Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "High gloss surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

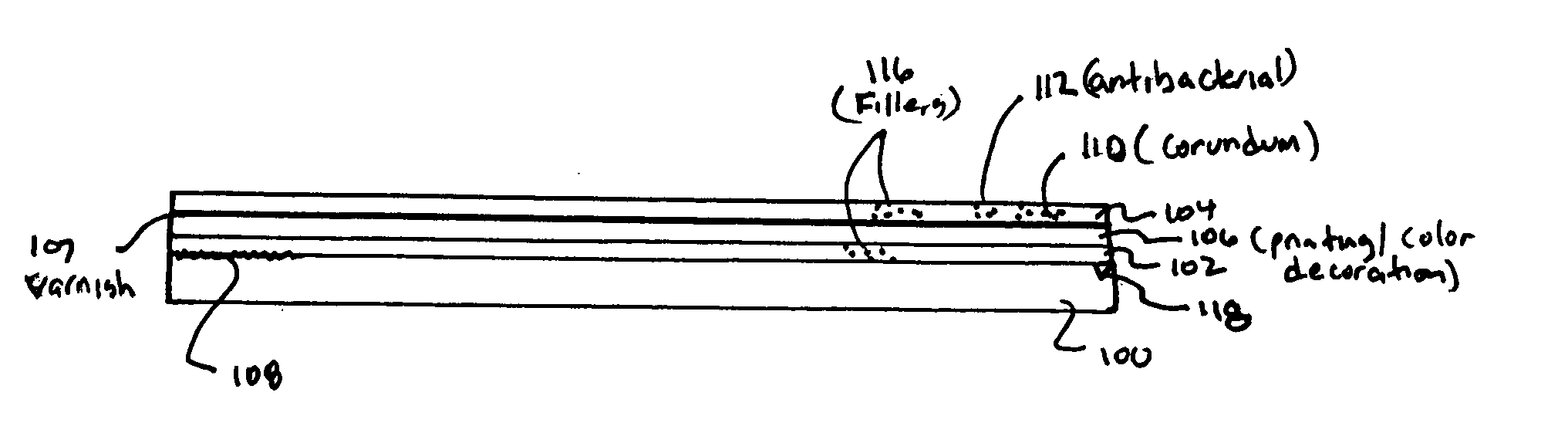

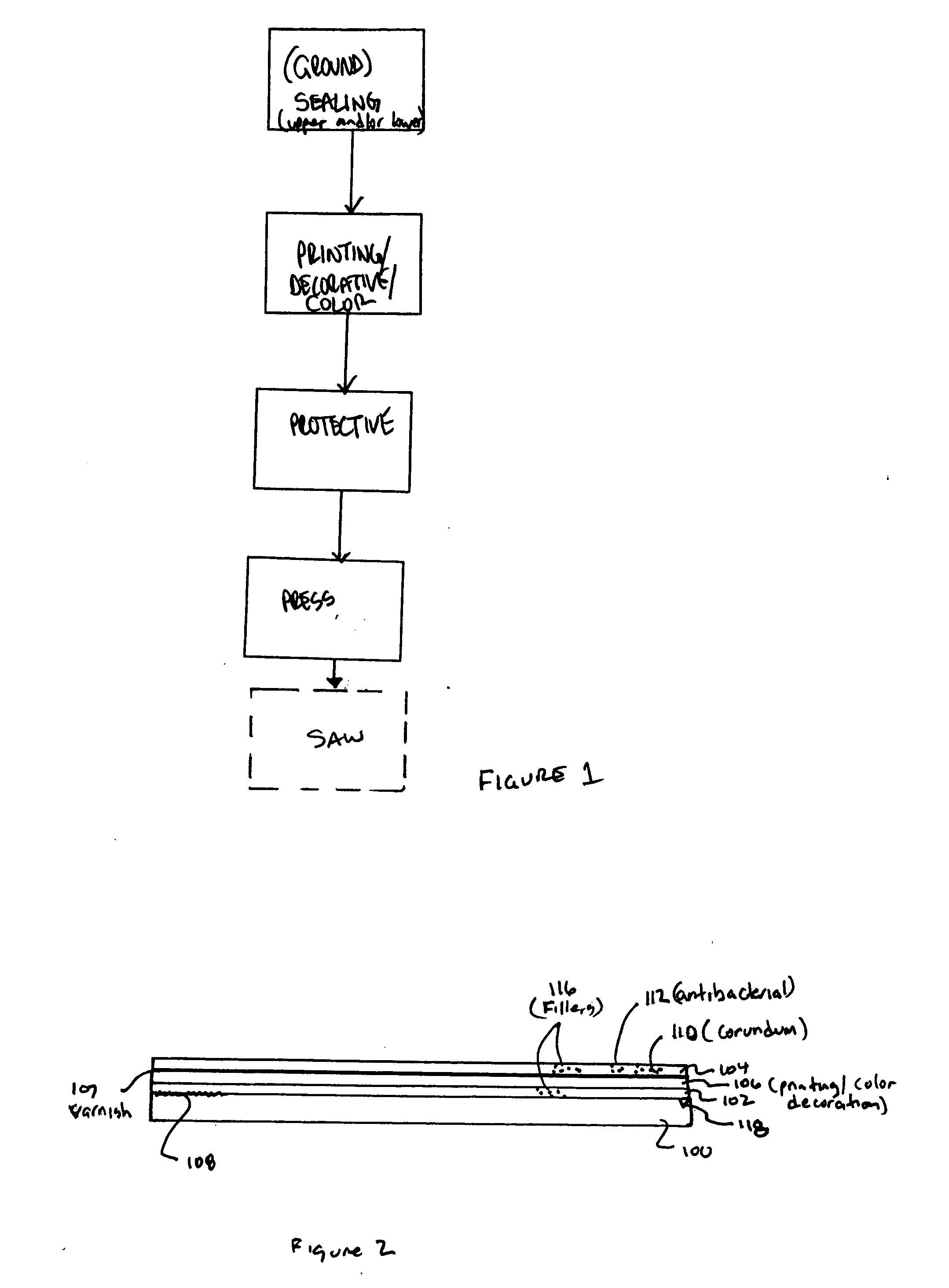

Process for finishing a wooden board and wooden board produced by the process

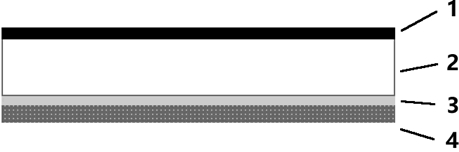

ActiveUS20040191547A1Avoid absorptionAdjustable levelFibreboardSynthetic resin layered productsMelamine resinEngineering

A process for finishing a wood or wooden board, in particular an MDF or HDF board, with an upper side and an underside. The process includes applying a sealing layer of melamine resin to the upper side of the board and printing a decoration onto the sealing layer. A protective layer is applied of melamine resin to the decoration and the board is pressed under the action of temperature until the protective layer and the sealing layer melt and bond to each other with the inclusion of the decoration printed on.

Owner:FLOORING TECH

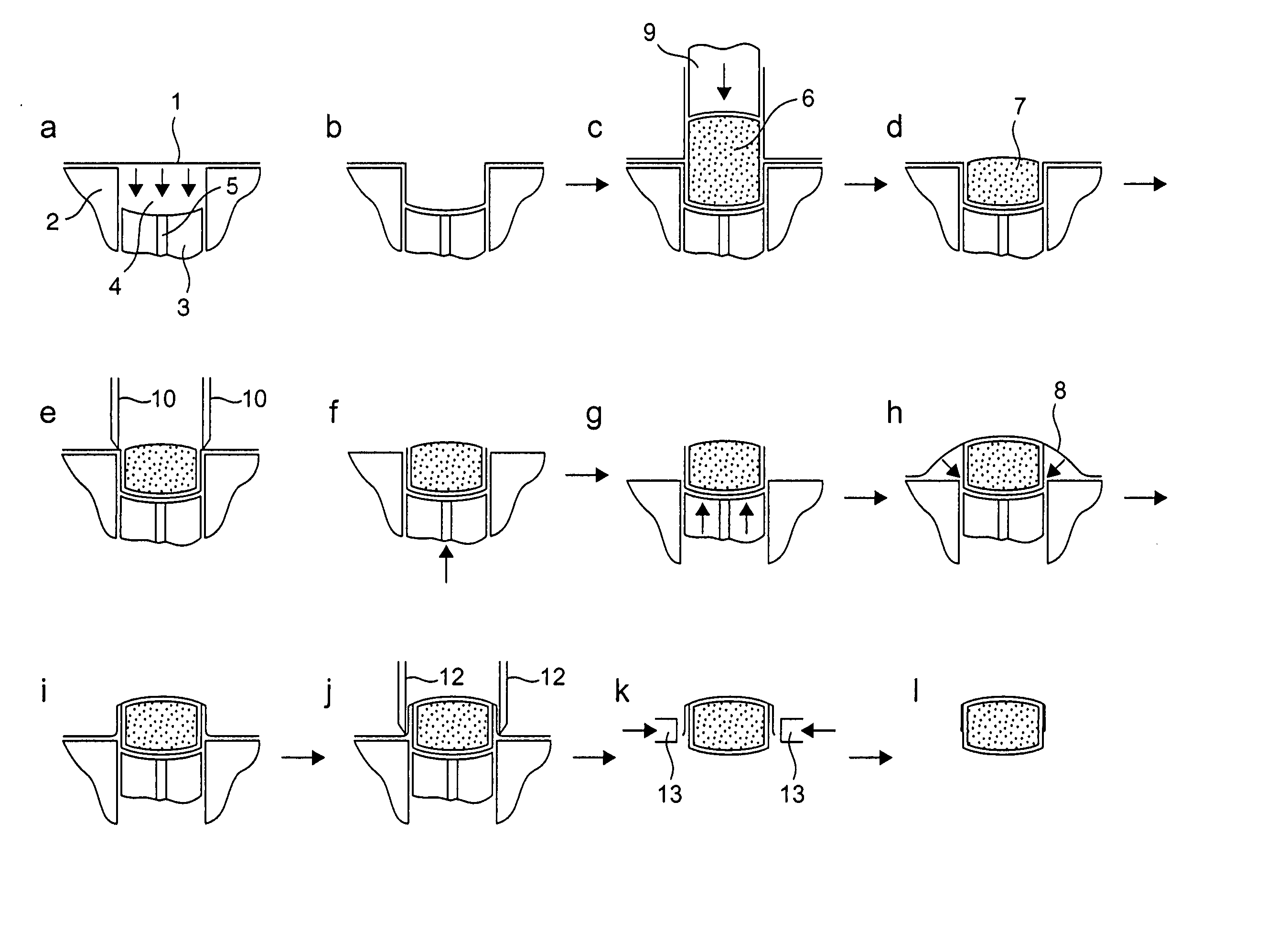

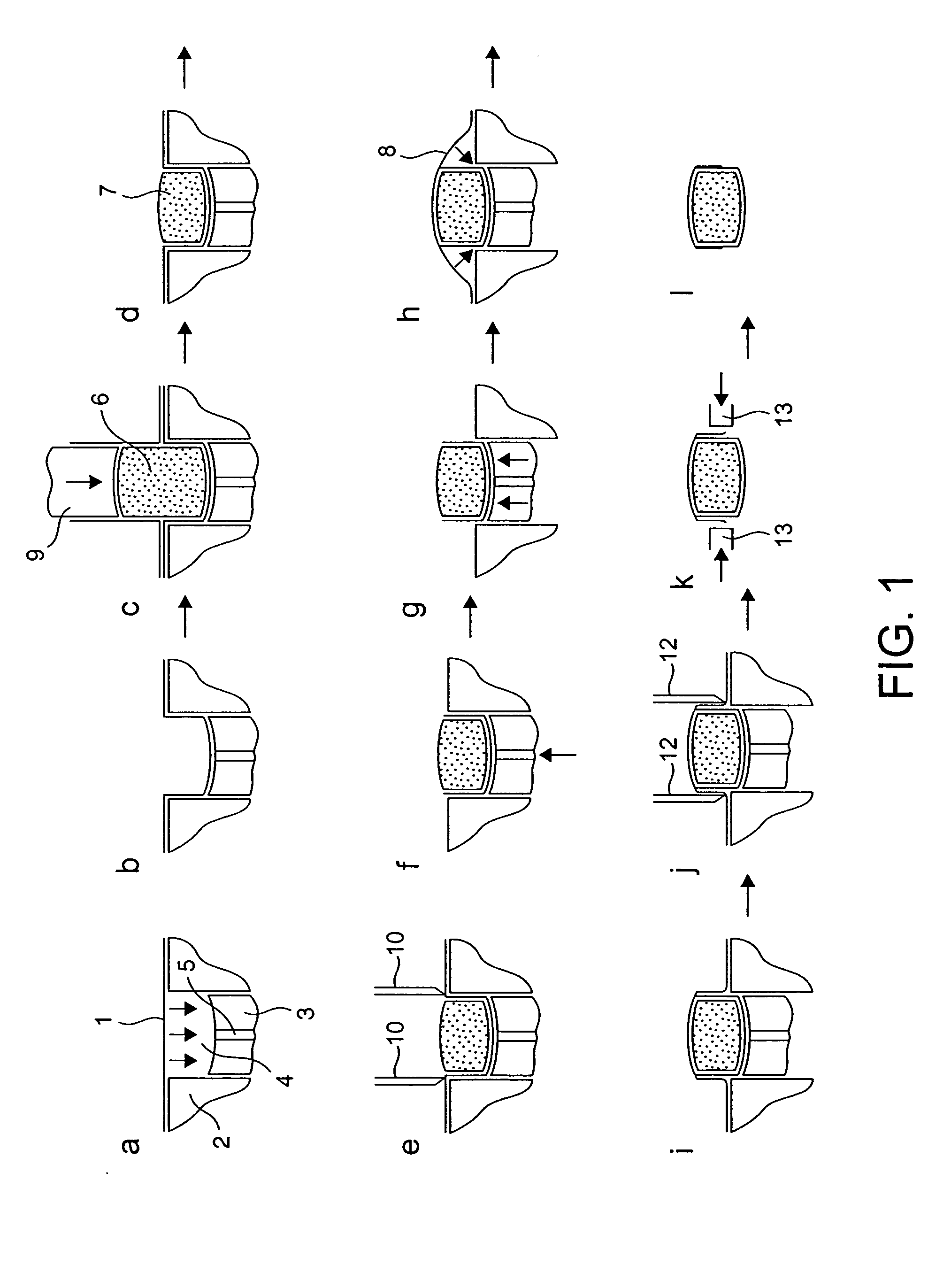

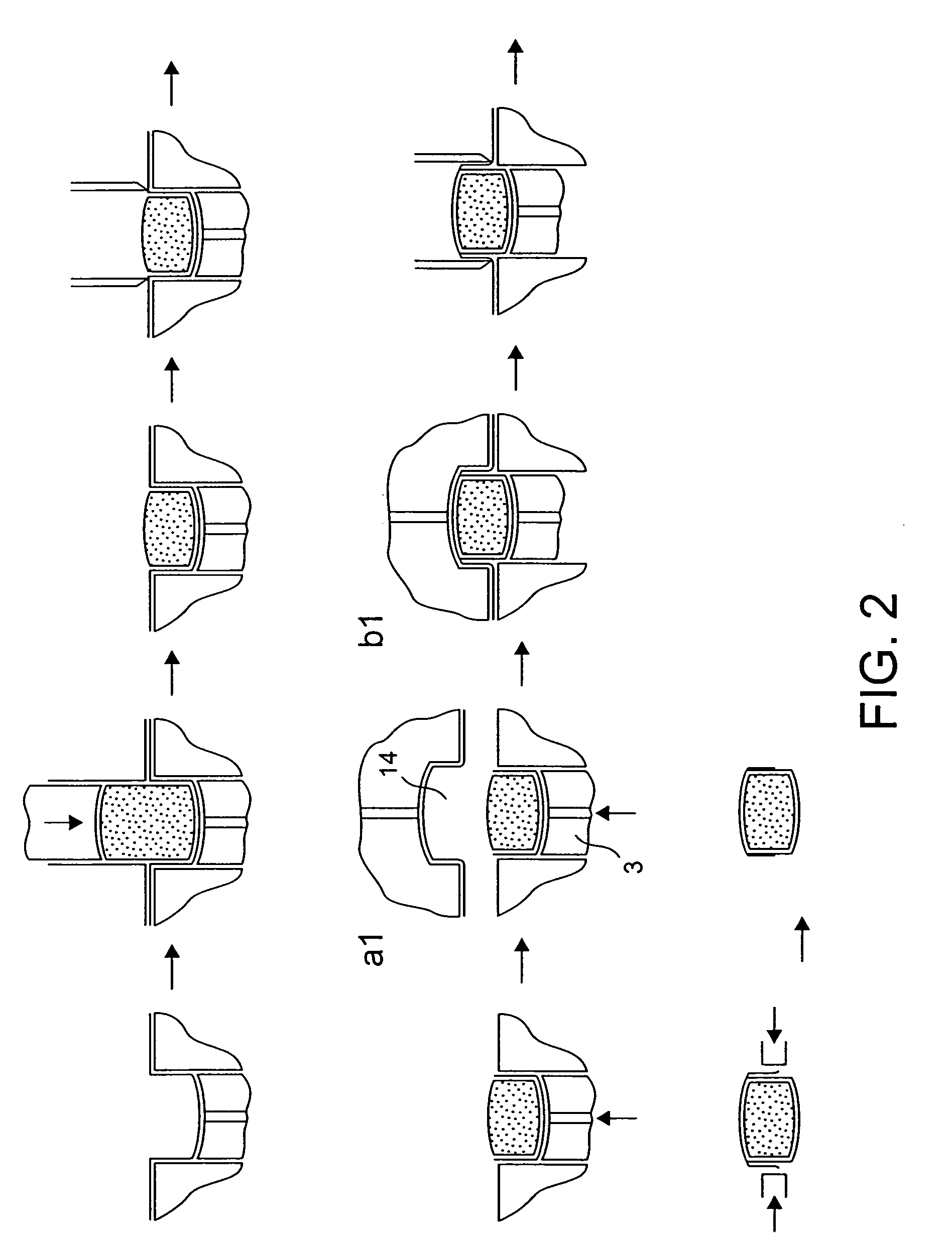

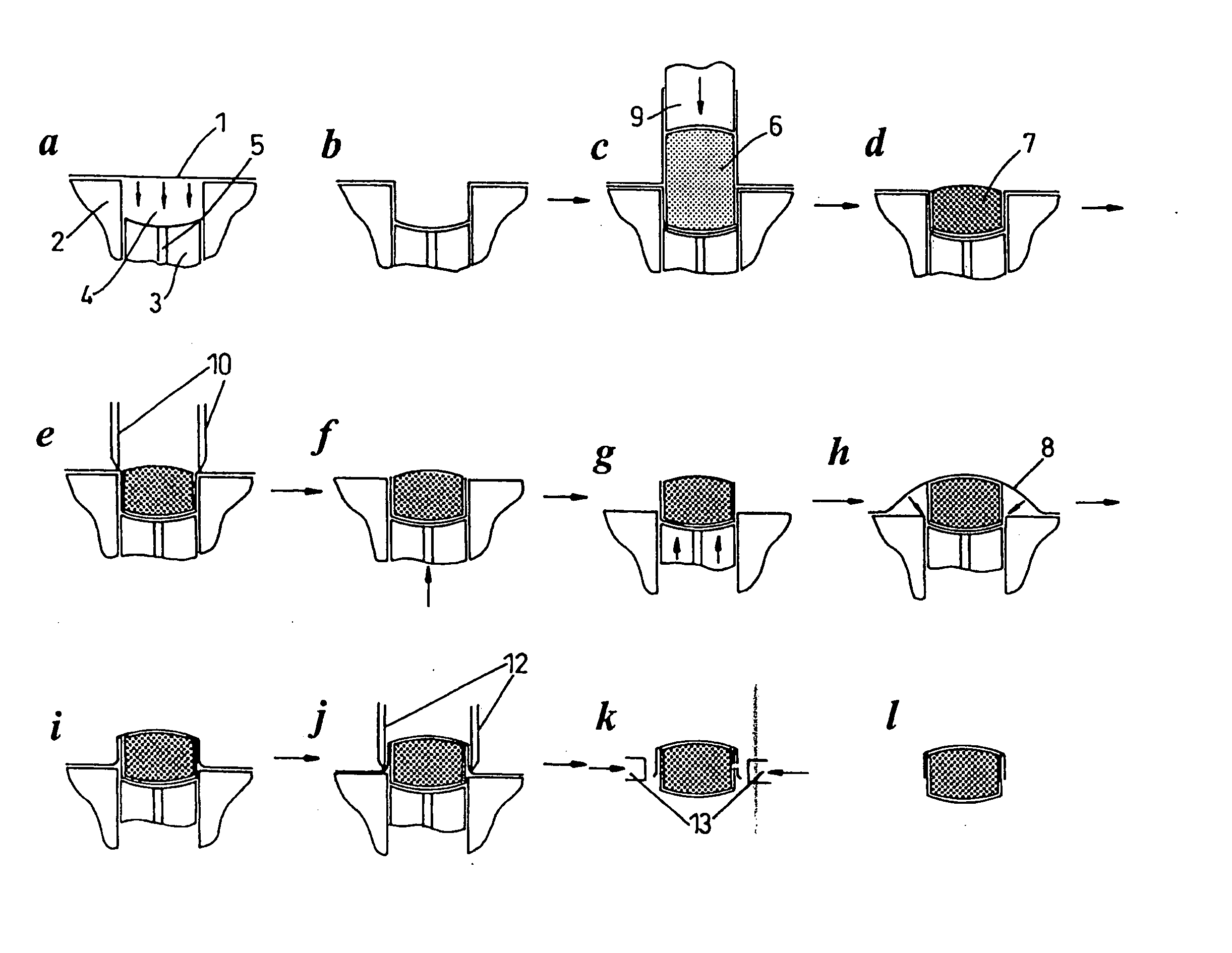

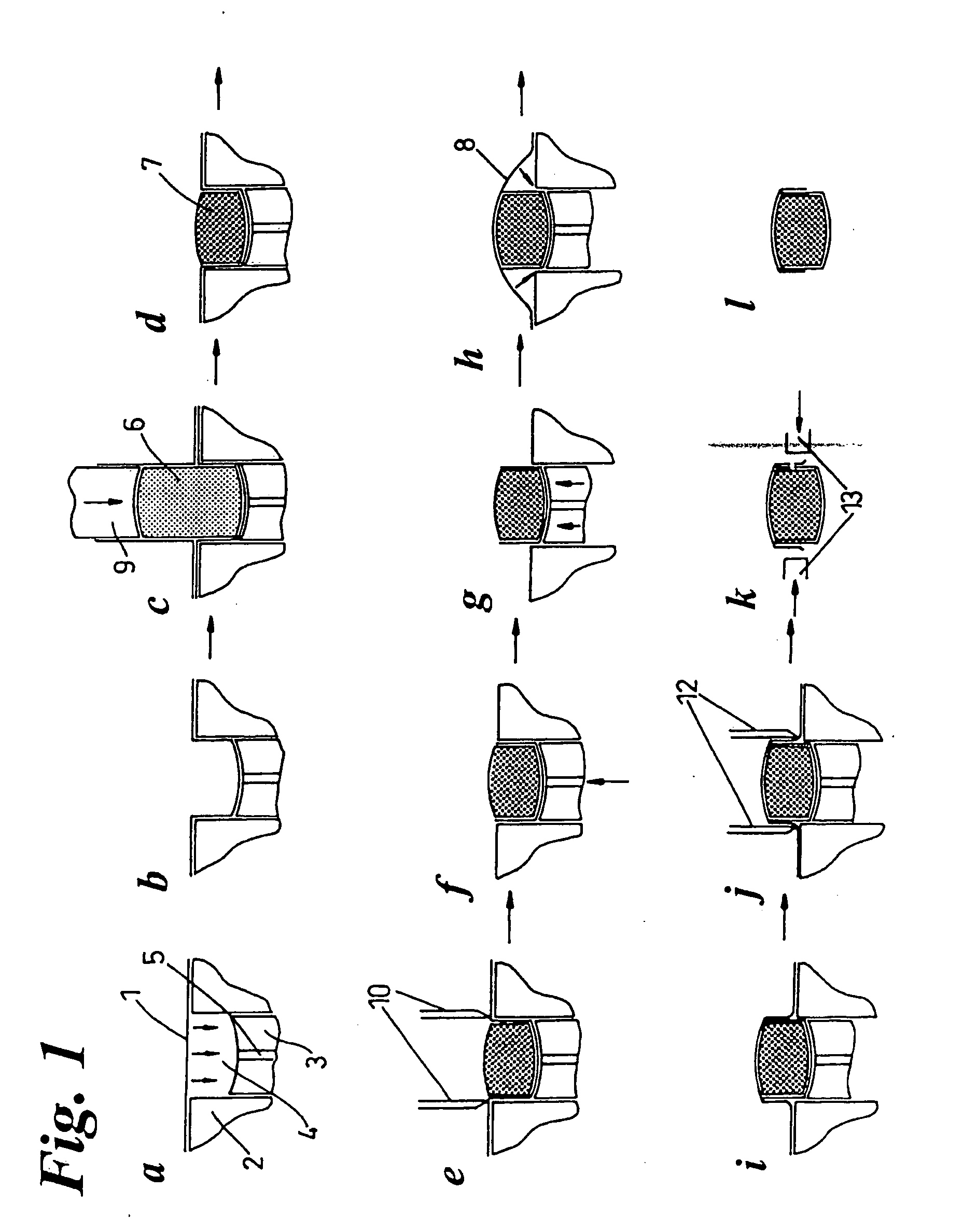

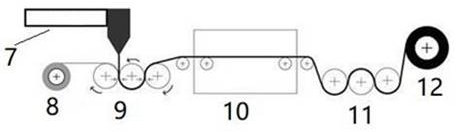

Powder compaction and enrobing

InactiveUS20050147710A1RobustQuicker release characteristicLayered productsConfectioneryMetallurgyMethyl cellulose

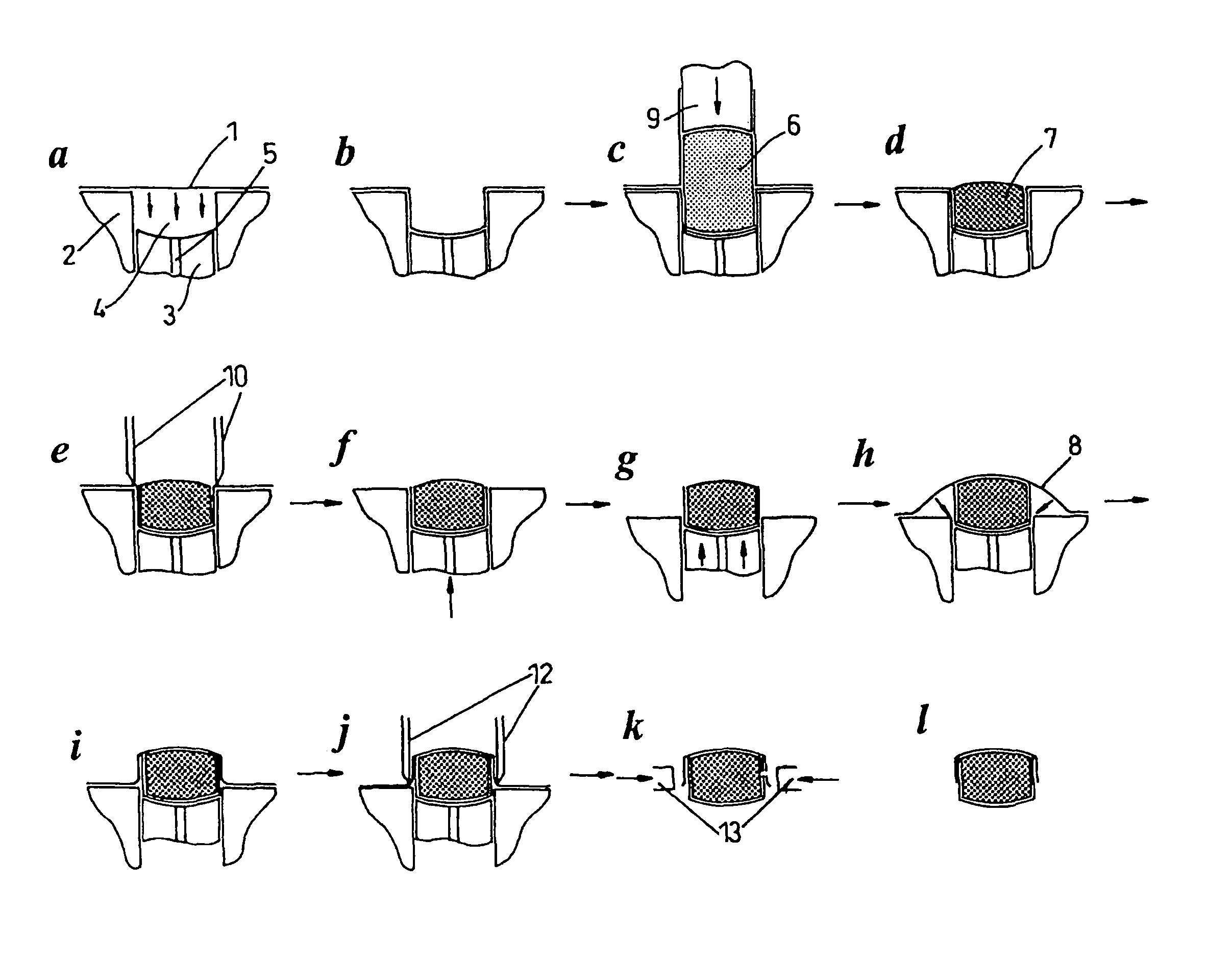

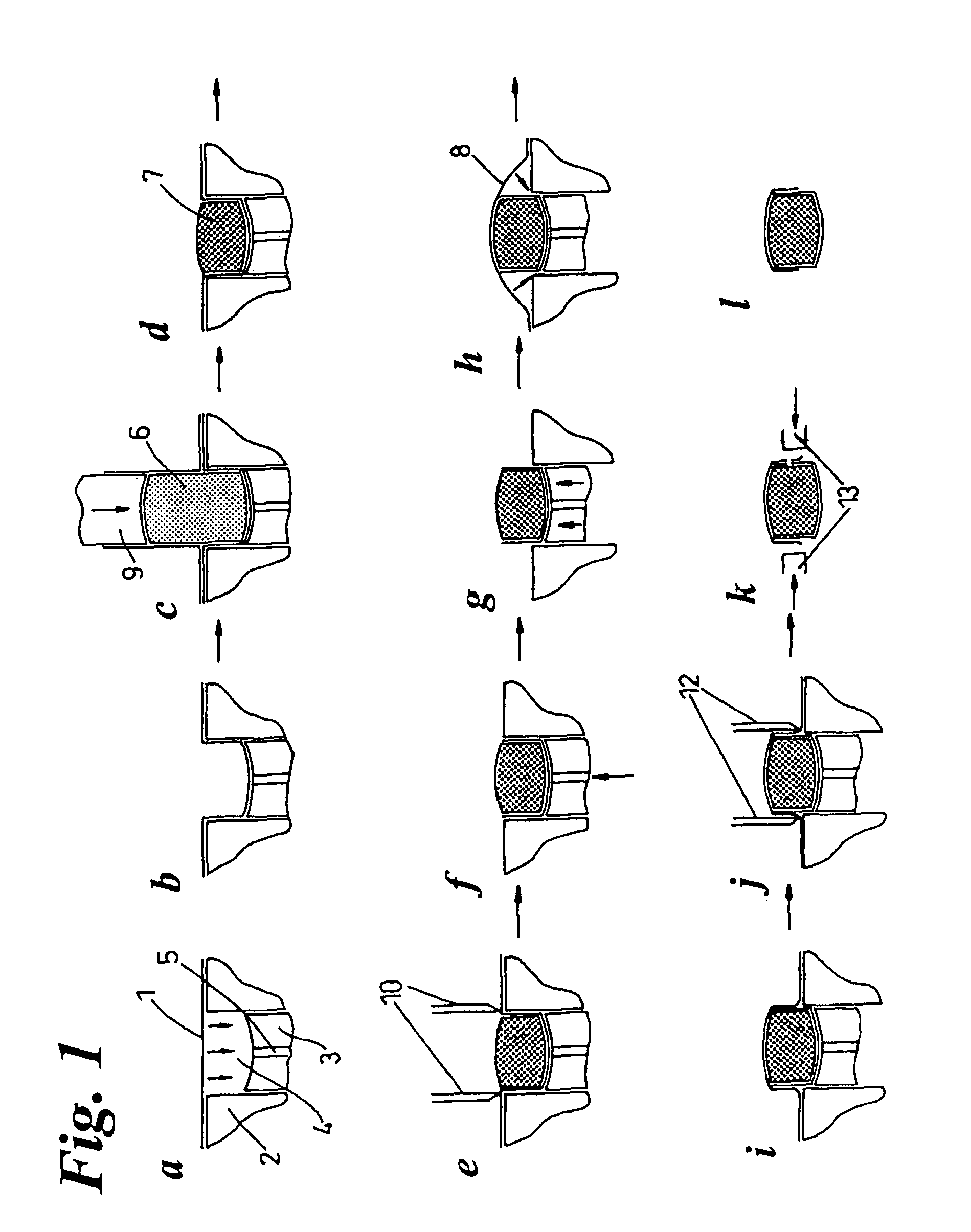

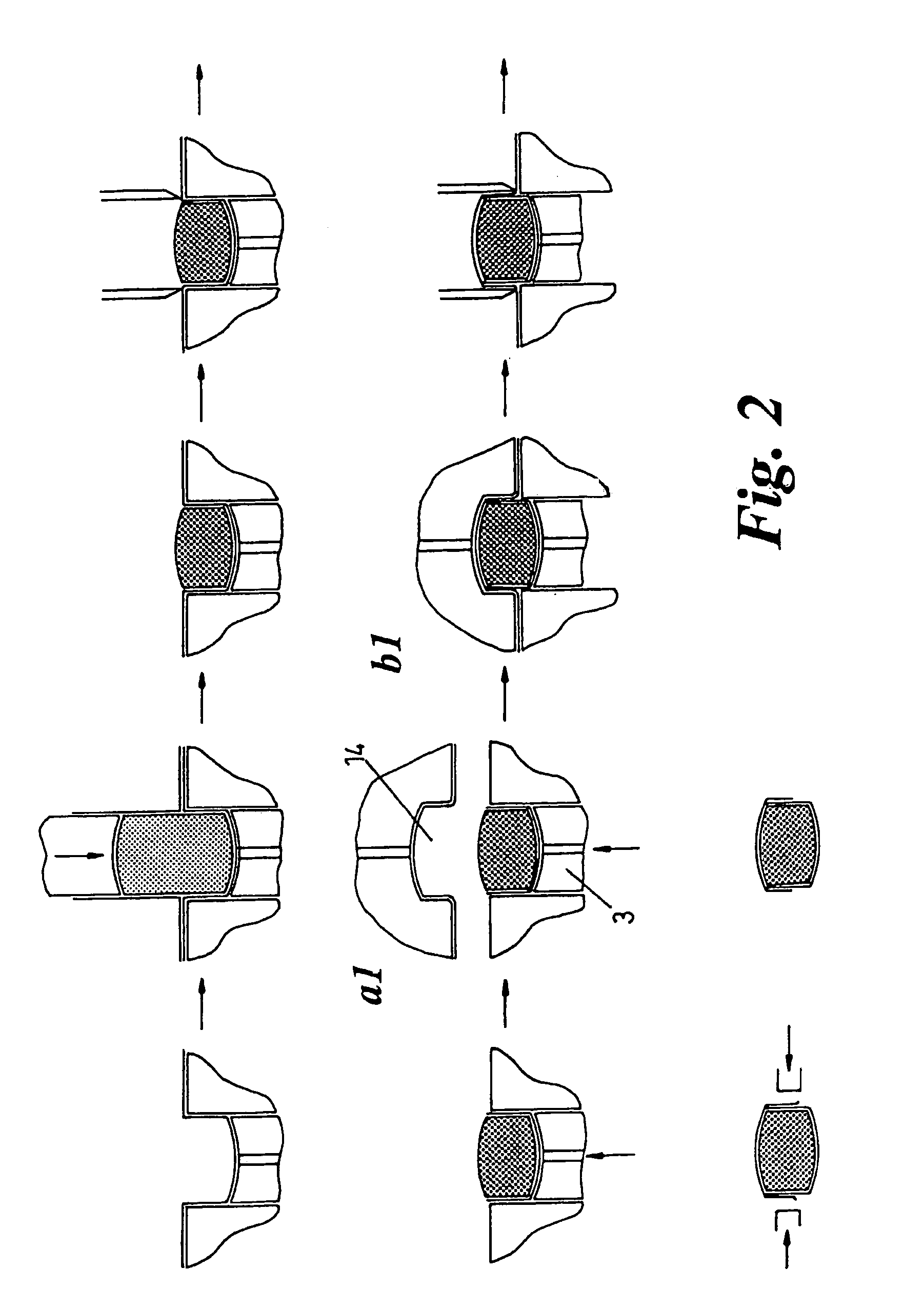

An apparatus and method is disclosed for forming a compacted powder slug coated with a film. The powder, e.g. of a medicament, is compacted and enrobed to produce compacted powder slugs by preferably mechanically compacting a powder and forming a film of a material, preferably hydroxy propyl methyl cellulose, by vacuum or pressure differential, about the surface of the powder thus compacted.

Owner:BIOPROGRESS TECH

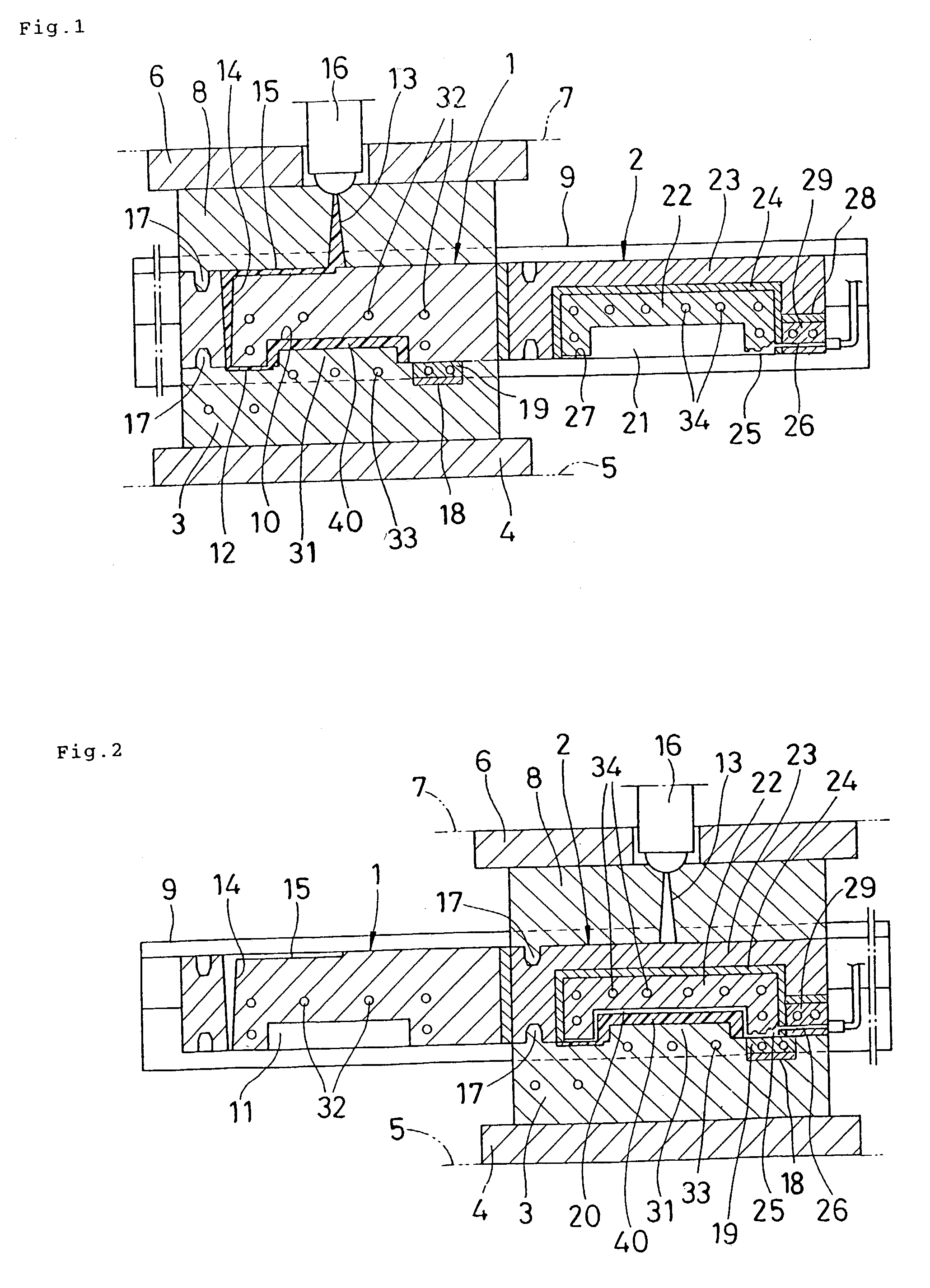

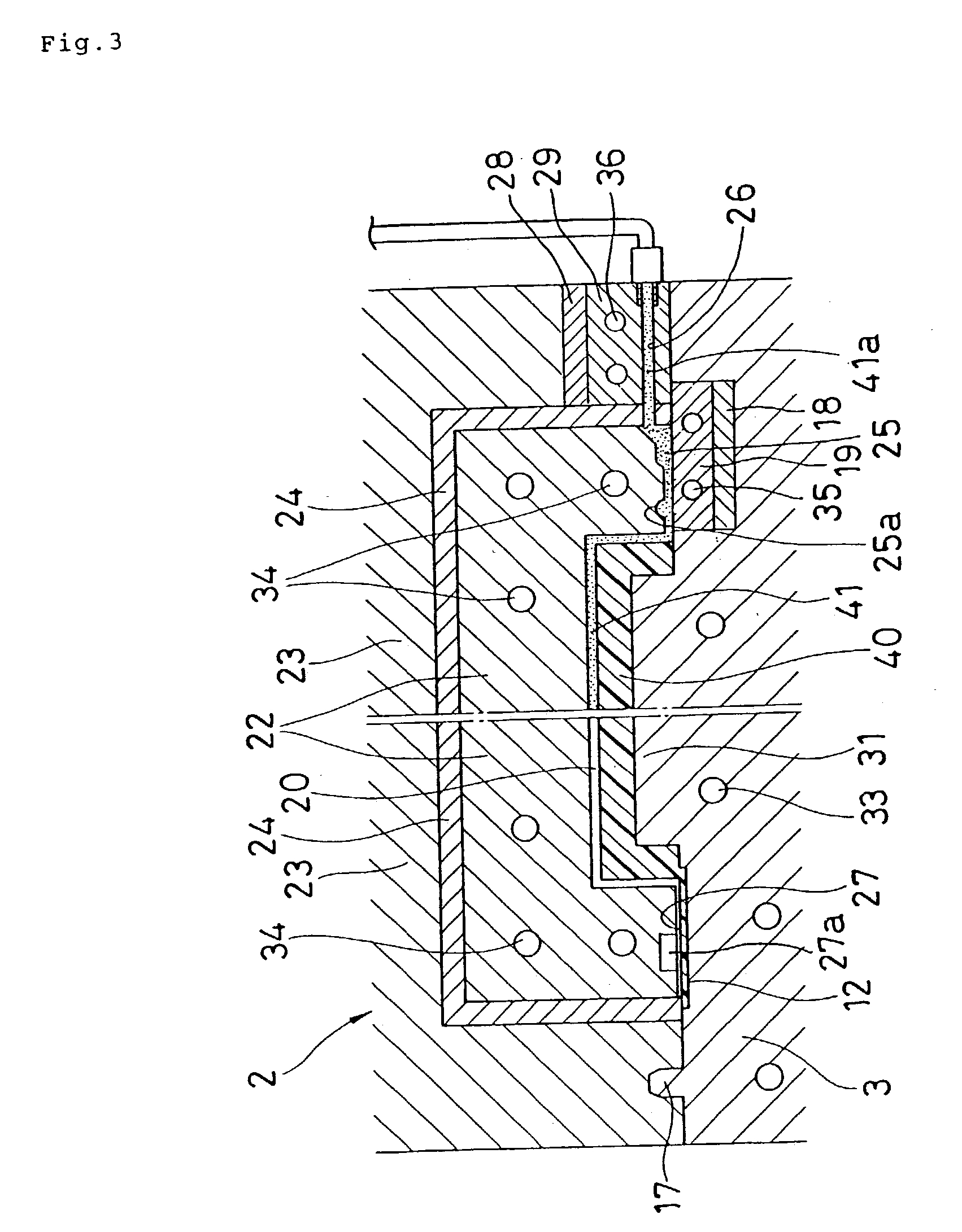

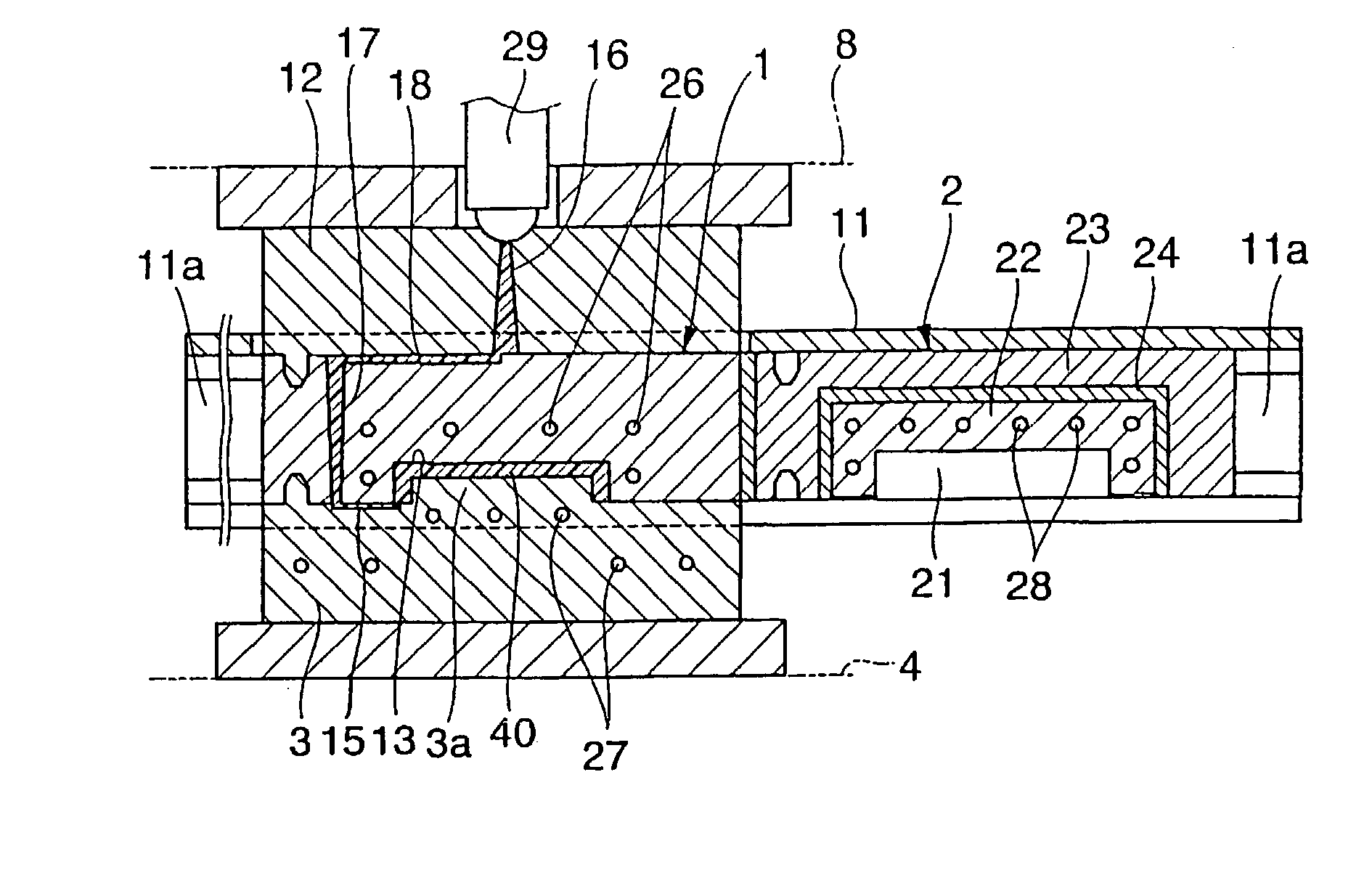

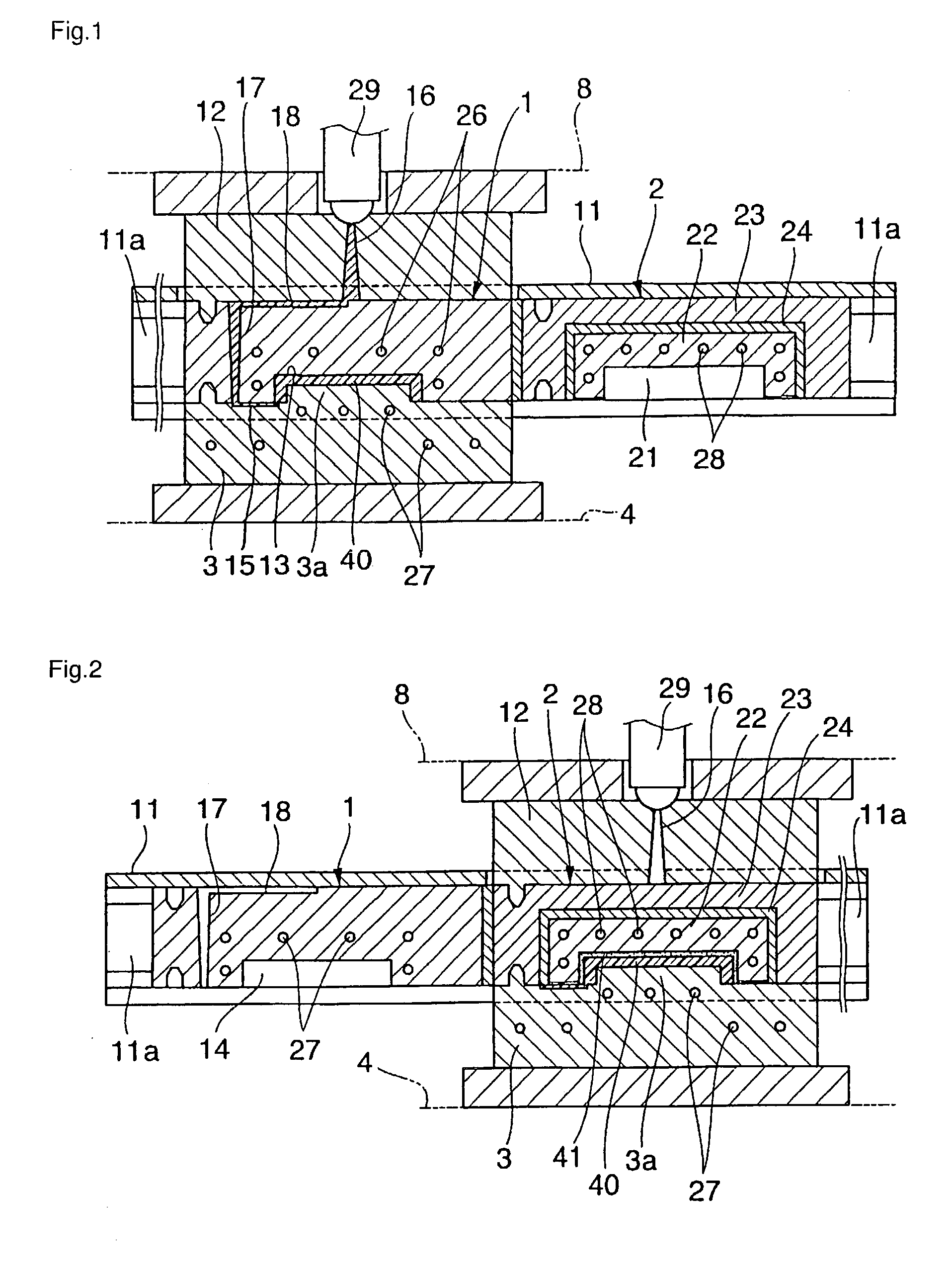

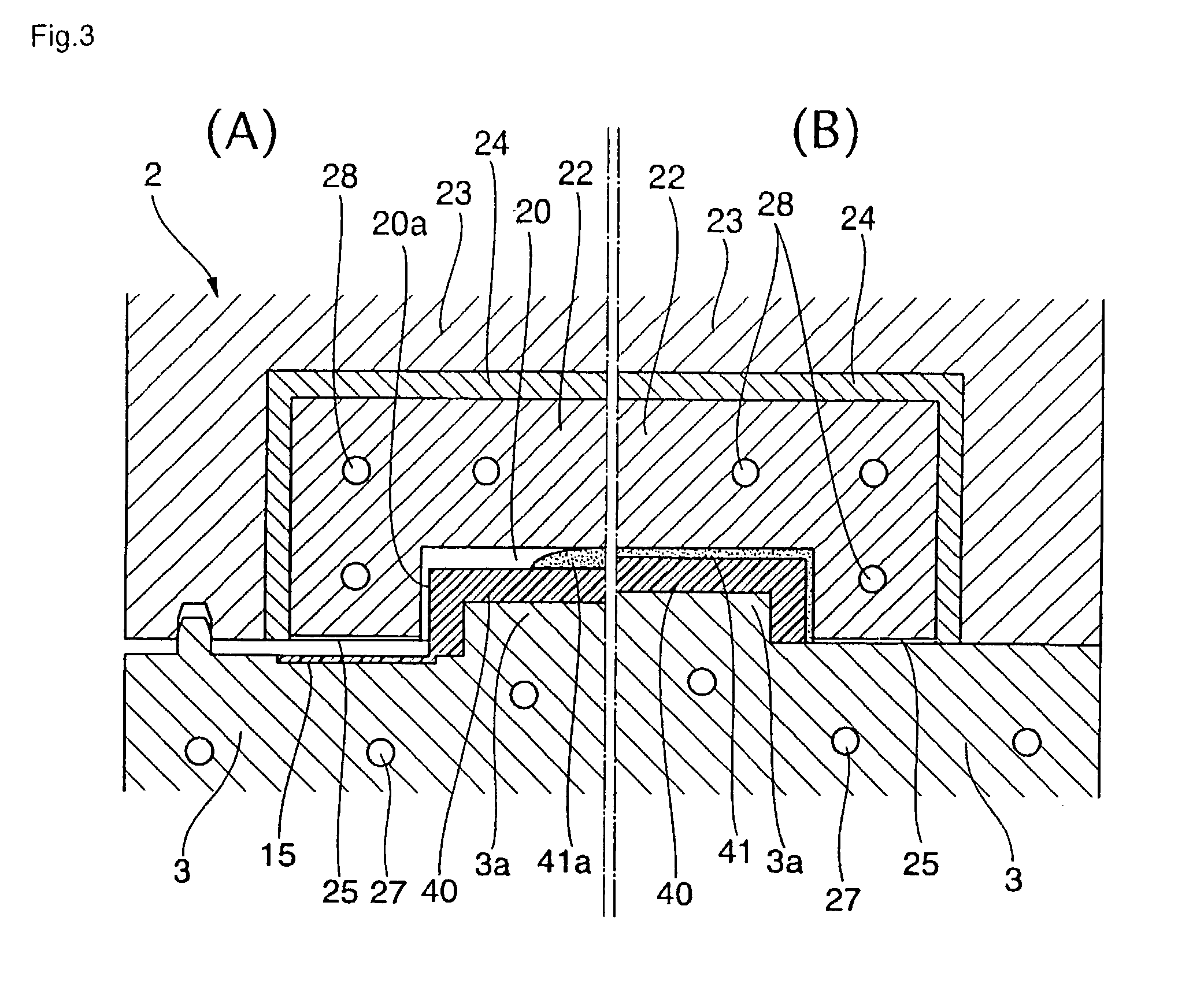

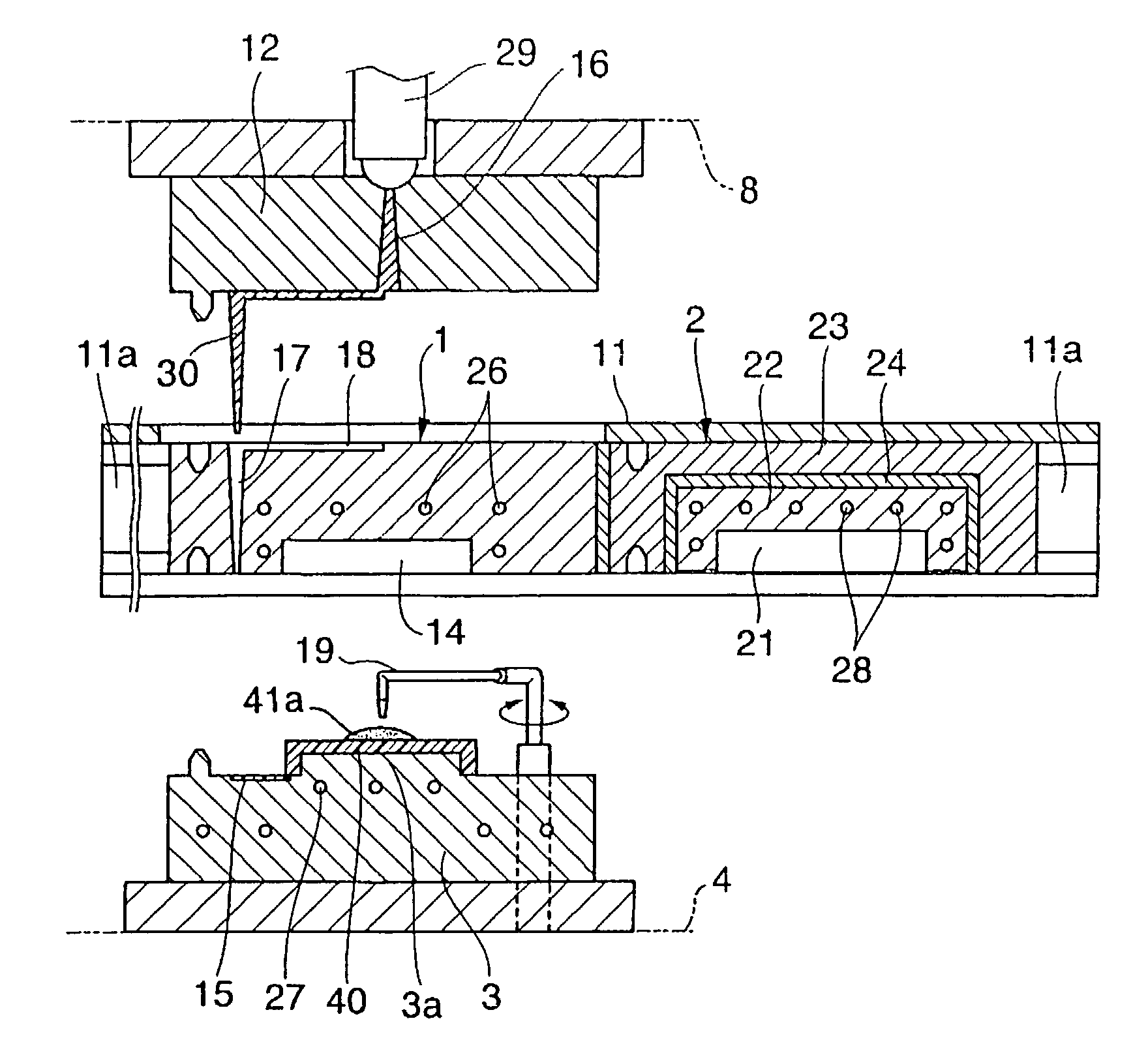

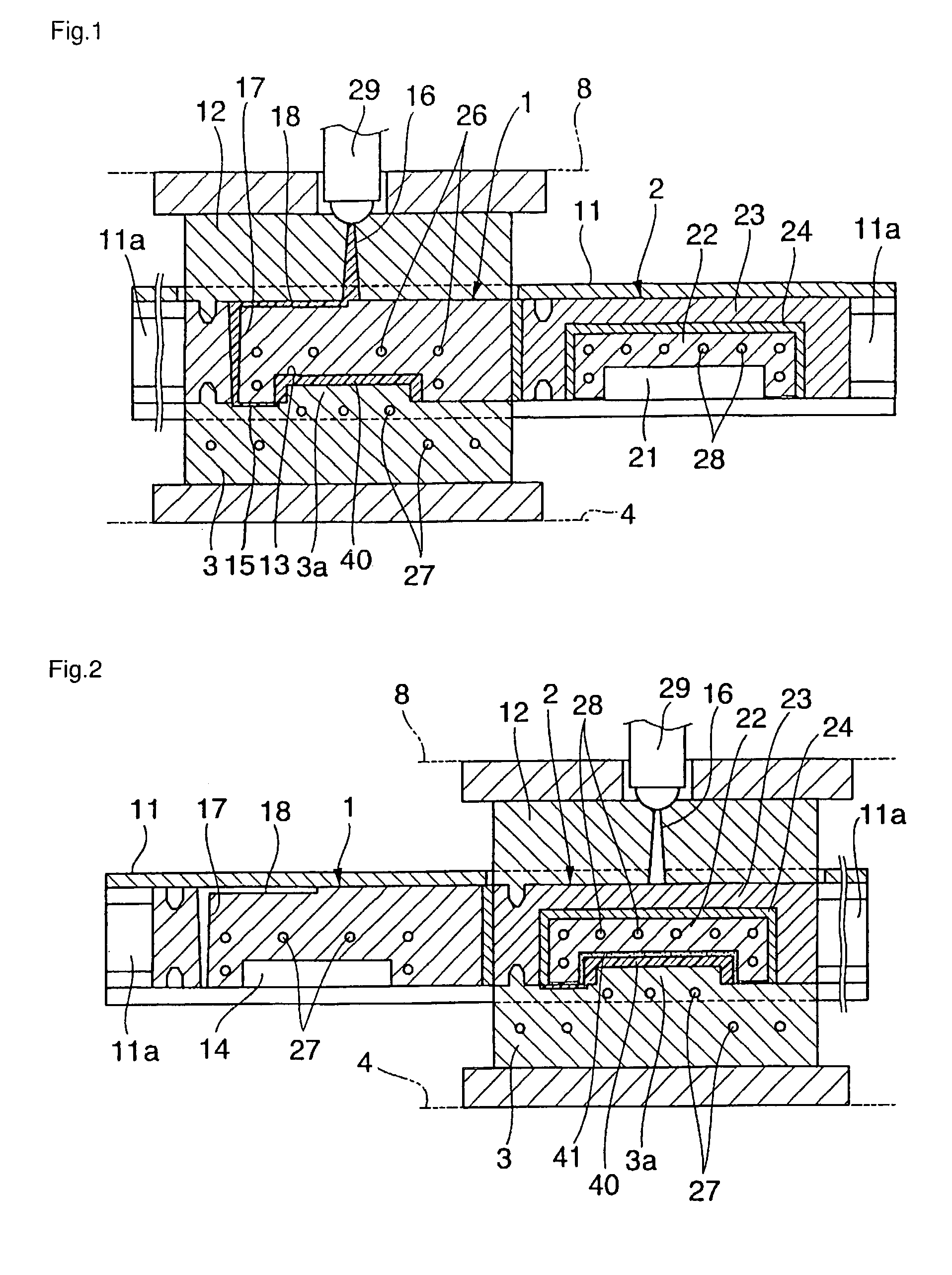

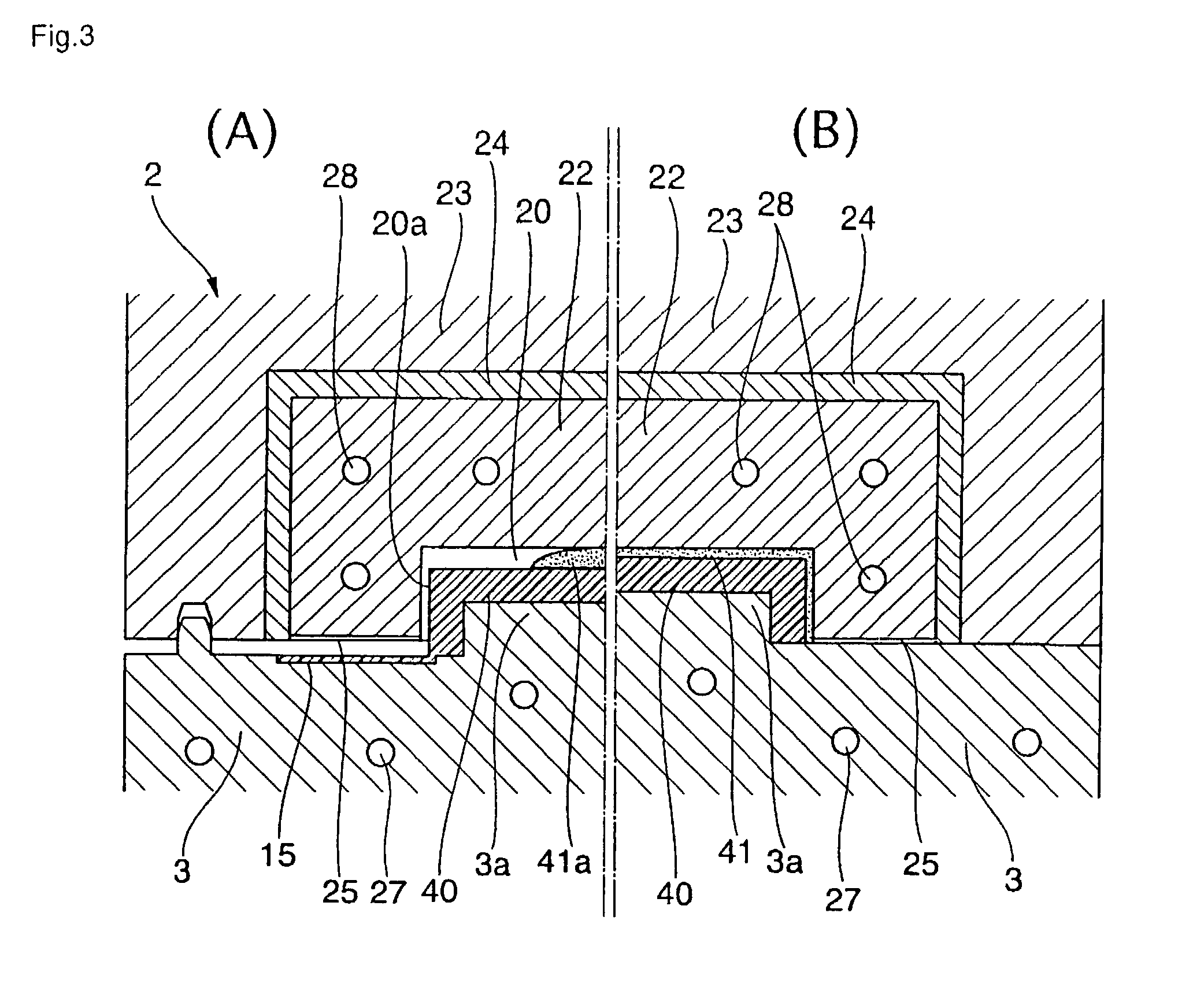

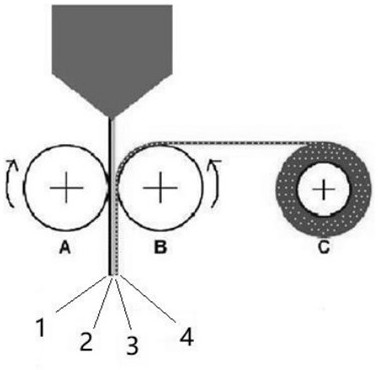

Method for the injection molding and successive decoration molding for a molded product

Injection molding of a product and decoration molding of a surface of the molded product are performed using individual cavity molds. A decorative film can be molded efficiently with a thermosetting coating material under suitable temperature control regardless of the shape of the molded product. An injection cavity mold and a decoration cavity mold are employed. The injection cavity mold is set at a hardening temperature of a thermoplastic resin. The decoration cavity mold is set at a thermosetting temperature of a coating material. A molded product is formed by injection molding in the injection cavity mold. The injection molded product is located within the decoration cavity mold to create a space as a cavity for decoration molding between an inner surface of the decoration cavity mold and a surface of the injection molded product. A decorative film is molded over the surface of the injection molded product by injecting a decorative coating material composed of a liquid thermosetting composition into the cavity under pressure. The coating material is composed of a liquid thermosetting composition that substantially contains no volatile component having a boiling point below the thermosetting temperature set on the cavity mold for decoration molding.

Owner:NIPPON BEE CHEM +1

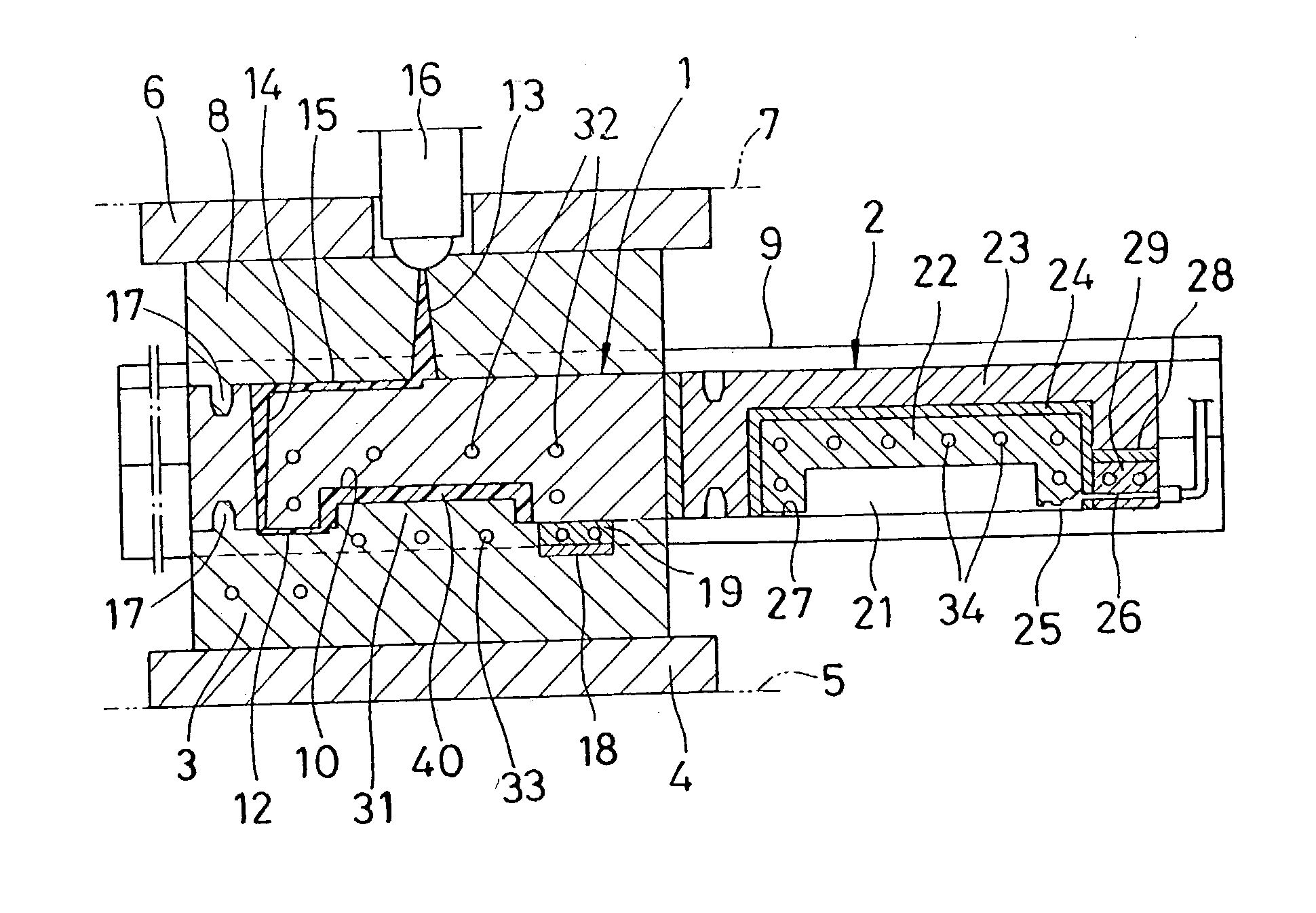

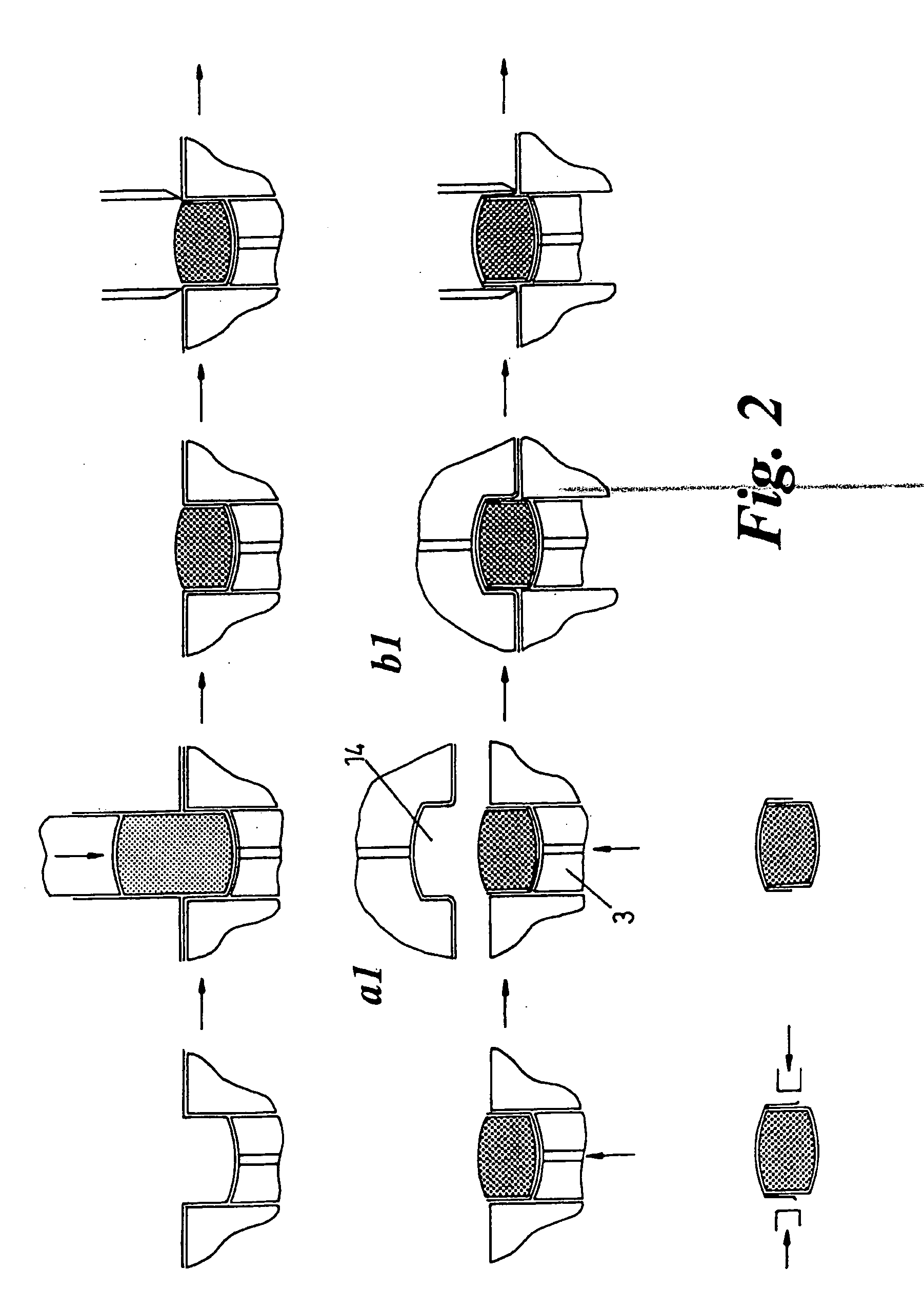

Method of injection molding and compressive decoration molding a molded product

InactiveUS20030227109A1Mold can be simplifiedEasy to storeMouldsWood working apparatusTemperature controlShell molding

Injection molding of a product and compressive decoration molding of a surface of the molded product are performed using individual cavity molds. A decorative film can be molded efficiently with a thermosetting coating material under suitable temperature control regardless of the shape of the molded product. An injection cavity mold and a decoration cavity mold are employed. The injection cavity mold is set at a hardening temperature of a thermoplastic resin. The decoration cavity mold is set at a thermosetting temperature of a coating material. A molded product is injection-molded in the cavity mold for injection molding and released from the mold. A decorative coating material composed of a liquid thermosetting composition is mounted at least on a part of the top of the injection-molded product. The molded product is located within the cavity mold for decoration molding. A thin decorative film is decoration-molded over the surface of the injection molded product by compression spreading the coating material within the cavity mold for decoration molding over the whole surface to be decorated. The coating material is composed of a liquid thermosetting composition that substantially contains no volatile component having a boiling point below the thermosetting temperature set on the cavity mold for decoration molding.

Owner:NIPPON BEE CHEM +1

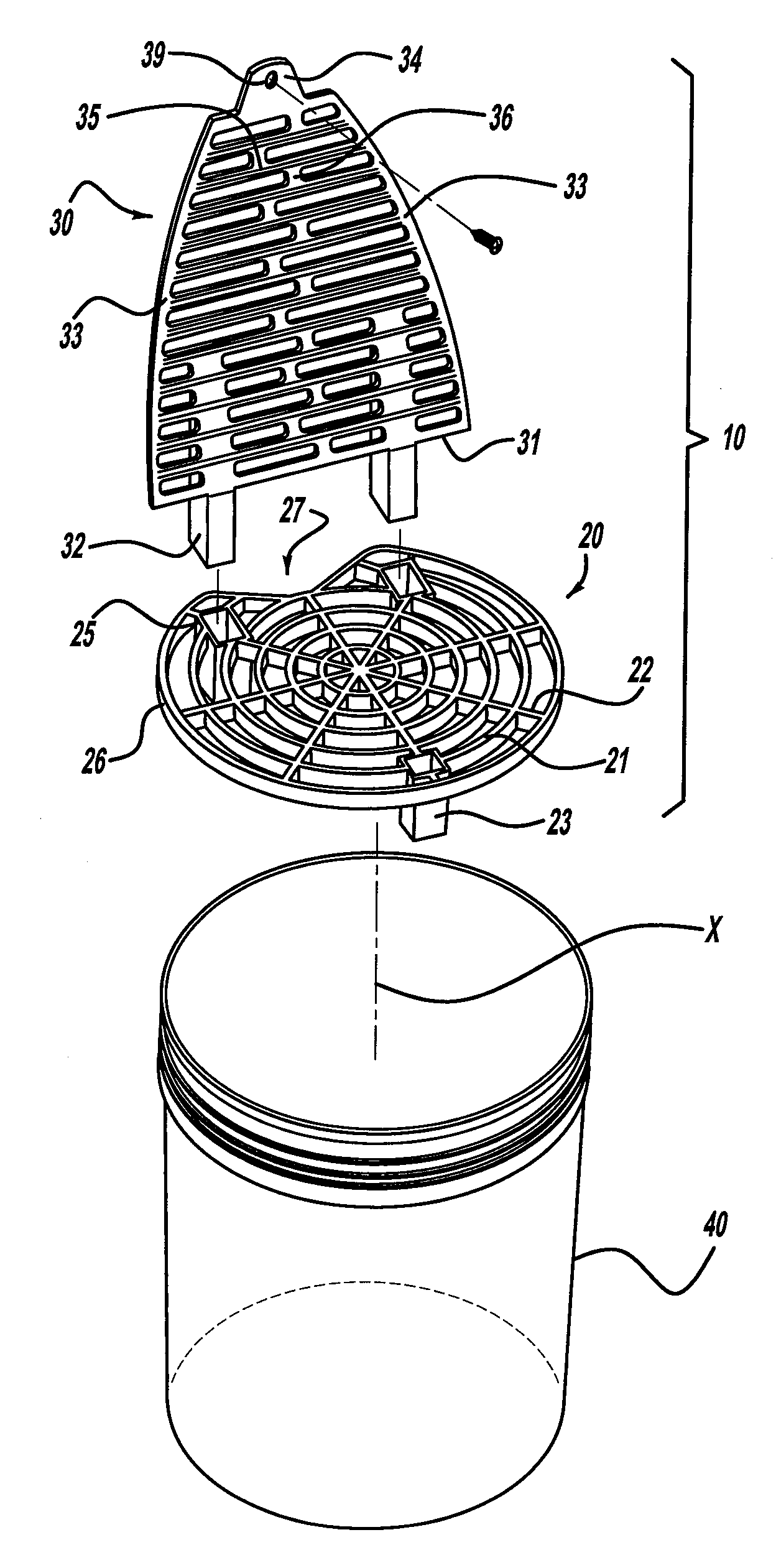

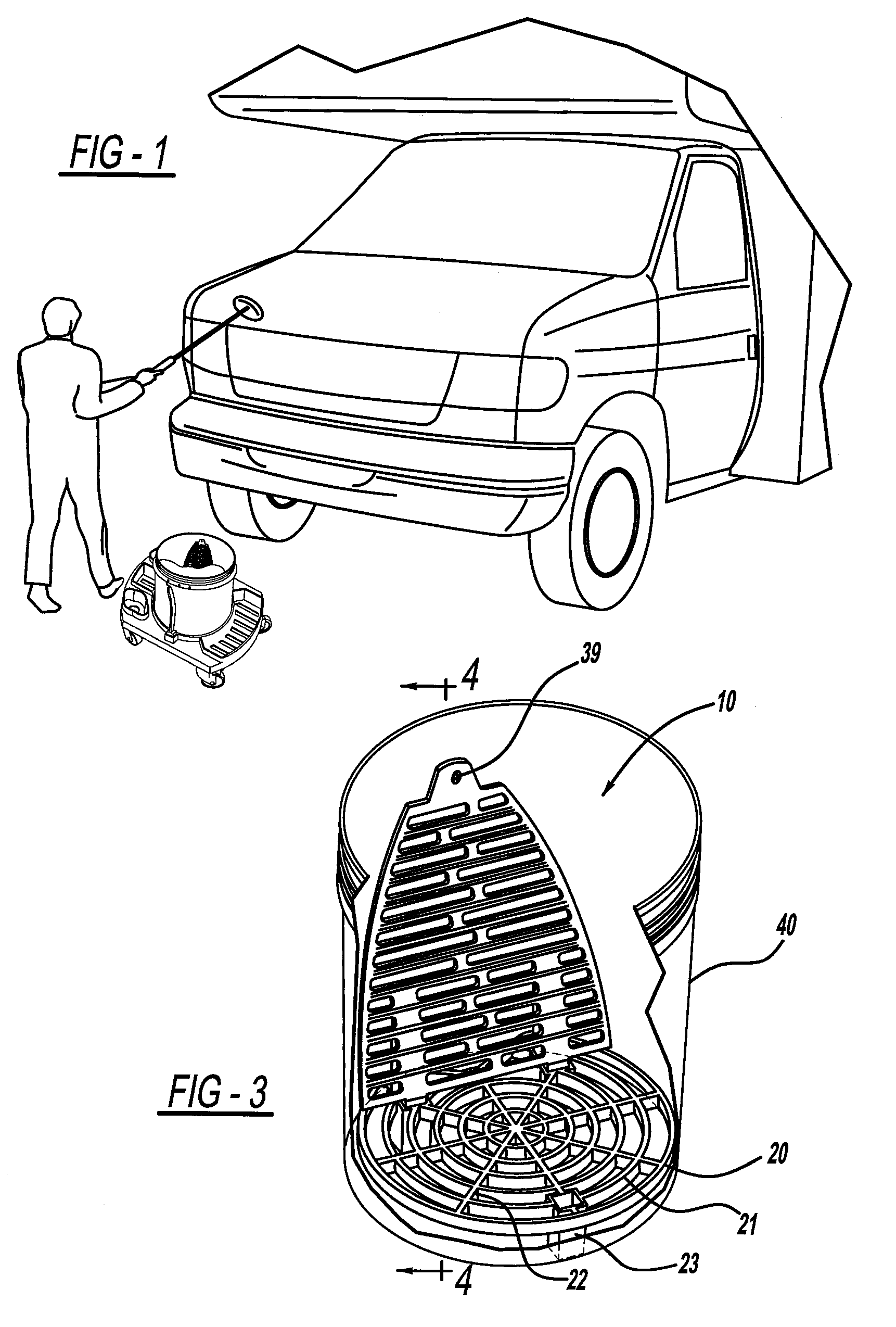

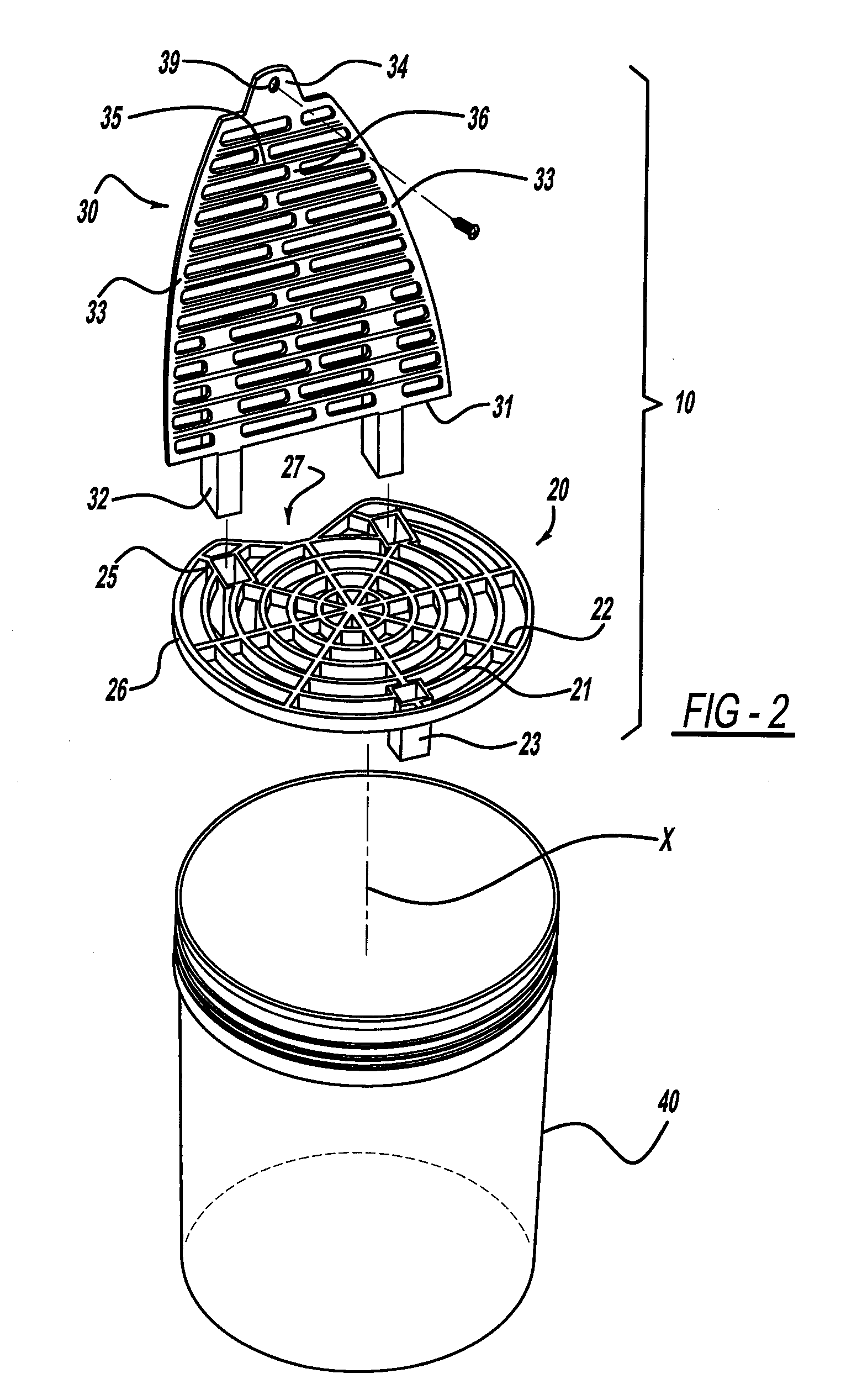

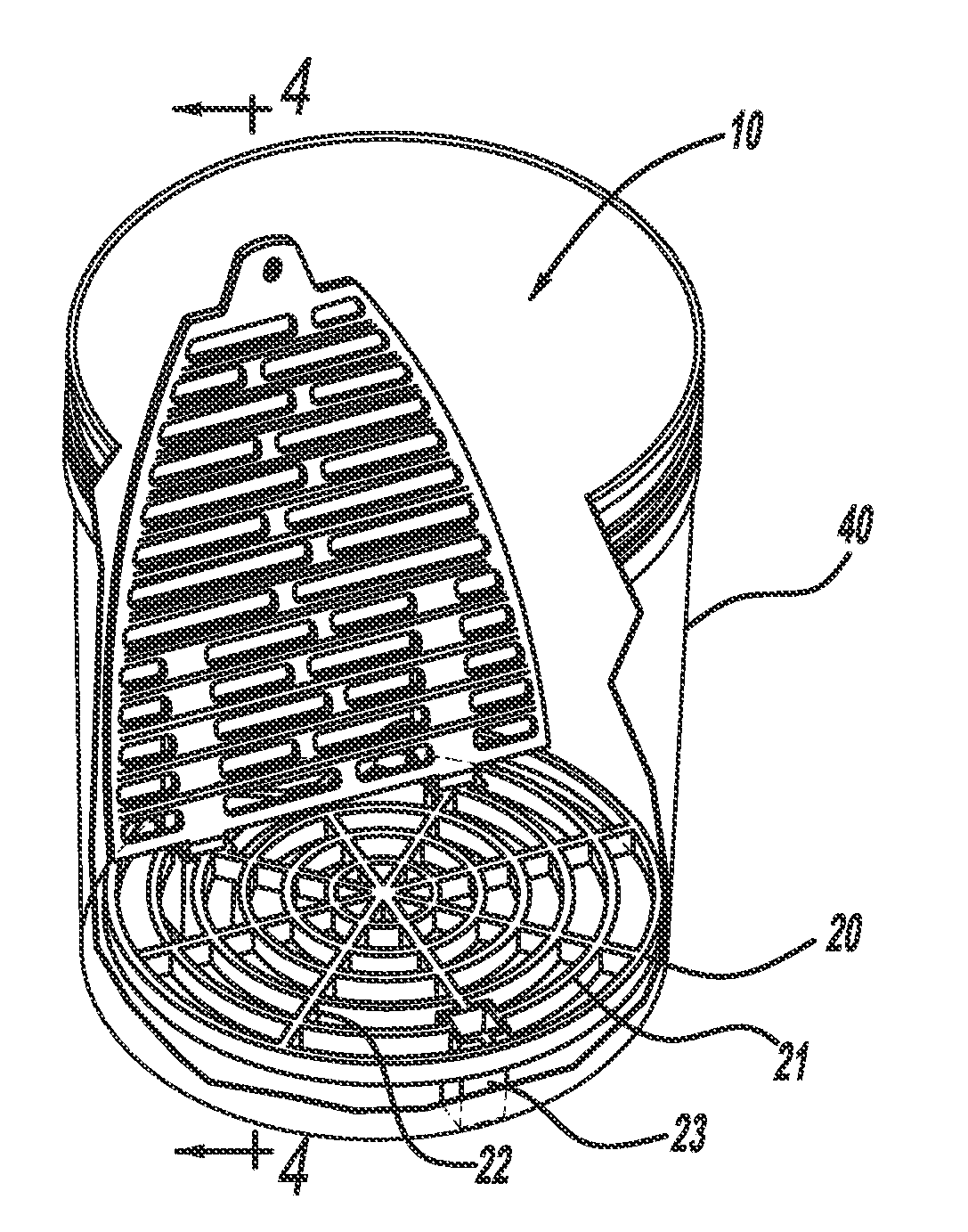

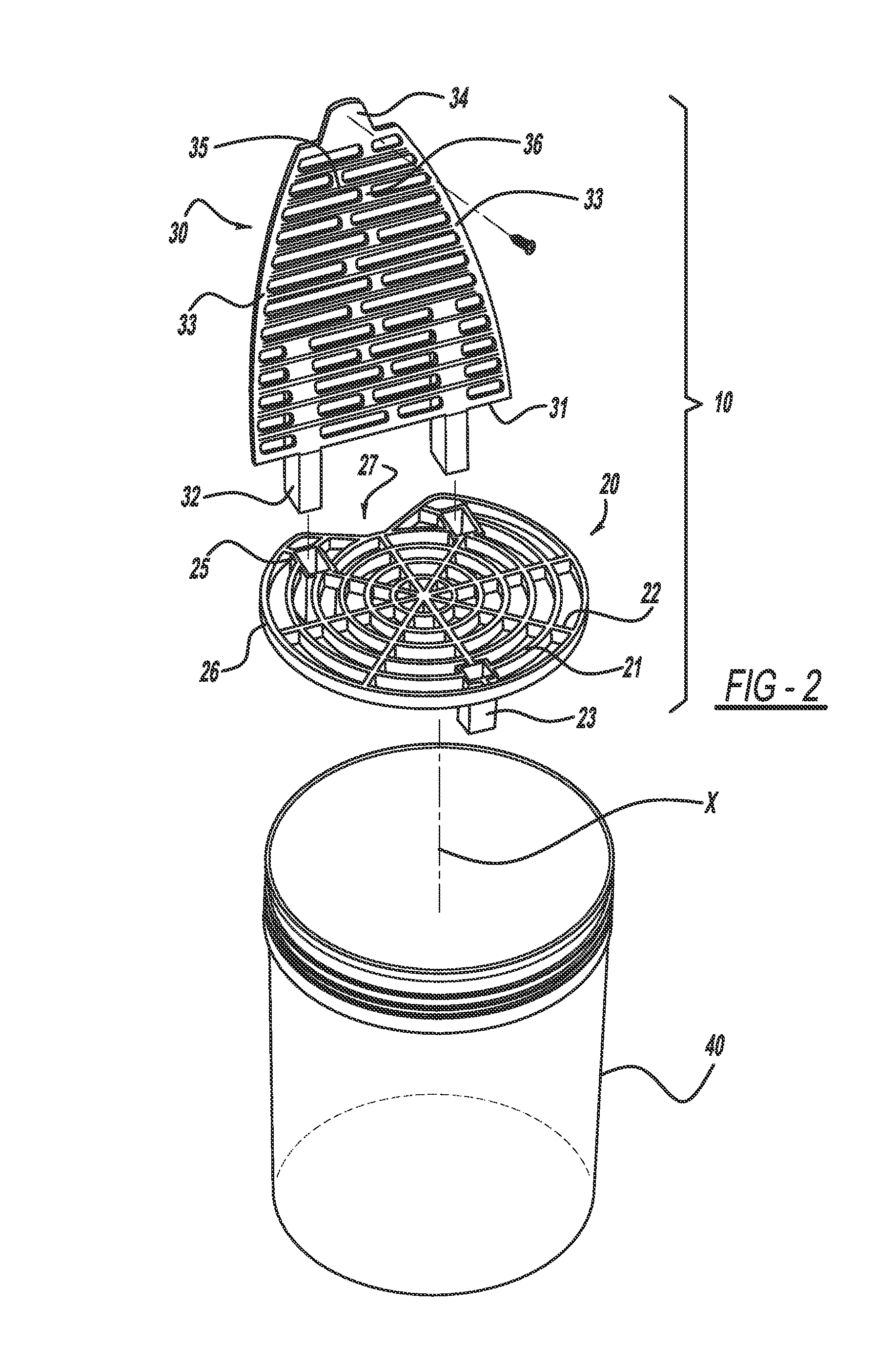

Cleaning system for removing abrading material

ActiveUS8042215B2Provide integrityEliminate scratch and abrasionLiquid surface applicatorsKitchenware cleanersScrubberAbrasive

Owner:THIBAULT RICHARD R

Powder compaction and enrobing

InactiveUS20050220824A1RobustSmall areaWrappers shrinkageWood working apparatusHydroxypropylmethyl celluloseMethyl cellulose

Powder, e.g. of a medicament, is compacted and enrobed to produce compacted powder slugs by preferably mechanically compacting a powder and forming a film of material, preferably hydroxy propyl methyl cellulose, by vacuum or pressure differential, about the surface of the powder thus compacted.

Owner:BIOPROGRESS TECH INT

Polypropylene impact copolymer compositions

The present invention relates to an impact-resistant olefin polymer composition including a polypropylene matrix having a weight average molecular weight and an ethylene-containing polymer including an ethylene-propylene copolymer having a molecular weight higher than the weight average molecular weight of the polypropylene matrix, the composition containing about 20 to 35 percent xylene solubles, and the xylene solubles fraction of the composition containing less than about 39 weight percent ethylene units, based on the combined weight of olefin monomers in the copolymer. The present invention further relates to impact copolymer compositions with a melt flow rate greater than about 8 that meet or exceed all pallet testing requirements. The compositions have superior stiffness-impact balance performance and excellent gloss and are useful for a number of applications including, but not limited to pallets, water-storm chambers, automotive compounding, septic tanks, bins, pales, crates, totes and plastic containers.

Owner:BRASKEM AMERICA

Exquisite gold bar ornament sand pointing technique

The invention discloses a pointing sand process of bullion jewelry, comprising pouring wax-drawing powder-roasting mold-reversing mold-holding mold-grinding-blowing sand-pointing sand-milling-shaping. The process combines with two technique of engraving and nailing sand. The product is subjected to nailing sand (pointing sand) using the surface density (fineness) of the diamond needle, therefore the contrast effect of the product is enhanced with more nicety and higher efficiency and the surface gloss of the product is very light and beautiful.

Owner:深圳明丰珠宝首饰有限公司

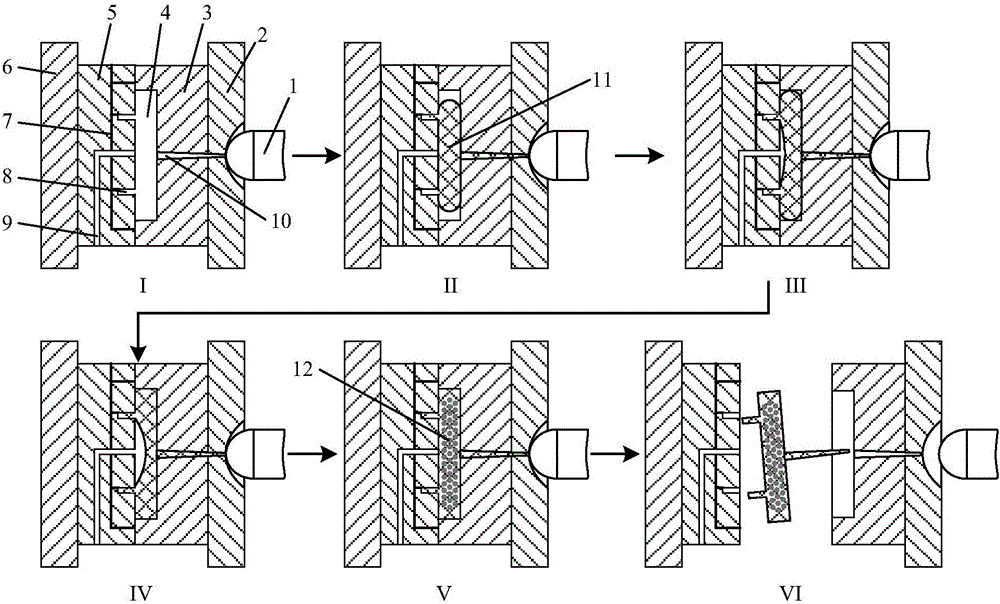

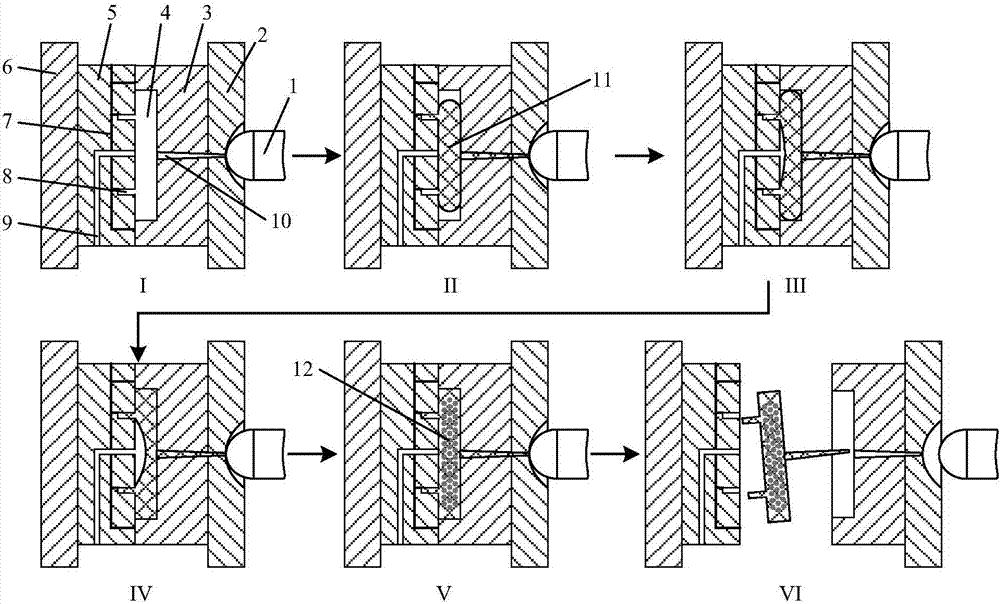

Microcellular foaming injection molding technology capable of realizing high surface glossiness and high bubble density as well as mold

ActiveCN105835299ASolve bottlenecksRequirements for lower measurement accuracyFoaming agentPolymer science

The invention discloses a microcellular foaming injection molding technology capable of realizing high surface glossiness and high bubble density as well as a mold. The technology comprises steps as follows: a physical foaming agent or a chemical foaming agent is evenly mixed with polymer melt in a high-pressure environment by the aid of a microcellular foaming injection molding machine; the temperature of a mold is increased, high-pressure gas is introduced into a cavity of the mold, the polymer melt smaller than the total volume of the cavity of the mold is injected into the cavity of the mold, and foaming space is reserved; the high-temperature state of the wall surface of the cavity of the mold is kept, gas channels located on a moving mold side wall surface of the cavity of the mold and a parting surface of the mold are opened in a matched manner, a gas is controlled to enter and leave the cavity of the mold, and the polymer melt is controlled to flow, so that the reserved foaming space is transferred to the moving mold side of the cavity of the mold; the mold is cooled, when the temperature of the melt is decreased to the foaming temperature, all gas channels of the mold are opened, gas inside the reserved space is exhausted, and a polymer foams and fills rest space of the cavity of the moving mold. The technology can prevent dynamic foaming and promote static foaming and can be used for producing plastic products with the high surface glossiness and the high inside bubble density.

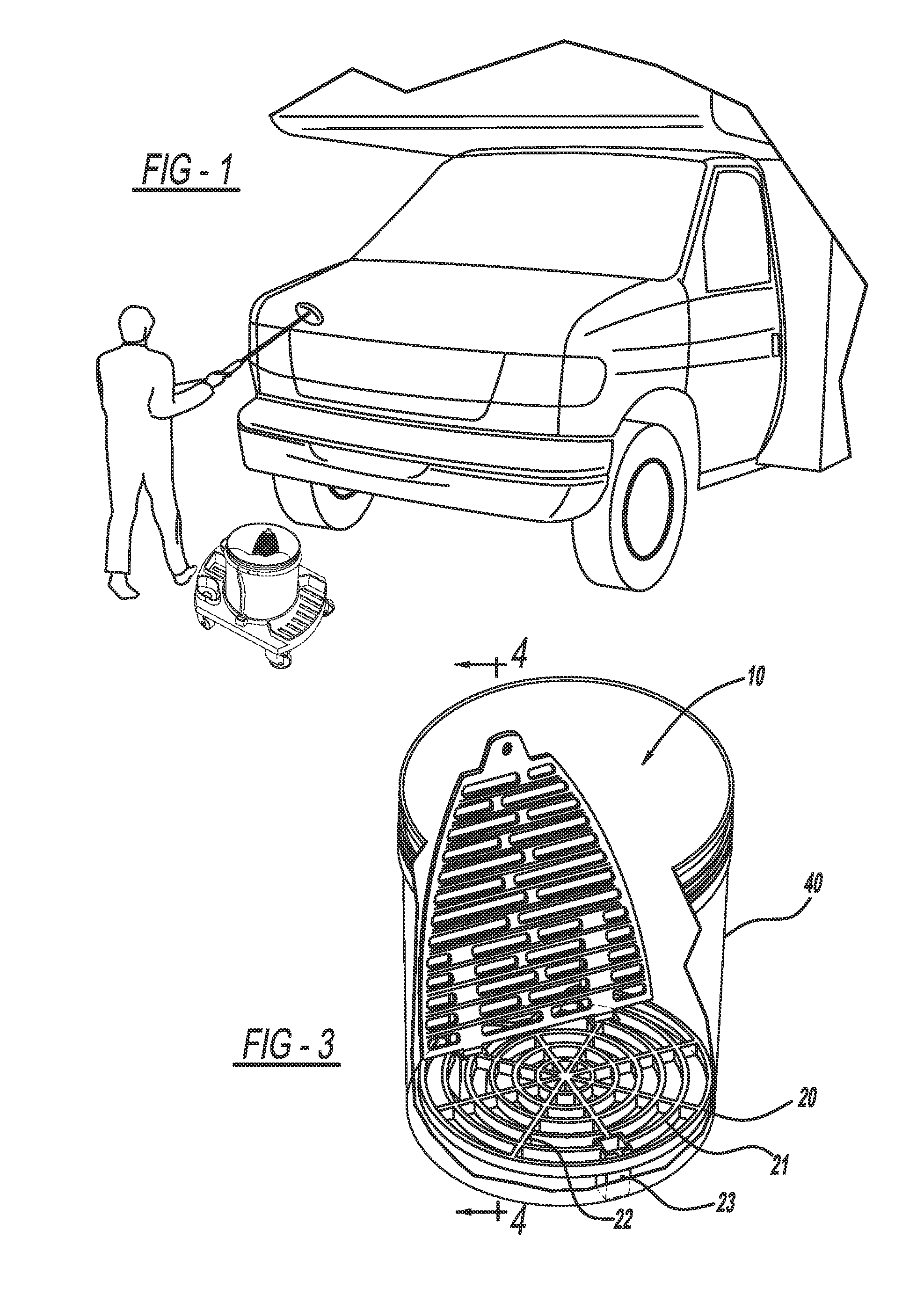

Cleaning System for Removing Abrading Material

ActiveUS20090300869A1Easy to cleanEasy to transportCarpet cleanersKitchenware cleanersScrubberAbrasive

A cleaning system for removing abrading material adapted to remove and keep separated the abrasive contaminants from a wash rag, mitt, or brush which is capable of being mounted within a standard 5 gallon bucket for the purposes of washing a car, boat, recreational vehicle or the like. The cleaning system is a lattice structure including a scrubber grate which is positioned within the bucket such that a wash rag, mitt, or long handled brush is capable of being vigorously rubbed against the scrubber grate such that any abrasive grit or contaminants within the wash rag, mitt, or long handled brush will become dislodged and settle to the bottom of the cleaning fluid within the bucket. The lattice structure also has a receiver base to support the scrubber grate and is located near the bottom of the bucket. The lattice structure receiver base allows abrasive contaminants and debris to settle to the bottom of the bucket. The lattice structure receiver base cross-bar structure results in dampening the agitation of the cleaning fluid below the receiver base causing the abrasive contaminants to remain near the bottom of the bucket.

Owner:THIBAULT RICHARD R

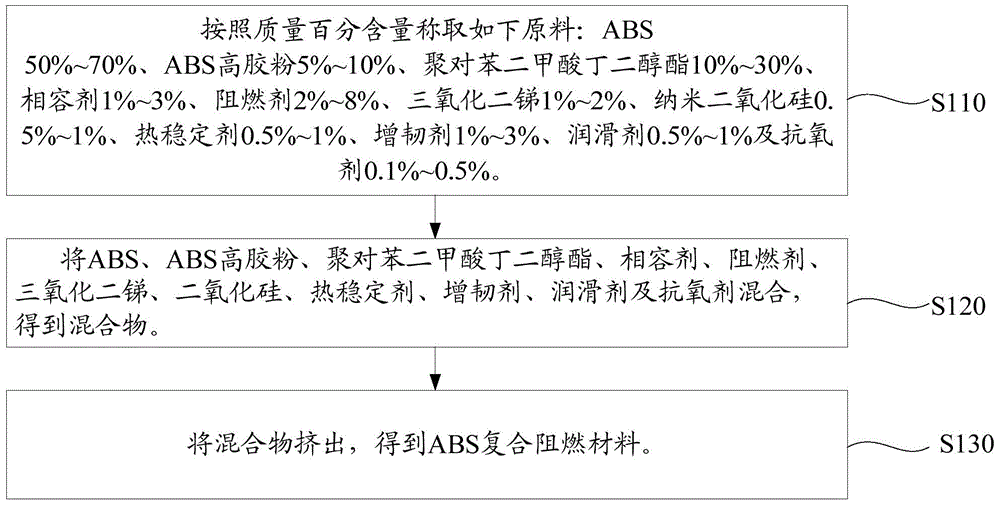

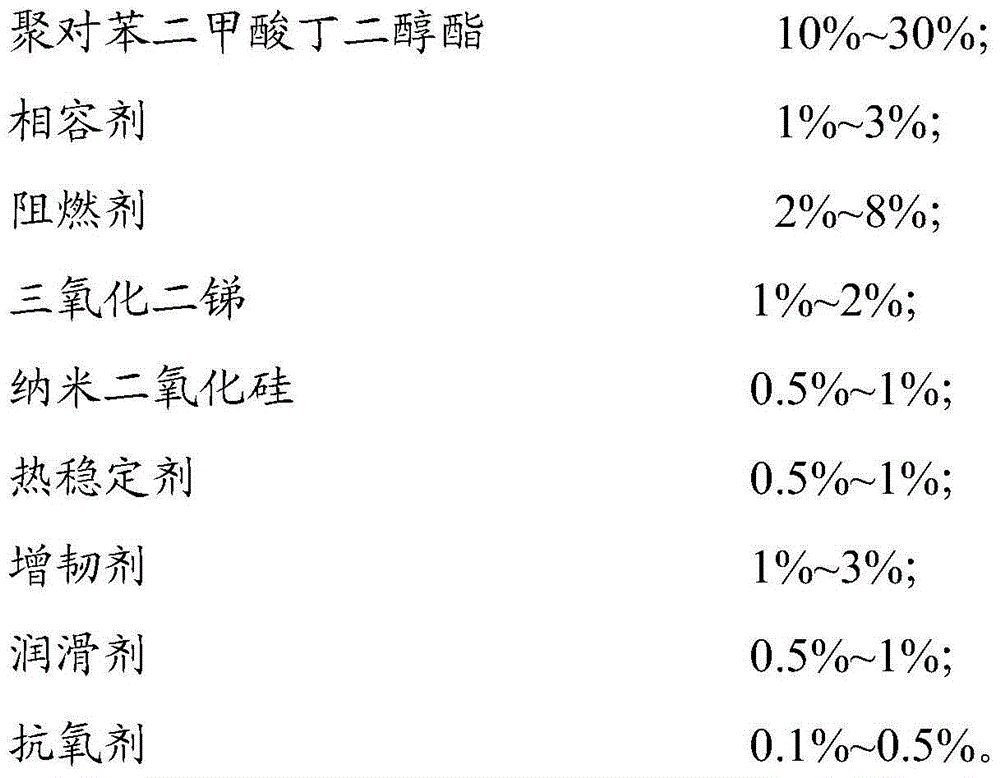

ABS composite flame resistant material and preparation method thereof

The invention relates to an ABS composite flame resistant material and a preparation method thereof. The ABS composite flame resistant material comprises the following raw materials by weight percentage: 50-70% of ABS, 5-10% of ABS high glue powder, 10-30% of polybutylene terephthalate, 1-3% of compatilizer, 2-8% of fire retardant, 1-2% of antimonous oxide, 0.5-1% of nano-silicon dioxide, 0.5-1% of thermal stabilizer, 1-3% of flexibilizer, 0.5-1% of lubricant and 0.1-0.5% of antioxidant. The ABS composite flame resistant material has good thermal stability and physical and mechanical properties, and simultaneously has a glossy outer surface.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

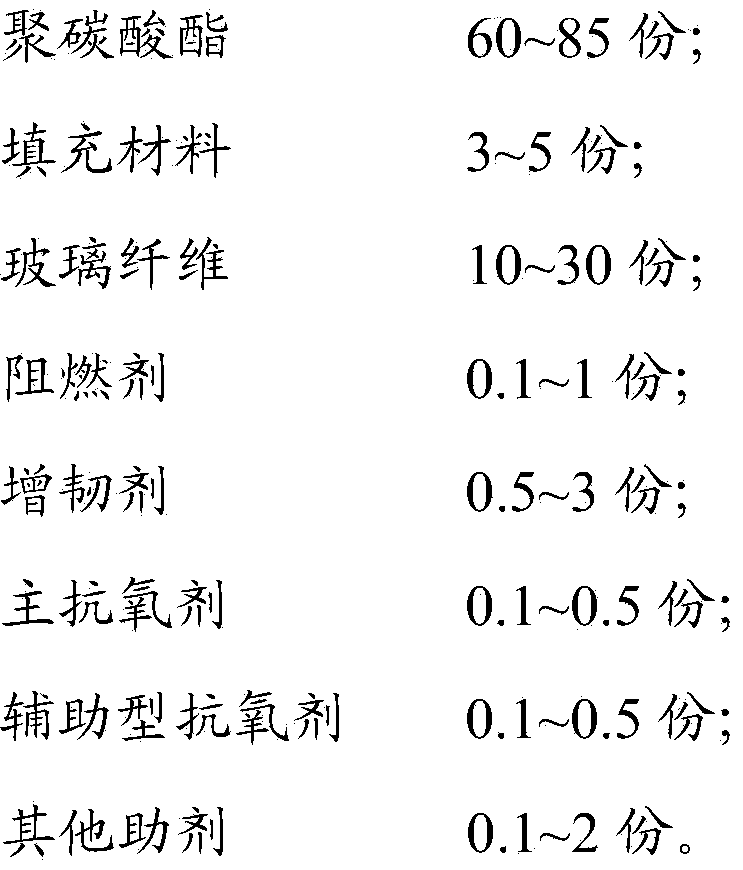

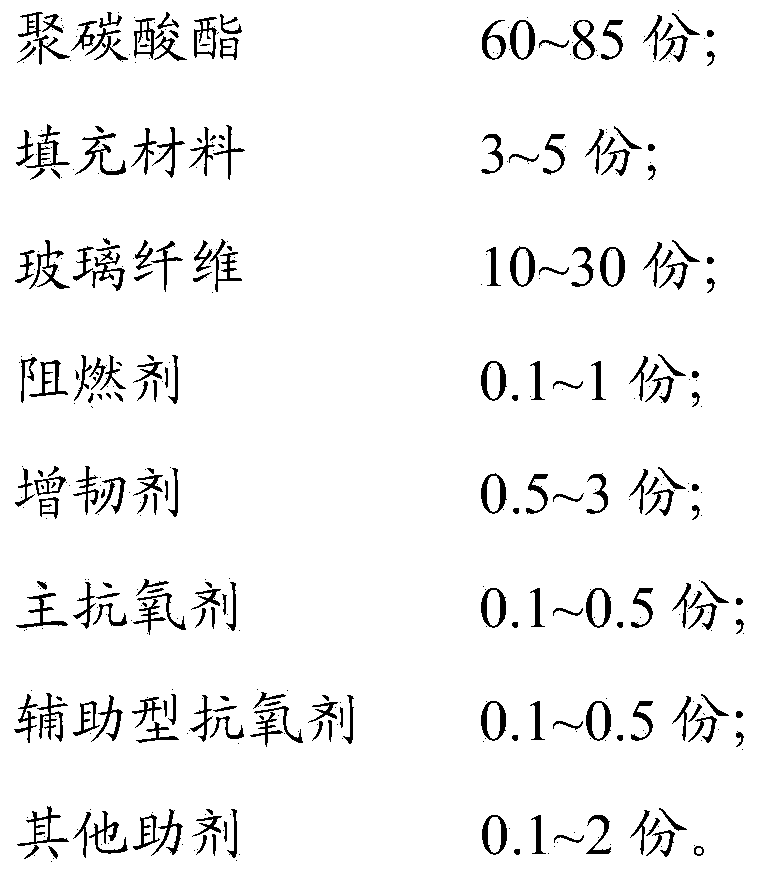

Polycarbonate composition and preparation method thereof

The invention discloses a polycarbonate composition and a preparation method thereof. The polycarbonate composition comprises the following components in parts by weight: 75-86 parts of polycarbonate, 3-5 parts of filling material, 10-15 parts of glass fibers, 0.1-1 part of flame retardant, 0.5-3 parts of toughening agent, 0.1-0.5 part of main antioxidant, 0.1-0.5 part of auxiliary antioxidant, and 0.1-2 parts of other agents. The polycarbonate is modified under the coordination of the reinforcing material, the toughening agent and the processing aid, so that the polycarbonate composition has the advantages of good stability, high strength, warping resistance, good surface glossiness and excellent high-speed puncture impact resistance and toughness. Meanwhile, the polycarbonate composition has a good flame-retardant performance.

Owner:惠州市沃特新材料有限公司

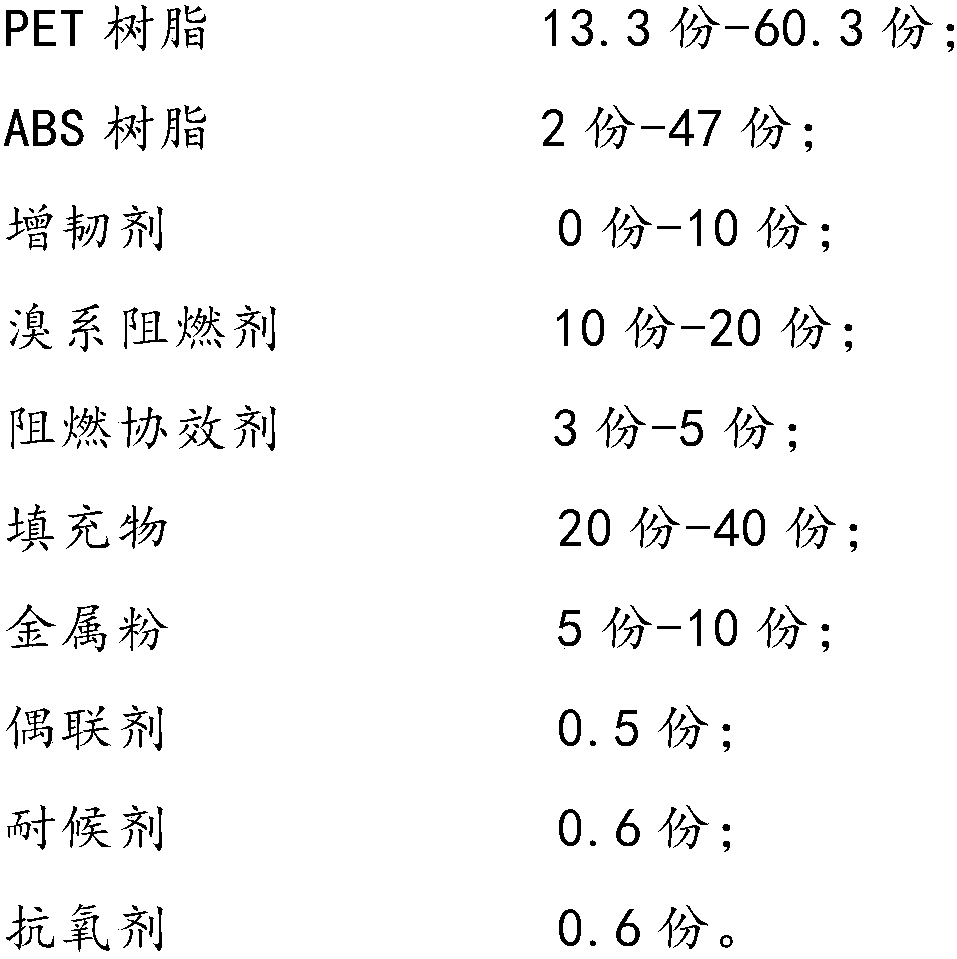

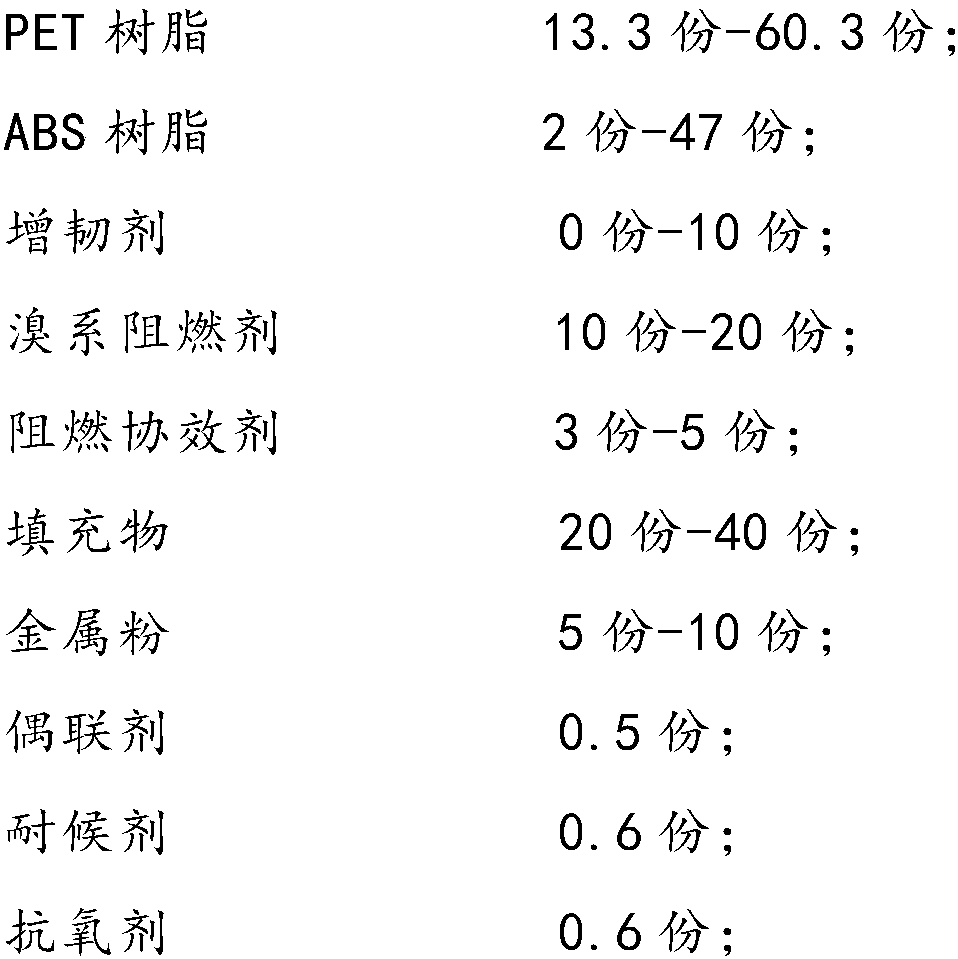

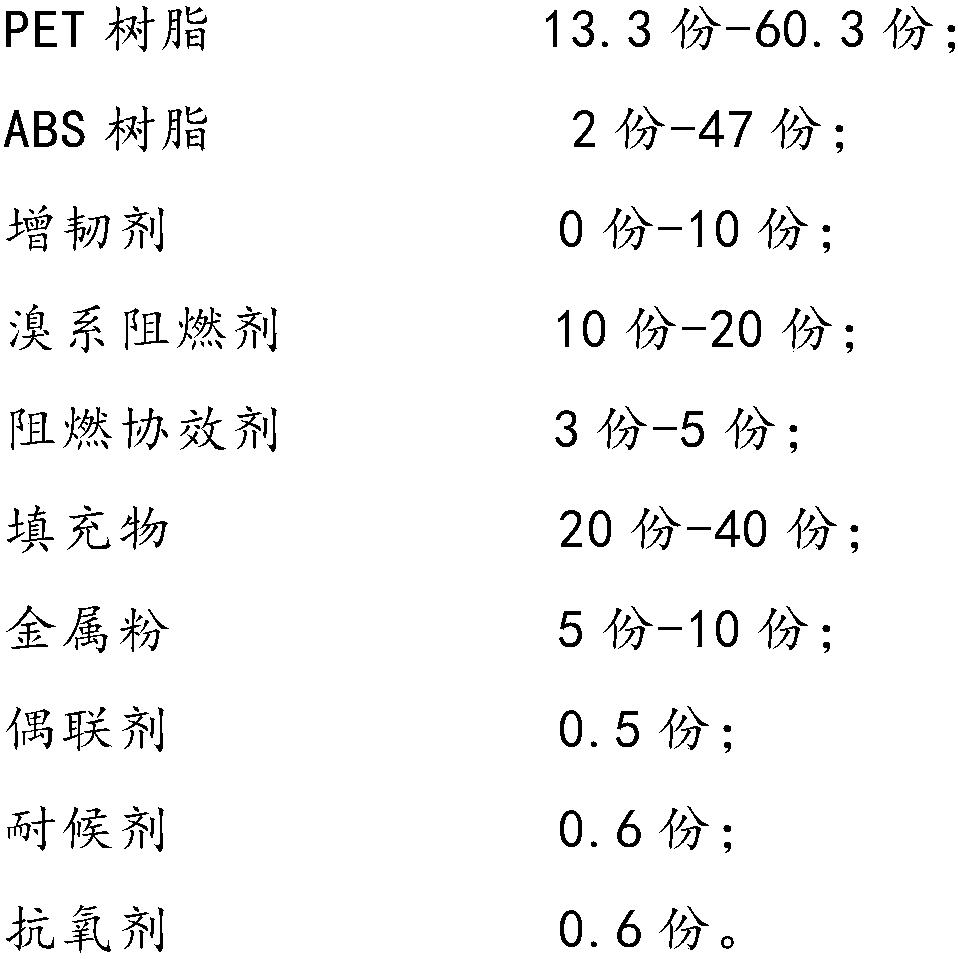

Ceramic-simulating flame-retardant PET/ABS (polyethylene terephthalate/acrylonitrile-butadienes-styrene) resin composition and preparation method thereof

The invention discloses a ceramic-simulating flame-retardant PET / ABS (polyethylene terephthalate / acrylonitrile-butadienes-styrene) resin composition and a preparation method thereof. The ceramic-simulating flame-retardant PET / ABS resin composition is prepared from the following components in parts by weight: 13.3 to 60.3 parts of PET resin, 2 to 47 parts of ABS resin, 0 to 10 parts of toughener, 10 to 20 parts of brominated flame retardant, 3 to 5 parts of flame-retardant synergist, 20 to 40 parts of filling matter, 5 to 10 parts of metal powder, 0.5 part of coupling agent, 0.6 part of weather-resistant agent and 0.6 part of antioxidant. The ceramic-simulating flame-retardant PET / ABS resin composition has the characteristics that the shock-resistant property is better, the surface gloss ishigh, the density is larger, the toughness is good, and the like; the ceramic-simulating flame-retardant PET / ABS resin composition can be used for replacing ceramic products in certain fields.

Owner:SHANGHAI KINGFA SCI & TECH +2

Cold-rolled ferritic stainless steel sheet

ActiveUS20170283923A1Excellent surface appearanceSufficient formabilityFurnace typesHeat treatment furnacesChemical compositionFerric

Provided is a cold-rolled ferritic stainless steel sheet having a chemical composition that contains, by mass %, C: 0.01% or more and 0.05% or less, Si: 0.02% or more and 0.75% or less, Mn: 0.1% or more and 1.0% or less, P: 0.04% or less, S: 0.01% or less, Al: 0.001% or more and 0.10% or less, N: 0.01% or more and 0.06% or less, Cr: 16.0% or more and 18.0% or less, and the balance being Fe and inevitable impurities. The metallographic structure includes a ferrite phase, in which the average grain diameter is 10 μm or less, in which the proportion of ferrite grains having a grain diameter of 10 μm or more and less than 40 μm is 60% or more, and in which the proportion of ferrite grains having a grain diameter of less than 5 μm is less than 20%.

Owner:JFE STEEL CORP

Method of injection molding and compressive decoration molding a molded product

InactiveUS7303712B2Mold can be simplifiedEasy to storeMouldsWood working apparatusTemperature controlBoiling point

Injection molding of a product and compressive decoration molding of a surface of the molded product are performed using individual cavity molds. A decorative film can be molded efficiently with a thermosetting coating material under suitable temperature control regardless of the shape of the molded product. An injection cavity mold and a decoration cavity mold are employed. The injection cavity mold is set at a hardening temperature of a thermoplastic resin. The decoration cavity mold is set at a thermosetting temperature of a coating material. A molded product is injection-molded in the cavity mold for injection molding and released from the mold. A decorative coating material composed of a liquid thermosetting composition is mounted at least on a part of the top of the injection-molded product. The molded product is located within the cavity mold for decoration molding. A thin decorative film is decoration-molded over the surface of the injection molded product by compression spreading the coating material within the cavity mold for decoration molding over the whole surface to be decorated. The coating material is composed of a liquid thermosetting composition that substantially contains no volatile component having a boiling point below the thermosetting temperature set on the cavity mold for decoration molding.

Owner:NIPPON BEE CHEM +1

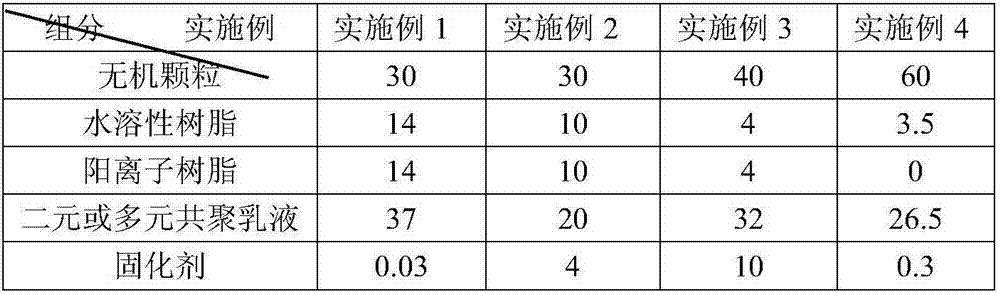

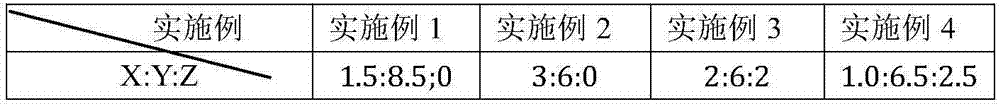

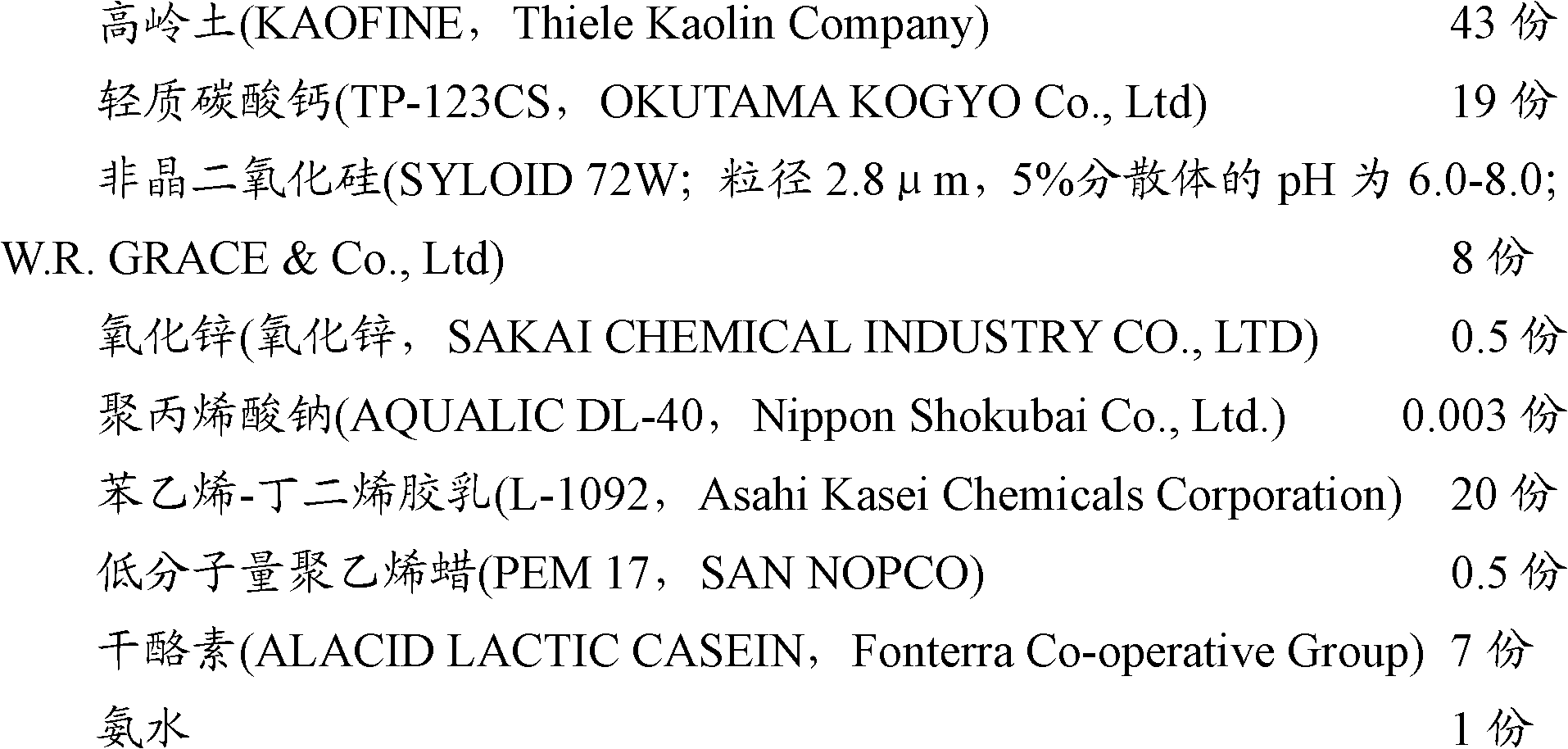

Liquid electronic ink receiving medium

ActiveCN106915171AGood coating fastnessHigh gloss surfaceDuplicating/marking methodsWater dispersibleAdhesive

A liquid electronic ink receiving medium comprises a support body and an ink receiving layer on one side or both sides of the support body. The ink receiving layer comprises, by weight, 30-60 parts of inorganic particles (a), 30-65 parts of an adhesive (b) and 0.03-10 parts of a curing agent (c). The inorganic particles are cationic inorganic particles. The adhesive is selected from one or more of water-soluble resin and binary or polybasic water-dispersible type copolymer emulsion. The liquid electronic ink receiving medium is smoothly conveyed on an HP Indigo series printing press without the paper jamming problem, the printed image is bright in color, the inking capacity is good, the printing ink fastness is good, and the image-stage image quality requirement is met.

Owner:乐凯胶片股份有限公司

Polishing composition

InactiveUS20150291850A1High gloss surfaceImprove surface smoothnessOther chemical processesSurface treatment compositionsSilica particlePh control

Provided is a polishing composition with which a high glossy surface is achieved by enhancing smoothness of a surface of an alloy material while maintaining a sufficiently high polishing speed for the alloy material. The present invention relates to a polishing composition used for an application of polishing an alloy material, which contains silica particles having a primary particle average aspect ratio of at least 1.10 and a pH controlling agent.

Owner:FUJIMI INCORPORATED

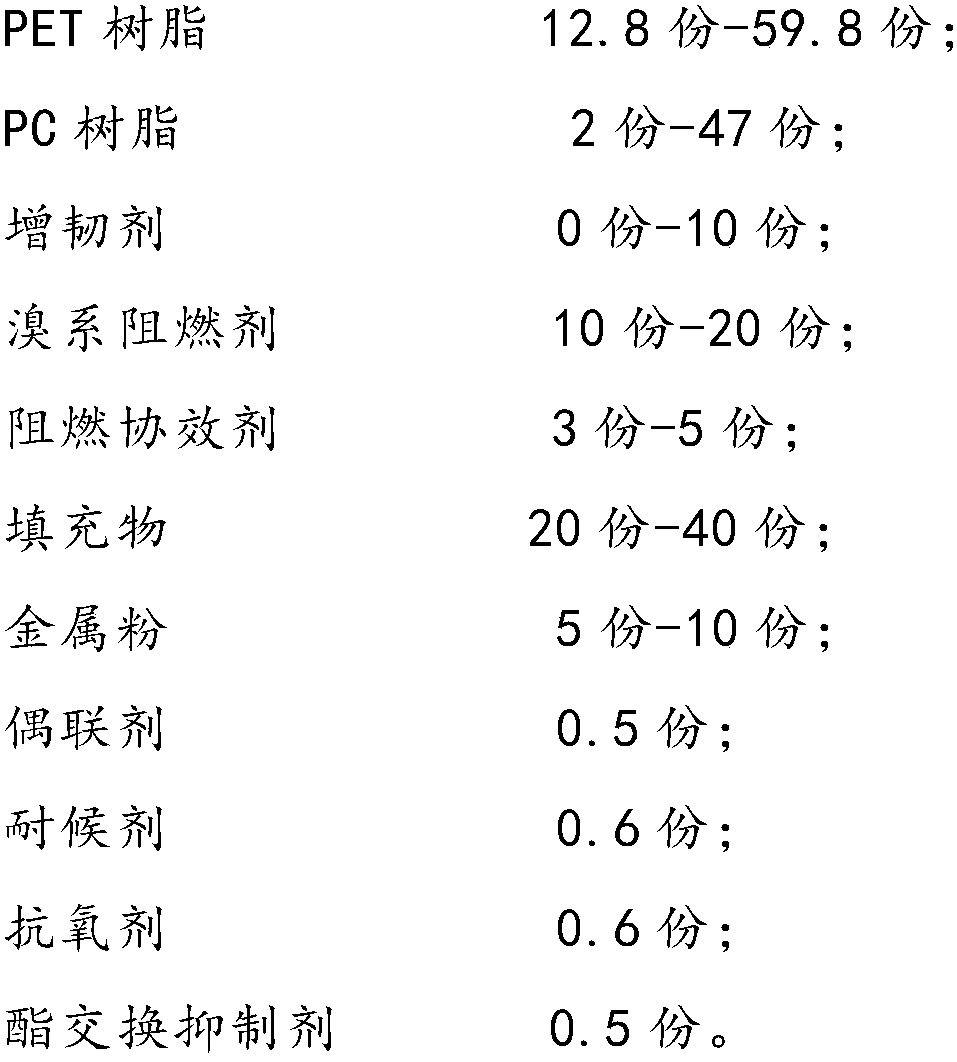

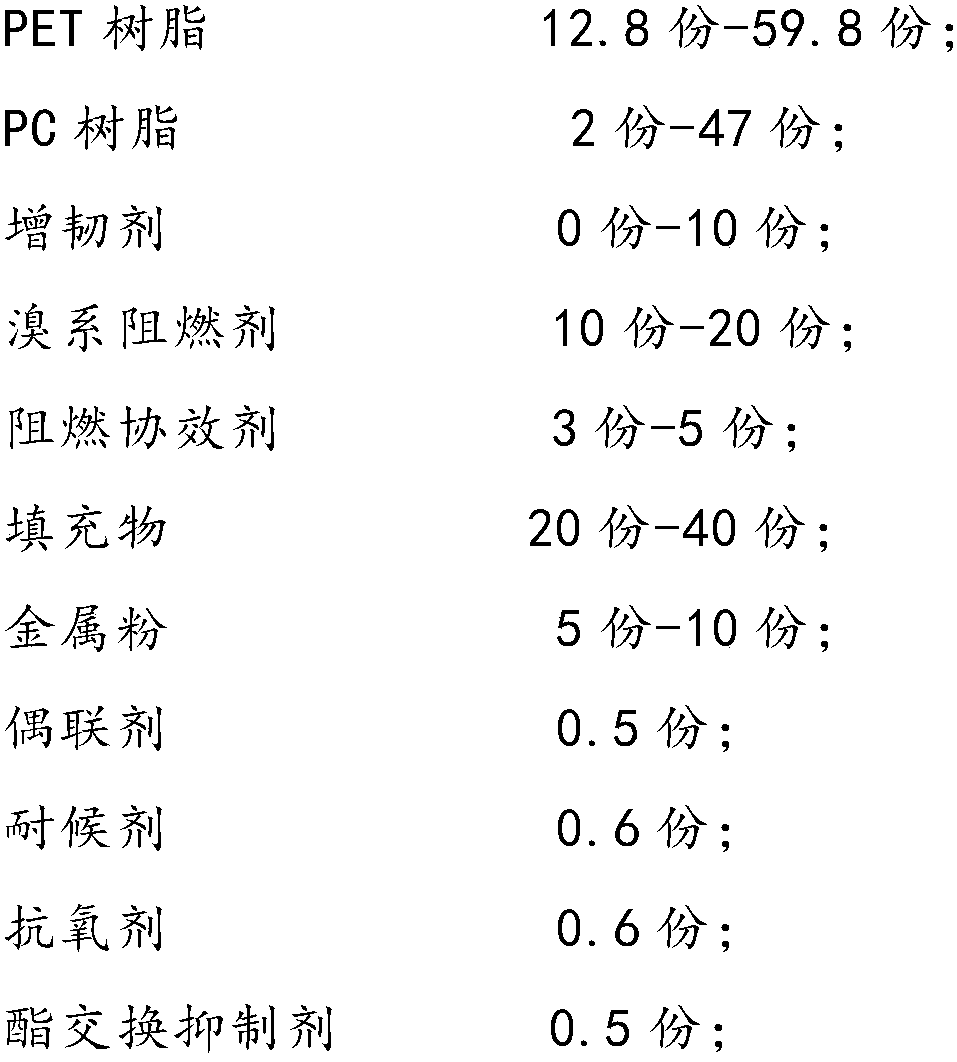

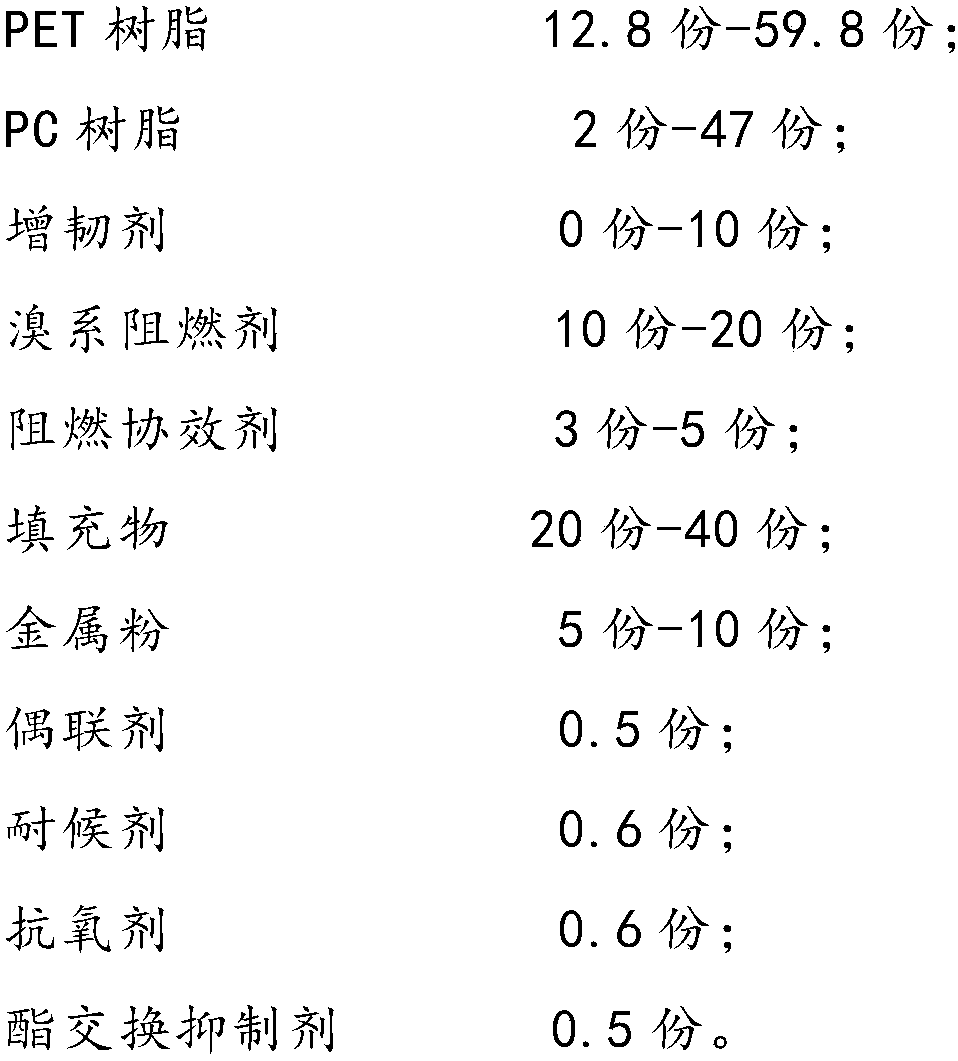

Ceramic-simulating flame-retardant PET/PC (polyethylene terephthalate/polycarbonate) resin composition and preparation method thereof

The invention discloses a ceramic-simulating flame-retardant PET / PC (polyethylene terephthalate / polycarbonate) resin composition and a preparation method thereof. The ceramic-simulating flame-retardant PET / PC resin composition is prepared from the following components in parts by weight: 12.8 to 59.8 parts of PET resin, 2 to 47 parts of PC resin, 0 to 10 parts of toughener, 10 to 20 parts of brominated flame retardant, 3 to 5 parts of flame-retardant synergist, 20 to 40 parts of filling matter, 5 to 10 parts of metal powder, 0.5 part of coupling agent, 0.6 part of weather-resistant agent, 0.6part of antioxidant and 0.5 part of ester exchange inhibiting agent. The ceramic-simulating flame-retardant PET / PC resin composition has the characteristics that the gloss is high, the density is large, the weather-resistant property is good, the toughness is good, and the like; the ceramic-simulating flame-retardant PET / PC resin composition can be used for replacing ceramic products in certain fields.

Owner:SHANGHAI KINGFA SCI & TECH +2

Polishing composition

ActiveUS20160186029A1Improve smoothnessHigh gloss surfaceOther chemical processesLapping machinesMetalAlloy surface

[Problem] An object is to provide a polishing composition which can improve smoothness of a surface of an alloy material to obtain a highly glossy surface, and can obtain a high-quality mirror surface having significantly reduced scratches or the like.[Solution] There is provided a polishing composition which is used for polishing an alloy material, and which comprises abrasive grains and an additive which does not form a complex with specific metal species and is adsorbed on a surface of the alloy to exhibit an anticorrosive effect.

Owner:FUJIMI INCORPORATED

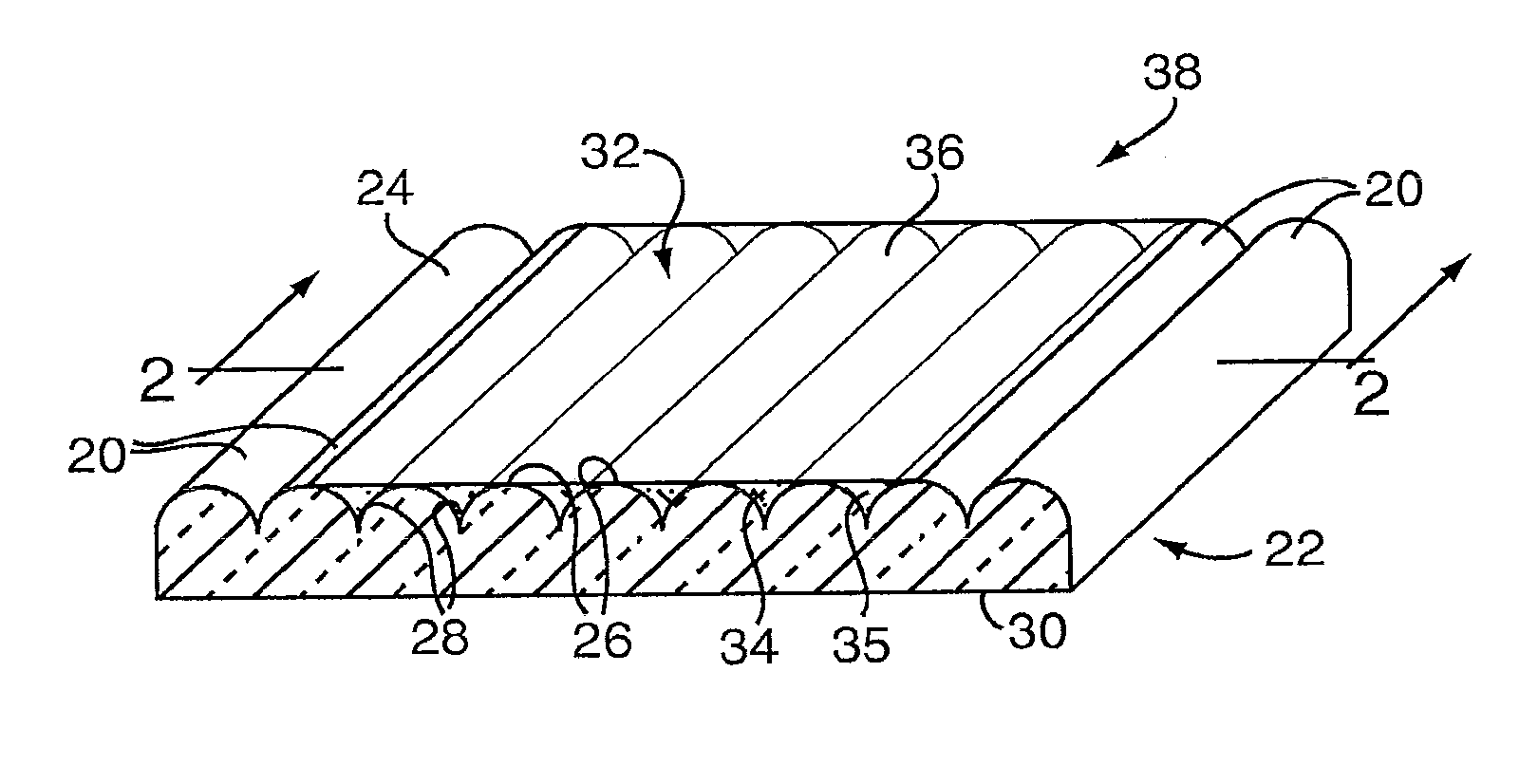

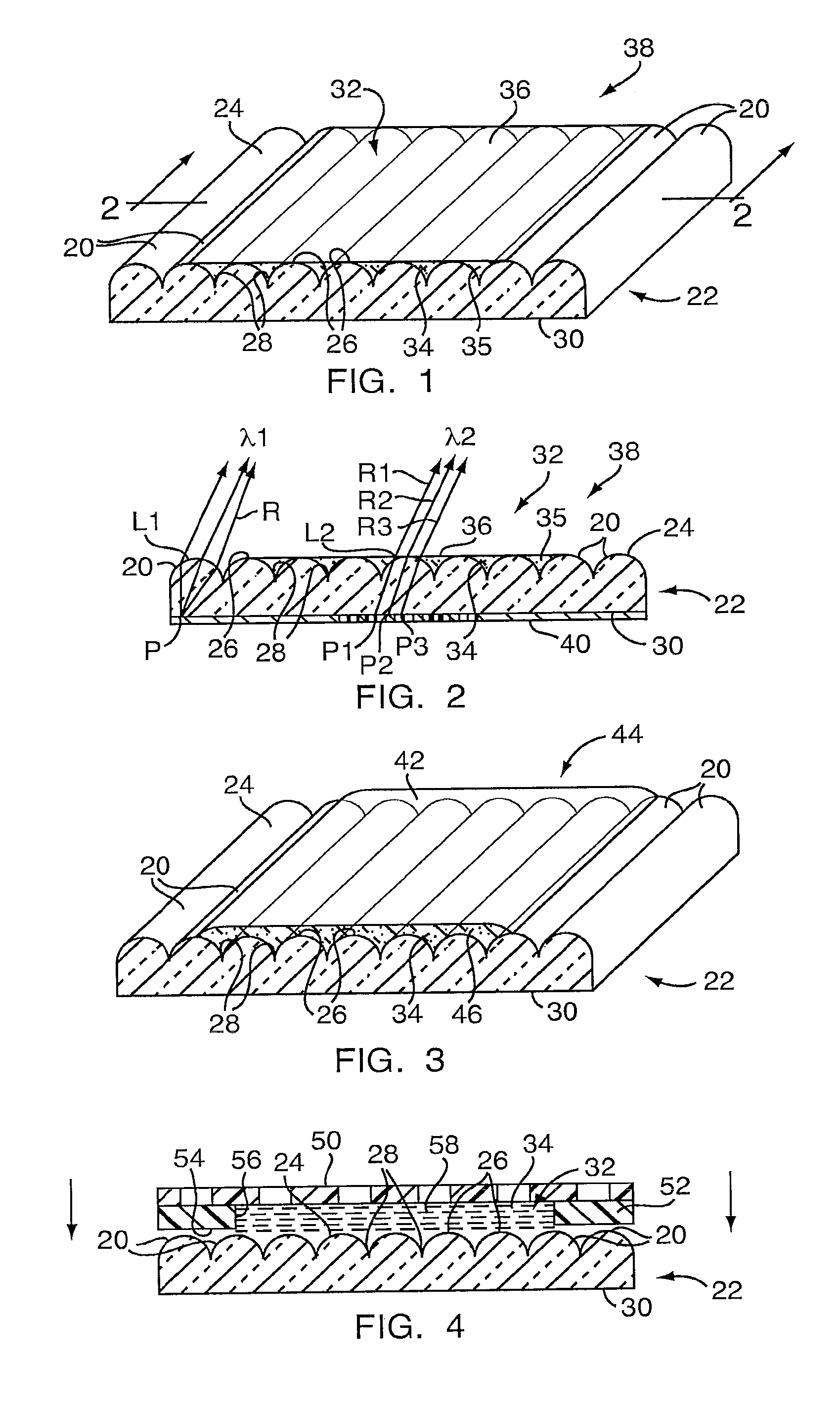

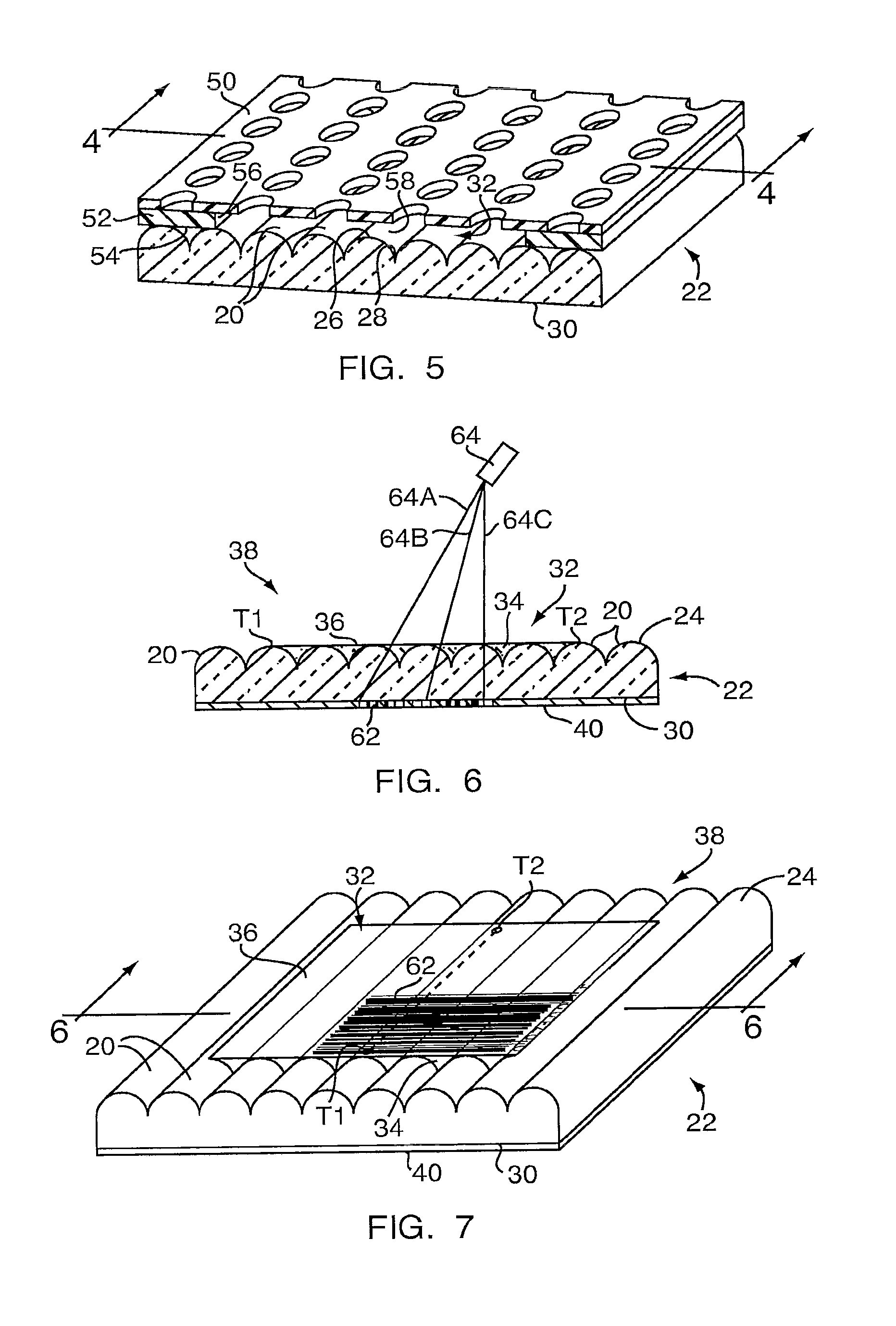

Lenticular product

InactiveUS20130077174A1Maximum optical flatnessEffectively disappearImage enhancementImage analysisMorphingAnimation

A lenticular product having a see-through window or lens is made by depositing a clear coating on a lenticular sheet. The lenticular product permits scanning a bar code or reading textual data that is printed on an image viewable through the lenticular product for animated, morphing, or stereographic effect. The window or lens of the lenticular product can also provide optical effects (e.g., magnification) in addition to the effects provided by the lenticular sheet. The lenticular product can be made by depositing fluid or resin in a one- or two-step process.

Owner:TRACER IMAGING

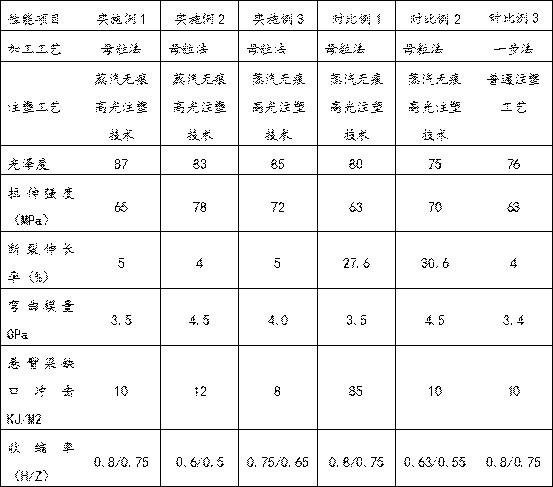

PC/ABS based low-shrinkage high strength and high gloss engineered polypropylene material and preparation method thereof

The invention relates to a PC / ABS based low-shrinkage high strength and high gloss engineered polypropylene material and a preparation method thereof. The material comprises: 65 weight parts of high fluidity polypropylene, 10 weight parts of grafted PP, 5 weight parts of POE, 5 weight parts of PA66 fiber, 15 parts of 5um glass fiber, 1.0 weight part of an anti-glass fiber exposure agent, and 0.3 weight part of an antioxidant. The preparation method mainly includes the following three processes: glass fiber masterbatch manufacturing, polypropylene and masterbatch granulation, and high gloss andtraceless injection molding. An internal mixer or an exhaust twin-screw extruder is adopted in the glass fiber masterbatch manufacturing process. Ultrafine glass fiber and flexible organic fiber areinnovatively used for strengthening, and 5% or more of high grafting rate polypropylene is used as an efficient compatilizer and greatly enhances the compatibility between fiber and polypropylene, also high gloss steam traceless injection molding technology is utilized in the injection molding process to further improve the gloss of the high gloss reinforced polypropylene product, and finally through combined action, the product glass can reach the requirements of high gloss exterior parts. The PC / ABS based low-shrinkage high strength and high gloss engineered polypropylene material provided by the invention is low in cost as the general purpose material PP, but has the gloss, water shrinkage, strength and the like reaching the standards of PC / ABS alloy, ABS, PA and other engineering materials, can be used as a substitute to lower the cost, and has enormous commercial value.

Owner:SHANDONG DAWN POLYMER CO LTD

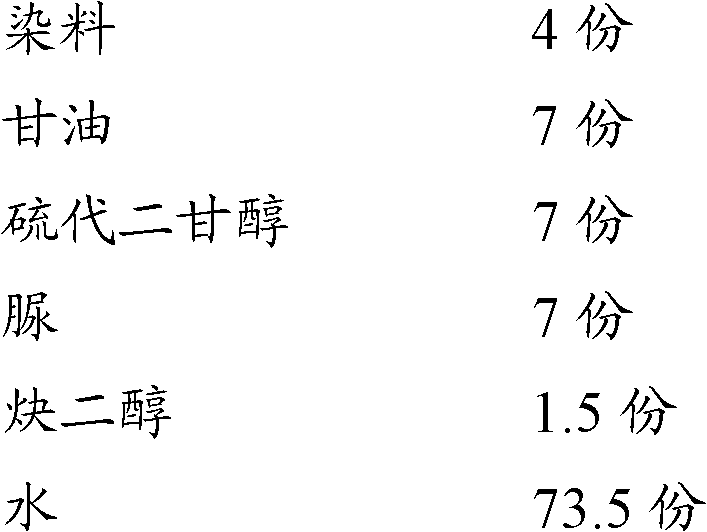

Variable printing medium having high glossiness, and recording method

InactiveCN102427950ALow costImprove printing qualityDuplicating/marking methodsInksSilicon dioxidePolymer chemistry

A printing medium including at least base paper and a coating layer, wherein the coating layer is directly formed on the base paper by a cast coating method using a coating liquid, which contains kaolin and amorphous silica and contains the amorphous silica in an amount of 3% by mass to 20% by mass.

Owner:RICOH KK +1

A microcellular foaming injection molding process and mold with high surface gloss and high bubble density

ActiveCN105835299BSolve bottlenecksRequirements for lower measurement accuracyPolymer scienceFoaming agent

Owner:SHANDONG UNIV

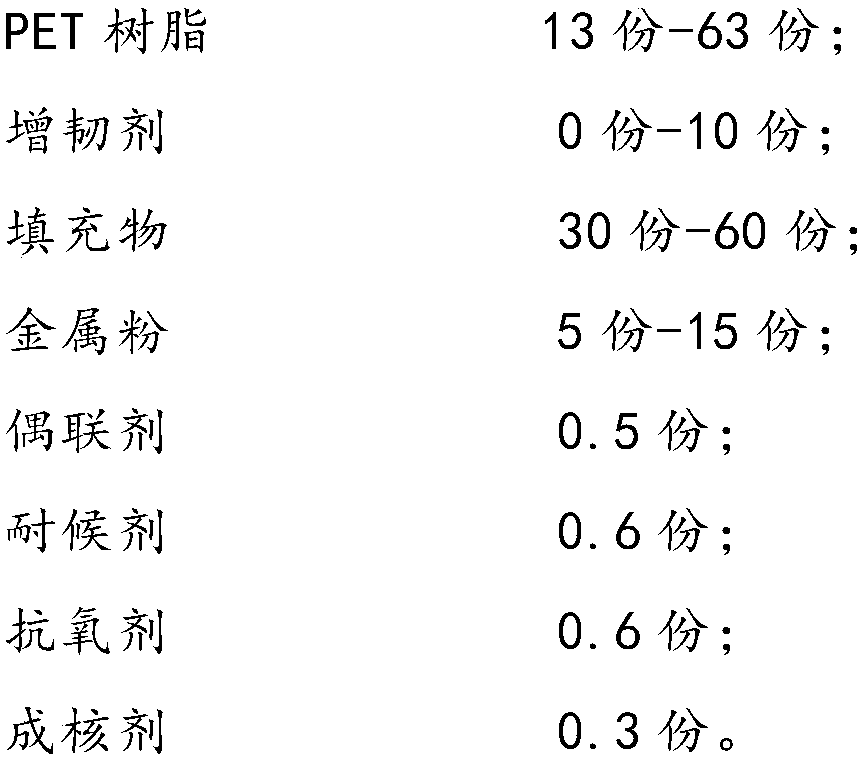

Ceramic-like PET resin composition and preparation method thereof

The invention discloses a ceramic-like PET resin composition and a preparation method thereof. The ceramic-like PET resin composition is prepared from the following components in parts by weight: 13-63 parts of PET resin, 0-10 parts of a toughening agent, 30-60 parts of a filler, 5-15 parts of metal powder, 0.5 part of a coupling agent, 0.6 part of a weather-resisting agent, 0.6 part of an antioxidant and 0.3 part of a nucleating agent. The ceramic-like PET resin composition has the characteristics of high gloss, high density, high weather resistance, high toughness and the like, and can replace ceramic products in certain fields for use.

Owner:SHANGHAI KINGFA SCI & TECH +2

Powder compaction and enrobing

InactiveUS7770361B2High gloss surfaceEasy to swallowWrappers shrinkageWood working apparatusMetallurgyMethyl cellulose

Powder, e.g. of a medicament, is compacted and enrobed to produce compacted powder slugs by preferably mechanically compacting a powder and forming a film of material, preferably hydroxy propyl methyl cellulose, by vacuum or pressure differential, about the surface of the powder thus compacted.

Owner:BIOPROGRESS TECH INT

Polishing composition

ActiveUS9994748B2Improve smoothnessHigh gloss surfaceOther chemical processesLapping machinesMetalMaterials science

[Problem] An object is to provide a polishing composition which can improve smoothness of a surface of an alloy material to obtain a highly glossy surface, and can obtain a high-quality mirror surface having significantly reduced scratches or the like.[Solution] There is provided a polishing composition which is used for polishing an alloy material, and which comprises abrasive grains and an additive which does not form a complex with specific metal species and is adsorbed on a surface of the alloy to exhibit an anticorrosive effect.

Owner:FUJIMI INCORPORATED

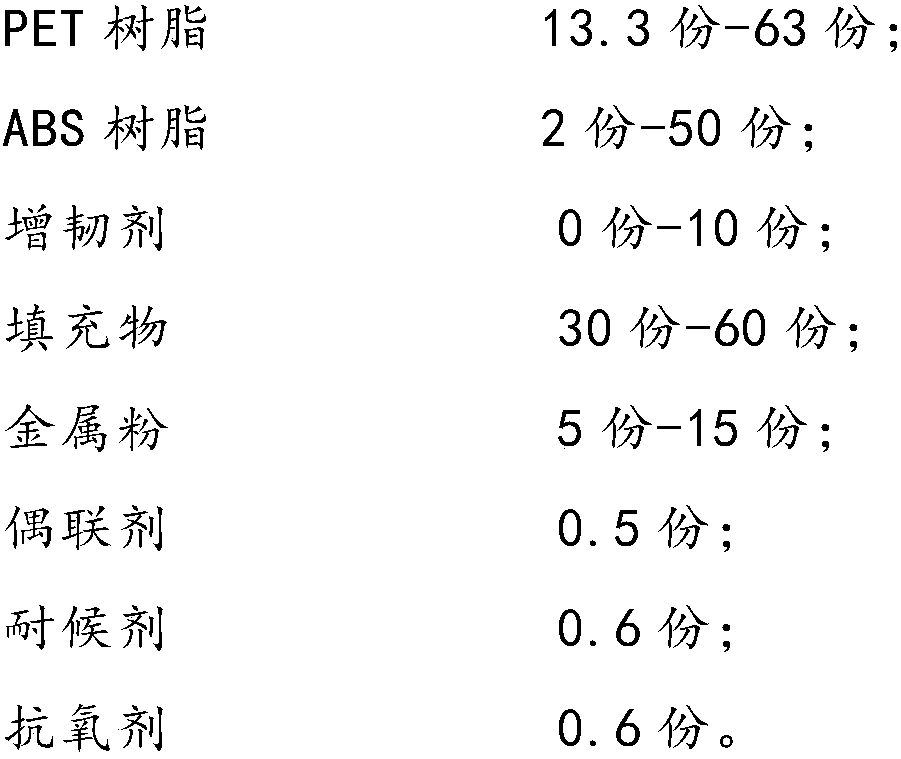

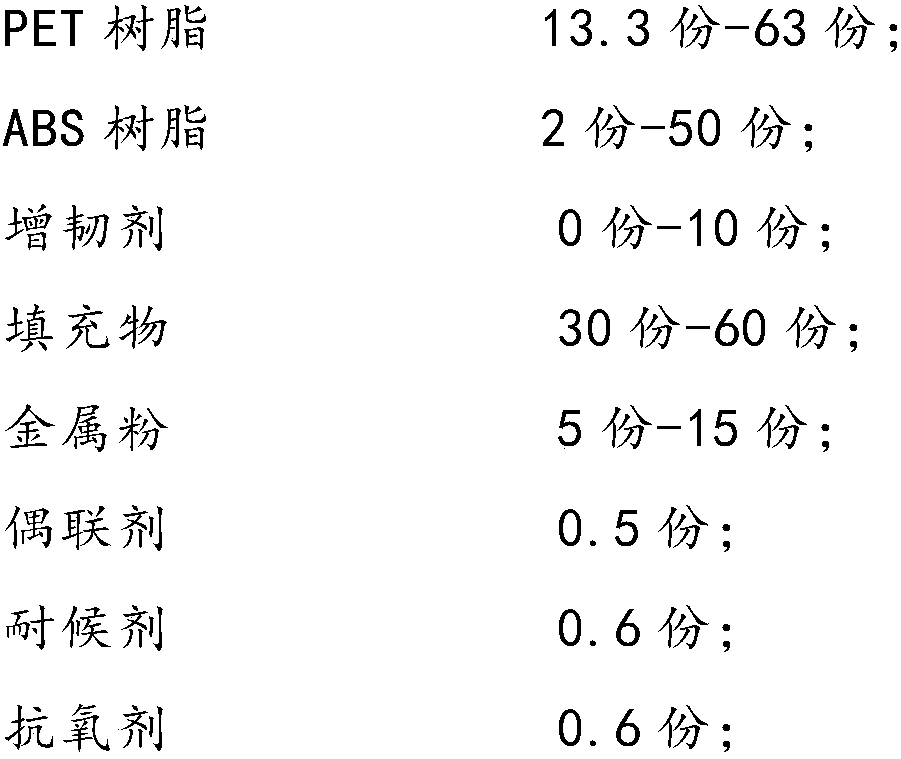

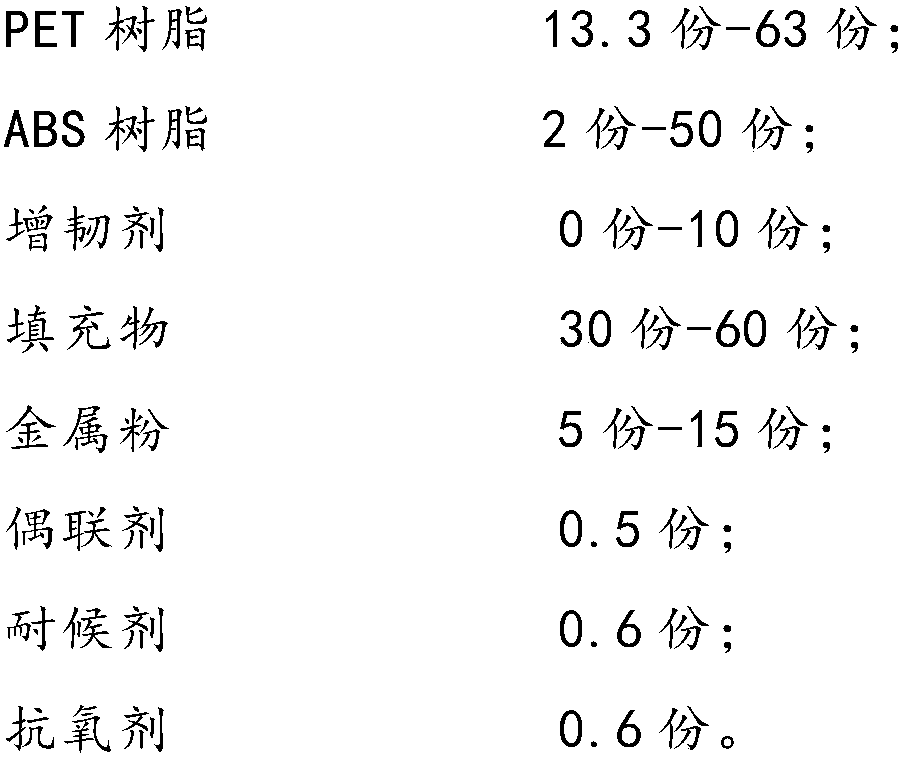

Imitation ceramic PET/ABS resin composition and preparation method thereof

The invention discloses an imitation ceramic PET / ABS resin composition and a preparation method thereof. The imitation ceramic PET / ABS resin composition is prepared from the following components in parts by weight: 13.3 to 63 parts of PET resin, 2 to 50 parts of ABS resin, 0 to 10 parts of a flexibilizer, 30 to 60 parts of filler, 5 to 15 parts of metal powder, 0.5 part of a coupling agent, 0.6 part of a weather-resisting agent and 0.6 part of an antioxidant. The imitation ceramic PET / ABS resin composition disclosed by the invention has the characteristics of better impact resistance, high surface gloss, relatively-large density and the like, and can be used in certain fields instead of ceramic products.

Owner:SHANGHAI KINGFA SCI & TECH +2

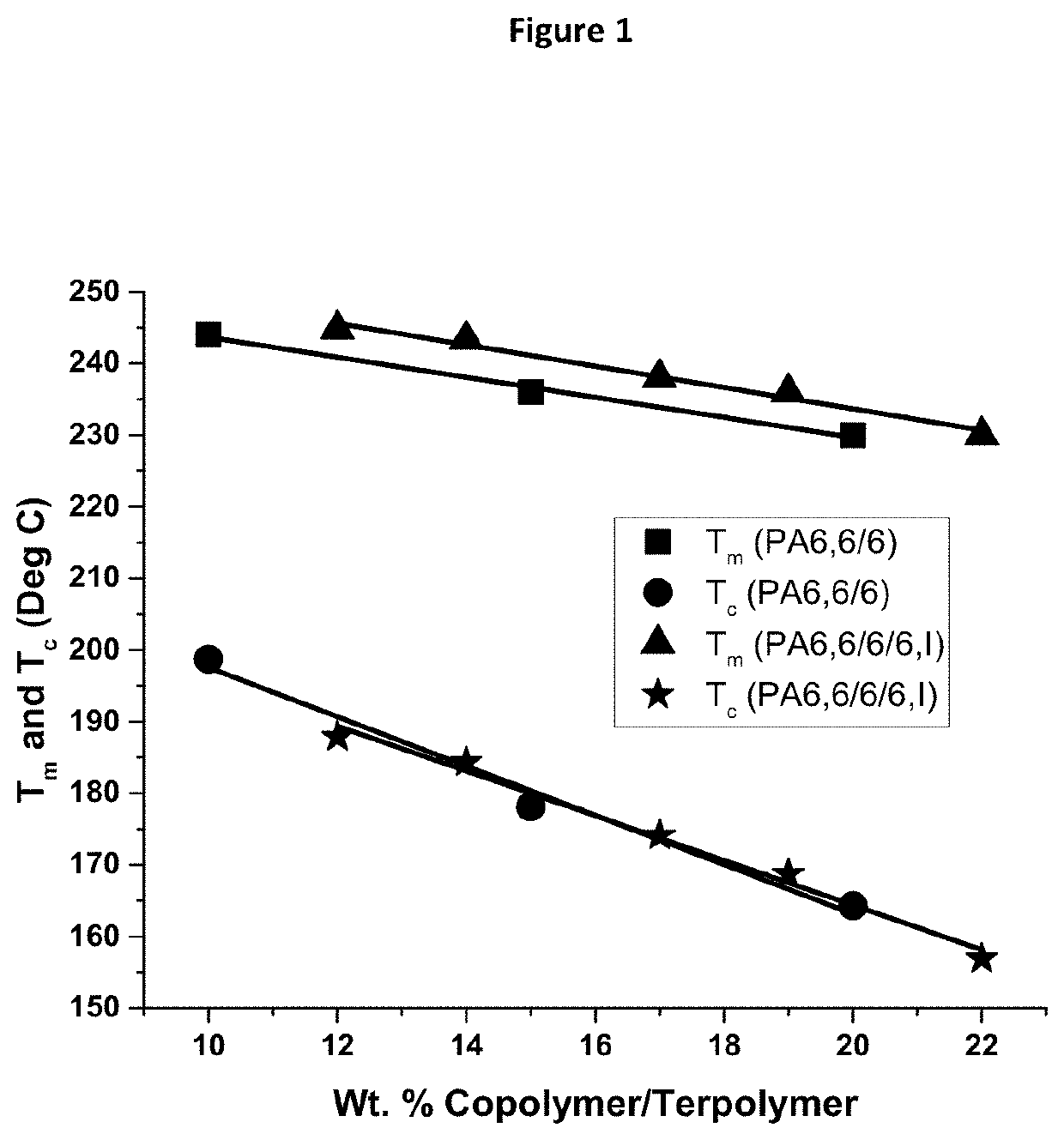

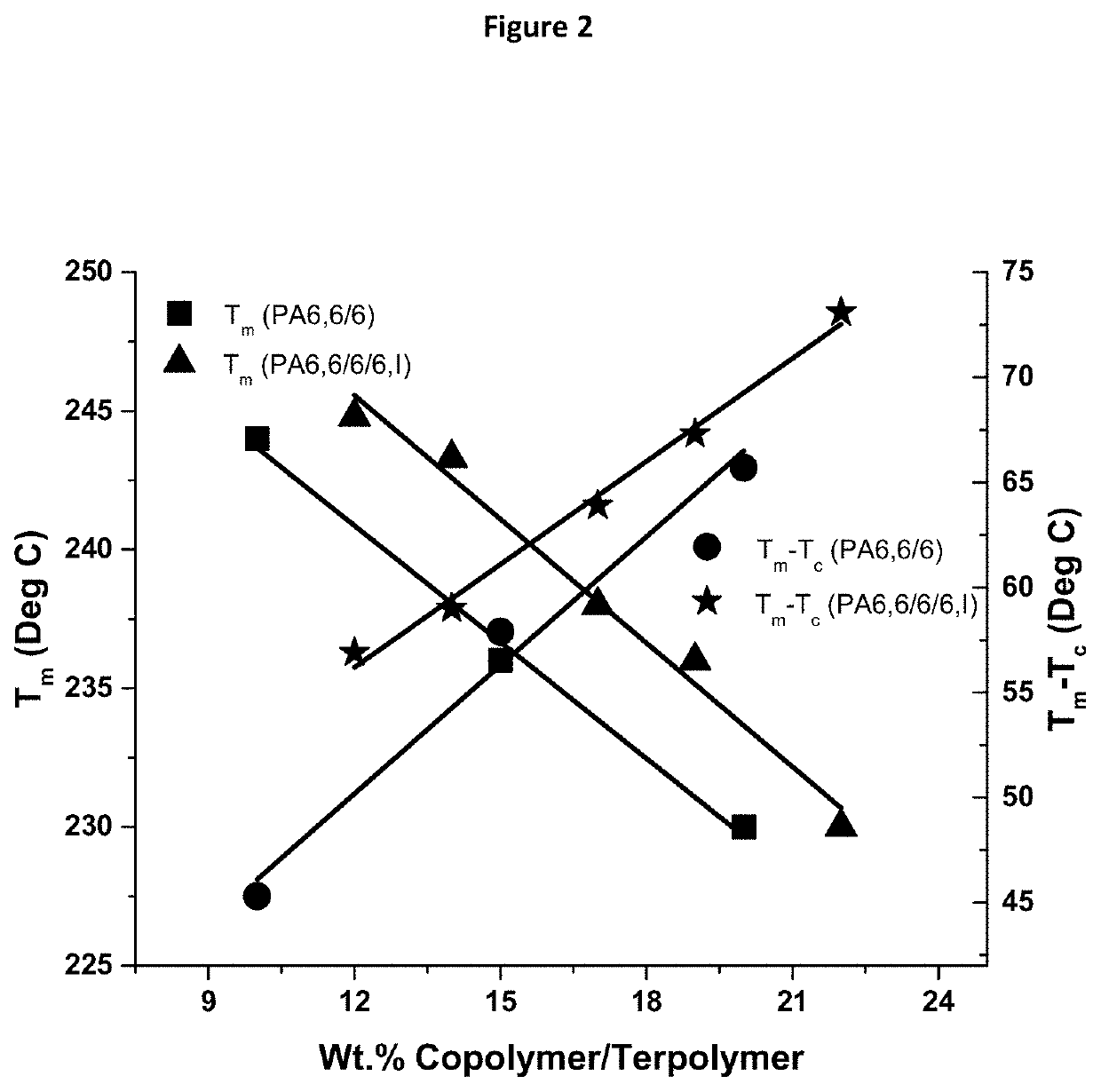

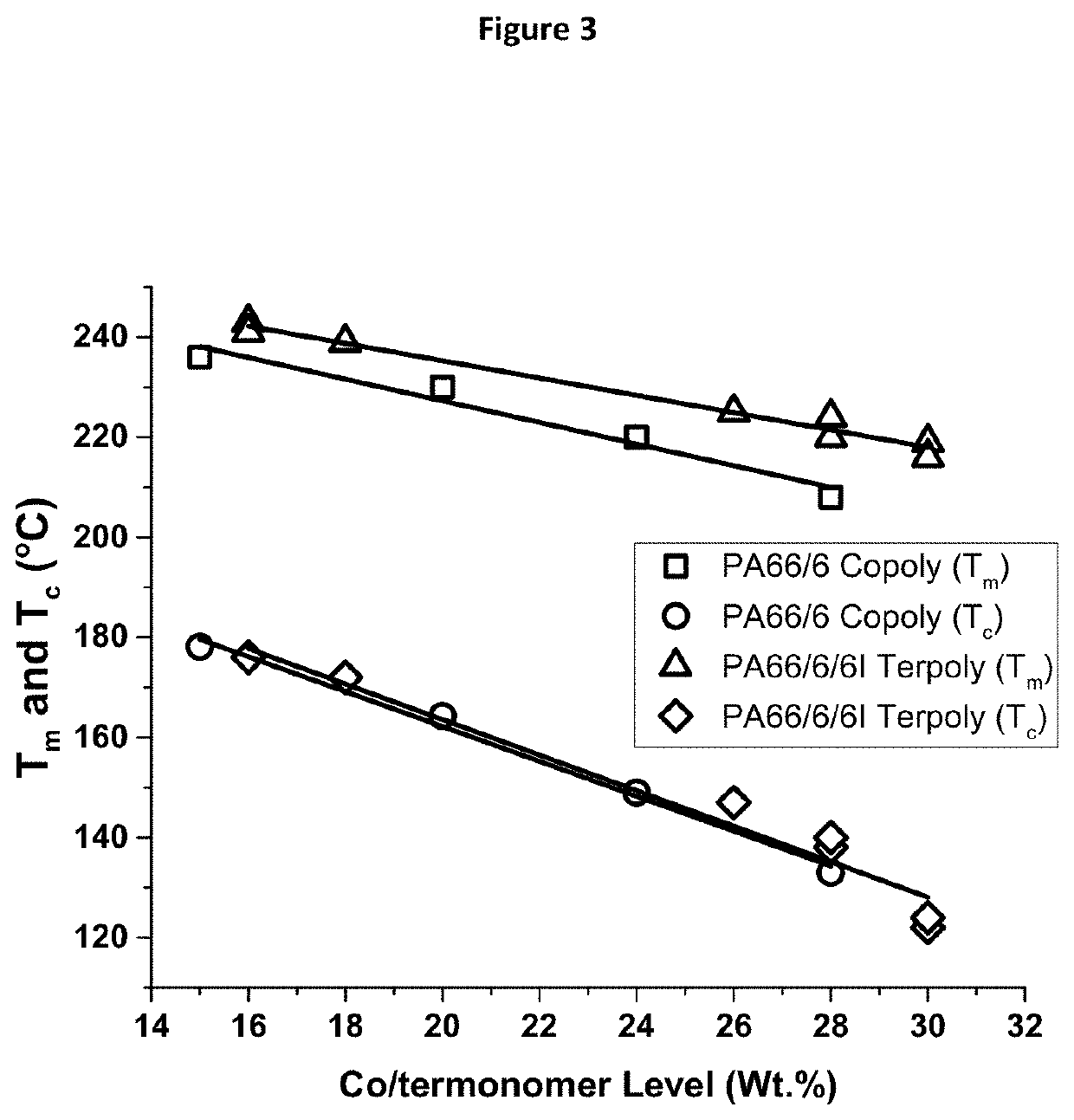

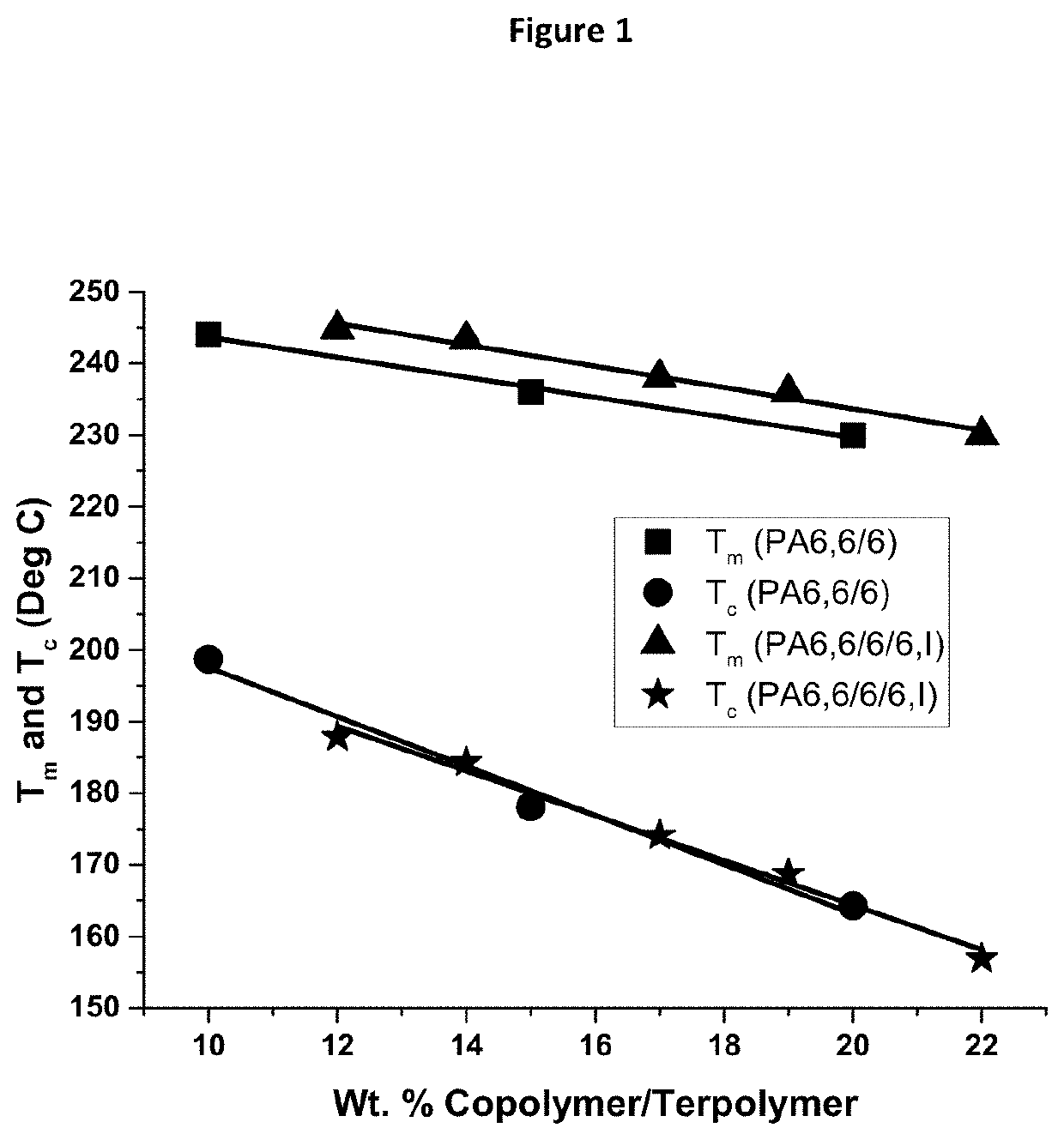

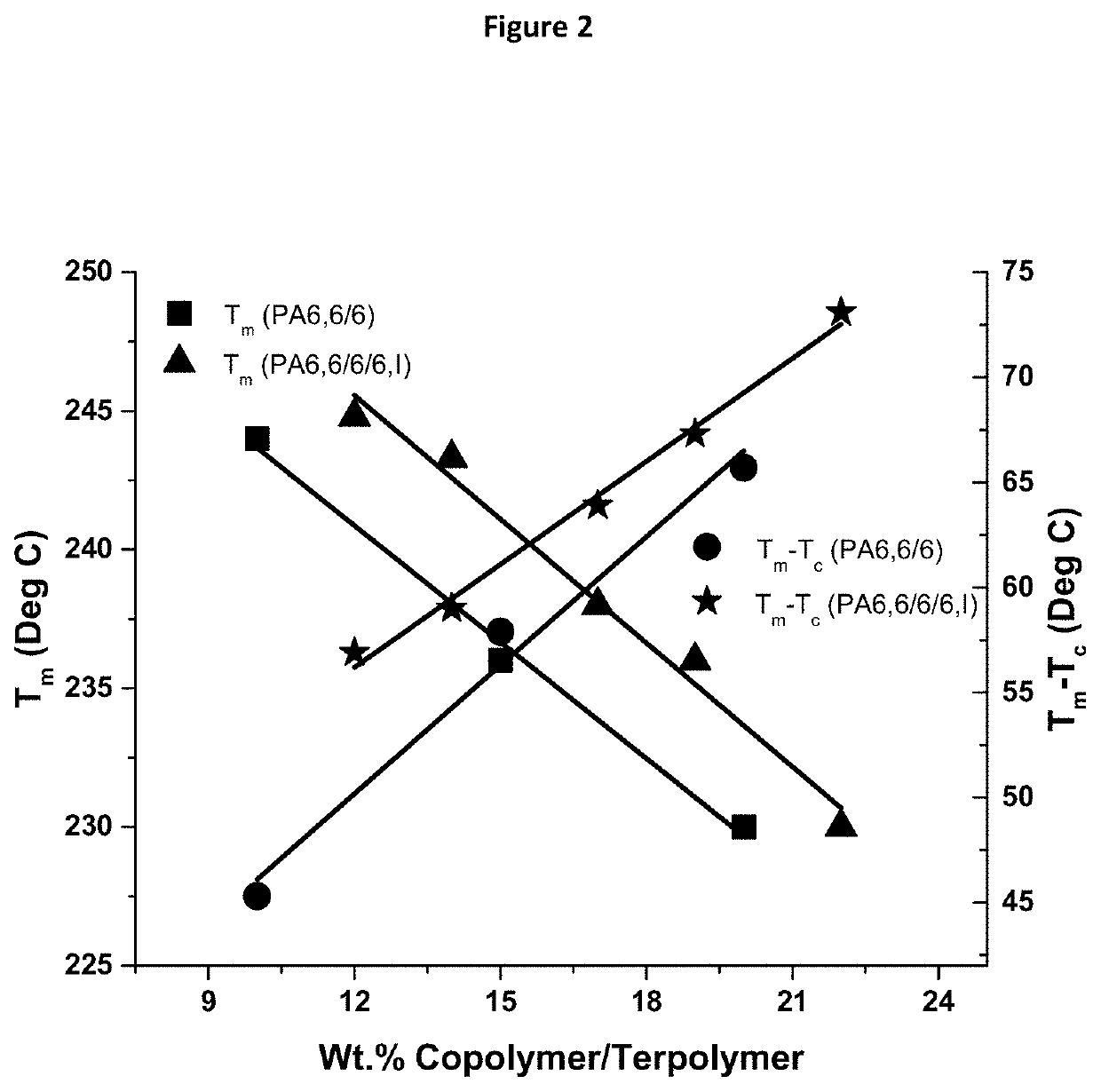

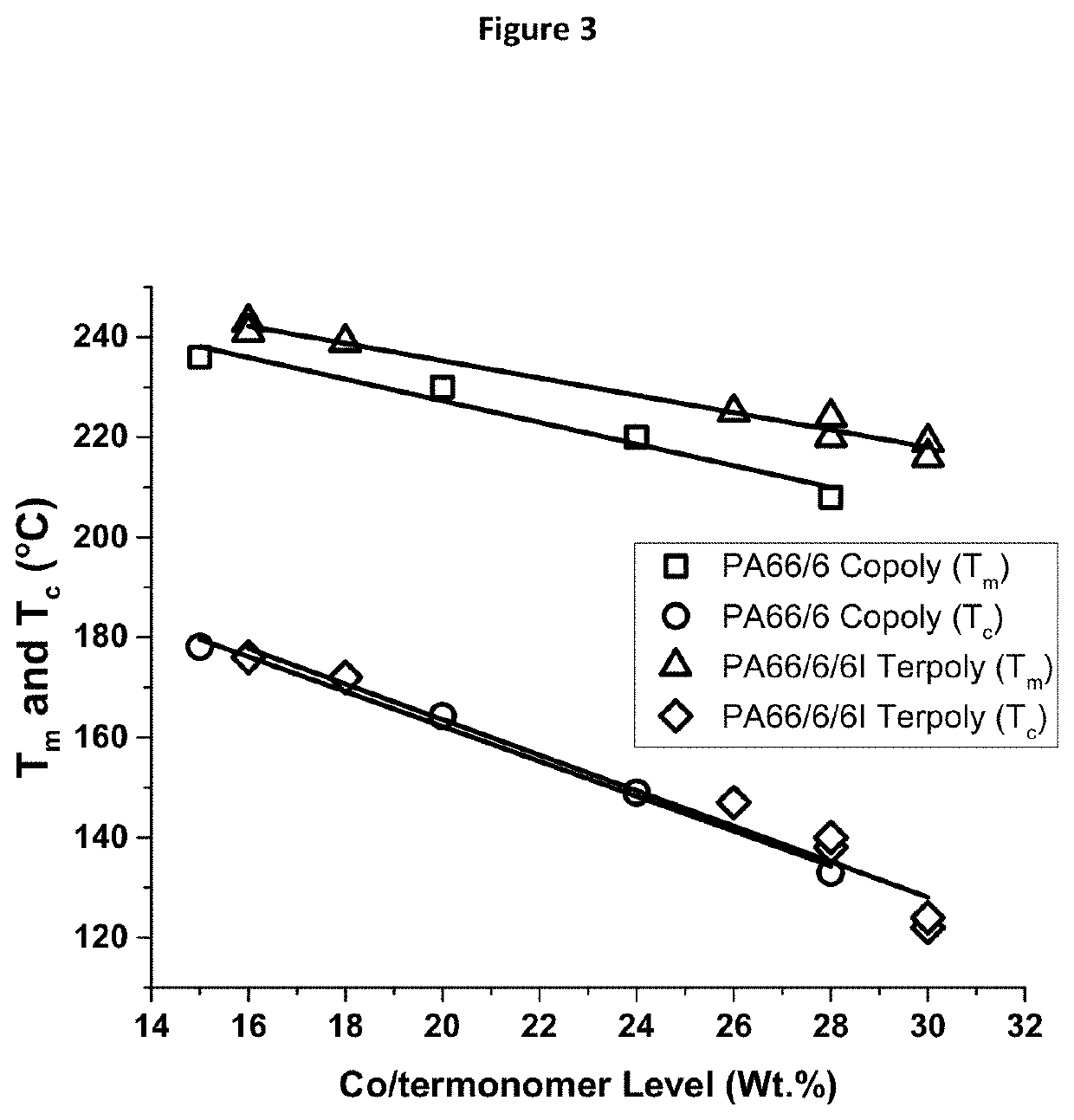

Nylon Terpolymers

ActiveUS20220325103A1High gloss surfaceHigh melting pointSynthetic resin layered productsDomestic containersPolymer scienceCrystallization temperature

A terpolymer composition is described that contains a statistical amount of 50-98 wt % of a first repeating AA-BB comonomer unit; 1-25 wt % of a second repeating AA-BB comonomer unit; and 1-25 wt % of a repeating lactam comonomer unit or 1-25 wt % of a third repeating AA-BB comonomer unit, where the terpolymer composition exhibits a high melting point similar to that of PA66 while also exhibiting a significantly reduced crystallization rate and crystallization temperature.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

Nylon terpolymers

ActiveUS11384242B2High gloss surfaceHigh melting pointSynthetic resin layered productsDomestic containersPolymer scienceCrystallization temperature

A terpolymer composition is described that contains a statistical amount of 50-98 wt % of a first repeating AA-BB comonomer unit; 1-25 wt % of a second repeating AA-BB comonomer unit; and 1-25 wt % of a repeating lactam comonomer unit or 1-25 wt % of a third repeating AA-BB comonomer unit, where the terpolymer composition exhibits a high melting point similar to that of PA66 while also exhibiting a significantly reduced crystallization rate and crystallization temperature.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

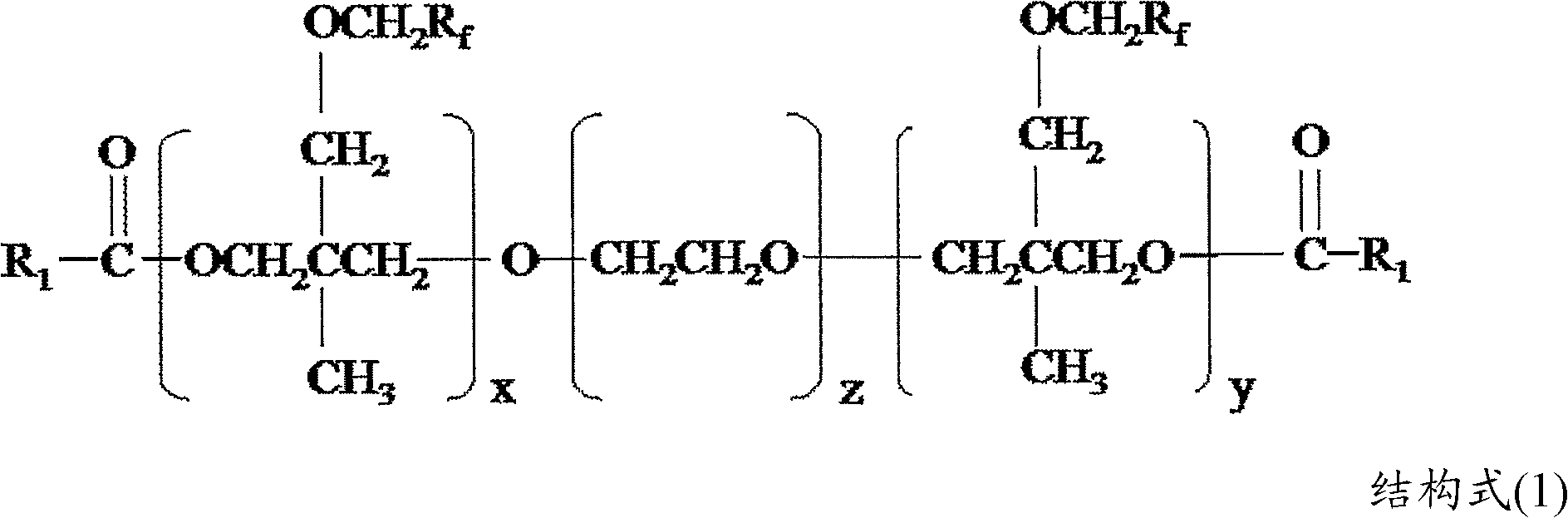

Composite membrane as well as preparation method and application thereof

InactiveCN113978087AImprove mechanical propertiesLower surface energyCeilingsNon-macromolecular adhesive additivesPolymer sciencePolyolefin

The invention belongs to the technical field of composite materials, and discloses a composite film as well as a preparation method and application thereof. The composite film comprises a polyolefin base material layer and a release type BOPET layer which are connected with each other; the composite film further comprises a gluing layer located on the side, away from the release type BOPET layer, of the polyolefin base material layer; and raw materials of the gluing layer comprise polyolefin and TPU. The composite film disclosed by the invention has good scratch resistance and stain resistance. When the composite film is connected with a substrate, the composite film has the characteristic of simple and convenient construction steps.

Owner:佛山(华南)新材料研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com