Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Has high temperature oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

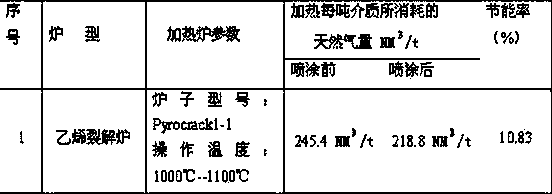

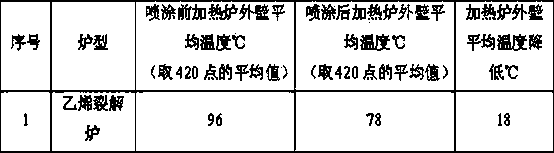

Ceramic coating used for heating furnace

InactiveCN102020475AExtended service lifeHas high temperature oxidation resistanceEmissivityRadiance

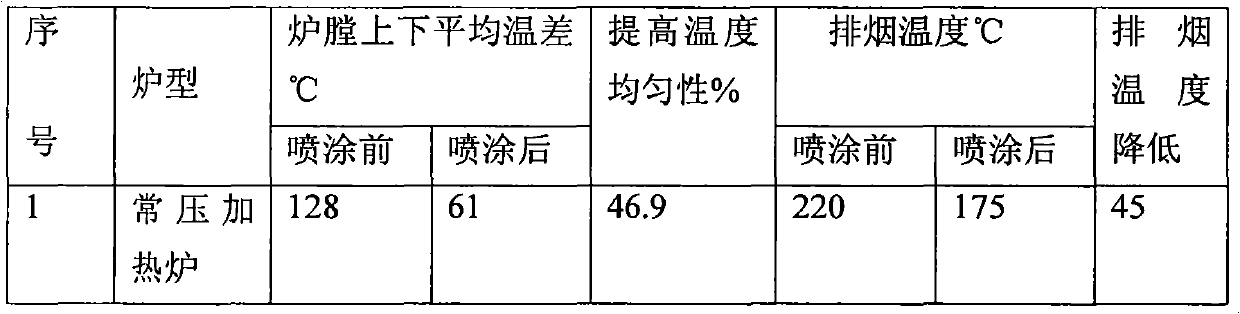

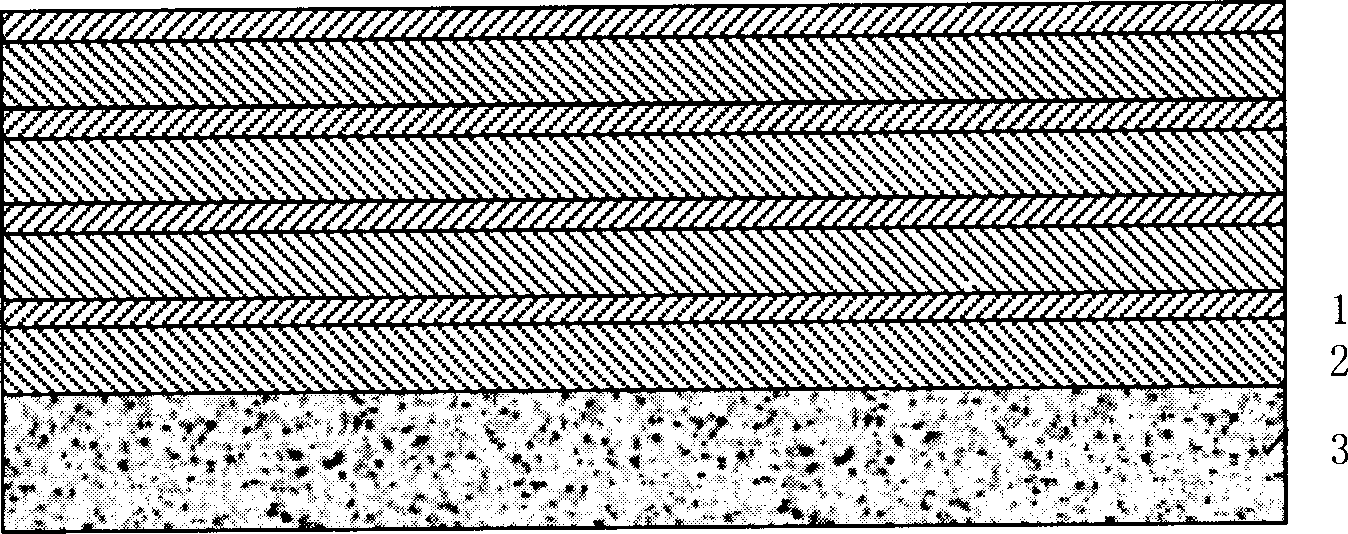

The invention relates to ceramic coating used for a heating furnace. The ceramic coating comprises the following components: ceramic micro powder, an inorganic bonding agent and a linear thermal expansivity regulator. The invention also provides a method for preparing the ceramic coating for the heating furnace. The ceramic coating has the characteristics of having improved radiance and thermal shock resistance, being efficient and energy-saving, prolonging the service life of furnace linings and furnace tubes, improving temperature uniformity and the like, as defined below: (1) the energy consumption is reduced, the energy is saved by more than 3 percent and pollutant discharge is reduced; (2) the temperature uniformity in the heating furnace is improved: (3) the metallurgy stability of the furnace tube of the heating furnace is improved, the coking and scaling of the furnace tub are delayed, and the absorbing capacity of the furnace tube can be maximized; (4) the emissivity of the surface of the refractory lining layer can be maximized so as to increase the secondary radiation of radiant heat (energy) and increase the efficiency of the radiant section; and (5) the outer wall temperature and the exhaust gas temperature of the heating furnace can be reduced by more than 5 percent.

Owner:北京安泰恒业科技有限公司

PVD nano multiple-layer coating for cutting stainless steel and preparation method thereof

InactiveCN101200797AHas high temperature oxidation resistanceExcellent high temperature oxidation resistanceLayered productsVacuum evaporation coatingSurface cleaningOxidation resistant

The invention discloses a PVD nanometer multiple-layer coating used for cutting stainless steel and a preparation method thereof. The specific manufacturing process is as follows: firstly, implementing the surface cleaning treatment on carbide base; secondly, adopting a multiple targets magnetic sputtering method to alternatively deposit the nanometer multiple-layer coating which takes TiN (Tix, Al1-x)N / (Tiy, Al1-y)N / (Tix, Al1-x)N as a modulation period on the rotating carbide base; adopting Ar2 as the sputtering gas. The flow of Ar is 180-300cm3 / s, the partial pressure is 1.7-9.0'10<-1>Pa, the reaction gas is N2, and the total pressure is controlled through controlling the partial pressure of N2. The invention introduces TiAlN with high Al content and perfect high temperature oxidation resistance into a multiple-layer coating material system, improves the high temperature oxidation resistance and the hardness of the coating, enhances the toughness of the coating through the microstructure optimization design and enables the coating to obtain both the high temperature oxidation resistance and excellent mechanical properties. The nanometer multiple-layer coating prepared through the invention is provided with great application value in the stainless steel cutting process.

Owner:CENT SOUTH UNIV

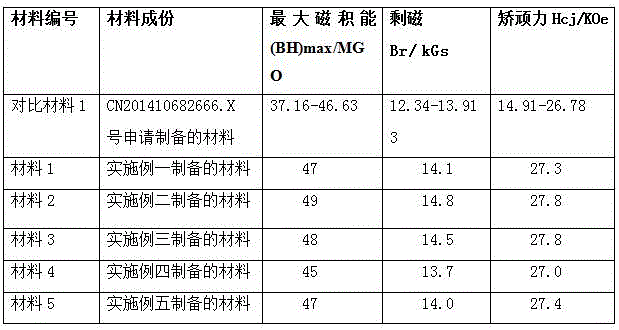

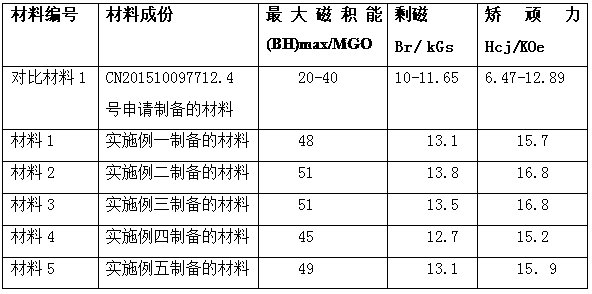

Corrosion-resistant neodymium-iron-boron permanent magnet material and preparation method thereof

ActiveCN103077796AImprove stray magnetic fieldReduce stray magnetic fieldMagnetic materialsAlloyWaste material

The invention discloses a corrosion-resistant neodymium-iron-boron permanent magnet material and a preparation method thereof. The corrosion-resistant neodymium-iron-boron permanent magnet material comprises the following components in percentage by weight: 20-26 percent of Nd, 5-6.5 percent of Pr, 1-4 percent of B, 0.05-0.065 percent of Ir, 0.05-0.065 percent of Os, 0.5-0.65 percent of Sc, 0.5-0.65 percent of Cu and the balance of Fe. The corrosion-resistant neodymium-iron-boron permanent magnet material disclosed by the invention is provided with uniform tissue and a robust structure, so that the corrosion resistance of the material can be enhanced, and the magnetic performance is improved. According to the preparation method of the corrosion-resistant neodymium-iron-boron permanent magnet material, raw materials of an alloy are directly produced by fully utilizing praseodymium and neodymium waste, a component mixture ratio is flexible, and the quality is controlled appropriately; and moreover, the cost can be reduced, a process is simple, and powder waste with high oxygen content is fully utilized.

Owner:XUZHOU NANFANG YONGCI MATERIAL

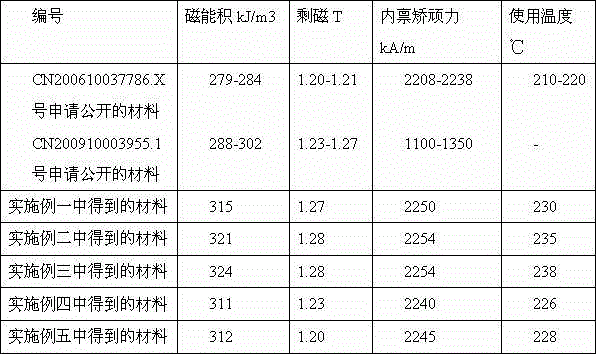

High bending force resistant permanent magnet materials and preparation method thereof

ActiveCN103106992AReduce stray magnetic fieldEasy to useMagnetic materialsRheniumManufactured material

The invention discloses high bending force resistant permanent magnet materials and a preparation method thereof. The magnet materials comprise, by weight, 22-30% neodymium, 4.4-6% praseodymium, 0.044-0.06% lanthanum, 2-5% boron, 0.044-0.06% molybdenum, 0.044-0.06% nickel, 0.044-0.06% rhenium, 0.044-0.06% scandium and the balance ferrum. The high bending force resistant permanent magnet materials are uniform in organization, strong in structure and capable of improving bending force resistant performance of the materials and magnetic performance. The preparation method of the magnet material takes full use of praseodymium-neodymium waste to directly produce raw materials used by alloy, composition proportion is flexible, quality is well controlled, cost is lowered, the process is simple and powder waste with high oxygen content is fully used.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Process for preparing ZrN/Al2 (O1-xNx)3 hard nano multi-layer coating

InactiveCN1793415AHas high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingSputteringResidence time

The invention relates to a ZrN / Al2(O1-xNx)3 solidness nanometer multi-layer coating preparing method. It belongs to ceramic material technique field. It adopts direct current cathode control metallic Zr target and radio frequency cathode control Al2O3 target, gains ZrN and Al2(O1-xNx)3 layer by reaction sputtering under the mixture gas of Ar gas and N2 gas, and gains ZrN / Al2(O1-xNx)3 nanometer multi-layer coating with periodic change component, high rigidity and oxidation resistance by adjusting each target sputtering frequency and basal piece rotating residence time. The rigidity of the formed coating is higher than 30GPa. And its high temperature oxidation resistance is over 1000 centigrade degree. As the nitride / oxide nanometer multi-layer coating manufacturing technique, the invention has high production efficiency, and can be used in coating industrial production.

Owner:上海工具厂有限公司 +1

Magnetic material containing nitrogen-boron composite phase and preparation method

ActiveCN105489337AUniform tissueStrong and stable structureInorganic material magnetismMetallurgyNitrogen

The invention provides a magnetic material containing a nitrogen-boron composite phase. The magnetic material is high in residual magnetic flux density; the preparation method is simple in process, low in production cost and suitable for industrial production. The permanent magnet material comprises the following components in percentage by mass: 24-30% of Nd, 2.4-3.0% of Y, 3.6-4.5% of Eu, 1.2-1.5% of Ce, 1.2-1.5% of Tb, 2-4% of B, 0.2-0.6% of P, 0.12-0.3% of Ba, 0.45-0.60% of V and the balance of Fe, wherein the permanent magnet material also comprises 0.55-0.86% of N in percentage by mass.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Rare earth permanent magnet material utilizing recycled waste materials and preparation method

The invention provides a rare earth permanent magnet material utilizing recycled waste materials. An alloy material is high in coercivity. The preparation method is simple in process, low in production cost and suitable for industrial production. The permanent magnet material comprises the following components in percentage by mass: 18-22% of Nd, 7.2-8.8% of Y, 3.6-4.4% of Eu, 3.6-4.4% of Dy, 2-6% of B, 0.1-0.5% of P, 0.15-0.20% of Ag, 0.45-0.60% of Ni, 0.01-0.04% of Si, 0.45-0.60% of Ti and the balance of Fe; the mass ratio of Nd to Y to Eu to Dy in the permanent magnet material is 10:4:2:2; and the permanent magnet material also comprises 0.045-0.060% of N in percentage by mass.

Owner:XUZHOU NANFANG YONGCI MATERIAL

High-temperature nano radiation coating for heating furnace and preparation process thereof

The invention provides a high-temperature nano radiation coating for a heating furnace and a preparation process thereof. The coating comprises radiation function powder particles, an inorganic adhesive and an expansion coefficient regulator. The preparation process comprises the following steps: preparing the radiation function powder particles, preparing the expansion coefficient regulator, synthesizing the inorganic adhesive, mixing the radiation function powder particles, the inorganic adhesive and the expansion coefficient regulator, and filtering and grinding the obtained mixture so as to obtain the high-temperature nano radiation coating for the heating furnace. The high-temperature-resistant nano radiation coating disclosed by the invention has the characteristics of capability of increasing the radiance and the thermal shock stability, energy conservation and environmental friendliness, corrosion resistance, and capability of prolonging the service life of the heating furnace and raising the temperature uniformity, and the like. The technical indexes of the products provided by the invention are as follows: a temperature of 1800 DEG C can be resisted, the radiance epsilon is greater than or equal to 0.92, the thermal shock resistance (1300 DEG C) is greater than or equal to 5 times, the thickness of the coating is 0.1-0.2 mm, and the service life is greater than or equal to 6 years.

Owner:BDES BEIJING ENERGY SAVING TECH SERVICE

Reaction and magnetically controlled sputtering process of preparing hard nanometer layered TiN/SiO2 coating

InactiveCN1888131ANo nitridingIncrease deposition rateVacuum evaporation coatingSputtering coatingSputteringNitrogen

The reaction and magnetically controlled sputtering process of preparing hard nanometer layered TiN / SiO2 coating belongs to the field of tool and mold coating preparing technology. In a multiple target magnetically controlled sputtering and coating apparatus with low pressure mixed Ar and N2 atmosphere and independent RF cathodes controlled Ti target and compound SiO2 target, the substrate is made to stay alternately in the plasmas these two targets generate to form the layered coating including TiN layers formed through the reaction between Ti material and N2 gas and the SiO2 layers formed directly with the sputtered SiO2 compound and containing no nitrogen. The present invention has high efficiency, and the formed coating has high hardness and excellent antioxidant performance and is suitable for high speed cutting and dry cutting.

Owner:SHANGHAI JIAO TONG UNIV

Heat-resistant neodymium iron boron material and preparation method thereof

The invention provides a heat-resistant neodymium iron boron material and a preparation method thereof. The material not only has good magnetic properties, but also has high heat resistance. The preparation method has a simple process and a low production cost, thus being suitable for industrialized production. The heat-resistant neodymium iron boron material comprises the following components by weight: 21-24% of Nd, 7-8% of Pr, 1-2% of B, 0.07-0.08% of Ir, 0.07-0.08% of Rh, 0.7-0.8% of Sc, and the rest Fe.

Owner:SHANXI SANYIQIANG MAGNETIC IND +1

Environmental friendly lead-free solder and its preparation method

InactiveCN1799757AImprove protectionAvoid poisoningWelding/cutting media/materialsSoldering mediaSludgeOxidation resistant

The invention relates to welding material, especially providing a high-temperature resistance oxidation environment-friendly leadless solder and relative preparation method. said leadless solder comprises following elements in weight percents: 2-5% AG, 0.1-2% Cu, 0.001-0.1% Ce, 0.001-0.5% Ni and Sn. Compared to present technique, the invention is environment-friendly, which can effectively avoid lead poisoning of operator and when the solder is welded in high temperature (380-500Deg. C), it has minute oxidation sludge. The invention has high-temperature resistance oxidation ability which can keep the surface of tin furnace bright without oxidation in this temperature, and the welded tin furnace can last non-oxidation condition for longer time. The invention has less welding defects compared to common Sn-Ag-Cu system, bright surface of welding point and improved welding quality.

Owner:THOUSAND ISLAND METAL FOIL

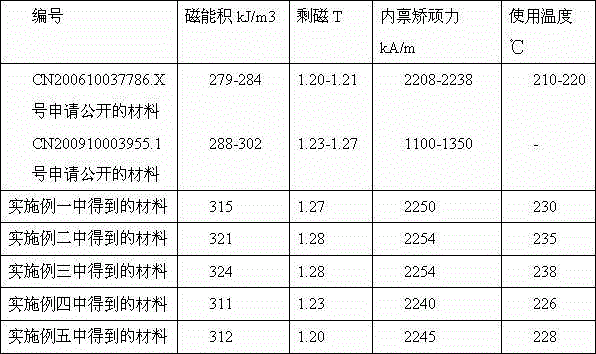

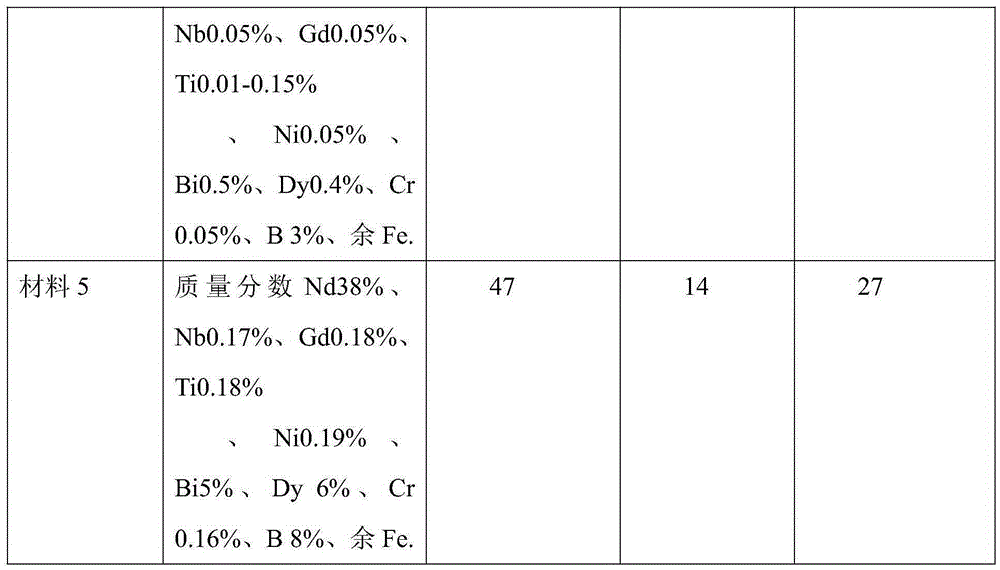

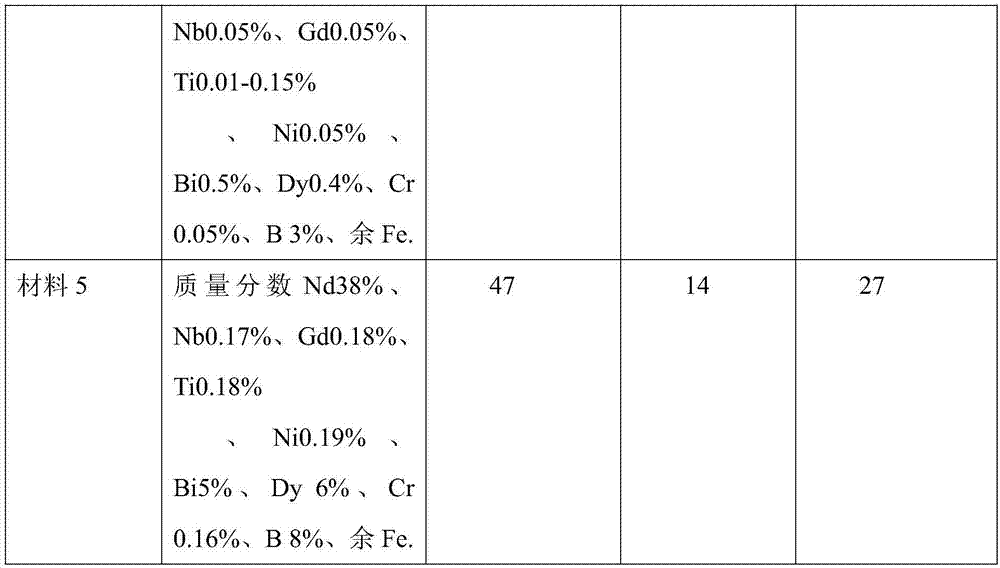

Functional material and preparation method

ActiveCN105355355AUniform tissueStrong and stable structureInorganic material magnetismMedical deviceAerospace technology

The invention discloses a functional material and a preparation method. The functional material is blended by components in percentage by mass as follows: 34%-36% of Nd, 0.01%-0.15% of Nb, 0.01%-0.15% of Gd, 0.01%-0.15% of Ti, 0.01%-0.15% of Ni, 1%-4% of Bi, 1%-4% of Dy, 0.01%-0.15% of Cr, 4%-7% of B and the balance of Fe. The functional material has uniform tissue and strong structure, the corrosion resistance of the material can be improved, and the magnetism is improved. The permanent magnet material has good stability and practicability and can be widely applied to various fields such as electronic devices, aerospace engineering, computer equipment, magnetic separators, communication equipment, medical equipment, electric bicycles, electronic toys and the like.

Owner:盐城市华达照明电器有限公司

Ceramic paint

InactiveCN104211372AHas high temperature oxidation resistanceWith thermal shock resistanceClaywaresGlycerolSilicon oxide

The invention discloses a ceramic paint which is composed of following raw materials including 20-50 parts of ceramic fiber, 50-80 parts of silicon micro-powder, 60-95 parts of hollow glass microbeads, 200-250 parts of kaolin, 6-8 parts of di-(2-ethylhexyl) phthalate, 10-12 parts of glycerol, 2-3 parts of dimethylbenzene, 5-8 parts of epoxy resin, 6-9 parts of sodium hexametaphosphate, 12-15 parts of sodium hydroxide, 5-10 parts of trisodium phosphate, 3-10 parts of sodium carboxymethylcellulose, 2-5 parts of hydroxyethyl cellulose, 5-10 parts of hydroxypropyl methyl cellulose, 3-10 parts of titanium carbide, 5-10 parts of titanium dioxide, 3-5 parts of zirconium nitride, 6-10 parts of titanium hydride, 5-8 parts of sodium carbonate, 8-15 parts of calcium carbonate, 12-15 parts of silicone oil, 12-15 parts of polydimethylsiloxane, 10-15 parts of carbon black, 15-20 parts of paraffin, 12-15 parts of graphene, 5-10 parts of magnesium nitride, 5-10 parts of magnesium oxide, 3-6 parts of silicon oxide, 3-8 parts of nano silicon dioxide and 300-350 parts of pure water. In the ceramic paint, the raw materials are reasonably blended. The paint has a high-temperature anti-oxidation property and a thermal shock resistant property when being sprayed on or brushed on a lining layer.

Owner:李兆源

Composite waste-material-recycled rare earth magnetic material and preparation method therefor

The invention provides a composite waste-material-recycled rare earth magnetic material and a preparation method therefor. The alloy material has relatively high coercivity. The preparation method is simple in process, low in production cost, and suitable for realizing industrial production. The material comprises the following components based on mass percentage: 30-35% of Nd, 0.6-0.7% of Y, 1.2-1.4% of Ce, 0.6-0.7% of La, 1.2-1.4% of Pr, 0.3-0.35% of Gd, 0.6-0.7% of Sm, 0.6-0.7% of Co, 2-6% of B, 1.25-1.86% of N, 0.3-0.35% of Hf, 0.3-0.35% of Be and the balance of Fe; and the 1.25-1.86% of N based on mass percentage is included in the material.

Owner:XUZHOU NANFANG YONGCI MATERIAL

PVD nano multiple-layer coating for cutting stainless steel and preparation method thereof

InactiveCN101200797BHas high temperature oxidation resistanceExcellent high temperature oxidation resistanceLayered productsVacuum evaporation coatingGas phaseSurface cleaning

The invention discloses a PVD nanometer multiple-layer coating used for cutting stainless steel and a preparation method thereof. The specific manufacturing process is as follows: firstly, implementing the surface cleaning treatment on carbide base; secondly, adopting a multiple targets magnetic sputtering method to alternatively deposit the nanometer multiple-layer coating which takes TiN (Tix, Al1-x)N / (Tiy, Al1-y)N / (Tix, Al1-x)N as a modulation period on the rotating carbide base; adopting Ar2 as the sputtering gas. The flow of Ar is 180-300cm3 / s, the partial pressure is 1.7-9.0'10<-1>Pa, the reaction gas is N2, and the total pressure is controlled through controlling the partial pressure of N2. The invention introduces TiAlN with high Al content and perfect high temperature oxidation resistance into a multiple-layer coating material system, improves the high temperature oxidation resistance and the hardness of the coating, enhances the toughness of the coating through the microstructure optimization design and enables the coating to obtain both the high temperature oxidation resistance and excellent mechanical properties. The nanometer multiple-layer coating prepared through the invention is provided with great application value in the stainless steel cutting process.

Owner:CENT SOUTH UNIV

Permanent magnet material containing multiple rare earth phases and preparation method

ActiveCN105489332AImproved structural stability and corrosion resistanceAvoid embrittlementInorganic material magnetismSolid state diffusion coatingMagnetMaterials science

The invention provides a permanent magnet material containing multiple rare earth phases and a preparation method. The permanent magnet material is high in magnetic energy product; the preparation method is simple in process, low in production cost and suitable for industrial production. The permanent magnet material containing the multiple rare earth phases comprises the following components in percentage by mass: 15-20% of Nd, 3-4% of Y, 4.5-6% of La, 6.0-8.0% of Ce, 3-4% of Pr, 0.15-0.20% of Pd, 0.3-0.4% of Sm, 2-5% of B, 0.45-0.60% of Co, 0.01-0.04% of Mn, 0.01-0.04% of Mo and the balance of Fe; the mass ratio of Pd to Co in the permanent magnet material is 1:3; the mass ratio of Nd to Y to La to Ce to Pr to Pd to Sm is 10:2:3:4:2:0.1:0.2; and the permanent magnet material also comprises 0.15-0.55% of N in percentage by mass.

Owner:XUZHOU NANFANG YONGCI MATERIAL

Self-healing type high-temperature adhesive and preparation method thereof

InactiveCN110003847AImprove adhesionGuaranteed conversion rateNon-macromolecular adhesive additivesAdhesiveOxidation resistant

The invention discloses self-heating type high-temperature adhesive and a preparation method thereof. The self-heating type high-temperature adhesive is prepared through polycarbosilane, sodium dihydrogen phosphate, silica aerosol and carbon tetrachloride. The preparation method comprises the following steps: fully grinding polycarbosilane; mixing with a mixture of sodium dihydrogen phosphate andsilica aerosol; then adding carbon tetrachloride; and dispersing at a high speed to obtain the target product. Compared with the prior art, the self-healing type high-temperature adhesive has the advantages that polycarbosilane particles are creatively and uniformly dispersed into silica aerosol, and the high temperature self-healing effect of a composite material can be achieved through the low-temperature viscidity and high-temperature decomposing property of polycarbosilane; silicon carbide obtained by porcelainizing polycarbosilane is resistant to high temperature oxidization, so that cracks in a sealing combining part can be effectively prevented from spreading, and the purpose of protecting a substrate material is achieved; in addition, the product use method is simple and free froma special construction tool; the adhesive is directly coated to a part to be adhered after being extruded and then is naturally dried or dried by air.

Owner:赛兴(北京)科技有限公司

Reaction and magnetically controlled sputtering process of preparing hard nanometer layered TiN/SiO2 coating

InactiveCN100424224CNo nitridingIncrease deposition rateVacuum evaporation coatingSputtering coatingSputteringNitrogen

The reaction and magnetically controlled sputtering process of preparing hard nanometer layered TiN / SiO2 coating belongs to the field of tool and mold coating preparing technology. In a multiple target magnetically controlled sputtering and coating apparatus with low pressure mixed Ar and N2 atmosphere and independent RF cathodes controlled Ti target and compound SiO2 target, the substrate is made to stay alternately in the plasmas these two targets generate to form the layered coating including TiN layers formed through the reaction between Ti material and N2 gas and the SiO2 layers formed directly with the sputtered SiO2 compound and containing no nitrogen. The present invention has high efficiency, and the formed coating has high hardness and excellent antioxidant performance and is suitable for high speed cutting and dry cutting.

Owner:SHANGHAI JIAOTONG UNIV

Antioxidant iron handicraft and manufacturing method thereof

InactiveCN112295881AImprove antioxidant capacityInhibited DiffusionLiquid surface applicatorsSpecial ornamental structuresCarrageenanCALCIUM LACTOBIONATE

The invention relates to a manufacturing method of an antioxidant iron handicraft. The manufacturing method comprises the following steps that S1, the surface of an iron handicraft is coated with an antioxidant liquid with the use amount of 2-5 g / m <2>, and then is dried at 20-25 DEG C for 18-24 hours; the antioxidant liquid is prepared from the following components of gelatin, carrageenan, chitosan, citric acid, calcium lactate, ethylenediamine tetraacetic acid disodium salt, glutamine transaminase and water; S2, the surface of the iron handicraft smeared in the step 1 is sprayed with a protective coating, wherein the thickness of the protective coating is 20-50 microns; the protective coating is prepared from the following components of AlPO4, nano SiO2, nano Al2O3 and nano SiC; and S3,at the temperature of 120-140 DEG C, the iron handicraft sprayed in the step 2 is cured for 2-3 h, the antioxidant iron handicraft is obtained, and the iron handicraft has high oxidation resistance, high-temperature oxidation resistance and lasting oxidation resistance.

Owner:安溪县贤发工艺制品有限公司

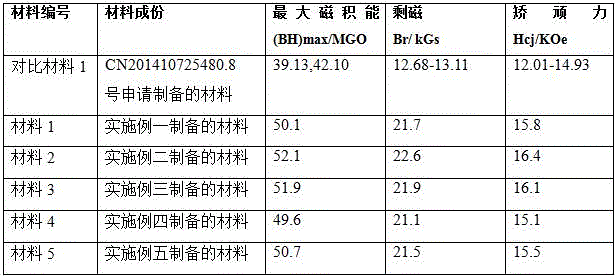

High magnetic energy product material and preparation method

The invention provides a high magnetic energy product material and a preparation method. The method comprises following steps of preparing materials according to following mass percent: 24-28% of Nd, 5.2-5.8% of Ce, 1.6-1.9% of Eu, 0.6-0.9% of Sn, 3-7% of B, 0.08-0.12% of P, 0.005-0.007% of Au, 0.7-0.9% of Ni and 0.045-0.060% of In, and the remainder being Fe; adding the prepared raw materials to the crucible in a vacuum induction furnace; heating to 1500-1530 degrees centigrade; keeping warm for 20 minutes; pouring the prepared materials into an ingot mould; naturally cooling, thus obtaining alloy ingot containing rare earth materials; carrying out tape preparation, preprocessing, nitriding, powder preparation, compression moulding and sintering technologies on the prepared alloy ingot containing the rare earth materials, thus obtaining the high magnetic energy product material.

Owner:SHANXI RAY WHEAT ELECTRONICS TECH

High temperature corrosion resistant ceramic coating for protecting float glass tin bath pendant and preparation method

The invention discloses a ceramic coating capable of resisting high-temperature corrosion for protecting a hanging part in a tin bath of float glass and a preparation method thereof. The preparation method comprises: dispersing SiO2, FeO, TiO2, Cr2O3, NiO, CoO and alkali metal compounds in water to obtain slurry with a solid content of 50-70%, grinding the slurry with a ball milling method to obtain an abrasive, then applying the abrasive on the cleaned surface of the hanging part and then sintering the surface of the hanging part and the coating. The resulting high-temperature ceramic coating has high-temperature anti-oxidation capacity and can also effectively improve the corrosion resistance of the surface of a Ni-Cr high-temperature alloy; and in addition, the ceramic coating can act as a heat barrier coating, forms effective protection on the hanging part in the tin bath of the float glass, and has important practical significance in prolonging the service life of the hanging part in the tin bath of the float glass.

Owner:武汉长利新材料科技有限公司 +1

Ceramic coating

InactiveCN108395818AHas high temperature oxidation resistanceWith thermal shock resistanceFireproof paintsEpoxy resin coatingsEpoxyCellulose

The invention provides a ceramic coating which is prepared from the following raw materials in parts by weight: 70 to 100 parts of ceramic micro powder, 25 to 35 parts of epoxy resin, 60 to 70 parts of asbestos fiber, 20 to 30 parts of submicron ceramic powder, 18 to 26 parts of sodium phosphate, 18 to 26 parts of silicon dioxide, 15 to 20 parts of alkyl cellulose, 7 to 13 parts of titanium dioxide, 8 to 16 parts of titanium nitride, 10 to 17 parts of hydroxymethyl cellulose, 11 to 19 parts of polysiloxane, 6 to 10 parts of calcium oxide, 4 to 8 parts of silicon dioxide and 30 to 50 parts of water. The ceramic coating has high-temperature oxidation resistance and thermal shock resistance; a coating film of the ceramic coating is compact and strict, cannot be cracked or swollen and has goodacid resistance and alkali resistance; the ceramic coating is environmental-friendly and safe.

Owner:黄建如

Multiphase permanent magnet material for waste recycling and preparation method thereof

Owner:XUZHOU NANFANG YONGCI MATERIAL

Waste-material-recycled multi-phase permanent magnet material and preparation method therefor

ActiveCN106876070AUniform tissueStrong and stable structureMagnetic materialsMagnetic energyMulti phase

The invention provides a waste-material-recycled multi-phase permanent magnet material and a preparation method therefor. The permanent magnet material has relatively high maximum magnetic energy product performance and coercivity. The preparation method is simple in process, low in production cost, and suitable for realizing industrial production. The permanent magnet material comprises the following components based on mass percentage: 25-30% of Nd, 2.5-3.0% of Y, 2.5-3.0% of Ce, 0.25-0.30% of Tb, 0.25-0.30% of Eu, 0.25-0.30% of La, 0.25-0.30% of Pr, 2-4% of B, 1.0-1.2% of N, 0.25-0.30% of V, 2.1-2.5% of W and the balance of Fe; and the 1.0-1.2% of N based on mass percentage is included in the material.

Owner:XUZHOU NANFANG YONGCI MATERIAL

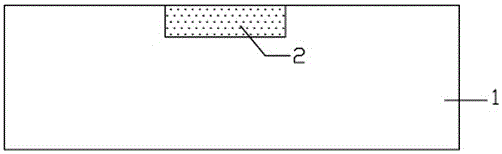

A kind of solid lubricating multilayer composite film and preparation method thereof

ActiveCN105568215BImprove bindingHigh bonding strengthVacuum evaporation coatingSputtering coatingComposite filmUltimate tensile strength

The invention discloses a solid lubricating multilayer composite membrane and a preparation method thereof. The solid lubricating multilayer composite membrane consists of a substrate (1), a metal bottom layer Me (2), a CuNiIn layer (3), a metal transition layer Me (4) and an MoS2-Me layer (5) in sequence. The preparation method comprises the following steps: by adopting a magnetron sputtering method, firstly depositing the metal bottom layer (2) on the substrate (1), and then alternately depositing the CuNiIn layer (3), the metal transition layer Me (4) and the MoS2-Me layer (5) in sequence to form a multilayer structure, wherein the MoS2-Me layer (5) is at the outermost layer. The solid lubricating composite membrane with the multilayer structure has the performance features of being high in bonding strength and low in friction coefficient which is as low as 0.06, has excellent self-lubricating performance, anti-occlusion performance and friction durability, and can be applied to the components such as bearings, gears, blades, tools and moulds.

Owner:GUANGDONG INST OF NEW MATERIALS

Ceramic coating used for heating furnace

InactiveCN102020475BExtended service lifeHas high temperature oxidation resistanceEmissivityRadiance

The invention relates to ceramic coating used for a heating furnace. The ceramic coating comprises the following components: ceramic micro powder, an inorganic bonding agent and a linear thermal expansivity regulator. The invention also provides a method for preparing the ceramic coating for the heating furnace. The ceramic coating has the characteristics of having improved radiance and thermal shock resistance, being efficient and energy-saving, prolonging the service life of furnace linings and furnace tubes, improving temperature uniformity and the like, as defined below: (1) the energy consumption is reduced, the energy is saved by more than 3 percent and pollutant discharge is reduced; (2) the temperature uniformity in the heating furnace is improved: (3) the metallurgy stability of the furnace tube of the heating furnace is improved, the coking and scaling of the furnace tub are delayed, and the absorbing capacity of the furnace tube can be maximized; (4) the emissivity of the surface of the refractory lining layer can be maximized so as to increase the secondary radiation of radiant heat (energy) and increase the efficiency of the radiant section; and (5) the outer wall temperature and the exhaust gas temperature of the heating furnace can be reduced by more than 5 percent.

Owner:北京安泰恒业科技有限公司

A heat-resistant NdFeB material and its preparation method

InactiveCN103146993BImprove stray magnetic fieldReduce stray magnetic fieldMetallurgyHeat resistance

The invention provides a heat-resistant neodymium-iron-boron material and a preparation method thereof. The material not only has good magnetism, but also has high heat resistance. The preparation method has simple process, low production cost and is suitable for industrialized production. The weight percentage of the heat-resistant NdFeB material is: Nd21-24%, Pr7-8%, B1-2%, Ir0.07-0.08%, Rh0.07-0.08%, Sc0.7-0.8 %, the rest is Fe.

Owner:SHANXI SANYIQIANG MAGNETIC IND +1

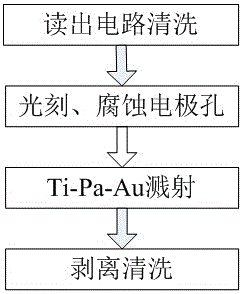

A high-temperature oxidation-resistant readout circuit lead-out electrode and its preparation method

ActiveCN105070786BHas high temperature oxidation resistanceEffective readoutFinal product manufactureSemiconductor devicesHigh resistanceComposite electrode

Owner:KUNMING INST OF PHYSICS

Corrosion-resistant neodymium-iron-boron permanent magnet material and preparation method thereof

ActiveCN103077796BImprove stray magnetic fieldReduce stray magnetic fieldMagnetic materialsAlloyWaste material

The invention discloses a corrosion-resistant neodymium-iron-boron permanent magnet material and a preparation method thereof. The corrosion-resistant neodymium-iron-boron permanent magnet material comprises the following components in percentage by weight: 20-26 percent of Nd, 5-6.5 percent of Pr, 1-4 percent of B, 0.05-0.065 percent of Ir, 0.05-0.065 percent of Os, 0.5-0.65 percent of Sc, 0.5-0.65 percent of Cu and the balance of Fe. The corrosion-resistant neodymium-iron-boron permanent magnet material disclosed by the invention is provided with uniform tissue and a robust structure, so that the corrosion resistance of the material can be enhanced, and the magnetic performance is improved. According to the preparation method of the corrosion-resistant neodymium-iron-boron permanent magnet material, raw materials of an alloy are directly produced by fully utilizing praseodymium and neodymium waste, a component mixture ratio is flexible, and the quality is controlled appropriately; and moreover, the cost can be reduced, a process is simple, and powder waste with high oxygen content is fully utilized.

Owner:XUZHOU NANFANG YONGCI MATERIAL

A kind of functional material and preparation method

ActiveCN105355355BImprove temperature stabilityWide operating temperature rangeInorganic material magnetismMedical equipmentMagnetic separator

The invention discloses a functional material and a preparation method. The functional material is blended by components in percentage by mass as follows: 34%-36% of Nd, 0.01%-0.15% of Nb, 0.01%-0.15% of Gd, 0.01%-0.15% of Ti, 0.01%-0.15% of Ni, 1%-4% of Bi, 1%-4% of Dy, 0.01%-0.15% of Cr, 4%-7% of B and the balance of Fe. The functional material has uniform tissue and strong structure, the corrosion resistance of the material can be improved, and the magnetism is improved. The permanent magnet material has good stability and practicability and can be widely applied to various fields such as electronic devices, aerospace engineering, computer equipment, magnetic separators, communication equipment, medical equipment, electric bicycles, electronic toys and the like.

Owner:盐城市华达照明电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com