Hot-wet comfortable polyester-fiber draw texturing yarns (DTYs) for winter, and preparation method of DTYs

A polyester fiber and comfortable technology, which is applied in the field of winter heat-moisture comfort polyester fiber DTY yarn and its preparation, can solve the problems of poor heat-moisture comfort performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

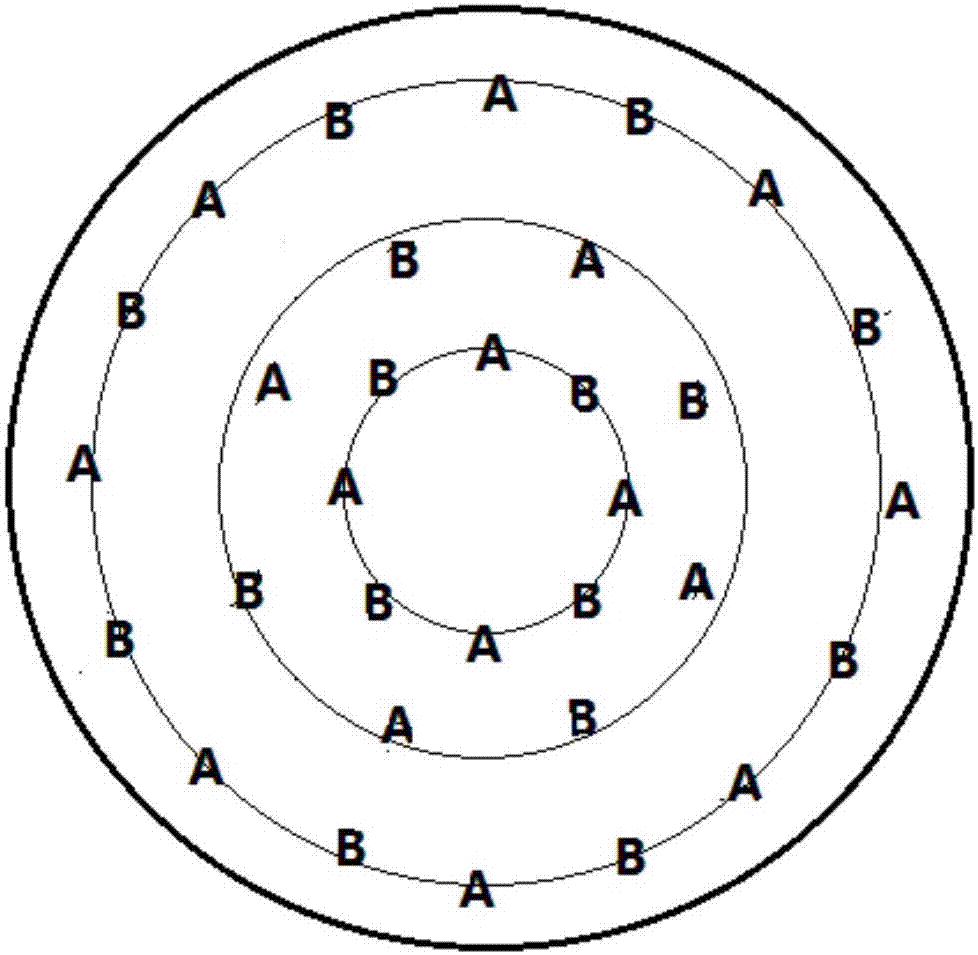

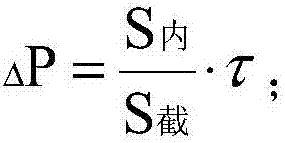

Image

Examples

Embodiment 1

[0066] A kind of preparation method of hot and humid comfortable polyester fiber DTY yarn for winter, the steps are as follows:

[0067] (1) Preparation of oiling agent for oiling: 2-hydroxymethyl-12-crown-4 and dodecyl phosphate potassium salt, trimethylolpropane laurate and sodium dodecyl sulfonate After mixing evenly at room temperature, add it to 9# mineral oil and stir evenly at 40°C for 1 hour to obtain an oil agent. The amount of each component added is as follows: 9# mineral oil is 2 parts; trimethylolpropane Lauric acid ester is 10 parts; 2-hydroxymethyl-12-crown-4 is 90 parts; dodecyl phosphate potassium salt is 8 parts; sodium dodecylsulfonate is 3 parts; the prepared oil The content of the crown ether is 79.6wt%, and the high temperature resistance of the oil is excellent, and the thermal weight loss is 14.5wt% after heat treatment at 200°C for 2 hours; the viscosity of the oil is low, and the kinematic viscosity 29.6mm 2 / s, the kinematic viscosity after the con...

Embodiment 2

[0073] A kind of preparation method of hot and humid comfortable polyester fiber DTY yarn for winter, the steps are as follows:

[0074] (1) Preparation of oiling agent for oiling: 15-crown ether-5 and isomeric tridecanol polyoxyethylene ether phosphate potassium salt, trimethylolpropane laurate and sodium pentadecylsulfonate in After mixing evenly at room temperature, add it to 10# mineral oil and stir evenly at 43°C for 1.5 hours to obtain the oil agent. In parts by weight, the addition amount of each component is as follows: 10# mineral oil is 2 parts; 15 parts of propane laurate; 70 parts of 15-crown-5; 10 parts of potassium isotridecyl polyoxyethylene ether phosphate; 7 parts of sodium pentadecyl sulfonate; prepared oil The content of crown ether in the agent is 67.30wt%. The high temperature resistance of the oil agent is excellent. After heat treatment at 200°C for 2 hours, the thermal weight loss is 13wt%. The viscosity of the oil agent is low. 28.1mm 2 / s, the kinem...

Embodiment 3

[0080] A kind of preparation method of hot and humid comfortable polyester fiber DTY yarn for winter, the steps are as follows:

[0081] (1) Preparation of oiling agent for oiling: mix 2-hydroxymethyl-15-crown-5 with potassium salt of tetradecyl phosphate, trimethylolpropane laurate and sodium pentadecylsulfonate After mixing evenly at room temperature, add it to 11# mineral oil and stir evenly at 48°C for 3 hours to obtain an oil agent. The addition amount of each component is as follows in parts by weight: 11# mineral oil is 8 parts; 10 parts of propane laurate; 85 parts of 2-hydroxymethyl-15-crown-5; 11 parts of potassium tetradecyl phosphate; 5 parts of sodium pentadecylsulfonate; The content of crown ether in the oil is 70.83wt%. The high temperature resistance of the oil is excellent. After heat treatment at 200°C for 2 hours, the thermal weight loss is 11wt%. The viscosity of the oil is low. Viscosity is 30.1mm 2 / s, the kinematic viscosity after the concentration is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com