Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1346 results about "Physical examination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

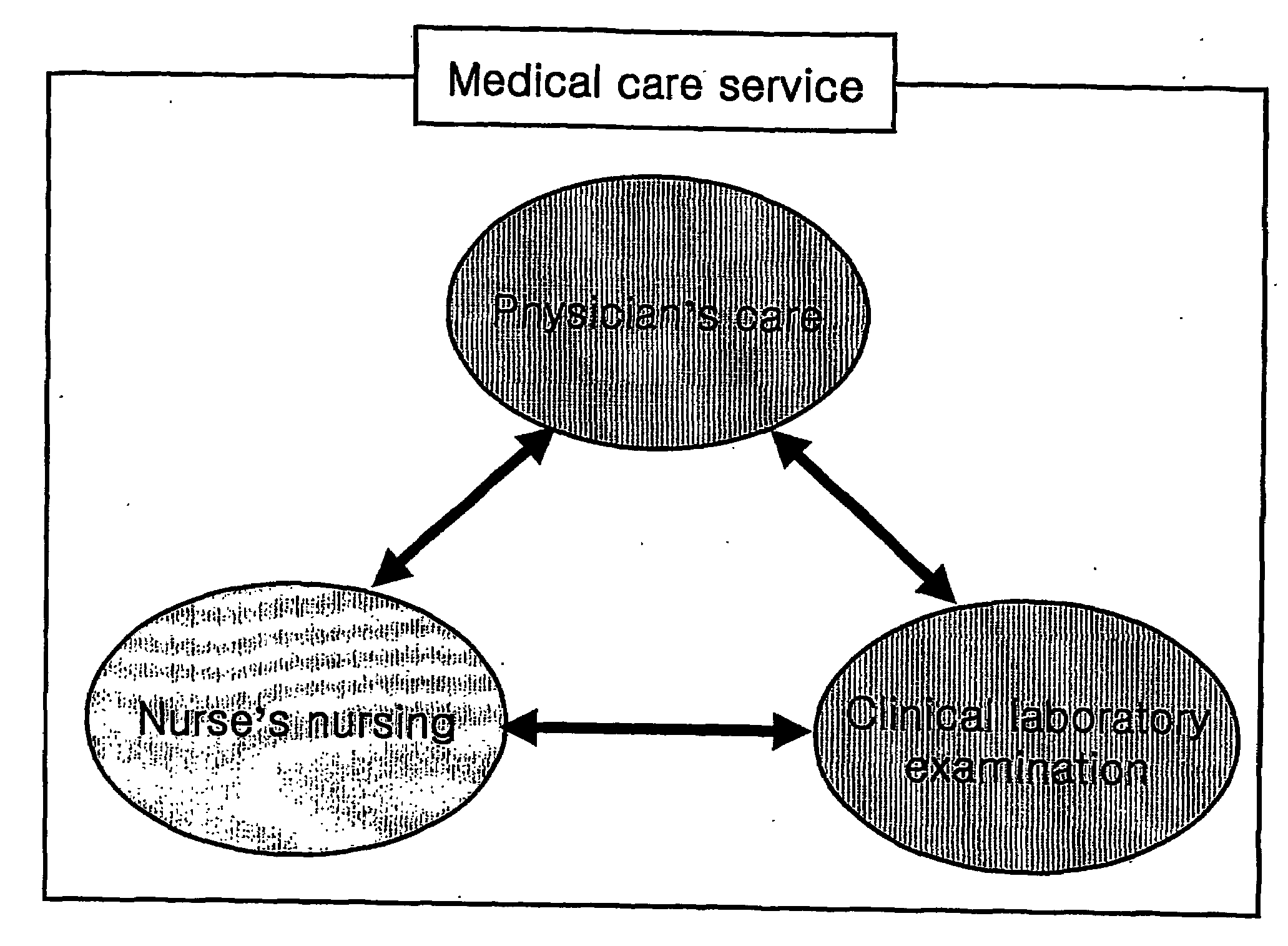

A physical examination, medical examination, or clinical examination is the process by which a medical practitioner examines the body of a patient for any possible signs or symptoms of a medical condition. It generally consists of a series of questions regarding patient medical history followed by an examination of the symptoms. Together, the medical history and the physical examination aids in determining the correct diagnosis and devising the treatment plan. This data then becomes part of the medical record. The physical examination may be used to investigate a patient's symptoms or complaints or as a routine screening procedure in an asymptomatic patient, in which case it is referred to as a routine physical, general medical examination or check-up.

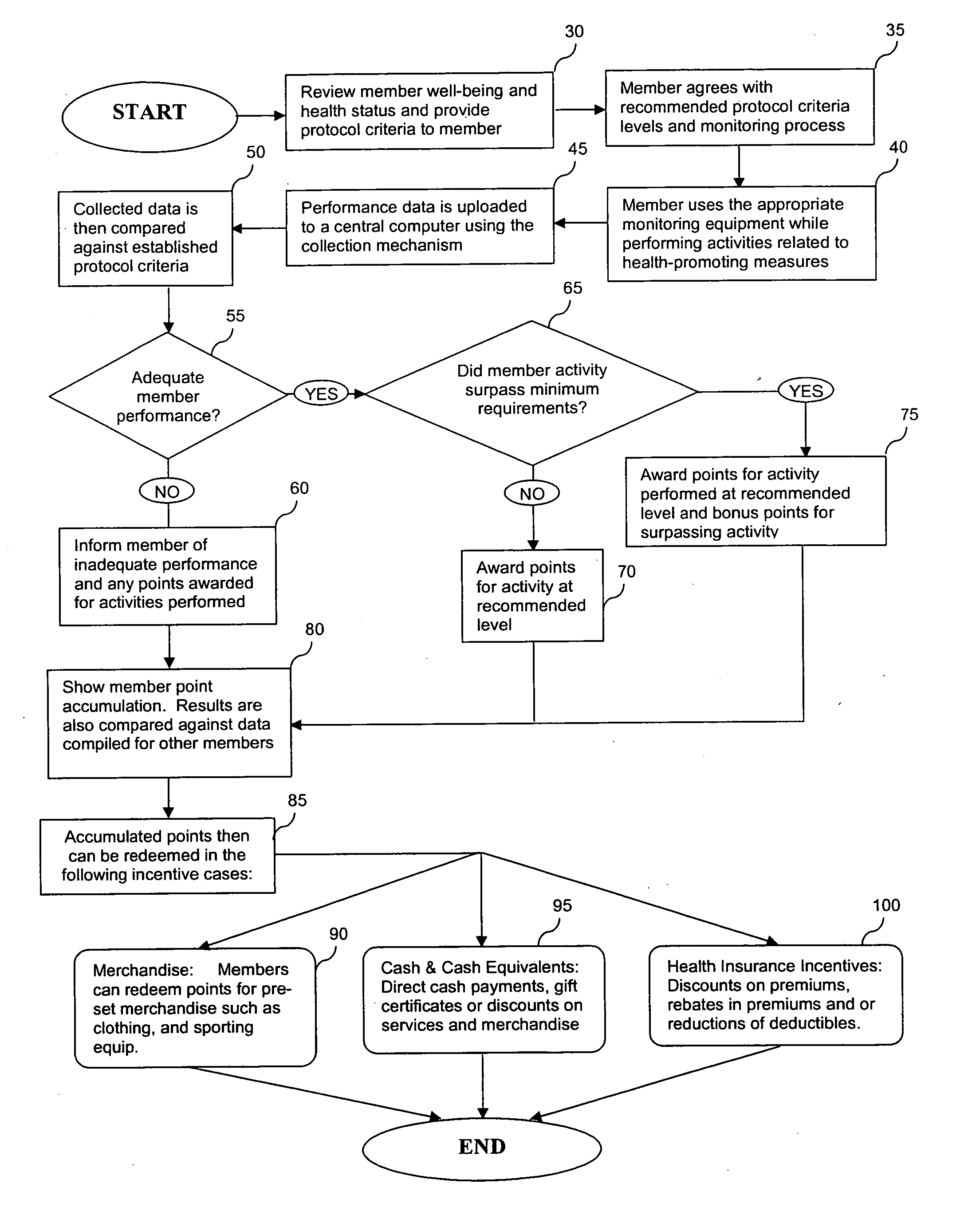

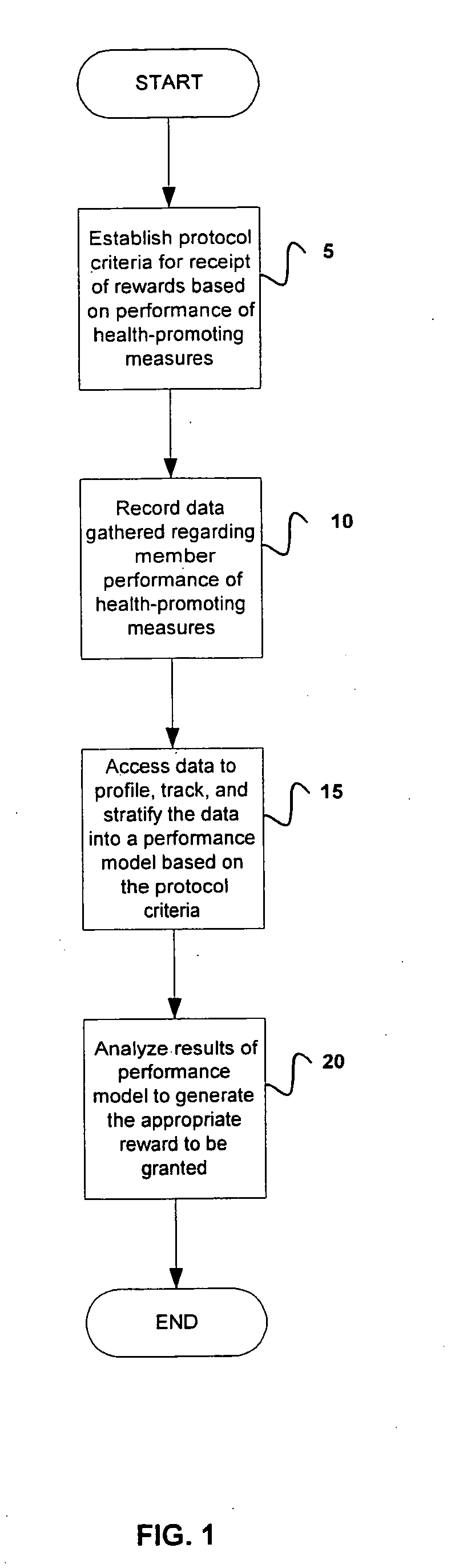

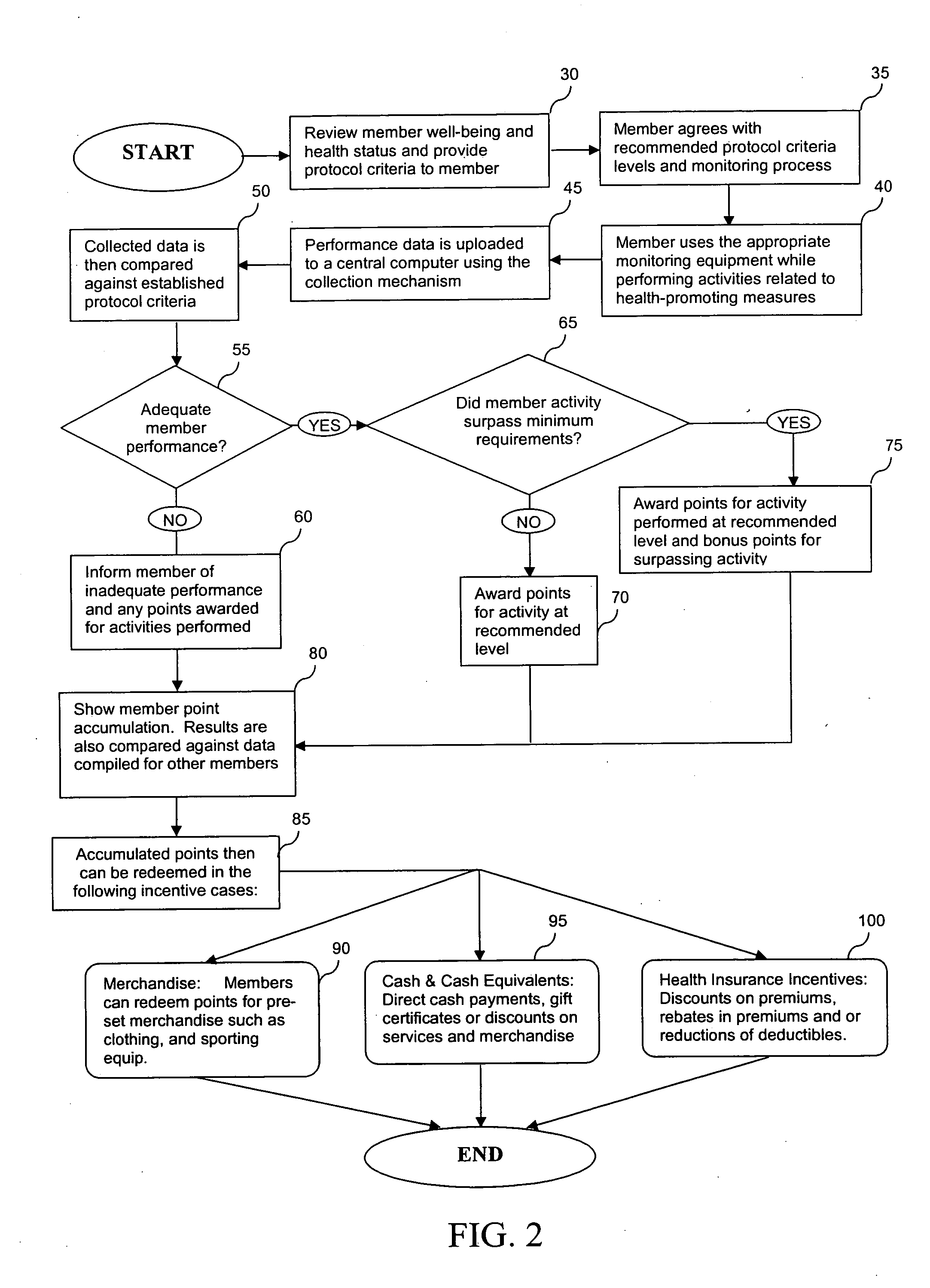

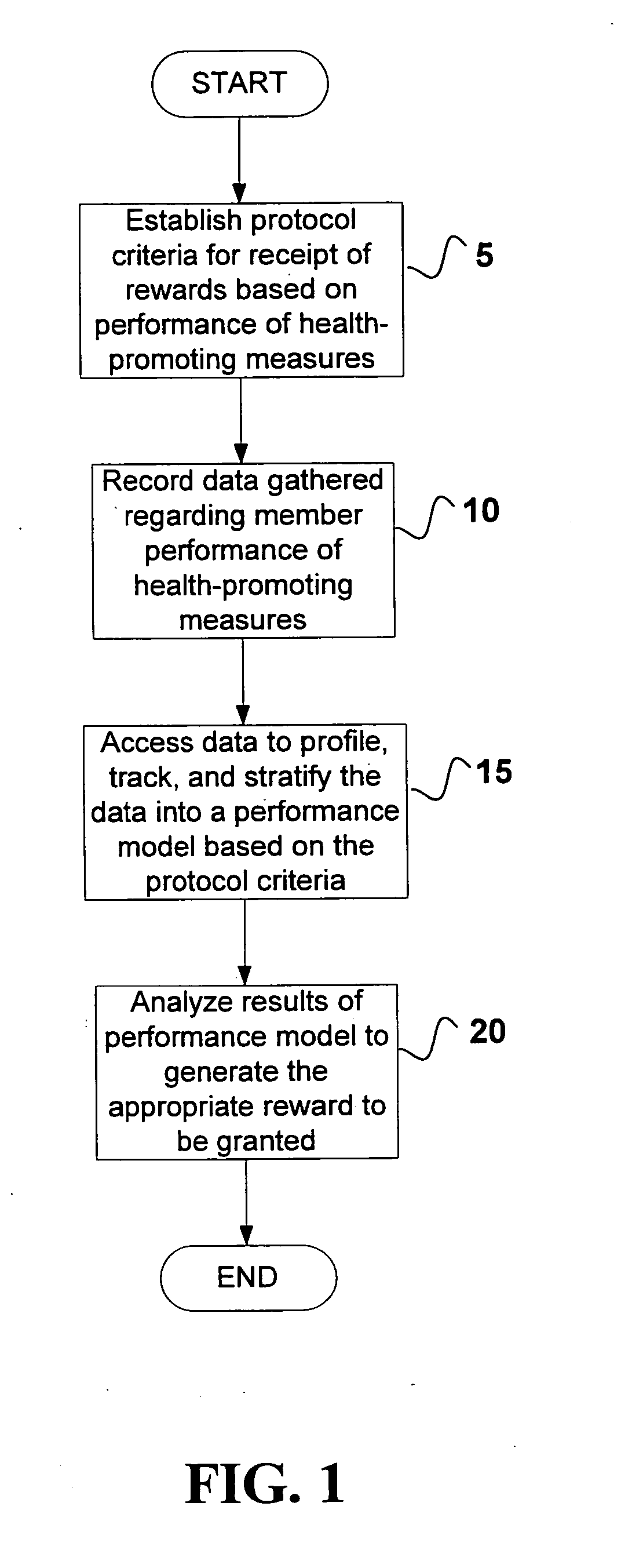

System and method for encouraging performance of health-promoting measures

InactiveUS20060111944A1Easy to modifyPhysical therapies and activitiesDiscounts/incentivesHealth related informationHealth promotion

The present invention relates to systems and methods for monitoring and promoting behavioral modification with regard to an individual's health. In particular, the present invention provides a means for monitoring an individual's performance of health-promoting measures and, based on the member compliance to health-promoting measures, issuing tangible and / or intangible incentive products. In one embodiment, exercise / activity monitors are worn by members to verify their identity and to record and transmit member compliance in performing health-promoting measures (i.e., heart rate, type of exercise, exercise intensity and duration). All health-related information, including physical examination results and recorded participation in health-promoting measures, are used to determine appropriate incentives (i.e., subsidize membership fees for health club) to be rewarded to said member.

Owner:SIRMANS JAMES R JR +1

System and method for evaluating insurance member activity and pricing insurance products

InactiveUS20050102172A1Reduced premiumFinanceSpecial data processing applicationsHealth related informationProduct base

The present invention relates to systems and methods for evaluating and establishing pricing of insurance products based on insured member compliance to health-promoting measures. Member participation in health-promoting measures are monitored and used as a basis for establishing incentives (i.e., reduction in insurance premiums) for said member. In one embodiment, exercise / activity monitors are worn by members to verify their identity and to record insurance member compliance in performing health-promoting measures (i.e., heart rate, type of exercise, exercise intensity and duration). All health-related information, including physical examination results and recorded participation in health-promoting measures, are used to determine appropriate incentives (i.e., subsidize membership fees for health club) to be rewarded to said member.

Owner:SIRMANS JAMES R JR

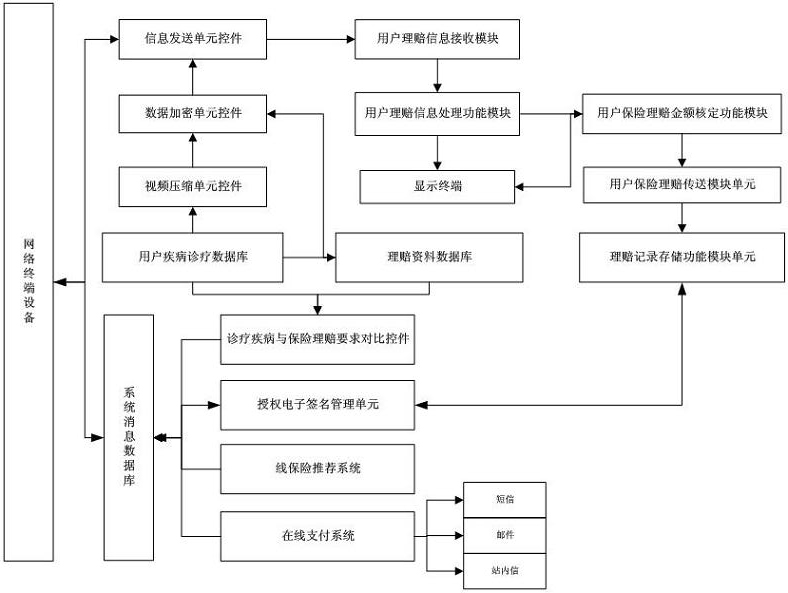

Method and system for verification and claim of on-line insurance claim settlement

The invention discloses a method and a system for verification and claim of on-line insurance claim settlement. According to the invention, on the basis of a user diagnosis and treatment record, a medication administration record and a physical examination record, a database of data of users' applications on insurance claim settlement is established; meanwhile, an insurance claim settlement standard check database is also established for an insurance company; according to an association control provided by the system, a comparison is carried out between the user application claim settlement database and the claim settlement standard check database of the insurance company; and then insurance claim settlement is carried out according to a resulted check standard and claim settlement fees can be paid to an insurance user in an on-line payment mode. A patient can complete operation on application for claim settlement through a network platform, so that labor and time are saved and operation can be completed conveniently and rapidly. According to check on an insurance claim settlement database, the system provided in the invention will automatically prompt the user that what a concrete claim payment standard is met, so that it is saved that the user confirms whether an insurance claim settlement standard is met by a call or a fax. And then insurance claim settlement fees will be directly transferred from an insurance company's account to a patient' s account by an on-line payment mode with convenience and rapidity.

Owner:DALIAN YICHUANG TIANDI TECH DEV

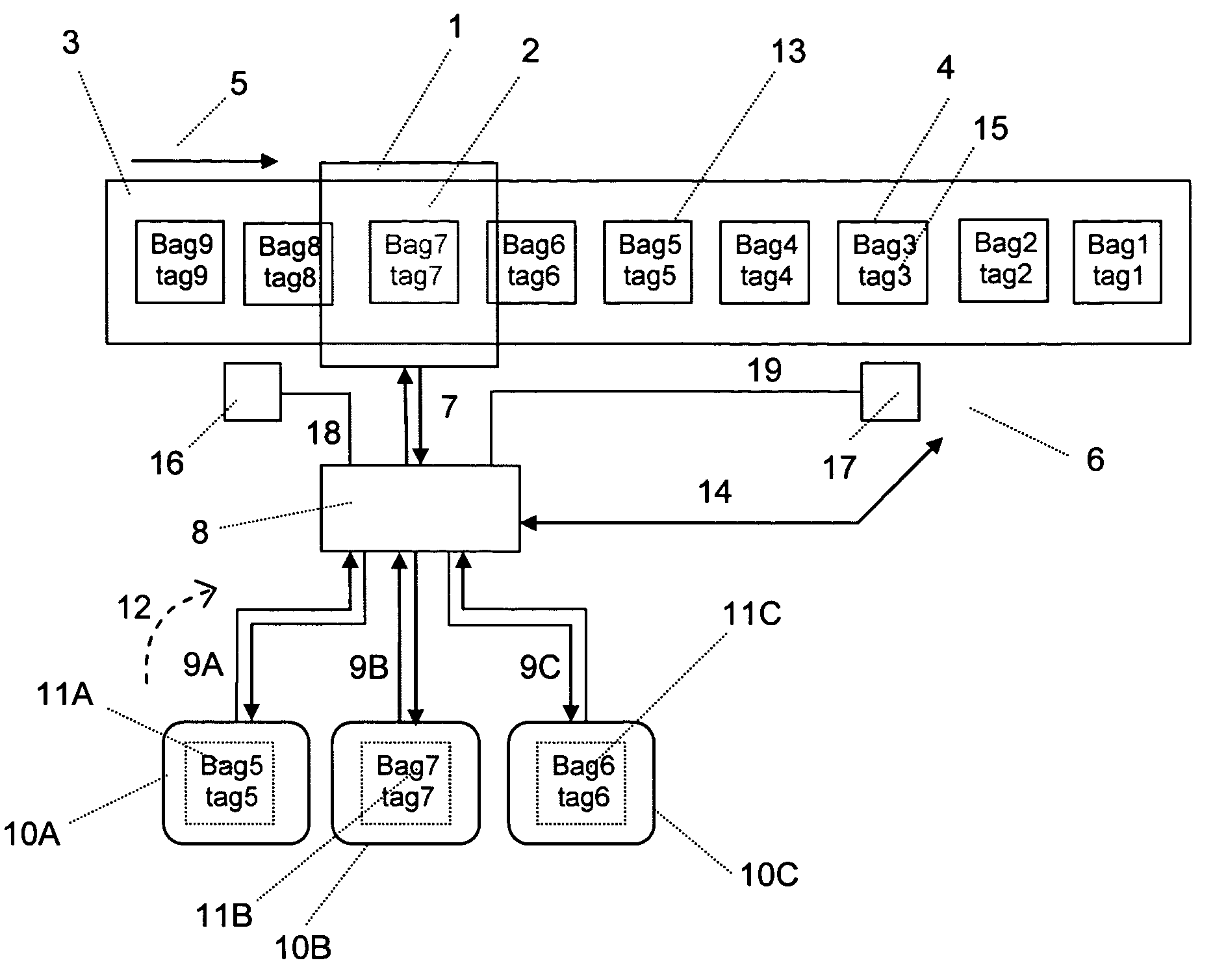

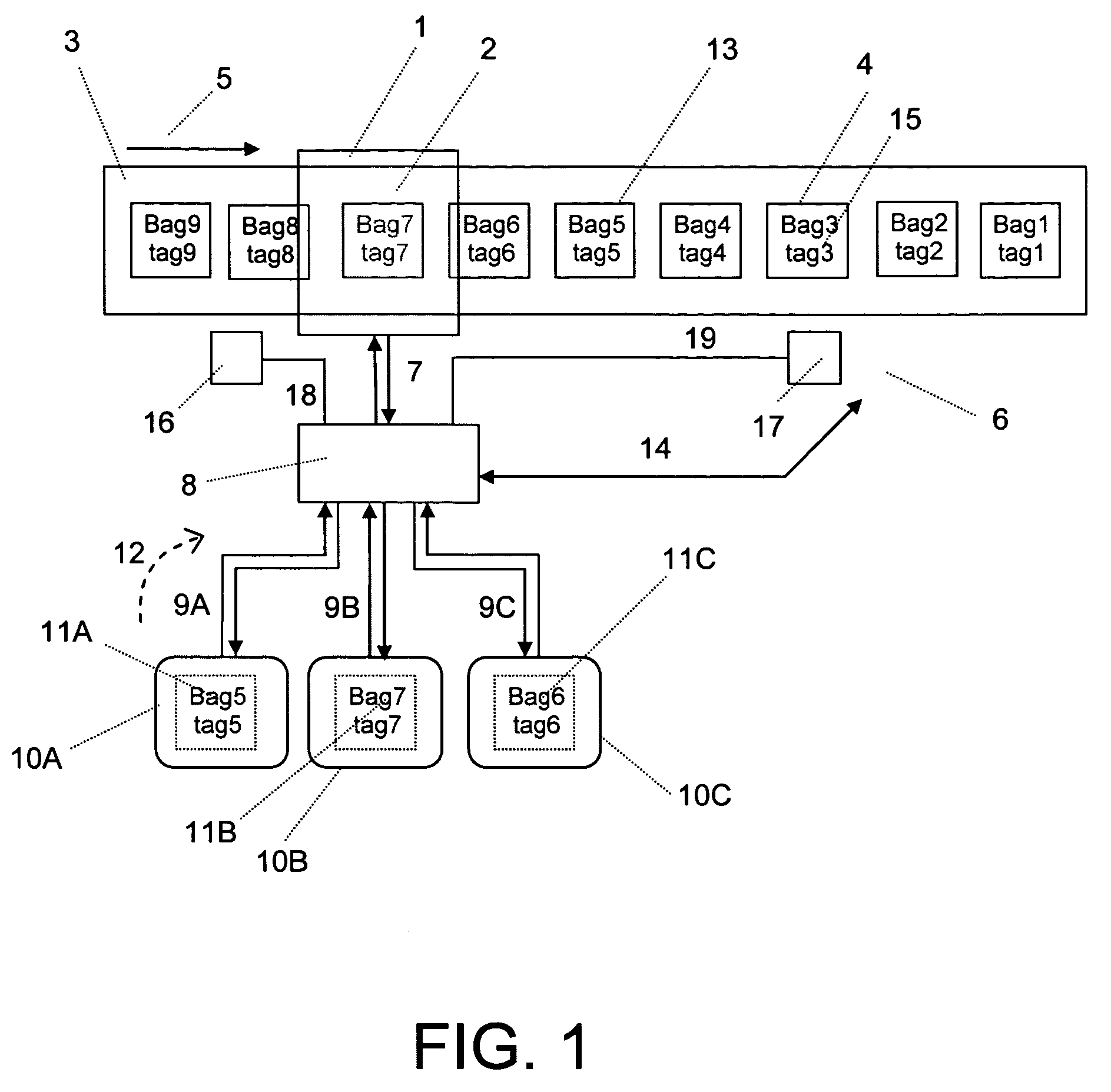

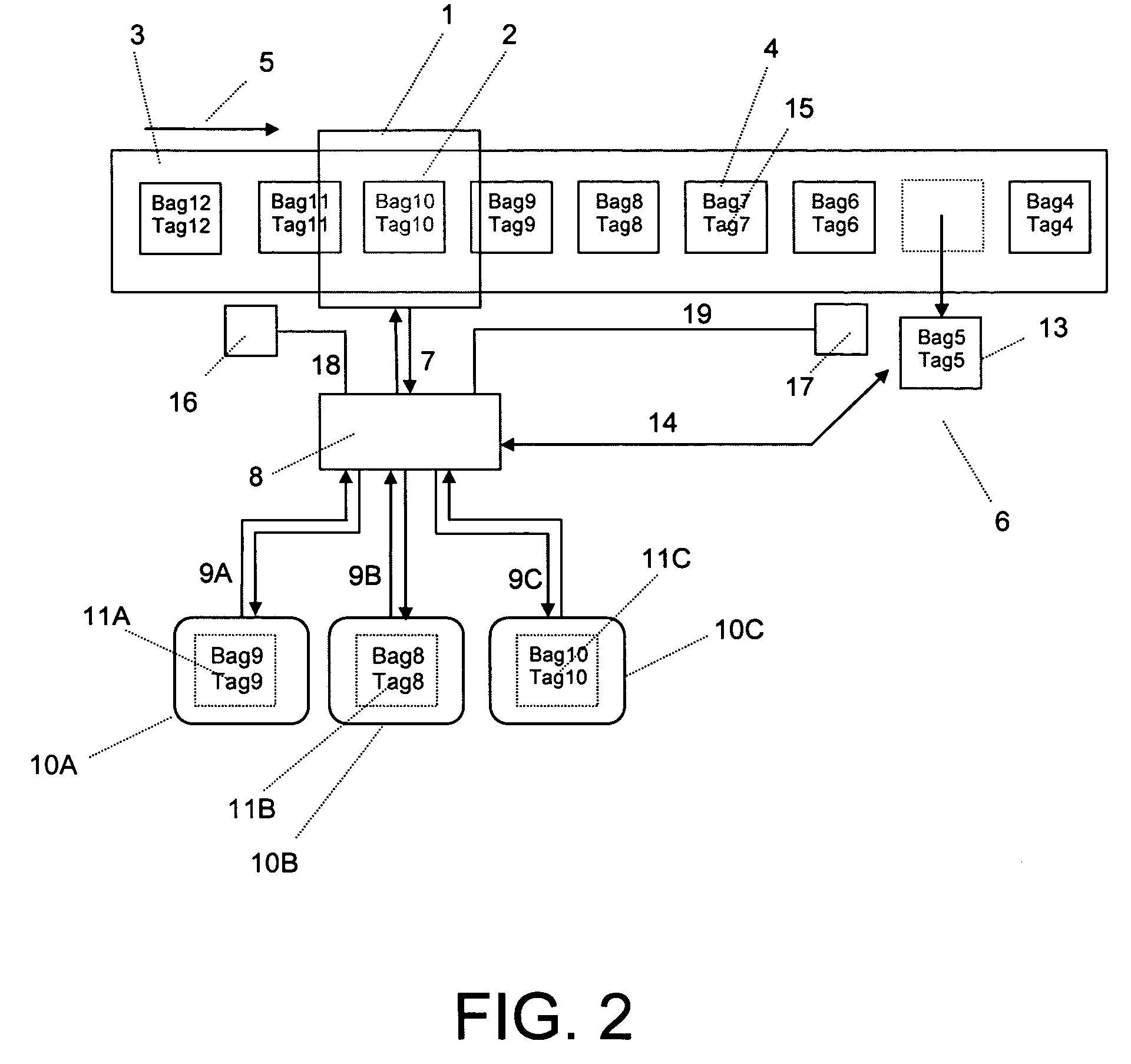

Method and apparatus for improving baggage screening examination

InactiveUS7286634B2Improve throughputLow costRadiation/particle handlingMaterial analysis by optical meansDisplay devicePointing device

A method and apparatus are disclosed for screening articles such as baggage, utilizing a computerized touch sensitive screen or other computerized pointing device for operator identification and electronic marking of objects within the article to be further examined. Baggage is electromagnetically scanned while traveling on a conveyer and an electronic image is taken of each article and stored in a computer. The present system utilizes a plurality of visual display devices, each with an examiner, which are likely located remotely of the screening operation. Each examination continues independently of the scanning such that there is no interruption in the flow of articles should an examiner detect an object of interest and worthy of further examination, either by screen or by physical examination.

Owner:NAT RECOVERY TECH

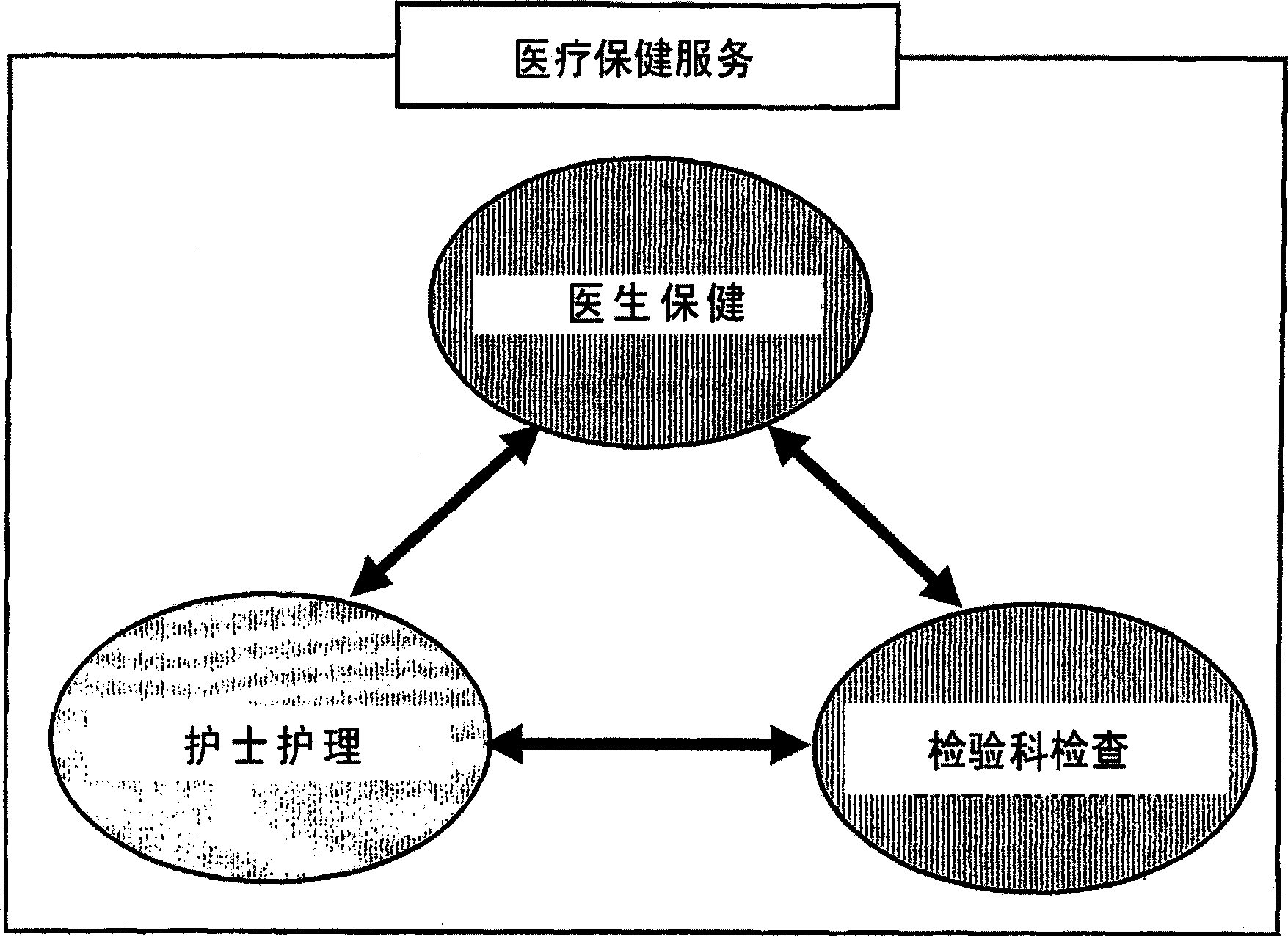

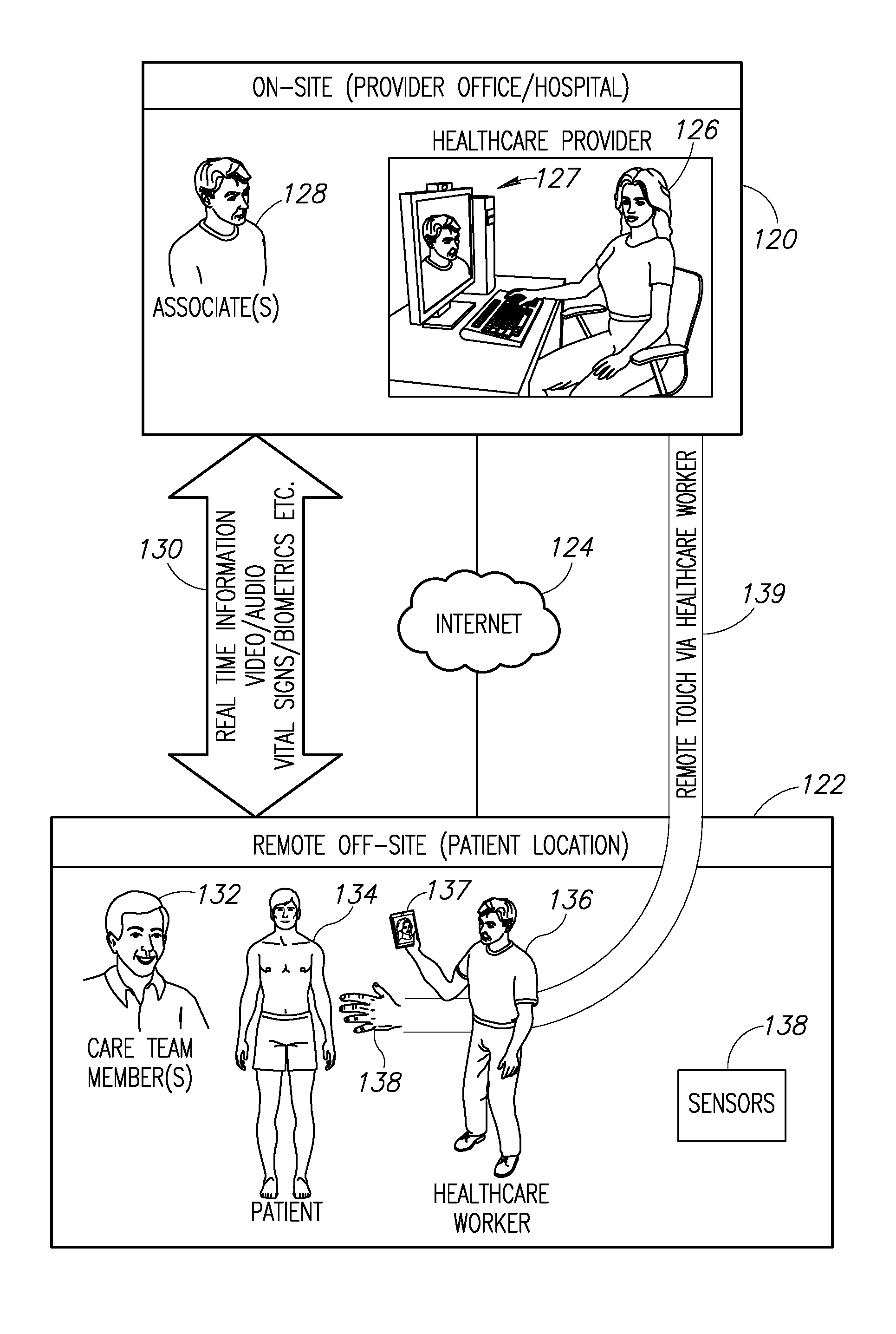

Connection Of Disparate Medical Personnel Networks And Associated Messaging In A Telemedicine System

InactiveUS20170011194A1Improve continuityNo room for improvementCharacter and pattern recognitionMedical imagesProper treatmentX-ray

A telemedicine system including a care coordination software platform allows for patient monitoring at home and connects patients to their medical teams via telemedicine using a HIPAA compliant video portal augmented by remote assisted physical examination, performance of diagnostic testing including labs and x-rays, and provision of appropriate treatment and prescriptions. Medical care is provided at the patient's location without the patient having to travel or spend time in waiting rooms, provides treatment based on objective physical examination data and any appropriate diagnostic testing, and provides validation of patient identity. Healthcare providers are made available via online video encounters to communicate with patients. Allied healthcare workers are dispatched to be in physical proximity to the patient to assist in physical examination, and provide diagnostic data. Providers order appropriate treatments and prescriptions based on examination findings and diagnostics. The telemedicine system interfaces with medical sensors and collects data wired or wirelessly.

Owner:MI EXPRESS CARE LICENSING CO LLC

System And Method Of Writing Electronic Prescriptions In A Telemedicine System

InactiveUS20170011200A1Improve continuityNo room for improvementCharacter and pattern recognitionMedical imagesProper treatmentX-ray

A telemedicine system including a care coordination software platform allows for patient monitoring at home and connects patients to their medical teams via telemedicine using a HIPAA compliant video portal augmented by remote assisted physical examination, performance of diagnostic testing including labs and x-rays, and provision of appropriate treatment and prescriptions. Medical care is provided at the patient's location without the patient having to travel or spend time in waiting rooms, provides treatment based on objective physical examination data and any appropriate diagnostic testing, and provides validation of patient identity. Healthcare providers are made available via online video encounters to communicate with patients. Allied healthcare workers are dispatched to be in physical proximity to the patient to assist in physical examination, and provide diagnostic data. Providers order appropriate treatments and prescriptions based on examination findings and diagnostics. The telemedicine system interfaces with medical sensors and collects data wired or wirelessly.

Owner:MI EXPRESS CARE LICENSING CO LLC

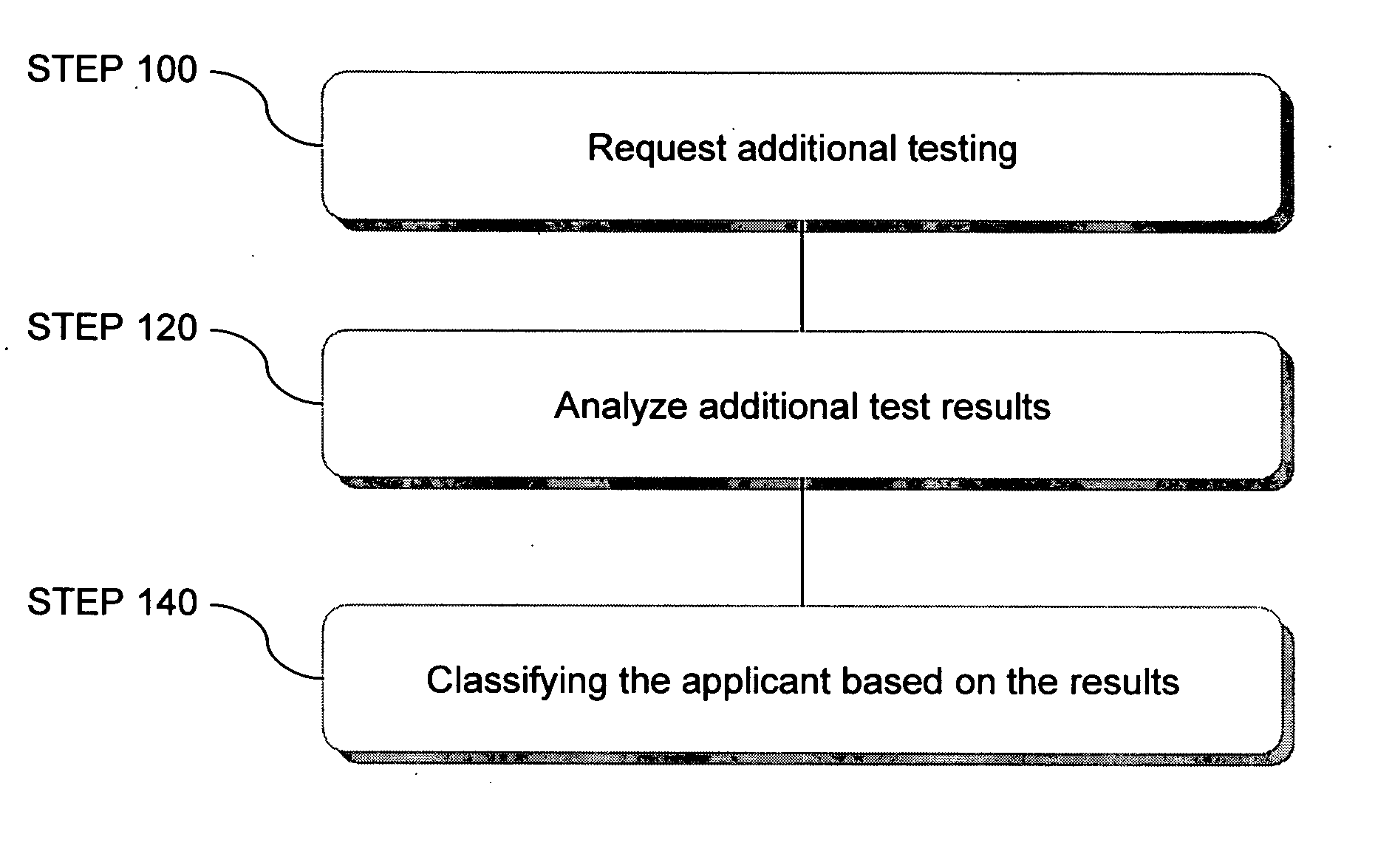

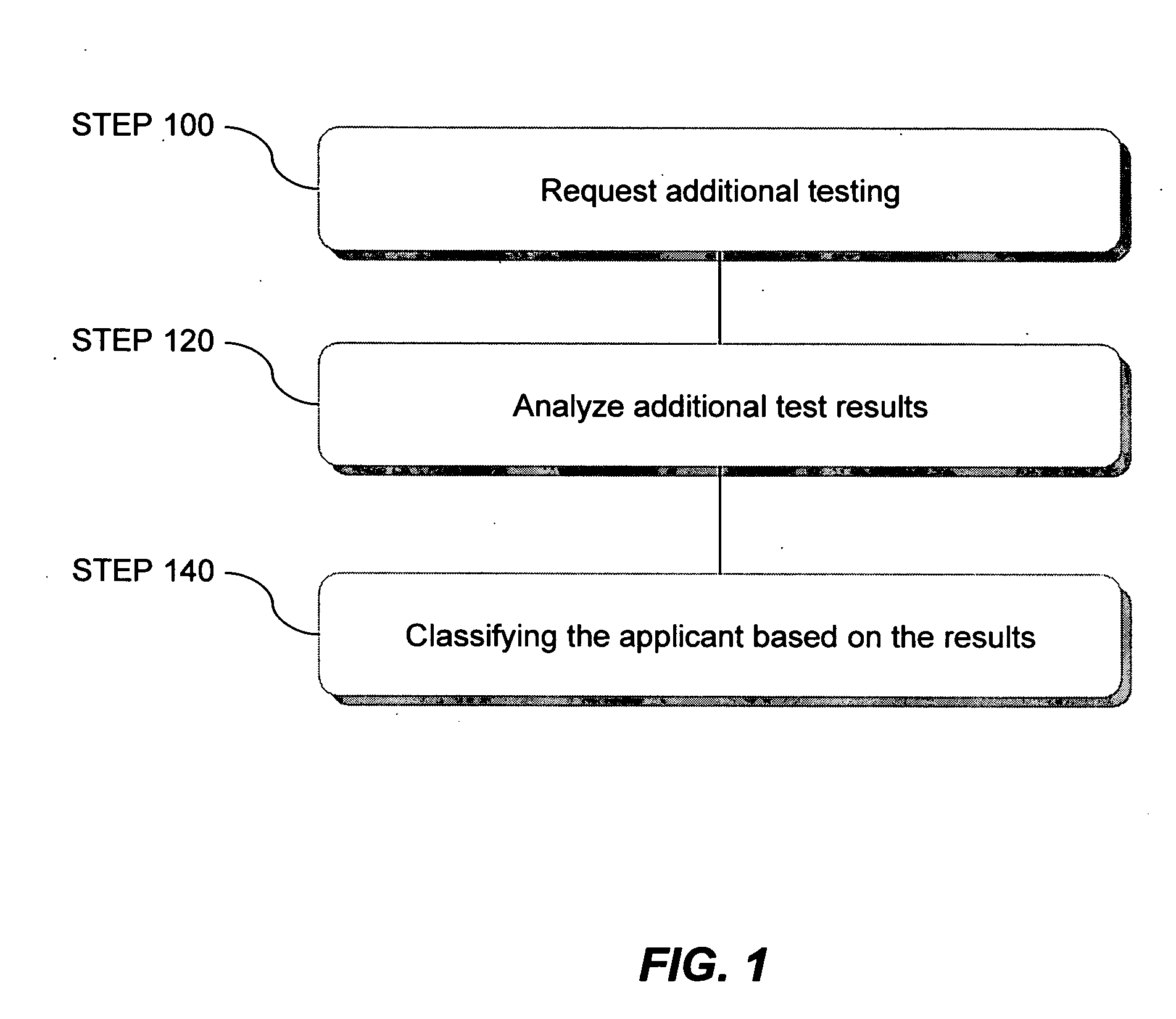

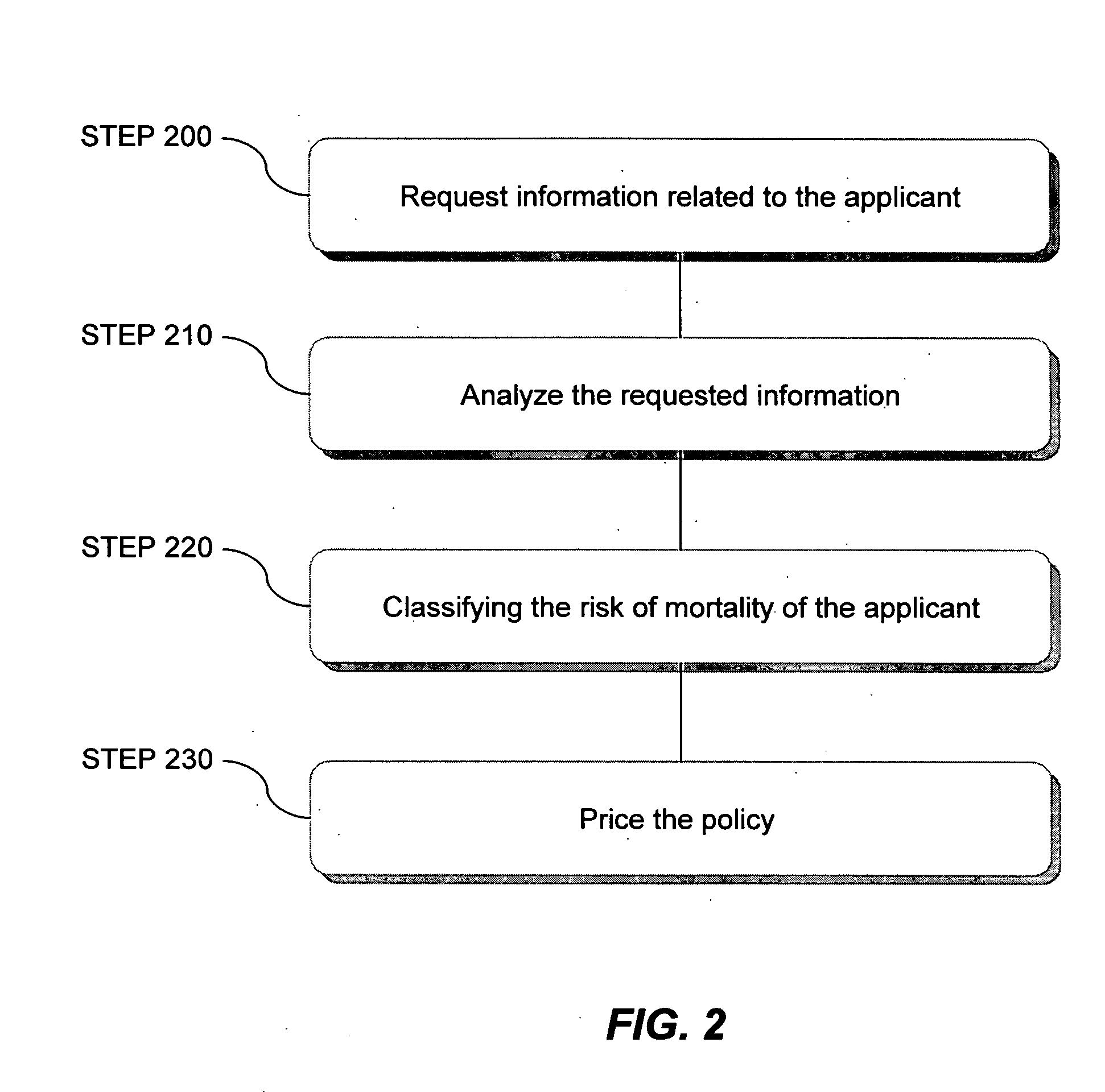

Elderly assessment protocol

Methods of classifying risk and adjusting policy pricing for elderly insurance applicants are provided. The methods preferably include the steps of requesting the applicant to perform tests in addition to a physical examination, analyzing the results of the tests, and classifying the risk of mortality of the applicant based on the results of the analysis. The additional test is preferably designed to analyze the applicant's physical performance, cognitive performance, executive function, and present physical health of an applicant.

Owner:GENERAL RE

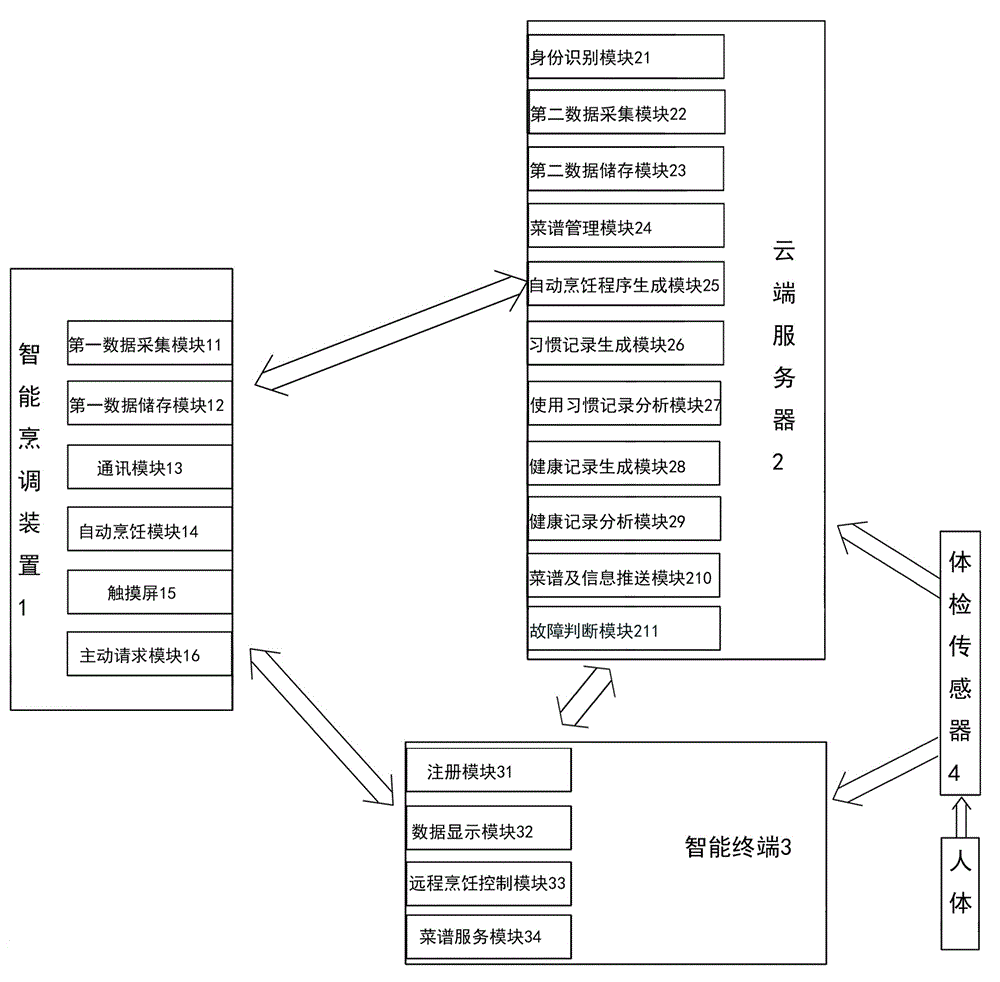

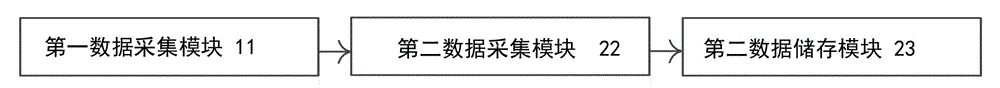

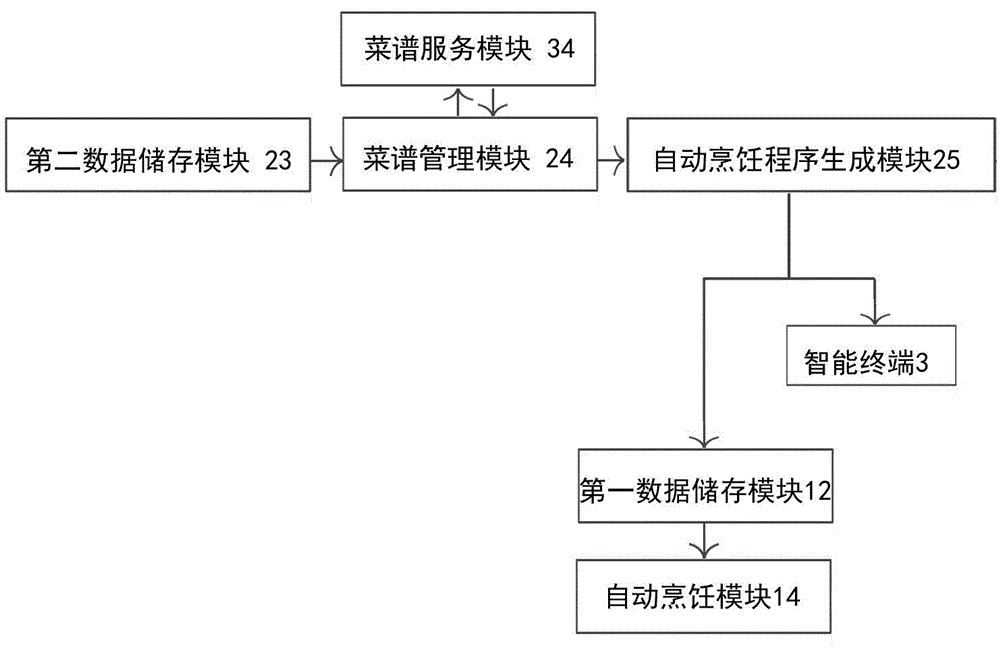

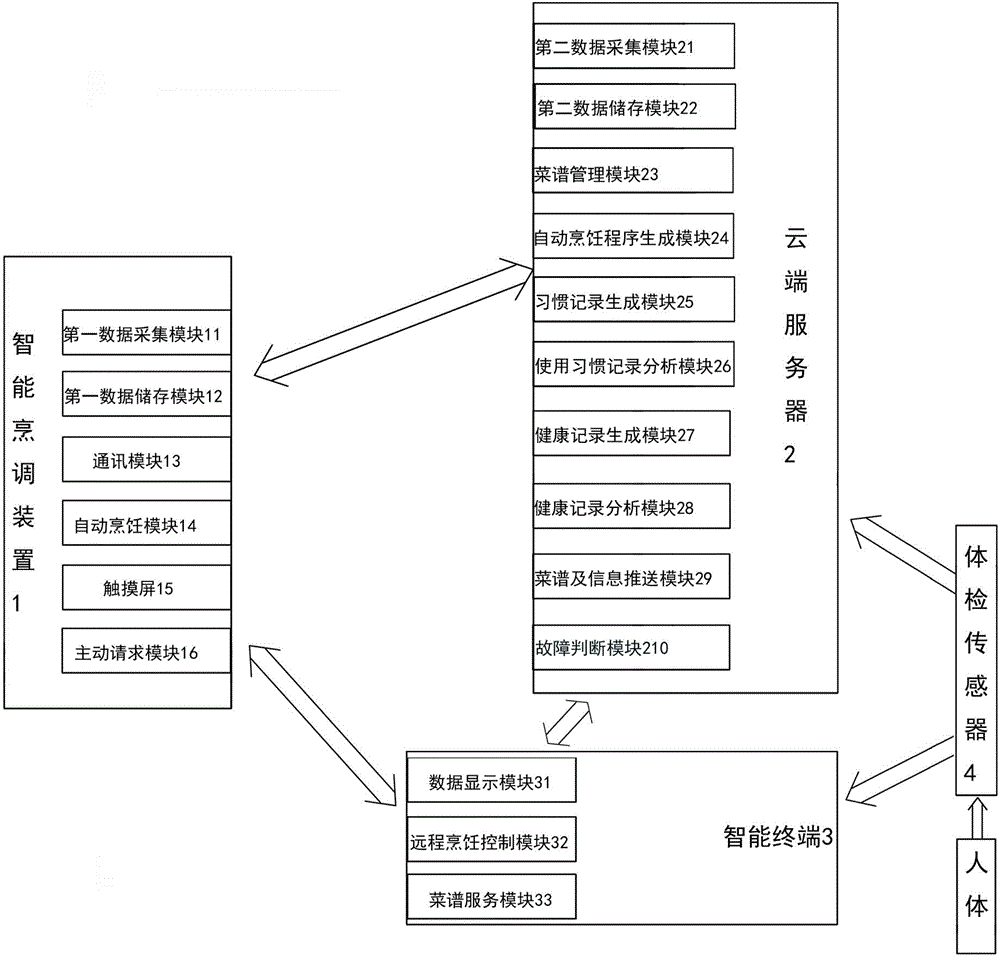

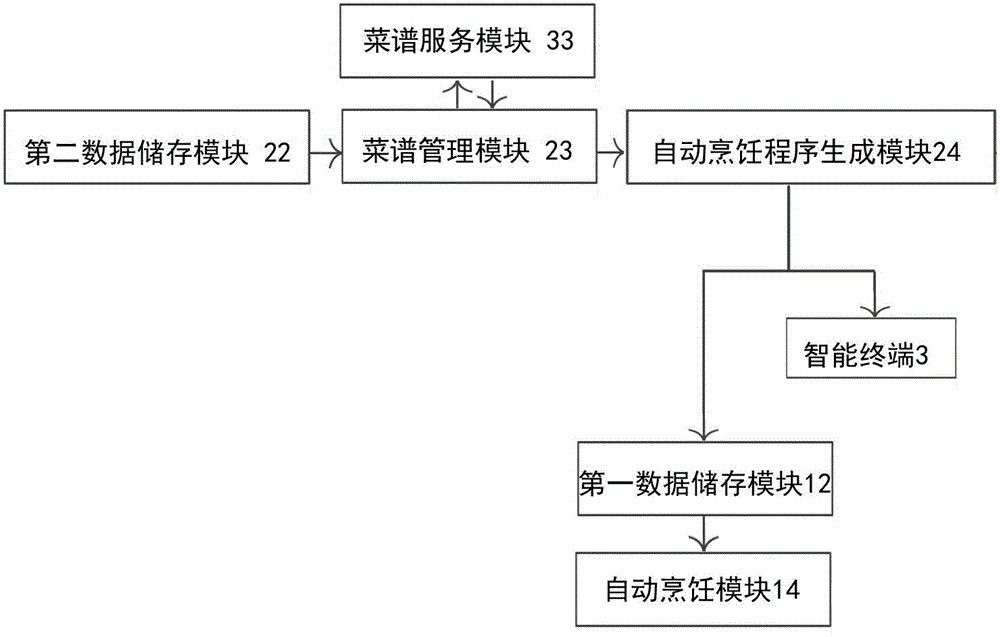

Intelligent cooking system and application thereof

InactiveCN105030040ARemote cooking control implementationReduce the burden onTransmission systemsComputer controlLife qualityHome environment

The invention relates to an intelligent cooking system which comprises an intelligent cooking device, a cloud-side server, an intelligent terminal and a physical examination sensor. The physical examination sensor produces health information and sends the health information to the intelligent terminal and the cloud-side server. The cloud-side server obtains an IP address of the intelligent cooking device and produces identifying information including geographical positions. The cloud-side server obtains feature information of the intelligent cooking device and produces usage habit records of a user. The cloud-side server produces recommending information according to the health information or the identifying information or the usage habit records and sends the recommending information to the intelligent terminal. The intelligent cooking system achieves full-automatic cooking by adopting an optimal scheme most meeting the current demand of the user and comprehensively provides a scientific, reasonable, suitable and healthy cooking service scheme conforming to the features of the user for the user on the aspects of geographical characteristics, usage habits, physical conditions and the like, a cloud-side service platform having powerful functions is formed, an energy-saving, environmentally-friendly, green and healthy home environment is created, and the living quality of people is remarkably improved.

Owner:GUANGDONG TONZE ELECTRIC CO LTD

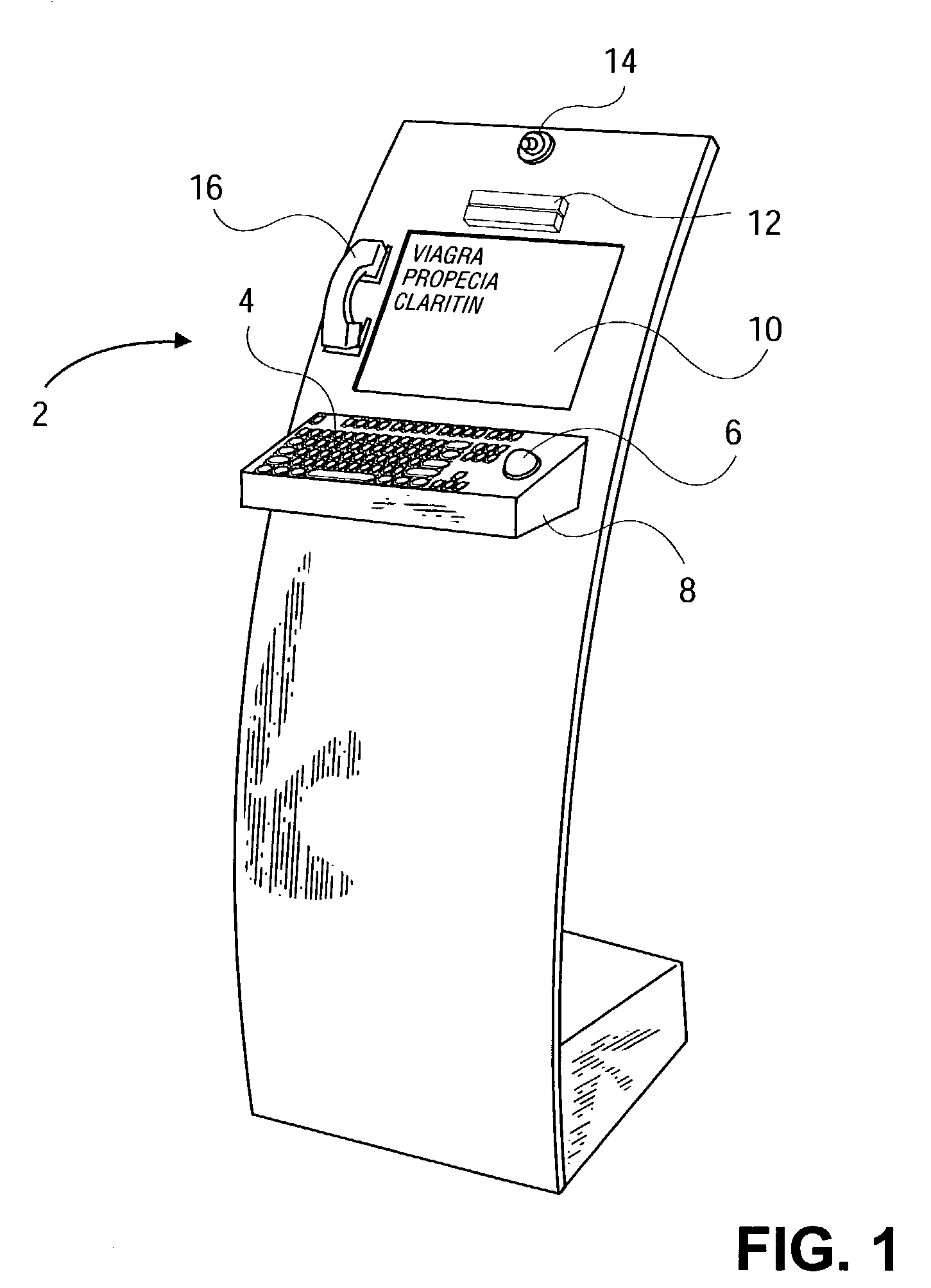

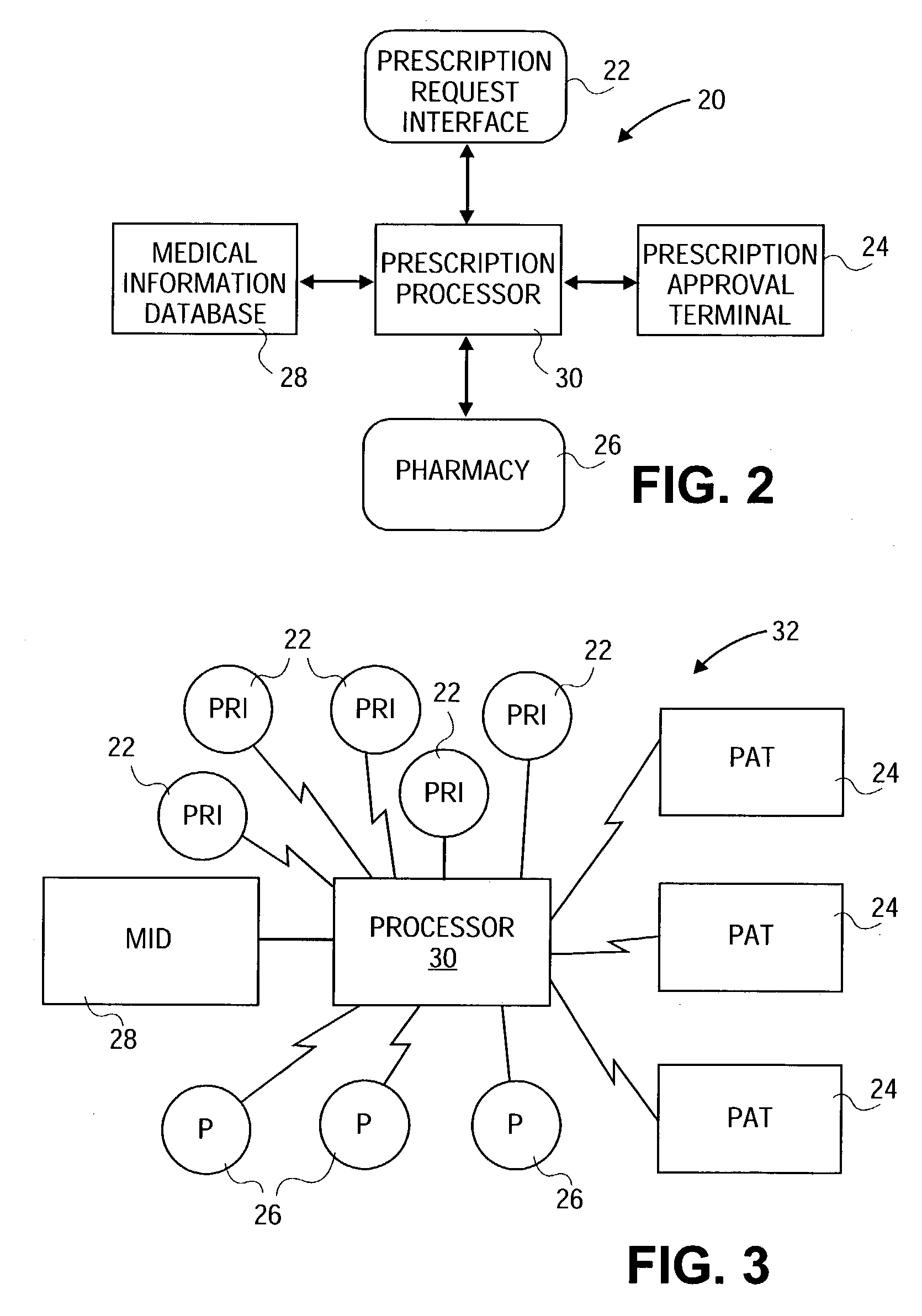

Prescription drug distribution system and methods

InactiveUS7469213B1Improve securityShort amount of timeDrug and medicationsPayment architectureLifestyle drugDistribution system

Secure methods of distributing and prescribing prescription medications and related systems significantly increase prescription medication distribution security. Applications of the present invention are particularly useful in prescribing and distributing lifestyle drugs where an actual physical examination is not necessarily required, but are similarly useful for all prescription medications. A system configured according to a particular embodiment of the present invention involves a prescription request kiosk, a prescription request review terminal, a medical information database, and a pharmacy all associated with a prescription distribution system processor. Particular embodiments of prescriptions of the present invention include a photograph of a prescription requestor on the prescription for added security along with additional follow-up questions to be asked by the pharmacist to the customer. Requestors initiate prescription requests by answering a plurality of questions related specifically to the prescription medications requested.

Owner:SECURE MEDICAL

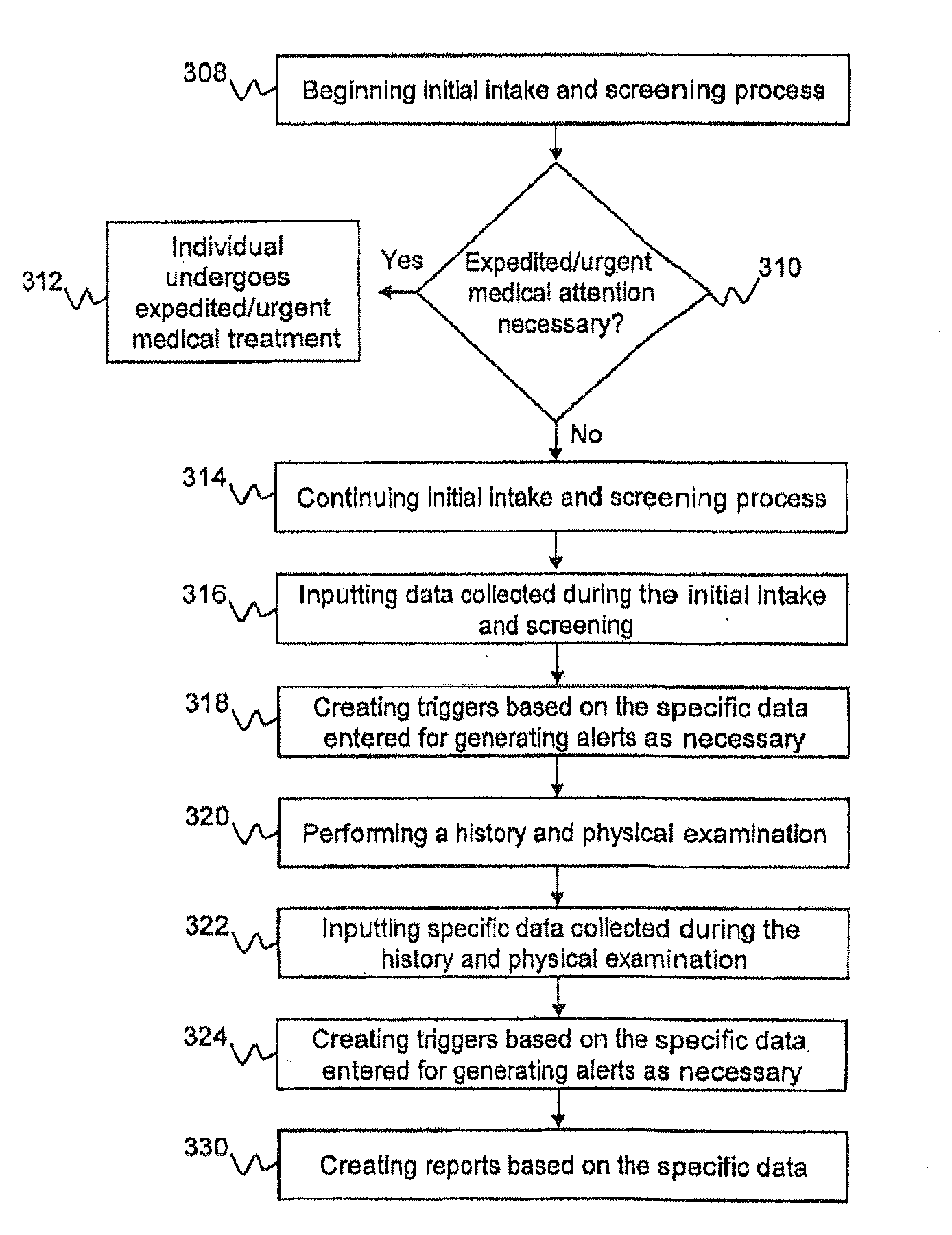

Comprehensive method and system for intake screening and medical records management

InactiveUS20110015943A1Little orDrug and medicationsComputer-assisted medical data acquisitionMedical recordRecords management

A system and method for providing health care services, such as medical intake screening and follow-up patient care, including management of medical records and access to patient information for incarcerated individuals. Data regarding medical information collected during an initial intake and screening process and subsequent physical examination may be inputted into a data repository. Triggers based upon the specific data entered may generate alerts for follow up medical care.

Owner:PRISON HEALTH SERVICES INC

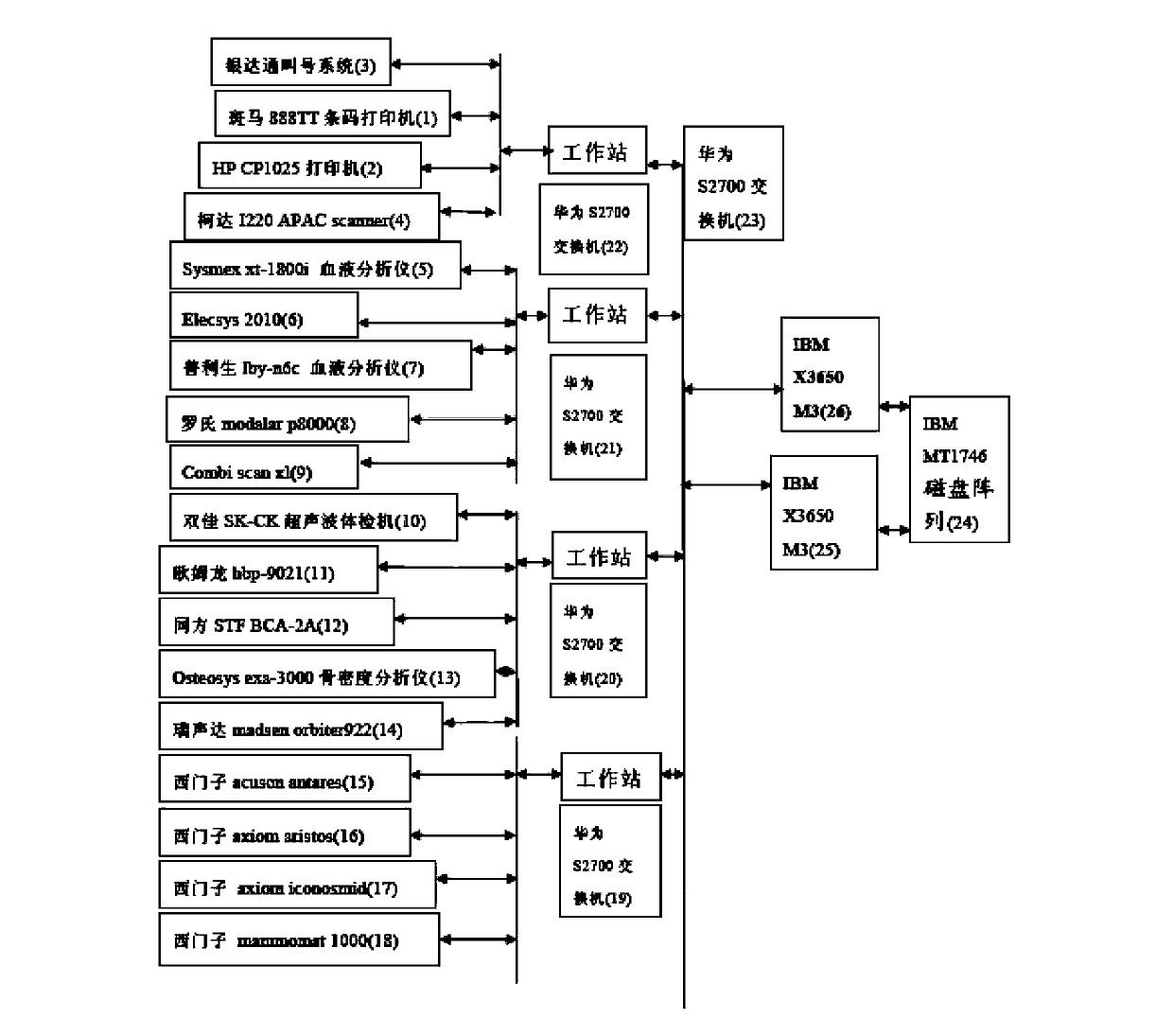

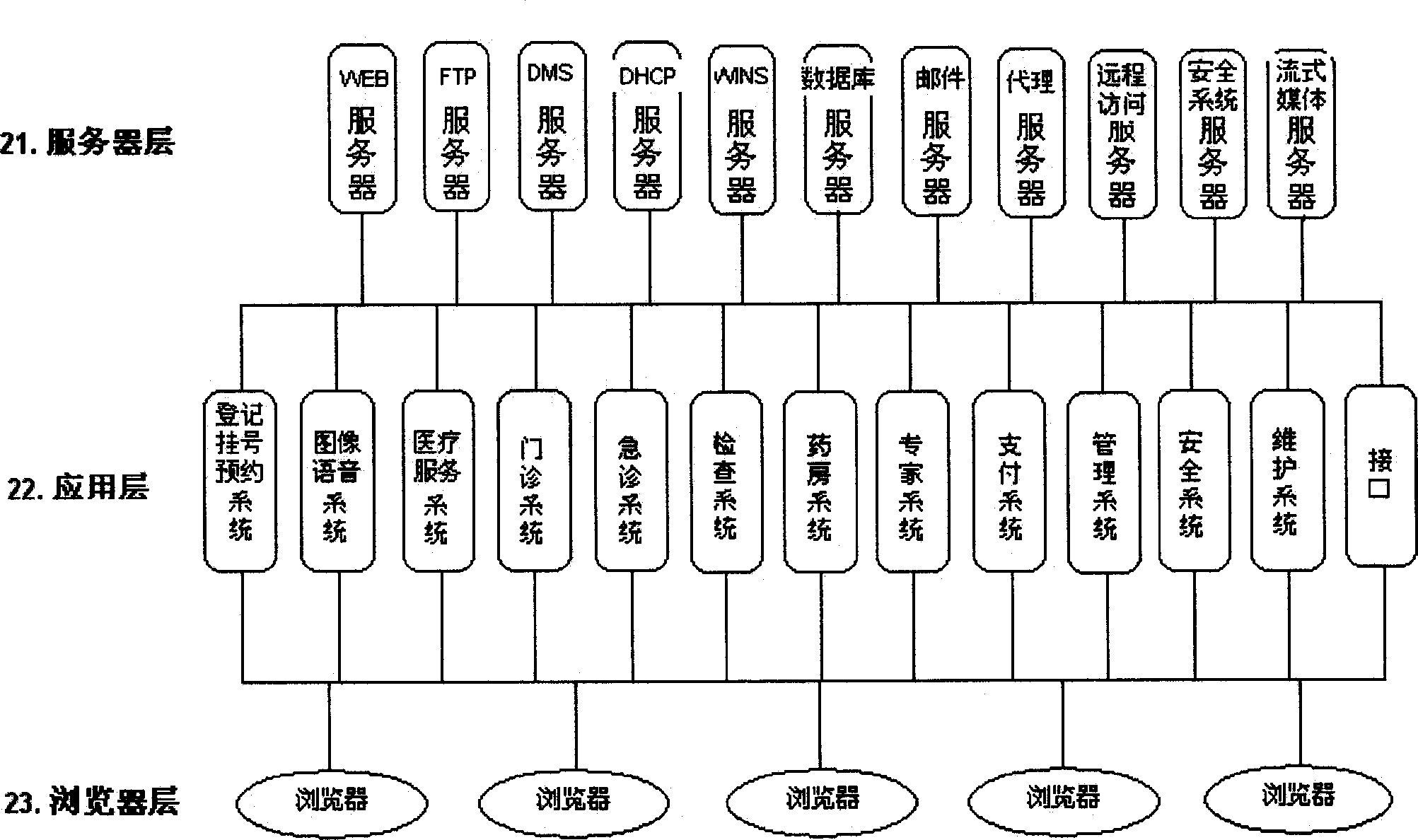

Physical examination control system and control method

ActiveCN103971304AContinuous Health ManagementContinuous tracking of health managementData processing applicationsControl systemPriority queuing

The invention discloses a physical examination control system and control method. The physical examination control system comprises an information system, a physical examination batch appointment module, a queuing module and multiple department examination modules, wherein the information system is used for storing all information of a physical examinee and allowing the information of the physical examinee to be retrieved, inquired and updated; the physical examination batch appointment module is used for making appointments on client information, physical examination dates and physical examination batches and informing the information system of the appointment information; the queuing module with dispatching priority is used for conducing automatic queuing and simultaneously receiving priority queuing information of the information system; the department examination modules are connected with corresponding examination devices in departments and used for conducting examination according to clients allocated by the queuing module, inputting results and centralizing the results into the information system for united sorting. Through the physical examination control system, automatic queuing integrating batch register and green channels can be achieved, and the physical examination control system can conduct continuous follow-up health management on the clients.

Owner:厦门湖里国宇门诊部

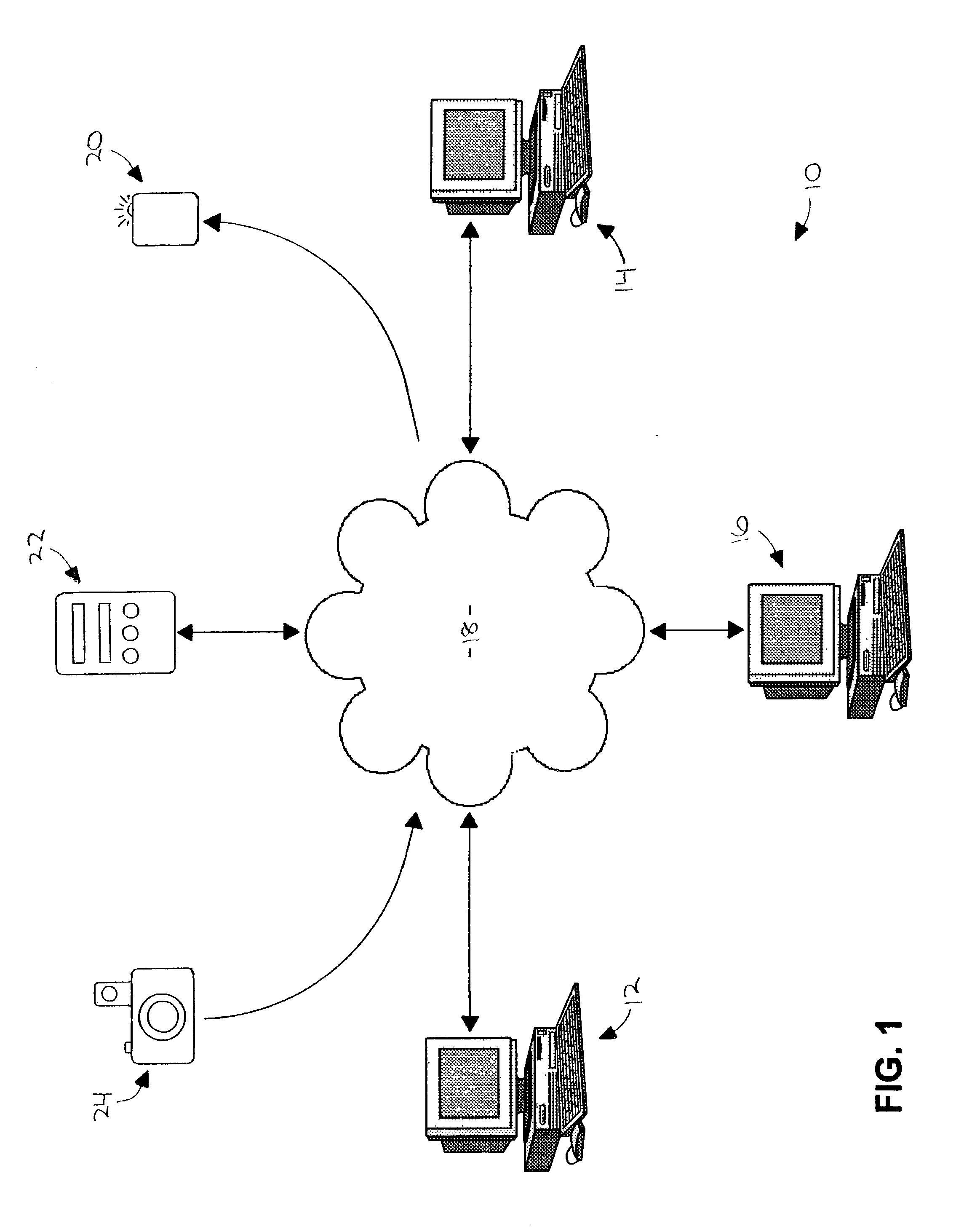

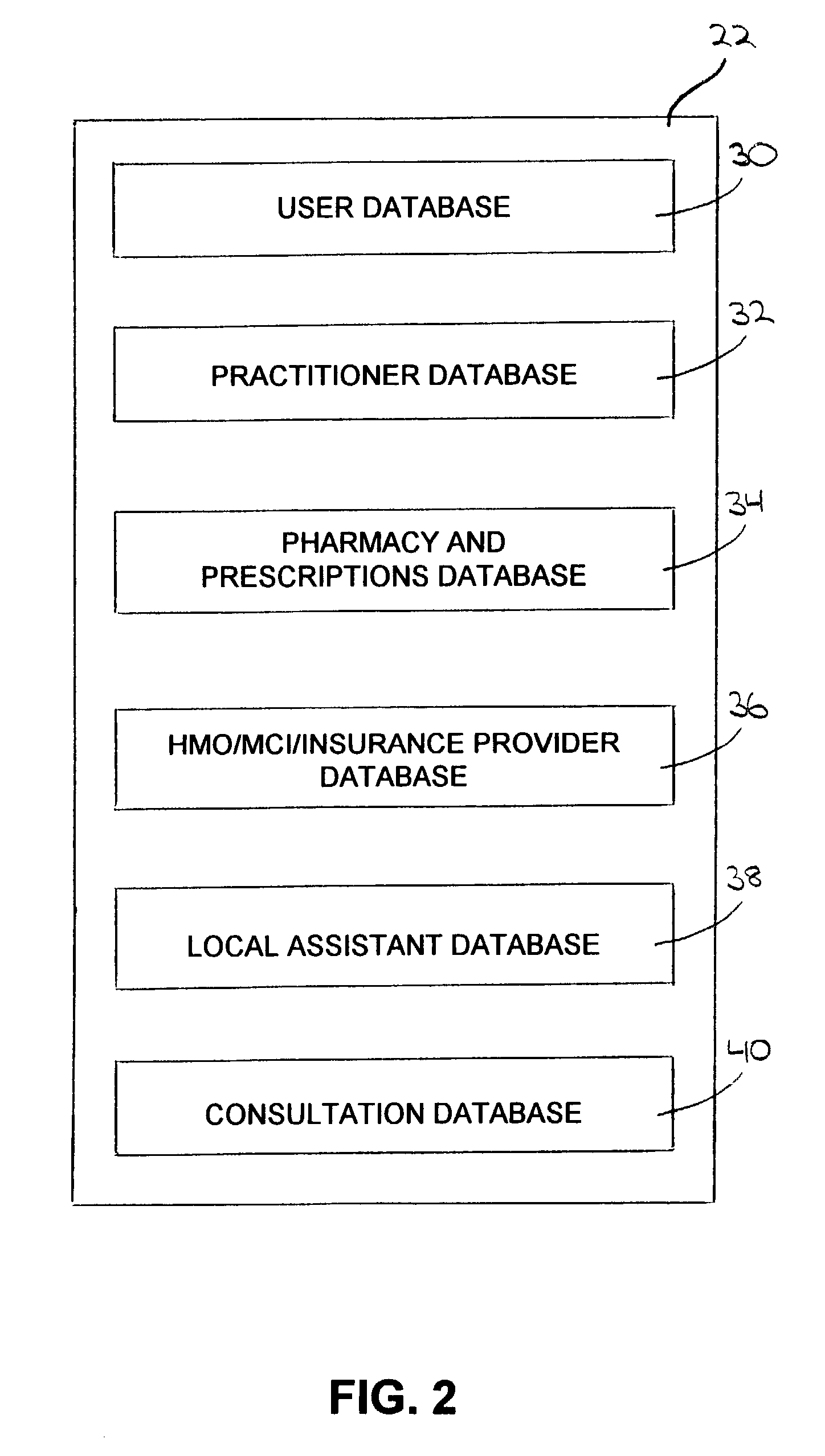

Method of facilitating access to remote health-related services, practitioners, and information

InactiveUS20030120513A1Expand accessLow costMedical communicationDigital data processing detailsPharmacyMedical prescription

A method of facilitating access to and consultation with a remote healthcare practitioner or other health-related service or information provider via a real-time interactive interface and over a network. Users can search via the interface among registered remote practitioners using a variety of search parameters to select a suitable remote practitioner. During the consultation, the remote practitioner can search via the interface among registered pharmacies using a variety of parameters to identify a suitable pharmacy to send prescription information to via the interface for the user. Also during the consultation, the remote practitioner can search via the interface among registered local assistants using a variety of search parameters to identify a suitable local assistant to send to the user's location to conduct a physical examination, procedure, or other action, the results of which are communicated via the interface to the remote practitioner.

Owner:SAMAQUIAL MICHAEL REY

Health diet control system and method thereof

InactiveCN101038656AImprove the level of scientific dietImprove nutritional healthData processing applicationsDiet controlledStatistical analysis

The invention relates to a healthy dietetic control system and a method thereof, the system comprises a server, a plurality of client terminals and a plurality of ID card, in which the server is connected with the plurality of client terminals by data lines; the system further comprises a physical examination recording device, wherein nutrition diet devices are provided in the client terminals. The invention is able to statistically analyse kinds and amount of nutritional food when a user repasts at different locations, generate a health evaluation information information by combining with a physical examination information to effectively control a bad dietetic structure, thereby realizing an object of uniform nutrition, effectively improving a scientific dietetic level of the user, increasing dietetic nutrition knowledge. With increase of individual users, the nutritional healthy level of a special public can be improved. The invention has a wide application to effectively improve the nutritional healthy level of the country and perform a positive action for accelerating health of the country.

Owner:DONGGUAN SAIKALYULA ELECTROMECHANICAL TECH DEV

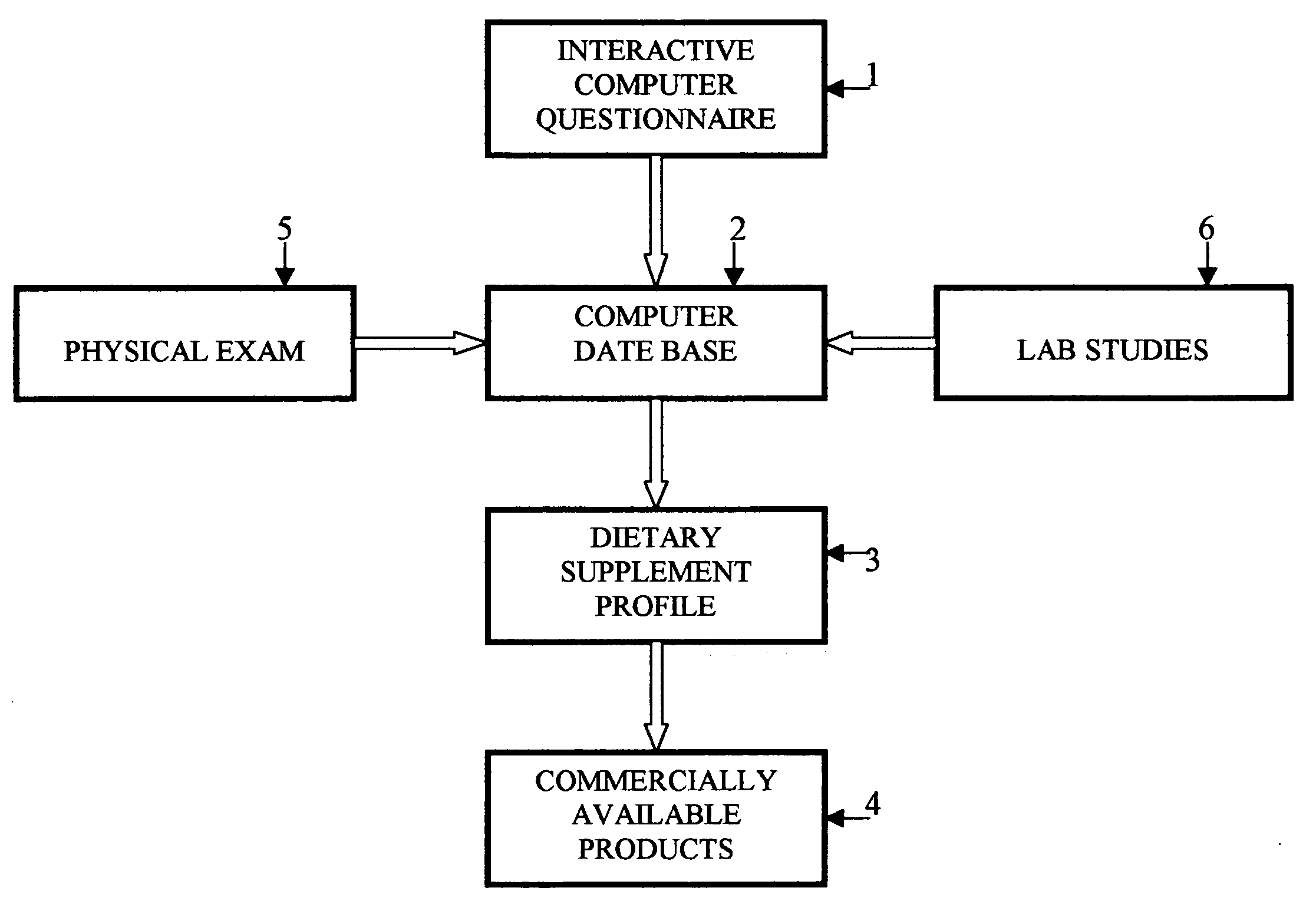

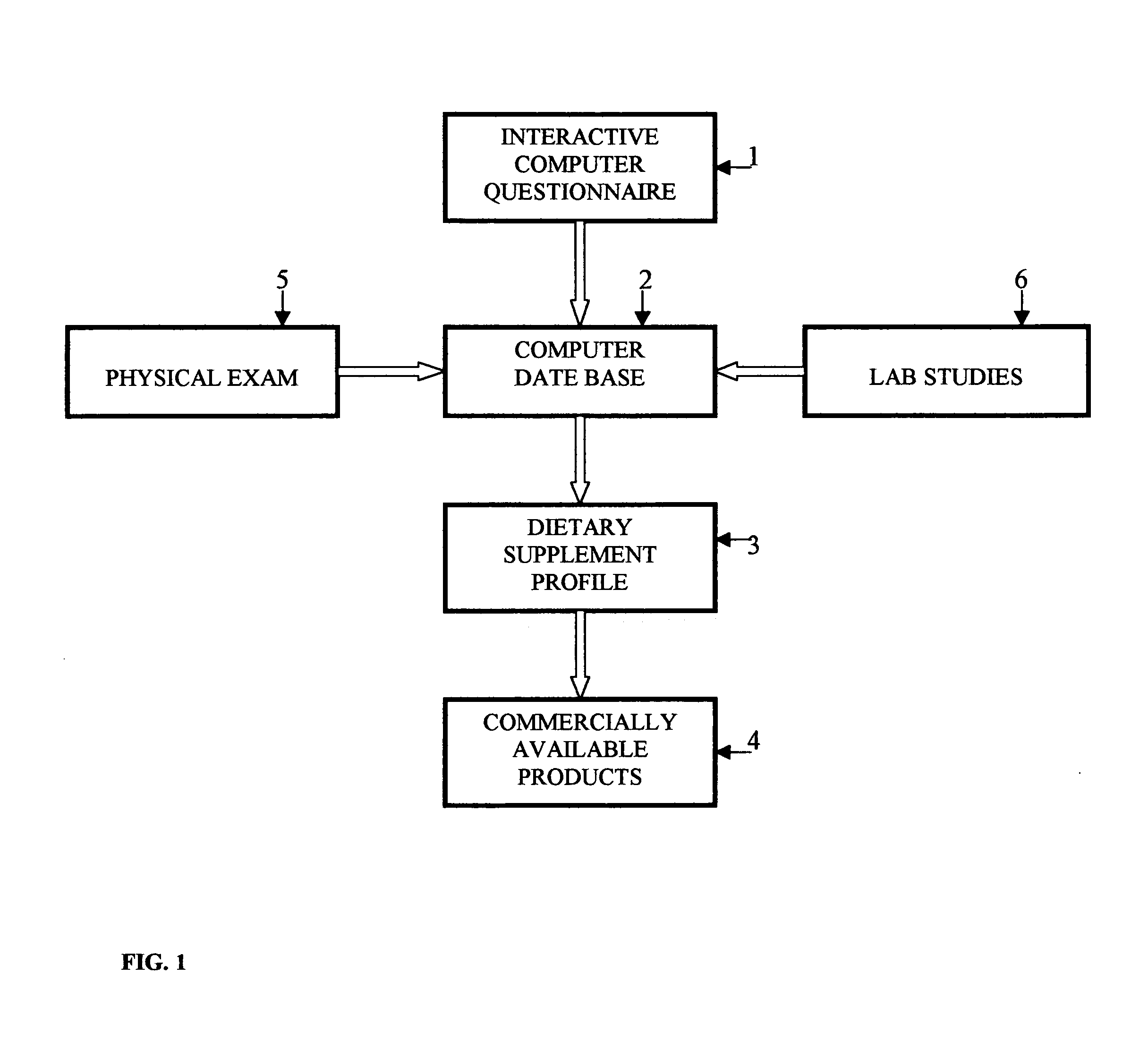

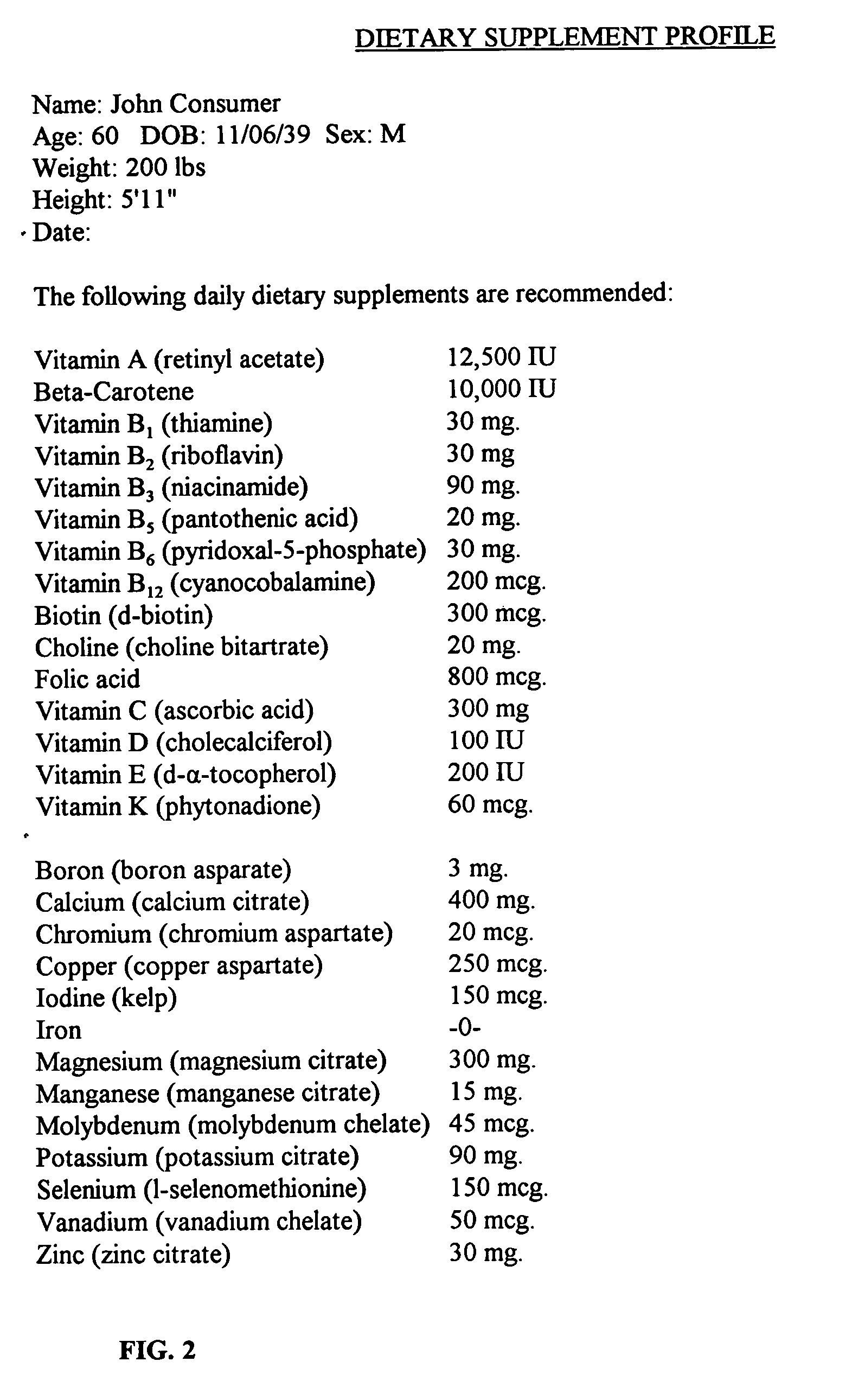

Method/process of determining a personal dietary supplement profile and recommending dietary supplements for an individual

InactiveUS7136820B1Enhance the imageData processing applicationsNutrition controlDietary supplementNutritional Supplementation

This invention provides a method / process of determining a personal dietary supplement profile of vitamins, minerals, amino acids, enzymes, herbs, and other nutritional supplements for an individual based on information from a health questionnaire and comparing the individual's health information to an ideal health profile in a computer data base. Optionally, information provided by physical examination and laboratory studies can be incorporated into the method / process of determining the dietary supplement profile. The profile can be further defined by listing commercially available products that provide the suggested dietary supplements.

Owner:ADVANCED MEDICAL INSTR

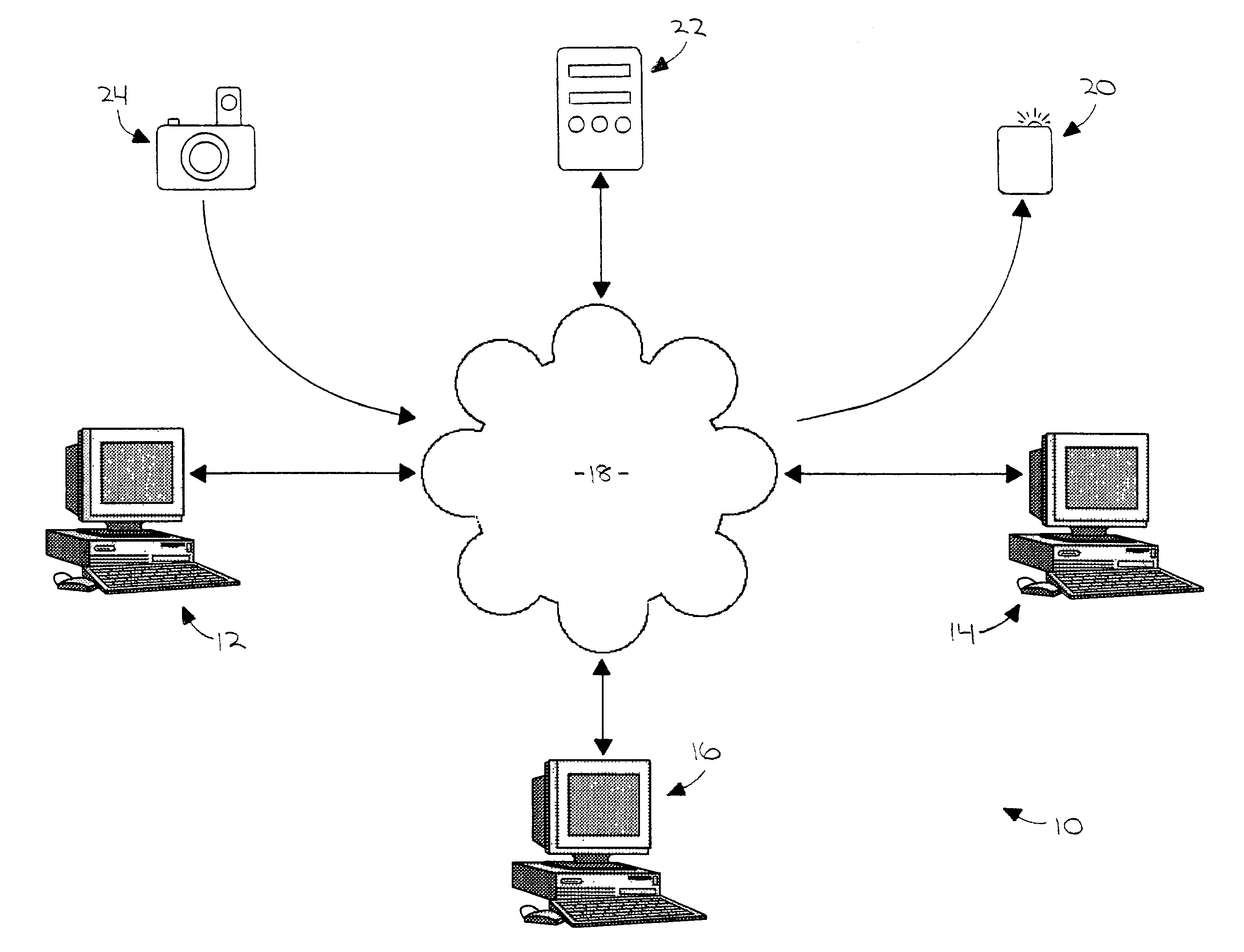

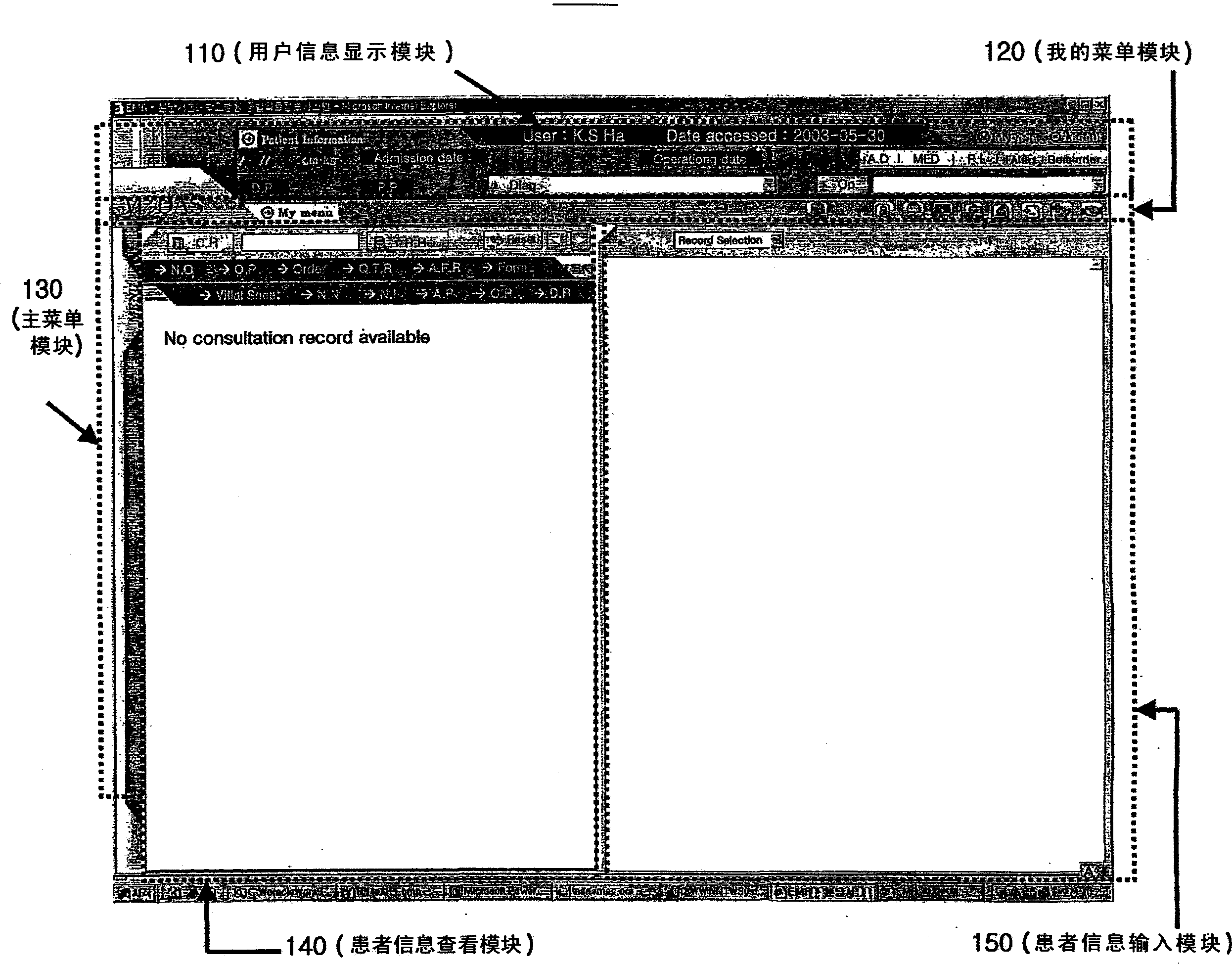

Method for Managing Medical Information Online

Disclosed is a method for managing medical information online, in which documents of various formats created by physicians during or after treatment, nursing notes created by nurses during or after nursing service, and other various notes or reports created by clinical laboratory staff during or after physical examinations performed on the patients are presented through a network and a variety of information input through the network is comprehensively managed to be later given users having access rights to the information, thereby enabling the users to share the variety of information.

Owner:EZCARETECH +1

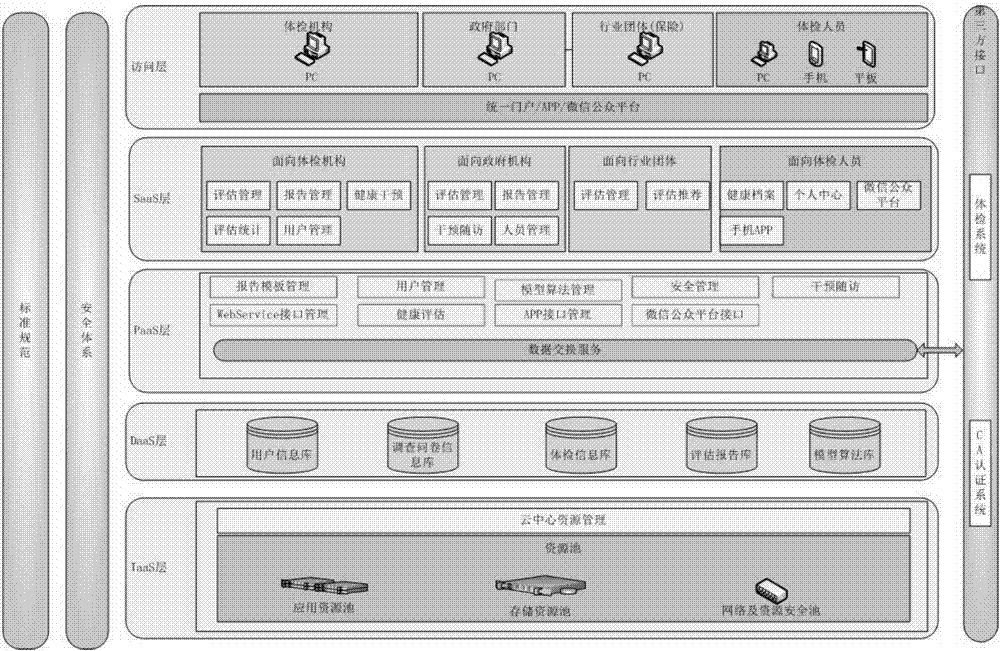

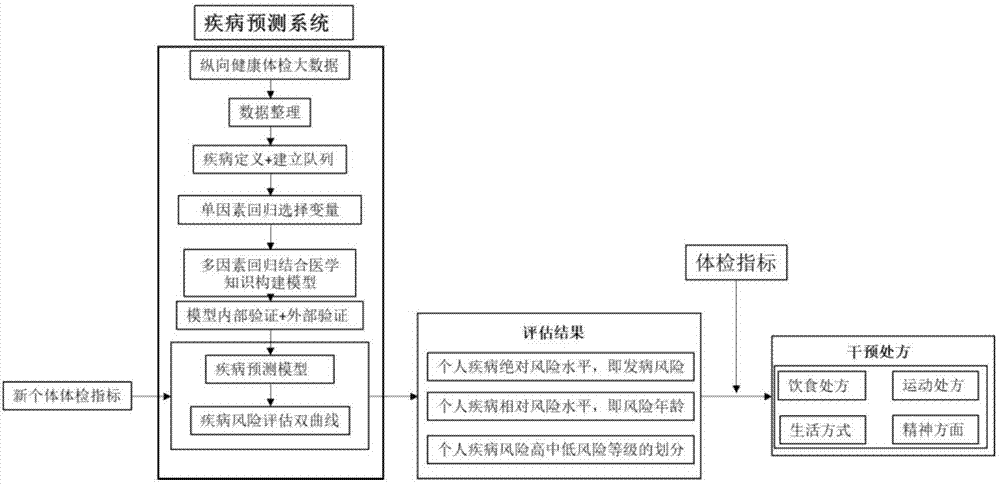

Disease risk assessment and personalized health report generation system and method

ActiveCN107085666AEfficient usabilityEasy to operateHealth-index calculationSpecial data processing applicationsDisease riskPersonalization

The present invention discloses a disease risk assessment and personalized health report generation system and method. The method comprises: inputting longitudinal health examination big data; arranging the data; defining the threshold range of various indicators of the disease according to the name of the disease, and using the sas software to establish a corresponding disease queue according to the threshold range of various indicators of the disease; and after establishing the queue, using the cox single factor regression analysis method to carry out variable selection on each variable; carrying out multi-factor regression analysis on the variables incorporated into the cox regression model; establishing a cox proportional risk model; verifying the inside of the cox proportional risk mode, and verifying the outside of the cox proportional risk model; obtaining a disease prediction model; generating a disease risk assessment hyperbola; inputting new individual physical examination indicators, generating disease risk assessment results according to the disease prediction model and the disease risk assessment hyperbola, and outputting a disease risk assessment and personalized health report according to the preset indicators.

Owner:SHANDONG UNIV +1

Method for managing medical information online

Disclosed is a method for managing medical information online, in which documents of various formats created by physicians during or after treatment, nursing notes created by nurses during or after nursing service, and other various notes or reports created by clinical laboratory staff during or after physical examinations performed on the patients are presented through a network and a variety of information input through the network is comprehensively managed to be later given users having access rights to the information, thereby enabling the users to share the variety of information.

Owner:EZCARETECH

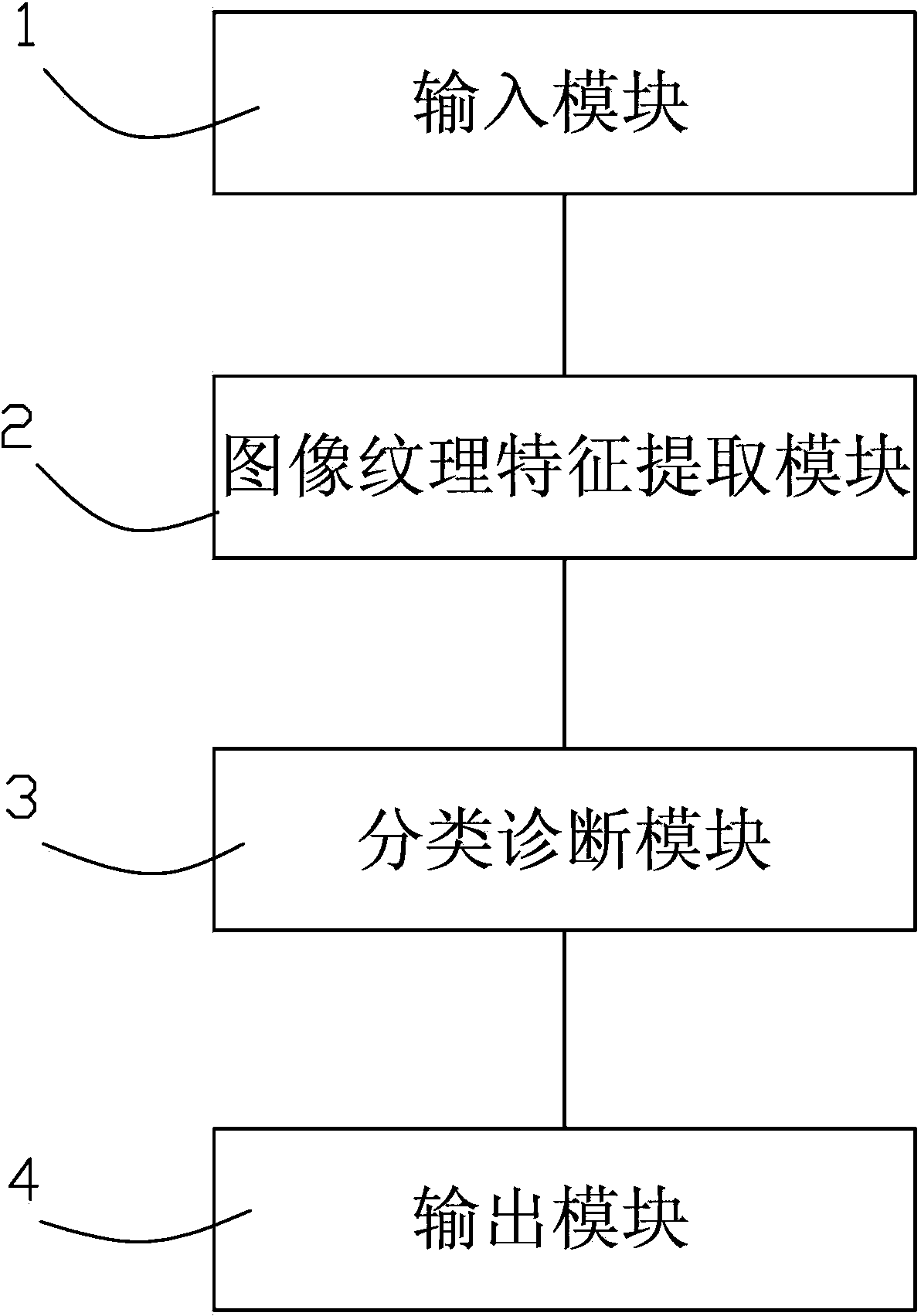

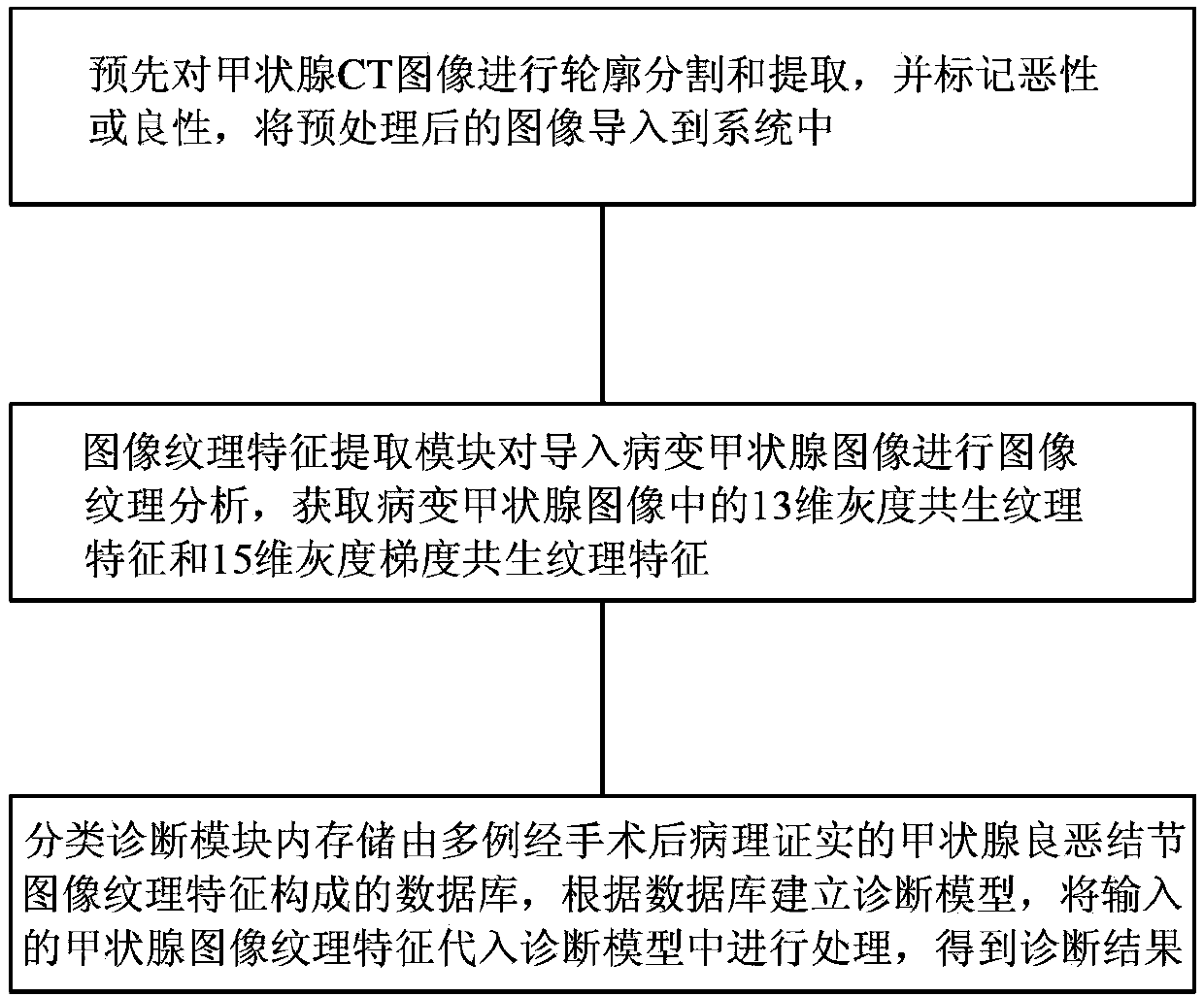

Thyroid CT image computer-aided diagnosis system and method

InactiveCN104000619AReduce complexityAvoid the influence of human subjective factorsComputerised tomographsTomographyPattern recognitionDisease

The invention relates to a thyroid CT image computer-aided diagnosis system and method. The problem that currently, many defects exist in the thyroid disease diagnosis through physical examination, ultrasonic scanning and radioisotope scanning is solved. The system comprises an input module, an image texture characteristic extracting module, a classified diagnosis module and an output module which are sequentially connected. The method includes the steps of conducting outline segmenting and extracting on an image, then conducting texture characteristic analysis on the image to obtain the 28-dimension texture characteristic, and finally substituting the 28-dimension texture characteristic into a diagnosis model to obtain a diagnosis result and a statistics index. The thyroid CT image computer-aided diagnosis system and method have the advantages that non-invasiveness, rapidness and timeliness are achieved; no chemical reagents or the like are needed, and cost is low; complexity of a lesion thyroid texture characteristic sample set is effectively reduced, and identification accuracy can be further improved; the result is not affected by man-made subjective factors and is prevented from being affected by man-made subjective factors in the pathological examination and other examinations.

Owner:彭文献

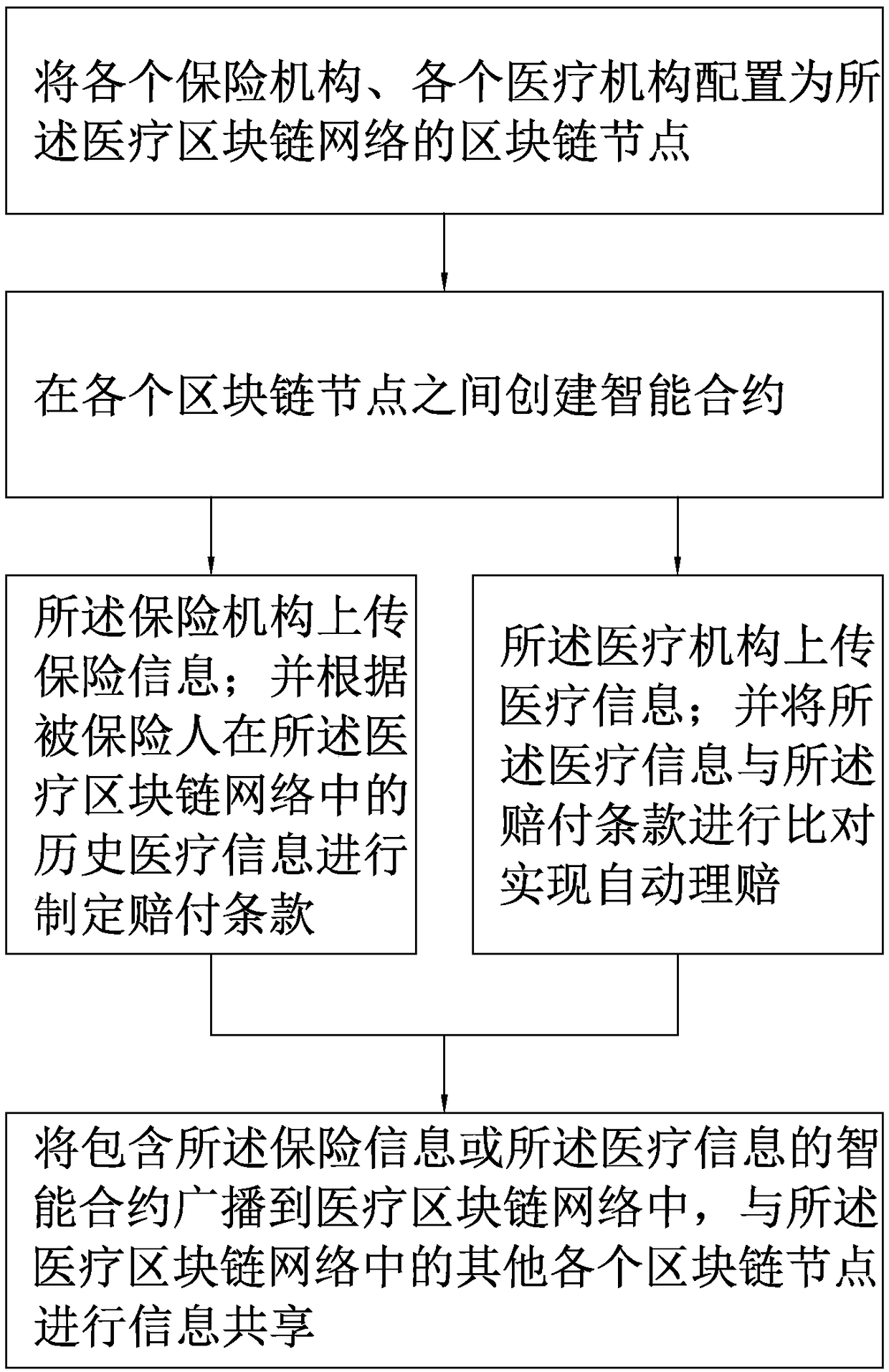

Block chain technology-based personal insurance decision support method and system

ActiveCN108711108ASave medical examination costsReduce claims riskFinanceChain networkSmart contract

The invention discloses a block chain technology-based personal insurance decision support method and system. The method comprises the following steps of: configuring each insurance mechanism and eachmedical mechanism as block chain nodes of a medical block chain network, uploading insurance information by the insurance mechanism through an intelligent contract, and uploading medical informationby the medical mechanisms through the intelligent contract; when the insurance mechanisms upload the insurance information, formulating compensation clauses according to history medical information ofthe insured in the medical block chain network; and when the medical mechanisms upload the medical information, inputting the medical information according to preset formats which are correspondinglymatched with the compensation clauses in the insurance information, and comparing the medical information with the compensation clauses to realize automatic claim settlement. According to the methodand system, insurance, treatment and claim settlement are arranged on a same medical block chain, and automatic matching is carried out through an anonymous identity and chain authentic right manner,so that the insurance efficiency of insurance companies is improved, the physical examination cost is saved, and personal privacies of the insured can be better protected.

Owner:XIAMEN KUAISHANGTONG INFORMATION TECH CO LTD

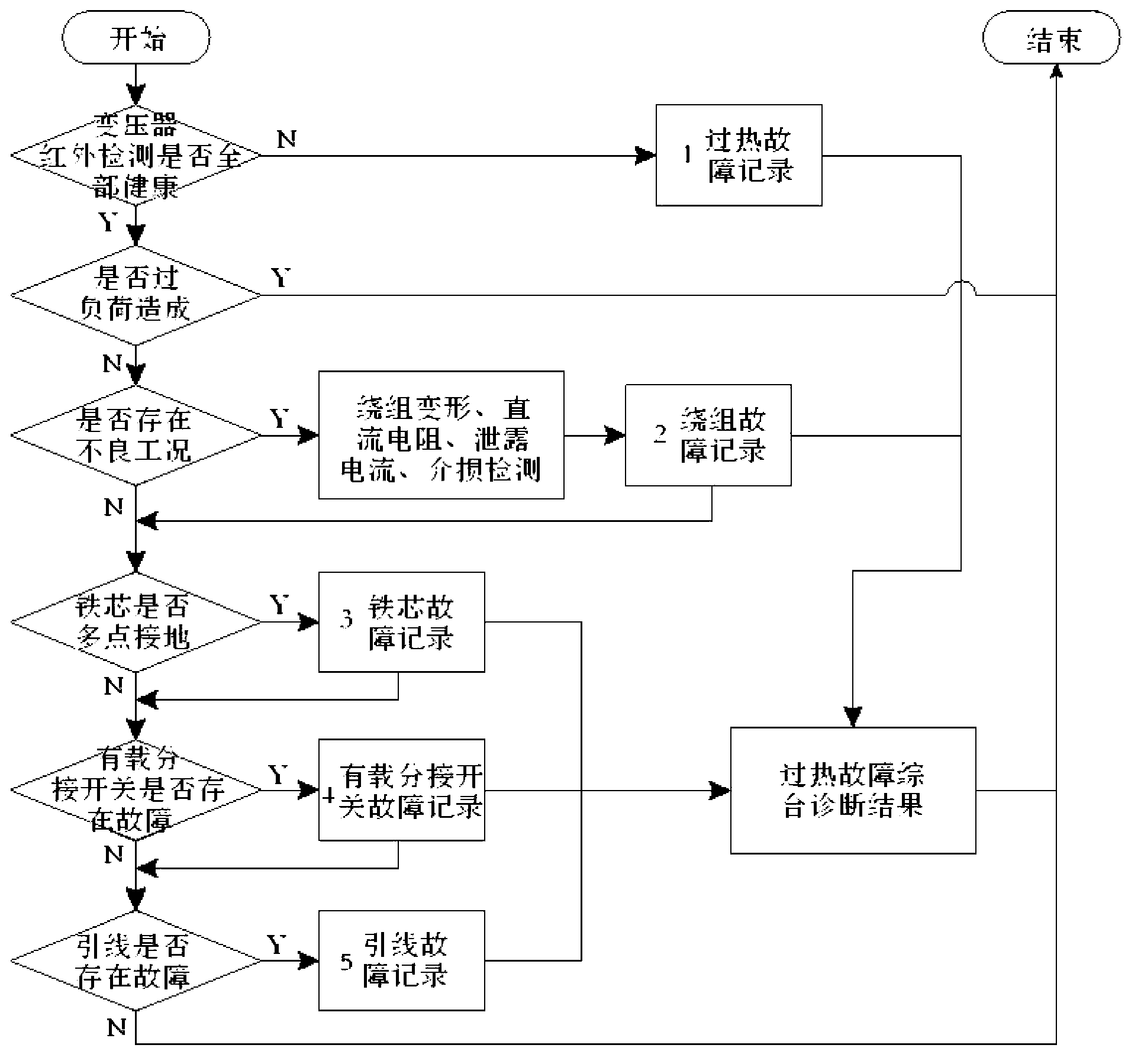

Fault diagnosis method based on transformer panoramic state information

InactiveCN103076526ACheck out hidden troublesSafe and stable operationElectrical testingDiagnosis methodsTransformer

The invention discloses a fault diagnosis method based on transformer panoramic state information, and the fault diagnosis method is characterized in that equipment panoramic information such as online monitoring, test data, infrared detection and unfavorable working conditions are combined, the diagnosis of dissolved gas in oil is adopted as a starting point, and the diagnosis of the working condition of each part of a transformer is adopted as supplementation. The fault diagnosis method based on the transformer panoramic state information belongs to an expert diagnosis system of the transformer, the comprehensive physical examination information of the transformer can be obtained through the method, a fault can be located, a fault potential danger of the transformer can be thoroughly examined, the overhauling efficiency of equipment can be increased, the repeated power failure caused by the overhauling of the equipment can be reduced, the power supply reliability can be improved, and an important significance for enabling the safe and stable running of a power system can be realized.

Owner:STATE GRID ELECTRIC POWER RES INST +2

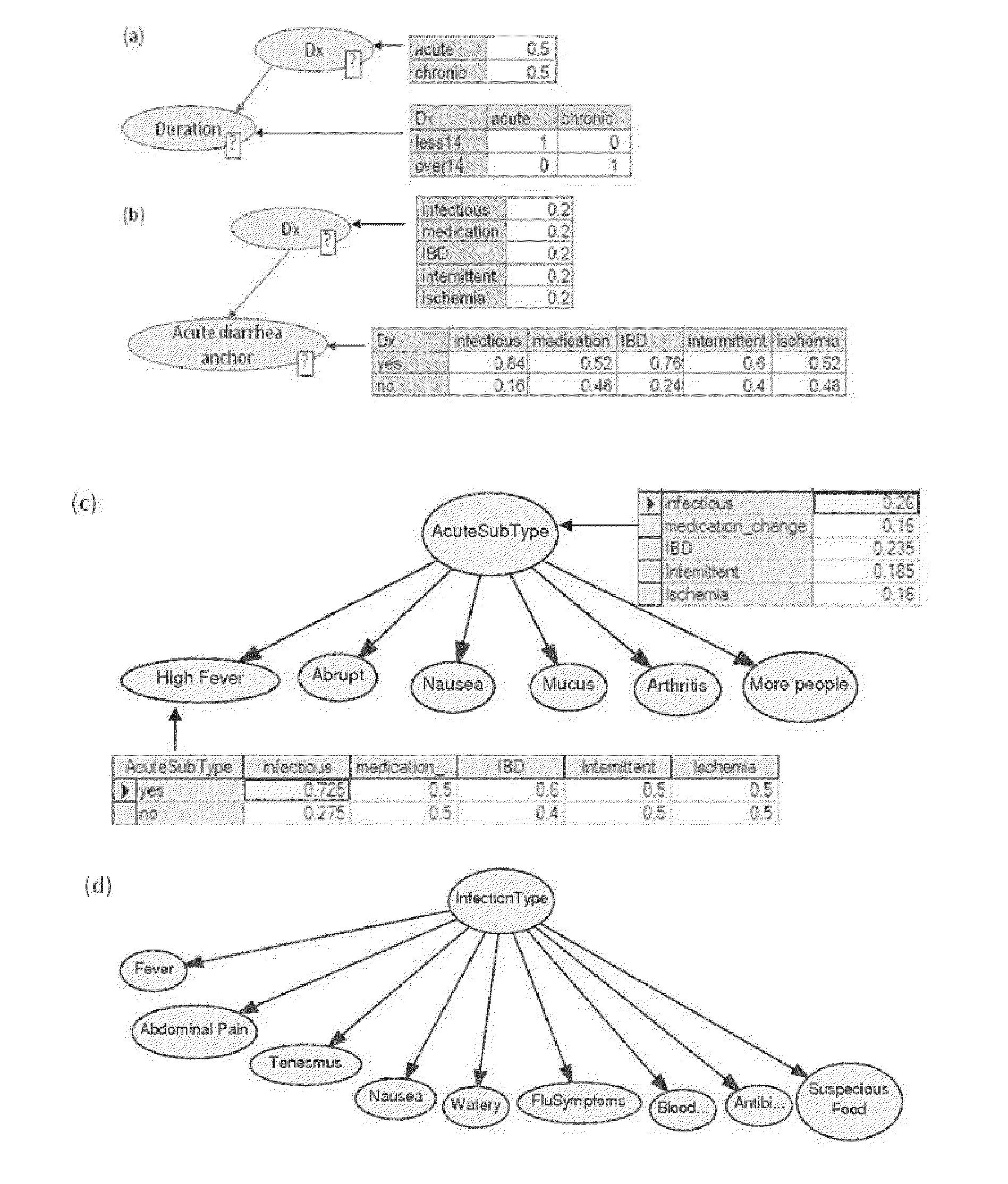

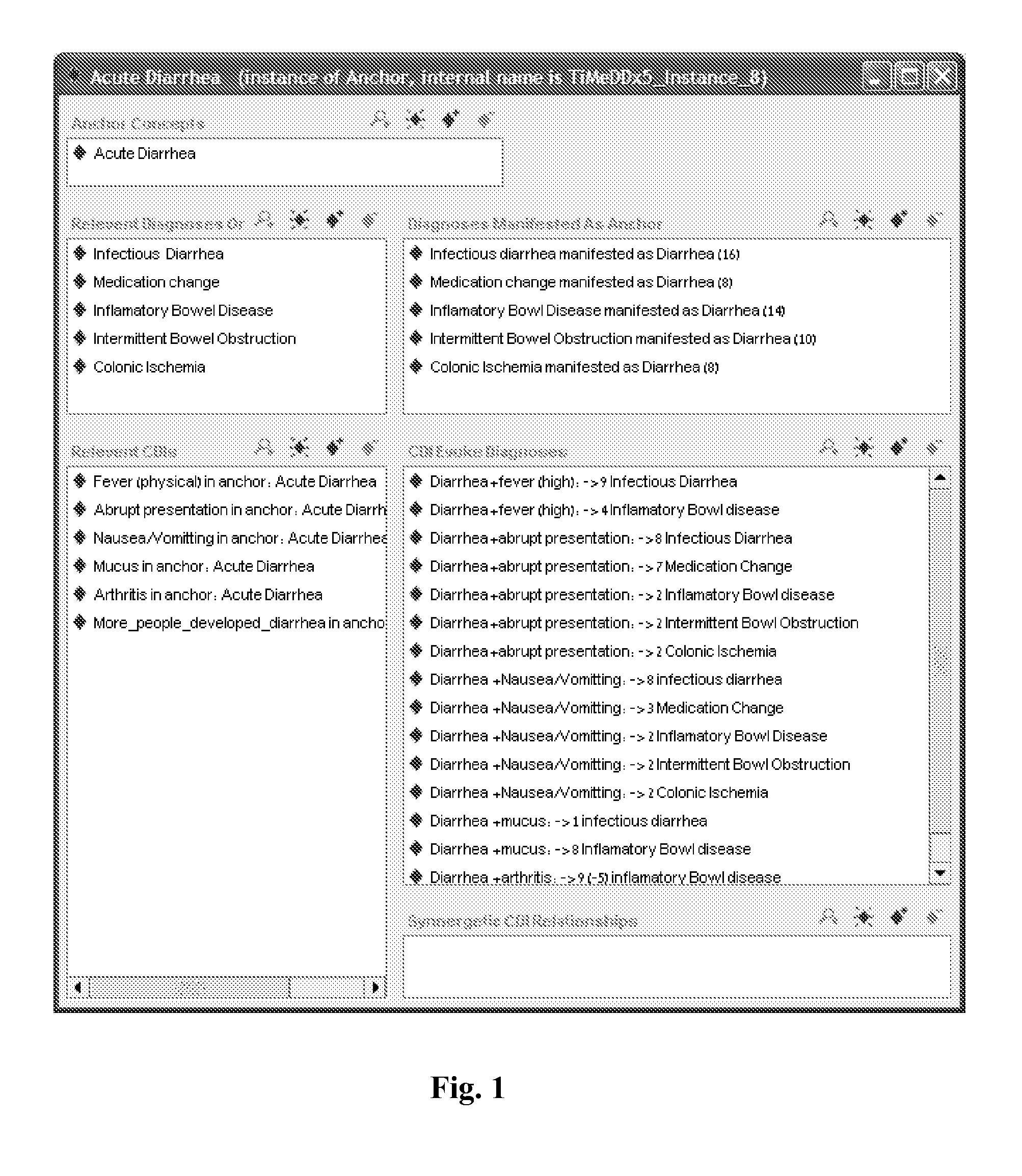

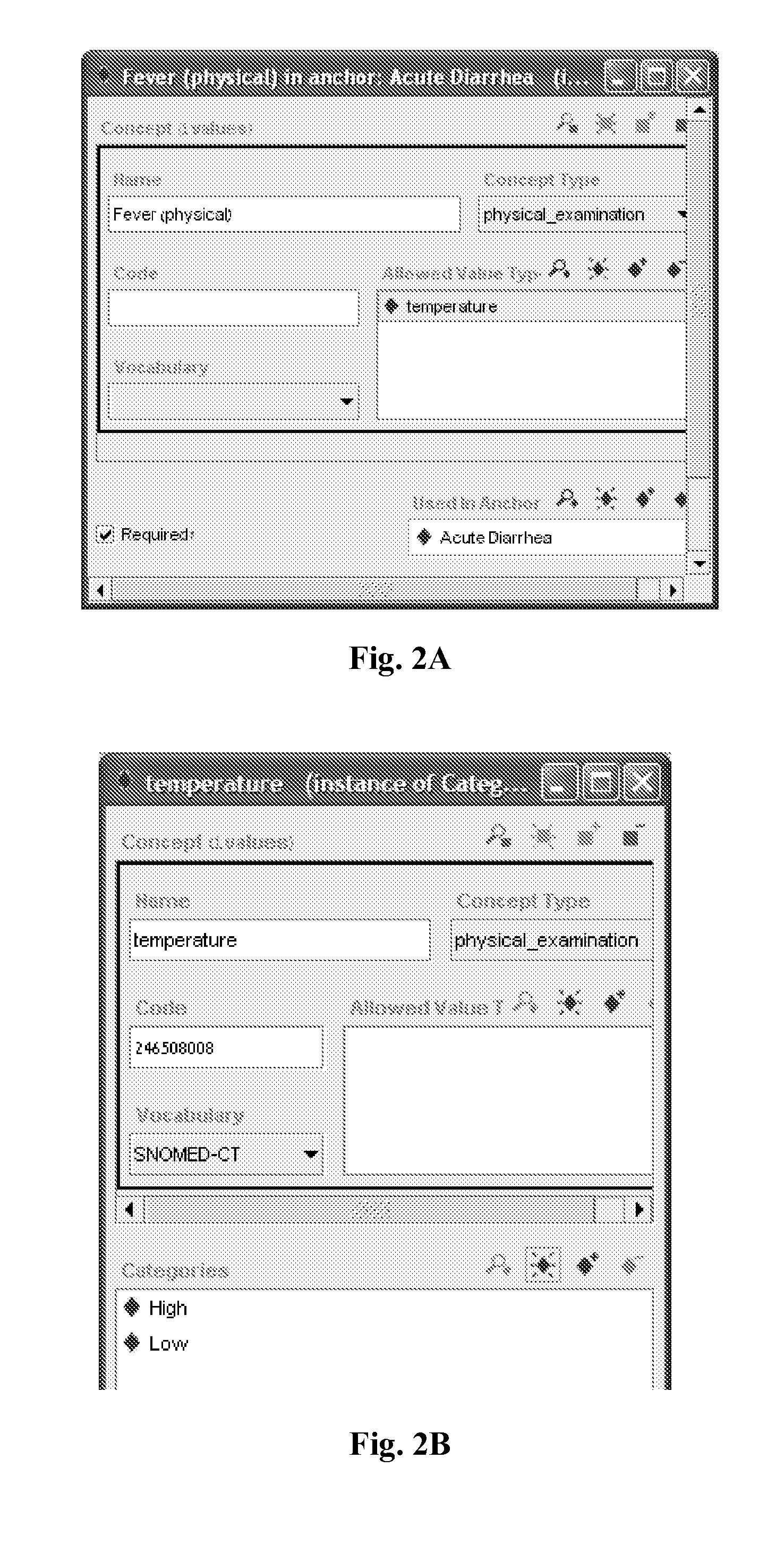

Multi-phase anchor-based diagnostic decision-support method and system

InactiveUS20110257988A1Efficient conductionData processing applicationsHealth-index calculationLaboratory Test ResultHealth professionals

A medical diagnosis decision support system for assisting a health professional to diagnose a medical condition. The system is first provided with an anchor condition that can be a symptom, a sign, a laboratory test result, or an imaging test results or any combination thereof The system then guides users in a series of predetermined phases regarding abstract or concrete diagnosis groups that should be considered and appropriate data that should be collected during the clinical investigation process. The system suggests history and physical examination clinical data items, laboratory, and imaging tests that should be collected in order to differentiate among alternative diagnoses. In each phase, possible diagnoses are listed and ranked.

Owner:MOR RES APPL LTD +1

Intelligent cooking system capable of judging user preferences and collecting user health information and application of intelligent cooking system

ActiveCN104983295AEarn trustRealize automatic operationCooking vesselsTransmissionLife qualityHome environment

The invention relates to an intelligent cooking system capable of judging user preferences and collecting user health information. The system comprises an intelligent cooking device, a cloud server, an intelligent terminal and a physical examination sensor. The physical examination sensor forms health information and sends the health information to the intelligent terminal and the cloud server. The cloud server acquires the characteristic information of the intelligent cooking device, and using habit records of a user are formed according to the characteristic information; the cloud server forms recommendation information according to the health information or the using habit records and sends the recommendation information to the intelligent terminal. The intelligent cooking system capable of judging the user preferences and collecting the user health information achieves full-automatic cooking according to an optimal scheme conforming to the current requirement of the user to the largest extent, a scientific, reasonable, suitable and healthy cooking service scheme according with the characteristics of the user is provided for the user by taking the using habits, health conditions and the like into consideration, a cloud service platform powerful in function is formed, an energy-saving, environment-friendly, green and healthy home environment is created, and the life quality of people is substantially improved.

Owner:GUANGDONG TONZE ELECTRIC CO LTD

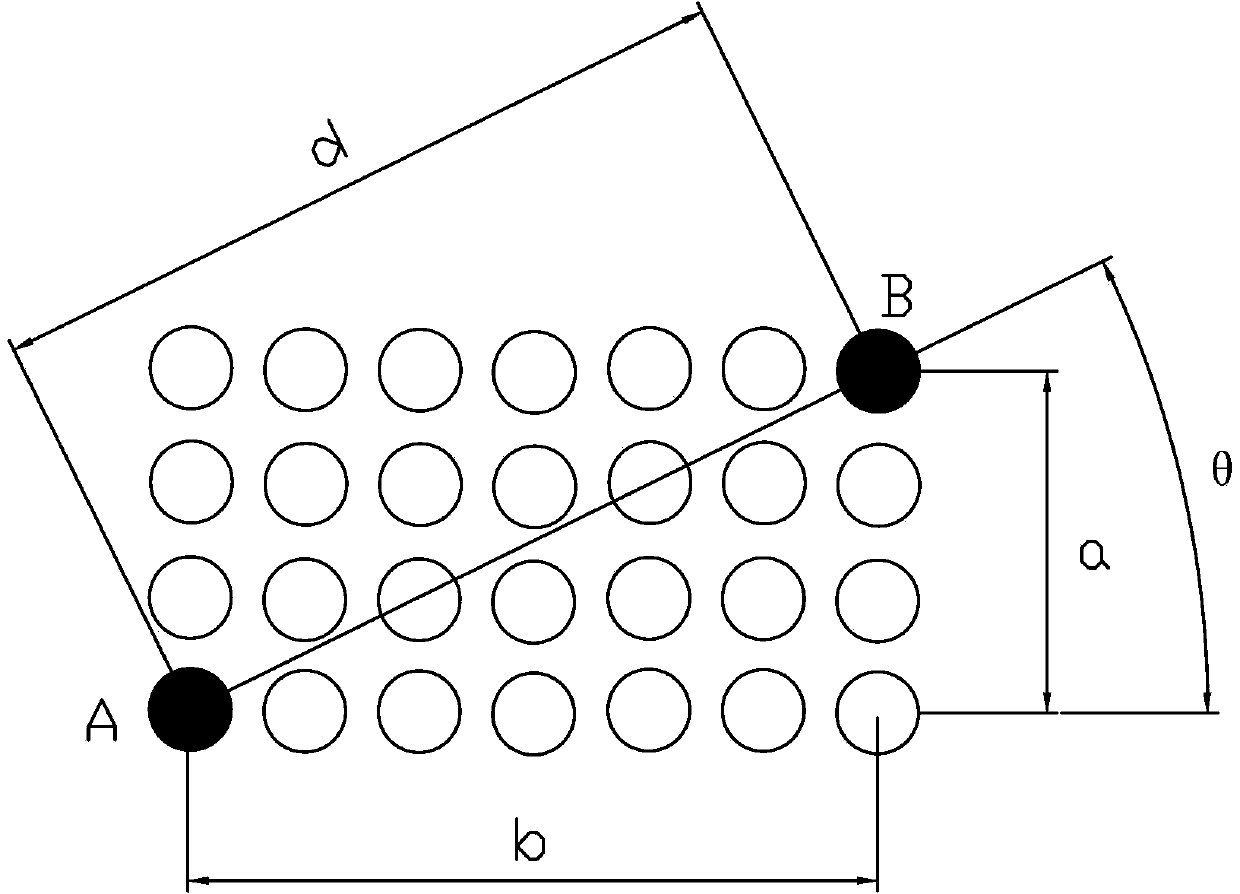

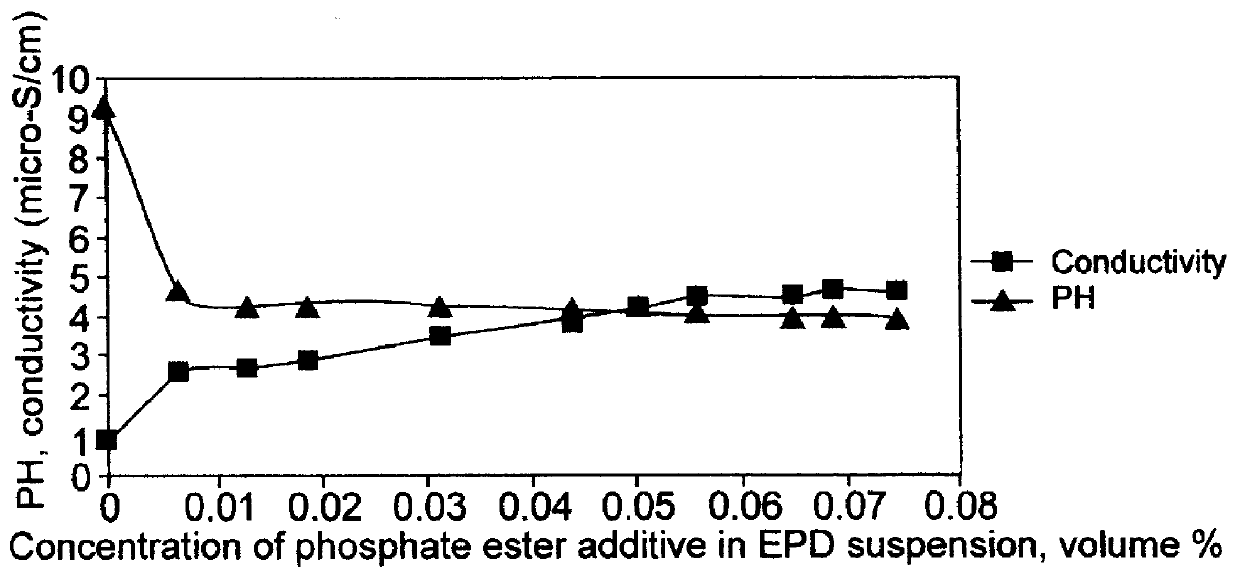

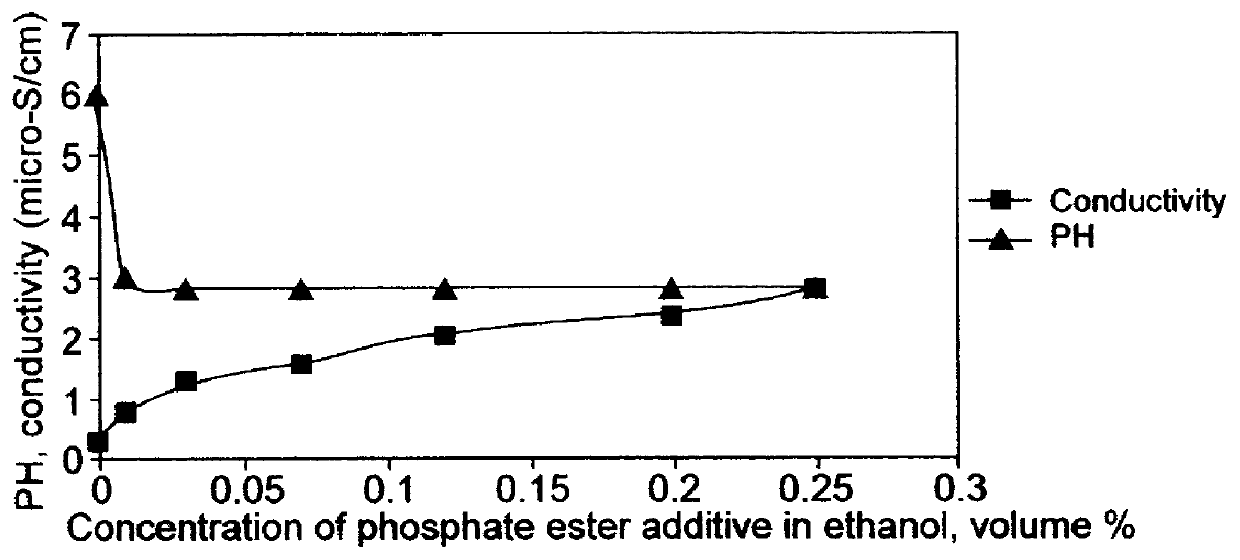

Method of electrophoretic deposition of ferroelectric films using a trifunctional additive and compositions for effecting same

InactiveUS6127283AEasy to manufactureSimple methodElectrolysis componentsVolume/mass flow measurementParticulatesPhosphate

An improved method for depositing ferroelectric particles on a surface of a substrate to form films or stand-alone bodies. The improvement is based on electrophoretic deposition (EPD) of ferroelectric films by using a tri-functional phosphate ester additive having a concentration less than 10 volume percent in the EPD suspension, without the need for addition of a binder. The method includes preparation of the suspension by washing and dispersing ferroelectric particles, for example, commercially available PZT powder, in a polar solvent such as ethanol, followed by addition of the phosphate ester additive to the suspension, and an ultrasound treatment. The suspension is used in EPD of the ferroelectric particles on a prepared substrate. Following EPD, the green film is dried and sintered at high temperature. Visual and physical examination of stand alone and patterned PZT deposited films show excellent quality obtained in manufacturing a diversity of piezoelectric products, featuring exceptionally high green film uniformity, thickness distribution, and reproducibility to within + / -2 microns for 20 micrometer film thickness. The phosphate ester additive functions by improving stabilization and control of suspension characteristics and properties during the electrophoretic migration process, and by improving desired dimensions, characteristics, and electrical properties of the deposited green film. Thin or thick ferroelectric films, either as stand alone products, or formed on geometrically demanding patterned or non-patterned substrates are produced by using the method. The improved method is applicable to different ferroelectric particulate materials and to different substrates used for manufacturing piezoelectric elements and devices, in a cost effective manner.

Owner:CEREL CERAMIC TECH

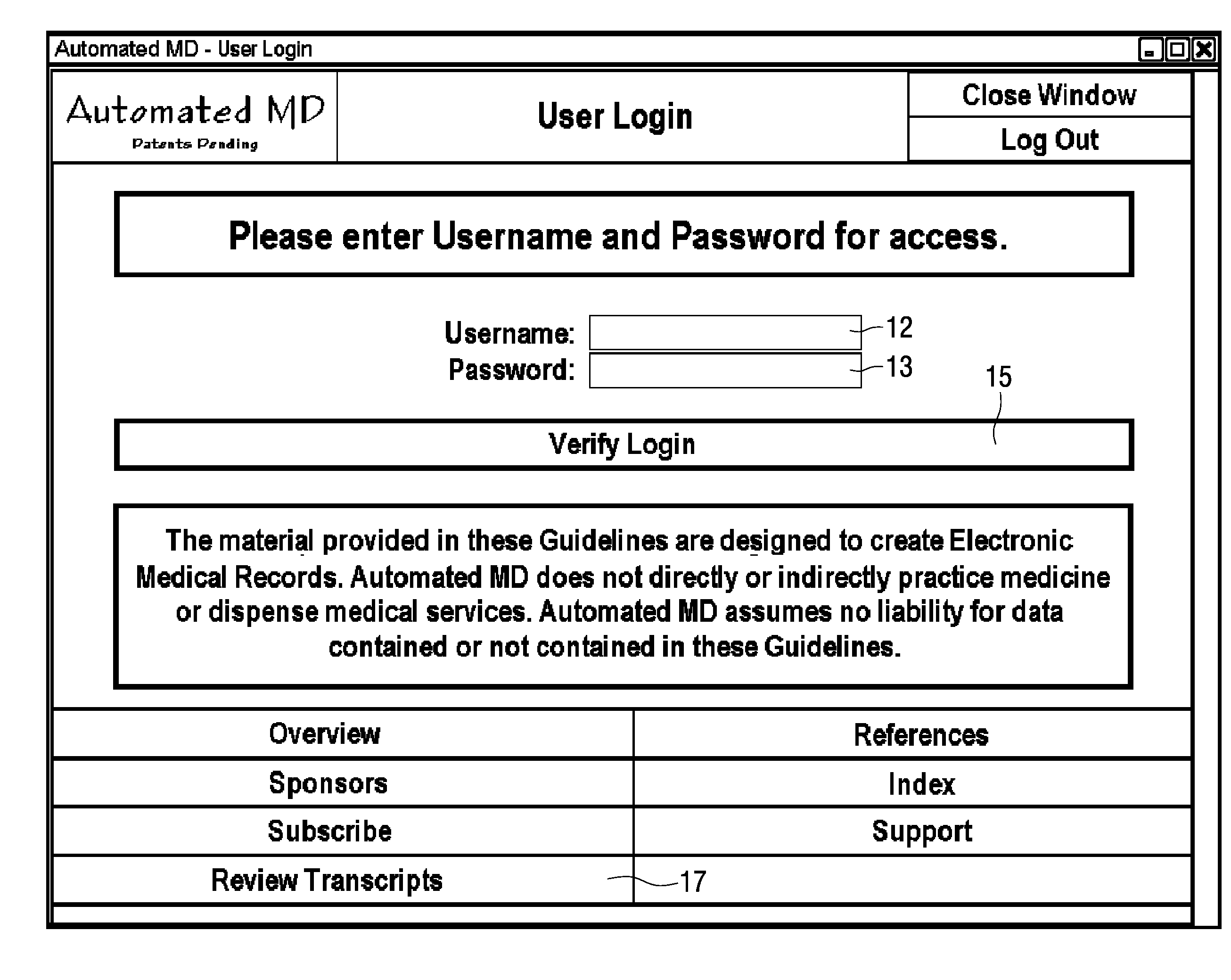

Apparatus, method and software for developing electronic documentation of imaging modalities, other radiological findings and physical examinations

ActiveUS20080242953A1Data processing applicationsMedical automated diagnosisImaging modalitiesRadiology studies

A system for guiding a user's physical examination of a patient and for generating a transcript. The system comprises: a screen requesting patient identification information, wherein the patient identification information excludes a patient name and further requesting patient medical history information; a screen requesting vital signs information; a screen requesting selection of an anatomical region of the patient for examination, wherein the user selects an anatomical region responsive to the request; a screen providing a plurality of possible observed symptoms related to the selected anatomical region, wherein the user selects one or more of the possible observed symptoms; a screen presenting possible findings that may be observed during the physical examination, wherein the user selects one or more of the possible findings based on the physical examination and a screen displaying a patient transcript responsive to information entered into the previous screens

Owner:DEW DOUGLAS K +5

Patient And Mobile Healthcare Worker Initiated Encounter In A Telemedicine System

InactiveUS20170011192A1Reduce complicationsObtain dataCharacter and pattern recognitionMedical imagesProper treatmentStatus changed

A telemedicine system including a care coordination software platform allows for patient monitoring at home and connects patients to their medical teams via telemedicine using a HIPAA compliant video portal augmented by remote assisted physical examination, performance of diagnostic testing including labs and x-rays, and provision of appropriate treatment and prescriptions. Medical care is provided at the patient's location without the patient having to travel or spend time in waiting rooms, provides treatment based on objective physical examination data and any appropriate diagnostic testing, and provides validation of patient identity. Healthcare providers are made available via online video encounters to communicate with patients. Allied healthcare workers are dispatched to be in physical proximity to the patient to assist in physical examination, and provide diagnostic data. Providers order appropriate treatments and prescriptions based on examination findings and diagnostics. The telemedicine system interfaces with medical sensors and collects data wired or wirelessly.

Owner:MI EXPRESS CARE LICENSING CO LLC

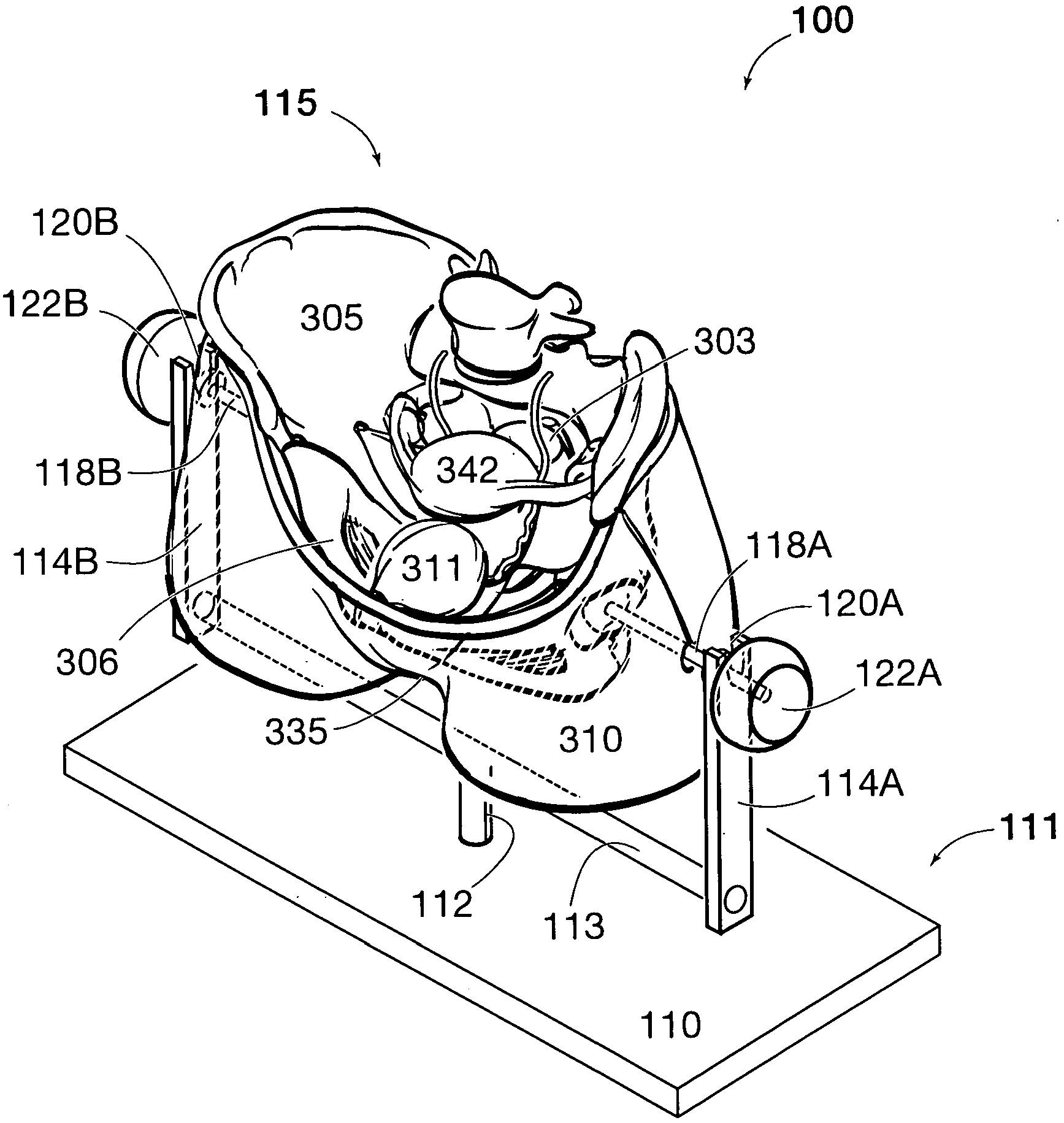

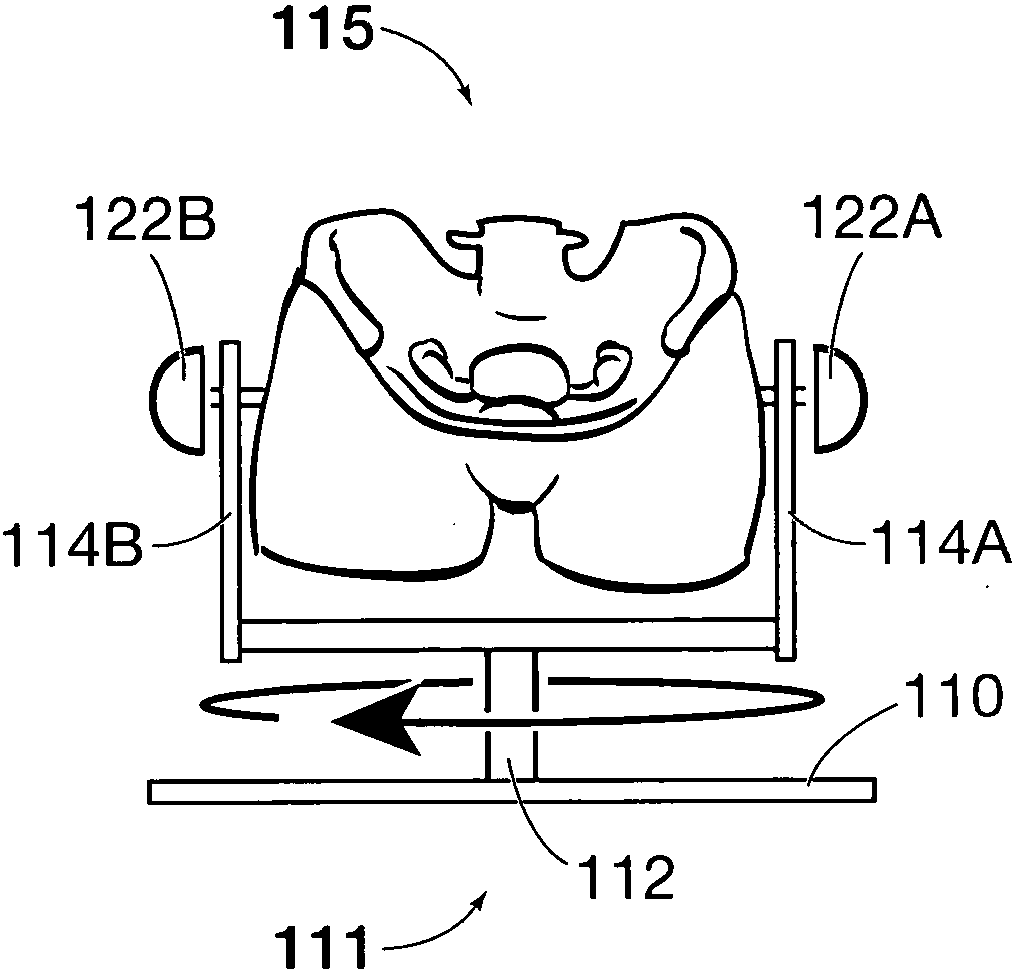

Pelvic Surgery Training Model

A male or female human pelvic model for teaching, practicing, or evaluating proficiency in physical examination, medical or surgical techniques, or procedures involving the pelvis are disclosed. The pelvic model can include replaceable pelvic skeletal frame and normal, pathological, or other modules providing 3D anatomical representations of various body components, such as skin, organs, muscles, vessels, connective tissues, ligaments, tendons, or nerves. The pelvic model can include portions that can retain pressurized fluid, such as to mimic a body organ, cavity, or vessel that retains fluid, so that leakage can occur, such as upon unintended cutting or puncture. A rotating open-top pelvic region structure can permit viewing or video capture during the simulated procedure.

Owner:道格拉斯 W 米雅萨基

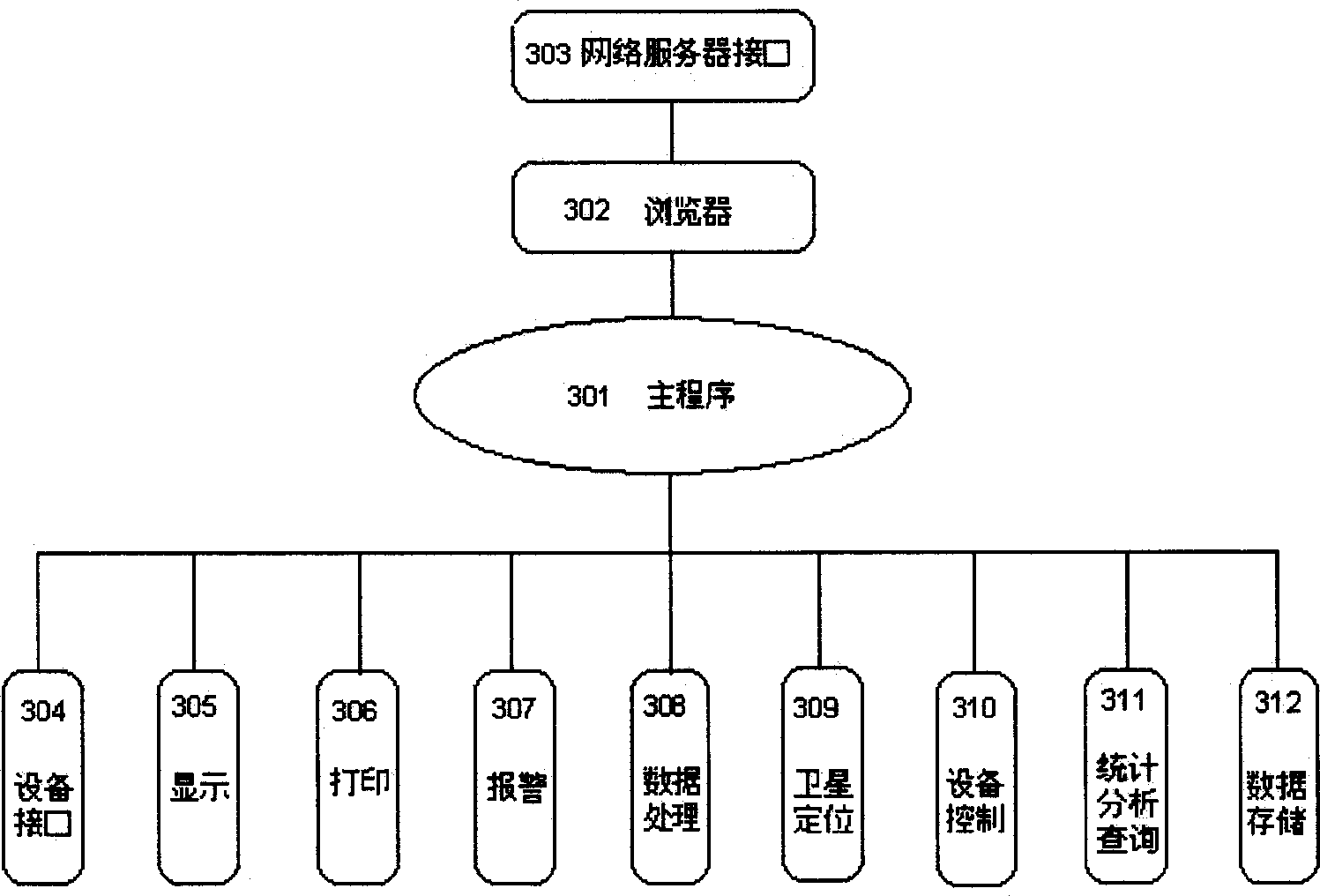

Community intelligent physical examination service system and working method thereof

InactiveCN105979006ARealize acquisitionRealize analysisData processing applicationsTransmissionWorking setComputer science

The invention relates to a community intelligent physical examination service system and a working method thereof. The community intelligent physical examination service system comprises a physical examination device which is used for collecting personal body detection data and is suitable for uploading the personal body detection data to a cloud server; and the cloud server which is suitable for generating personal health reports and sending the reports to a personal terminal. According to the community intelligent physical examination service system and the working method thereof, the body detection data can be collected and analyzed, the abnormity of the body condition of a user can be discovered early; an illness can be treated in advance; and the probability of suffering from a heavy illness can be greatly reduced.

Owner:HOHAI UNIV CHANGZHOU

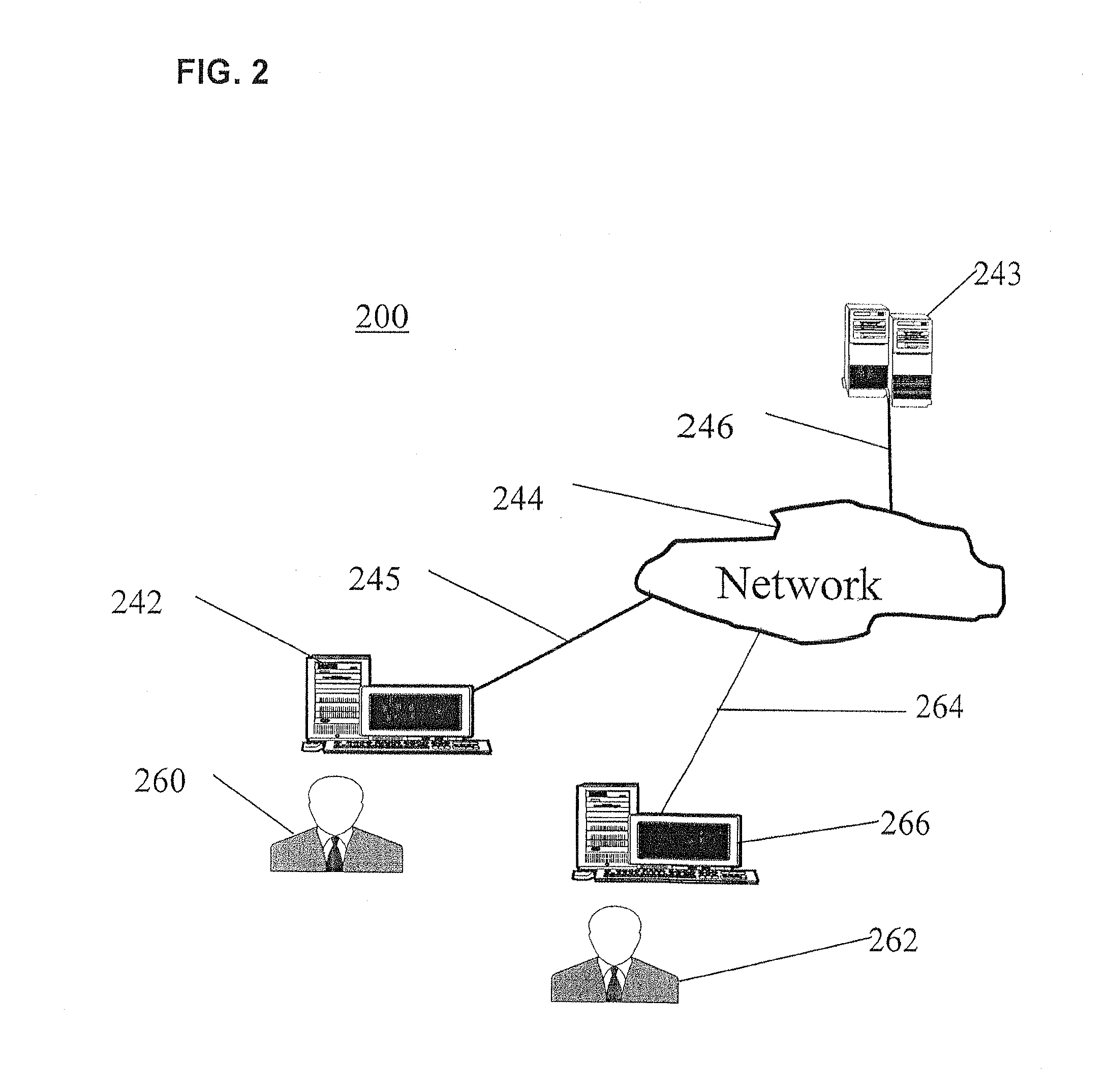

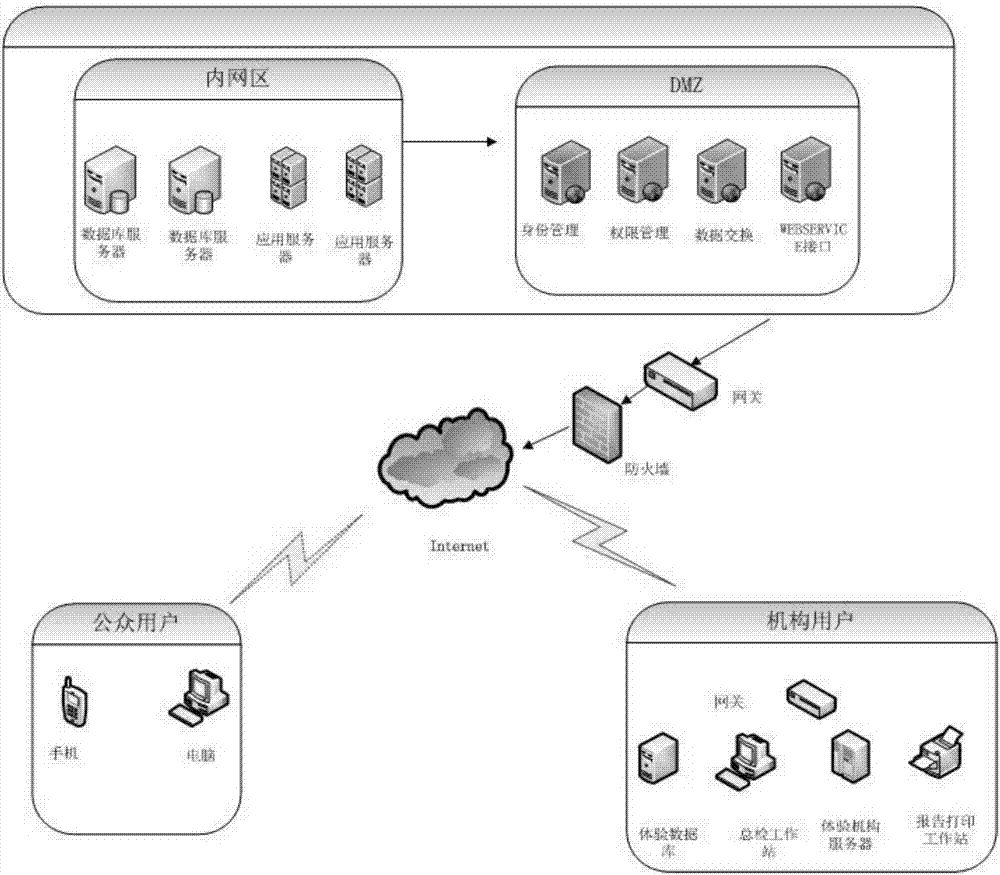

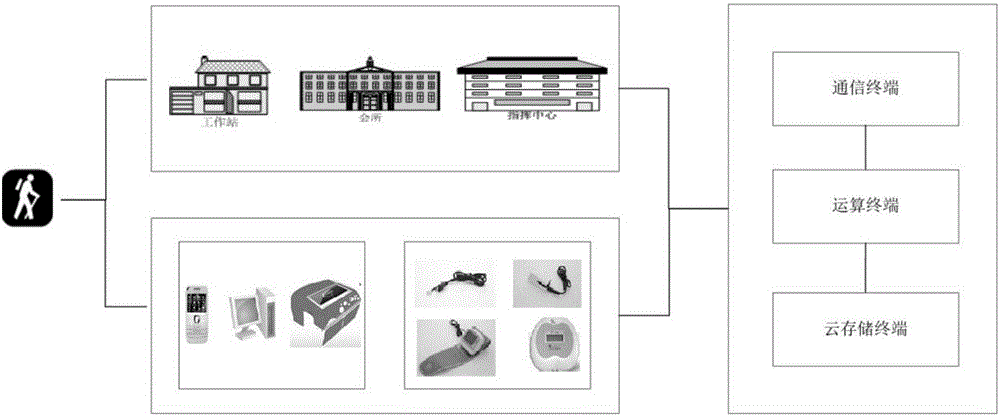

Remote online health management system

ActiveCN106021912AAccurate graspImprove timelinessHealth-index calculationTelemedicineBlood pressure monitorsWorkstation

The invention discloses a remote online health management system. The remote online health management system comprises an offline health management system, an online health management system and a remote service system, wherein the offline health management system comprises one or more sites such as a workstation, a club, a command center and a user home, and medical treatment and physical examination apparatuses in various sites, and is used for acquiring and transmitting the human health data of users; the online health management system consists of a user remote operation terminal and a user remote probe terminal, and is used for acquiring and transmitting the human health data of the users; the user remote operation terminal comprises one or more of a health handheld terminal, a personal online health terminal and a household health machine; the user remote probe terminal comprises one or more of a Bluetooth blood pressure monitor, a Bluetooth body fat meter, vital capacity monitor, a blood sugar monitor, an electro-cardio monitor, a heart rate monitor, an ear temperature monitor, a fetal heart monitor and an energy monitor; and the remote service system comprises a communication terminal, a computation terminal and a cloud storage terminal.

Owner:武汉康一生科技有限公司

Network hospital system for keeping direct connection with vulnerable crowd or patient

InactiveCN1822043AIncrease and decrease functionImprove publicityData processing applicationsMicrocontrollerCrowds

This invention relates to a network hospital system keeping contact directly with easy-ill people or patients characterizing that said network hospital system includes a network server, a wire and / or wireless network, terminals(desk computers, notebook computers, palm computers or intelligent cell phones), devices(the mono-chip processor system includes information testing process and satellite locating functions in ECG, blood pressure, blood sugar, blood-fat, temperature, breath and blood oxygen), a medical treatment service system( drug-stores, distribution station, a test and a physical examination center and a emergency center), in which, the device timely communicates with the server about the situations of the easy-ill people and patients by the terminal and network, at the same time, the system is connected with traditional hospitals, community hospitals, drug-stores, emergency centers, banks and government departments to provide various medical services.

Owner:张士东

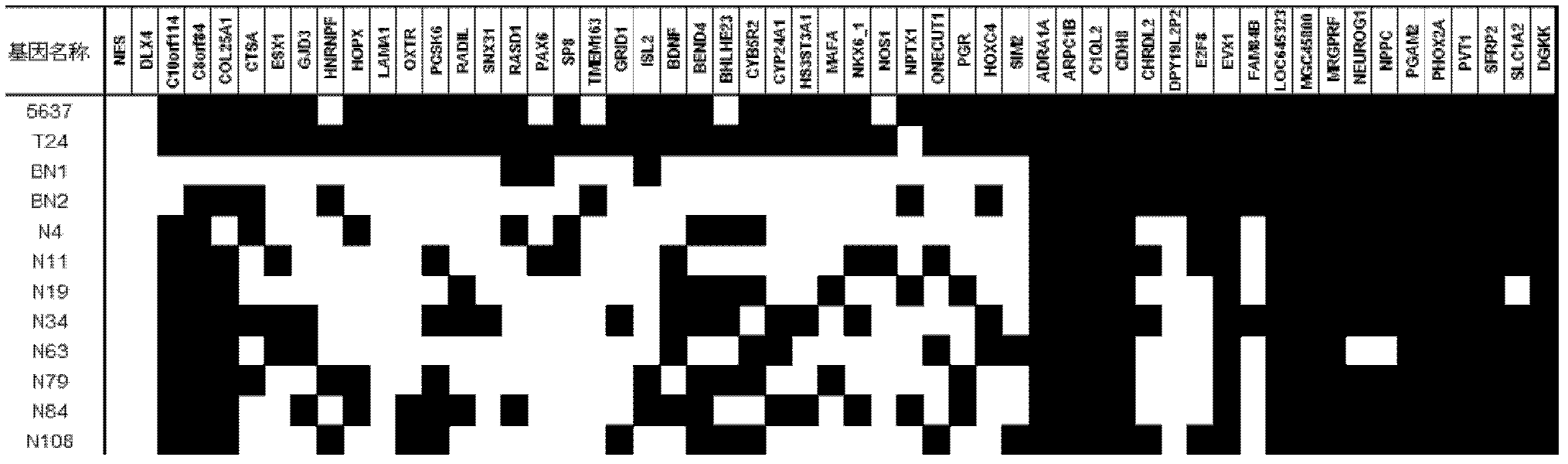

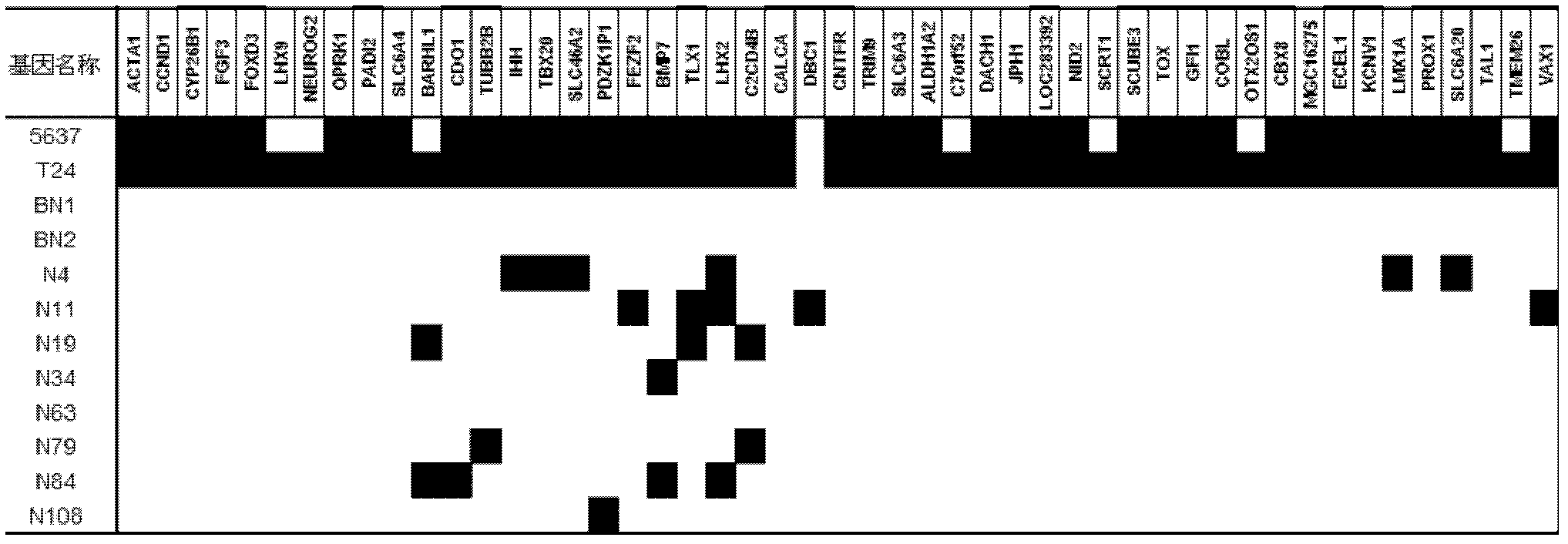

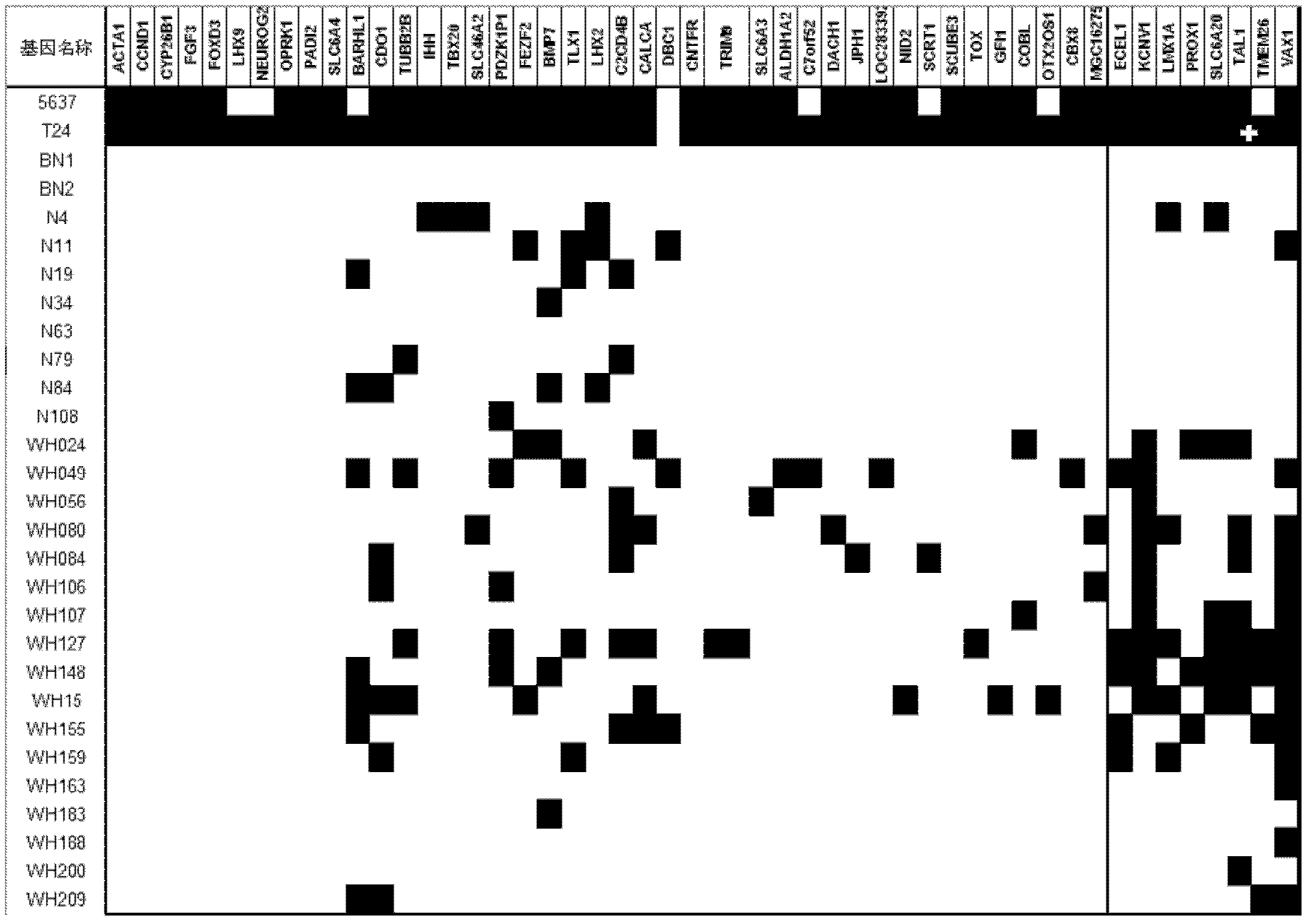

Method and kit for diagnosing bladder cancer with urine

InactiveCN102311953AMicrobiological testing/measurementDNA/RNA fragmentationCommunity health centerBiomarker (petroleum)

The invention relates to a method and a kit for diagnosing bladder cancer with urine. The invention discloses a group of methylated sensitive genes, comprising ECEL1, KCNV1, LMX1A, PROX1, SLC6A20, TAL1, TMEM 26, and VAXI gene. In urine samples of bladder cancer patients, the specific CpG sites of the genes are showed the highest methylation levels. Accordingly, the genes are the biological marker of bladder cancer. The method and the kit can be used as the basic of designing diagnostic reagents of bladder cancer, and are suitable for auxiliary detection of cancer in hospitals, postoperative followup, screening of high risk group of bladder cancer in community health centers, and screening of common people and high risk practitioners of bladder cancer in physical examination center.

Owner:SHANGHAI INST OF ONCOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com