Non-benzene blending oil

A technology for adjusting gold oil and weight, applied in the field of gold adjusting oil, can solve the problems of hematopoietic function damage, residual product residues, and health accumulation hazards of consumers, and achieve the effect of high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 Embodiment 2 Embodiment 3

[0012] Acrylic 20% 25% 30%

[0013] Nitrocellulose resin 10% 8% 5%

[0014] Dibutyl phthalate 6% 4% 3%

[0015] n-Propyl acetate 30% 32% 40%

[0016] Ethyl acetate 30% 28% 17.5%

[0017] Filler 3.5% 1% 2%

Embodiment 4 Embodiment 5

[0019] Acrylic 10% 40%

[0020] Nitrocellulose resin 10% 5%

[0021] Dibutyl phthalate 6% 3%

[0022] n-Propyl acetate 30.5% 30%

[0023] Ethyl acetate 40% 20%

[0024] Filler 3.5% 2%

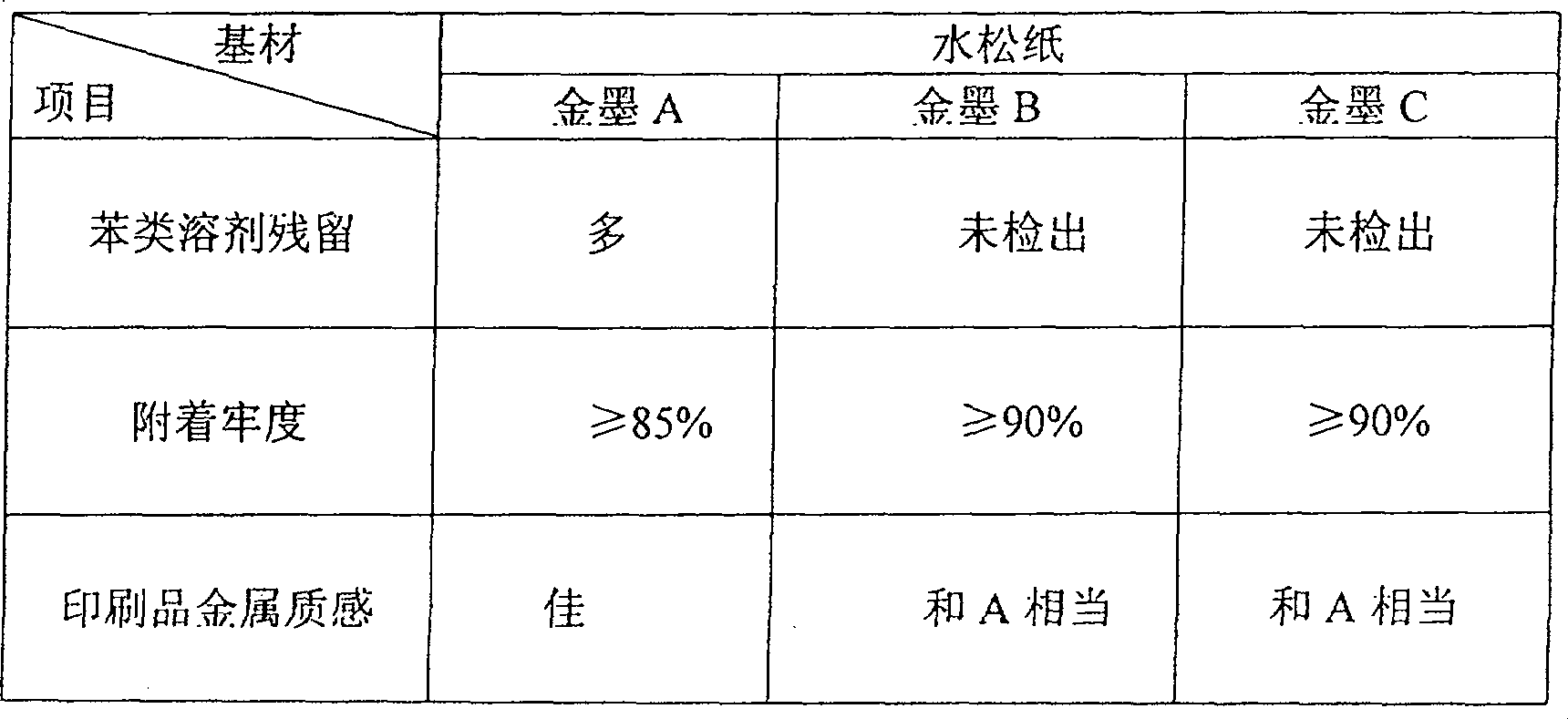

[0025] The effect of the product of the embodiment of the present invention can be illustrated by three groups of contrastive experiments:

[0026] Gold ink A: Ordinary benzene solvent type gold oil + moon palace gold powder (1200 mesh)

[0027] Gold ink B: embodiment 1+moon palace gold powder (1200 orders)

[0028] Gold ink C: embodiment 2+moon palace gold powder (1200 orders)

[0029] When printing, the ratio of each gold ink is: gold oil: gold powder = 7:3, and the viscosity of gold ink is the same. The printing machine is a CMR gravure four-color machine, and the printing substrate is 35 grams of white tip paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com