Process for preparing ZrN/Al2 (O1-xNx)3 hard nano multi-layer coating

A nano-multilayer, coating technology, applied in the coating, metal material coating process, ion implantation plating and other directions, can solve the problem of low coating preparation efficiency and achieve the effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

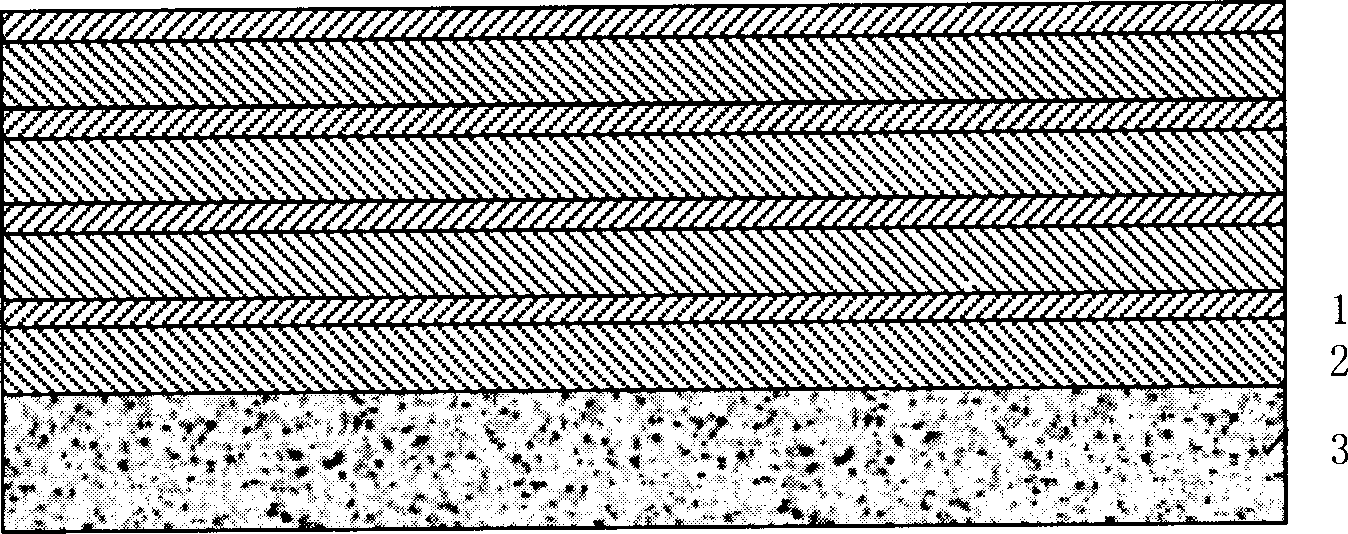

Image

Examples

example 1

[0021] ZrN / Al of the present invention 2 (O 1-x N x ) 3 The concrete process parameter of the preparation method of multi-layer coating is: Ar gas partial pressure is 0.2Pa, N 2 The gas partial pressure is 0.012Pa, the Zr target sputtering power is 260V×0.2A, the deposition time is 10 seconds, the Al 2 o 3 The target sputtering power is 30W, the deposition time is 1 second, and the substrate temperature is 2 (O 1-x N x ) 3 The thickness of the ZrN layer in the multilayer coating is 2 nm, Al 2 (O 1-x N x ) 3 (x=0.06) The layer thickness is 0.3nm, the hardness of the coating is 30GPa, and the anti-oxidation temperature exceeds 1000°C.

example 2

[0023] ZrN / Al of the present invention 2 (O 1-x N x ) 3 The concrete process parameter of the preparation method of multi-layer coating is: Ar gas partial pressure is 0.2Pa, N 2 The gas partial pressure is 0.012Pa, the Zr target sputtering power is 260V×0.2A, the deposition time is 10 seconds, the Al 2 o 3 The target sputtering power is 50W, the deposition time is 1 second, and the substrate temperature is 2 (O 1-x N x ) 3 The thickness of the ZrN layer in the multilayer coating is 2 nm, Al 2 (O 1-x N x ) 3 (x=0.06) The layer thickness is 0.5nm, the hardness of the coating is 33GPa, and the anti-oxidation temperature exceeds 1000°C.

example 3

[0025] ZrN / Al of the present invention 2 (O 1-x N x ) 3 The concrete process parameter of the preparation method of multi-layer coating is: Ar gas partial pressure is 0.2Pa, N 2 The gas partial pressure is 0.030Pa, the Zr target sputtering power is 260V×0.2A, the deposition time is 10 seconds, the Al 2 o 3 The target sputtering power is 70W, the deposition time is 3 seconds, and the substrate temperature is 2 (O 1-x N x ) 3 The thickness of the ZrN layer in the multilayer coating is 2 nm, Al 2 (O 1-x N x ) 3 (x=0.06) The layer thickness is 1.1nm, the hardness of the coating is 30GPa, and the anti-oxidation temperature exceeds 1000°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com