Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "High oil film strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle engine oil additive and engine oil

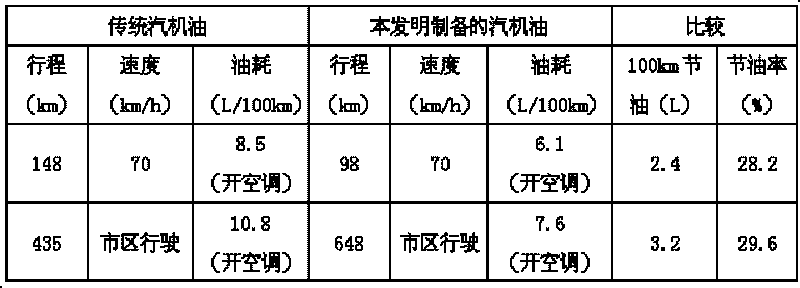

The invention provides a vehicle engine oil additive and engine oil. The additive comprises the following components: 15 to 34 weight percent of nano WS2 powder, 0 to 24 weight percent of nano MoS2 powder, 20 to 20.5 weight percent of dispersant, 0 to 0.5 weight percent of antioxidant, 0 to 1 weight percent of metal passivant and the balance of base oil, wherein the kinematic viscosity of the base oil at 40 DEG C is 70 to 190mm2 / s, and the kinematic viscosity of the base oil at 100 DEG C is 12 to 20mm2 / s. The engine oil of the invention comprises 5 to 20 weight percent of additive and 80 to 95 weight percent of petrolic oil or comprises 15 to 25 weight percent of additive and 75 to 85 weight percent of diesel engine oil. The engine oil can improve the service life of engine, reduce oil consumption and has obvious energy-saving and emission-reducing effects and other effects.

Owner:CENT SOUTH UNIV

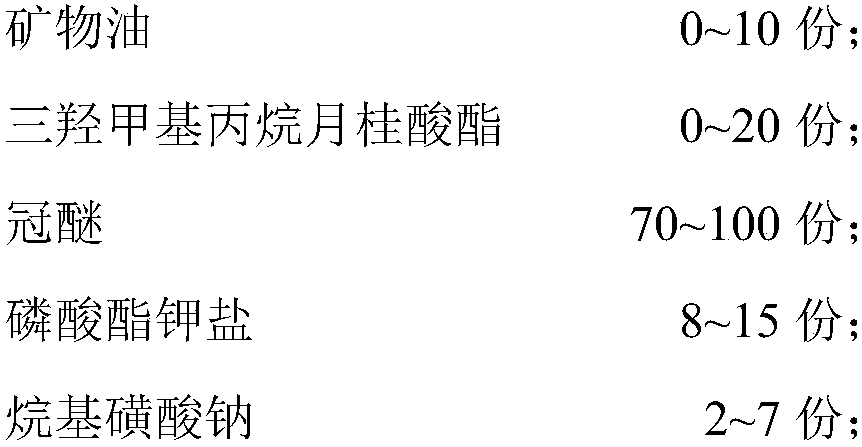

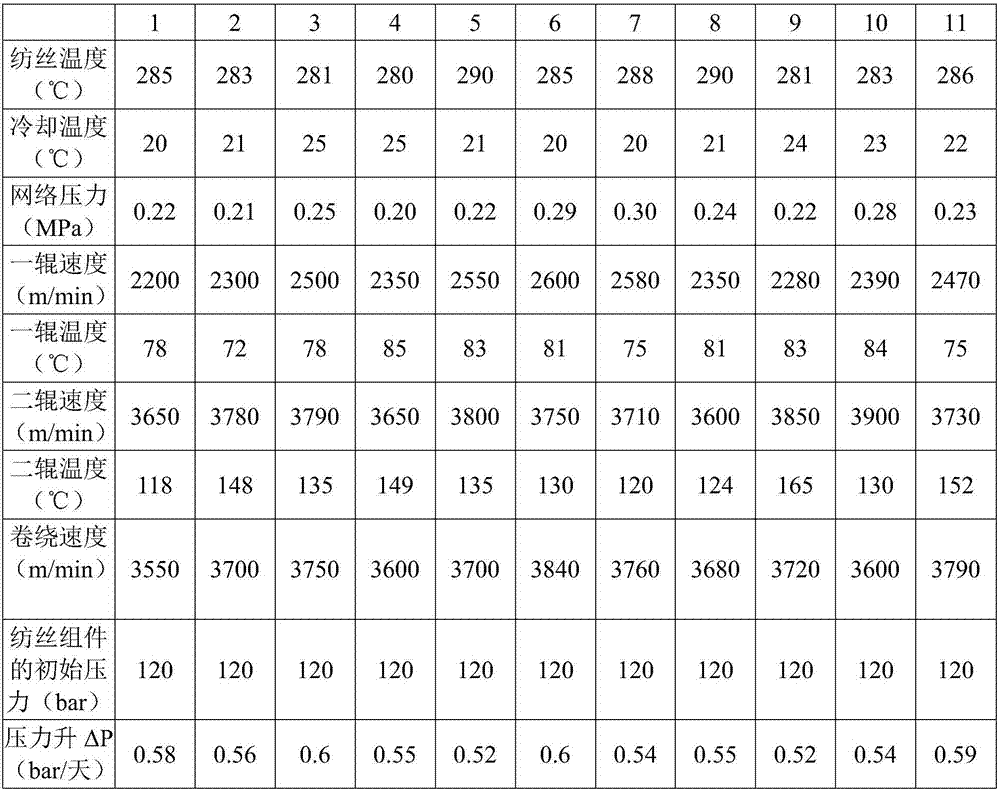

Low-shrinkage high-strength polyester industrial yarn and preparation method thereof

ActiveCN108385189AIncrease the cross-sectional areaReduce the temperatureSpinnerette packsFibre typesYarnThermal insulation

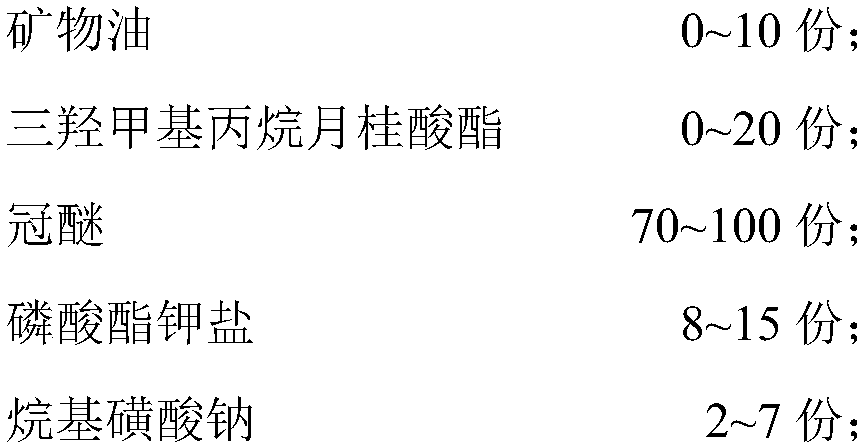

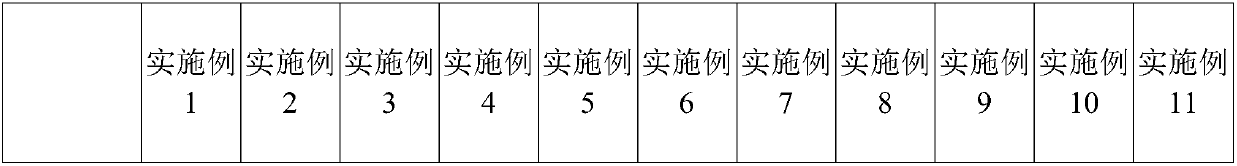

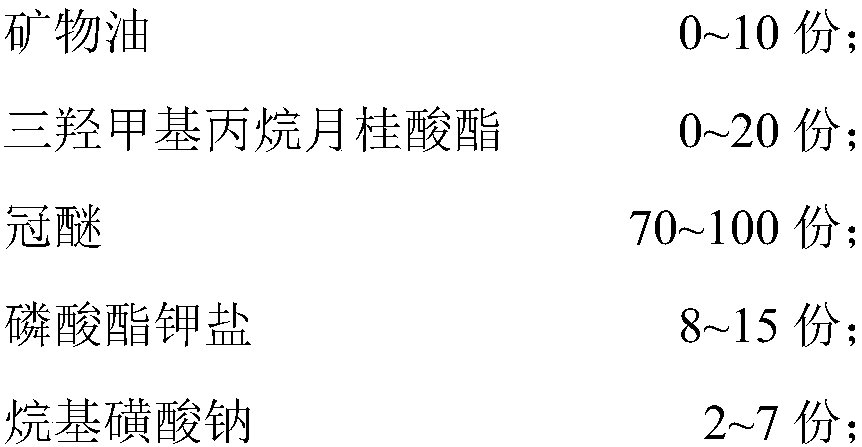

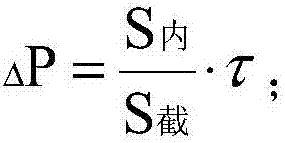

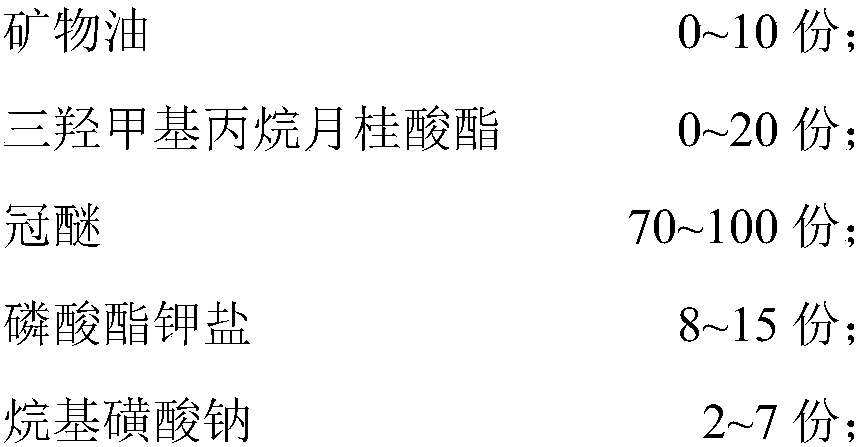

The invention relates to a low-shrinkage high-strength polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, and winding, wherein the unchanged longitudinal height is maintained during thecooling, the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method, and the oil agent for oiling contains 67.30-85.58 wt% of crown ether. According to the present invention, the preparation method is simple; the material of the prepared low-shrinkage high-strength polyester industrial yarn is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the fracture strength is more than or equal to 7.3 cN / dtex, and the dry heat shrinkage rates at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex respectively are 1.8+ / -0.5% and 3.5+ / -0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

Soft polyester fiber and preparation method thereof

ActiveCN108048940ALow viscosityHigh viscosityMonocomponent copolyesters artificial filamentMelt spinning methodsBreaking strengthSmallerThan

The invention relates to soft polyester fiber and a preparation method thereof. The preparation method comprises steps as follows: modified polyester is subjected to metering, extrusion, cooling, oiling, stretching, heat setting and winding, and the soft polyester fiber is prepared, wherein an oil agent for oiling contains 67.30wt%-85.58wt% of crown ether. The soft polyester fiber is prepared frommodified polyester with a molecular chain containing a terephthalic acid chain segment, an ethylene glycol chain segment and an adipic acid chain segment and has the initial modulus smaller than or equal to 80 cN / dtex, the fineness of 75-300 dtex, the breaking strength higher than or equal to 3.6 cN / dtex, the elongation at break of 45.0% plus or minus 3.0%, the breaking strength CV value smallerthan or equal to 5.0%, the breaking elongation CV value smaller than or equal to 10.0%, the boiling water shrinkage of 7.5% plus or minus 0.5% and the oil content of 0.90% plus or minus 0.20%. The preparation method is simple, and the acquired polyester fiber has better flexibility and very considerable application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

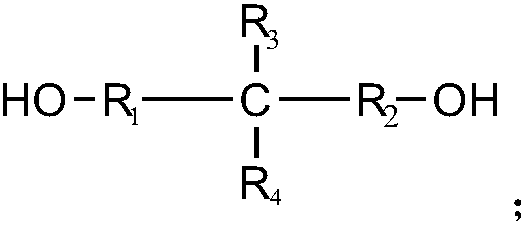

Low-shrinkage polyester industrial filament and preparation method thereof

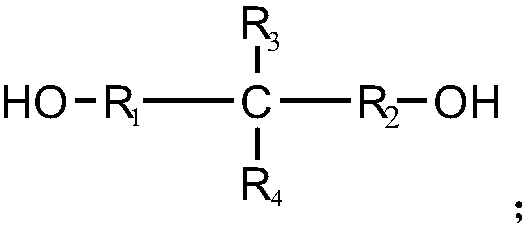

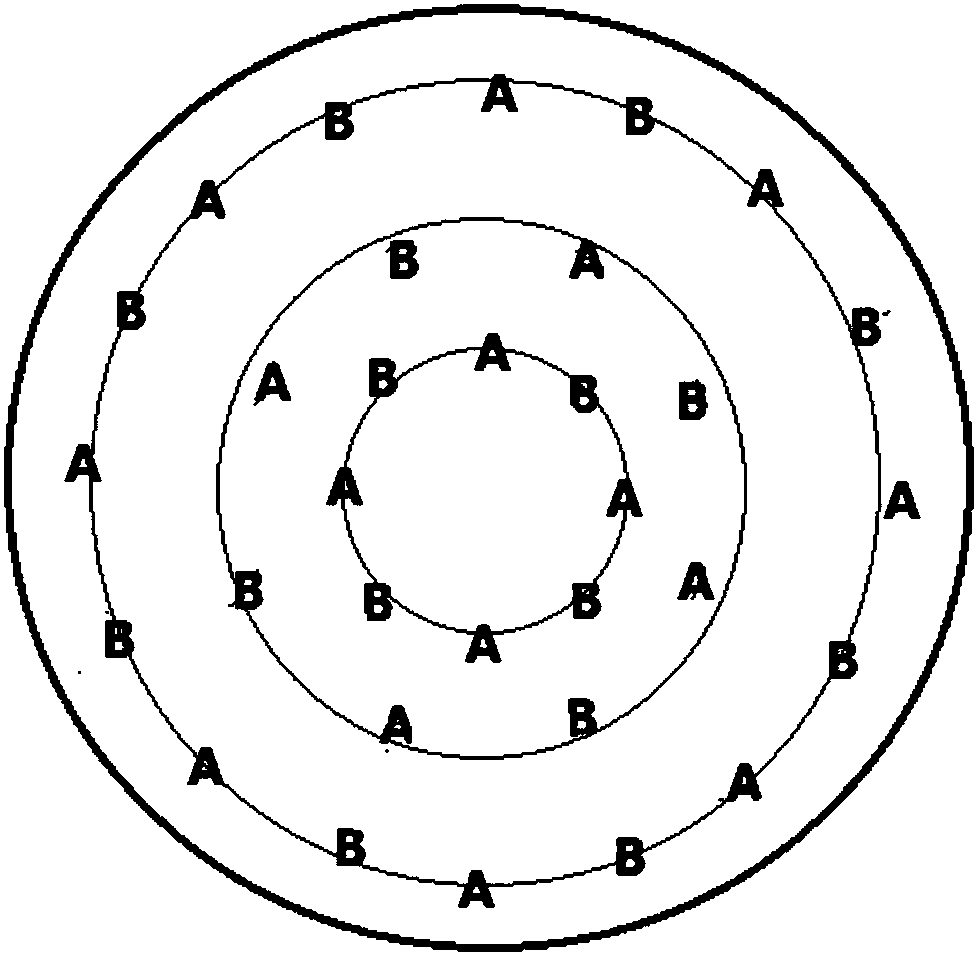

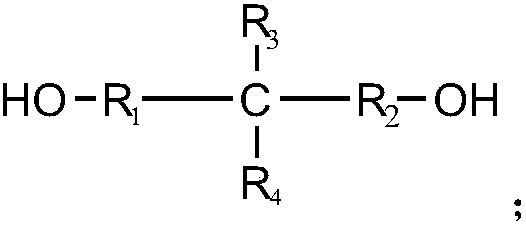

ActiveCN108130609ALow dry heat shrinkageSimple preparation processFilament/thread formingMonocomponent copolyesters artificial filamentStructural formulaConductor Coil

The invention relates to a low-shrinkage polyester industrial filament and a preparation method thereof. The preparation method comprises that modified polyester is subjected to solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding, wherein an oil agent for oiling contains crown ether, and the content of the crown ether is 67.30-85.58 wt%. The preparation method is simple and reasonable; the dry-hot shrinkage rate of the finally prepared low-shrinkage polyester industrial filament under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex is 2.5-4.7%. The low-shrinkage polyester industrial filament is made of the modified polyester, and a molecular chain of the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3, R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5.

Owner:JIANGSU HENGLI CHEM FIBER

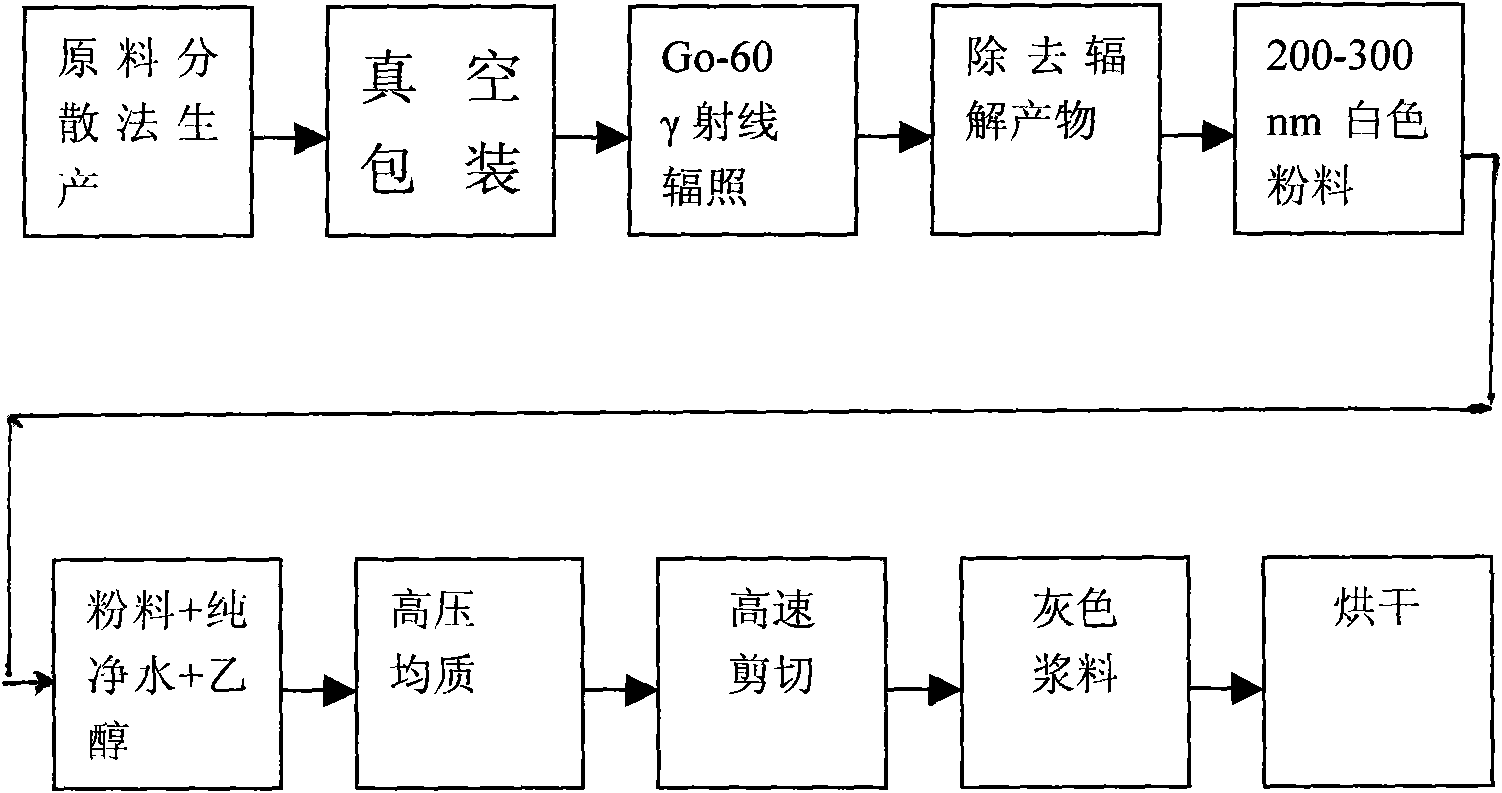

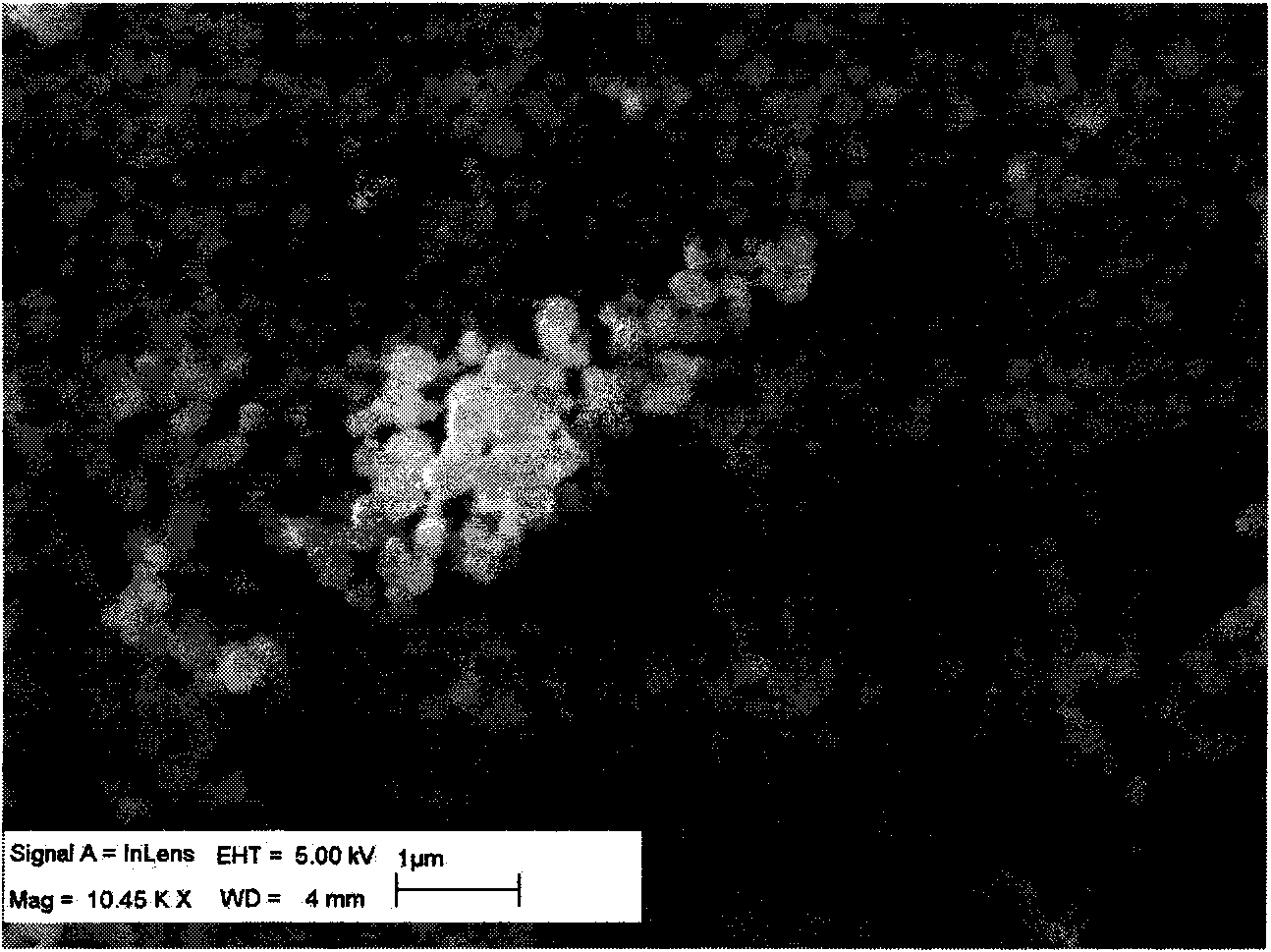

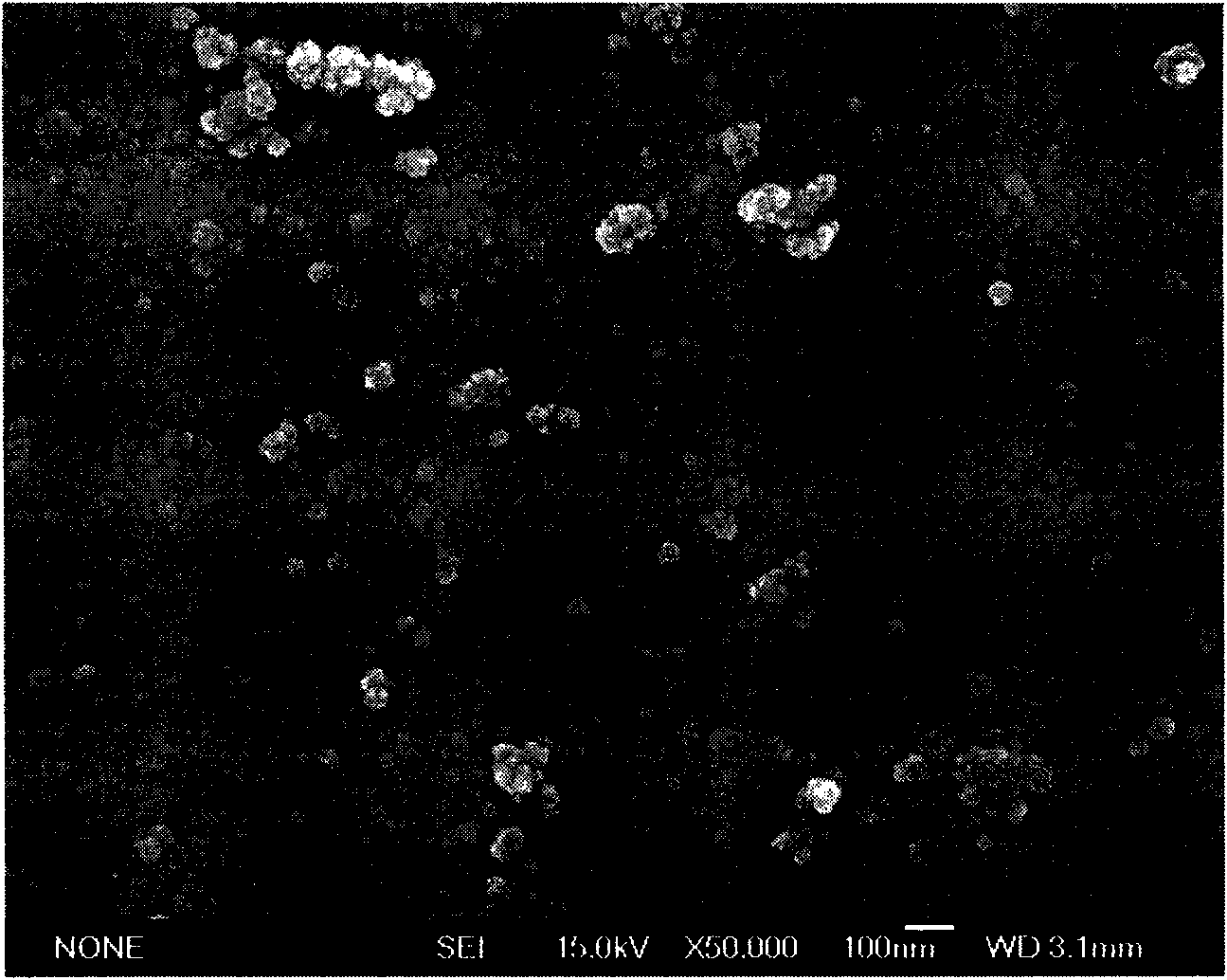

Polytetrafluoroethylene nanoscale powder material and preparation method thereof

InactiveCN101638487AReduce coefficient of frictionImprove extreme pressure performancePerformance indexPolytetrafluoroethylene

The invention relates to a polytetrafluoroethylene nanoscale powder material which is characterized in that the particle diameter of the polytetrafluoroethylene nanoscale powder material is 20nm-50nm,and the color of the polytetrafluoroethylene nanoscale powder material is gray. In the invention, when the polytetrafluoroethylene material is pulverized to 20nm-50nm, compared with the original polytetrafluoroethylene material, the color and two performance indexes are obviously changed: (1) the lubricating performance is changed, the friction coefficient is obviously reduced, and the diameter of a worn spot is reduced to 0.33mm from 0.58mm; and (2) the capability of resisting the extreme pressure is increased. In a lubricating oil system, the test data of the increase of the capability of resisting the extreme pressure is improved in multiples, wherein the test data is improved to 6080N from 2500N.

Owner:SHANGHAI LINGMU NEW MATERIAL TECH CO LTD

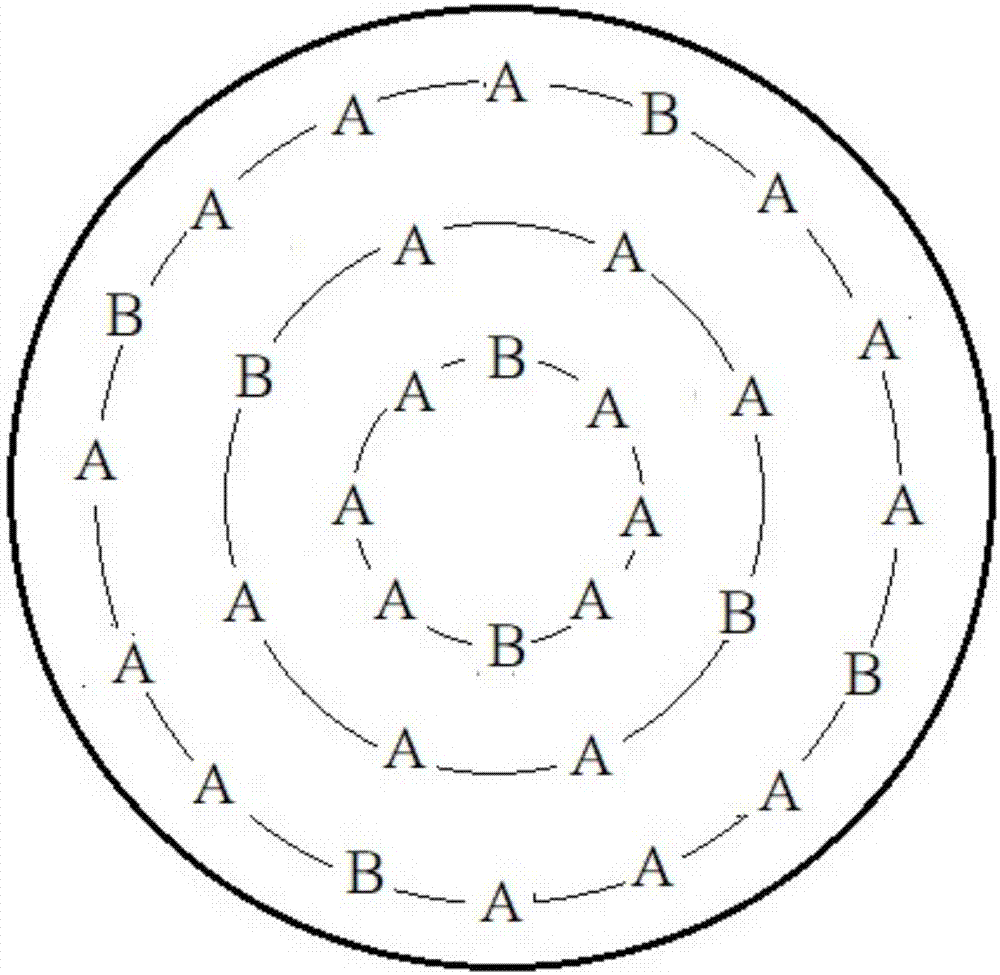

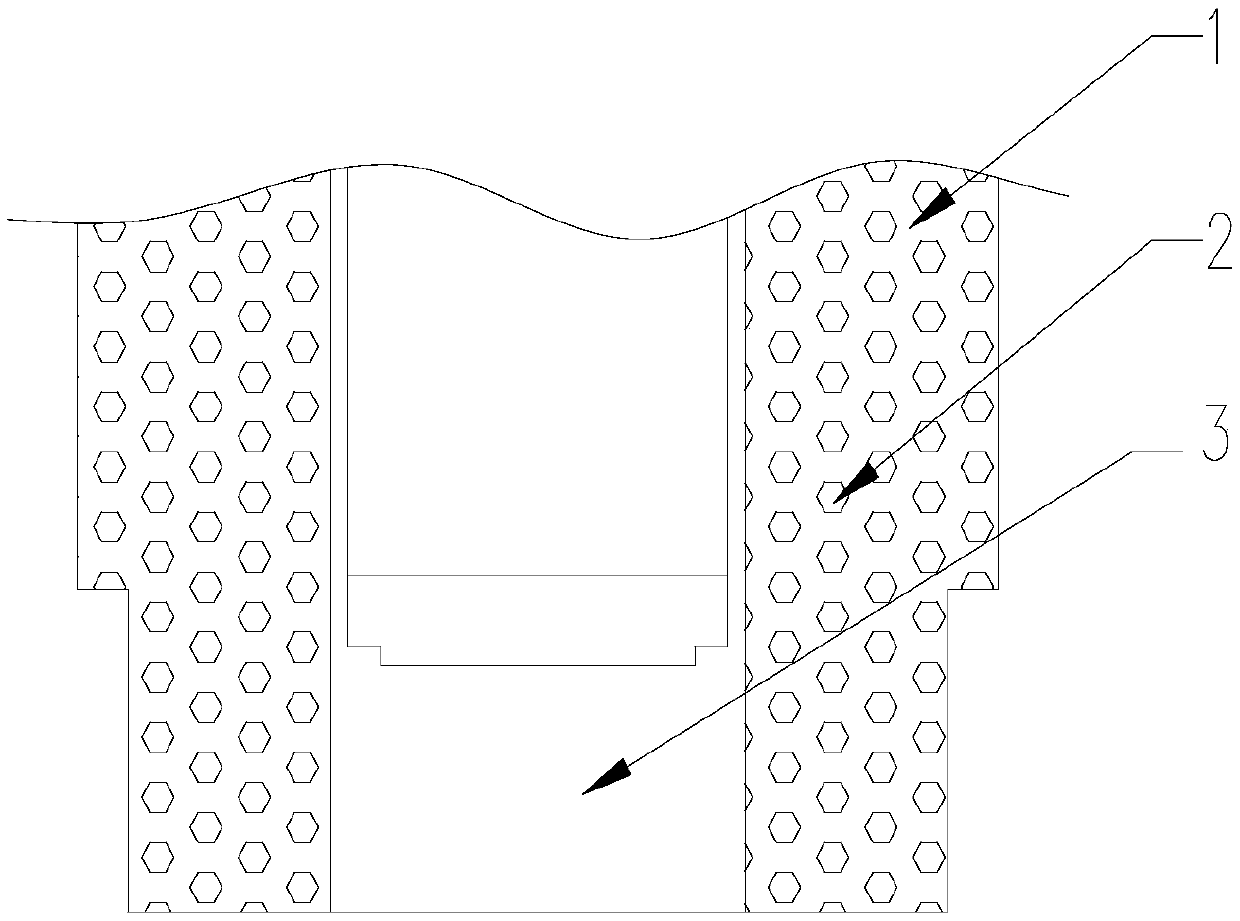

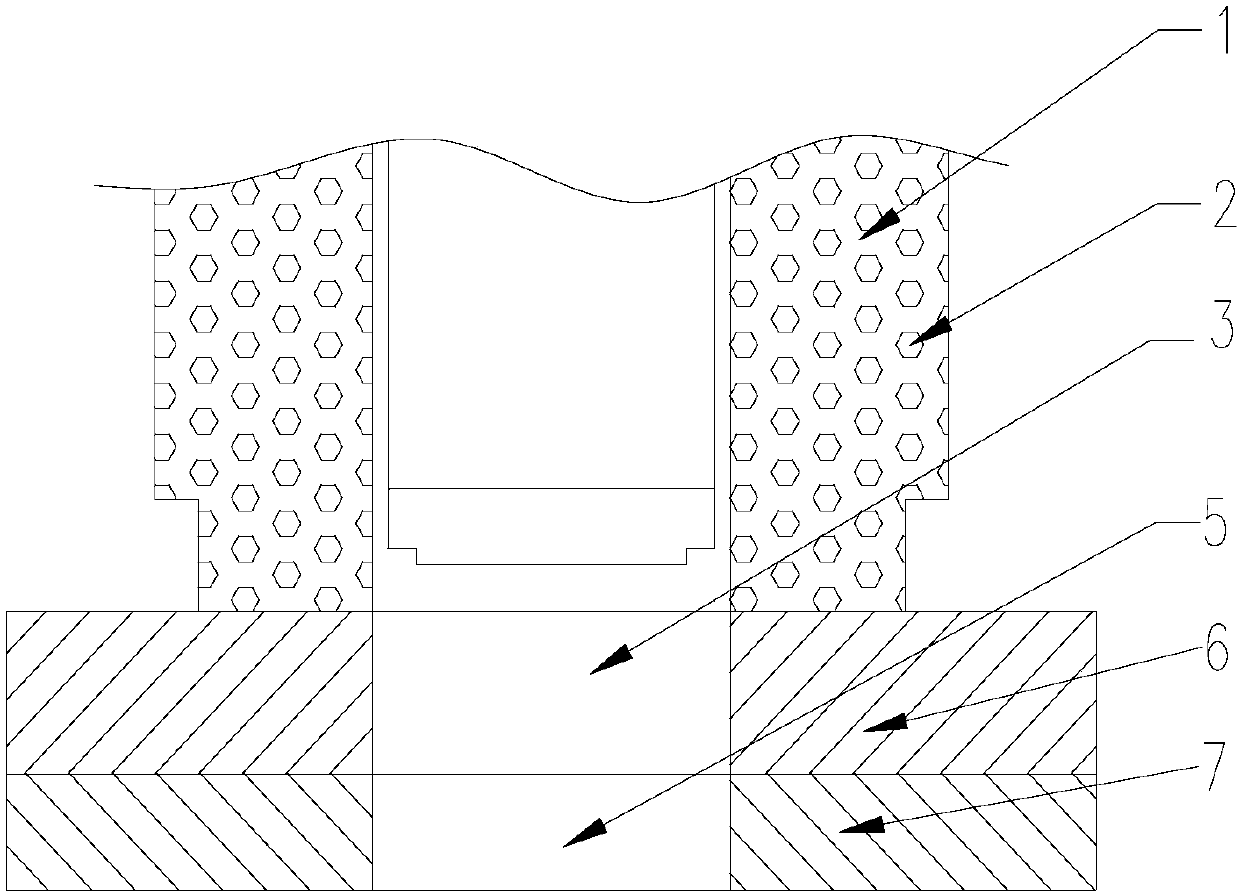

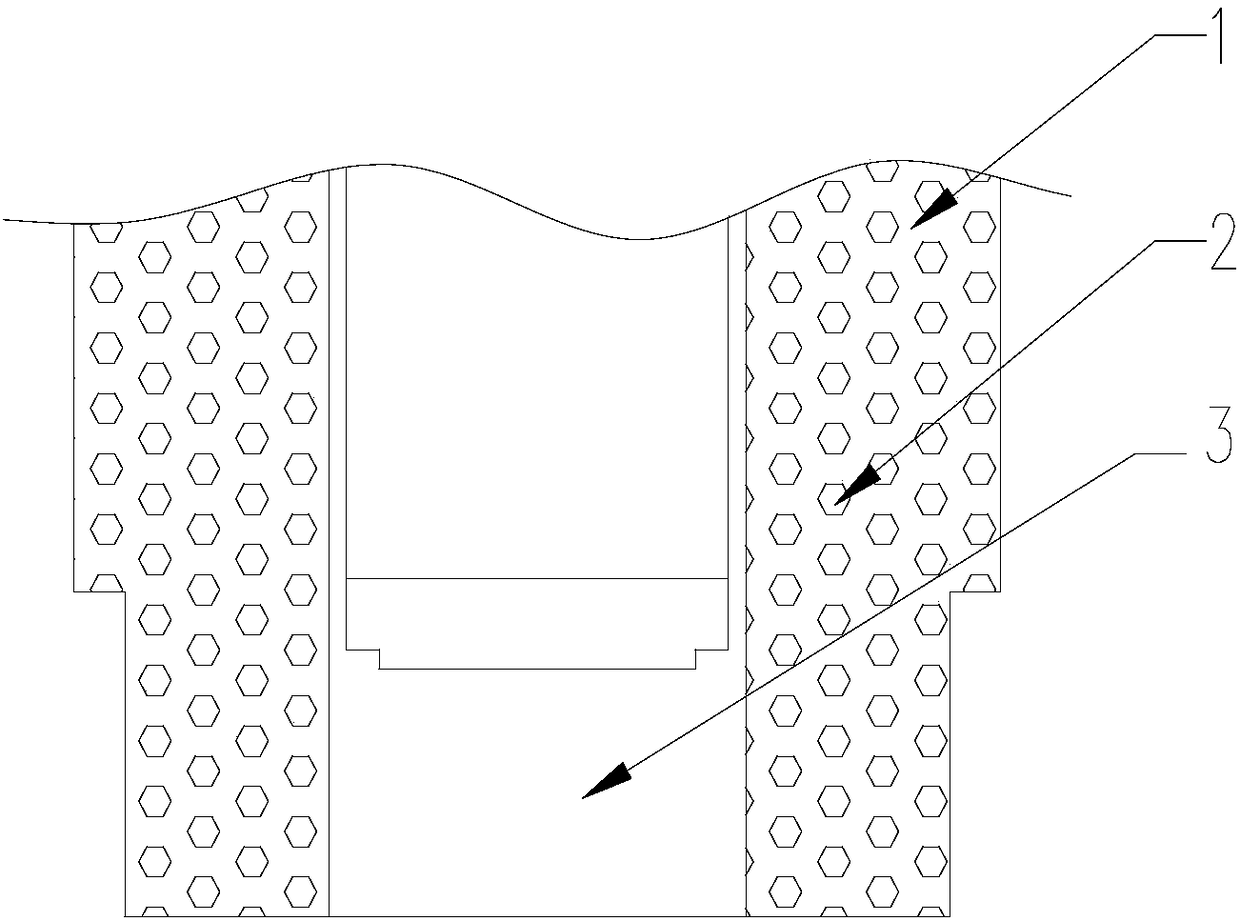

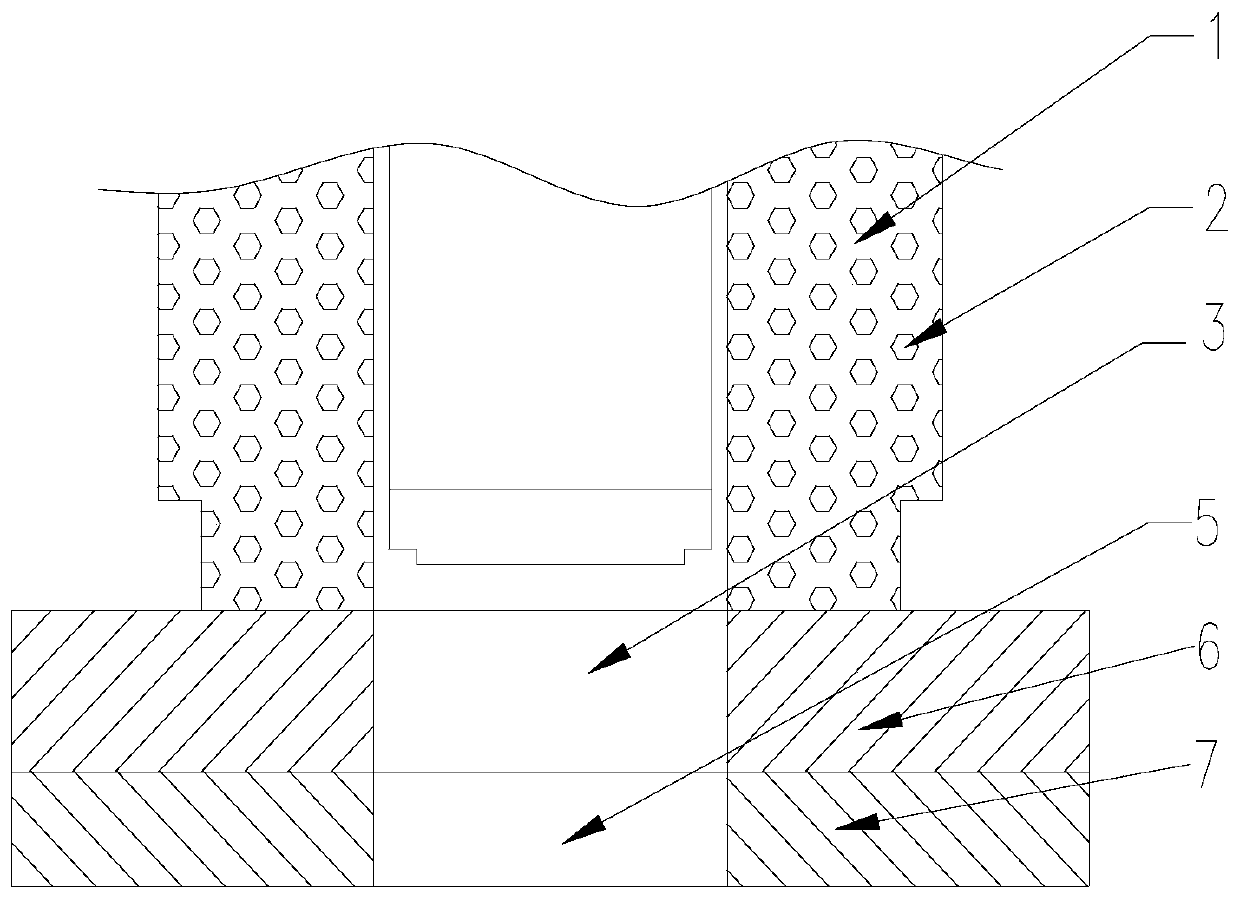

Rolled lubricating process of rolling band-steel

ActiveCN101028632AGood adhesionImprove sintering resistanceRollsMetal rolling arrangementsStrip steelPetroleum engineering

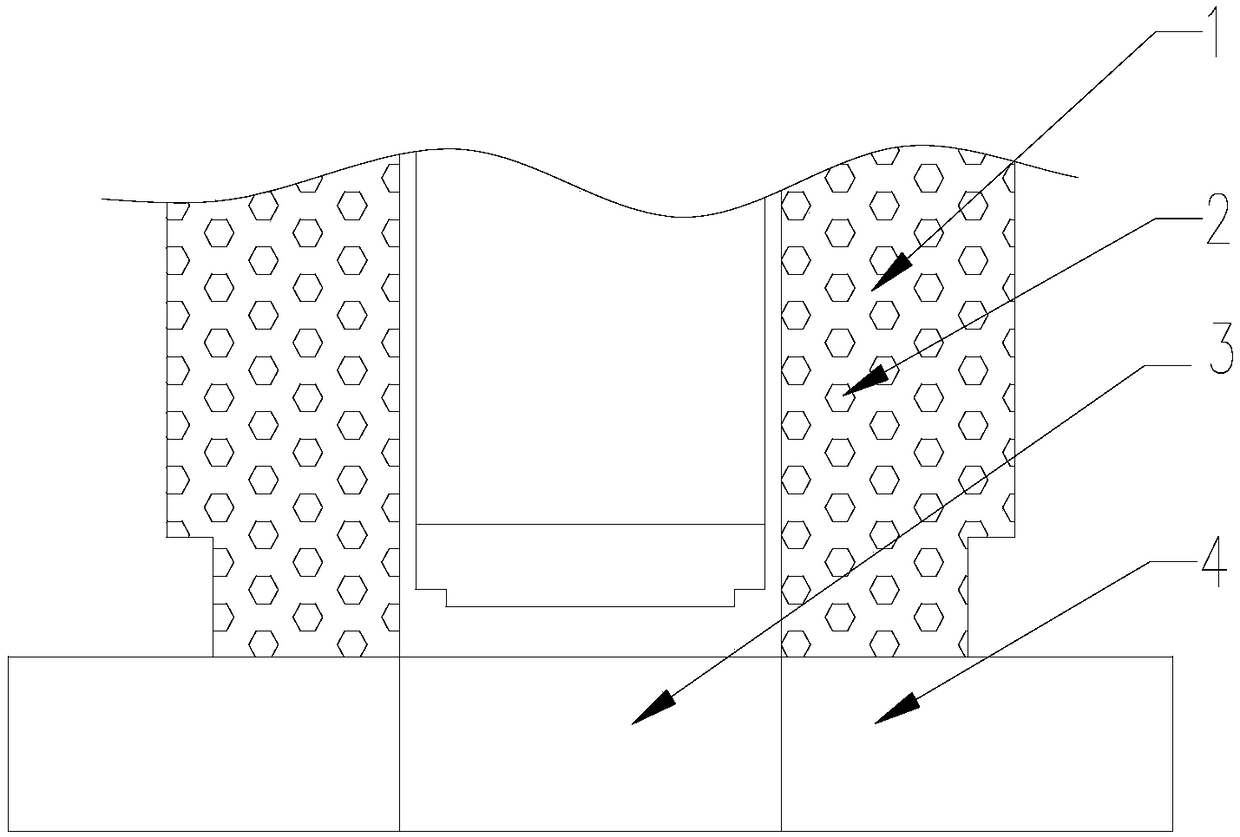

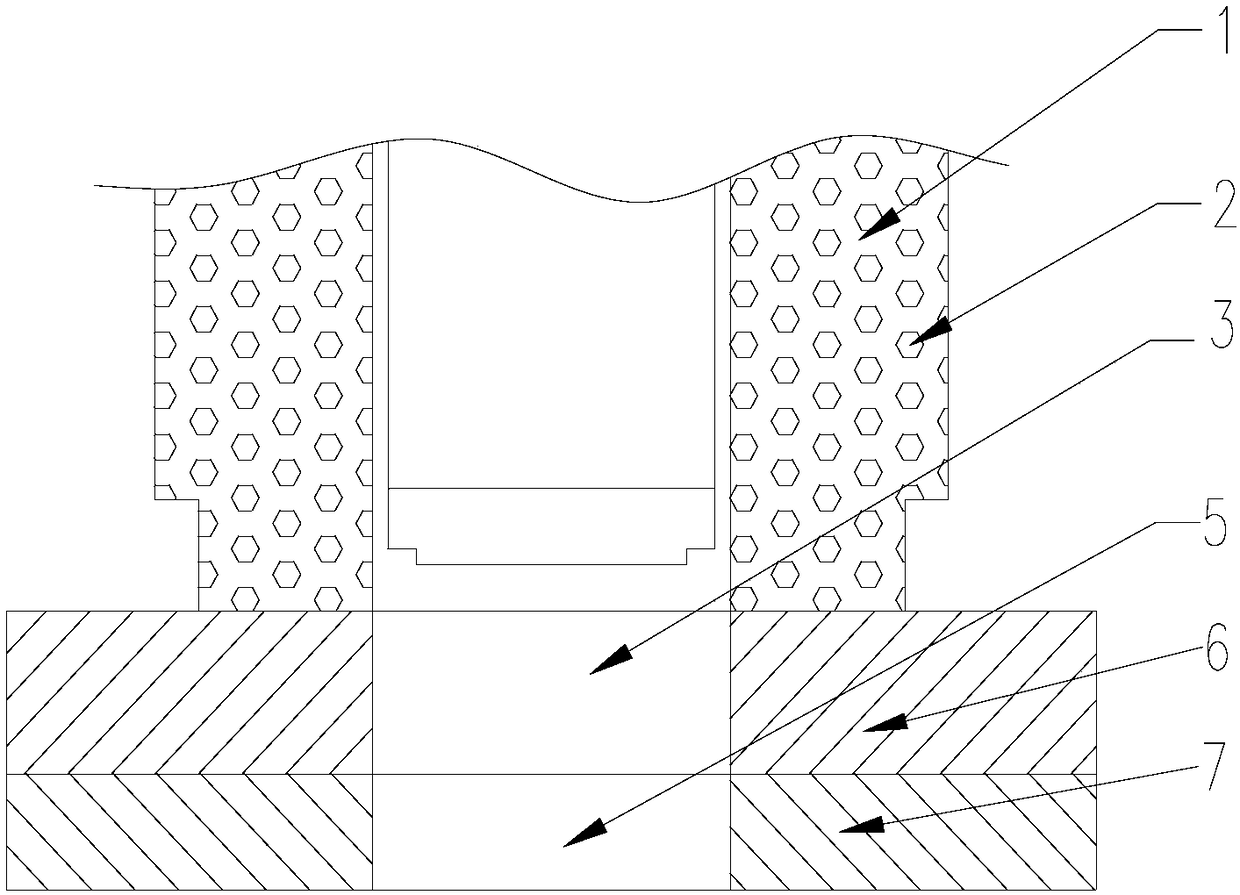

A roller-type lubricating method for rolling steel band features that the lubricating oil is transferred via oil tube onto the oil applying roller pressed on the working roller, and the oil applying roller is driven to rotate by said working roller to coat the surface of working roller to form an oil film layer.

Owner:BAOSHAN IRON & STEEL CO LTD

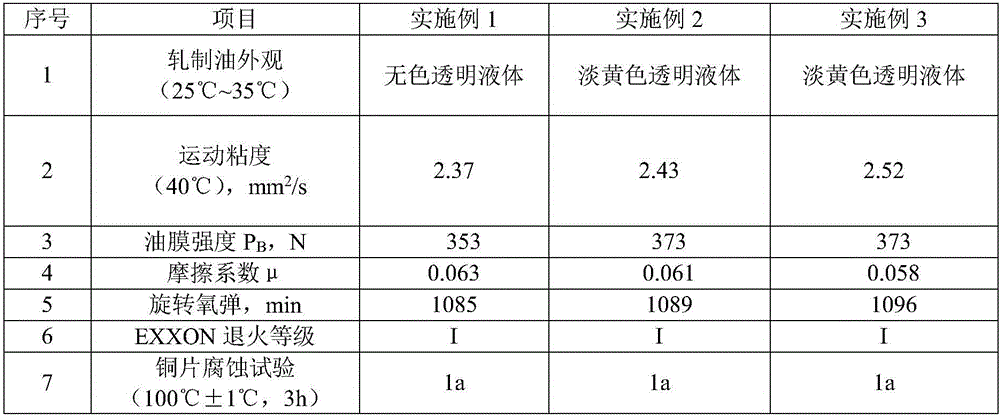

Universal nonferrous metal and stainless steel cold rolling oil composite additive and preparation method thereof

ActiveCN106566598AImprove anti-friction and anti-wear effectImprove anti-wear and anti-friction performanceAdditivesAntioxidantSolvent

The invention provides a universal nonferrous metal and stainless steel cold rolling oil composite additive and a preparation method thereof and belongs to the field of lubricating agents. According to the universal nonferrous metal and stainless steel cold rolling oil composite additive, lauryl alcohol, butyl stearate, pentaerythritol oleate and lauric acid are selected as oily agents; 2,6-di-tert-butyl-4-methylphenol is selected as an antioxidant; benzotriazole and thiadiazole derivatives are used as metal deactivators; dialkyl phosphorodithioate serves as an antiwear agent; and hydrogenated base oil serves as a solvent. The alcohol-ester type oily agents are mainly used for compounding with a little amount of acid oily agents as supplementation; a little amount of dialkyl phosphorodithioate is used as the antiwear agent to reinforce an oil film so as to improve the surface quality of a rolled stock; the service life of rolling oil is prolonged through a little amount of the antioxidant and the metal deactivators, the cyclic use frequency is increased, and rolled pieces are protected against corrosion. The universal nonferrous metal and stainless steel cold rolling oil composite additive is convenient to use, low in cost and little in dosage, and has the characteristics of high oil film strength, good antiwear and antifriction effect, high oxidation resistance and excellent annealing performance.

Owner:UNIV OF SCI & TECH BEIJING

Hot and humid and comfortable polyester fiber FDY silk for winter and preparation method thereof

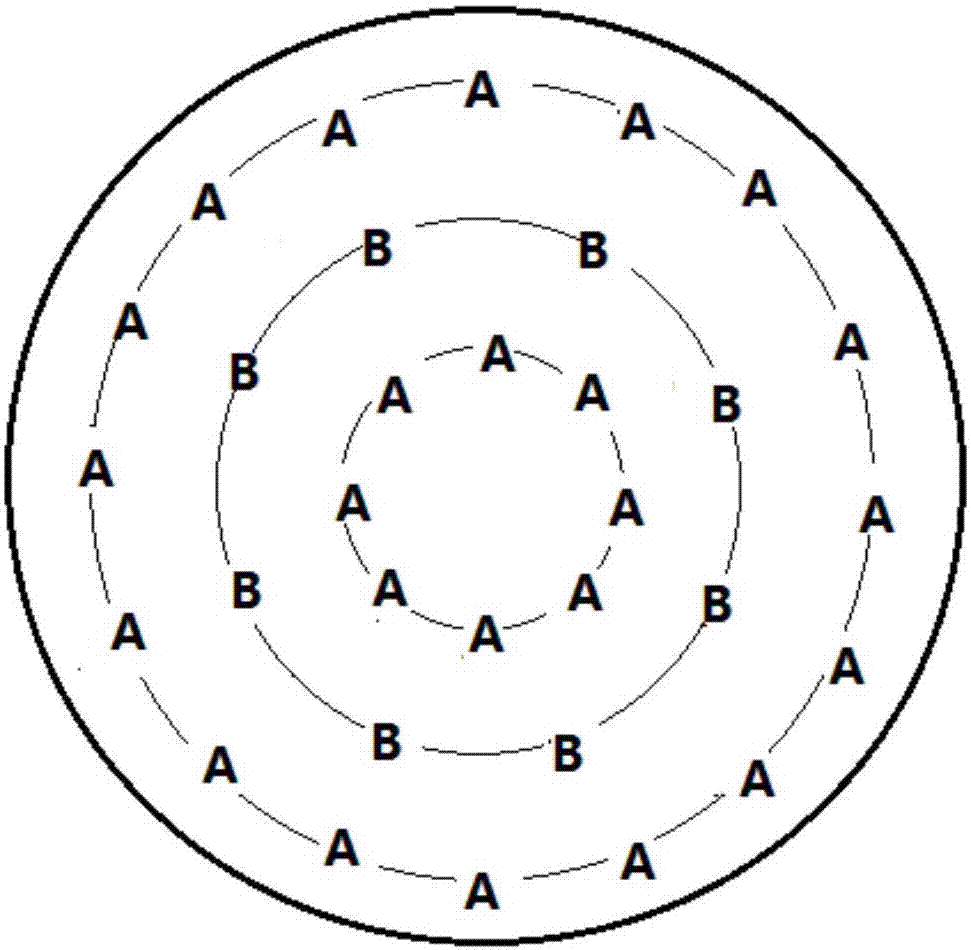

ActiveCN108035009AGood thermal and humidity comfortEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a hot and humid and comfortable polyester fiber FDY silk for winter and a preparation method thereof. The preparation method comprises the following steps that the hot and humid and comfortable polyester fiber FDY silk for winter is prepared by conducting weighing, extrusion by a composite spinneret plate, cooling, oiling, stretching, heat shaping and winding on a spinningmelt, the texture of the silk is polyester with a matte agent being dispersed, the thermal resistance of the obtained woven fabric is higher than or equal to 0.18m<2>. DEG C / W, the moisture vapor resistance of the woven fabric is lower than or equal to 14 Pa.m<2> / W, cross-shaped spinneret orifices and double-cross-shaped spinneret orifices are formed in the composite spinneret plate simultaneously, the micropore length ratio of the cross-shaped spinneret orifices and the double-cross-shaped spinneret orifices is equal to product of the equivalent diameter ratio and the coefficient K, the value range of the coefficient K is between 0.97 and 1.03, an oiling agent used in the oiling contains crown ether, and the content of crown ether is 67.30-85.58wt%. The preparation method is simple, theobtained polyester fiber FDY is excellent in thermal-wet comfort, and has considerable application prospects.

Owner:JIANGSU HENGLI CHEM FIBER

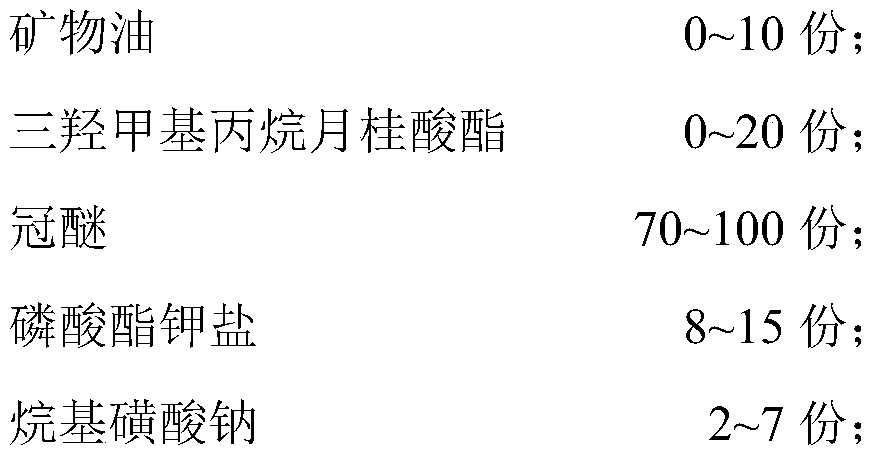

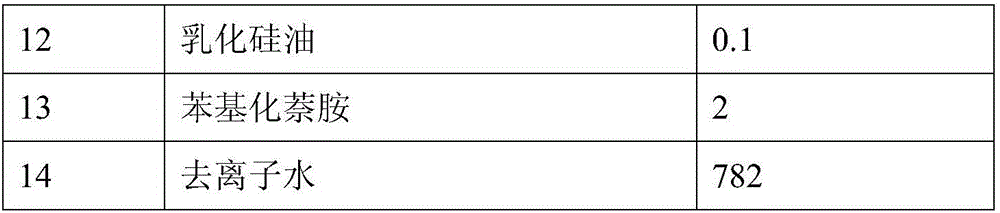

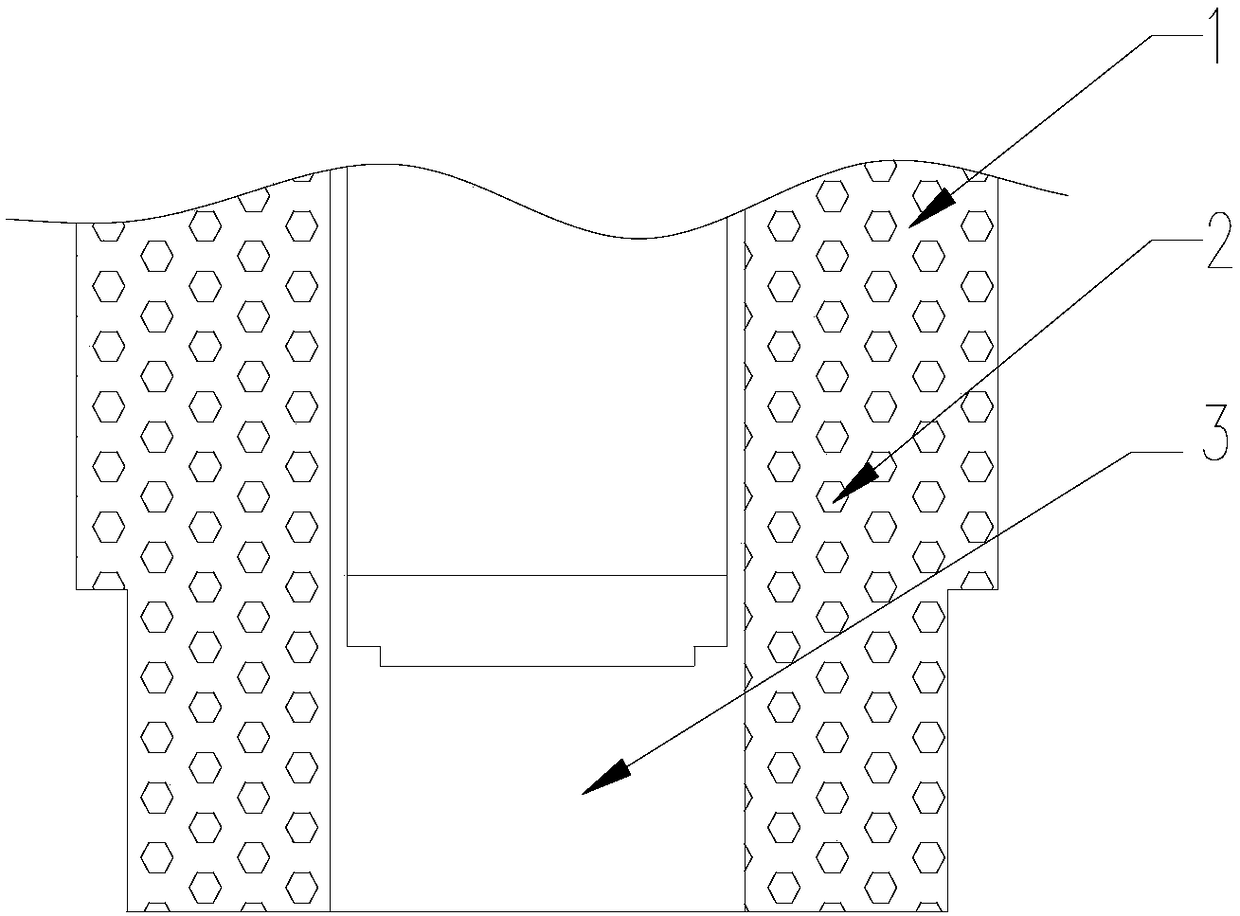

Magnesium alloy plate and strip rolling emulsion and preparation method thereof

ActiveCN106566640AHigh strengthReduce coefficient of frictionLubricant compositionAntioxidantFatty acid

The invention discloses a magnesium alloy plate and strip rolling emulsion and a preparation method thereof, and relates to the field of lubricants and magnesium alloy plate and strip rolling. The magnesium alloy plate and strip rolling emulsion with lubricating, antirust, cleaning, environmental protection and recycling properties is prepared through selecting pentaerythritol oleate, mixed acid ester of trimethylol propane and PAO-10 as base oil, TX-4 and TX-7 as an emulsifier, butyl stearate and C12-14 alcohol as an oily agent, phosphate ester and nitrogen-containing borate as an extreme pressure agent, triethanolamine and fatty acid alkanolamide as an antirust agent, emulsified silicone oil as an antifoaming agent and phenyl naphthylamine as an antioxidant. The emulsion has the advantages of reduction of damages caused by plate and strip surface adhesion, reduction of the corner cracking of products, wash-off of a large amount of magnesium powder generated in the rolling process, effective improvement of the surface quality and the dimension precision of the products, and reduction of the enterprise's production cost.

Owner:UNIV OF SCI & TECH BEIJING

Superfine dacron low stretch yarn and preparation method thereof

ActiveCN107988649AEasy to spreadImprove fiber qualityFibre typesMonocomponent copolyesters artificial filamentPolyesterYarn

The invention relates to a superfine dacron low stretch yarn and a preparation method thereof. Modified polyester fusant is subjected to metering, extrusion, cooling, oiling and winding to prepare POYyarns; the POY yarns are subjected to yarn guide tube passing, networking, heating stretching, false twisting, heat setting and winding formation to prepare DTY yarns, i.e., the superfine dacron lowstretch yarn is obtained. During cooling, the longitudinal height is kept unchanged; the cross section area of a slow cooling chamber is increased; meanwhile, the slow cooling chamber maintains the plate surface temperature of a spinneret plate in a heat insulation mode; an oil agent for oiling contains crown ether; the content of the crown ether is 67.30 to 85.58 weight percent; the dihydric alcohol chain segment with branched chain is introduced into modified polyester; the prepared superfine dacron low stretch yarn has the filament number being smaller than 0.3dtex; the crimp shrinkage is 8.0+ / -1.0 percent; the crimp stability is greater than or equal to 75 percent. The method is simple and reasonable; the prepared superfine dacron low stretch yarn has the advantage of low fiber number.

Owner:JIANGSU HENGLI CHEM FIBER

Full-dull polyester and polyester composite yarn and preparation method thereof

ActiveCN107988635ASoft lusterSoft touchSpinnerette packsFibre typesYarnPolyethylene terephthalate glycol

The invention relates to a full-dull polyester and polyester composite yarn and a preparation method thereof. According to the preparation method, dull PET (polyethylene terephthalate) melts and super-bright PET melts are metered, extruded by a composite spinneret plate, cooled, coated with oil and wound to prepare POYs (polyester pre-oriented yarns); the POYs are heated, drawn, falsely twisted, shaped in a heating manner and wound to prepare DTYs (draw texturing yarns) through a yarn guide pipe and a network, namely, the full-dull polyester and polyester composite yarn. An oil agent for oiling contains crown ether, the content of the crown ether is 67.30-85.58wt%, a full-dull polyester and polyester composite yarn extruded by the same composite spinneret plate simultaneously contain dullPET monofilaments dispersed matt agents and super-bright PET monofilaments dispersed matt agents, the matt agents are mixture of unformed titanium dioxide and unformed silicon dioxide or mixture of calcium carbonate and unformed silicon dioxide, and the composite yarn gloss is lower than 20%. The preparation method is simple, the smooth spinning of fibers is achieved in the preparation process, and fabrics prepared by the method are excellent in performance and has great application values.

Owner:JIANGSU HENGLI CHEM FIBER

High-modulus low-shrinkage stiff cord and preparation method thereof

ActiveCN108385418AIncrease the cross-sectional areaReduce the temperatureFibre typesFilament/thread formingYarnSlow cooling

The invention relates to a high-modulus low-shrinkage stiff cord and a preparation method thereof. The preparation method comprises the following steps: performing solid-phase polycondensation-viscosity enhancement, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding to obtain high-modulus and low-shrinkage polyester industrial yarns; twisting to obtain a cord; making the cord into a high-modulus low-shrinkage stiff cord by a two-bath impregnation method, wherein during cooling, the longitudinal height is kept constant and the cross-sectional area of a slow cooling chamber is increased; meanwhile, the surface temperature of a spinneret plate is kept in a heat preserving way in the slow cooling chamber; an oiling agent contains 67.30 to 85.58 percent by weight of crown ether; during use of the oiling agent, 14 to 18 percent by weight emulsion is prepared with water. The preparation method disclosed by the invention is simple; the prepared high-modulus low-shrinkage stiff cord is made from modified polyester of which the molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain, is greater than or equal to 80N in breaking strength, and is greater than or equal to 37KN / m in cord bonding strength.

Owner:JIANGSU HENGLI CHEM FIBER

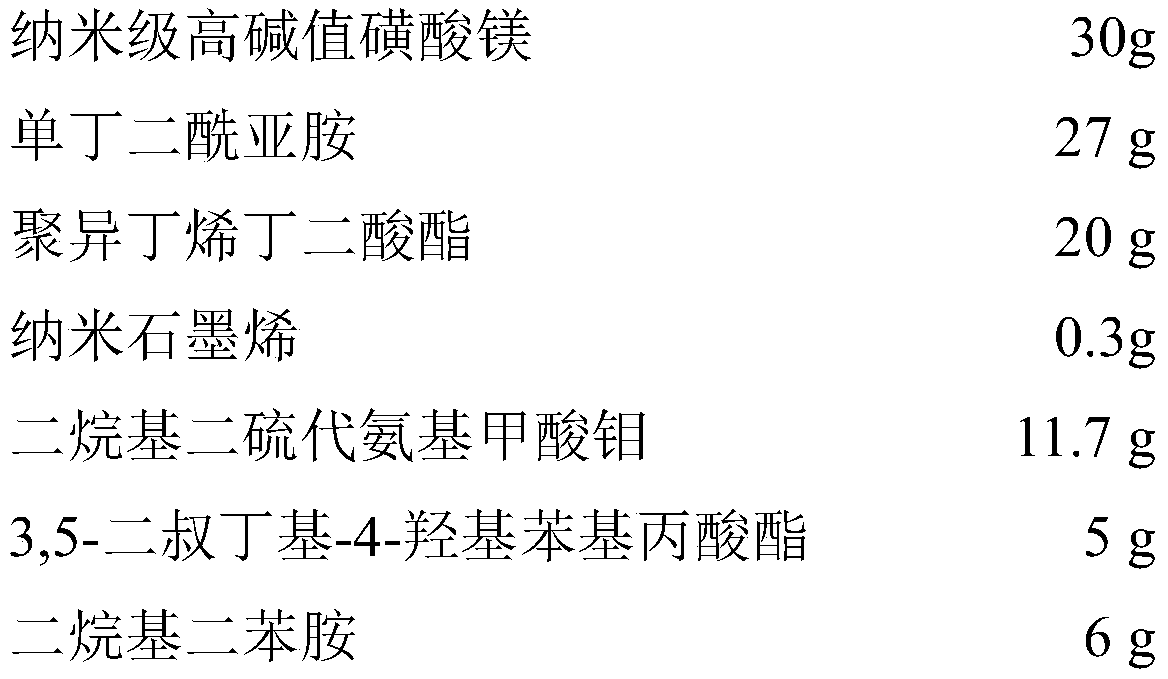

Coal-based fully-synthetic SN-grade lubricating oil and preparation method thereof

ActiveCN111234907AReduce manufacturing costGood low temperatureLubricant compositionFoaming agentGasoline

The invention relates to the field of lubricating oil, and provides coal-based fully-synthetic SN-grade lubricating oil and a preparation method thereof. The lubricating oil solves the problem that atraditional method for improving the performance of lubricating oil through cooperation of petroleum-based base oil and an additive cannot meet requirements. The coal-based fully-synthetic SN-grade lubricating oil comprises the following components in percentage by weight: 40-55wt% of 1# coal-based base oil, 25-40wt% of 2# coal-based base oil, 7-10wt% of a gasoline engine oil complexing agent, 0.3-0.8 wt% of a pour point depressant, 6-10wt% of a viscosity index improver and 0.02 wt% of a composite anti-foaming agent, the preparation method comprises the steps of compounding agent preparation,base oil blending and lubricating oil preparation. The obtained product lubricating oil has excellent low-temperature performance and antioxidant and anti-wear performance, has longer service life compared with existing fully synthetic lubricating oil of the same grade, and shows better fuel economy.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

Hot-wet comfortable polyester fiber FDY filament for summer and preparation method of hot-wet comfortable polyester fiber FDY filament

ActiveCN108035010AGood thermal and humidity comfortEasy to processNew-spun product collectionFibre typesChemistryPolyester

The invention relates to a hot-wet comfortable polyester fiber FDY filament for summer and a preparation method of the hot-wet comfortable polyester fiber FDY filament. The preparation method comprises the following steps: measuring spinning melt, extruding by a composite spinneret plate, cooling, oiling, stretching, thermally shaping and coiling, thus obtaining the hot-wet comfortable polyester fiber FDY filament for summer which is made of polyester dispersed with a matt agent, a core absorption height of a prepared woven fabric is greater than or equal to 135 mm, an evaporation rate of thewoven fabric is greater than or equal to 0.22g / h, the composite spinneret plate is simultaneously provided with a cross spinneret hole and a circular spinneret hole, a length ratio of micropores of the cross spinneret hole and the circular spinneret hole is equal to a product of an equivalent diameter ratio and a coefficient K, a valuing range of the coefficient K is 0.97 to 1.03, an oiling agentcomprises crown ether, and the content of the crown ether is 67.30 to 85.58 percent by weight. The preparation method is simple, and the obtained fiber is excellent in hot-wet comfortability and remarkable in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

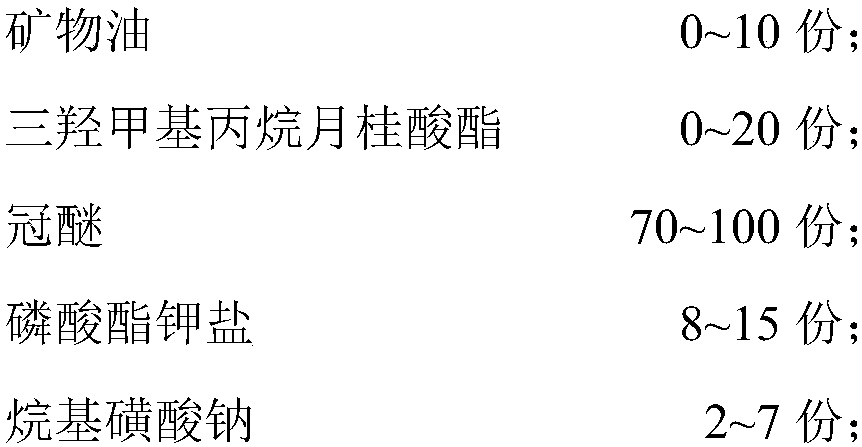

Oil solution for ramie production and use thereof

InactiveCN101353825AHigh oil film strengthGood cohesionVegetal fibresFibre treatment to obtain bast fibreChemistryAqueous solution

The invention relates to an oil agent applied to ramie production and the application thereof. The ingredients of the oil agent comprise: a lubricating cohesive agent, an emulsifier, a penetrating agent, a wetting agent and a softener, the weight ratio of which are: 67-85: 26.5-8.5: 1.5-0.5: 2.5-0.5: 2.5-0.5. The application of the invention is that: after de-gumming and dehydration of the ramie, oil is applied at one time, the condition of oil supplying is that the oil supplying solution is water solution with the oil agent of 40g to 80g per liter and the temperature of the oil supplying solution is 30 DEG C to 70 DEG C. The oil agent of the invention has better penetrability and the oil film strength of the fabric surface is high with good cohesion performance. Oil supplying technology adopting the oil agent in the ramie production is optimized to be one-time oil supplying, reduces the original processes and dosage of raw materials of the oil agent, improves efficiency, reduces cost and has the advantages that plant field occupied is decreased and product quality is improved.

Owner:DONGHUA UNIV

Ultra-fine denier polyester drawn yarn and preparation method thereof

ActiveCN108035007ASimple preparation processSoft and delicateFibre typesMonocomponent copolyesters artificial filamentUltra fineFineness

The invention relates to an ultra-fine denier polyester drawn yarn and a preparation method thereof. A modified polyester is subjected to metering, extruding, cooling, oiling, stretching, heat settingand winding to obtain the ultra-fine denier polyester drawn yarn. An oiling agent used for oiling contains crown ether, and content of the crown ether is 67.30 to 85.58wt%. A modified polyester molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain. A structural formula of the ethylene glycol with thebranched chain is as follows: the structural formula is shown in the description. R1 and R2 are each independently selected from straight-chain alkylene groups with 1 to 3 carbon atoms, R3 is selected from alkyl groups with 1 to 5 carbon atoms, and R4 is selected from alkyl groups with 2 to 5 carbon atoms, and the resulting ultra-fine denier polyester drawn yarn is obtained. The single-filament fineness of the ultra-fine denier polyester drawn yarn is 0.2 to 0.3 dtex. The method is simple and reasonable, and the prepared ultra-fine denier polyester drawn yarn is soft and delicate, and has high quality.

Owner:JIANGSU HENGLI CHEM FIBER

Melt directly-spun colored polyester fiber and preparation method thereof

ActiveCN108035011AHigh glossColorfulMelt spinning methodsPigment addition to spinning solutionPolymer scienceAlcohol

The invention relates to melt directly-spun colored polyester fiber and a preparation method thereof. The melt directly-spun colored polyester fiber is prepared by the steps of adding color master batch into modified polyester melt, metering, extruding, cooling, oiling, drawing, carrying out heat setting and winding; an oil agent for oiling contains crown ether, and the content of the crown etheris 67.30-85.58wt%. The preparation method is simple and reasonable, the glossiness of the finally-prepared melt directly-spun colored polyester fiber is more than or equal to 60%, the melt directly-spun colored polyester fiber is black, red, blue or yellow in color and is made of modified polyester with the molecular chain including a terephthalic-acid chain segment, an ethylene-glycol chain segment and a dihydric-alcohol chain segment with branch chains; the structural formula of dihydric alcohol is shown in the description, wherein R1 and R2 are independently and respectively selected from straight-chain alkylene with the number of carbon atoms being 1-3, R3 is selected from alkyl groups with the number of carbon atoms being 1-5, and R4 is selected from alkyl groups with the number of carbon atoms being 2-5. The melt directly-spun colored polyester fiber has the advantages of high glossiness and diversified color, so that the application prospect is very considerable.

Owner:JIANGSU HENGLI CHEM FIBER

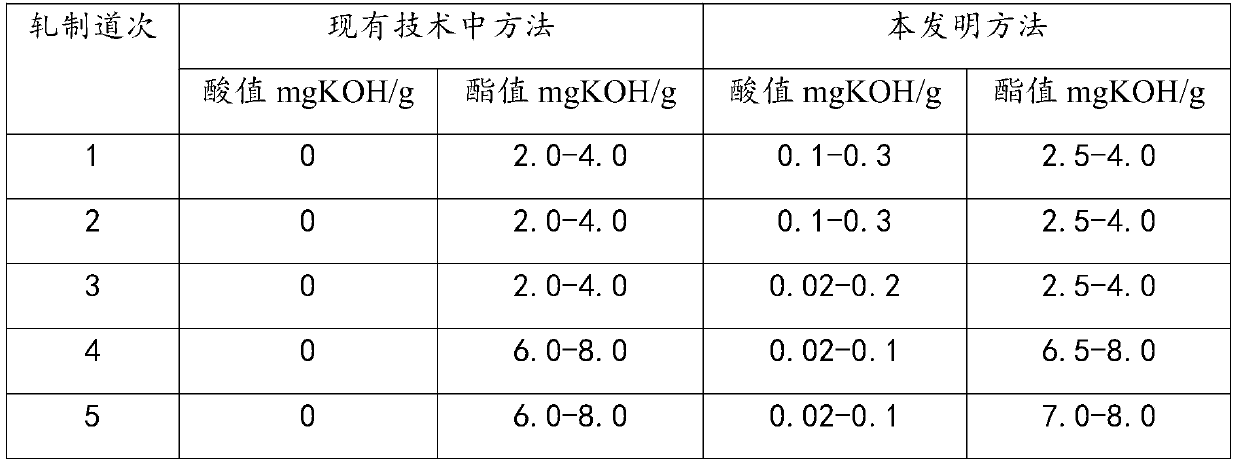

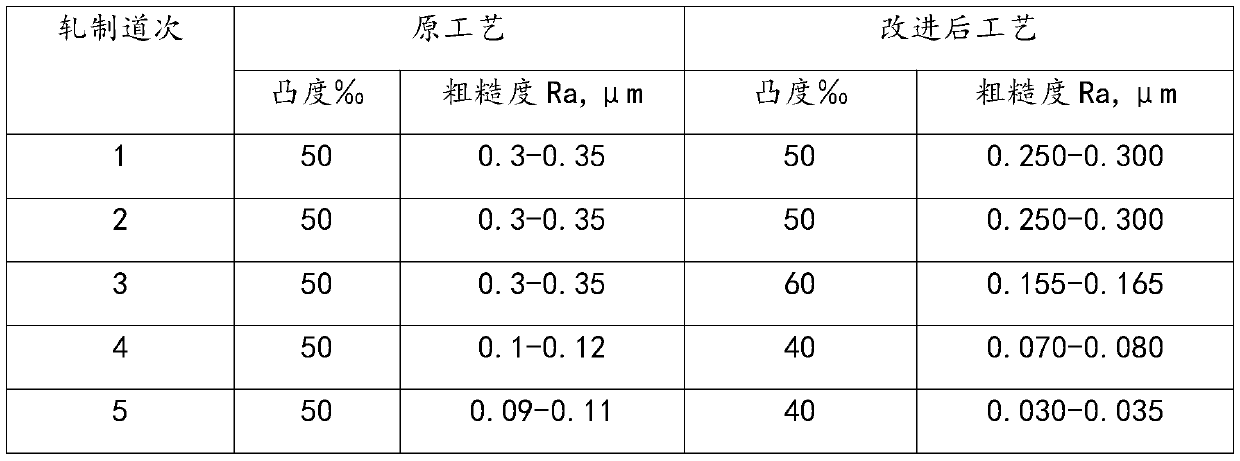

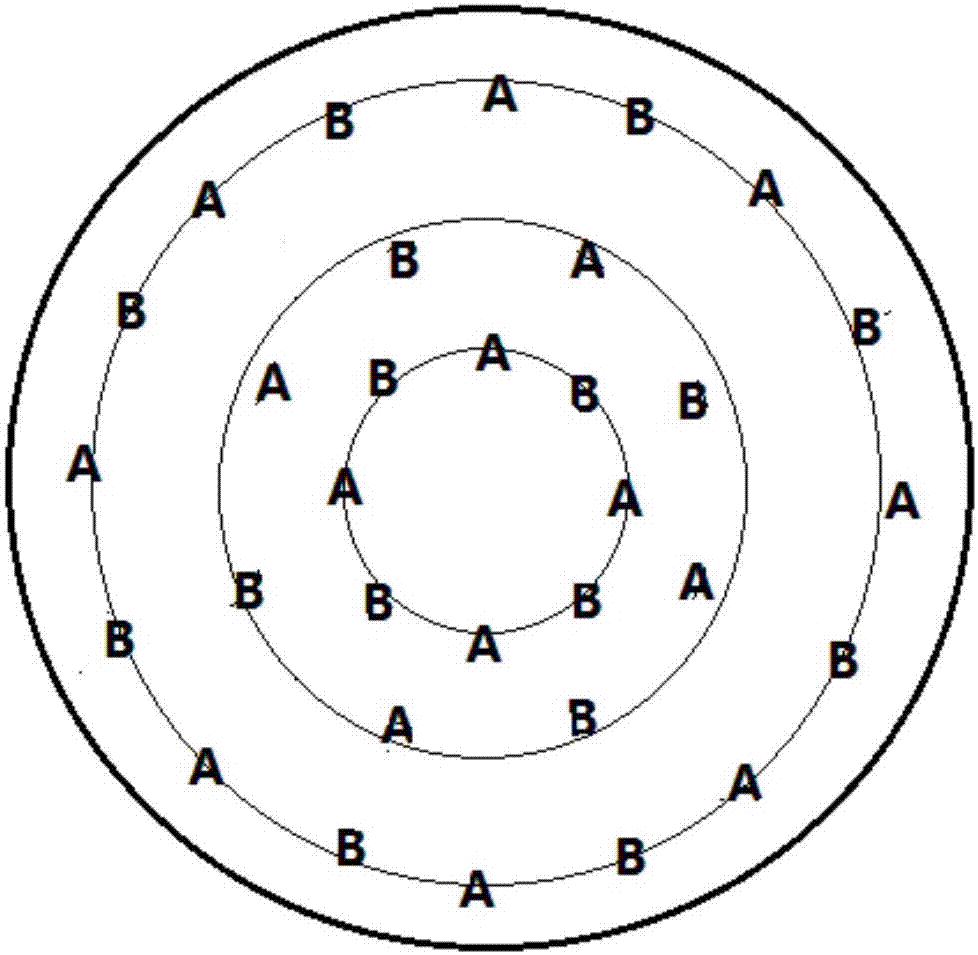

Preparation method for double-sided light aluminum foil

InactiveCN109759474AIncrease pass reduction rateGuarantee the shape qualityReduction rateRoom temperature

The invention discloses a preparation method for a double-sided light aluminum foil. The preparation method comprises the following steps that (1) cast-rolling is performed, wherein an aluminum alloymaterial and an aluminum ingot are put into a melting furnace for melting, after standing is performed through a standing furnace, a molten liquid is filtered, and a cast-rolled plate is obtained after multiple times of cast-rolling is performed by a cast-rolling machine; (2) cold rolling is performed, wherein the cast-rolled plate is cooled to room temperature, multiple times of cold pressing isperformed by a cold press, and then multiple times of annealing treatment is performed to obtain an aluminum foil stock; (3) an aluminum foil working procedure is performed, wherein the aluminum foilstock undergoes five passes of rolling working procedures to obtain a finished aluminum foil, the first pass of the rolling working procedure to the third time of the rolling working procedure are rough rolling, the thickness of the obtained aluminum foil is 0.03 mm, the fourth pass of the rolling working procedure is intermediate rolling, the thickness of the obtained aluminum foil is 0.014 mm, the fifth pass of rolling working procedure is finish rolling, and the aluminum foil with the thickness of 0.009 mm is obtained. According to the method, the distribution of reduction pass of an aluminum foil rolling working procedure is adjusted again, the pass reduction rate of the third pass is properly improved, the pass reduction rate of the fifth pass, namely, the pass reduction rate of the final pass is reduced, so that the reduction process speed is reduced, and the thickness of the product is reduced easier.

Owner:HANGZHOU FIVE STAR ALUMINUM

Hot-wet comfortable polyester-fiber draw texturing yarns (DTYs) for winter, and preparation method of DTYs

ActiveCN107988648AGood thermal and humidity comfortEasy to processFibre typesFilament/thread formingYarnPolyester

The invention relates to hot-wet comfortable polyester-fiber draw texturing yarns (DTYs) for winter, and a preparation method of the DTYs. The preparation method comprises the steps of metering spinning melt, extruding by using a composite spinneret, cooling, oiling and winding to obtain polyester pre-oriented yarns (POYs); enabling the POYs to pass through a yarn guide pipe and a network, stretching under the condition of heating, carrying out false twisting and heat-setting, and molding by winding so as to obtain the hot-wet comfortable polyester-fiber DTYs; the material of the DTYs is polyester with a dispersed matting agent; the thermal resistance and moisture resistance of knitted fabric made from the DTYs are respectively more than or equal to 0.16m<2>.DEG C / W and less than or equalto 12Pa.m<2> / W; the composite spinneret is provided with a cross-shaped spinneret orifice and a double-cross shaped spinneret orifice; the ratio of the micropore length of the cross-shaped spinneret orifice to the micropore length of the double-cross shaped spinneret orifice is equal to a product of the ratio of the equivalent diameter and a coefficient K, wherein the value range of the coefficient K is 0.97-1.03; an oiling agent for oiling contains crown ether, and the content of the crown ether is 67.30-85.58wt%. The preparation method provided by the invention is simple, and the obtained hot-wet comfortable polyester-fiber DTYs are excellent in hot-wet comfort performance.

Owner:JIANGSU HENGLI CHEM FIBER

Melt direct-spinning polyester and polyester supersoft composite yarn and preparation method thereof

ActiveCN107868997ASimple preparation processGood lookingFibre treatmentConjugated synthetic polymer artificial filamentsYarnSlow cooling

The invention relates to a melt direct-spinning polyester and polyester supersoft composite yarn and a preparation method thereof. The preparation method comprises the following steps of firstly, respectively preparing modified polyester POY (polyester pre-oriented yarn) and modified polyester FDY (fully drawn yarn); then, combining strands of the modified polyester POY and the modified polyesterFDY into a network, heating and stretching, falsely twisting, thermally shaping, coiling and shaping, so as to obtain the melt direct-spinning polyester and polyester supersoft composite yarn. The preparation method has the advantages that in the preparation process of modified polyester POY and modified polyester FDY, the oil for oil applying contains crown ether, the content of crown ether is 67.30 to 85.58wt%, the distance of a slow cooling area is 80 to 120mm in the cooling process, and molecular chains of the modified polyester contain a terephthalic acid chain section, an ethylene glycolchain section and a hexanediol chain section. The prepared melt direct-spinning polyester and polyester supersoft composite yarn has the advantages that the initial modulus is less than or equal to 70cN / dtext; the method is simple and reasonable; the softness is realized, the appearance shaping is good, and the quality is high.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method for high-strength activated form polyester industrial yarns

ActiveCN107904694AIncrease the cross-sectional areaIncrease surface temperatureFibre typesArtificial filament heat treatmentBreaking strengthYarn

The invention relates to a preparation method for high-strength activated form polyester industrial yarns. Polyester is subjected to solid phase polycondensation tackifying, melting, measurement, extrusion, cooling, oil application, stretching, thermoforming, activating oil application, coiling and pre-activation processing to obtain the high-strength activated form polyester industrial yarns. During cooling, longitudinal height is kept constant, the cross-sectional area of a slow cooling cavity is enhanced, meanwhile, the slow cooling cavity adopts a heat preservation way to keep the plate surface temperature of a spinneret plate; oil agent used for oil application contains crown ether, and the content of the crown ether is 67.30-85.58wt%; when the oil agent is used, the oil agent is prepared into emulsified liquid of which the concentration is 14-18wt%. The preparation method is reasonable and simple, the breaking strength of the prepared high-strength activated form polyester industrial yarns is greater than or equal to 8.1cN / dtex, wicking height is less than or equal to 5mm, and an application prospect is considerable.

Owner:JIANGSU HENGLI CHEM FIBER

Moisture absorption and perspiration fiber and preparation method thereof

ActiveCN108035006ALow viscosityHigh viscosityArtificial filament heat treatmentMelt spinning methodsPolyesterFiber

The invention relates to a moisture absorption and perspiration fiber and a preparation method thereof. The moisture absorption and perspiration fiber is prepared by measuring polyester melt, extruding by a compositing spinneret plate, cooling, oiling, stretching, thermally shaping and coiling, wherein the composite spinneret plate is provided with a cross spinneret hole and a spinneret hole shaped like the Chinese character Wang, a length ratio of micropores of the cross spinneret hole and the spinneret hole shaped like the Chinese character Wang is equal to a product of an equivalent diameter ratio of the cross spinneret hole and the spinneret hole shaped like the Chinese character Wang and a coefficient K, the equivalent diameter is a ratio of an area and perimeter of a cross section ofthe spinneret hole, the valuing range of the coefficient K is 0.97 to 1.03, an oiling agent comprises crown ether, the content of the crown ether is 67.30 to 85.58 percent, and a capillary parameterof the prepared moisture absorption and perspiration fiber is greater than or equal to 0.16. The preparation method is simple and reasonable in method, and the prepared fiber has excellent moisture absorption and perspiration performance and has good popularization value.

Owner:JIANGSU HENGLI CHEM FIBER

Lightweight warmth retention fiber and preparation method thereof

ActiveCN107988640ALow viscosityHigh viscosityNew-spun product collectionHollow filament manufacturePolyesterDiameter ratio

The invention relates to a lightweight warmth retention fiber and a preparation method thereof. Polyester melts are metered, extruded by a composite spinneret plate, cooled, coated with oil, stretched, thermoformed and wound to prepare the lightweight warmth retention fiber, a hollow spinneret hole and a circular spinneret hole are formed in the composite spinneret plate, the ratio of the hollow spinneret hole to the micro-hole length of the circular spinneret hole is equal to the product of the equivalent diameter ratio of the hollow spinneret hole to the circular spinneret hole and a coefficient K, the equivalent diameter is the ratio of cross-sectional areas of the spinneret holes to cross-sectional area perimeters, value range of the coefficient K is 0.7-1.03, an oil agent for oiling contains crown ether, the content of the crown ether is 67.30-85.58wt%, the heat conductivity coefficient of a knitting fabric prepared from the prepared lightweight warmth retention fiber is smaller than or equal to 0.150W / m*K, and the weight of the knitting fabric is 100g / m<2>. The method is simple and reasonable, and the prepared fiber has good lightweight warmth retention, moisture absorption and sweat-releasing performances and has excellent popularization values.

Owner:JIANGSU HENGLI CHEM FIBER

Complete-extinction network stretch yarn and preparation method thereof

ActiveCN107904693AReduce glossImprove performanceNew-spun product collectionFibre typesYarnPolyester

The invention relates to a complete-extinction network stretch yarn and a preparation method thereof. The preparation method comprises the following steps: metering, extruding, cooling, oiling and winding polyester melt to obtain POY yarns, enabling the POY yarns to pass through a yarn guide pipe and a network, heating and stretching the POY yarns, false twisting the POY yarns, thermosetting, winding molding the POY yarns to obtain DTY yarns, thus obtaining the complete-extinction network stretch yarns, wherein oil for oiling comprises crown ether, the content of the crown ether is 67.30 to 85.58 percent by weight, a matt agent is dispersed in the polyester melt, the matt agent is a mixture of amorphous titanium dioxide and amorphous silicon dioxide or a mixture of calcium carbonate and amorphous silicon dioxide. The gloss of the prepared complete-extinction network stretch yarn is less than 20 percent, a curling shrinkage rate is greater than or equal to 35 percent, and the curling stability is 75 to 85 percent. The method is simple and reasonable, and the prepared complete-extinction network stretch yarn has the advantages of complete extinction and good performance and is high in popularization value.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of polyester porous yarn

ActiveCN107988647ASoft and delicateImprove appearance and textureFibre typesFilament/thread formingPolyesterYarn

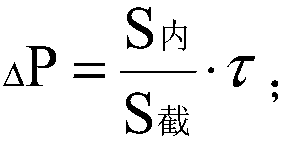

The invention relates to a preparation method of a polyester porous yarn. A polyester fusant is subjected to metering, porous spinning plate extrusion, cooling, oiling, stretching, heat setting and winding to prepare the polyester porous yarn, wherein the pore number of a porous spinning plate is 144 to 288; an oil agent for oiling contains crown ether; the content of crown ether is 67.30 to 85.58weight percent; after the oil agent is subjected to heating treatment for 2h at 200 DEG C, the heat weight loss is smaller than 15 weight percent; when the oil agent is 50+ / -0.01 DEG C, the movementviscosity is 27.5 to 30.1 mm<2> / s; after the oil agent is prepared into an emulsion with the concentration being 10 weight percent, the movement viscosity is 0.93 to 0.95 mm<2> / s; the oil film intensity of the oil agent is 121 to 127N. The preparation method is simple and reasonable; the prepared product has the advantages of softness, fine and smooth effect, good appearance and good texture.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing high-uniformity military soft polyester industrial yarn

ActiveCN107893264AIncrease the lengthEasy to spreadArtificial thread manufacturing machinesFibre typesPolyesterThermal insulation

The invention relates to a method for preparing high-uniformity military soft polyester industrial yarn. Through polyester solid-phase polycondensation tackifying, melting, metering, extrusion, cooling, oil coating, stretching, hot setting and winding, the high-uniformity military soft polyester industrial yarn is prepared. In cooling, vertical height is kept, the cross-sectional area of a slow cooling chamber is increased, the plate surface temperature of a spinneret plate in the slow cooling chamber is kept through a thermal insulation method, an oil agent used in oil coating contains 67.30to 85.58 wt% of crown ether, in oil agent use, an emulsion with a concentration of 13 to 18 wt% is prepared from water, and the high-uniformity military soft polyester industrial yarn has a breaking strength CV value of 2.5% or less and single filament fineness of 3.0 dtex or less. The method prepares the high-uniformity military soft polyester industrial yarn, has simple and reasonable processesand has a very high promotion value.

Owner:JIANGSU HENGLI CHEM FIBER

Special polyimide fiber spinning oil and method for preparing same

The invention relates to the field of textile auxiliaries, and discloses special polyimide fiber spinning oil and a method for preparing the same. The special polyimide fiber spinning oil comprises, by weight, 30-40% of dimethyl silicone oil, 6-10% of sorbitan mono-olein polyether, 8-12% of dodecyl phosphate ester diethanol amine, 10-20% of fatty alcohol polyoxyethylene ether, 6-10% of triethanolamine, 11-17% of isomeric tridecanol random polyether, 8-12% of tri-polyglyceryl fatty acid ester and 2-6% of dodecyl polyoxylethylene ether. The special polyimide fiber spinning oil and the method have the advantages that the special polyimide fiber spinning oil is specially used for preparing polyimide fibers and is outstanding in heat stability, emulsifying property, wettability and oil film covering performance, the requirements on realizing effects of protecting fiber silver in high-temperature states can be met, and the fiber product quality and production stability can be guaranteed.

Owner:浙江浩睿新材料科技有限公司

Double-abnormal-shape fiber and preparation method thereof

ActiveCN108130613AExcellent performanceLow viscosityFibre typesFilament/thread formingEthylene glycolPolymer science

The invention relates to double-abnormal-shape fibers and a preparation method thereof. A spinning melt is subjected to metering, composite spinneret plate extrusion, cooling, oiling, stretching, heatsetting and winding to obtain the double-abnormal-shape fibers; a bunch of the prepared double-abnormal-shape fibers contain a two-barred cross monofilament and a round monofilament at the same time;the fibers are made of modified polyester, and a matte agent is dispersed in the modified polyester; a molecular chain of the modified polyester consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment with a branched chain, and diol with the branched chain has the following structural formula defined in the specification, wherein R1 and R2 are independently selected from straight-chain alkylene with the carbon atom number of 1-3, R3 is selected from alkyl with the carbon atom number of 1-5, and R4 is selected from alkyl with the carbon atom number of 2-5; the matte agent is a mixture of amorphous titanium dioxide and amorphous silicon dioxide or a mixture of calcium carbonate and amorphous silicon dioxide. The method is simple and reasonable, and the prepared fibers have stiff and smooth performance and softness.

Owner:JIANGSU HENGLI CHEM FIBER

Super-low shrinkage type sun shading cloth and preparation method thereof

ActiveCN108130743ALow dry heat shrinkageImprove mechanical propertiesFilament/thread formingPolyurea/polyurethane coatingsCooling chamberSlow cooling

The invention relates to super-low shrinkage type sun shading cloth and a preparation method thereof. A super-low shrinkage polyester industrial filament is prepared by solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding of modified polyester and then is woven to obtain a fabric layer; the fabric layer is subjected to two-dipping and two-rolling coating to synthesize polyurethane resin; the polyurethane resin is dried and baked to obtain the super-low shrinkage type sun shading cloth; when the sun shading cloth is cooled,the vertical height is kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation. An oil agent for oiling contains crown ether, and the fabric layer is made of modified polyester having a molecular chain including a terephthalic acid chainsegment, an ethylene glycol chain segment and a diol chain segment with a branched chain. The preparation method is simple, the finally prepared super-low shrinkage type sun shading cloth has the dryhot-shrinkage rate of 2.2+ / -0.35% under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex, and the mechanical properties are good.

Owner:JIANGSU HENGLI CHEM FIBER

Ultra-low shrinkage sunshade cloth and preparation method thereof

ActiveCN108130743BLow dry heat shrinkageImprove mechanical propertiesFilament/thread formingPolyurea/polyurethane coatingsPolymer scienceGlycol synthesis

The invention relates to super-low shrinkage type sun shading cloth and a preparation method thereof. A super-low shrinkage polyester industrial filament is prepared by solid phase polycondensation tackifying, melting, metering, extrusion, cooling, oiling, stretching, heat setting and winding of modified polyester and then is woven to obtain a fabric layer; the fabric layer is subjected to two-dipping and two-rolling coating to synthesize polyurethane resin; the polyurethane resin is dried and baked to obtain the super-low shrinkage type sun shading cloth; when the sun shading cloth is cooled,the vertical height is kept unchanged and the cross section area of a slow cooling chamber is increased; at the same time, the slow cooling chamber maintains the plate surface temperature of a spinneret plate by the way of heat preservation. An oil agent for oiling contains crown ether, and the fabric layer is made of modified polyester having a molecular chain including a terephthalic acid chainsegment, an ethylene glycol chain segment and a diol chain segment with a branched chain. The preparation method is simple, the finally prepared super-low shrinkage type sun shading cloth has the dryhot-shrinkage rate of 2.2+ / -0.35% under the conditions of 190 DEG C, 15 min and 0.01 cN / dtex, and the mechanical properties are good.

Owner:JIANGSU HENGLI CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com