Wear-resistant coating mixture for waste heat power generation pipelines

A waste heat power generation and smearing material technology, which is applied in the field of monolithic refractory materials, can solve problems such as high viscosity, volume expansion, and resistance to erosion, and achieve high volume density, good thermal shock resistance, high compressive strength and flexural resistance intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

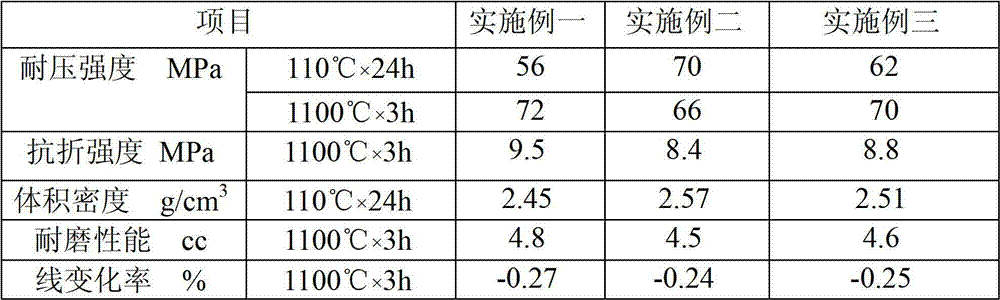

Embodiment 1

[0025] A wear-resistant smearing material for waste heat power generation pipelines, the components of which include:

[0026] Brown corundum with a particle size of 3-5mm 15%;

[0027] High alumina bauxite with a particle size of 1-3mm 25%;

[0028] High alumina bauxite with a particle size of 0.088-1mm 20%;

[0029] Bauxite fine powder 11%;

[0030] Silica powder 3%;

[0031] α-Al 2 o 3 Micropowder 6%;

[0032] Guangxi white mud 2%;

[0033] Bentonite 2%;

[0034] High alumina cement 16%;

[0035] The sum of the contents of the above components is 100%.

[0036] The above-mentioned wear-resistant smear material for waste heat power generation pipelines also includes sodium tripolyphosphate and sodium carboxymethylcellulose in terms of mass ratio, and the specific content ratio is: the total content of the above-mentioned components: sodium tripolyphosphate: Sodium carboxymethyl cellulose is 1:0.001:0.006.

[0037] Al in the brown corundum 2 o 3 ≥94%, Al in high ...

Embodiment 2

[0039] A wear-resistant smearing material for waste heat power generation pipelines, the components of which include:

[0040] Brown corundum with a particle size of 3-5mm 30%;

[0041] High alumina bauxite with a particle size of 1-3mm 15%;

[0042] High alumina bauxite with a particle size of 0.088-1mm 15%;

[0043] Bauxite fine powder 8%;

[0044] Silica powder 3%;

[0045] α-Al 2 o 3 Micropowder 4%;

[0046] Guangxi white mud 2%;

[0047] Bentonite 2%;

[0048] ρ-Al 2 o 3 3%;

[0049] High alumina cement 18%.

[0050] The index content of each component in the wear-resistant smear is the same as that in Example 1. When using it, it is only necessary to add 7% water of the total amount of the material, and then stir for 5-8 minutes to make the material evenly mixed.

Embodiment 3

[0052] A wear-resistant smearing material for waste heat power generation pipelines, the components of which include:

[0053]Brown corundum with a particle size of 3-5mm 25%;

[0054] High alumina bauxite with a particle size of 1-3mm 17%;

[0055] High alumina bauxite with a particle size of 0.088-1mm 18%;

[0056] Bauxite fine powder 8%;

[0057] Silica powder 3%;

[0058] α-Al 2 o 3 Micropowder 5%;

[0059] Guangxi white mud 3%;

[0060] Bentonite 2%;

[0061] ρ-Al 2 o 3 3%;

[0062] High alumina cement 16%;

[0063] The sum of the contents of the above components is 100%.

[0064] The above-mentioned wear-resistant smear material for waste heat power generation pipelines, in terms of mass ratio, also includes sodium tripolyphosphate, sodium carboxymethylcellulose and coagulant KAD-20, and the specific content ratio is: the total content of the above components Quantity: sodium tripolyphosphate: sodium carboxymethylcellulose: coagulant KAD-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com