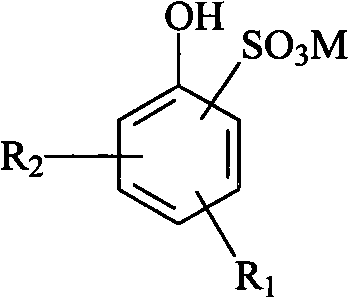

Method of using SO*-air mixture to produce alkylphenol sulfonic acid and salts thereof via film sulfonator sulfonated alkylphenol

A technology of alkyl phenol sulfonate and alkyl phenol sulfonic acid, which is applied in the preparation of sulfonate, the reaction of liquid and gas in thin film, the preparation of sulfonic acid, etc., can solve the problem of low recovery yield and consumption of sulfonated phenol. Use large organic solvents and high inorganic salt content to achieve the effects of environmental protection, high sulfonation rate and low inorganic salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of mixing potassium cresyl sulfonate

[0018] mixed cresol with SO 3 - The air mixture is metered separately into the membrane sulfonator, where the SO 3 The molar ratio with mixed cresol is 1.05:1, SO 3 - SO in the air mixture 3 The volume concentration is 3%; the sulfonation temperature is 30°C, and the sulfonation reaction is an instantaneous continuous reaction; after the reaction product passes through the gas-liquid separator, the liquid part enters the aging kettle and is aged at the sulfonation temperature for half an hour to obtain mixed cresolsulfonic acid ; Add process water to the neutralization kettle, add mixed cresolsulfonic acid and potassium hydroxide solution, carry out neutralization reaction at 30°C, stir for 2 hours, make the product pH value reach 7-9, and obtain a mass concentration of 50% Mix Potassium Cresol Sulfonate.

Embodiment 2

[0019] Embodiment 2: the preparation of 2-sec-butylphenol ammonium sulfonate

[0020] Combine 2-sec-butylphenol with SO 3 - The air mixture is metered separately into the membrane sulfonator, where the SO 3 The molar ratio to 2-sec-butylphenol is 1.3:1, SO 3 - SO in the air mixture 3 The volume concentration is 4%; the sulfonation temperature is 40°C, and the sulfonation reaction is an instantaneous continuous reaction; after the reaction product passes through the gas-liquid separator, the liquid part enters the aging kettle and is aged for 45 minutes at the sulfonation temperature to obtain 2-sec-butyl Phenolsulfonic acid; add process water to the neutralization kettle, add 2-sec-butylphenolsulfonic acid and ammonium hydroxide solution with a mass concentration of 28%, carry out neutralization reaction at 40°C, stir for 2 hours, and make the product pH Reach 7~9, obtain mass concentration and be 50% ammonium 2-sec-butylphenolsulfonate.

Embodiment 3

[0021] Embodiment 3: Preparation of p-tert-amylphenolsulfonic acid monoethanolamine salt

[0022] P-tert-amylphenol and SO 3 - The air mixture is metered separately into the membrane sulfonator, where the SO 3 The molar ratio to p-tert-amylphenol is 1.1:1, SO 3 - SO in the air mixture 3 The volume concentration is 5%; the sulfonation temperature is 50°C, and the sulfonation reaction is an instantaneous continuous reaction; after the reaction product passes through the gas-liquid separator, the liquid part enters the aging kettle and is aged at the sulfonation temperature for 1 hour to obtain p-tert-amyl Phenolsulfonic acid; add process water to the neutralization kettle, add p-tert-amylphenolsulfonic acid and monoethanolamine, carry out neutralization reaction at 50°C, stir for 2 hours, make the pH value of the product reach 7-9, and obtain the mass concentration It is 60% p-tert-amylphenol sulfonic acid monoethanolamine salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com