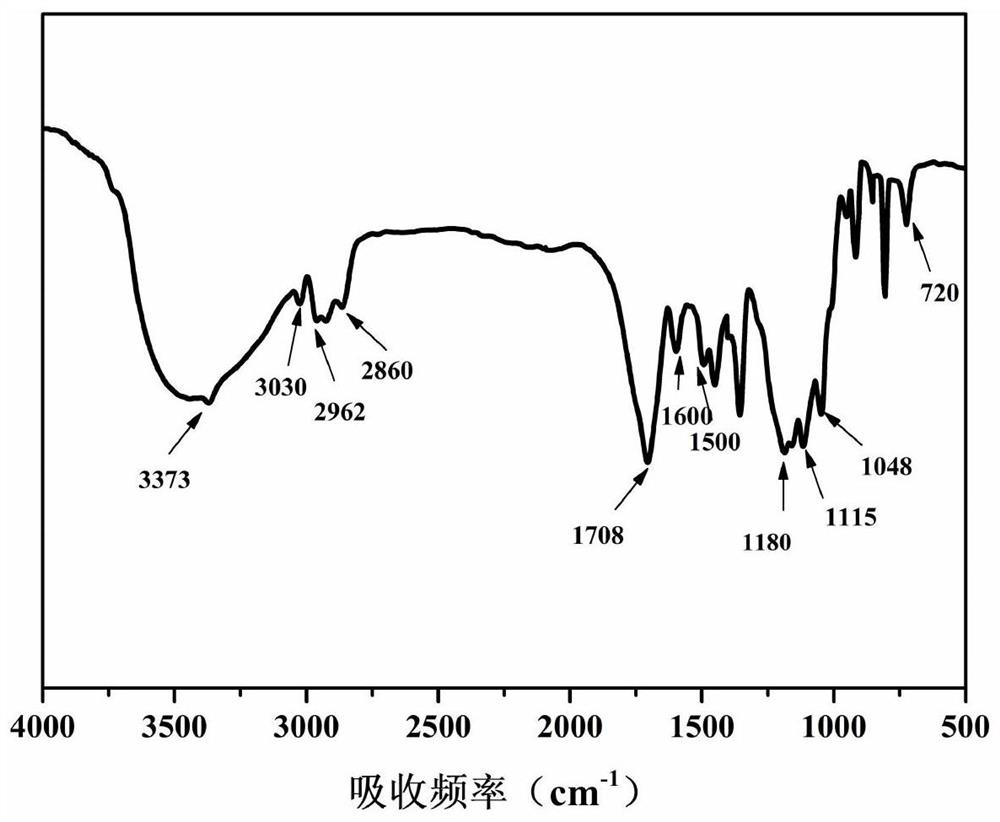

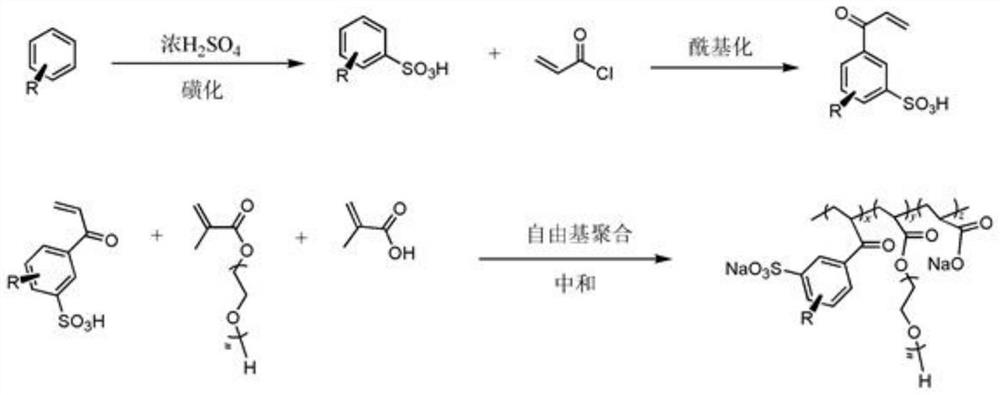

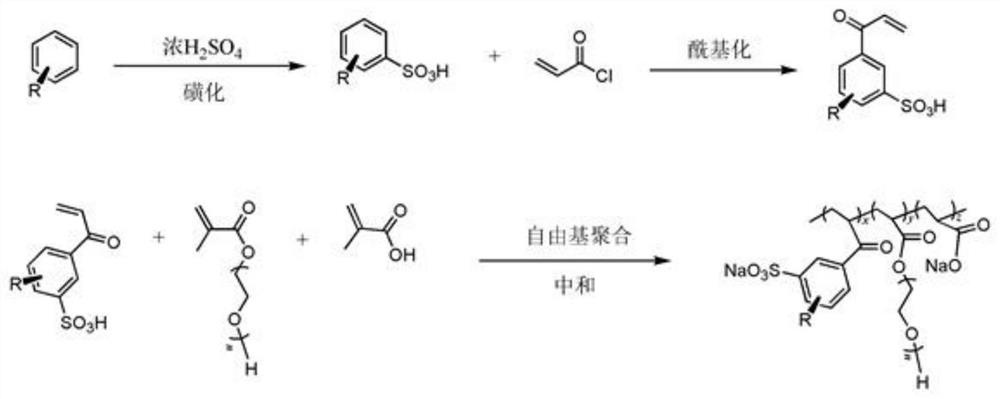

Method for preparing polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues

ActiveCN113698546AImprove workabilityHigh water reduction rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsMolecular sieveCarbon nanotube

The invention relates to a method for preparing a polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues. The polyether polycarboxylic acid type high-efficiency water reducing agent is prepared by free radical polymerization of arone olefin, a double-bond-containing macromonomer and a micromolecular monomer, and the arone olefin is prepared by catalytic acylation of poly-ethylbenzene sulfonic acid and unsaturated acylate by using a bifunctional molecular sieve encapsulated catalyst. The bifunctional molecular sieve encapsulated catalyst is prepared by one-step hydrothermal reaction of sodium metaaluminate, sodium hydroxide, modified silicon dioxide, N,N,N-trimethyl-1-amantadine, carbon nanotubes and (2,2'-bipyridine) nickel diiodide. The polyethylbenzene sulfonic acid is prepared by sulfonating the high-boiling residues at the bottom of a polyethylbenzene tower. According to the method, the polyethylbenzene tower bottom high-boiling residues serve as raw materials, polyether polycarboxylic acid type high-efficiency water reducing agent molecules are prepared through the steps of sulfonation, acylation, free radical polymerization and the like, and the polyether polycarboxylic acid type high-efficiency water reducing agent is practically applied to the building field and has important significance in resourceful treatment of the ethylbenzene tower bottom high-boiling residues.

Owner:CHINA PETROLEUM & CHEM CORP +1

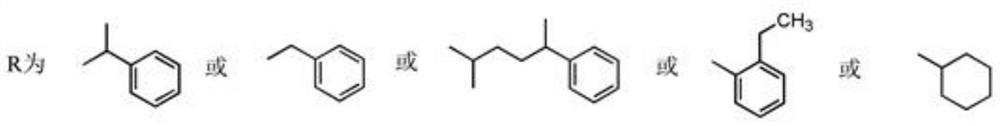

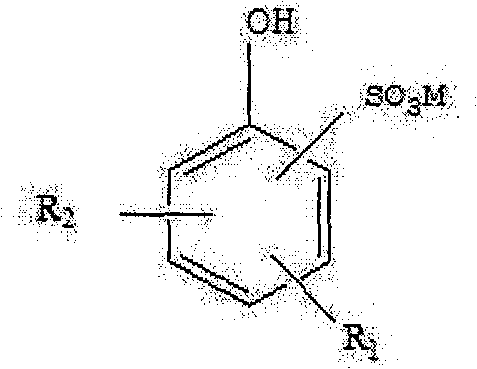

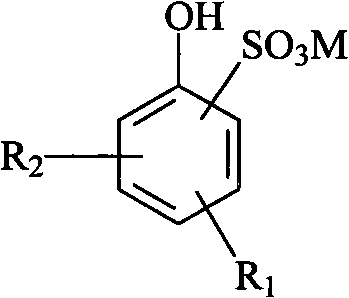

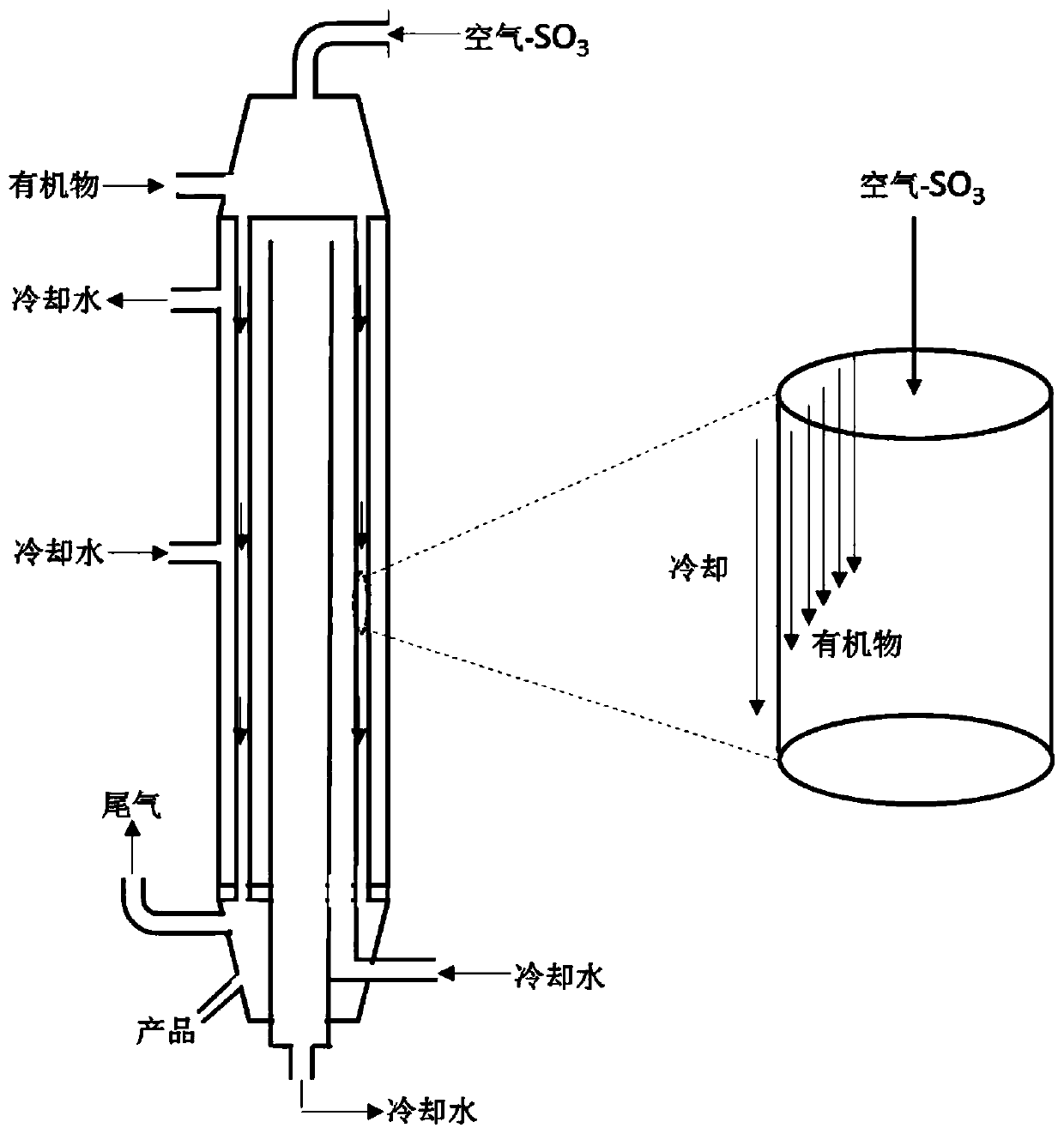

Method of using SO*-air mixture to produce alkylphenol sulfonic acid and salts thereof via film sulfonator sulfonated alkylphenol

ActiveCN101585786AHigh sulfonation rateLow free oil contentLiquid-gas reaction of thin-film typeSulfonic acids salts preparationInorganic saltsAlkylphenol

Method of using SO*-air mixture to produce alkylphenol sulfonic acid and salts thereof via film sulfonator sulfonated alkylphenol, belongs to sulphonate preparing technology field. The invention uses alkylphenol as raw material, and uses SO[3]-air mixture to sulfonate the raw material via film sulfonator to obtain alkylphenol sulfonic acid, and uses alkaline solution such as NaOH to neutralize the alkylphenol sulfonic acid to obtain alkylphenol sulphonate, the alkylphenol used is a alkylphenol containing one or two C[1]-C[20] straight-chain or branched chain alkyl; the alkylphenol sulfonic acid and salt thereof prepared by the method has high sulphonation rate, low free oil content, low inorganic salt content and producing no spend acid, which is no corrosion to equipments and helpful for environmental protection.

Owner:TAIXING LINGFEI CHEM TECH CO LTD

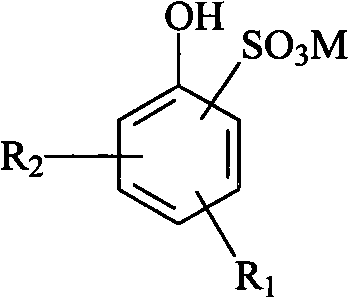

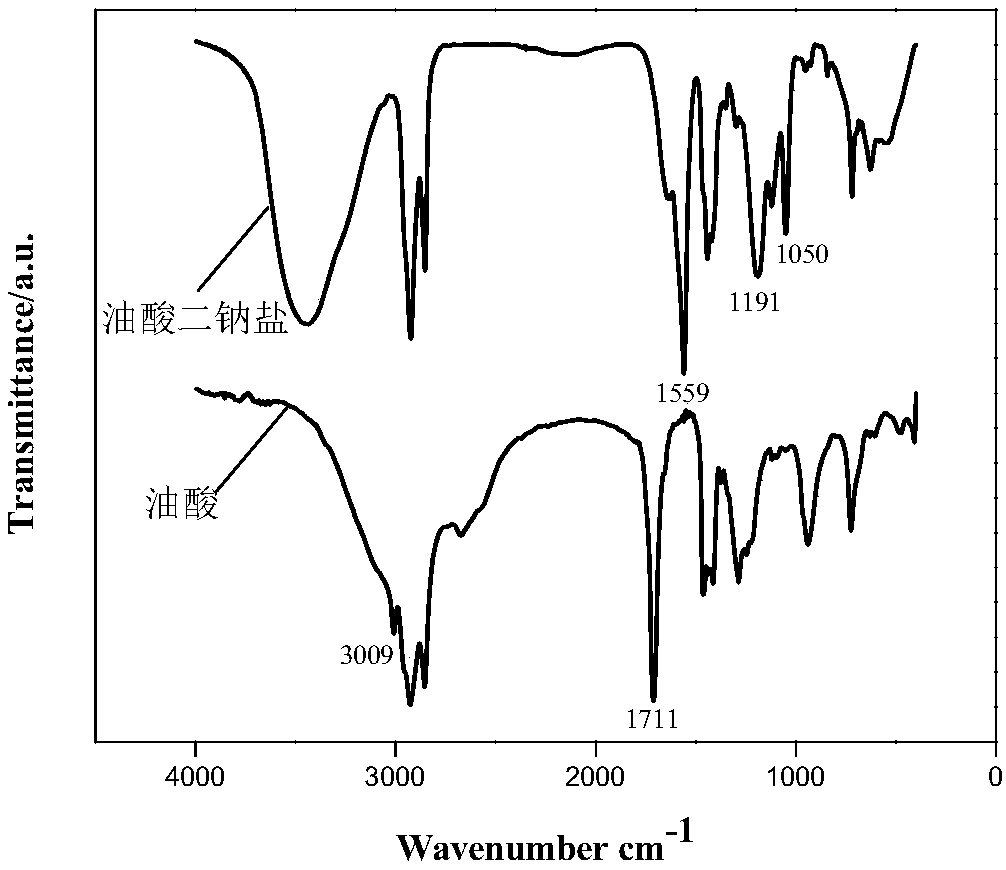

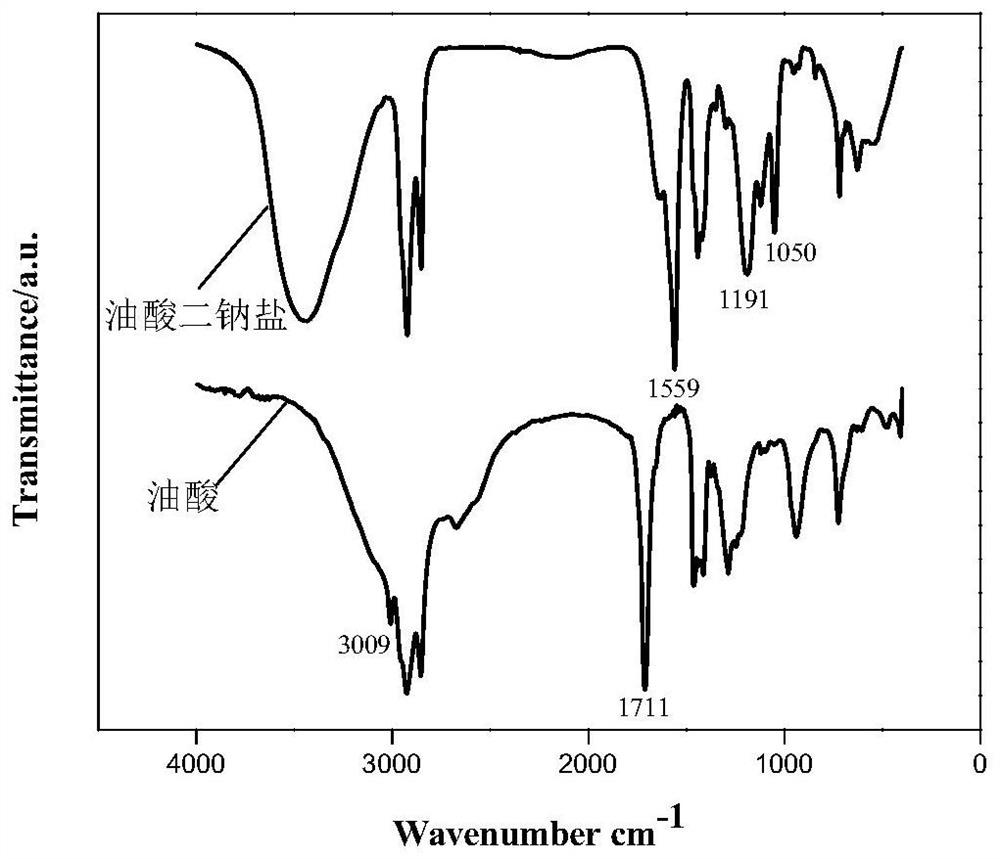

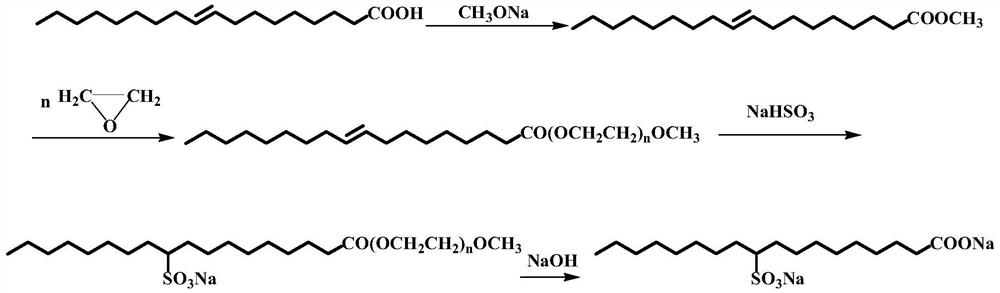

Synthesis method of disodium oleate

ActiveCN108484450AChange hydrophilicityImprove mass transfer efficiencyOrganic compound preparationCarboxylic acid esters preparationSynthesis methodsSolvent

The invention relates to a synthesis method of disodium oleate. The synthesis method of the disodium oleate comprises the following steps: performing reaction on oleic acid, methanol and p-toluenesulfonic acid to obtain methyl oleate; performing addition on the methyl oleate and ethylene oxide to obtain methyl oleate ethoxylate; and performing sulfonated addition reaction on an intermediate product and sodium hydrogen sulfite to obtain methyl oleate ethoxylate sulfonate, performing saponification reaction, and performing extraction and separation on ethyl acetate and a saturated sodium chloride aqueous solution of 30 percent by weight to obtain the disodium oleate. The synthesis method of the disodium oleate has the following advantages: the raw materials are rich and can be regenerated, and the sulfonation rate is high; the solvent used in the preparation process is cheap, easily available and recyclable; and reaction is mild, energy consumption is low, sulfonation rate is high and yield is high.

Owner:CHINA RES INST OF DAILY CHEM IND

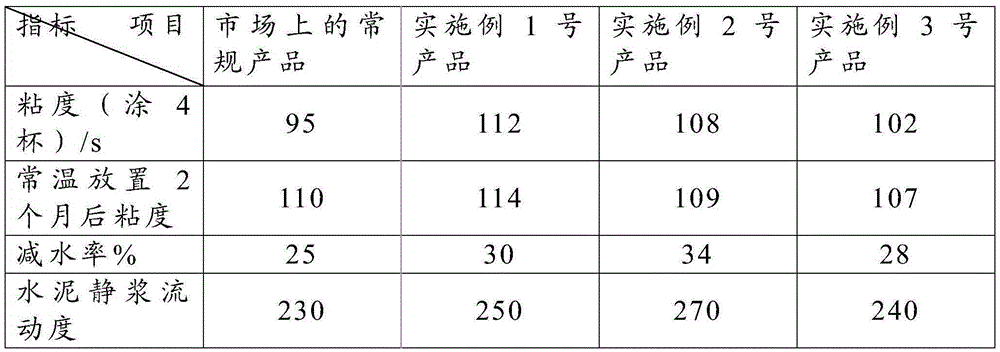

Method for preparing sulphated castor oil

InactiveCN102304066AHigh speedHigh sulfonation rateSulfuric acid esters preparationChemical recyclingPtru catalystPhysical chemistry

The invention relates to a method for preparing sulphated castor oil. The method comprises the following specific steps of: sulphating: carrying out sulphation reaction by adding a catalyst into the castor oil and dropping fuming sulphuric acid, wherein the dropping temperature is 20-28 DEG C; and the dropping time is 1-2 h; continuously reacting for 3-5 h, controlling the temperature at 28-38 DEG C, and obtaining a castor oil sulphate solution; salt washing: washing the castor oil sulphate solution by using saturated salt water to obtain salt washed castor oil sulphate; and neutralizing: neutralizing the salt washed castor oil sulphate by using ammonia water, and controlling the pH value at 7-8 to obtain the sulphated castor oil. According to the method disclosed by the invention, the catalyst is used in the castor oil sulphation process, therefore, the castor oil sulphation speed is increased; the sulphonated rate is increased; the catalyst can be recycled in the salt washing process; the sulphation reaction temperature is 20-38 DEG C; the by-products in the reaction process are reduced; the product impurities are reduced; the product performance is better; the neutralization process is easy to master by using ammonia water; and the excess neutralization is difficult.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues

ActiveCN114752020AImprove workabilityHigh water reduction rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPolymer sciencePtru catalyst

The invention relates to a method for preparing a polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues. The polyether polycarboxylic acid type high-efficiency water reducing agent is prepared by free radical polymerization of arone olefin, a double-bond-containing macromonomer and a micromolecular monomer, and the arone olefin is prepared by catalytic acylation of poly-ethylbenzene sulfonic acid and unsaturated acylate by using a bifunctional molecular sieve encapsulated catalyst. The bifunctional molecular sieve encapsulated catalyst is prepared by one-step hydrothermal reaction of sodium metaaluminate, sodium hydroxide, modified silicon dioxide, N, N, N-trimethyl-1-amantadine, carbon nanotubes and (2, 2 '-bipyridine) nickel diiodide, and the polyethylbenzene sulfonic acid is prepared by sulfonating high-boiling residues at the bottom of a polyethylbenzene tower. According to the method, the polyethylbenzene tower bottom high-boiling residues serve as raw materials, polyether polycarboxylic acid type high-efficiency water reducing agent molecules are prepared through the steps of sulfonation, acylation, free radical polymerization and the like, and the polyether polycarboxylic acid type high-efficiency water reducing agent molecules are practically applied to the building field and have important significance in resourceful treatment of the ethylbenzene tower bottom high-boiling residues.

Owner:CHINA PETROLEUM & CHEM CORP +1

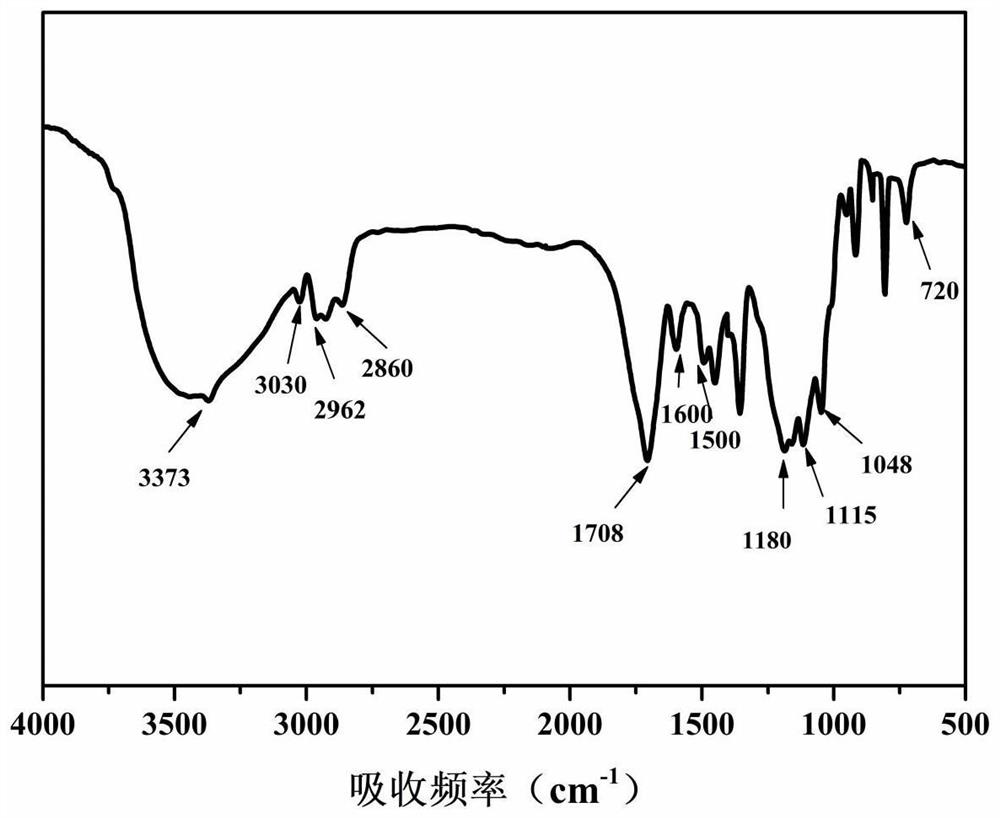

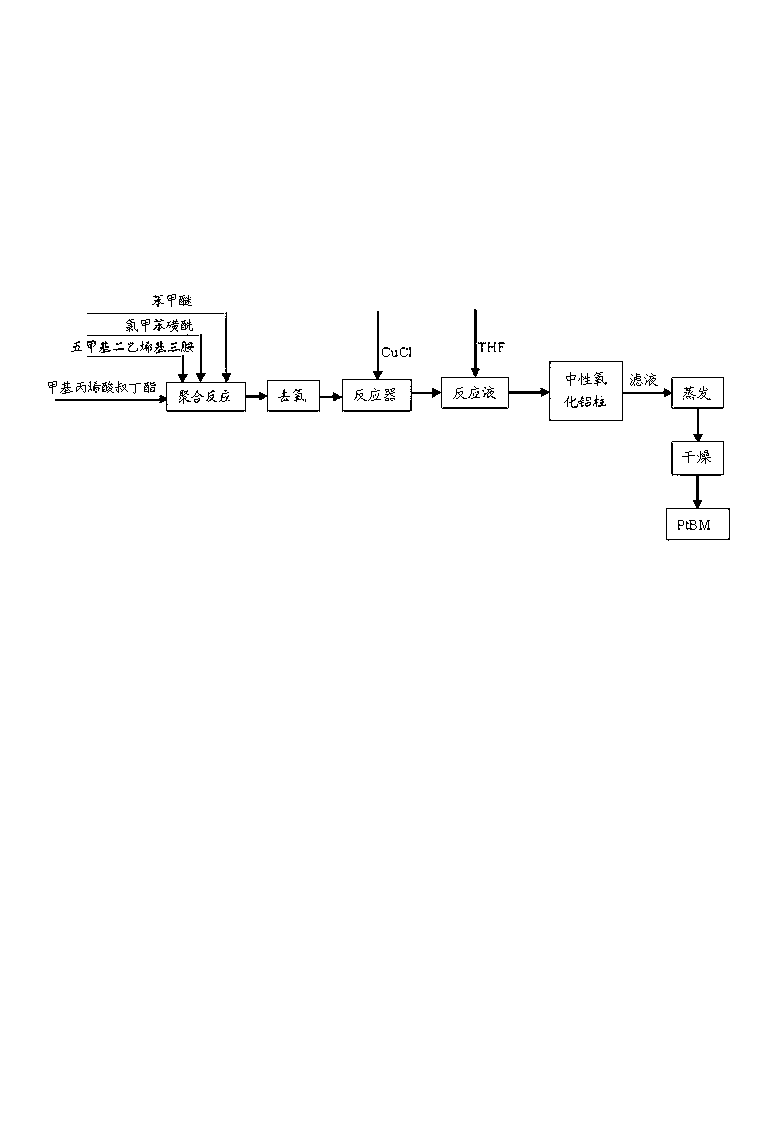

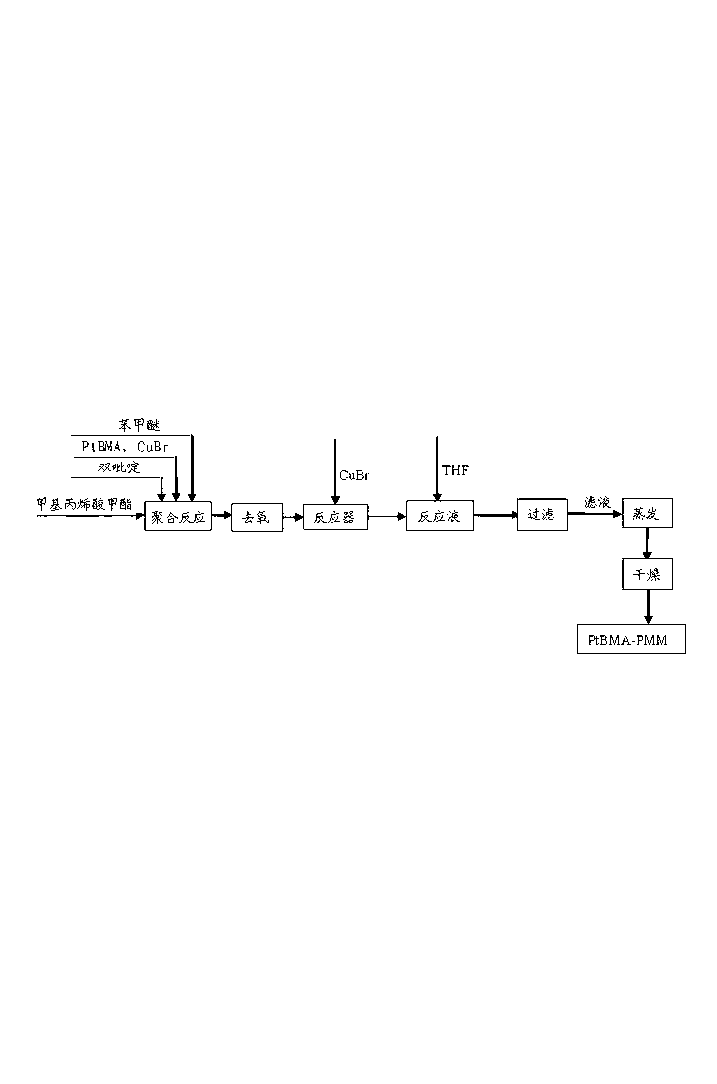

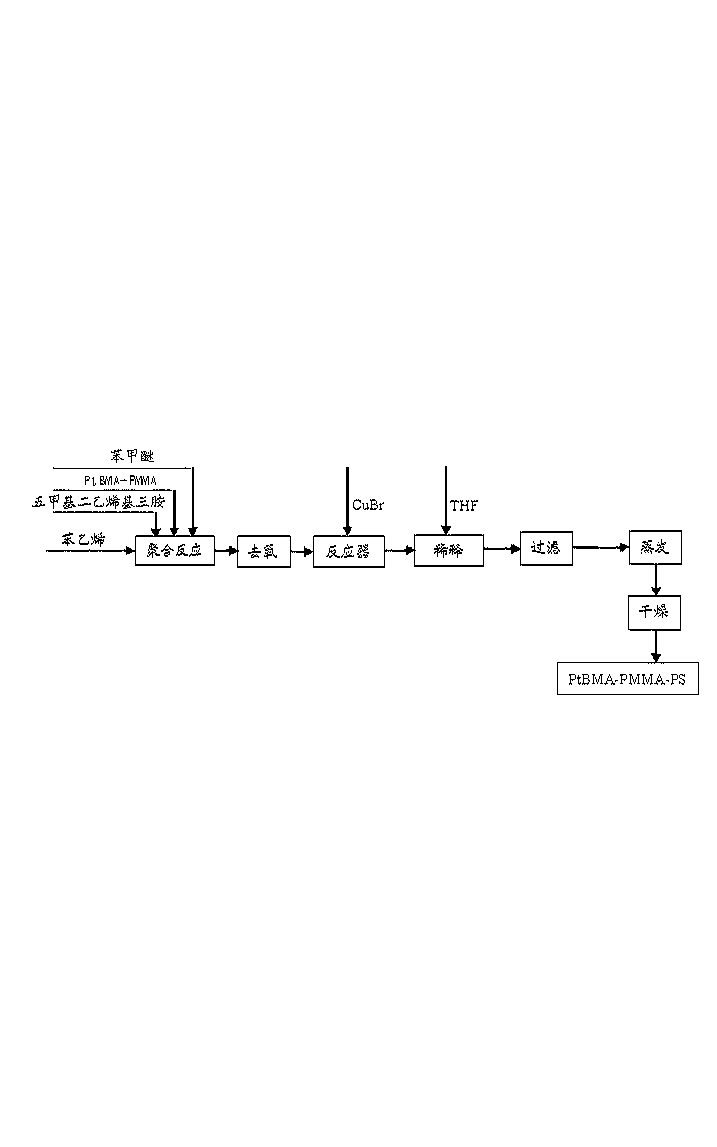

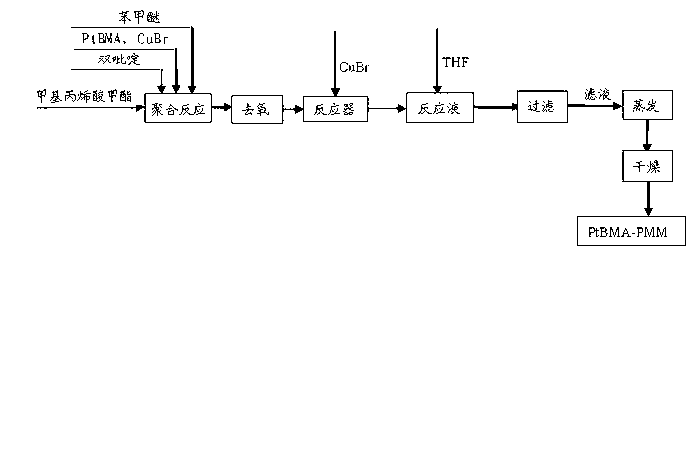

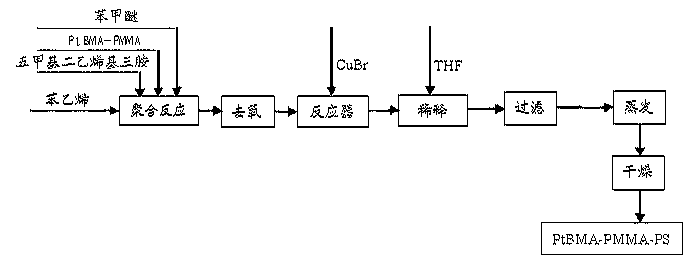

Preparation method of triblock polymers with suspension nanometer zero-valent irons

InactiveCN102702452AHigh reactivityGood suspensionOther chemical processesPolymethyl methacrylateAtom-transfer radical-polymerization

The invention discloses a preparation method of triblock polymers with suspension nanometer zero-valent irons. The preparation method comprises the steps of utilizing an atom transfer radical polymerization(ATRP) method to synthetize triblock polymers of poly(t-butyl methacrylate), polymethyl methacrylate and polrvinyl benzene, hydrolyzing the poly(t-butyl methacrylate) to prepare polymethacrylicacid using trifluoroacetic acid, and finally sulfonating the polrvinyl benzene to prepare polystyrolsulfon acid using sulfuric acid acetyl. The method improves the original three-step reaction into aone-step reaction in the synthetic process of the polymers, thereby reducing the operation steps, reducing the consumption of raw materials, improving reaction stability and improving the productivity of aimed compounds; and adding trifluoroacetic acid in a hydrolysis process, so that the hydrolysis process is thorough and the reactivity and the suspension property of products are improved. The experiment results show that the triblock polymers comprise functional groups in required target products, the molecular weight can reach about 100 thousand, and the stabilization time of suspension effects of nanometer zero-valent irons can reach more than two months.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

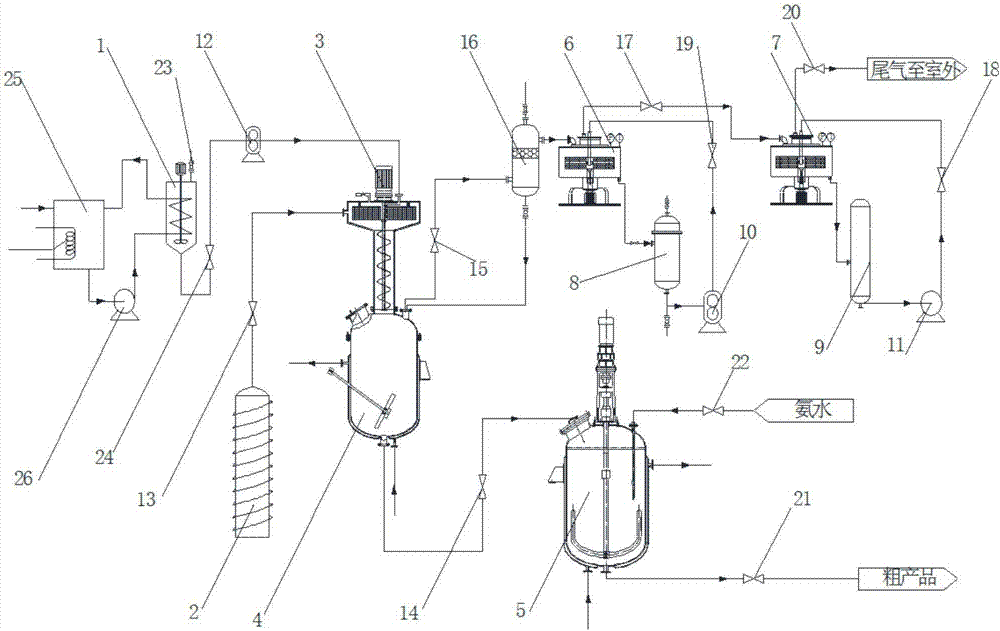

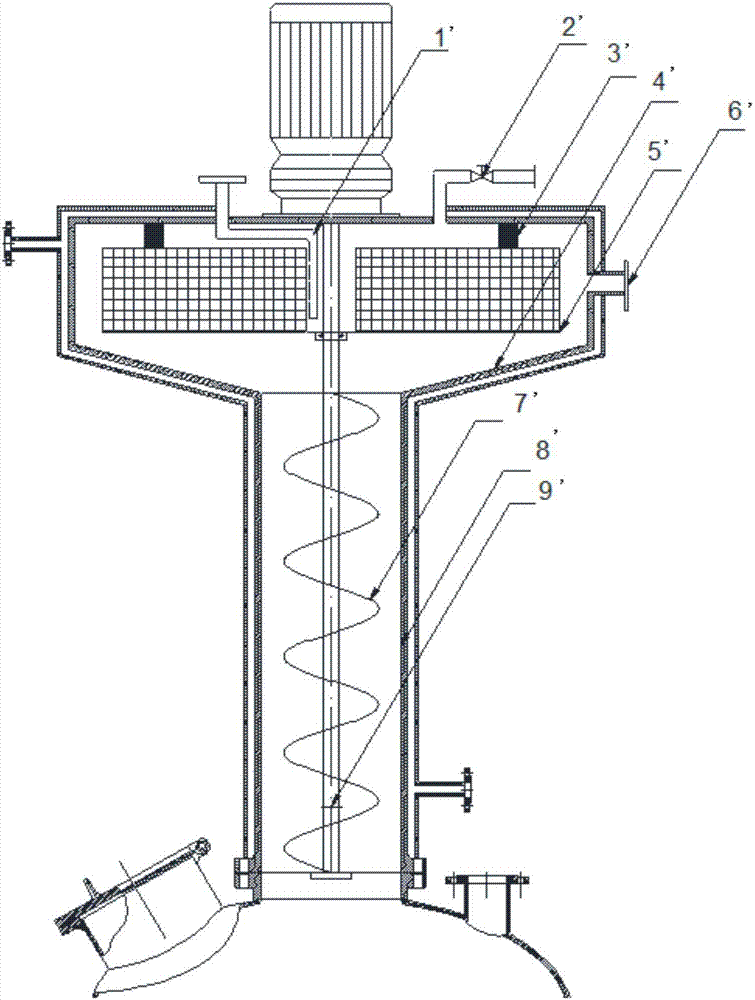

Method for green synthesis of tertiary oil recovery petroleum sulfonates in high gravity reactor

ActiveCN106966930AReduce volumeLow installation requirementsSulfonic acids salts preparationDrilling compositionGas phaseActive matter

The invention a method for green synthesis of tertiary oil recovery petroleum sulfonates in a high gravity reactor and belongs to the field of fine chemicals. The method comprises the steps: using distillate oil as a raw , sulfonating and aging the distillate oil through the high gravity-screw combination reactor to obtain an obtained petroleum sulfonate surfactant, and then neutralizing the obtained petroleum sulfonate surfactant. The method is mainly characterized in that the wide distillate oil is used as the raw material, and gas phase SO3 is used as a sulfonation agent; the petroleum sulfonates obtained after neutralizing with ammonium hydroxide is free of solvent removal process, so that the process is shortened; sulfonation efficiency is high, the content of active matters is high and the interfacial tension is low; and in the method, the production equipment and process which can realize processing strengthening, safety, high efficiency and cleaning are used. The method is suitable for scale and continuous production of the tertiary oil recovery petroleum sulfonates.

Owner:BEIJING UNIV OF CHEM TECH

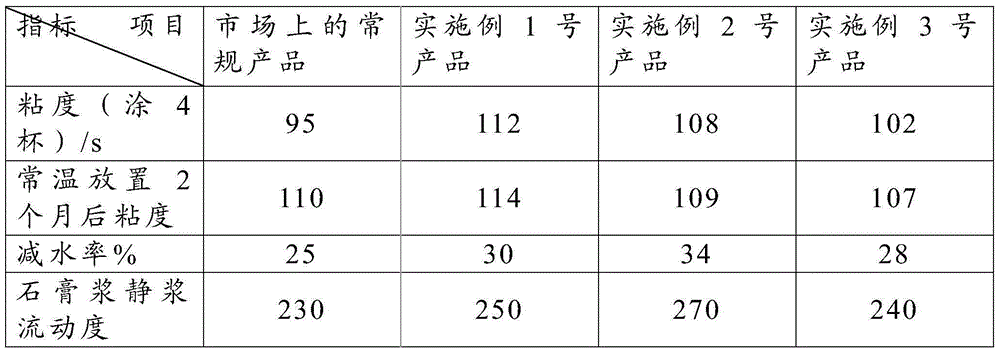

A kind of sulfonated melamine formaldehyde resin water reducing agent and preparation method thereof

The invention belongs to the technical field of resin and particularly relates to a sulfonated melamine formaldehyde resin water reducing agent and a preparation method thereof. The sulfonated melamine formaldehyde resin water reducing agent comprises the raw materials of melamine, liquid formaldehyde and water, wherein the ratio of weight parts of the melamine to the liquid formaldehyde to the water is (10-20):(25-52):(7-15). The sulfonated melamine formaldehyde resin water reducing agent is stable in resin molecular weight, excellent in dispersion for cement, high in water reducing rate and remarkable in early strength effect in the concrete application.

Owner:SHANDONG ZHANHUA OSITER CHEM

Method of preparing alpha-sulphonic acid fatty acid ester

InactiveCN101508660BImprove securityRelaxed reaction conditionsSulfonic acid preparationState of artReaction temperature

The invention relates to a method for preparing alpha-sulfonic fatty acid ester by sulfonating fatty acid ester, comprising the following steps: injecting the fatty acid ester and a sulfonating agent into a micro-structural reactor (5) and a reactor (6) inside diameter of which is a micro passage respectively, mixing and sulfonating the fatty acid ester and the sulfonating agent, controlling the reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 1ms to 1s in the micro-structural reactor (5) and stay for 0.5 to 30 minutes in the micro-passage reactor (6); and then injecting the reaction materials into a micro-passage reactor (7), aging the reaction materials at a reaction temperature between 50 and 100 DEG C, and controlling the reaction materials to stay for 0.5 to 30 minutes in the micro-passage reactor to obtain the alpha-sulfonic fatty acid ester. In the method, the novel micro-structural reactor is adopted, the defect of difficult control due to strong reaction heat release in the prior art is overcome, the materials can be mixed evenly, the released reaction heat can be removed in time, the reaction time can be controlled accurately, and the method has the advantages of good sulfonating efficiency, simple and safe operation and good product quality.

Owner:NANJING TECH UNIV

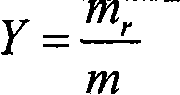

A kind of production technology of high-quality sodium fatty acid methyl ester sulfonate

ActiveCN111116432BFast separationSpeed up molecular motionSulfonic acids salts preparationSulfonateActive agent

The invention relates to a production process of a surfactant. The purpose is to provide a fatty acid methyl ester sulfonate production process to ensure product quality and improve product conversion rate. The technical solution is: a high-quality production process of sodium fatty acid methyl ester sulfonate, which is realized through the following steps in turn: 1) sulfonation: fatty acid methyl ester and 5-7% gas-concentrated SO3 enter a membrane reactor to undergo a sulfonation reaction , the molar ratio of fatty acid methyl ester to SO3 is 1: 1.25~1.35; 2) aging: the material output from the sulfonator enters the gas-liquid separator for separation, and the sulfonate is separated from the bottom of the separator and then enters the reactor for aging treatment to obtain MES intermediate; 3) Re-esterification, bleaching, and neutralization: put the aged MES intermediate and an appropriate amount of methanol into the re-esterification system to obtain MES slurry; Neutralize with the system, and enter the temporary storage tank after cooling to obtain the finished MES.

Owner:ZANYU TECH GRP CO LTD +1

Preparation method of triblock polymers with suspension nanometer zero-valent irons

InactiveCN102702452BHigh reactivityGood suspensionOther chemical processesPolystyreneAtom-transfer radical-polymerization

The invention discloses a preparation method of triblock polymers with suspension nanometer zero-valent irons. The preparation method comprises the steps of utilizing an atom transfer radical polymerization(ATRP) method to synthetize triblock polymers of poly(t-butyl methacrylate), polymethyl methacrylate and polrvinyl benzene, hydrolyzing the poly(t-butyl methacrylate) to prepare polymethacrylic acid using trifluoroacetic acid, and finally sulfonating the polrvinyl benzene to prepare polystyrolsulfon acid using sulfuric acid acetyl. The method improves the original three-step reaction into a one-step reaction in the synthetic process of the polymers, thereby reducing the operation steps, reducing the consumption of raw materials, improving reaction stability and improving the productivity of aimed compounds; and adding trifluoroacetic acid in a hydrolysis process, so that the hydrolysis process is thorough and the reactivity and the suspension property of products are improved. The experiment results show that the triblock polymers comprise functional groups in required target products, the molecular weight can reach about 100 thousand, and the stabilization time of suspension effects of nanometer zero-valent irons can reach more than two months.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

A kind of sulfonated leather fatliquor containing fatty acid low-carbon ester and preparation method thereof

The invention discloses a sulfonated leather greasing agent containing fatty acid low-carbon ester. The sulfonated leather greasing agent containing fatty acid low-carbon ester disclosed by the invention is prepared by comprising the following steps: sulfonating by taking saturated fatty acid low-carbon ester as the raw material so as to obtain sulfonated fatty acid low-carbon ester, adding grease or modified grease, uniformly mixing, putting in an aging tank to age, decolourizing, and finally, adjusting pH of the decolourized sulfonated fatty acid low-carbon ester to be 4-8 so as to obtain the leather greasing agent. The invention further discloses a preparation method of the leather greasing agent. Because of being a liquid product, the leather greasing agent disclosed by the invention is convenient for down-stream customers to use; furthermore, the leather greasing agent is steady in property and has good fillibility; and thus, leather is plump and soft in hand feeling and smooth in surface.

Owner:广州浪奇日用品有限公司 +1

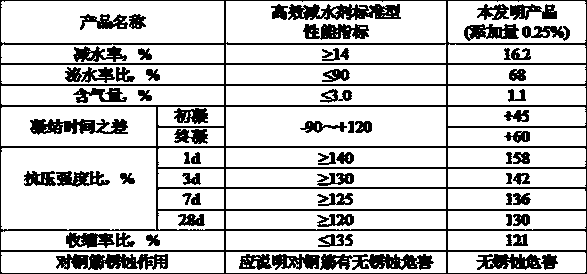

Method for producing sodium lignosulfonate by using pulping black liquor of sulphate method

The invention discloses a method for producing sodium lignosulfonate by using pulping black liquor of a sulphate method, which belongs to the fields of pulping and papermaking, environmental protection and comprehensive utilization of resources. The process adopts the pulping black liquor of a sulphate method as a main raw material, and produces sodium lignosulfonate by filtration, evaporation concentration, sulfonation modification, spray drying, etc. The black liquor is turned into wealth from wastes, and resources are made full use of, to produce high value-added fine chemical products, andreduce waste of resources. The sodium lignosulfonate product produced by the method is used for a concrete water reducing agent, and various performance indexes meet the standard requirements of a concrete high-efficiency water reducing agent.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Sodium lignin sulfonate water reducing agent and preparation method thereof

The invention provides a sodium lignin sulfonate water reducing agent which is prepared by the following steps: S1, drying chestnut shells, crushing, ball-milling and sieving to obtain chestnut shellpowder, and extracting to obtain degreased chestnut shell powder; S2, adding the degreased chestnut shell powder into 1-hexyl-3-methyl-imidazolium bisulfate to obtain a mixed solution, adding the mixed solution into a micro-jet extractor, and extracting to obtain lignin; S3, carrying out a reaction among lignin, sodium sulfite, formaldehyde and distilled water to obtain sodium lignin sulfonate; and S4, grafting sodium lignin sulfonate and tartaric acid to obtain the sodium lignin sulfonate water reducing agent. The invention also provides a preparation method of the sodium lignin sulfonate water reducing agent. The sodium lignin sulfonate water reducing agent provided by the invention has the advantages of higher sulfonation rate, higher water reducing rate, better dispersity and higher effect of improving the compressive strength of concrete.

Owner:茂名市红福化学有限公司

A method for green synthesis of petroleum sulfonate for tertiary oil recovery in a high-gravity reactor

ActiveCN106966930BShort processProcess safetySulfonic acids salts preparationDrilling compositionGas phaseActive matter

The invention a method for green synthesis of tertiary oil recovery petroleum sulfonates in a high gravity reactor and belongs to the field of fine chemicals. The method comprises the steps: using distillate oil as a raw , sulfonating and aging the distillate oil through the high gravity-screw combination reactor to obtain an obtained petroleum sulfonate surfactant, and then neutralizing the obtained petroleum sulfonate surfactant. The method is mainly characterized in that the wide distillate oil is used as the raw material, and gas phase SO3 is used as a sulfonation agent; the petroleum sulfonates obtained after neutralizing with ammonium hydroxide is free of solvent removal process, so that the process is shortened; sulfonation efficiency is high, the content of active matters is high and the interfacial tension is low; and in the method, the production equipment and process which can realize processing strengthening, safety, high efficiency and cleaning are used. The method is suitable for scale and continuous production of the tertiary oil recovery petroleum sulfonates.

Owner:BEIJING UNIV OF CHEM TECH

Gemini alkylamine ether succinate sulfonate surfactant and preparation method thereof

ActiveCN106076190BAvoid hydrolysisPrevents yellowingTransportation and packagingSulfonic acids salts preparationEtherStructural formula

The present invention relates to gemini alkylamine ether succinate sulfonate surfactants as shown in chemical structural formulas I, II, III and IV, wherein R1 and R2 are respectively selected from linear or branched saturated or non-linear C4-C22. Saturated hydrocarbon group, wherein R1, R2 are the same or different; a=1~100, b=1~100, n=1~10, all are integers; M is one or more selected from Li+, Na+, K+, NH4+ kind. Its preparation method is to carry out monoester or diesterization of secondary amine ether, primary amine ether, polyamine ether and maleic anhydride, and then carry out sulfonation to obtain disubalkyl amine ether succinate. According to amine ether alkyl, The addition number of EO and PO and the number of amine ether functional groups are different, which can adjust the performance of the final gemini surfactant from the molecular structure. The preparation method of the invention is simple, easy to operate, and less harmful to the environment.

Owner:山东转化科技有限公司

Method of using SO<3>-air mixture to produce alkylphenol sulfonic acid and salts thereof via film sulfonator sulfonated alkylphenol

ActiveCN101585786BHigh sulfonation rateLow free oil contentLiquid-gas reaction of thin-film typeSulfonic acids salts preparationInorganic saltsAlkylphenol

A method of using SO3-air mixture to produce alkylphenol sulfonic acid and salts thereof through sulfonating the alkylphenol via a film sulfonator belongs to sulphonate preparing technology field. The invention uses alkylphenol as raw material, and uses the SO3-air mixture to sulfonate the raw material via the film sulfonator to obtain alkylphenol sulfonic acid, and uses alkaline solution such as NaOH to neutralize thealkylphenol sulfonic acid to obtain alkylphenol sulphonate. The alkylphenol used is a alkylphenol containing one or two C1-C20 straight-chain or branched chain alkyl. The alkylphenol sulfonic acid and salt thereof prepared by the method has high sulphonation rate, low free oil content, low inorganic salt content and producing no spend acid, which is no corrosion to equipments and helpful for environmental protection.

Owner:TAIXING LINGFEI CHEM TECH CO LTD

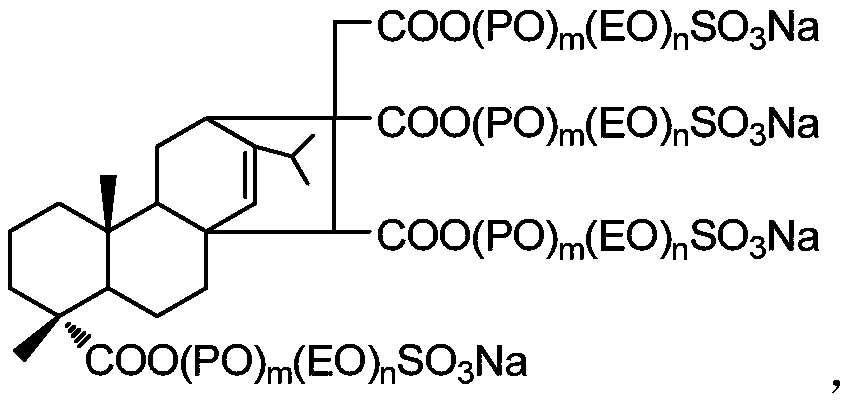

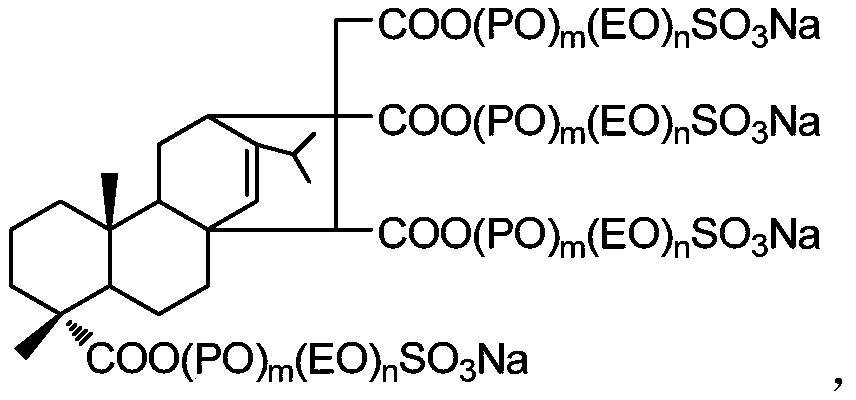

A comb-type multi-hydrophilic chain rosin block polyether sulfonate and its preparation method

ActiveCN108250428BStrong emulsificationImprove dispersion stabilityTransportation and packagingMixingSulfonatePolymer science

The invention discloses a comb-shaped multi-hydrophilic chain rosin block polyether sulfonate and a preparation method thereof. The general structural formula of the rosin block polyether sulfonate is: wherein, m is an integer of 0-100, n is an integer of 0-100, and m and n are not 0 at the same time. The preparation method is as follows: first modify the rosin with aconitic acid to obtain the aconitic acid modified rosin, then polymerize the aconitic acid modified rosin, propylene oxide and ethylene oxide to obtain the rosin block polyether, then SO 3 The rosin block polyether is sulfonated by a falling film method as a sulfonating agent to obtain a comb-shaped multi-hydrophilic chain rosin block polyether sulfonate. The rosin block polyether sulfonate of the present invention has a comb structure, has 4 hydrophilic chains, has strong emulsifying performance, good dispersion stability, and its preparation method is simple, and can be widely used in the emulsification and dispersion of pesticides, coatings, Ink and other fields.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

A kind of sulfonation method of chitosan oligosaccharide

ActiveCN109134552BHigh sulfonation rateReduce generationEsterified saccharide compoundsSugar derivativesPolymer scienceDistilled water

The invention discloses a method for sulfonating chitosan oligosaccharides, which specifically comprises the following steps: first preparing a chitosan oligosaccharide solution, and then mixing sodium dodecylbenzenesulfonate, monoalkyl titanate, ethanol and sulfuric acid solution to prepare To obtain the sulfonated reagent, add the composite sulfonated reagent into the chitosan oligosaccharide solution, stir and mix, react in a water bath at 50-90°C for 1-5h, cool to room temperature after the reaction, and place the reaction product in a dialysis bag in distilled water Dialyze, and finally dry the intercepted product to obtain sulfonated chitosan oligosaccharide. The method has the advantages of simple operation, low energy consumption, high yield and high purity of sulfonated products.

Owner:浙江工业大学上虞研究院有限公司

The synthetic method of oleic acid disodium salt

ActiveCN108484450BChange hydrophilicityImprove mass transfer efficiencyOrganic compound preparationCarboxylic acid esters preparationSodium hydrogen sulphiteEthyl acetate

The invention relates to a synthesis method of disodium oleate. The synthesis method of the disodium oleate comprises the following steps: performing reaction on oleic acid, methanol and p-toluenesulfonic acid to obtain methyl oleate; performing addition on the methyl oleate and ethylene oxide to obtain methyl oleate ethoxylate; and performing sulfonated addition reaction on an intermediate product and sodium hydrogen sulfite to obtain methyl oleate ethoxylate sulfonate, performing saponification reaction, and performing extraction and separation on ethyl acetate and a saturated sodium chloride aqueous solution of 30 percent by weight to obtain the disodium oleate. The synthesis method of the disodium oleate has the following advantages: the raw materials are rich and can be regenerated, and the sulfonation rate is high; the solvent used in the preparation process is cheap, easily available and recyclable; and reaction is mild, energy consumption is low, sulfonation rate is high and yield is high.

Owner:CHINA RES INST OF DAILY CHEM IND

A tire casting gypsum powder containing sulfonated melamine formaldehyde resin water reducing agent and its preparation method

The invention belongs to the technical field of resin and particularly relates to tire casting gypsum powder containing a sulfonated melamine formaldehyde resin water reducing agent and a preparation method of the tire casting gypsum powder. The tire casting gypsum powder containing the sulfonated melamine formaldehyde resin water reducing agent comprises raw materials of quartz, gypsum, water and the sulfonated melamine formaldehyde resin water reducing agent. Formaldehyde resin in the tire casting gypsum powder containing the sulfonated melamine formaldehyde resin water reducing agent is stable in molecular weight, and is favorable in dispersion for the gypsum powder and is high in water reducing rate in the tire casting application.

Owner:SHANDONG ZHANHUA OSITER CHEM

A resource disposal method of kraft wood pulp black liquor

ActiveCN109179845BLow viscositySave on enrichment costsMultistage water/sewage treatmentWater/sewage treatment by neutralisationBlack liquorKraft process

The invention discloses a resource disposal method for kraft wood pulp black liquor, which belongs to the fields of pulp and paper making, environmental protection and resource comprehensive utilization. In this process, the cooking black liquor from kraft wood pulp papermaking is centrifuged to remove water-insoluble matter, and then filtered with a ceramic ultrafiltration membrane, and the filtrate is reused; Purification, washing and purification, vulcanization reaction, evaporation concentration and simultaneous sulfonation modification, spray drying to produce sodium lignosulfonate. The acid analysis waste liquid is treated with alkali recovery process to recover sodium sulfide and reuse it for cooking and pulping. The present invention recycles the black liquor of kraft process wood pulp, and the produced sodium lignosulfonate product has high purity and good quality, and when used in concrete water reducer, each performance index meets the standard requirements of concrete high-efficiency water reducer .

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com