Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Enough viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tooth blenching liquid harmless for dental enamel and its using method

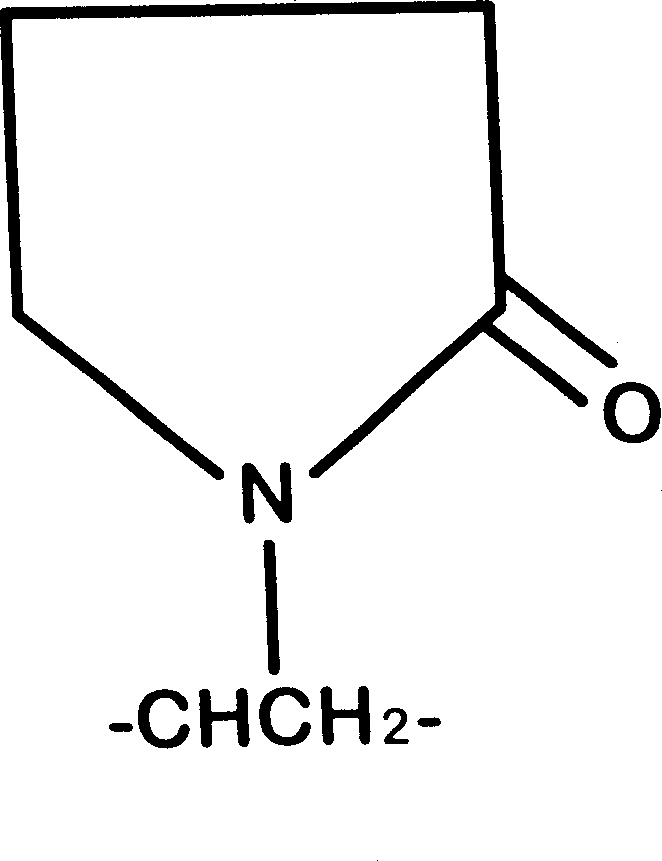

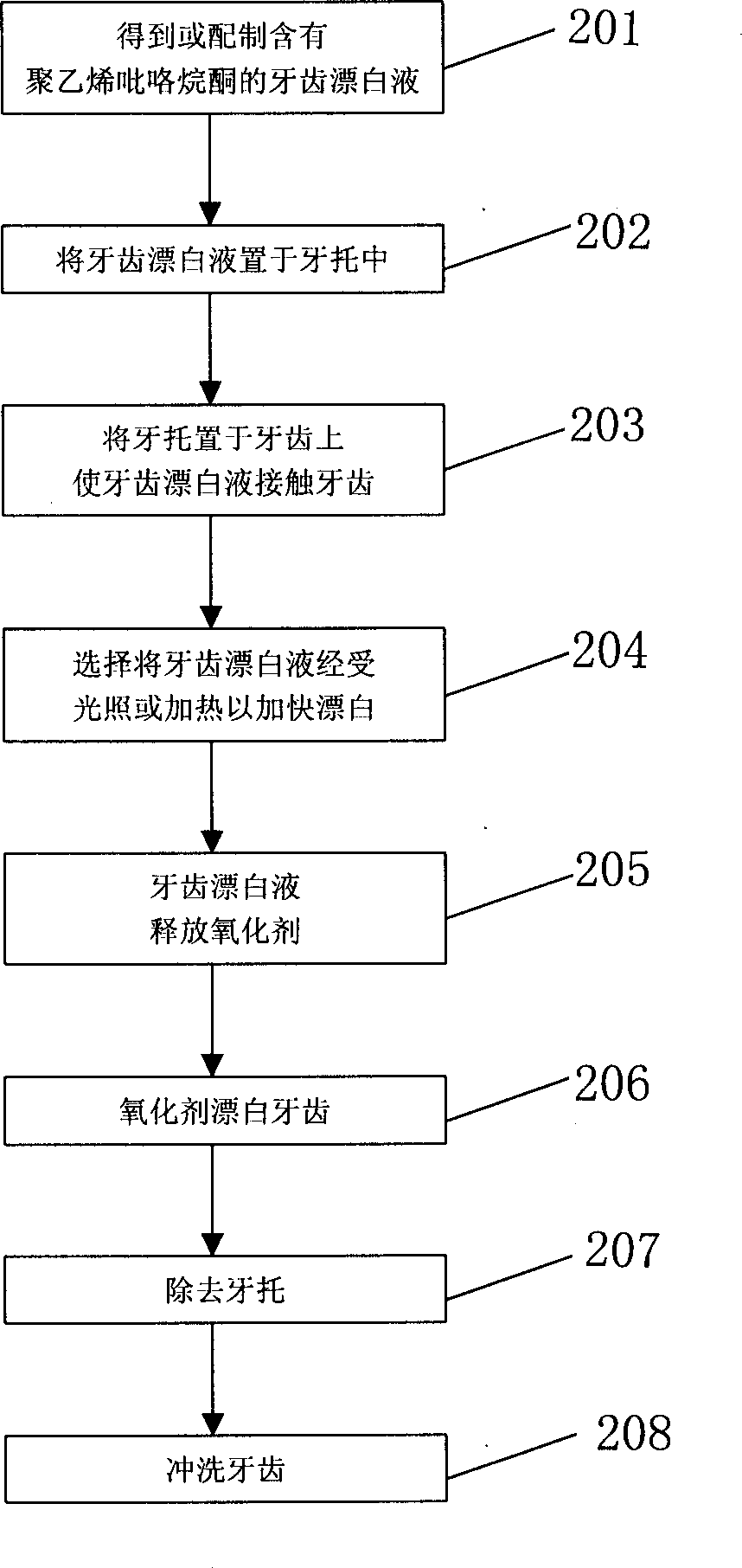

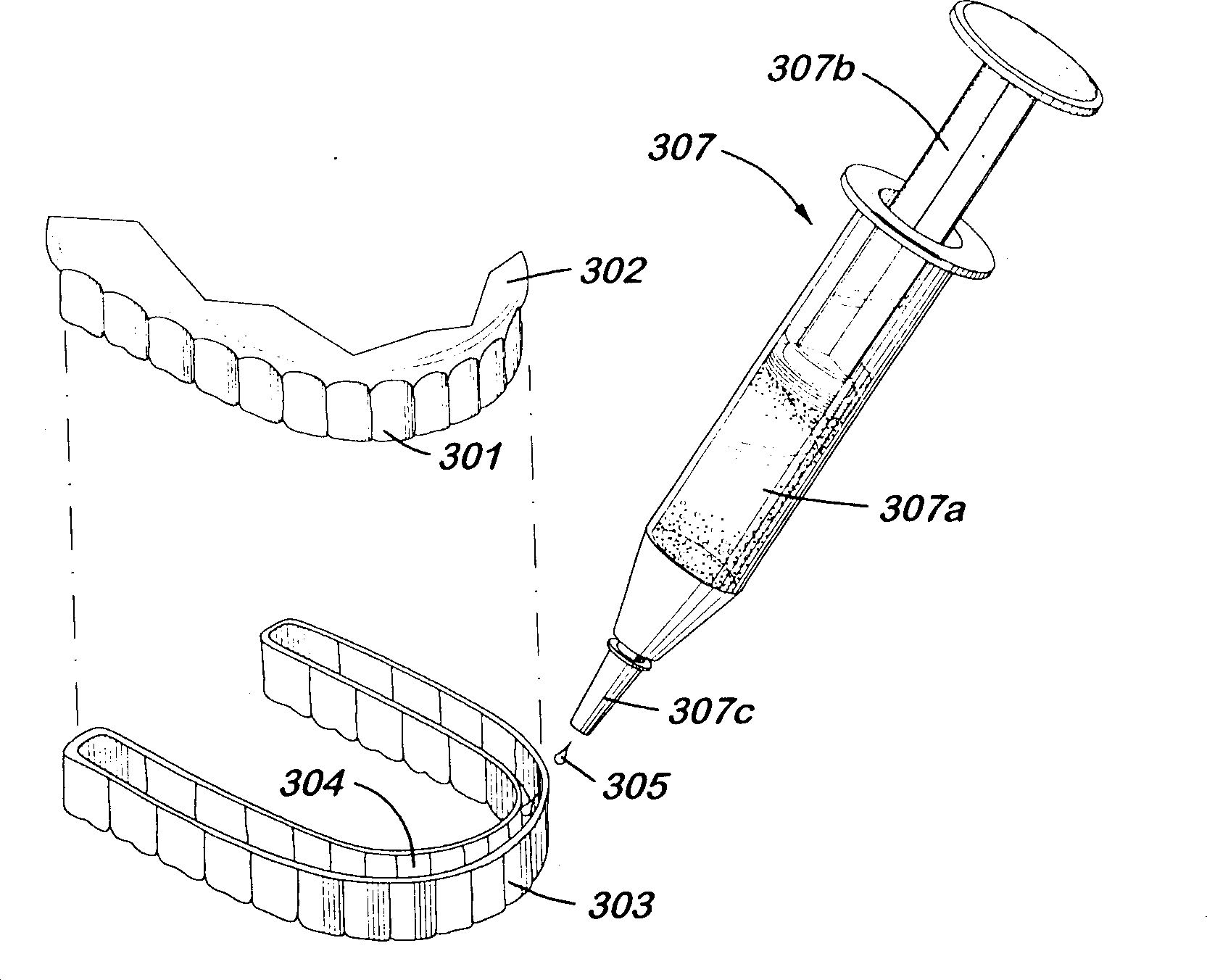

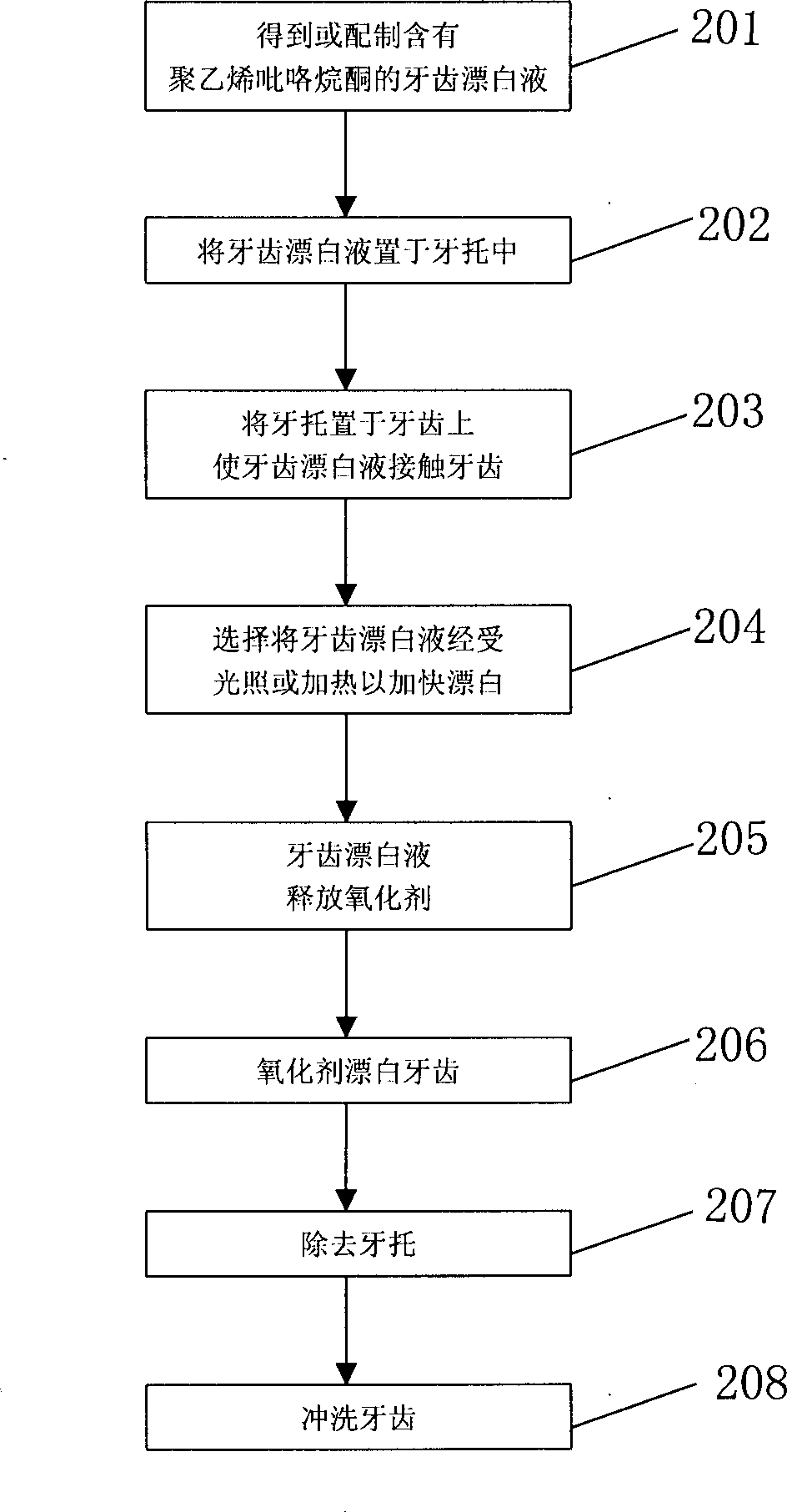

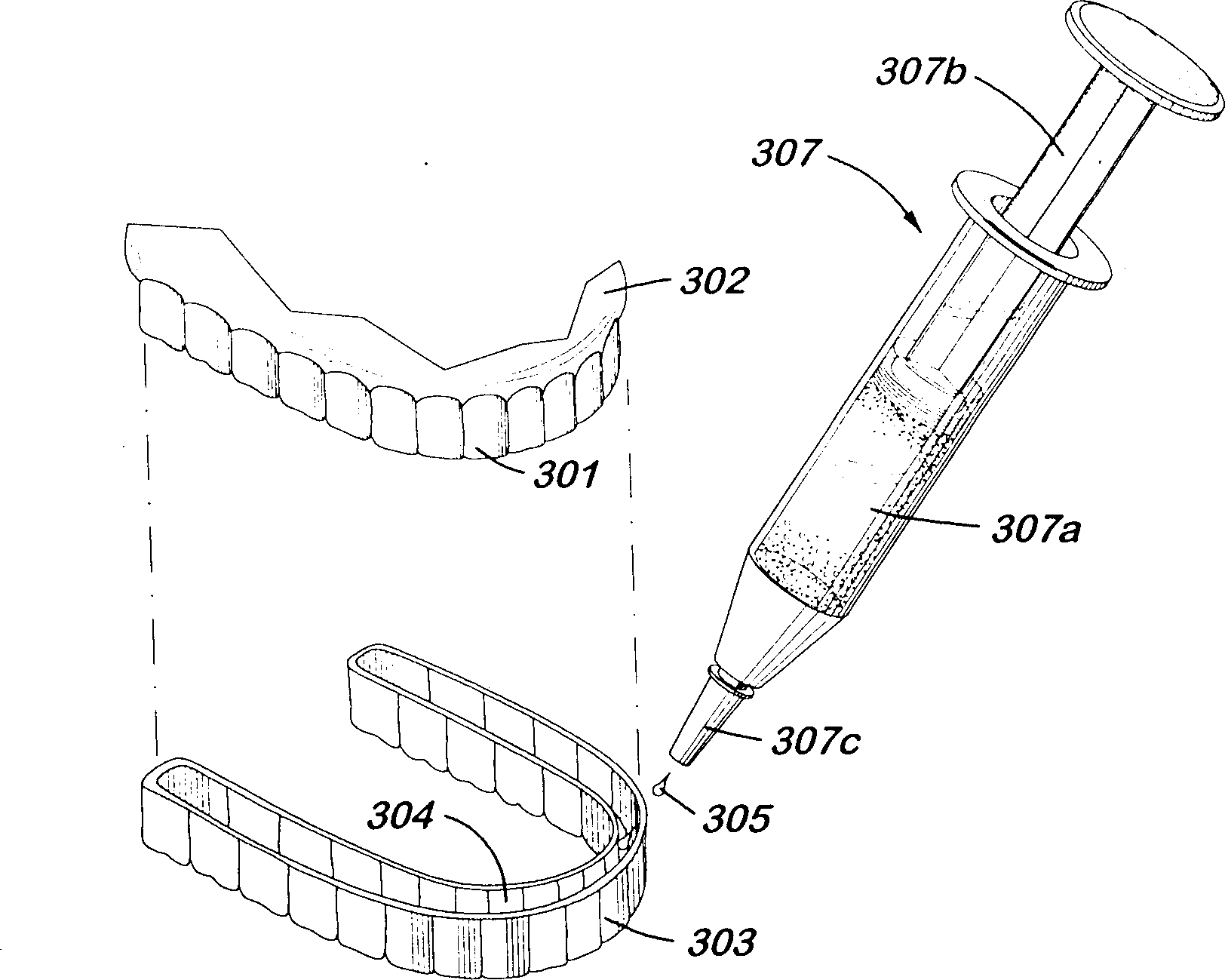

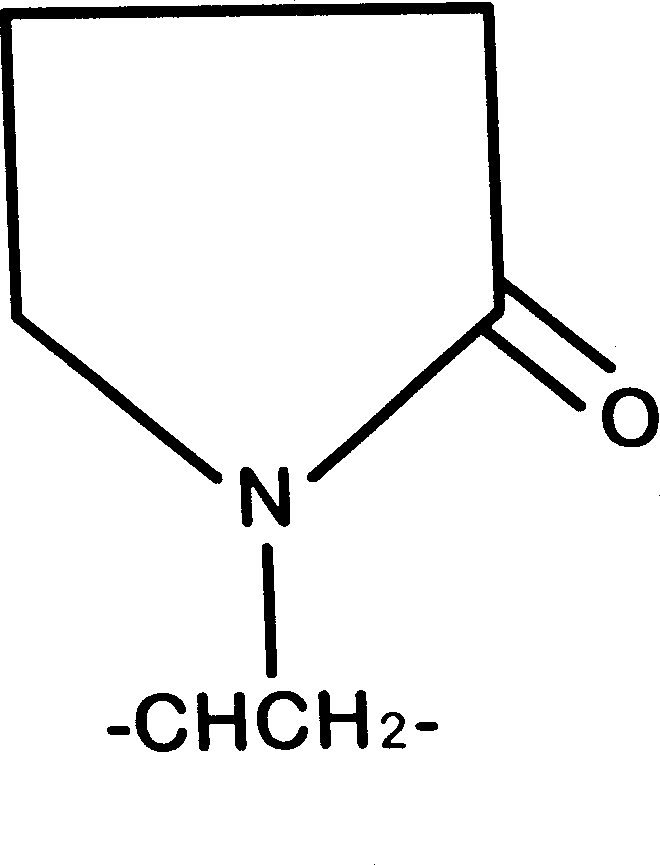

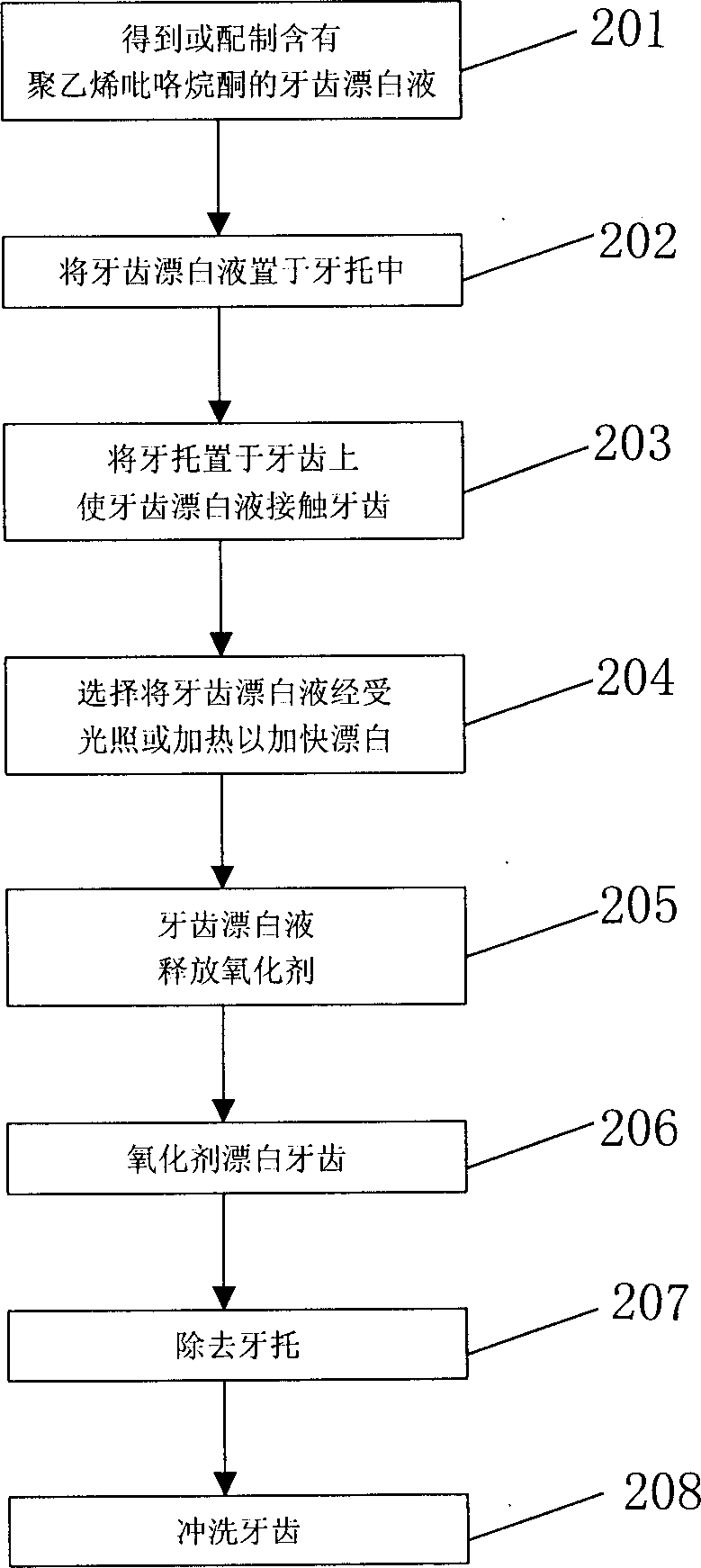

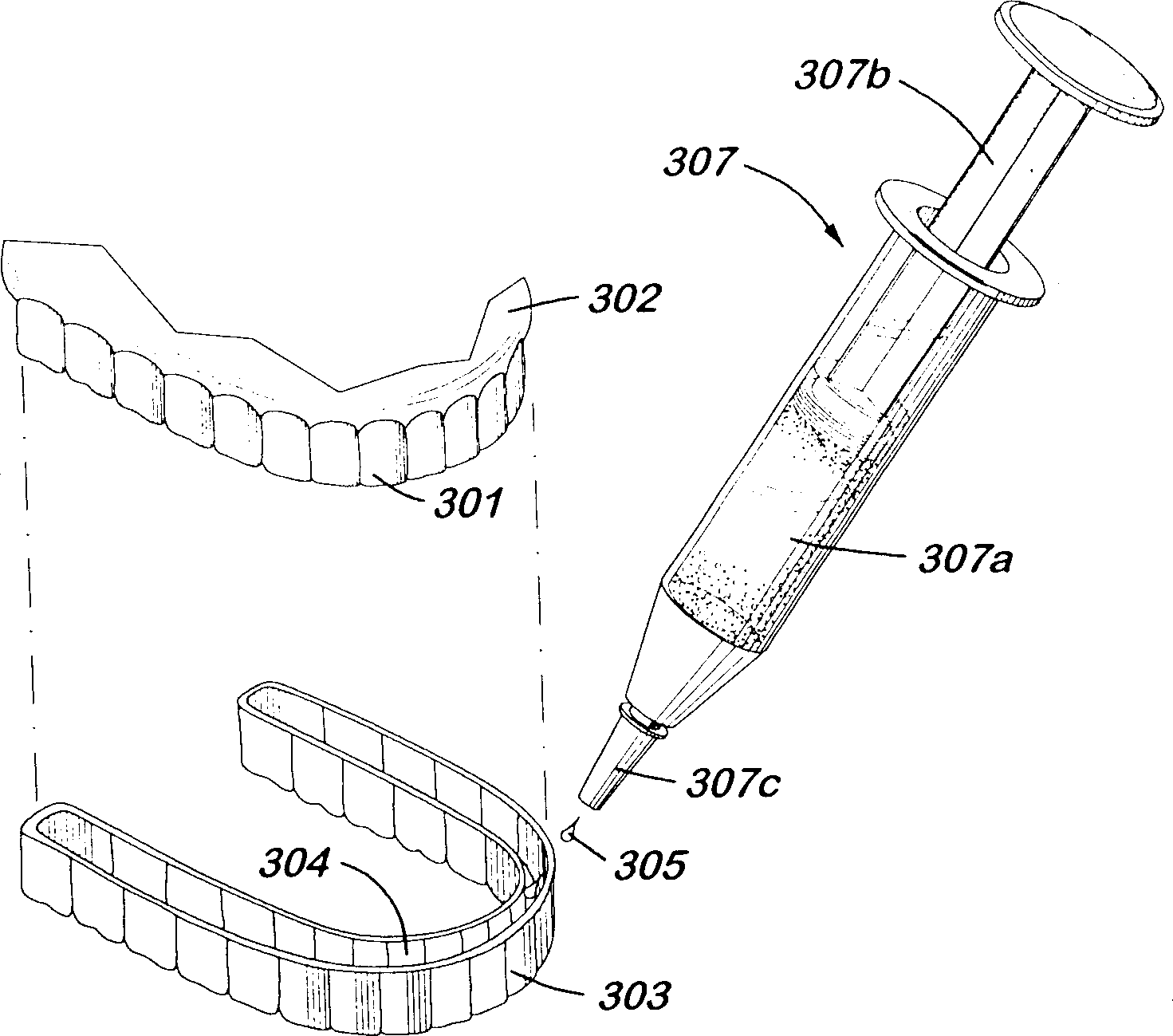

The invention discloses a tooth bleaching liquid which is harmless to tooth enamel and its application method. The tooth bleaching solution includes a bleaching agent and a thickening agent. Wherein the bleaching agent is a typical peroxide, and the thickener is polyvinylpyrrolidone. The two make up a viscous or viscous tooth bleaching solution. Choose to add alkaline reagents to the bleaching solution, increase light or heat can promote bleaching. Dental trays can be used for bleaching. The bleaching solution is pushed into the tooth tray by a syringe, and the syringe can be a single-chamber, double-chamber or multi-chamber syringe, which contains various components of the bleaching solution. The bleaching solution can be attached to a strip of elastic material and placed on the teeth for bleaching.

Owner:JESY TECH CORP

Fracturing fluid capable of resisting low pH value environment and higher salinity and preparation method thereof

The invention relates to a fracturing fluid capable of resisting low pH value environment and higher salinity and a preparation method thereof. Most conventional fracturing fluid can have favorable viscoelasticity only in an alkaline environment, and the natural vegetable glue used under normal conditions is difficulty for crosslinking under acidic conditions. The preparation method comprises the following steps: uniformly mixing a viscoelastic surfactant, an acid and a dispersion pour-point depressant to form a liquid component mixture; and dissolving a water-soluble nonionic polymer thickener at normal temperature, adding the liquid component mixture, and stirring uniformly to obtain the fracturing fluid. Under the condition of not using any crosslinking agent, the vermiform accumulation of the viscoelastic surfactant is utilized to coat the linear high-polymer part inside the viscoelastic surfactant, so that the linear high polymer generates the crosslinking-like effect due to the existence of the viscoelastic surfactant when meeting the acid and shrinking. The fracturing fluid has high viscosity in a neutral environment due to the linear high polymer, and thus, can not have the solid carrying capacity due to greatly lowered viscosity under acidic conditions.

Owner:SHAANXI BANGXI CHEM +1

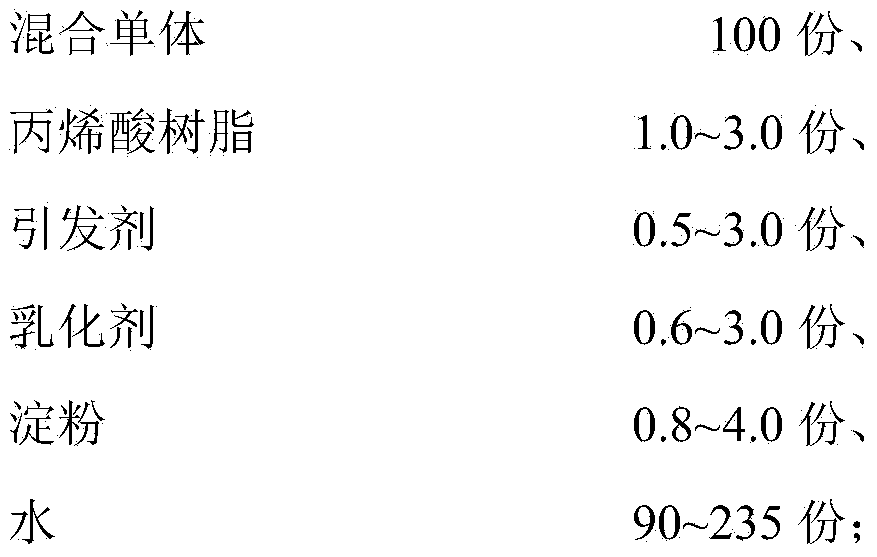

Preparation method and application of papermaking coating styrene-acrylic latex

ActiveCN102850974AResolubilizingWith smoothnessNon-fibrous pulp additionPaper coatingEmulsionAcrylic resin

The invention provides a preparation method and application of a papermaking coating styrene-acrylic latex. The preparation method comprises the following steps: (1) evenly mixing 5-40 wt% of initiator, 10-50 wt% of emulsifier and 5-30 wt% of water, and adding 50-80 wt% of mixed monomers to obtain a homogeneous emulsion A, wherein the mixed monomers are composed of (methyl) acrylate, (methyl) styrene and (methyl) acrylic acid; and (2) reacting acrylic resin, the rest of initiator, the rest of emulsifier, the rest of mixed monomers and the rest of water, dropwisely adding the homogeneous emulsion A obtained in the step (1) to react, adding a starch water solution, continuing the reaction, and neutralizing with an alkaline matter until the pH value is 6-9, thereby obtaining the papermaking coating styrene-acrylic latex. By using the method of adding the acrylic resin through the kettle bottom and adding the coating starch subsequently, the bonding property of the styrene-acrylic latex is greatly enhanced, and the smoothness of the coated paper is improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

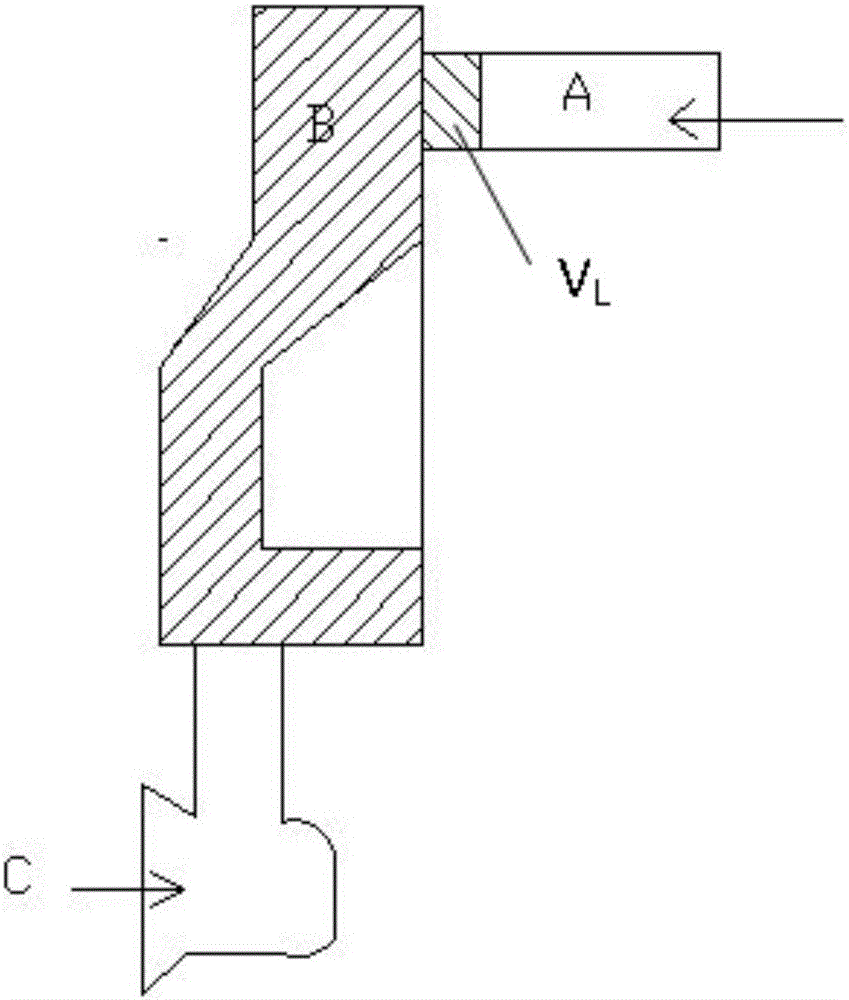

Die-casting forming method free from shrinkage cavity and shrinkage porosity defects for thick wall die-casting fitting

InactiveCN106270441ASolve the shrinkage porosity that is easy to appearSolve defects such as poresMold fillingDie casting

The invention discloses a die-casting forming method free from shrinkage cavity and shrinkage porosity defects for a thick wall die-casting fitting. By the adoption of the method, the problems of shrinkage cavity, shrinkage porosity and air hole defects which are likely to happen to a thick wall aluminum alloy die-casting fitting frequently can be solved effectively. The die-casting forming method includes the main contents that a specific pouring method with the low superheat degree is adopted, large fullness pouring with the pressure chamber fullness being 60%-70% is used, the high-pressure mold filling die-casting technique is utilized, and the internal compactness zero-defect performance of the die-casting fitting is achieved. The local pressurization structure is added in mold design, and pressurization feeding at the thick wall position far away from the position of an inner casting gate is realized. By the adoption of the method, the casting defects of the thick wall die-casting fitting can be reduced, the rejection rate of products is lowered, material wasting is avoided, cost is reduced and benefits are increased.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD +1

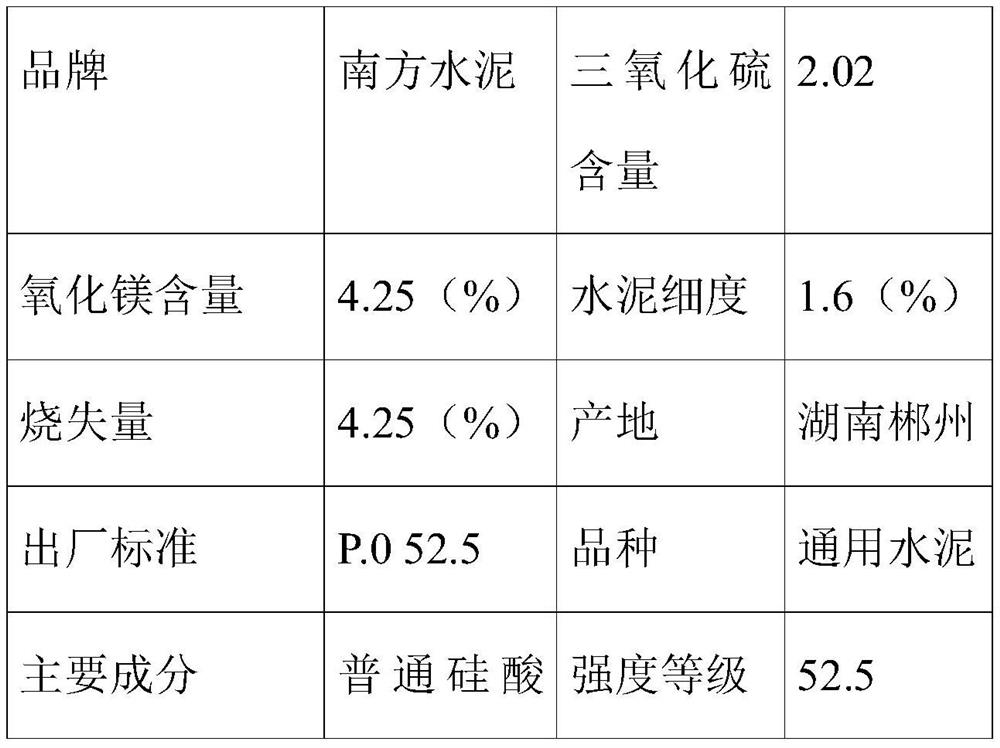

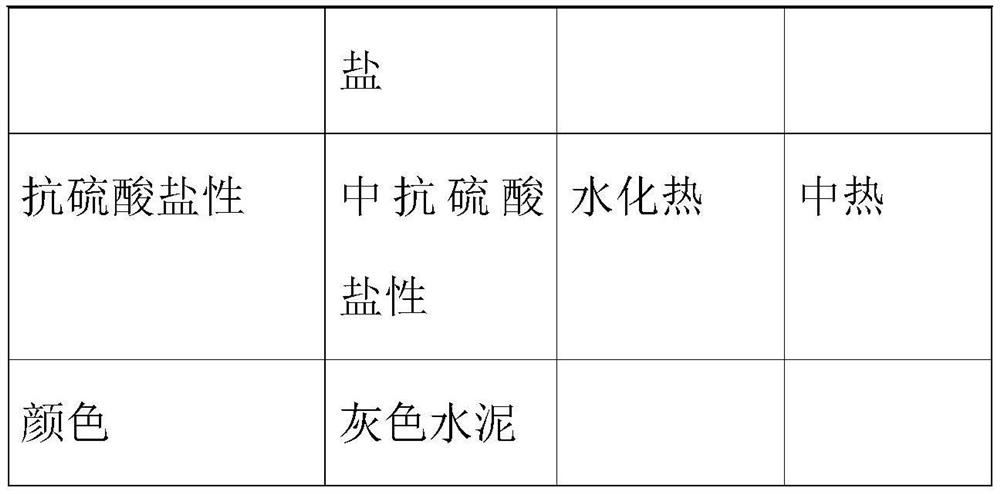

Concrete accelerator and preparation method thereof

The invention provides a concrete accelerator. The concrete accelerator is prepared from the following raw materials: aluminum sulfate, aluminum nitrate, phosphoric acid, ammonia water, a halloysite nanotube modified alkylol amine polymer grinding aid, a stabilizer, magnesium fluorosilicate, a tackifier and water. Various coagulation accelerating components are compounded, the coagulation time ofsprayed concrete can be further shortened, the comprehensive performance of cement is improved, a good coagulation accelerating effect is achieved on premixed concrete subjected to initial hydration,the coagulation time of the concrete can be obviously shortened, the early strength is improved, the stability, durability and safety of the concrete can be remarkably improved, and the cost is low. The concrete accelerator is particularly suitable for premixed concrete spraying construction of long-time and long-distance transportation.

Owner:海南佳益混凝土有限公司

Tooth decolorizer harmless for dental enamel blenching liquid and its using method

The invention discloses a tooth bleaching liquid which is harmless to tooth enamel and its application method. The tooth bleaching solution includes a bleaching agent and a thickening agent. Wherein the bleaching agent is a typical peroxide, and the thickener is polyvinylpyrrolidone. The two make up a viscous or viscous tooth bleaching solution. Choose to add alkaline reagents to the bleaching solution, increase light or heat can promote bleaching. Dental trays can be used for bleaching. The bleaching solution is pushed into the tooth tray by a syringe, and the syringe can be a single-chamber, double-chamber or multi-chamber syringe, which contains various components of the bleaching solution. The bleaching solution can be attached to a strip of elastic material and placed on the teeth for bleaching.

Owner:JESY TECH CORP

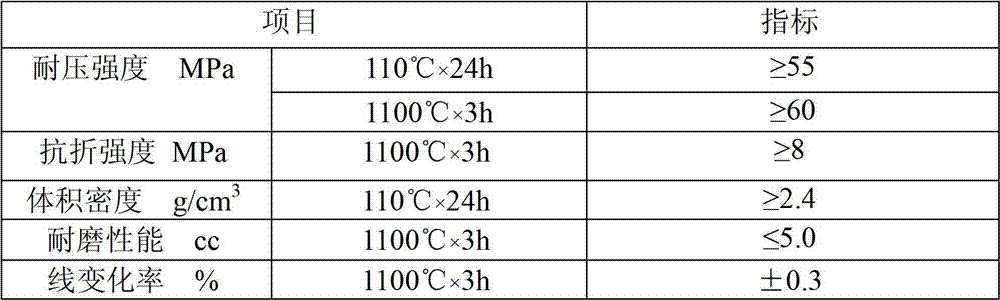

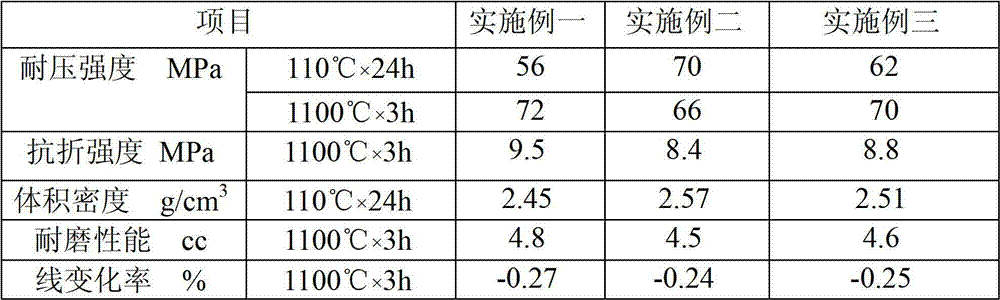

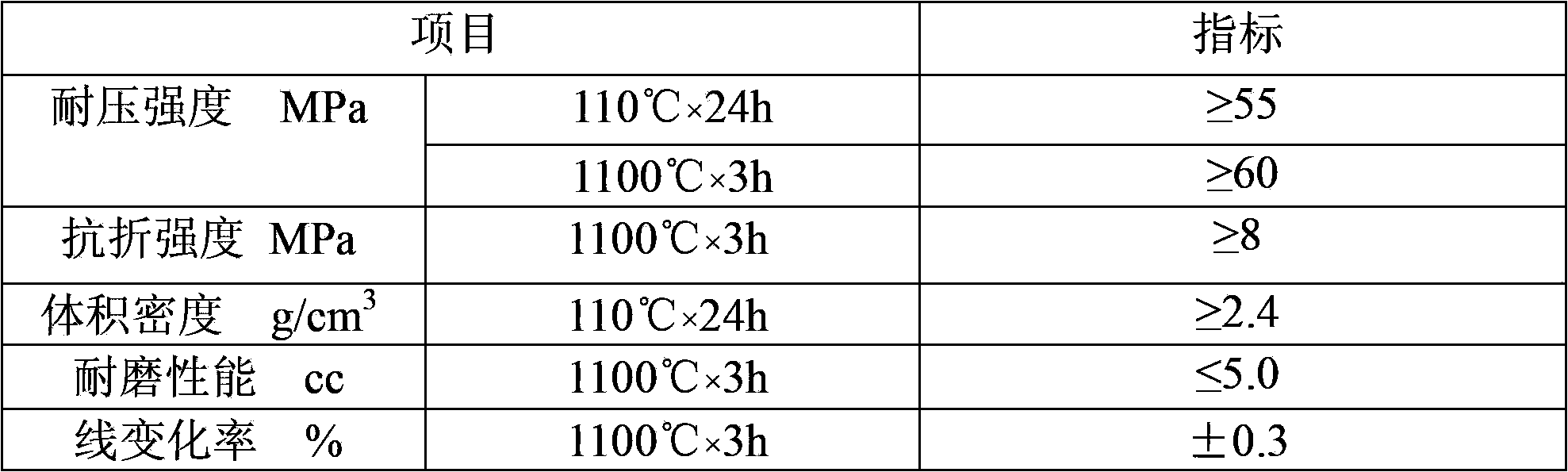

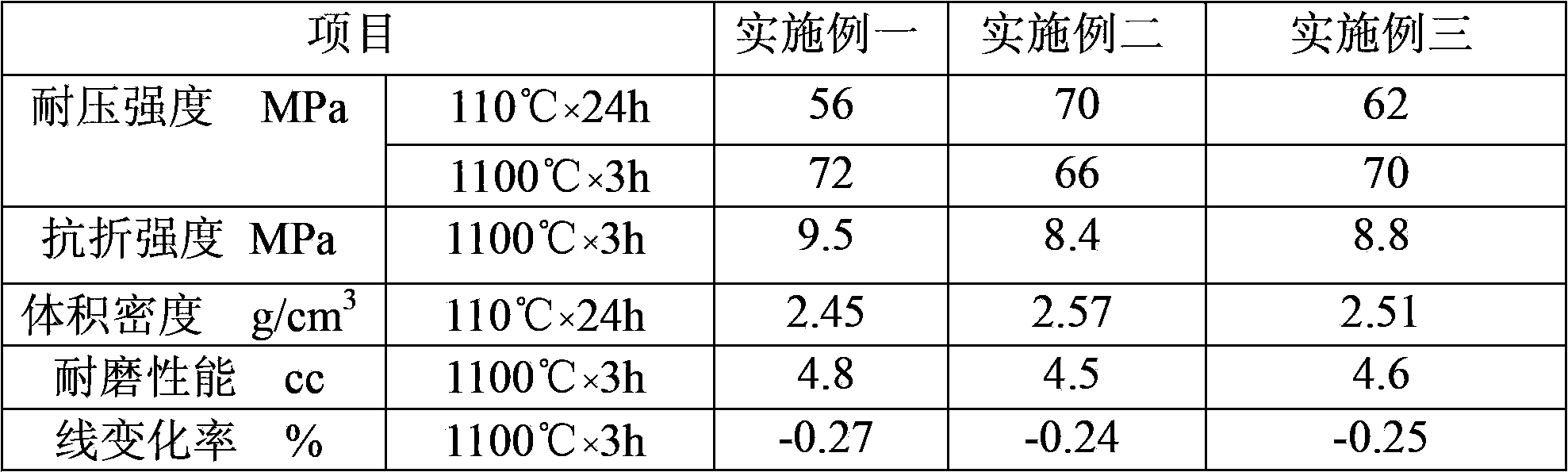

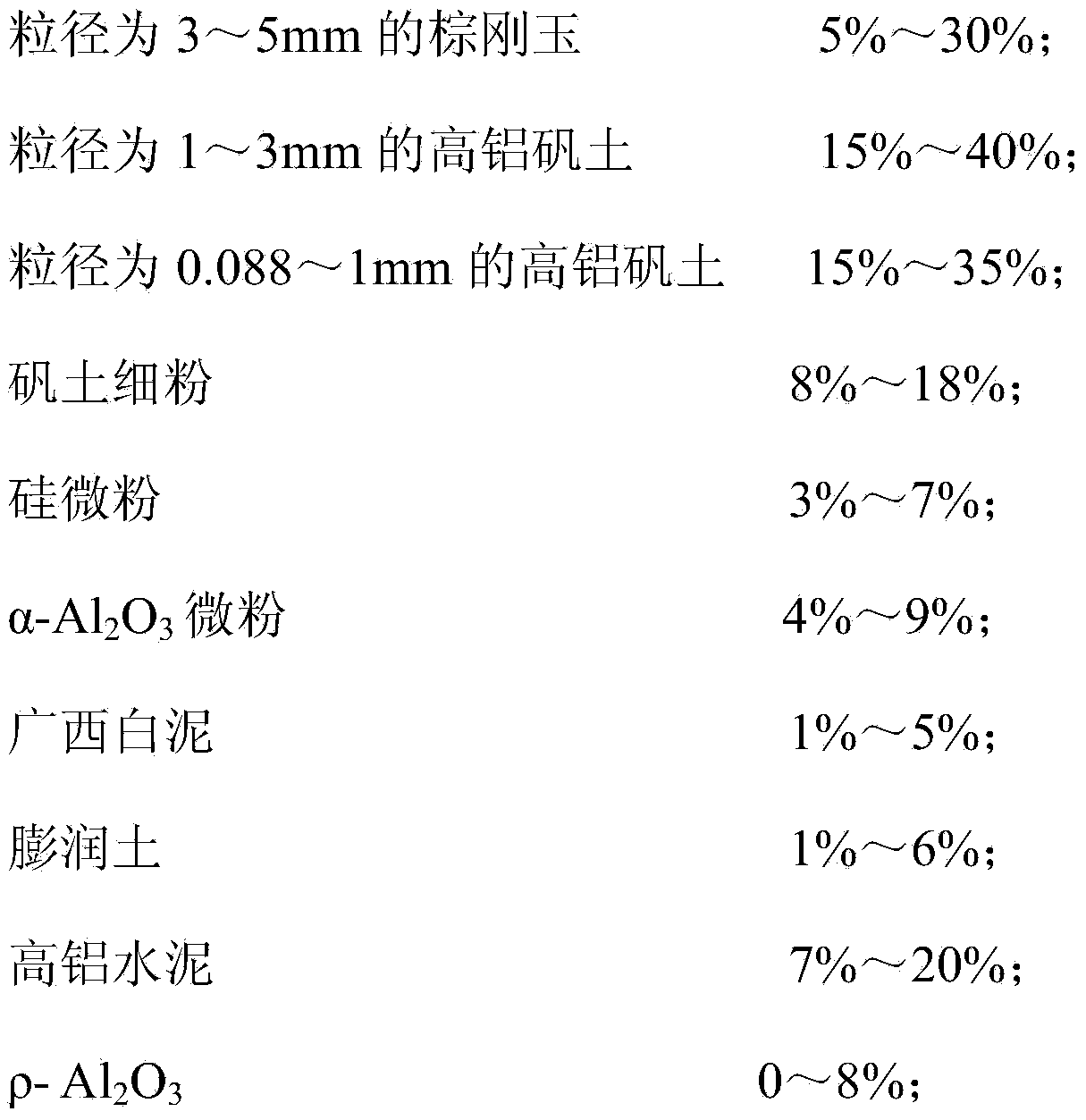

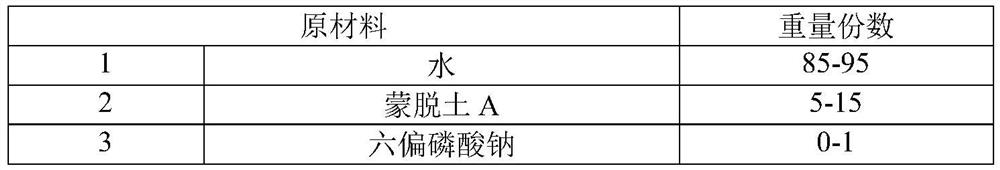

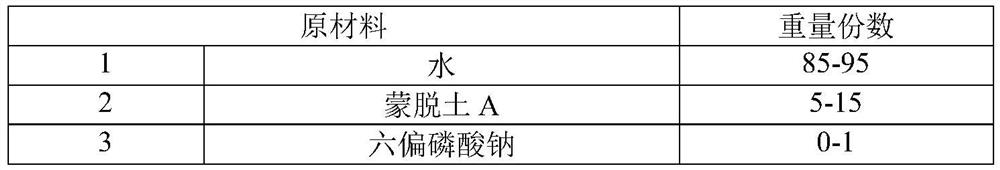

Wear-resistant coating mixture for waste heat power generation pipelines

The invention relates to the technical field of unshaped refractory materials, particularly a wear-resistant coating mixture for waste heat power generation pipelines, which comprises brown corundum, high-aluminum alumina, alumina fine powder, silicon micropowder, alpha-Al2O3 micropowder, Gangxi white clay, bentonite, high-aluminum cement, rho-Al2O3, sodium tripolyphosphate, sodium carboxymethyl cellulose and setting accelerator KAD-20. The wear-resistant coating mixture has the advantages of favorable thermal shock resistance, scour resistance and volume stability, and the service period is up to more than 24 months.

Owner:JIANGSU HENGNAI FURNACE CHARGE GRP

Tooth blenching liquid harmless for dental enamel and its using method

The invention discloses a tooth bleaching liquid which is harmless to tooth enamel and its application method. The tooth bleaching solution includes a bleaching agent and a thickening agent. Wherein the bleaching agent is a typical peroxide, and the thickener is polyvinylpyrrolidone. The two make up a viscous or viscous tooth bleaching solution. Choose to add alkaline reagents to the bleaching solution, increase light or heat can promote bleaching. Dental trays can be used for bleaching. The bleaching solution is pushed into the tooth tray by a syringe, and the syringe can be a single-chamber, double-chamber or multi-chamber syringe, which contains various components of the bleaching solution. The bleaching solution can be attached to a strip of elastic material and placed on the teeth for bleaching.

Owner:JESY TECH CORP

Lubricant pump

ActiveCN106065992ACompact designCompact structureLubricating pumpsPressure lubricationEngineeringLubricant

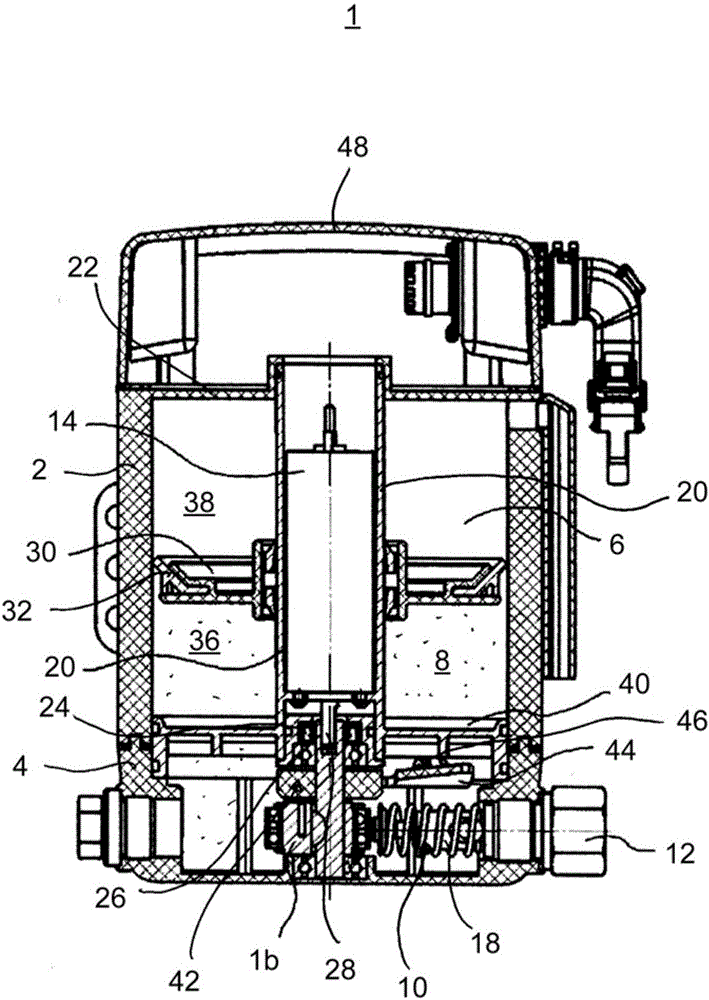

The present invention relates to a lubricant supply device (1) having at least a first casing section (2) constituting a storage container (6) for a lubricant (8), a second casing section (4) comprising a transfer pump (10) for transferring a lubricant (8) from the storage container (6) to the a lubricant outlet (12) and a motor (14) at least driving the transfer pump (10), the motor (14) is arranged in the first casing section (2) constituting the storage container (6).

Owner:德国斯凯孚润滑油系统有限责任公司

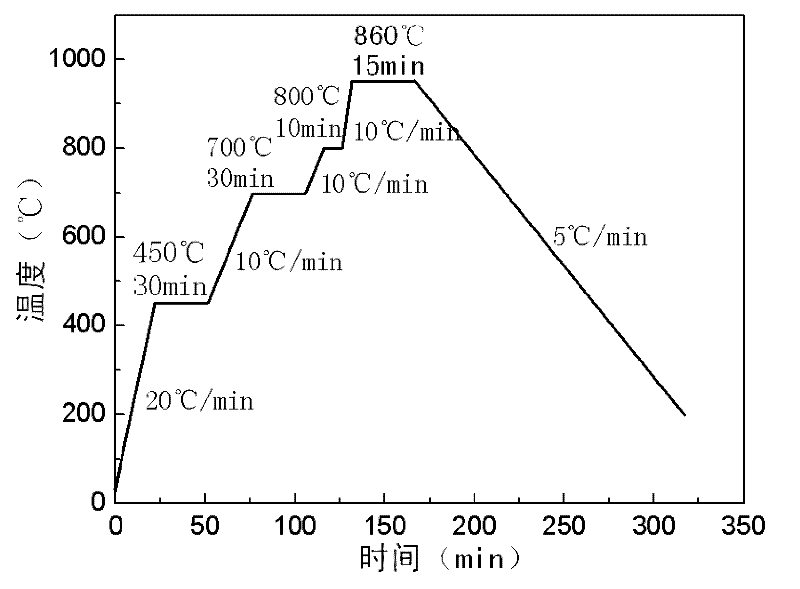

Method for preparing insulating foam glass ceramic material from lithium tailings

InactiveCN108191231ASolve environmental problemsAchieve low temperature preparationGlass shaping apparatusLithiumFoaming agent

The invention provides a method for preparing an insulating foam glass ceramic material from lithium tailings. The method comprises the following steps: 1, the lithium tailings and cleaned cullet aresubjected to wet ball milling, dried and sieved by a 120-200-mesh sieve respectively; 2, the lithium tailings, the cullet, sodium fluoride, potassium carbonate and mirabilite are uniformly mixed in percentage by mass to serve as a base material; 3, a foaming agent is added to the base material, and a mixture is obtained; 4, uniformly mixed powder is placed into a refractory container, heated rapidly to 800 DEG C, then heated to 900-1050 DEG C at reduced rate for melting foaming, and subjected to heat preservation for 15 min; 5, after heat preservation, quenching is performed to 500-600 DEG C for annealing treatment for 1 h, slow cooling is performed, and a product is obtained after demolding and cutting. Through adoption of the method, the environmental problem in the slag treatment process is solved, production cost of the product is reduced, the product with high added value is prepared, and compared with other products, the product has high strength and good insulating performance.

Owner:WUHAN UNIV OF TECH

Wear-resistant coating mixture for waste heat power generation pipelines

The invention relates to the technical field of unshaped refractory materials, particularly a wear-resistant coating mixture for waste heat power generation pipelines, which comprises brown corundum, high-aluminum alumina, alumina fine powder, silicon micropowder, alpha-Al2O3 micropowder, Gangxi white clay, bentonite, high-aluminum cement, rho-Al2O3, sodium tripolyphosphate, sodium carboxymethyl cellulose and setting accelerator KAD-20. The wear-resistant coating mixture has the advantages of favorable thermal shock resistance, scour resistance and volume stability, and the service period is up to more than 24 months.

Owner:JIANGSU HENGNAI FURNACE CHARGE GRP

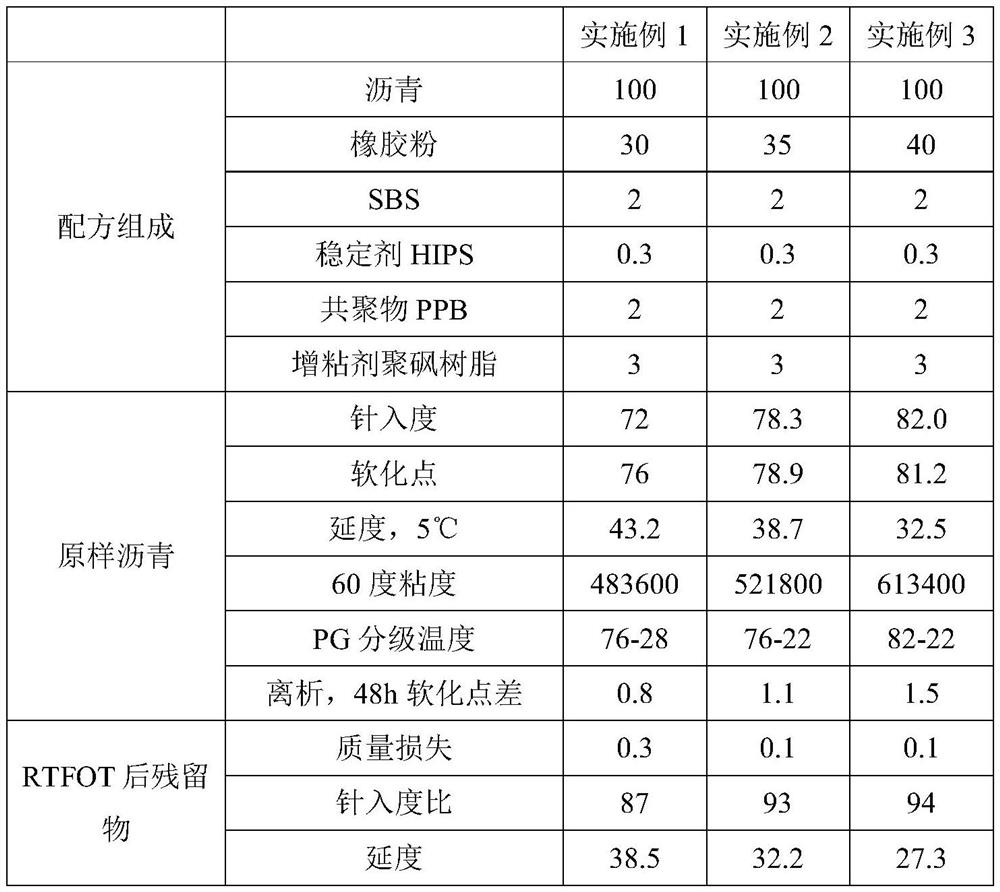

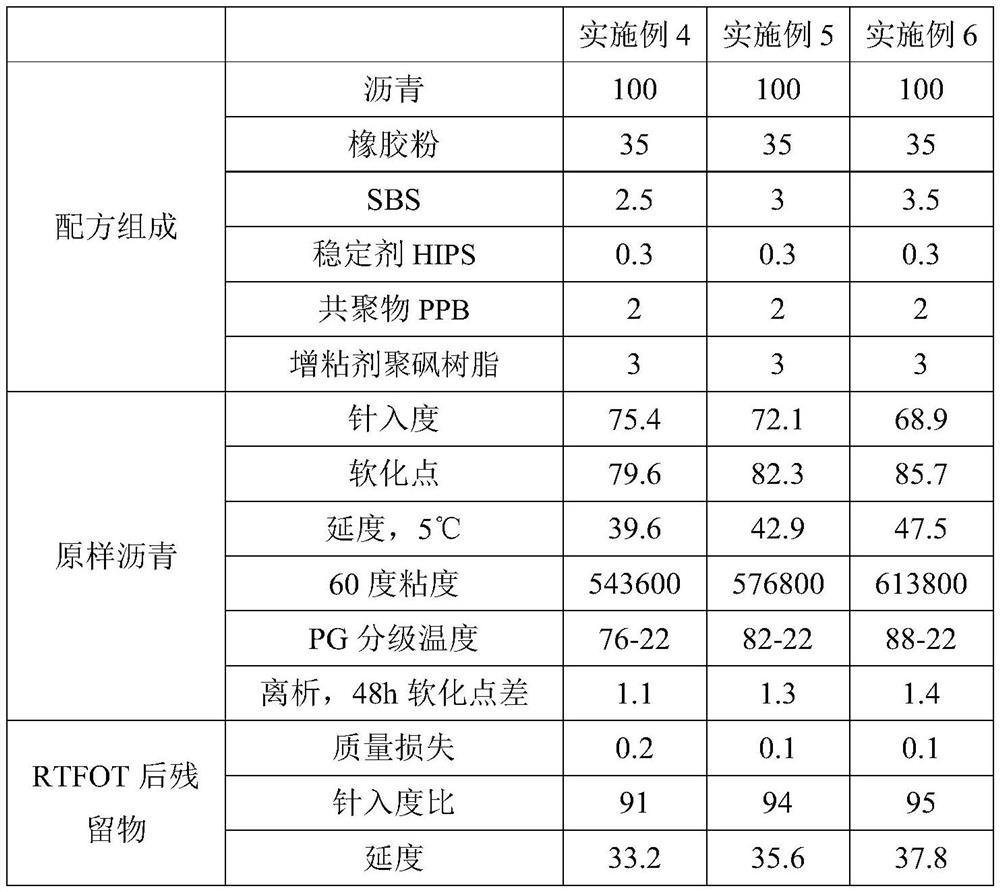

Rubber powder modified asphalt for pavement patching and preparation method thereof

ActiveCN113801489AImprove road performanceSufficient storage stabilityBuilding insulationsElastomerPolymer science

The invention belongs to the technical field of road engineering materials, and discloses rubber powder modified asphalt for pavement patching and a preparation method of the rubber powder modified asphalt. The rubber powder modified asphalt comprises the following components in parts by weight: 100 parts of asphalt; 30 to 40 parts of rubber powder; 2 to 3.5 parts of thermoplastic elastomer; 0.1 to 0.5 part of HIPS (High Induced Polystyrene); 1 to 3 parts of PPB; and 2 to 5 parts of tackifying resin. The preparation method comprises the following steps: heating the asphalt to 240-260 DEG C, then adding the rubber powder, uniformly conducting stirring and mixing, then conducting cooling to 180-200 DEG C, adding the thermoplastic elastomer and the tackifying resin, uniformly conducting stirring and mixing, and finally adding the HIPS and the PPB, and conducting stirring and reacting to obtain the rubber powder modified asphalt for pavement patching. The rubber powder modified asphalt has the advantages of good stability, good high and low temperature performance, high strength and aging resistance, can be used for pavement patching, and prolongs the service life of a pavement.

Owner:广州高速运营管理有限公司

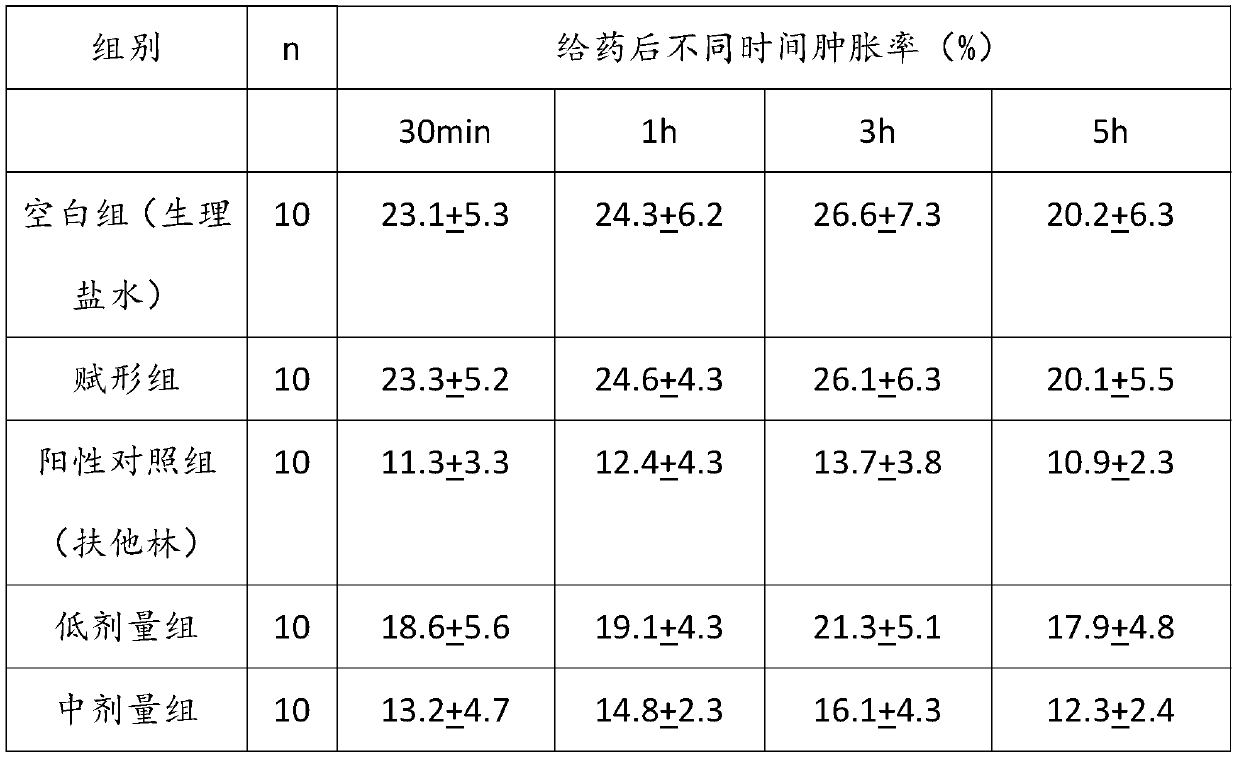

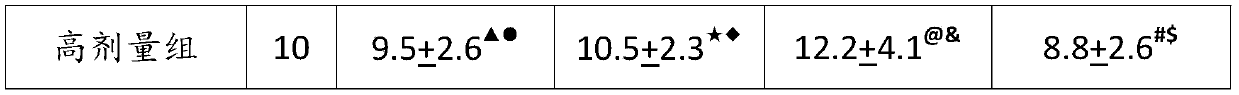

Traditional Chinese medicine compound cataplasm for treating cervical spondylosis due to Qi stagnation and blood stasis, and preparation method thereof

InactiveCN110731953ASignificant effectWith promoting blood circulation and dispelling stasisAnthropod material medical ingredientsAntipyreticCaesalpinia sappanCervical spondylosis

The invention discloses a traditional Chinese medicine compound cataplasm for treating cervical spondylosis due to Qi stagnation and blood stasis and a preparation method thereof. The traditional Chinese medicine compound cataplasm for treating cervical spondylosis comprises the following raw materials in parts by weight: 10-20 parts of kudzu root, 10-20 parts of cassia twig, 10-20 parts of gardenbalsam stem, 5-15 parts of safflower, 5-15 parts of Angelica dahurica, 5-15 parts of Common club moss Herb, 5-15 parts of angelica sinensis, 5-15 parts of Sargentodoxa cuneata, 5-15 parts of Acanthopanax cortex, 5-15 parts of ground beeltle, 5-15 parts of Corydalis tuber, 5-15 parts of radix dipsaci, 5-15 parts of peach kernels, 5-15 parts of rhizoma Ligustici Chuanxiong, 5-15 parts of Caesalpinia sappan, 5-15 parts of dragon's blood, 5-15 parts of stone crab, 5-15 parts of notopterygium root, 5-15 parts of frankincense and 5-15 parts of myrrh. The traditional Chinese medicine compound cataplasm has the effects of promoting blood circulation, dispelling blood stasis, reducing swelling and relieving pain, and has remarkable curative effect on cervical spondylosis of qi stagnation and bloodstasis type. The traditional Chinese medicine compound cataplasm is convenient, safe, comfortable and painless to use, and the cataplasm has sufficient viscosity, the plaster does not dirty clothes,and the patient has good physical examination.

Owner:SHENZHEN TRADITIONAL CHINESE MEDICINE HOSPITAL

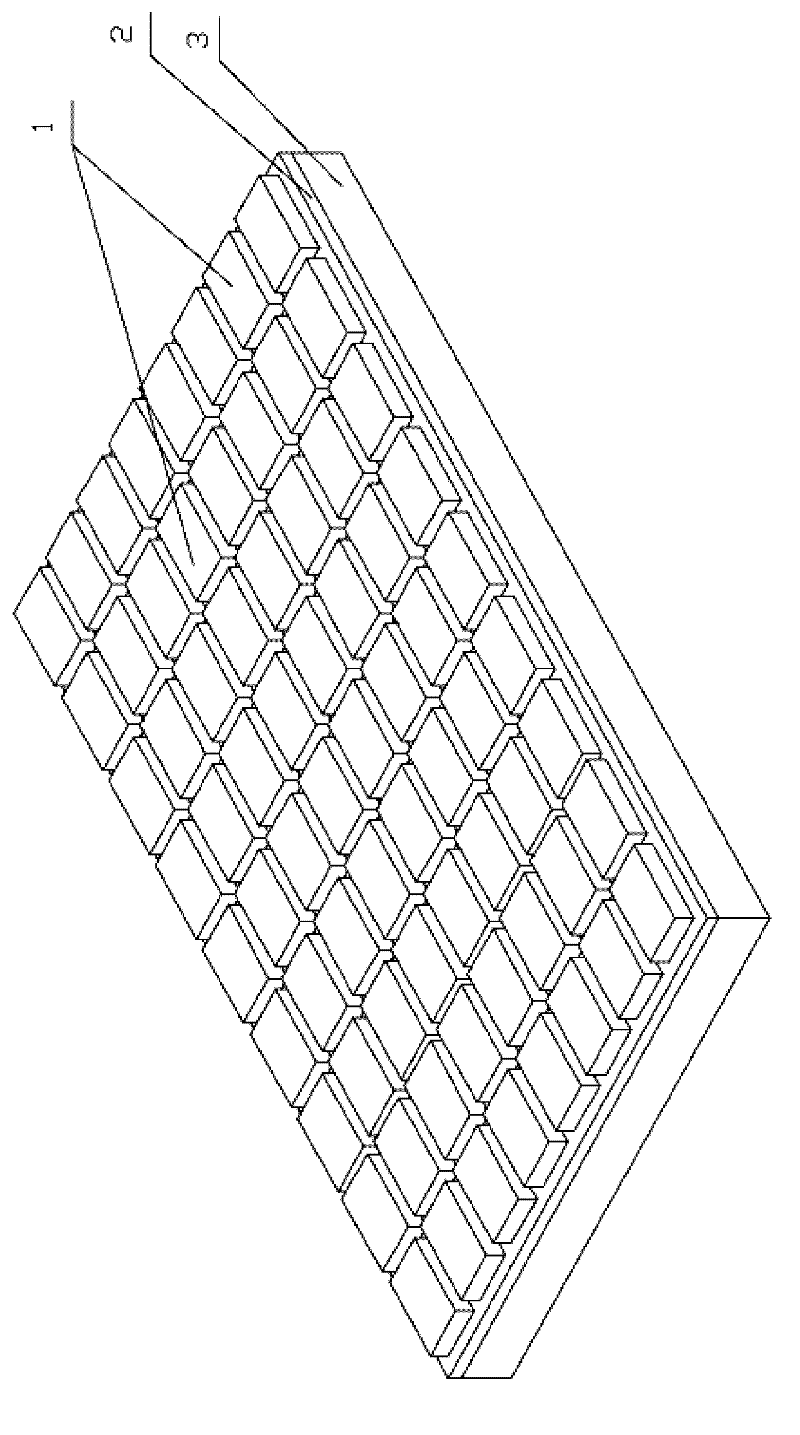

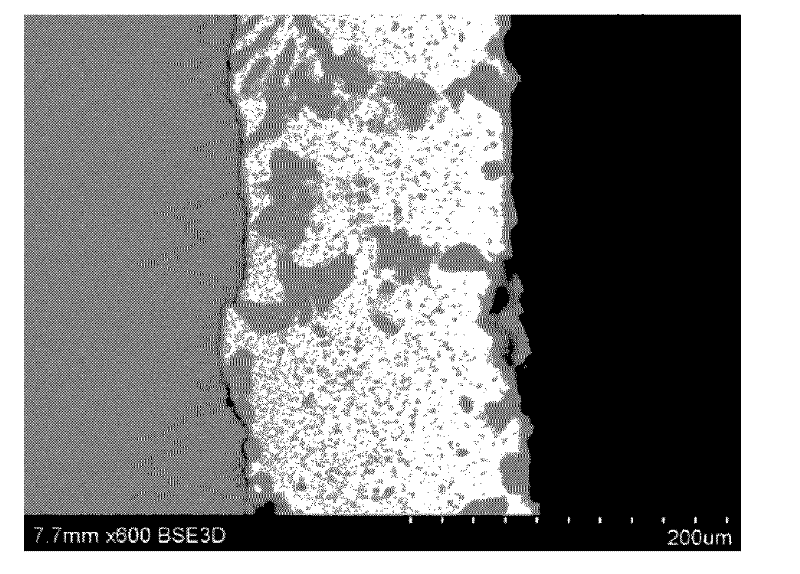

A method of preparing wear-resistant ceramic lining board by active brazing method

The invention discloses a method for preparing a wear-resistant ceramic liner by an active brazing method, which relates to a method for preparing a wear-resistant ceramic liner. The invention solves the problems of low bonding strength, easy falling off of ceramics and easy aging of rubber materials in the existing adhesive and wear-resistant ceramic rubber liners, and the problems that the existing wear-resistant ceramic liners connected by bolts are easy to break and have short anti-wear life. The method of the invention is as follows: 1. preparing active metal paste solder; 2. surface-treating ceramic blocks and steel plates; 3. preparing welding assembly parts; The wear-resistant ceramic liner of the present invention cancels the rubber layer, improves the bonding strength, wear resistance and high-temperature service life, and the shear strength of the brazing joint reaches 191MPa; the low cooling rate reduces the residual stress of the liner, and the liner is not easy Breakage, extended service life. The obtained liner can be used for coal conveying and ash discharge systems in thermal power plants, as well as anti-wear liners in material conveying and batching systems in metallurgical iron and steel industries, such as silos and hoppers.

Owner:HARBIN INST OF TECH

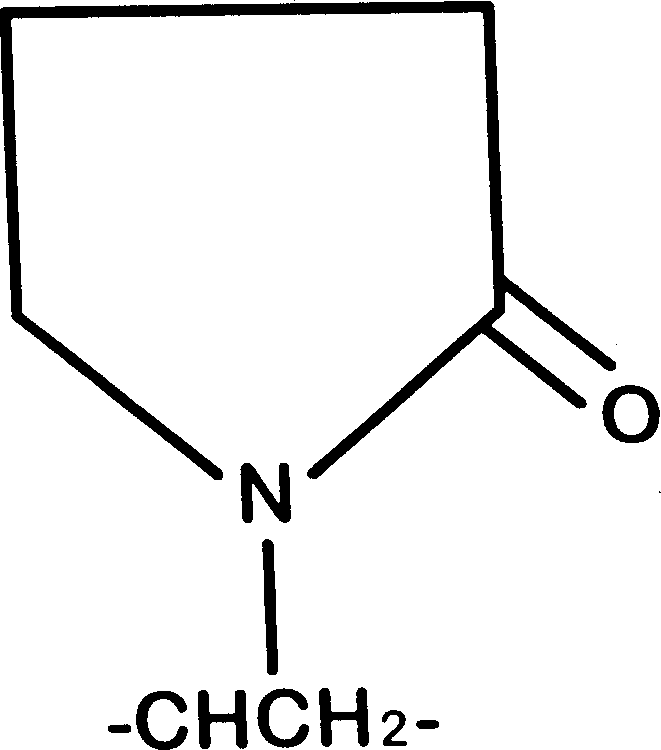

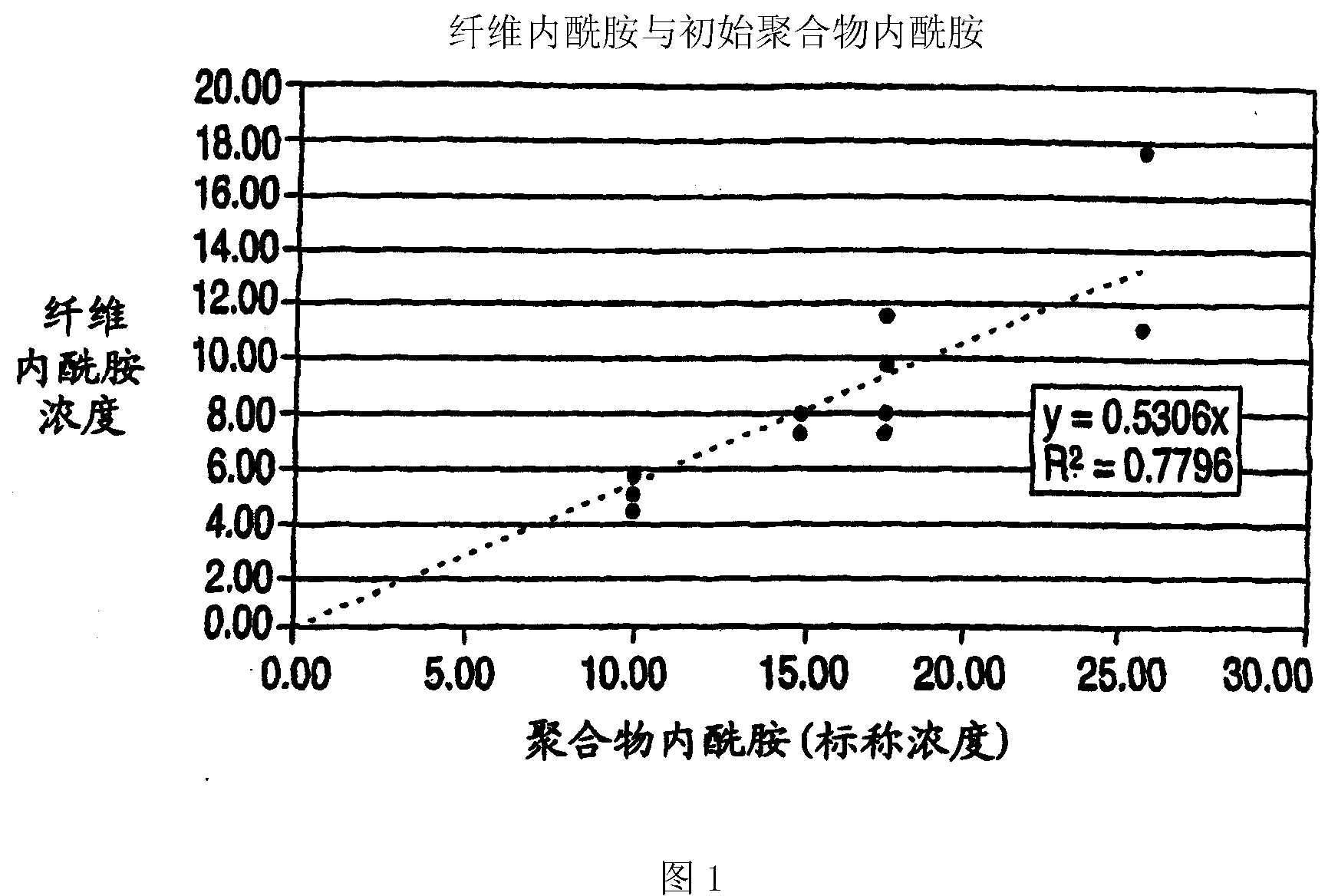

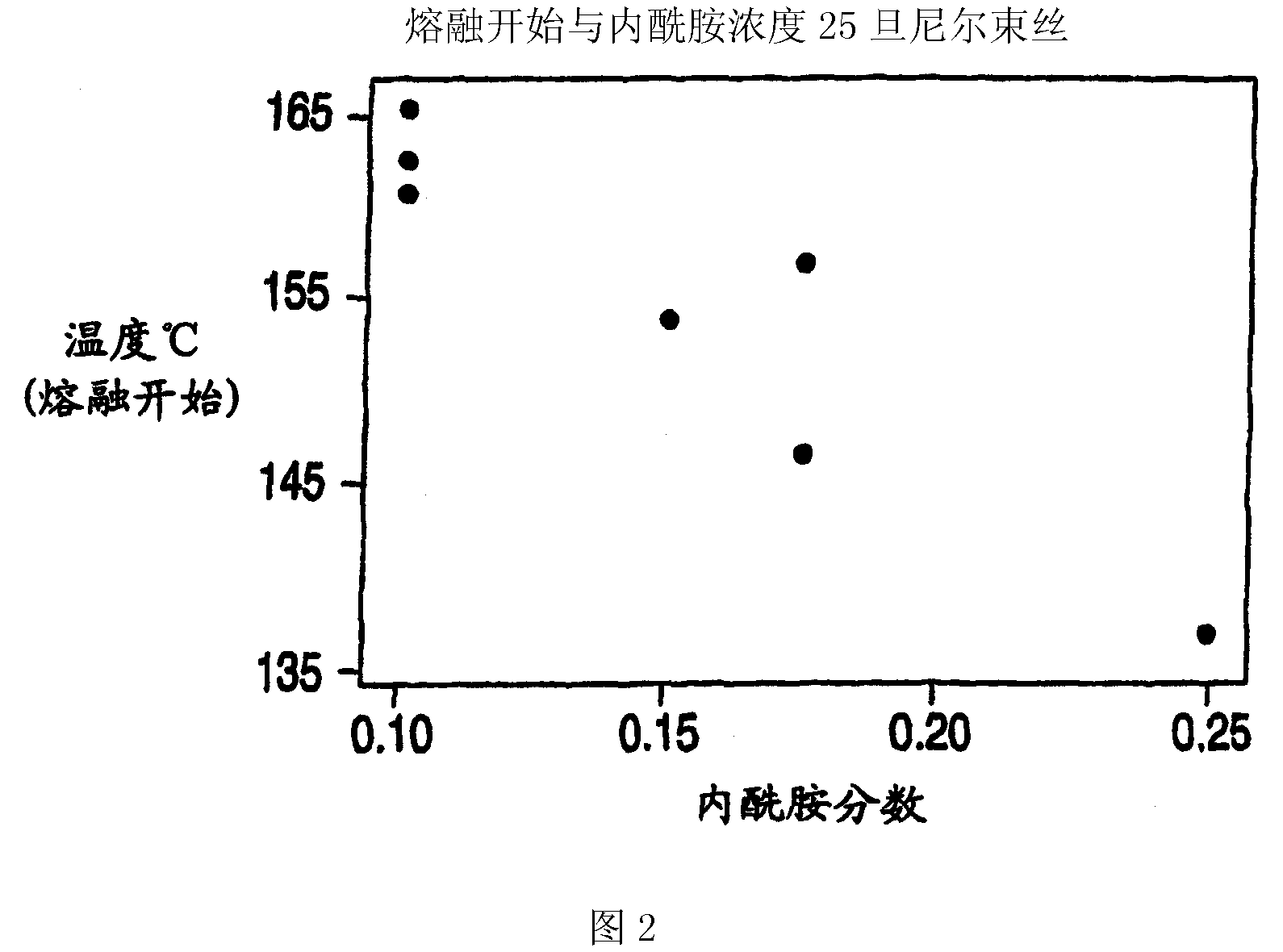

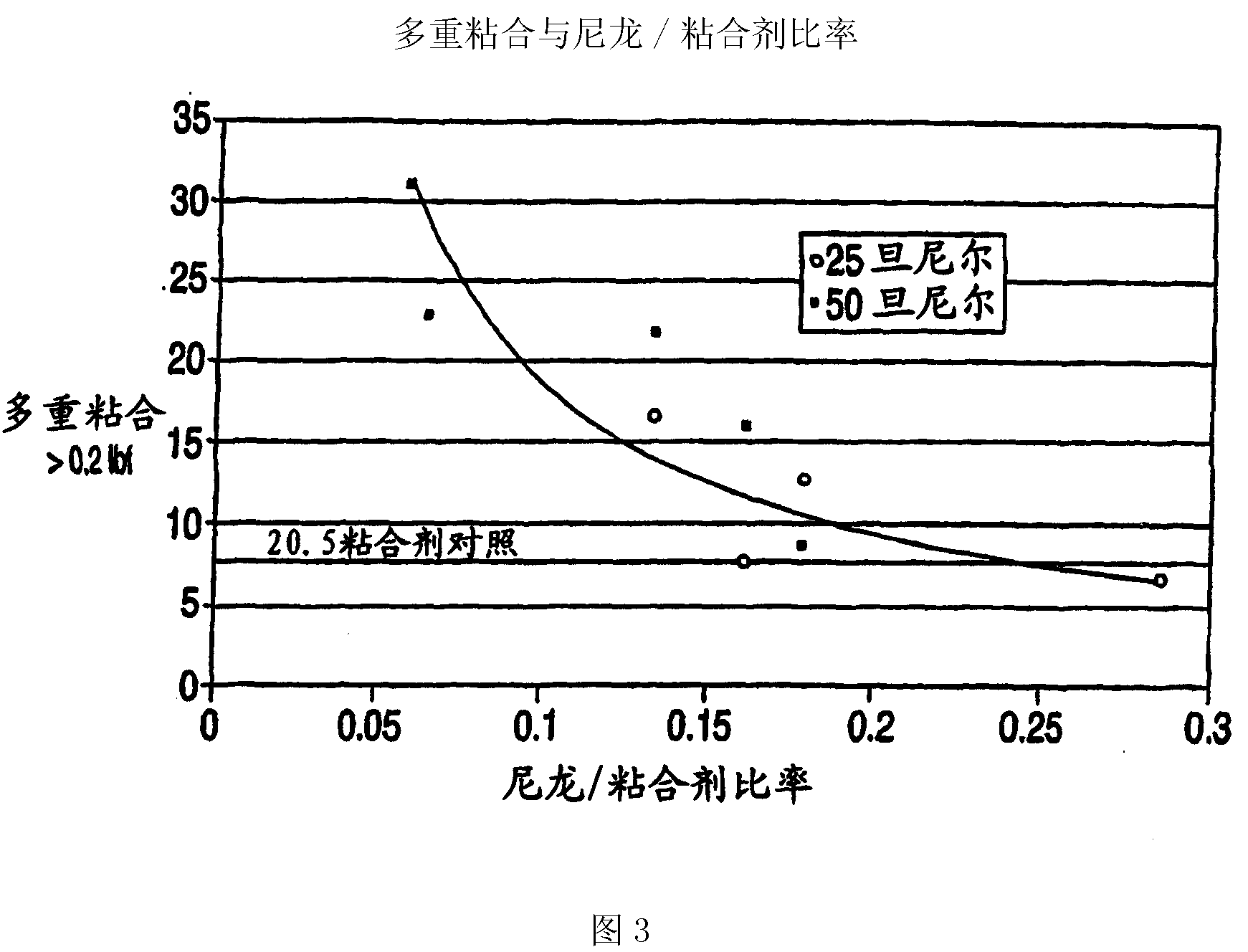

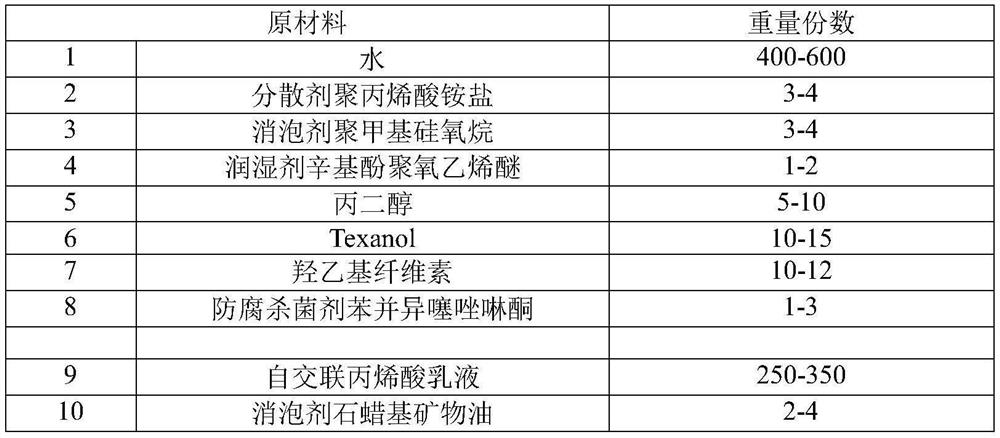

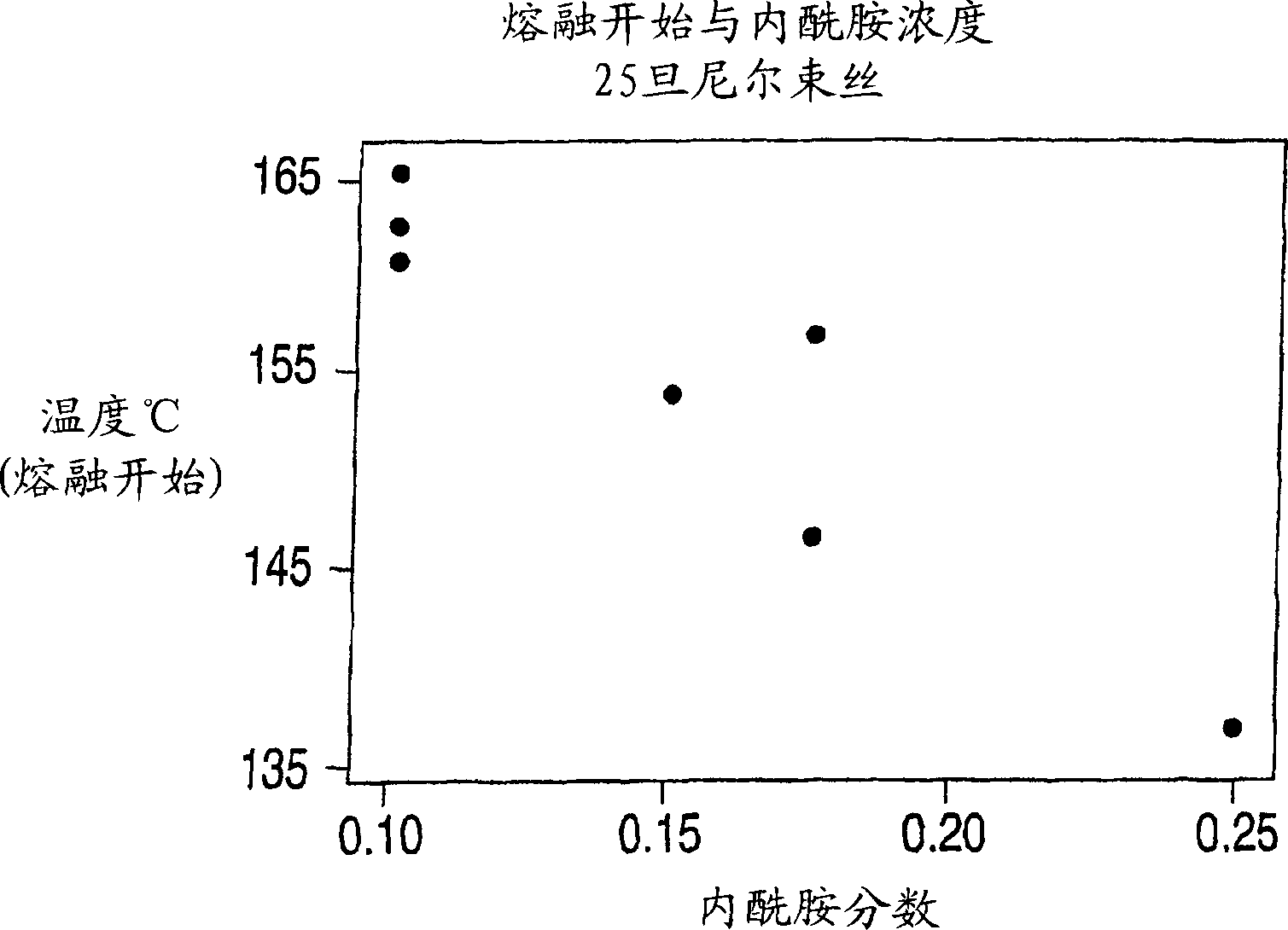

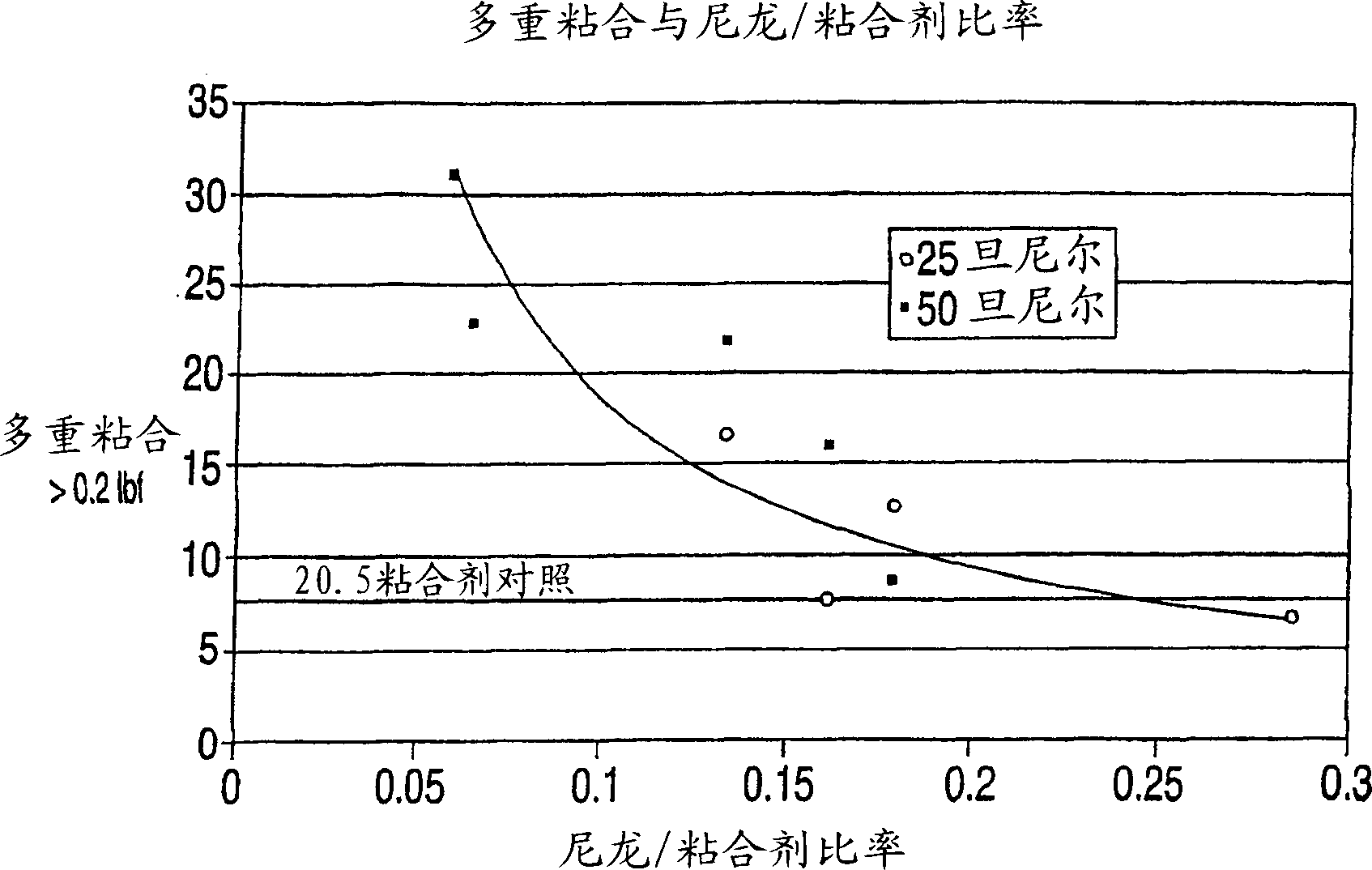

Multiphase fiber materials and compositions, methods of manufacture and uses thereof

ActiveCN1906242BEnough viscosityAdequate melt strengthThin material handlingMonocomponent polyamides artificial filamentFiber compositionViscosity

A pre-fiber composition is disclosed herein that includes: a) a first fiber constituent having a first melting point; b) a second fiber constituent having a second melting point; and c) a gelling agent that solvates at least one of the first fiber constituent or the second fiber constituent, wherein the gelling agent significantly reduces co-polymerization of either of the constituents in the composition. A fiber is also disclosed herein that includes: a) at least two amide-based polymers, each having a melting point, wherein the melting point of one amide-based polymer is dissimilar to the melting point of a second amide-based polymer; and b) a gelling agent that is compatible with at least one of the amide-based polymers, wherein the fiber comprises two differentiatable melting points that are substantially similar to the melting points of each of the amide-based polymers. A method of producing a pre-fiber composition is disclosed herein that includes: a) providing a first fiber constituent having a first melting point; b) providing a second fiber constituent having a second melting point, wherein the first melting point and the second melting point are dissimilar; c) providing at least one gelling agent; and d) mixing the first constituent, the second constituent and the at least one gelling agent such that there is sufficient viscosity and sufficient melt strength in the composition so that it can be spun into a fiber and such that the first melting point and the second melting point in the fiber are substantially similar to their original values before mixing.

Owner:ADVANSIX RESINS & CHEM LLC

A liquid metal with anti-melting properties for heat dissipation at 54-61°C

ActiveCN106756382BNo side leakageEnough viscosityModifications by conduction heat transferAlloyLiquid metal

Owner:NINGBO SYRNMA METAL MATERIALS CO LTD

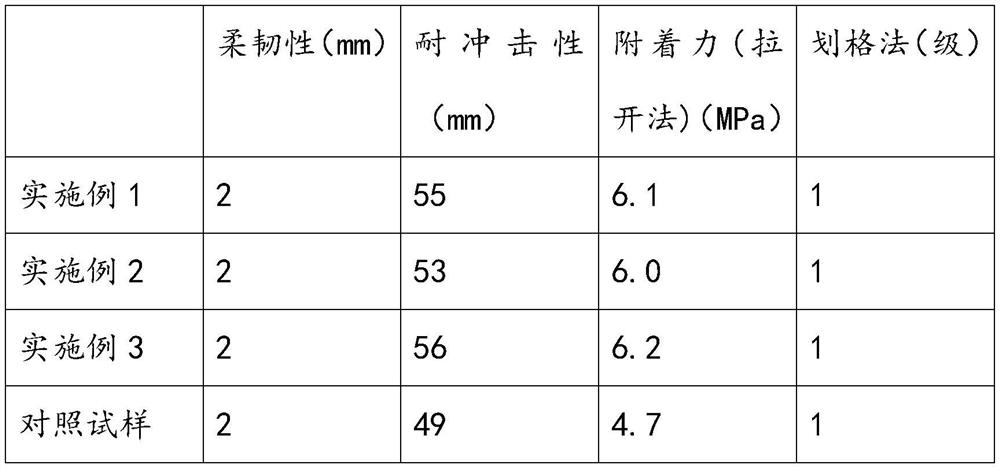

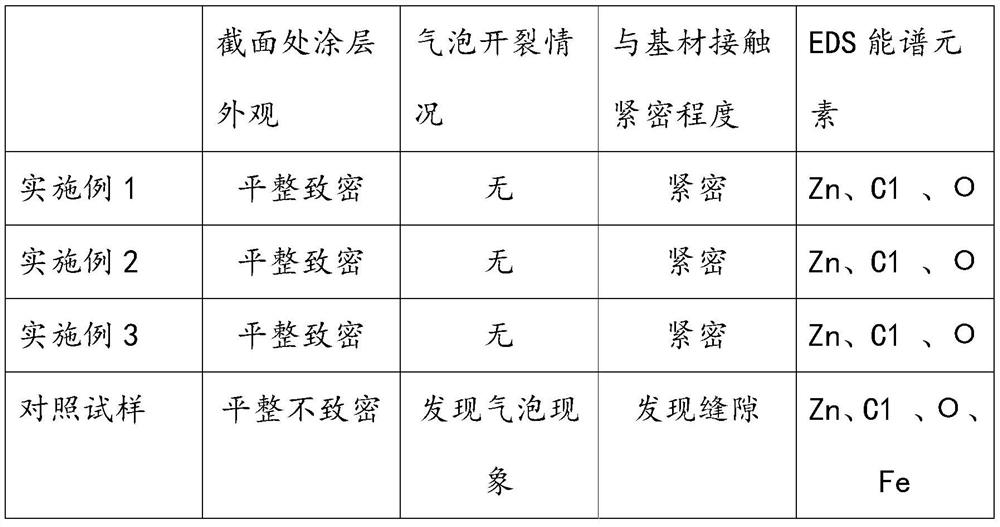

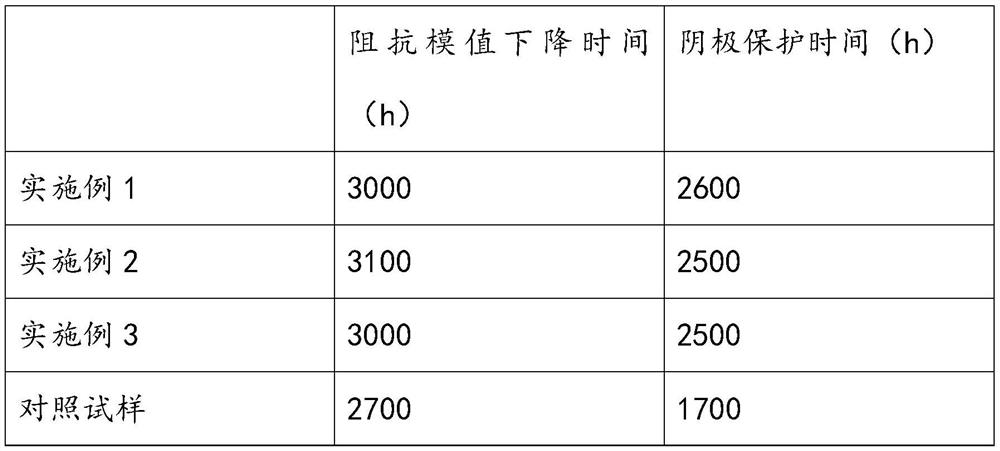

Environment-friendly solvent-free thick-coating high-adhesion cold spraying zinc sealing agent and construction method thereof

InactiveCN112760005AImprove bindingImprove compactnessAnti-corrosive paintsBuilding material handlingPolymer scienceThiourea

The invention discloses an environment-friendly solvent-free thick-coating high-adhesion cold spraying zinc sealing agent which comprises a base material, a curing agent for mixing and a rapid curing agent, wherein the base material at least comprises the following components in parts by mass: 45-55 parts of epoxy resin; 30-40 parts of pigment; 4-8 parts of a reactive diluent; 5-10 parts of a silicon-based polymerization agent; 1-2 parts of thixotropic agent; 1-2 parts of a toughening agent; 0.5-1.5 parts of a defoaming agent; the curing agent for mixing at least comprises the following components in parts by mass: 80-90 parts of modified polyamide; 5-10 parts of a silicon-based polymerization agent; the rapid curing agent at least comprises the following components in parts by mass: 20-30 parts of phenol; 25-35 parts of paraformaldehyde; 30-40 parts of diethylenetriamine; 20-25 parts of thiourea; 1-2 parts of accelerant; the rapid curing effect of the rapid curing agent on the epoxy resin and the permeation effect on the cold spraying zinc layer are utilized, firm combination of the epoxy resin sealing layer and the cold spraying zinc layer and compactness of hierarchical curing are achieved, and rapid spraying is achieved.

Owner:江苏鑫能材料科技有限公司

A kind of concrete accelerator and preparation method thereof

The invention proposes a concrete quick-setting agent, which is prepared from the following raw materials: aluminum sulfate, aluminum nitrate, phosphoric acid, ammonia water, halloysite nanotube modified alkanolamine polymer grinding aid, stabilizer, magnesium fluorosilicate , tackifier, water. The invention combines various coagulation-accelerating components, which can further shorten the setting time of shotcrete and improve the comprehensive performance of cement. It has a good coagulation-accelerating effect on ready-mixed concrete that has already undergone initial hydration, and can significantly shorten the coagulation of concrete. Time, improve the early strength, but also significantly improve the stability, durability and safety of concrete, and the cost is low. It is especially suitable for spraying construction of ready-mixed concrete for long-term and long-distance transportation.

Owner:海南佳益混凝土有限公司

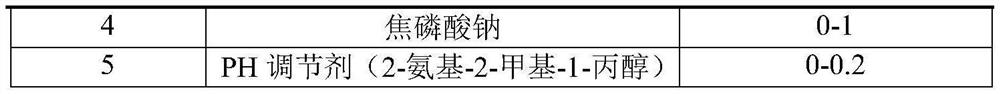

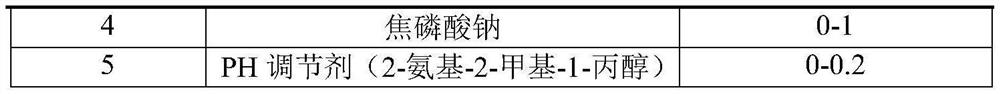

A kind of preparation method of water-based colorful paint

ActiveCN113913063BAppropriate viscosity of dispersed phaseControllable shapeMulticolor effect coatingsColored whiteOrganic chemistry

The invention belongs to the technical field of water-based paint, and discloses a preparation method of water-based colorful paint. The method is to add various color pastes into the white base paint B solution containing titanium dioxide to obtain a colored base paint, add the colored base paint to the transparent dispersed phase C and stir evenly to obtain a dispersed phase of the colored paint, and add the dispersed phase of the colored paint to the protective glue A The finished water-based colorful paint is obtained by granulating in the solution; wherein, the mass fraction of titanium dioxide in the white base paint B is within 10%, and the mass fraction of the color paste in the color base paint is not more than 20%. The viscosities of the dispersed phases of the basic paints of various colors prepared by the method are basically the same, and the particle size of the granulation is controllable, which creates conditions for the stability between batches during mass production in the workshop.

Owner:东营利丰化工新材料有限公司

Multiphase fiber materials and compositions, methods of manufacture and uses thereof

ActiveCN1906242AEnough viscosityAdequate melt strengthThin material handlingMonocomponent polyamides artificial filamentFiberViscosity

Disclosed herein is a pre-fiber composition comprising: a) a first fiber component having a first melting point; b) a second fiber component having a second melting point; and c) a gelling agent that combines the first fiber component or the second fiber component Solvation of at least one of the two fiber components, wherein the gelling agent substantially reduces copolymerization of any one component of the composition. Also disclosed herein is a fiber comprising: a) at least two amide-based polymers, each having a melting point, wherein one amide-based polymer has a different melting point than the second amide-based polymer; and b) a gelling agent compatible with at least one of said amide-based polymers, wherein said fibers have two distinguishable melting points substantially similar to those of said amide-based polymers Each melting point. Disclosed herein is a method of producing a pre-fiber composition comprising: a) providing a first fiber component having a first melting point; b) providing a second fiber component having a second melting point, wherein the first melting point and the second melting point are different c) providing at least one gelling agent; and d) mixing the first component, the second component, and the at least one gelling agent such that the composition has sufficient viscosity and sufficient melt strength so that it can be Spinning forms fibers, and the first and second melting points of the fibers are substantially similar to their original values prior to blending.

Owner:ADVANSIX RESINS & CHEM LLC

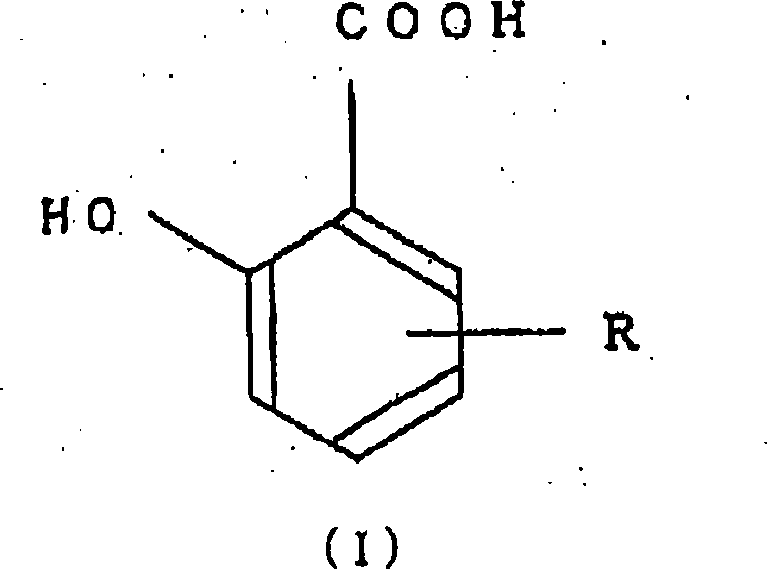

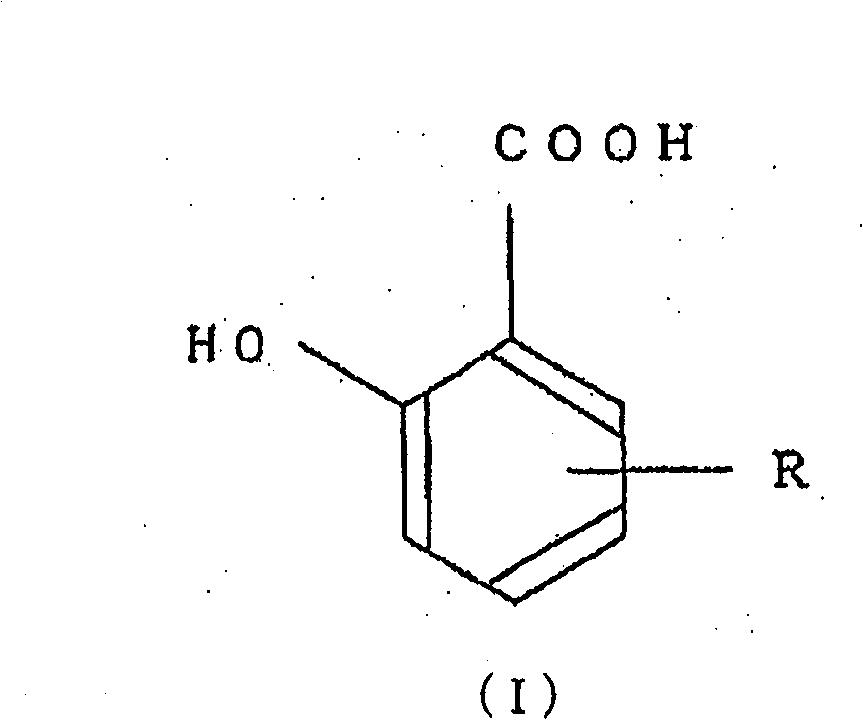

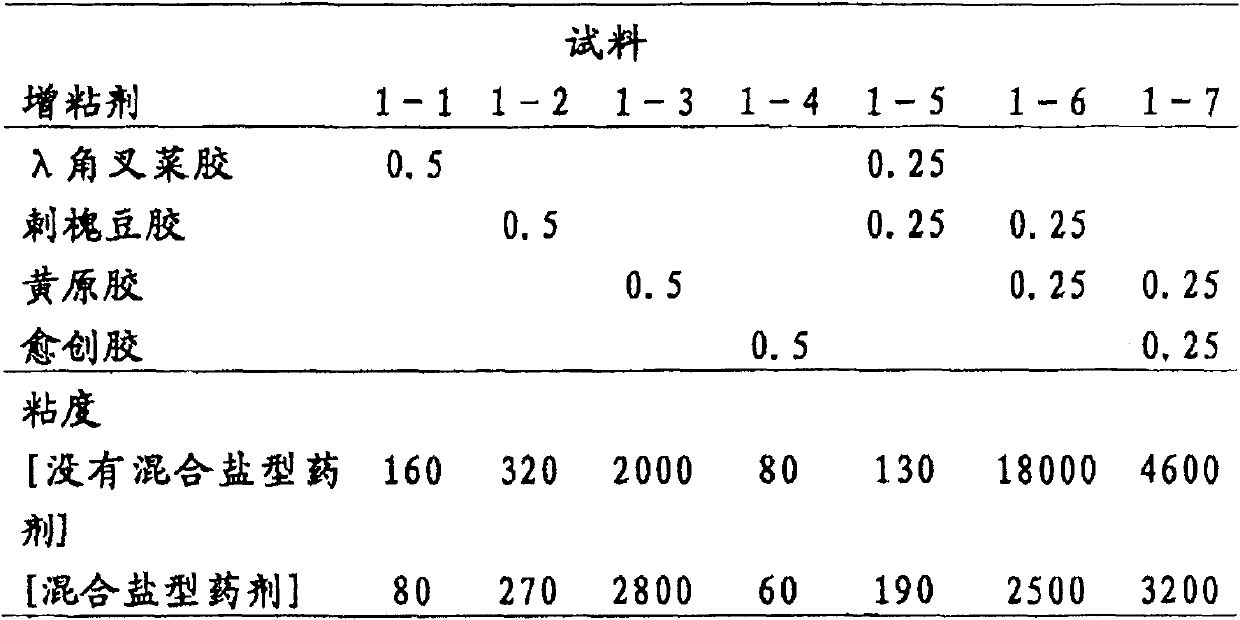

External preparation for skin

InactiveCN101164620AEnough viscosityExcellent stability over timeCosmetic preparationsToilet preparationsMedicineGuar gum

The invention provides an external preparation for skin capable of providing sufficient viscosity by a simple operation and excellent in feelings upon use in a salt type agent formulation system. The external preparation for skin is obtained by formulating a salt type agent with xanthan gum and guar gum. It is preferable for the external preparation that the weight ratio of the xanthan gum to the guar gum is (10:90) to (90:10), further (20:80) to (80:20). The external preparation for skin is excellent in viscosity stability at high temperature when the weight ratio is particularly (50:50) to (20:80). The salt type agent is preferably an ascorbic acid-based and / or alkoxysalicylic acid-based bleaching agent.

Owner:SHISEIDO CO LTD

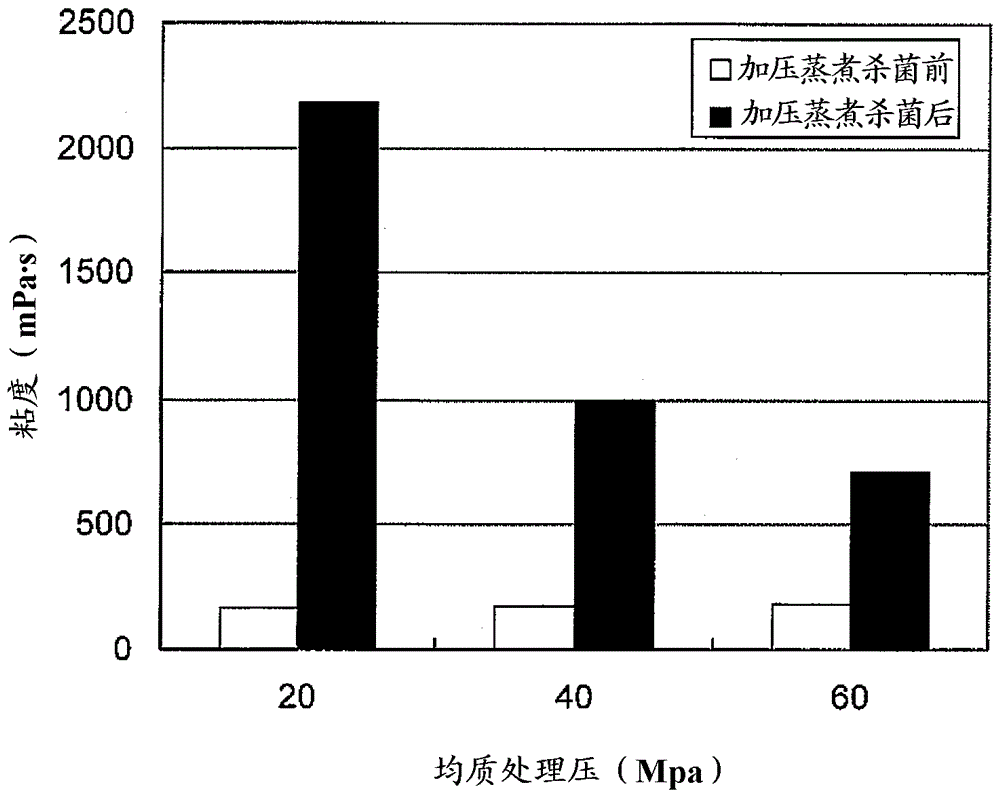

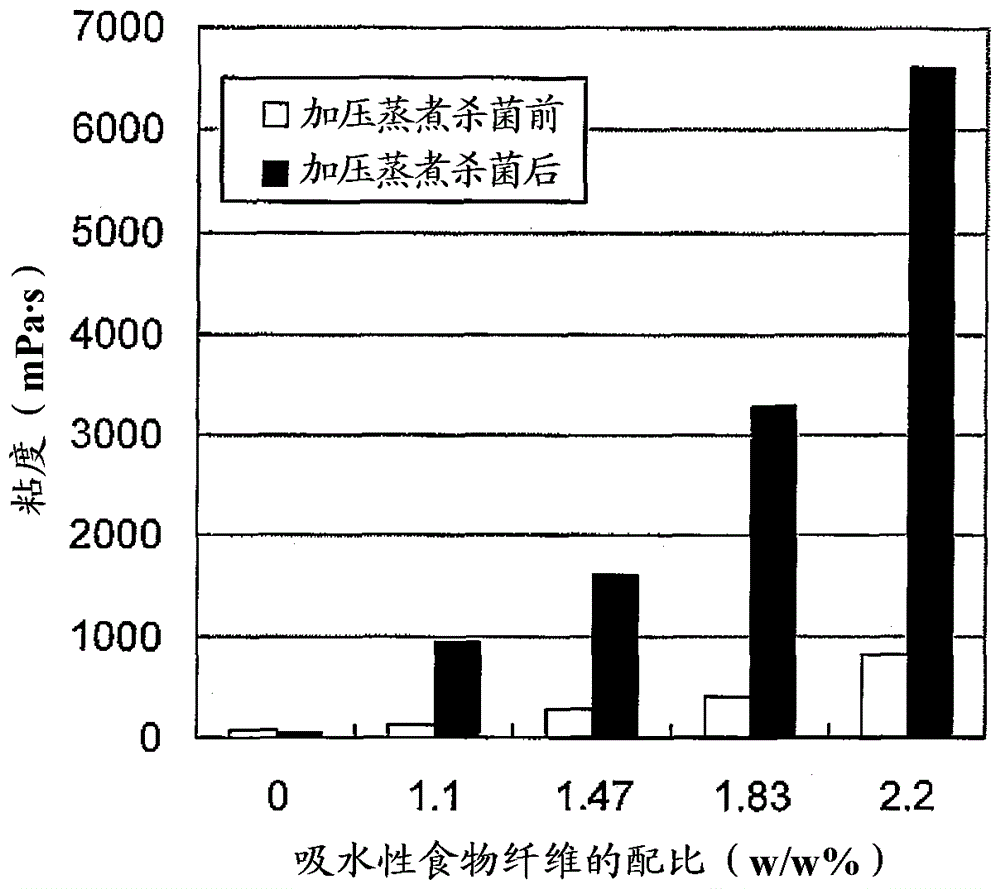

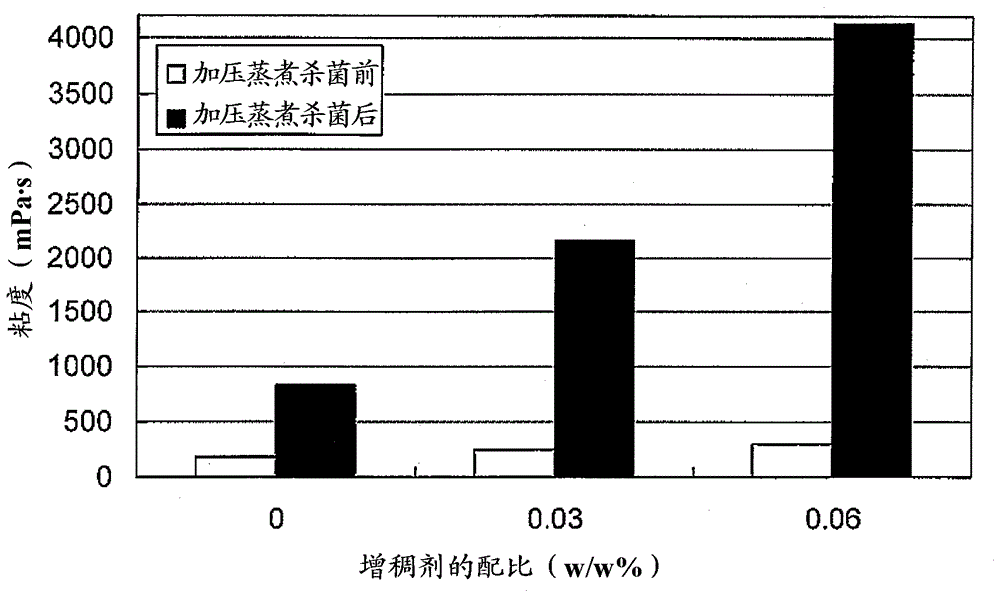

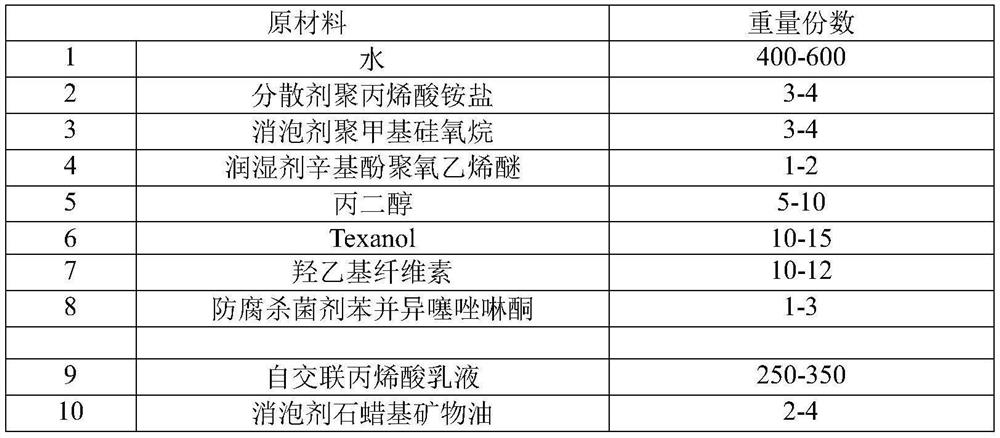

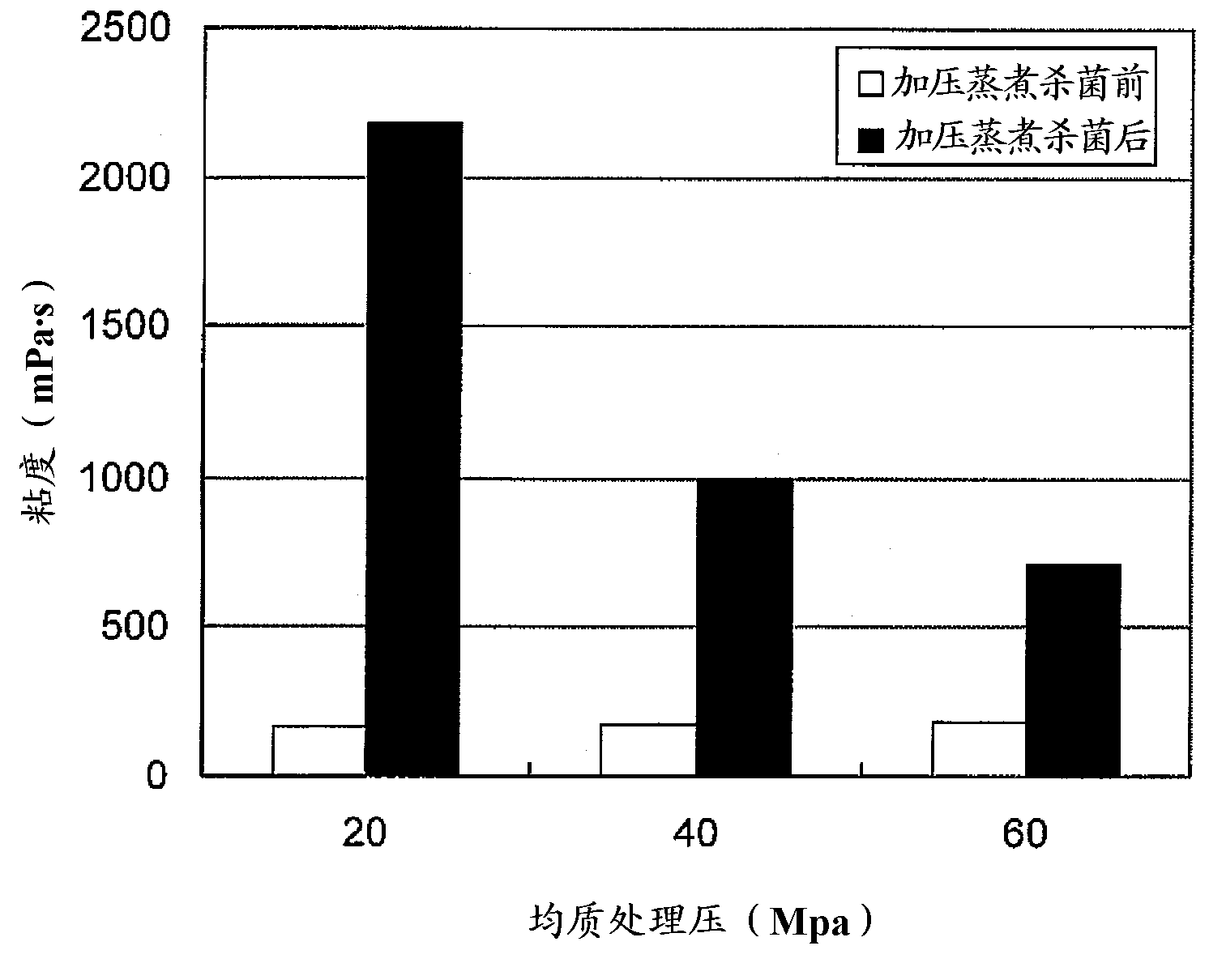

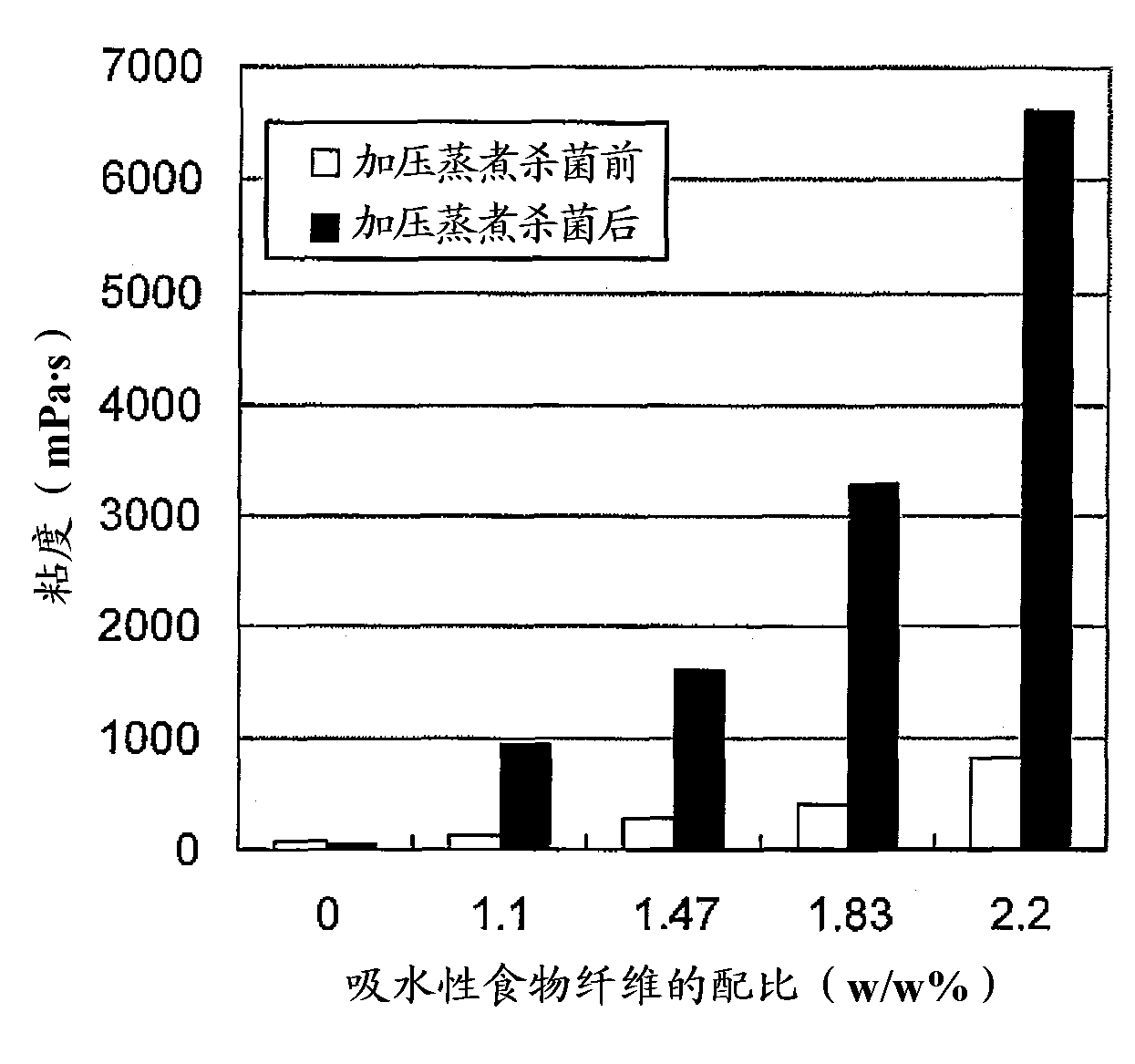

viscous nutritional composition

ActiveCN103533852BHigh viscosityEconomic savingsFood ingredientsIodine compound active ingredientsFiberDietary fiber

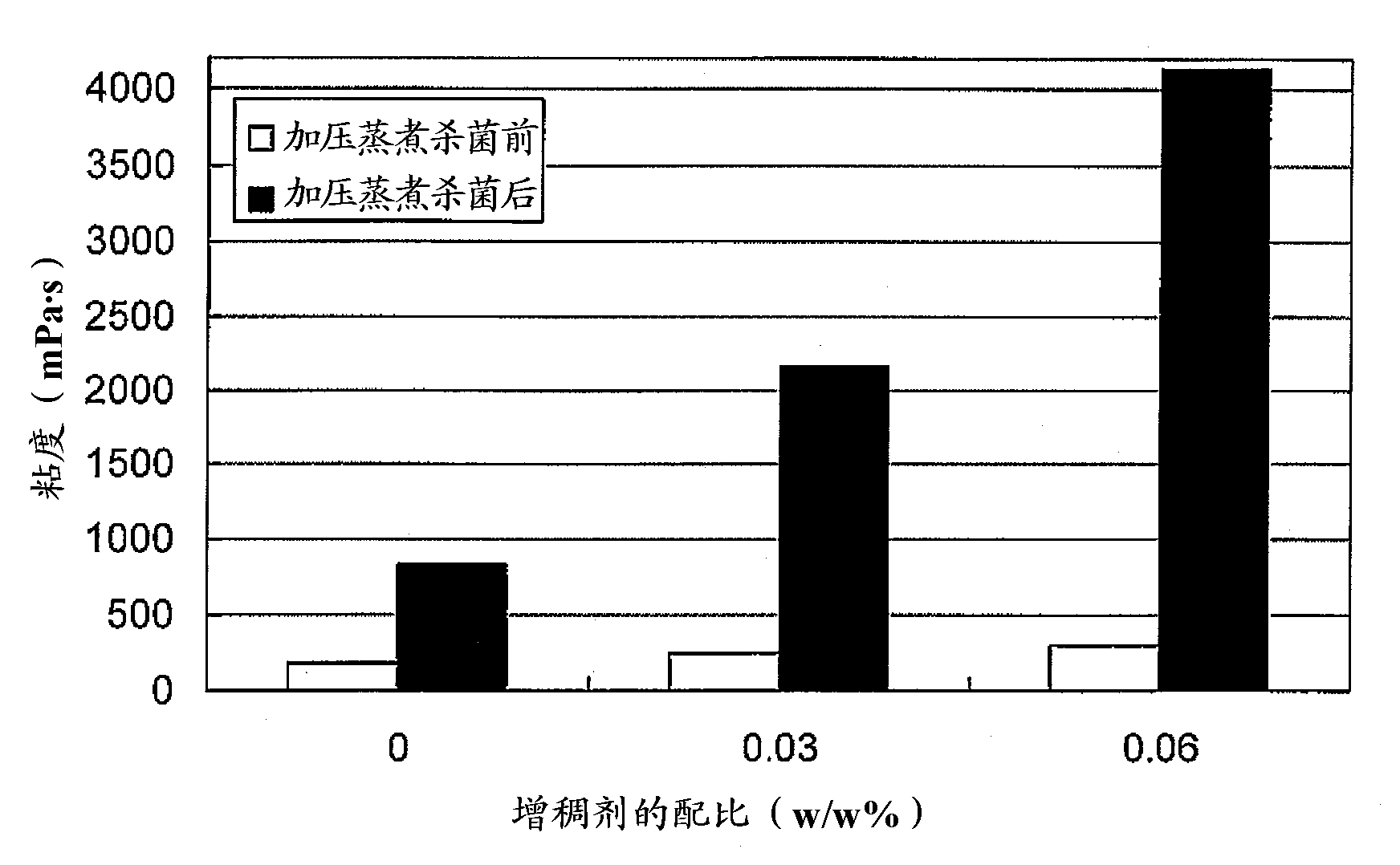

In order to provide a liquid food that can be used in drip treatments and has a more physiologically desirable viscosity than a liquid food with extremely low viscosity, a nutritional composition is provided by using water-absorbing dietary fiber and starch that has not been subjected to gelatinization. The viscosity of the nutritional composition is maintained during a simple manufacturing process involving steps from preparing raw materials to filling containers with the nutritional composition, and said nutritional composition has a viscosity that is suitable for flexible containers with an outlet used for intubation administration by drip, or oral administration, after being treated by heat.

Owner:MEIJI CO LTD

Therapy device

A therapy device comprises a flexible sealed envelope and a gel within the envelope. The gel comprises water, thickening agent, and biodiesel by-product glycerin comprising glycerol and soap.

Owner:3M INNOVATIVE PROPERTIES CO

Fracturing fluid resistant to low pH value environment and high salinity and preparation method thereof

The invention relates to a fracturing fluid capable of resisting low pH value environment and higher salinity and a preparation method thereof. Most conventional fracturing fluid can have favorable viscoelasticity only in an alkaline environment, and the natural vegetable glue used under normal conditions is difficulty for crosslinking under acidic conditions. The preparation method comprises the following steps: uniformly mixing a viscoelastic surfactant, an acid and a dispersion pour-point depressant to form a liquid component mixture; and dissolving a water-soluble nonionic polymer thickener at normal temperature, adding the liquid component mixture, and stirring uniformly to obtain the fracturing fluid. Under the condition of not using any crosslinking agent, the vermiform accumulation of the viscoelastic surfactant is utilized to coat the linear high-polymer part inside the viscoelastic surfactant, so that the linear high polymer generates the crosslinking-like effect due to the existence of the viscoelastic surfactant when meeting the acid and shrinking. The fracturing fluid has high viscosity in a neutral environment due to the linear high polymer, and thus, can not have the solid carrying capacity due to greatly lowered viscosity under acidic conditions.

Owner:SHAANXI BANGXI CHEM +1

Preparation method of water-based multicolor paint

ActiveCN113913063AAppropriate viscosity of dispersed phaseControllable shapeMulticolor effect coatingsColored whiteTitanium dioxide

The invention belongs to the technical field of water-based coatings, and discloses a preparation method of a water-based multicolor paint. The method comprises the following steps: adding color pastes of various colors into a white base paint B solution containing titanium dioxide to obtain a colored base paint, adding the colored base paint into a transparent dispersion phase C, uniformly stirring to obtain a colored paint dispersion phase, adding the colored paint dispersion phase into a protective glue A solution, and granulating to obtain a finished product of the water-based multicolor paint. The mass fraction of titanium dioxide in the white base paint B is within 10%, and the mass fraction of color paste in the colored base paint does not exceed 20%. The viscosity of the dispersion phase of each color of basic color paint prepared by the method is basically consistent, the granulation particle size is controllable, and conditions are created for the stability of batches during large-scale production in a workshop.

Owner:东营利丰化工新材料有限公司

Viscous nutritional composition

ActiveCN103533852AHigh viscosityEconomic savingsFood ingredientsFood preparationBiotechnologyDietary fiber

The invention provides a liquid food that can be used in drip treatments and has a more physiologically desirable viscosity than a liquid food with extremely low viscosity, a nutritional composition is provided by using water-absorbing dietary fiber and starch that has not been subjected to gelatinization. The viscosity of the nutritional composition is maintained during a simple manufacturing process involving steps from preparing raw materials to filling containers with the nutritional composition, and said nutritional composition has a viscosity that is suitable for flexible containers with an outlet used for intubation administration by drip, or oral administration, after being treated by heat.

Owner:MEIJI CO LTD

Thick-coating quick-drying cold-spraying zinc sealing agent and construction method thereof

InactiveCN112724778AImprove bindingImprove compactnessLiquid surface applicatorsAnti-corrosive paintsChemistryDefoaming Agents

The invention discloses a thick-coating quick-drying cold-spraying zinc sealing agent. The sealing agent comprises an agent A and an agent B, wherein the agent A at least comprises the following components in parts by mass: 20 to 30 parts of phenol; 25 to 35 parts of paraformaldehyde; 30 parts to 40 parts of diethylenetriamine; 20 to 25 parts of thiourea; and 1 to 2 parts of an accelerant; and the agent B at least comprises the following components in parts by mass: 30 to 50 parts of epoxy resin; 30 to 60 parts of a solvent; 0.5 to 2 parts of a cosolvent; 1 to 2 parts of a coloring agent; 0.5 to 1.5 parts of a defoaming agent; 20 to 50 parts of a curing agent; and 0.1 to 1 part of a supramolecular auxiliary agent. according to the invention, a step-by-step coating method is adopted, and the rapid curing effect of the agent A on epoxy resin and the permeation effect of the agent A on the cold-sprayed zinc layer are utilized, so that the firm combination of the epoxy resin sealing layer and the cold-sprayed zinc layer and the compactness of hierarchical curing are realized, and the rapid spraying of a thicker sealing layer can be realized.

Owner:江苏鑫能材料科技有限公司

External preparation for skin

InactiveCN101164620BExcellent stability over timeEasy to useCosmetic preparationsToilet preparationsSalicylic acidXanthan gum

The invention provides an external preparation for skin capable of providing sufficient viscosity by a simple operation and excellent in feelings upon use in a salt type agent formulation system. The external preparation for skin is obtained by formulating a salt type agent with xanthan gum and guar gum. It is preferable for the external preparation that the weight ratio of the xanthan gum to the guar gum is (10:90) to (90:10), further (20:80) to (80:20). The external preparation for skin is excellent in viscosity stability at high temperature when the weight ratio is particularly (50:50) to (20:80). The salt type agent is preferably an ascorbic acid-based and / or alkoxysalicylic acid-based bleaching agent.

Owner:SHISEIDO CO LTD

Preparation method and application of papermaking coating styrene-acrylic latex

ActiveCN102850974BResolubilizingWith smoothnessNon-fibrous pulp additionPaper coatingEmulsionAcrylic resin

The invention provides a preparation method and application of a papermaking coating styrene-acrylic latex. The preparation method comprises the following steps: (1) evenly mixing 5-40 wt% of initiator, 10-50 wt% of emulsifier and 5-30 wt% of water, and adding 50-80 wt% of mixed monomers to obtain a homogeneous emulsion A, wherein the mixed monomers are composed of (methyl) acrylate, (methyl) styrene and (methyl) acrylic acid; and (2) reacting acrylic resin, the rest of initiator, the rest of emulsifier, the rest of mixed monomers and the rest of water, dropwisely adding the homogeneous emulsion A obtained in the step (1) to react, adding a starch water solution, continuing the reaction, and neutralizing with an alkaline matter until the pH value is 6-9, thereby obtaining the papermaking coating styrene-acrylic latex. By using the method of adding the acrylic resin through the kettle bottom and adding the coating starch subsequently, the bonding property of the styrene-acrylic latex is greatly enhanced, and the smoothness of the coated paper is improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com