Variable printing medium having high glossiness, and recording method

A technology of printing medium and inkjet recording method, which is applied in the direction of duplication/marking method, printing, household utensils, etc., can solve the problems of poor ink absorption, impractical use of cast-coated paper, difficult to use high-speed printing quality photos, etc., to achieve High-speed and low-cost printing, the effect of excellent printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

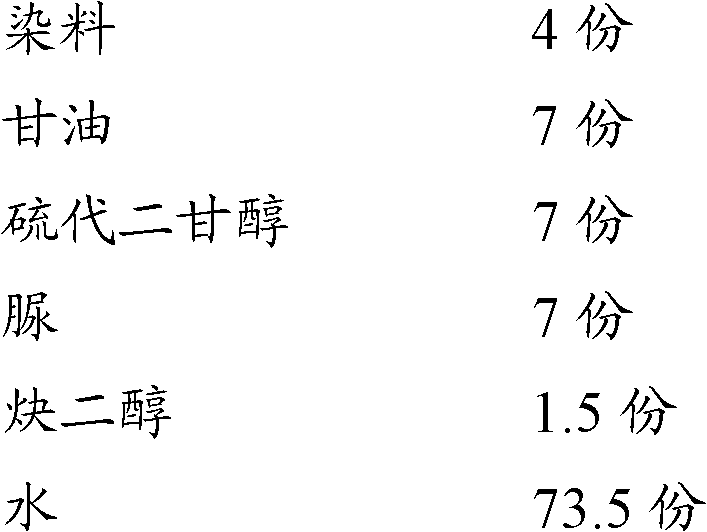

[0173] [Preparation of ink]

[0174] The ink of the present invention contains at least water, a colorant, a water-soluble organic solvent, a wetting agent, and a surfactant, and further contains other components as necessary. These components are dispersed or dissolved in an aqueous solvent, and further stirred and mixed as necessary to prepare the ink of the present invention. The dispersion can be performed using a sand mill, a homogenizer, a ball mill, a paint shaker, or an ultrasonic disperser, and stirring and mixing can be performed by using a stirrer using a typical blade, a magnetic stirrer, or a high-speed disperser.

[0175] Physical properties of the ink such as viscosity, surface tension and pH are preferably within the following ranges.

[0176] The viscosity of the ink at 25°C is preferably 1 cps-30 cps, more preferably 2 cps-20 cps. When the viscosity is higher than 20 cps, it is difficult to ensure discharge stability.

[0177] The pH is preferably, for exa...

Embodiment

[0199] Hereinafter, examples of the present invention will be described, however, the examples should not be construed as limiting the present invention.

[0200]

manufacture example 1

[0201] (Manufacturing Example 1: Dispersion containing cyan pigment)

[0202] -Preparation of polymer fine particle dispersion containing copper phthalocyanine pigment-

[0203] Fully replace the interior of a 1L flask equipped with a mechanical stirrer, a thermometer, a nitrogen introduction tube, a reflux tube and a dropping funnel with nitrogen, and then charge 11.2 g of styrene, 2.8 g of acrylic acid, 12.0 g of lauryl methacrylate, 4.0 g polyethylene glycol methacrylate, 4.0 g styrene macromonomer (product name: AS-6, manufactured by TOGAOSEI CO., LTD.) and 0.4 g mercaptoethanol, and the temperature was raised to 65° C. Subsequently, 100.8g styrene, 25.2g acrylic acid, 108.0g lauryl methacrylate, 36.0g polyethylene glycol methacrylate, 60.0g hydroxyethyl methacrylate, 36.0g styrene macromer (product Name: AS-6, manufactured by TOAGOSEI CO., LTD.), a mixed solution of 3.6 g of mercaptoethanol, 2.4 g of azobisdimethylvaleronitrile, and 18 g of methyl ethyl ketone was droppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com