viscous nutritional composition

A nutritional composition and a technology for the composition are applied in the directions of active ingredients of iodine compounds, medical preparations containing active ingredients, food science, etc., can solve the problems such as no records or hints of water-absorbing dietary fibers, etc., achieve easy administration through tubes, Easy to prepare, easy to prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097] In the preparation of the nutritional composition of the present invention, heat treatment or heat sterilization is performed. The heat sterilization conditions can adopt the sterilization conditions of common food, and heat sterilization can be carried out using conventional devices. For example, sterilization at 62°C to 65°C for 30 minutes, 72°C or higher for 15 seconds or more, 72°C or higher for 15 minutes or more, or 120 to 150°C for 1 to 5 seconds, or 121 to 124°C for 5 to 20 minutes , sterilization at 105 to 140° C., retort (heating under pressure) sterilization, high-pressure steam sterilization, etc., but are not limited to these examples. Heat sterilization is preferably performed under pressure. Sterilization can be performed by heat sterilization, and the viscosity of the nutritional composition can be increased at the same time. In this specification, sterilization and sterilization can be used in the same meaning. In addition, pressure cooking steriliza...

Embodiment 1

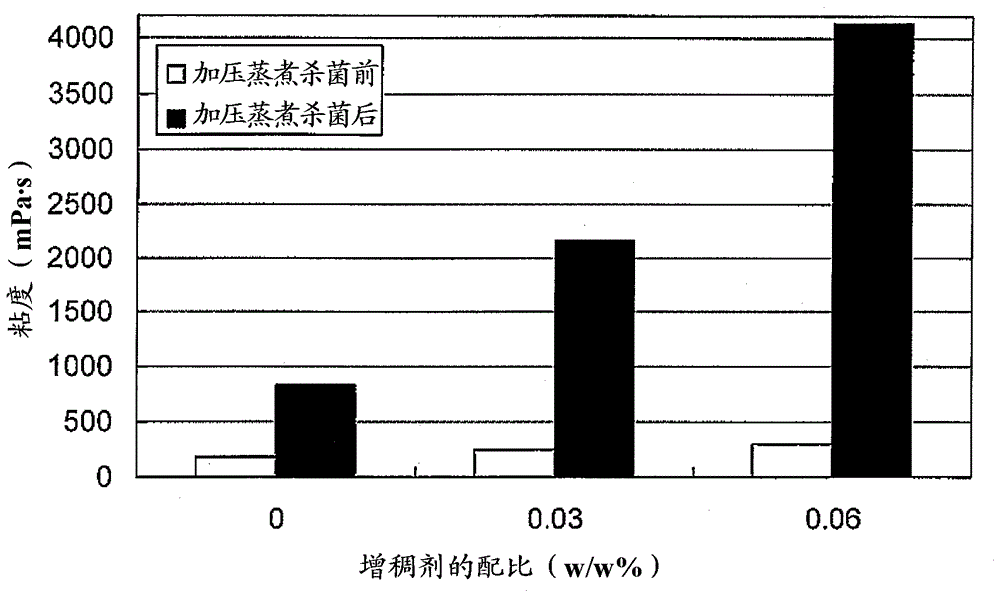

[0111] Embodiment 1 Thickener Addition Effect on Composition Viscosity

[0112] For the nutritional composition, a thickener was added to a certain amount of water-absorbing dietary fiber and emulsifier and its ratio was changed to investigate the effect of the added amount of the thickener on the viscosity of the composition. Stir and mix the raw materials according to the compounding table in Table 1, blend various nutritional compositions (preparation examples 1-3), carry out the homogenization treatment under the homogenization treatment pressure condition of 50~60 ℃ and 20MPa, then in 50 The homogenization treatment is carried out under the conditions of ~60°C and a homogenization treatment pressure of 30MPa. The actual value measured at 20° C. using a densitometer was recorded as the specific gravity. After measuring the viscosity of the nutritional composition [before retort sterilization], the nutritional composition was filled in a container and sealed, and retort st...

Embodiment 2

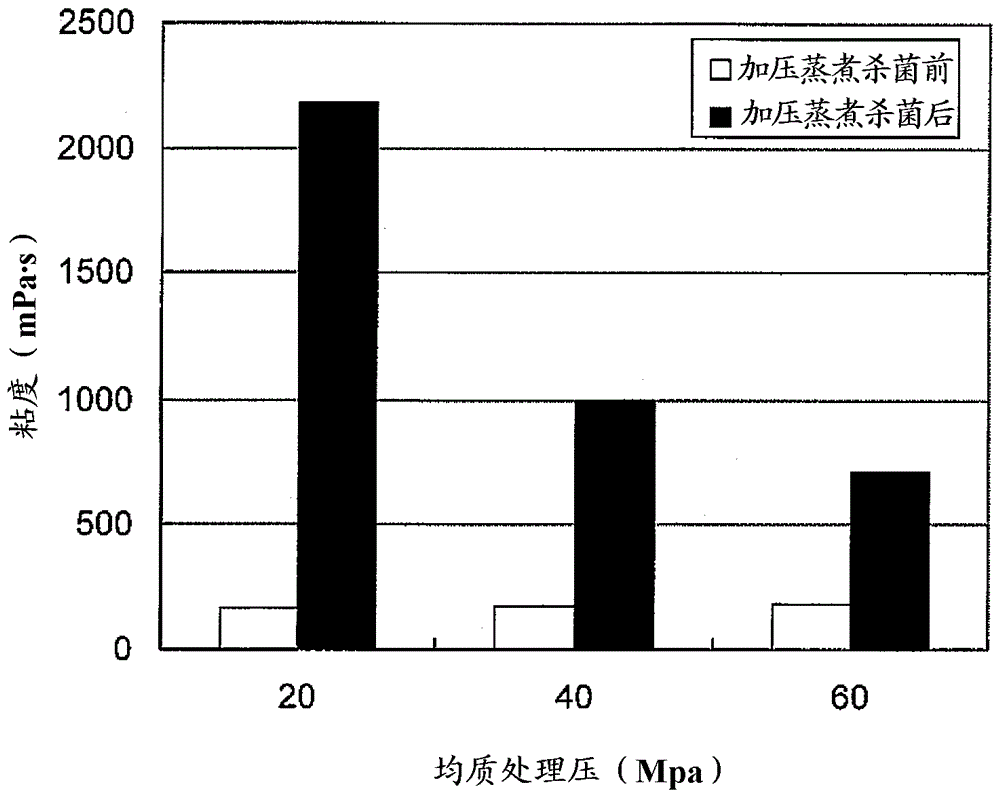

[0120] Example 2 Effect of Homogenization Treatment Pressure on Composition Viscosity, etc.

[0121] A certain amount of thickener and emulsifier was added to the nutritional composition, and the homogenization treatment was carried out by changing the homogenization treatment pressure, and the influence of the homogenization treatment pressure on the viscosity of the composition was investigated. Stir and mix the raw materials according to the formula in Table 2, prepare the nutritional composition (Preparation Example 4), and perform homogenization treatment at 50-60° C. and a homogenization treatment pressure of 20, 40 or 60 MPa. The actual value measured at 20° C. using a densitometer was recorded as the specific gravity. Then, the nutritional composition is filled in the container and sealed, and the pressure cooking sterilization is carried out under the condition of 121-123.5° C. for 5-20 minutes. The nutritional composition after retort sterilization was stored at 15° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com