A kind of preparation method of water-based colorful paint

A water-based colorful paint and color technology, applied in the direction of multi-color effect paints, coatings, etc., can solve the problems of uncontrolled granulation and large viscosity gap in the mixing system, and achieve easy batch reproduction, appropriate viscosity, and easy shape control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention discloses a preparation method of a water-based colorful paint, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to achieve. It should be particularly pointed out that all similar substitutions and modifications will be apparent to those skilled in the art, and are deemed to be included in the present invention. The method and application of the present invention have been described through the preferred embodiments, and it is obvious that relevant persons can make changes or appropriate changes and combinations of the methods and applications described herein without departing from the content, spirit and scope of the present invention to achieve and Apply the technology of the present invention.

[0022] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below with reference to specific emb...

Embodiment 1

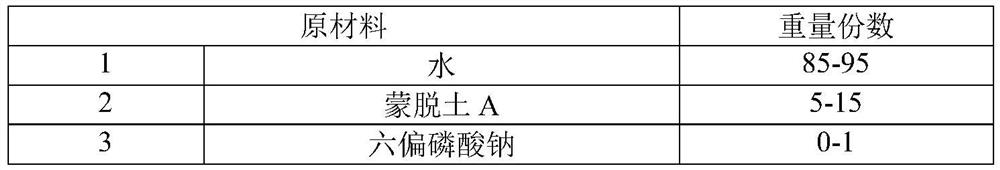

[0024] (1) Prepare protective glue A Prepare protective glue A solution and set it aside for use;

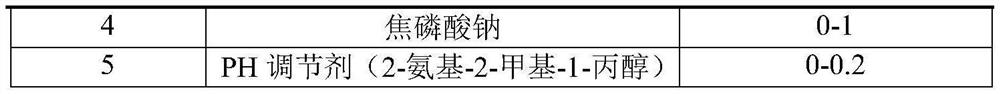

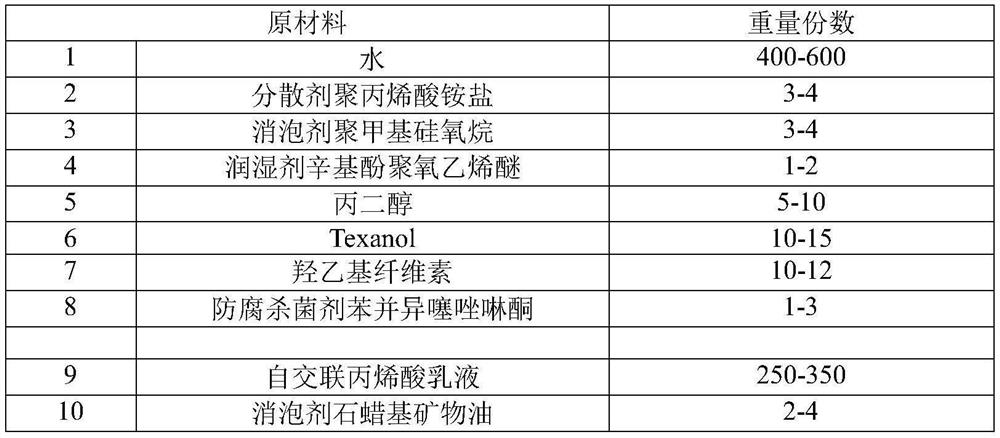

[0025](2) Toning According to the required pattern, add the white base paint B with titanium dioxide content within 10%, and add the color pastes of various colors to the white base paint B solution for toning to obtain the color base paint that has been adjusted according to the color. A white base paint B with a suitable titanium dioxide content can be selected for the depth. As a preference, in this example, a base paint latex paint with a titanium dioxide content of 10% and a base paint latex paint containing no titanium dioxide and only 0% filler are selected to mix the final A white base paint B with a titanium dioxide content of 5% is obtained, the mass fraction of the color paste in the final color base paint does not exceed 7%, the viscosity of the color base paint is adjusted to 110±5KU, and the viscosity of the transparent dispersed phase C is adjusted to 125± 10KU, a...

Embodiment 2

[0050] (1) Prepare protective glue A Prepare protective glue A solution and set it aside for use;

[0051] (2) Toning According to the desired pattern, add the white base paint B solution with a titanium dioxide content of less than 10%, and use various color pastes (iron black, iron red and iron yellow) to add the white base paint B solution to the solution. The color base paint of 5 colors of dark red, light red, dark gray, light gray and light white is obtained by color matching. According to the color depth, a white base paint B with a suitable titanium dioxide content can be selected. White base paint B with a white powder content of 8%, the mass fraction of color paste in the final color base paint is not more than 3%, the viscosity of the color base paint can be easily adjusted to 110±5KU, and the viscosity of the transparent dispersed phase C is adjusted to 125±10KU, add 5 colored base paints into the transparent disperse phase C and stir for 5-10 minutes to obtain 5 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com