Polytetrafluoroethylene nanoscale powder material and preparation method thereof

A polytetrafluoroethylene, nano-scale technology, applied in the field of polytetrafluoroethylene nano-scale powder and its preparation, can solve the problems of inability to crush fine particles, poor resistance to extreme pressure, etc., and achieve improved shear efficiency and uniform particle size The effect of increasing the degree, extreme pressure resistance, and improving performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

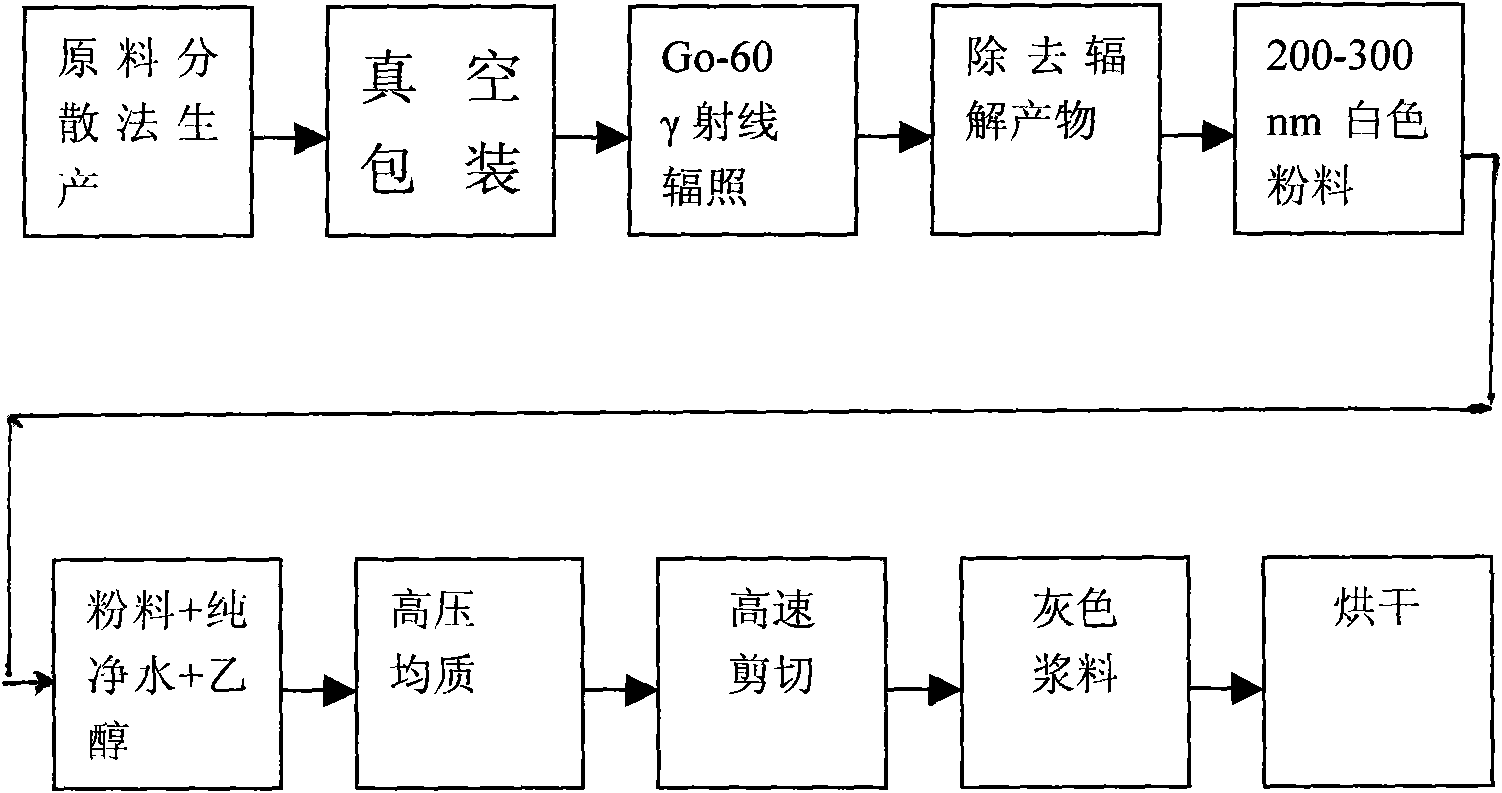

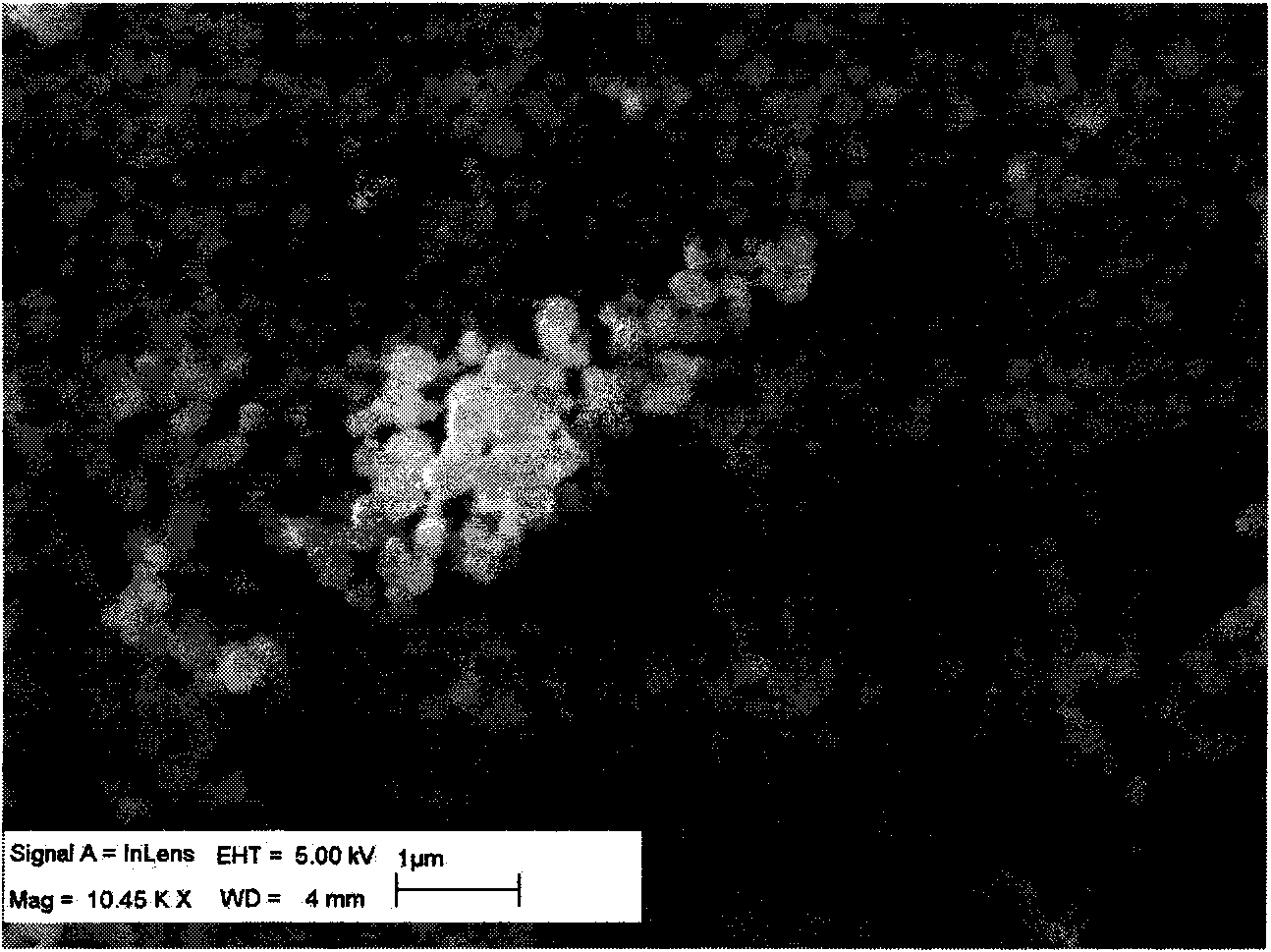

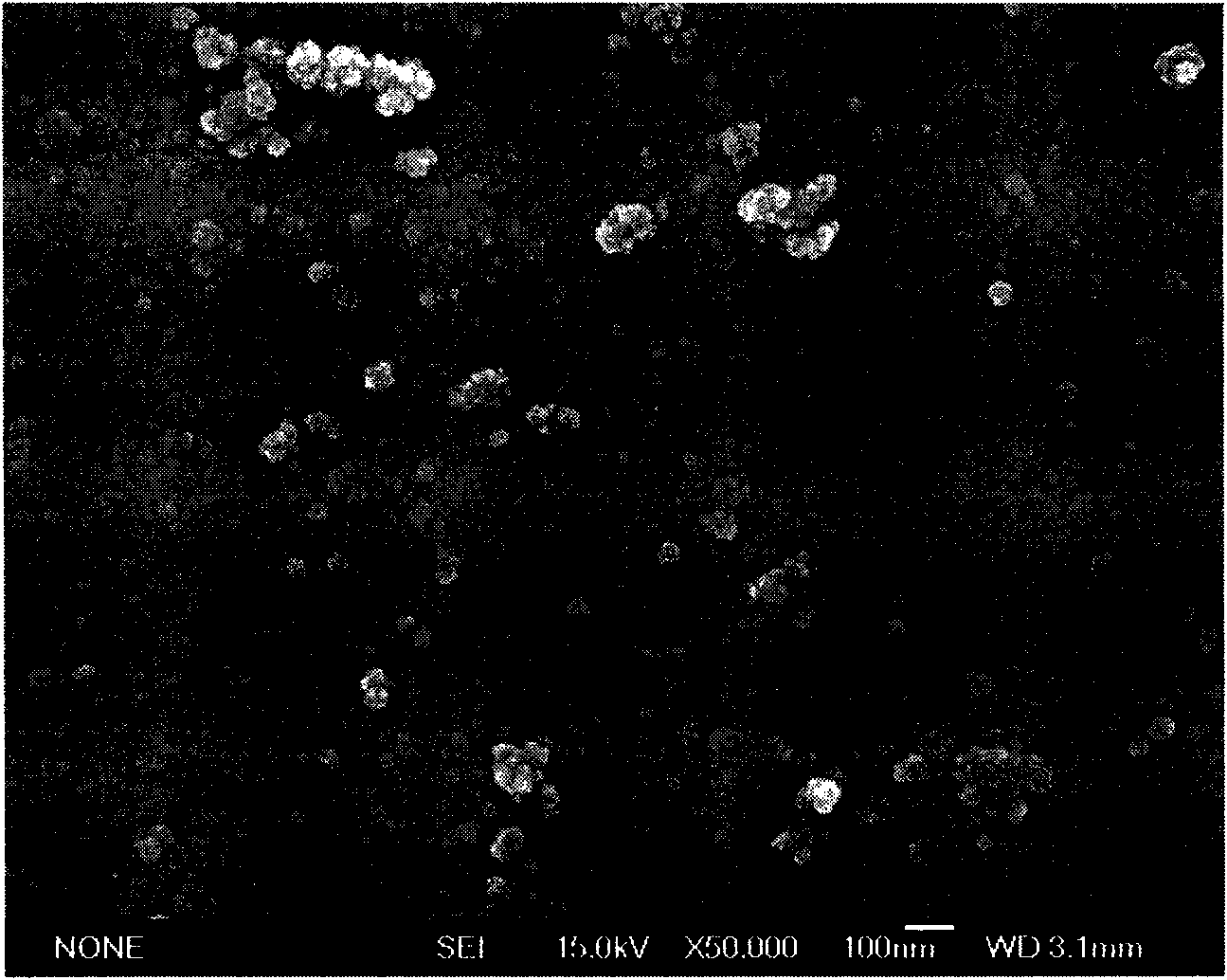

[0025] The present invention is a polytetrafluoroethylene nanoscale powder, which is different from the prior art in that the polytetrafluoroethylene nanoscale powder has a particle diameter of 20nm-50nm and a gray color. A method for preparing polytetrafluoroethylene nano-scale powder, characterized in that, the preparation method of polytetrafluoroethylene nano-scale powder comprises the following steps: a, using polytetrafluoroethylene with a particle diameter between 50 μm and 500 μm Vinyl fluoride ultrafine powder, the polytetrafluoroethylene ultrafine powder with a particle diameter between 50 μm and 500 μm is used in the implementation, which is a polytetrafluoroethylene ultrafine powder produced by a dispersion method. Ultra-fine powder is the prior art, and it is not described in detail here; b, under the condition of vacuuming, carry out sealed packaging, the condition of vacuuming is 100 Pa-150 Pa; c, put the packaged raw material into radiation Cobalt-60 gamma ray ...

Embodiment 1

[0030] The polytetrafluoroethylene powder produced by the dispersion method is sealed and packaged under the condition of vacuuming. Radiation cobalt-60 gamma ray radiation pyrolysis, the irradiation dose is 420kGy; pump out the gas products of radiation pyrolysis in the package, open the package, and you will get white polytetrafluoroethylene ultrafine powder with particle diameter between 200nm and 300nm. The polytetrafluoroethylene ultrafine powder with a white particle diameter of 200nm-300nm after ray radiation cracking is hydrated with industrial ethanol and mixed with pure water to form a fluid slurry, and their weight percentage is 50% of the polytetrafluoroethylene powder , industrial ethanol 30%, the ethanol content of industrial ethanol is 99%, pure water 20%; the fluid slurry is added to the ultra-high pressure homogenizer for homogenization, the pressure of the ultra-high pressure homogenizer is 100Mpa-120Mpa, the homogenization time 6 minutes; add the homogenized...

Embodiment 2

[0032] The polytetrafluoroethylene powder produced by the dispersion method is under vacuum conditions. Carry out sealed packaging; put the packaged polytetrafluoroethylene ultrafine powder into nuclear radiation equipment and undergo nuclear radiation cobalt-60γ ray radiation cracking, the irradiation dose is 480kGy; pump out the gas products of radiation cracking in the package, open the package, A white polytetrafluoroethylene ultrafine powder with a particle diameter between 200nm and 300nm will be obtained. The polytetrafluoroethylene ultrafine powder with a white particle diameter of 200nm-300nm after ray radiation cracking is mixed with industrial ethanol and purified water to form a fluid slurry, and their weight percentage is 58% of the polytetrafluoroethylene powder , the ethanol concentration of industrial ethanol 25% industrial ethanol is 99%, pure water 17%; The fluid slurry is added in ultra-high pressure homogenizer for homogenization, the pressure of ultra-high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com