Multiphase fiber materials and compositions, methods of manufacture and uses thereof

A technology of composition and gel composition, applied in the direction of final product manufacturing, sustainable manufacturing/processing, textile/flexible product manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The preparation of embodiment 1-lactam

[0069] In a covered vessel, melt four liters of caprolactam overnight in a convection oven. The lactam was poured into a 5 liter 3-neck distillation flask with a magnetic stir bar and electric heating mantle (top and bottom mantle). The distillation column has a vacuum jacket and consists of a 29 / 42 column and 10 tray section, 5 tray section, split distillation head and condenser. The condenser was maintained at 50°C using a heated water circulator. The system reduces the pressure from 7 mmHg to 4 mmHg. Heat was applied to bring the column to reflux conditions and held for 30 minutes. After allowing the column to stabilize for 30 minutes, the distillation head sampler was started, 4 seconds off, and 10 seconds to reflux. Slightly less than 1 liter of lactam was distilled off. The heat was turned off, and the heating mantle was removed, the lactam in the 5-liter flask was allowed to drop to 90°C, and then the vacuum on the sy...

Embodiment 2

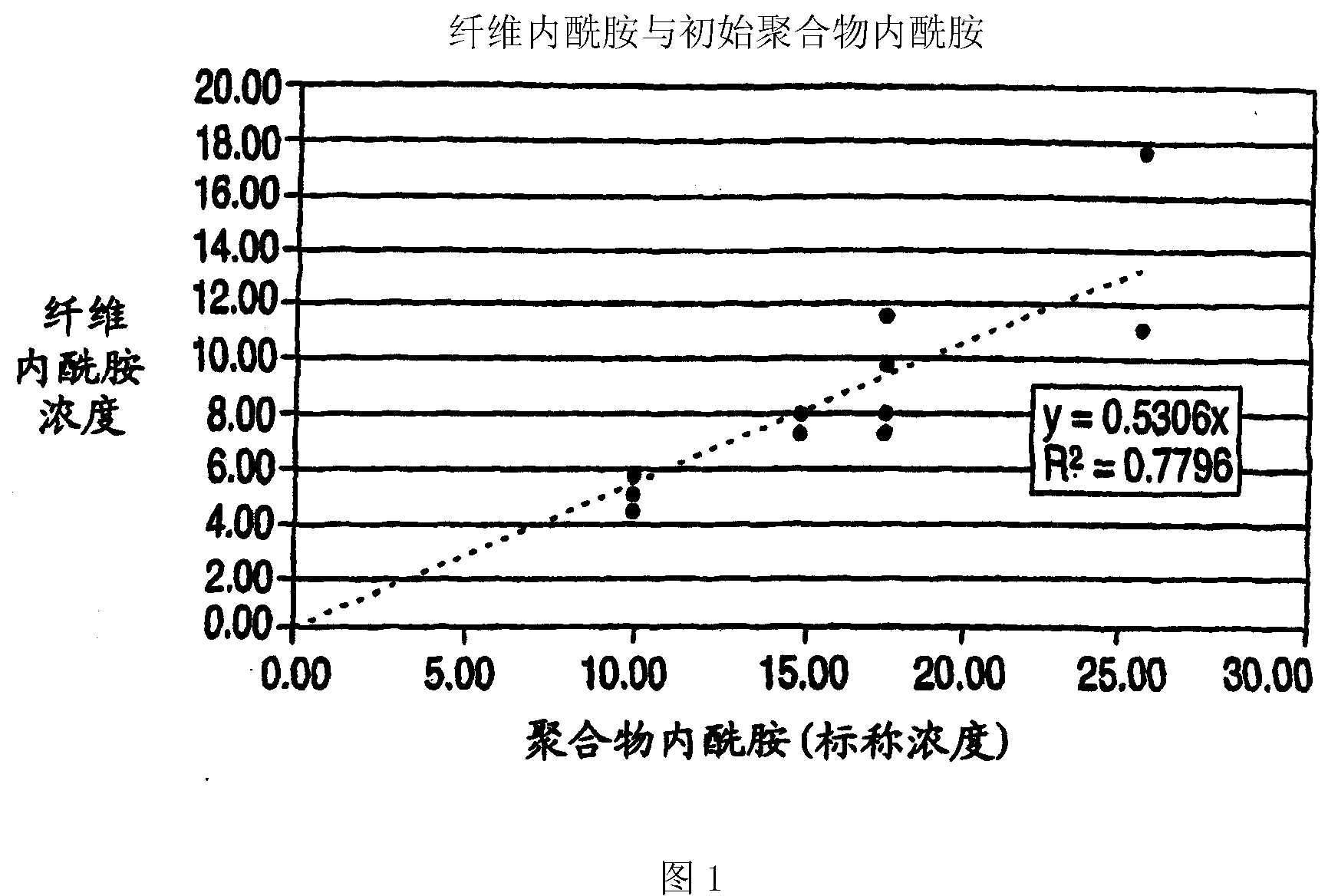

[0070] Example 2 - Preparation of contemplated pre-fiber gel compositions

[0071] Nylon-6 is ground into a fine powder and mixed with a lactam gelling agent, which in this case is caprolactam. A Braybender mixer was used to mix nylon and caprolactam at a speed of 60 RPM. The addition time was approximately 5 minutes and the gel was allowed to mix for 15 minutes after addition at the temperature indicated. Remove the sample while running the Braybender using a brass wiper. The samples were then ground in a Willey mill using a course screen. Weighed quantities of each ground gel mixture were extracted for 16+ hours using a jacketed Soxhlet extractor. The extract was filtered using folded #54 paper and rinsed into a 100 ml volumetric flask. The extract was brought up to volume with deionized water and then analyzed for % lactam by means of gas chromatography using a polyethylene glycol column.

[0072] gel

[0073] The resulting gel was gel-spun on a twin-screw ex...

Embodiment 3

[0074] Example 3 - Preparation of contemplated pre-fiber compositions

[0075] background

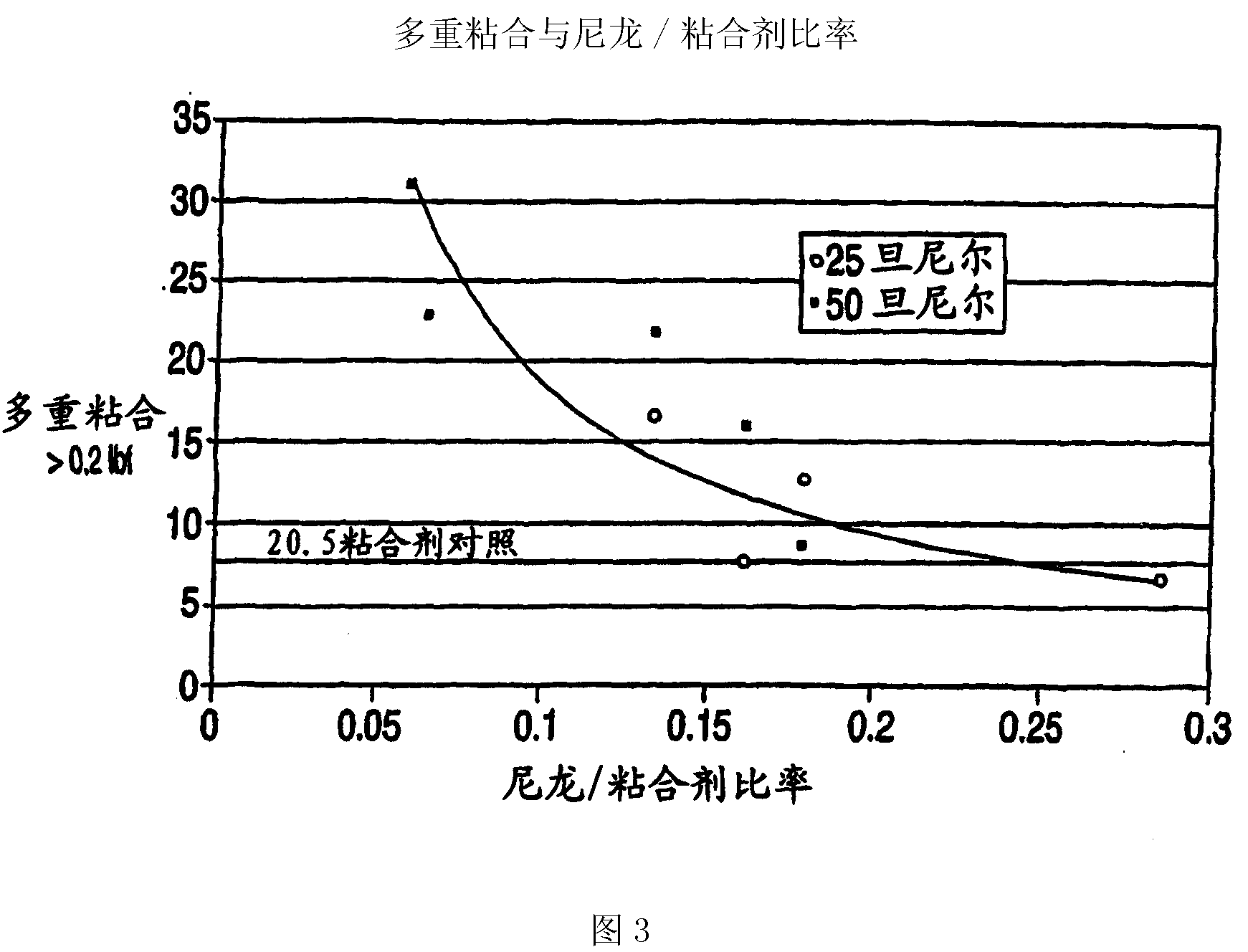

[0076] A conventional binder alloy sample (1-end of 22 denier / 12 monofilaments) was inserted into a 1202mp 2-plied yarn during cabling and performed heat set. exist After heat setting, the Plybond test of the yarns did not show any signs of bonding. Subsequently, the yarn is autoclave heat set before being processed into banded carpet. No significant aesthetic effect was observed in the carpet using any of the conventional binder alloy samples. However, at the lowest nylon / binder ratio, there was a slight impact on carpet hand (firmness), but no texture or surface changes were observed in the carpet.

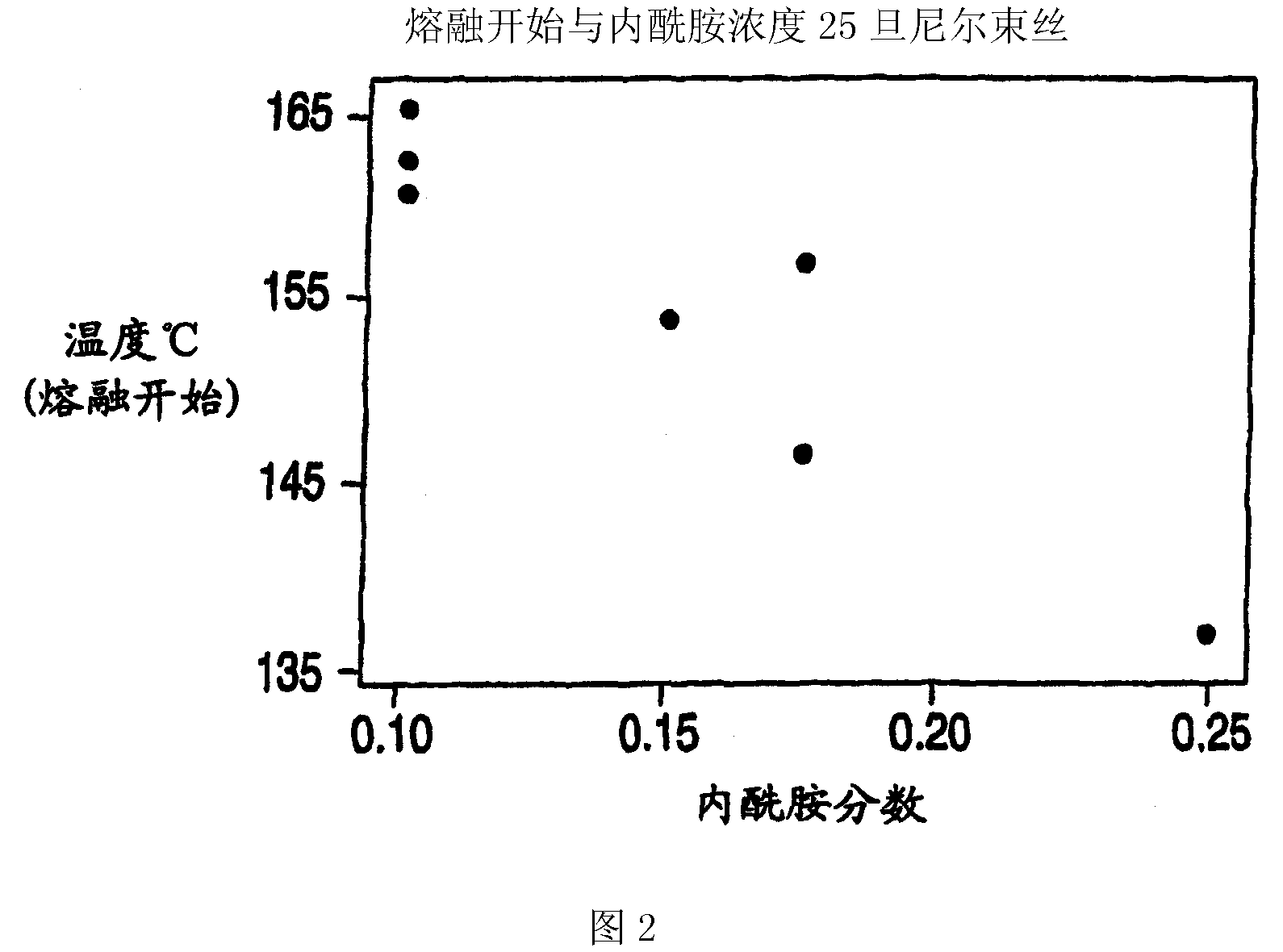

[0077] This study tested compositionally altered low-melt alloy fibers (higher process "binder" and higher lactam concentration). The purpose of the study was to find an alloy composition which in Capable of melting and bonding the fibers together within the bundle during heat s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com