Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Eliminate Stability Issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

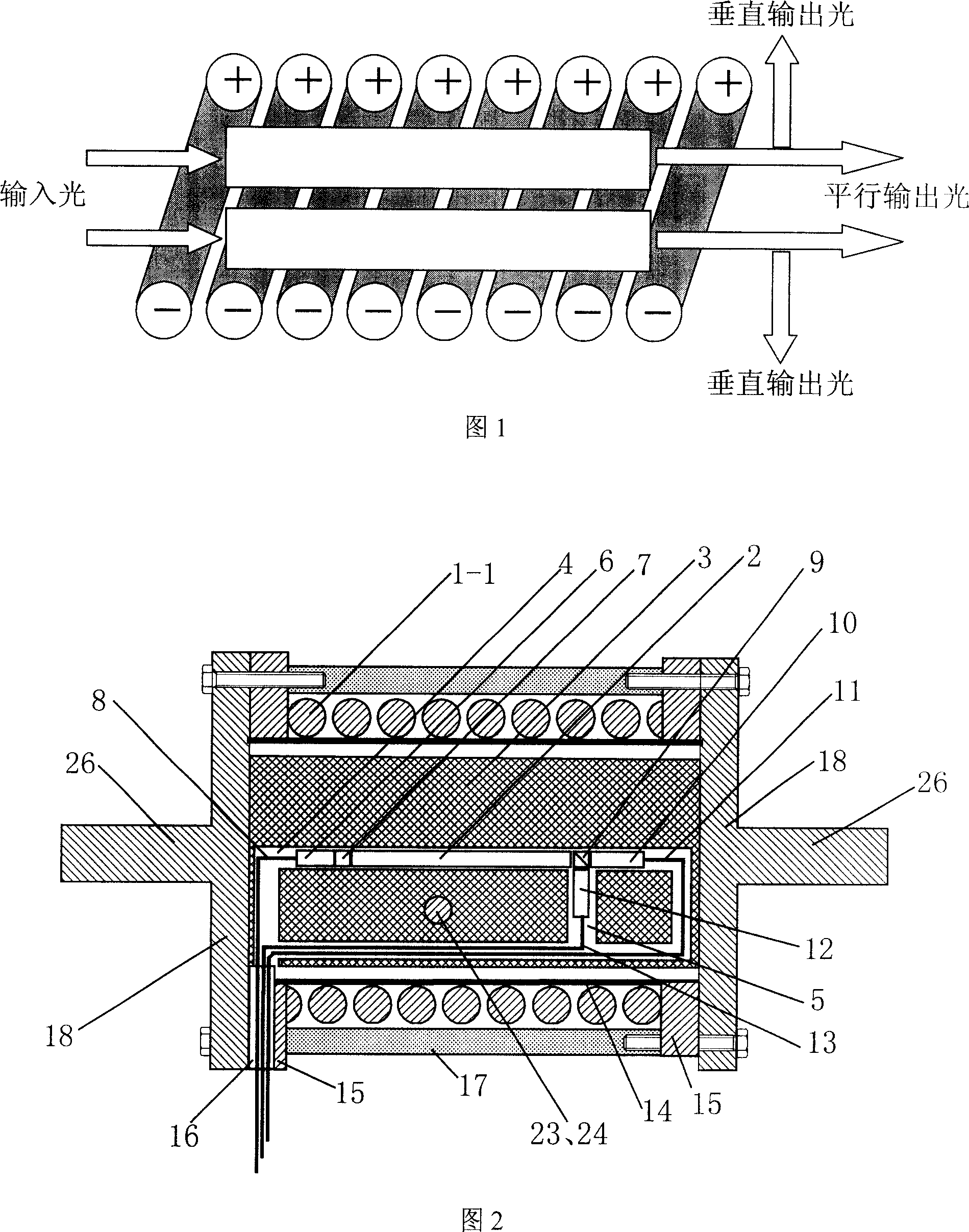

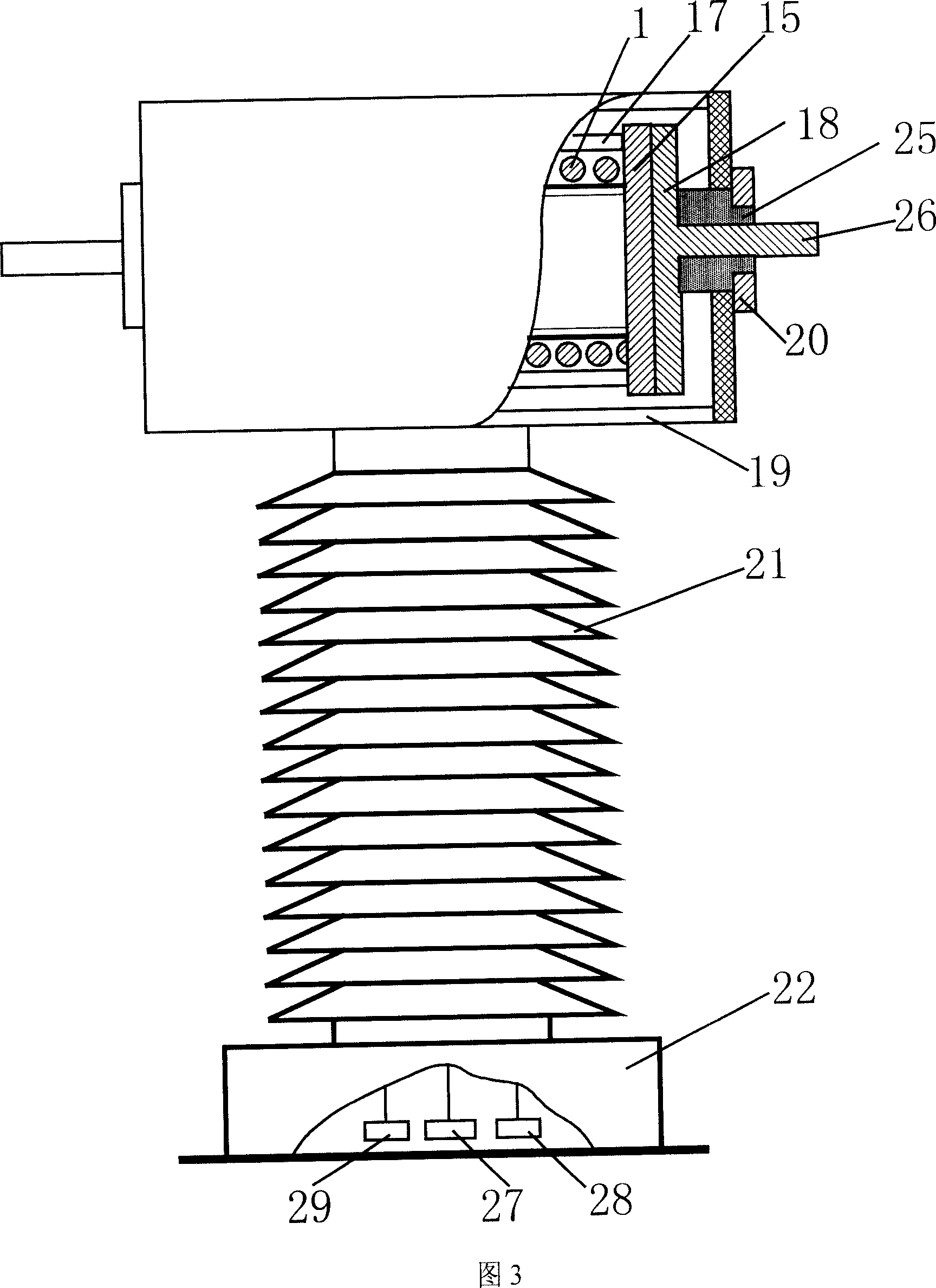

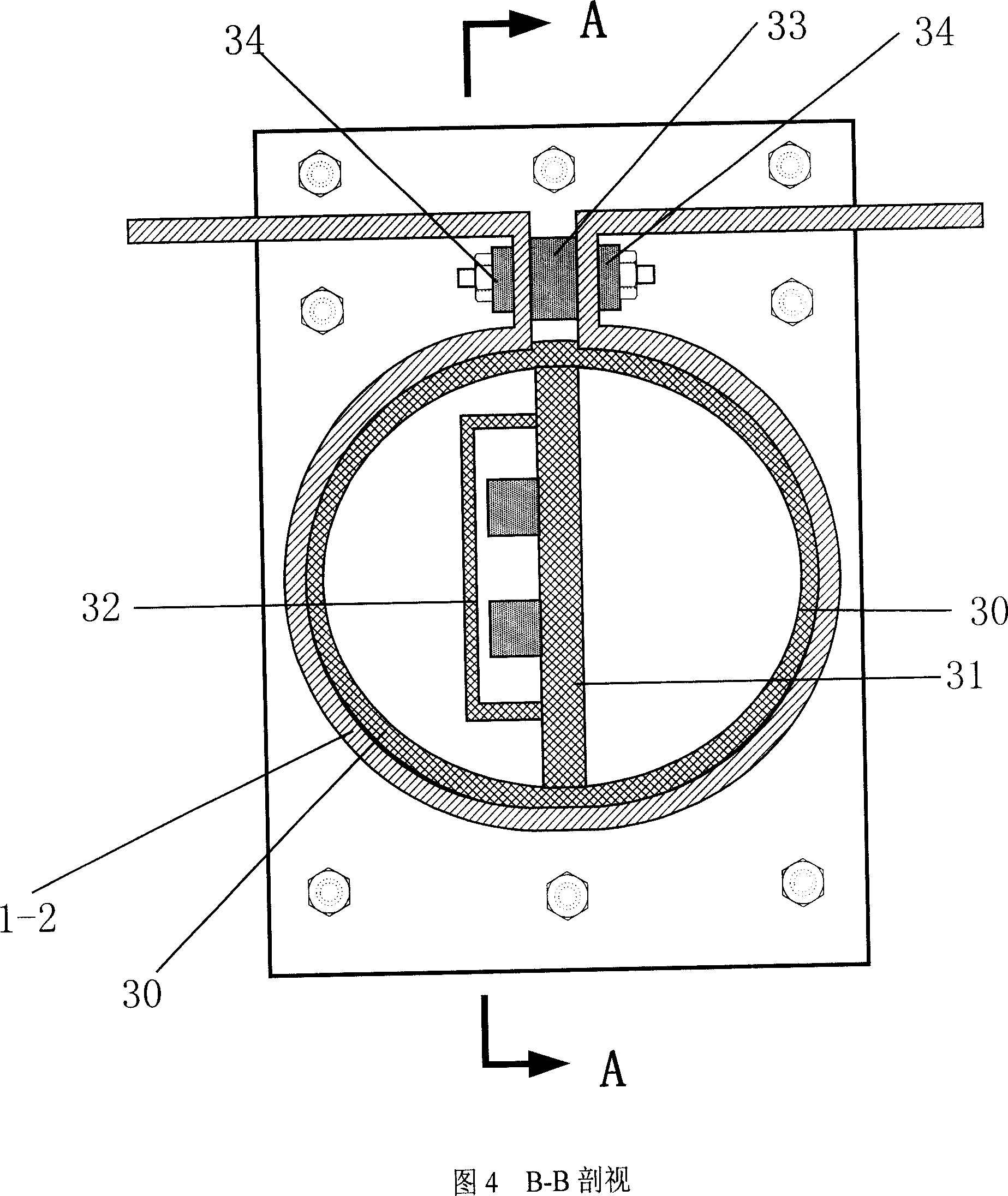

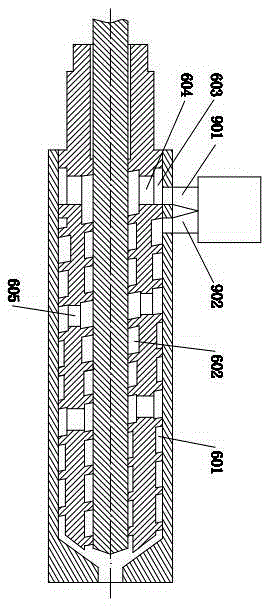

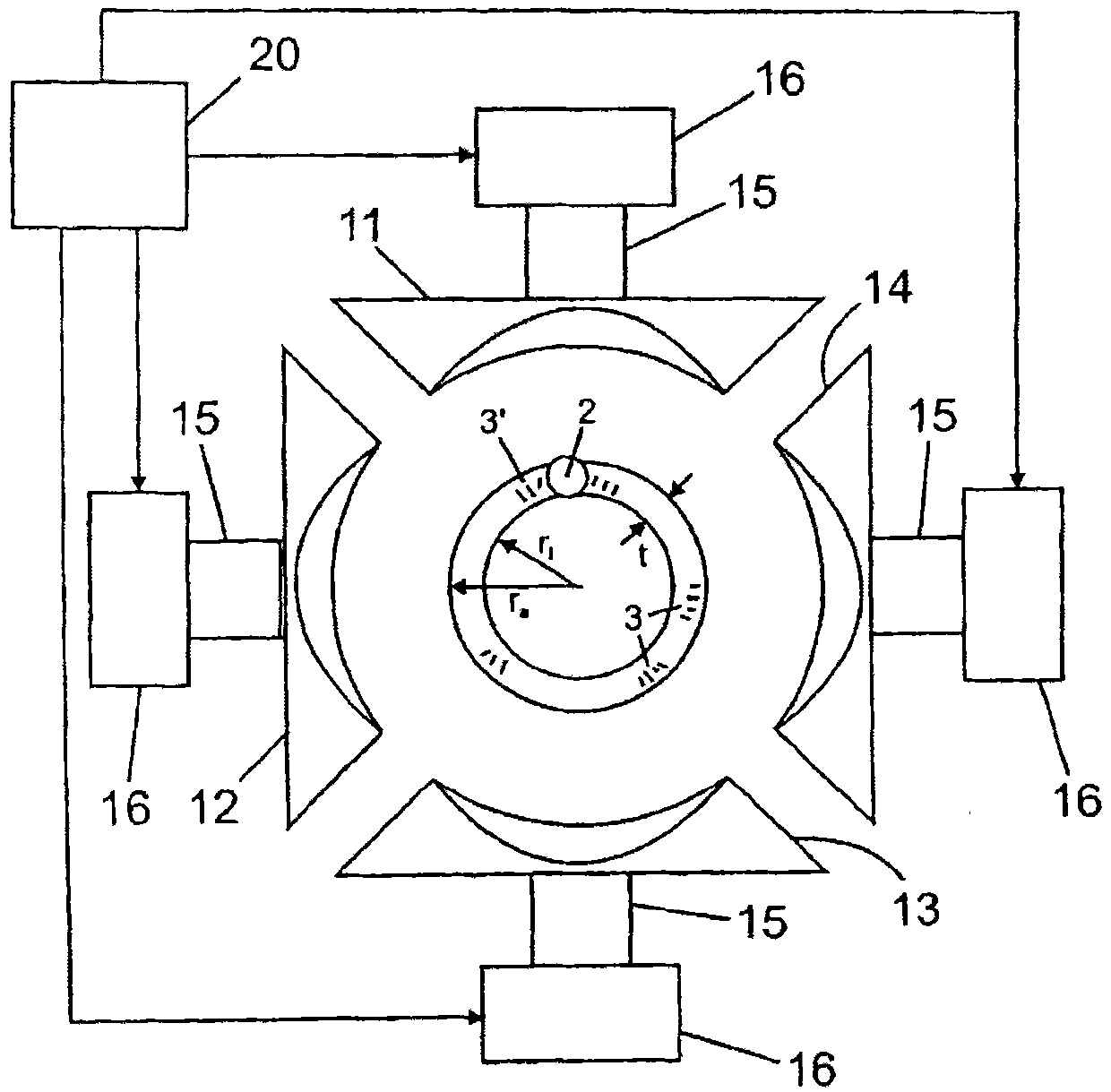

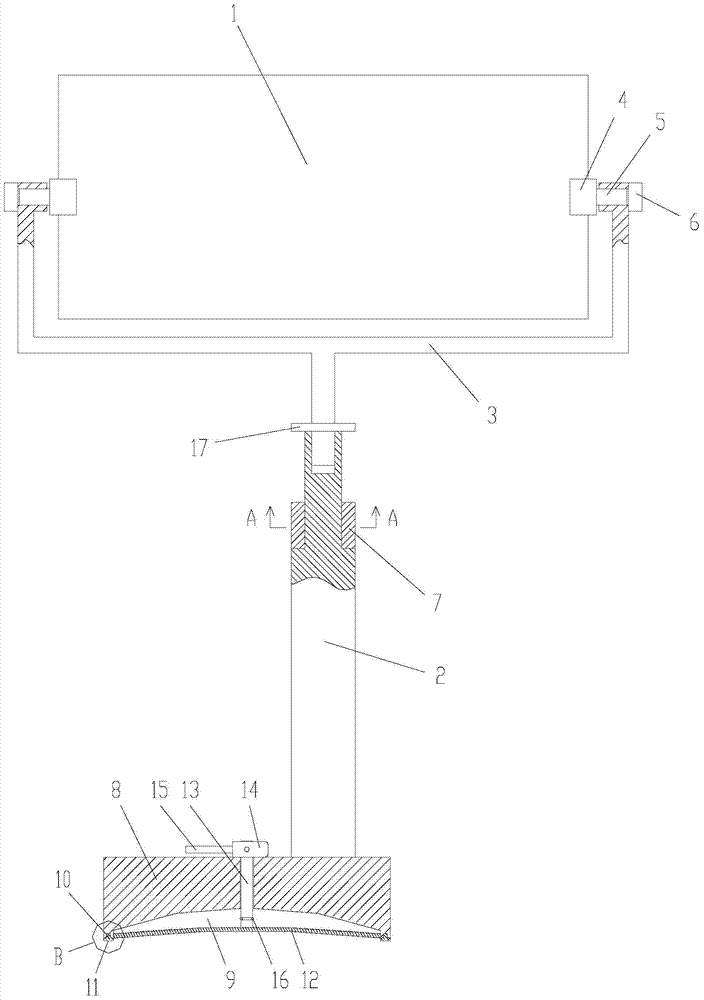

Optical current transformer and method for measuring current with the same

InactiveCN1963539AImprove performanceGuaranteed uptimeCurrent/voltage measurementVoltage/current isolationFiberElectrical conductor

This invention relates to high voltage circuit current measurement optical inductor and its test method, wherein, the sensor head is of bar magnetic materials along line distribution input fiber; the basic path is composed of self focus lens, bias device, optical sensor head, test bias device, parallel output self focus lens and fiber and vertical output focus lens and fiber. The test current passes through ring conductor to establish parallel magnetic field with at least one basic light path. The multiple light paths each sensor head is of same distance separately connected to low voltage two photoelectricity converters to output voltage signal and vertical voltage to compute test current.

Owner:李岩松 +1

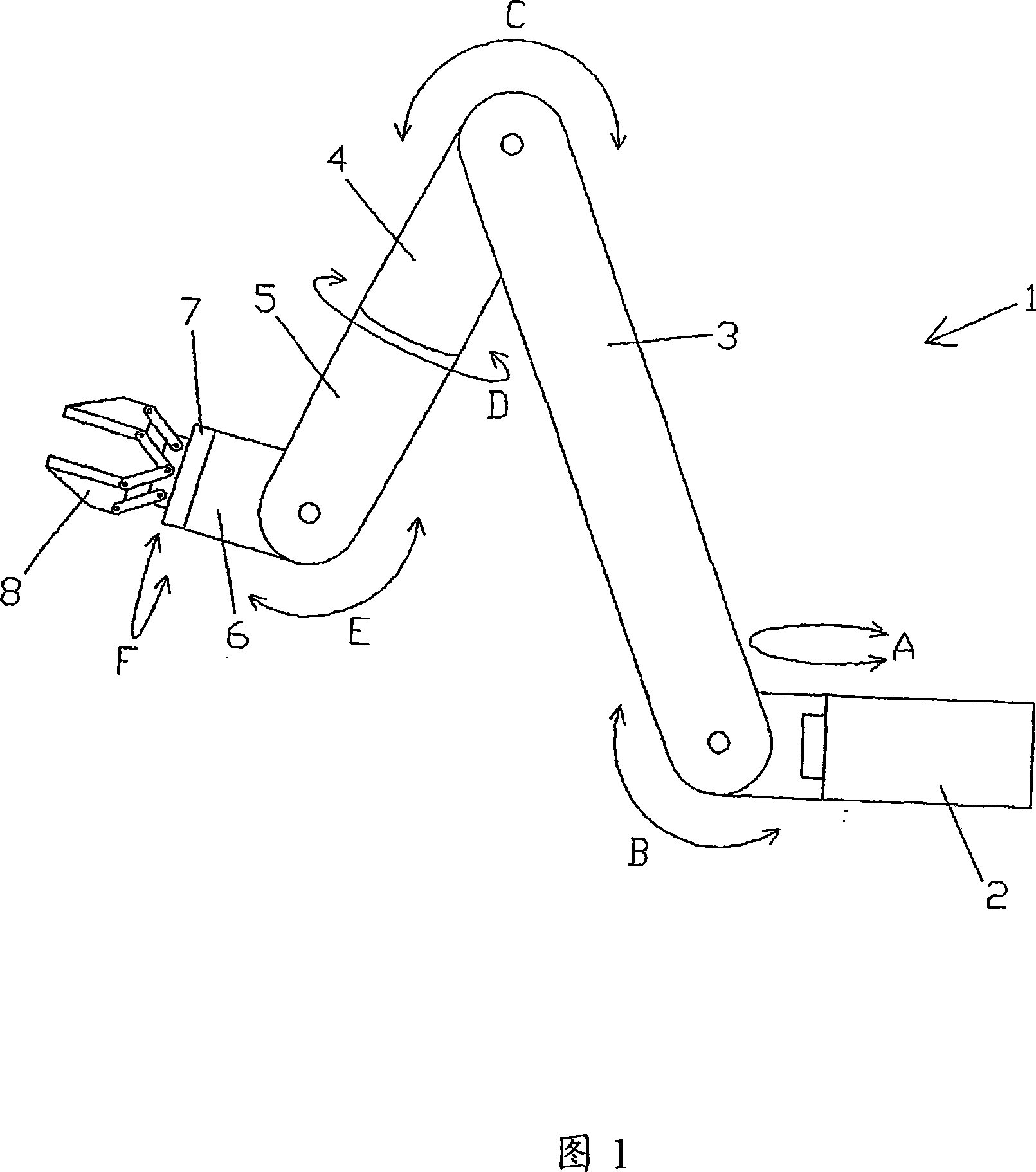

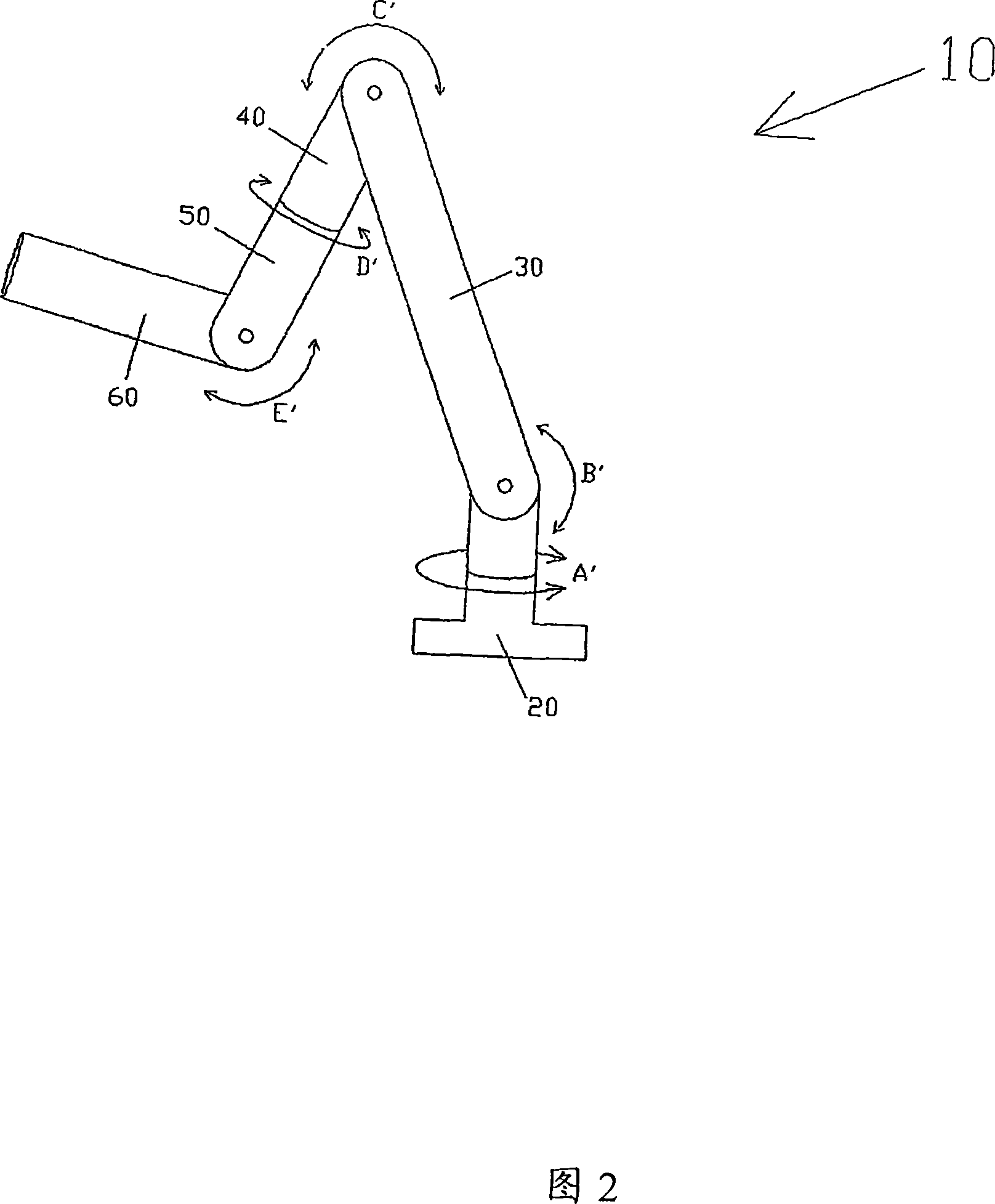

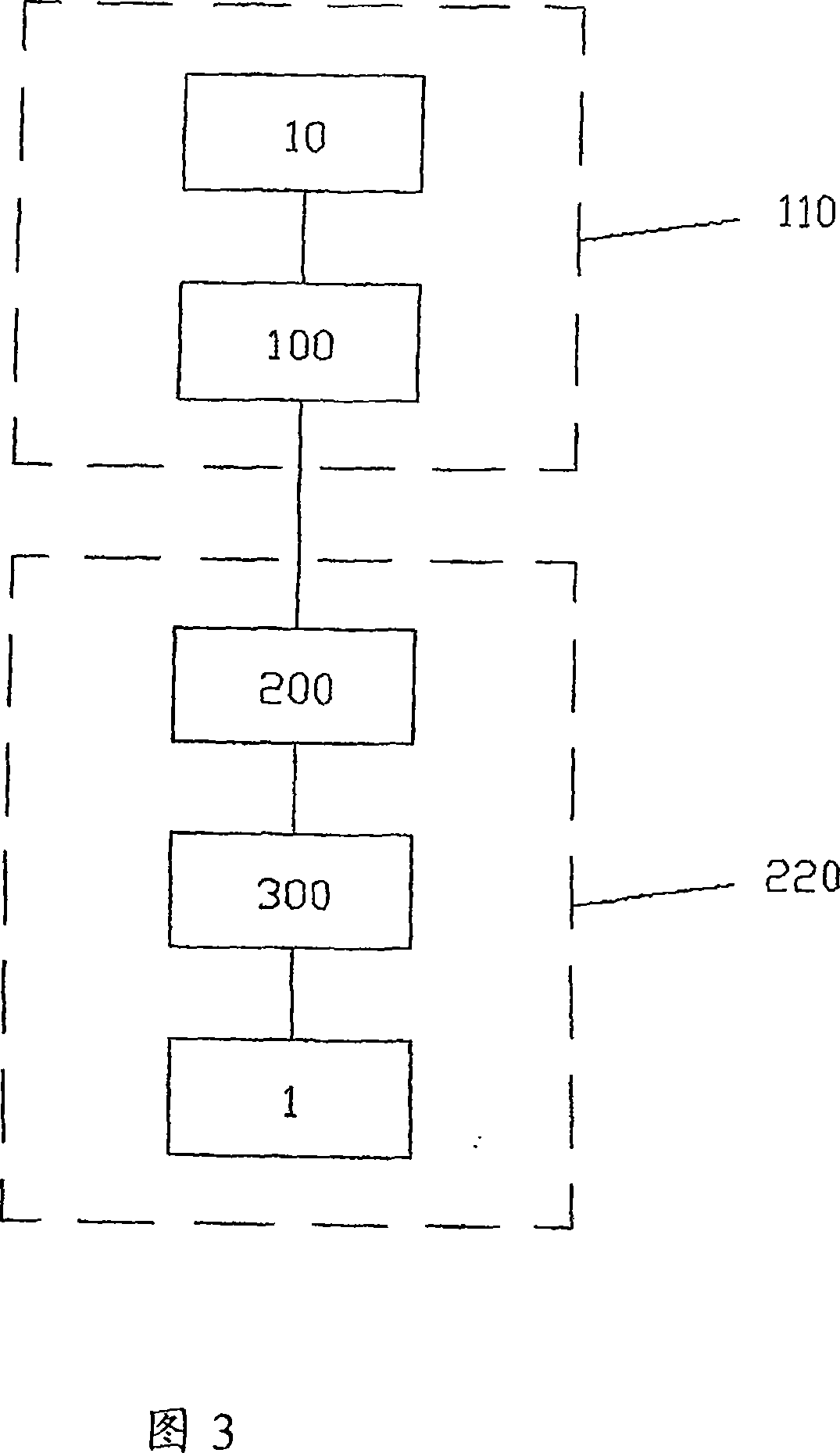

Control system for an articulated manipulator arm

InactiveCN101102869AEliminate Stability IssuesPrecise controlProgramme-controlled manipulatorManipulatorMaster controller

A control system for an articulated manipulator arm (1), the manipulator arm having at least three degrees of freedom, said control system comprising a master controller (10) moveable to replicate the at least three degrees of freedom of the manipulator arm (1); means for determining the rate of movement of the master controller in each direction replicating a degree of freedom of the manipulator arm; and control means (200) for controlling actuation of the manipulator arm whereby the rate of movement of the manipulator arm in each of said at least three degrees of freedom is proportional to the rate of movement of the master controller (10) in each direction replicating a degree of freedom of the manipulator arm.

Owner:佩里·斯林斯里系统有限公司

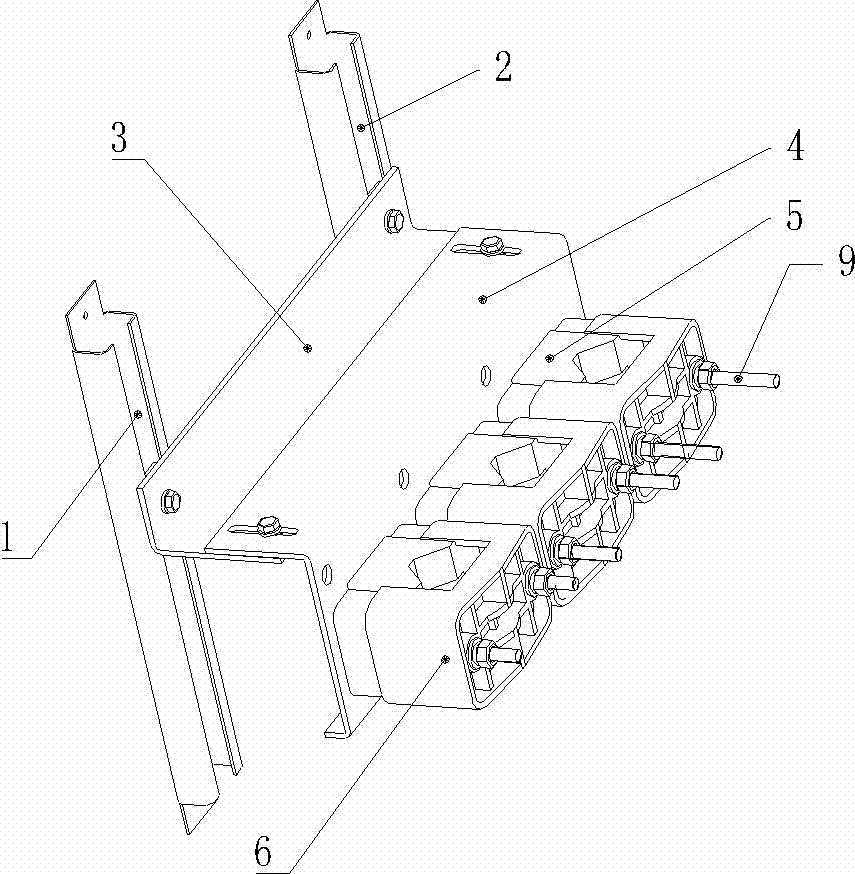

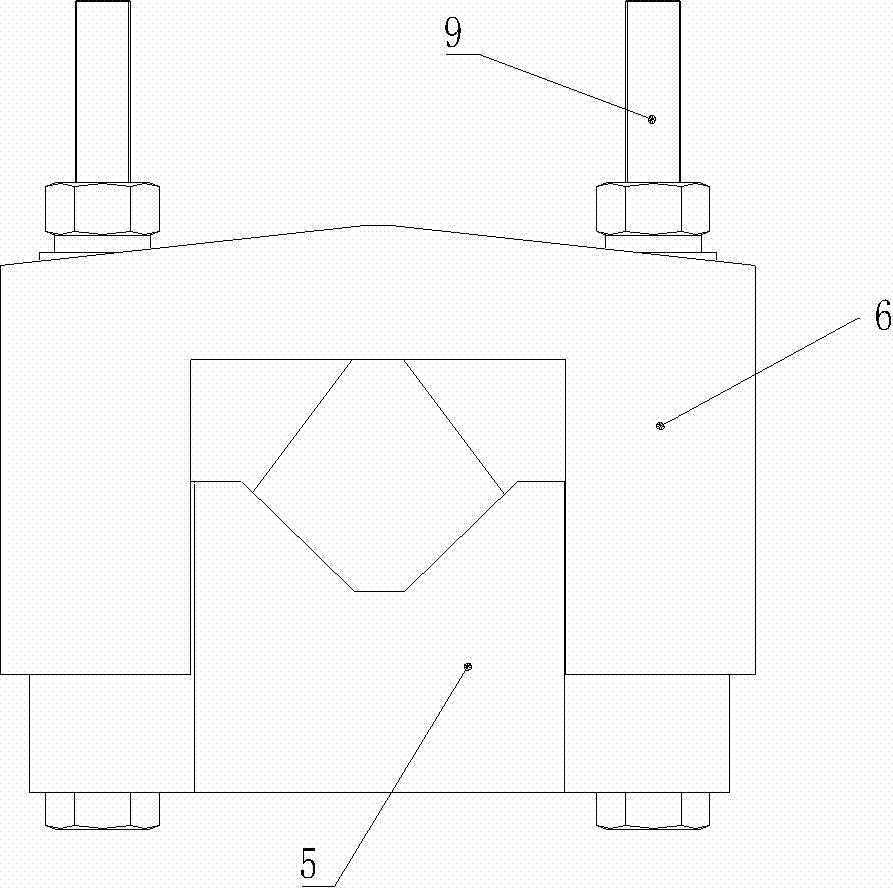

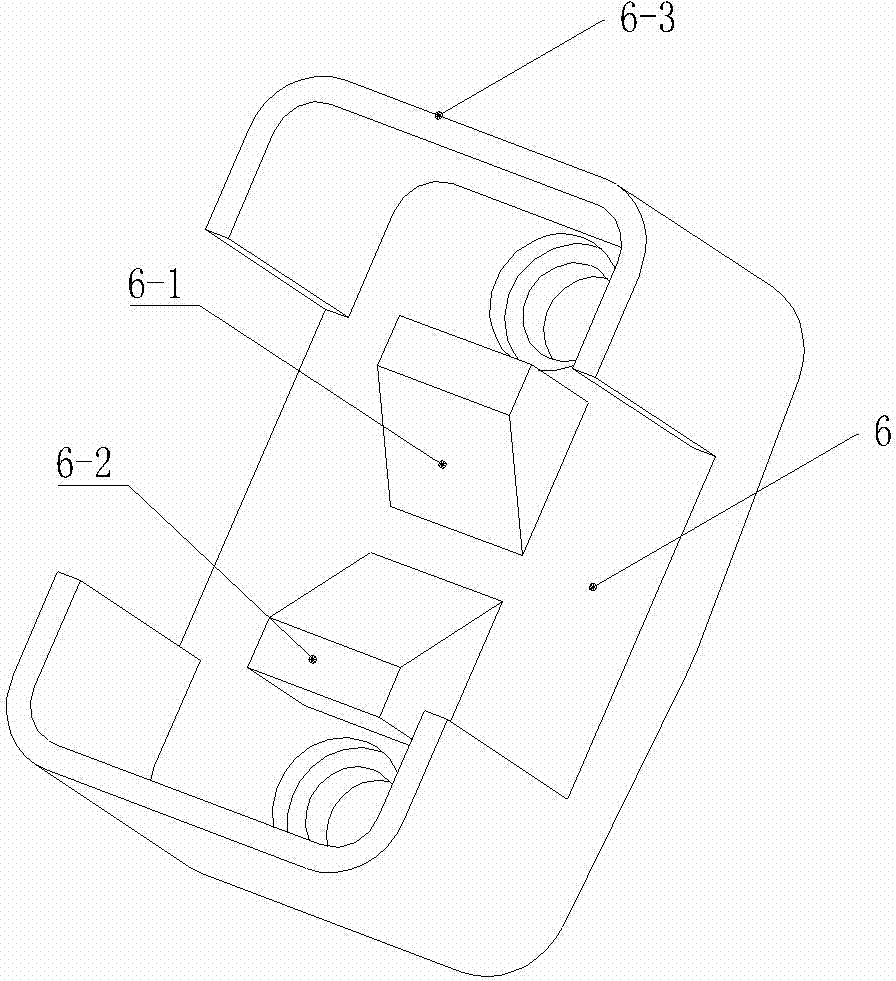

Cable fixing clamp and cable fixing device employing cable fixing clamp

InactiveCN102889430AReduce stressAvoid deformationPipe supportsElectrical apparatusEngineeringMechanical engineering

Owner:XUJI GRP +2

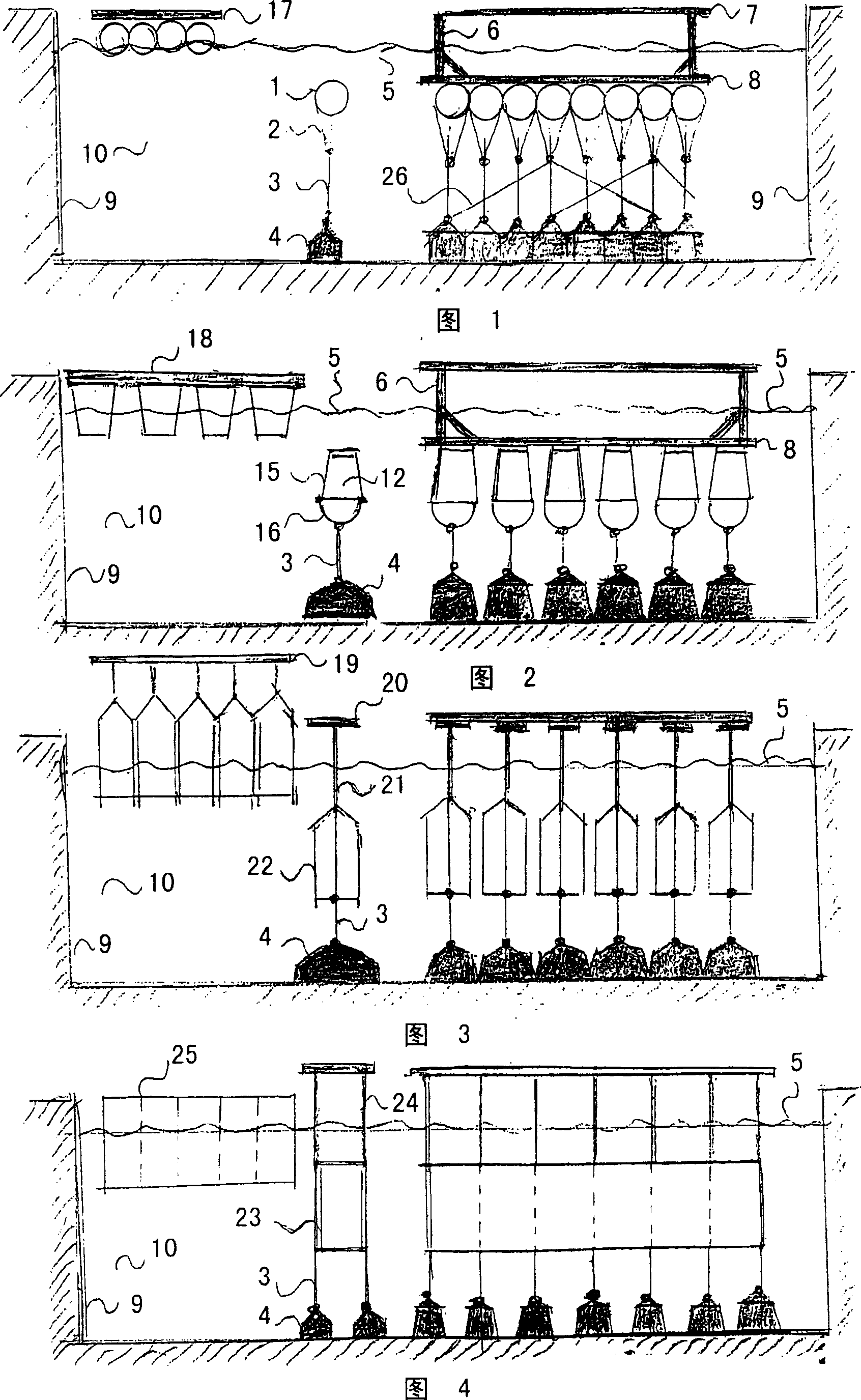

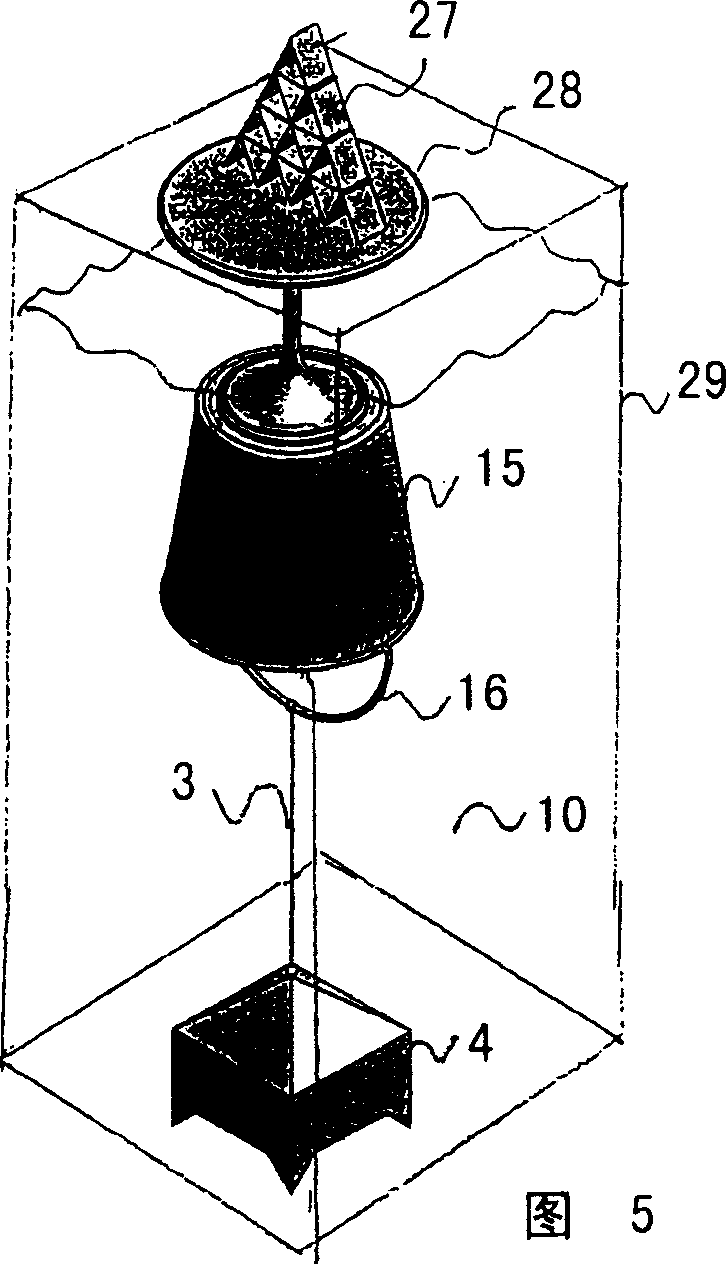

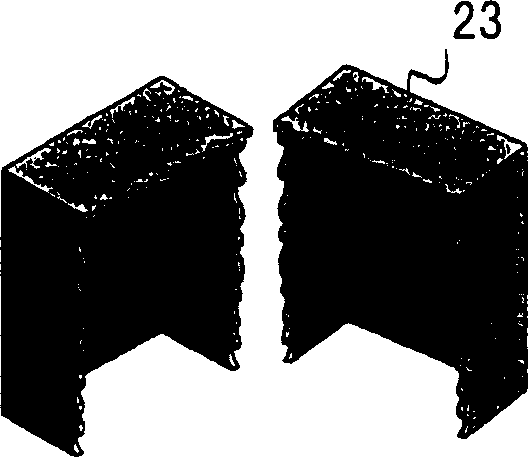

Fixed structure platform on water

InactiveCN101389527AEasy to manufactureEasy to assembleVessels for aircraftAnchorsComing outMarine engineering

The invention relates to a fixed platform which enables to locate on the water any fixed structure such as the house, garden, road, airport, car park, children's park and holiday village in the seas, lakes and rivers. Our invention comprises the platform (7) where the floats (22) thereof capable of floating are submerged up to a safe zone 3-5 m from the water (10) surface, the floats (22) spending energy to come out on the water surface (5) produce forces to try to maintain the platform (7) always at the same point owing to the tightness of the ropes (3) of the floats (22) and where said platform (7) is prevented from being drifted by the violent storms and huge waves and the currents in the sea, wherein the platform (7) which is manufactured in a manner suitable for its purpose comprises the weight (4) to the end of which the ropes (3) are connected, the connecting ropes (3) serving to maintain the floats (22) at a constant distance from the floor and in submerged state, the floats (22) producing the buoyancy carried over by the platform (7), the carrier columns (21) connecting the floats (22) with the platform (7) and the connecting pieces (20) that connect the columns (21) with the platform (7).

Owner:阿尔帕伊·英斯

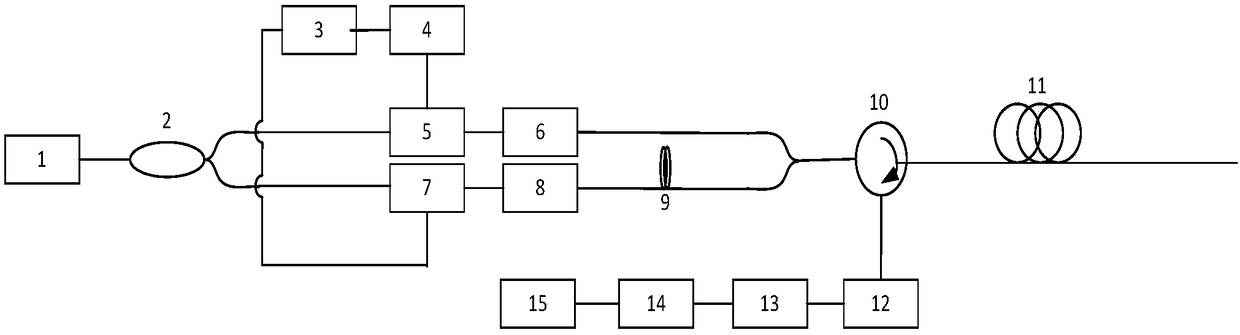

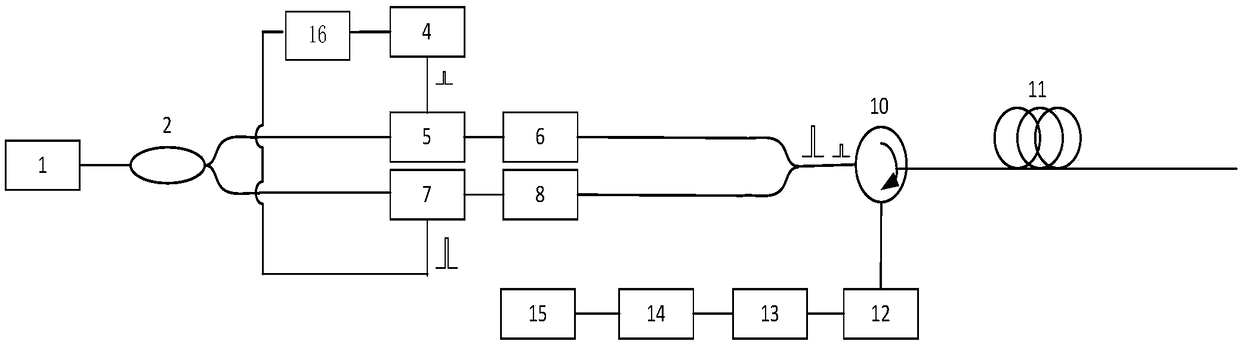

Method and device for demodulating distributed optical fiber vibration sensing system

PendingCN109405956AElimination of Polarization ChangesEliminate Stability IssuesSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFiberRayleigh scattering

The invention discloses a method and device for demodulating a distributed optical fiber vibration sensing system. The method comprises that two continuous ultra-narrow linewidth lasers with the sameoptical power are subjected to acousto-optic modulation and electro-optic modulation to be converted into two pulsed light signals; the two pulsed light signals are input into a sensing fiber at an interval of set pulse width; the backward Rayleigh scattered light of the two pulsed light signals generate a set frequency difference such that the returned Rayleigh light signals exhibit sinusoidal interference fringes; when a disturbance signal has an effect on the sensing fiber, the phase difference of the returned Rayleigh light signals changes, and the vibration waveform and position sensed bythe sensing fiber are obtained according to the phase difference. When the disturbance signal appears, a detector can quickly obtain the position of the disturbance signal and the intensity of the disturbance signal, which solves the problem that the demodulation algorithm of a [phi]-OTDR system is complex and a laser frequency drifts, and guarantees that the positioning error of the system is within + / -1m.

Owner:珠海任驰光电科技有限公司

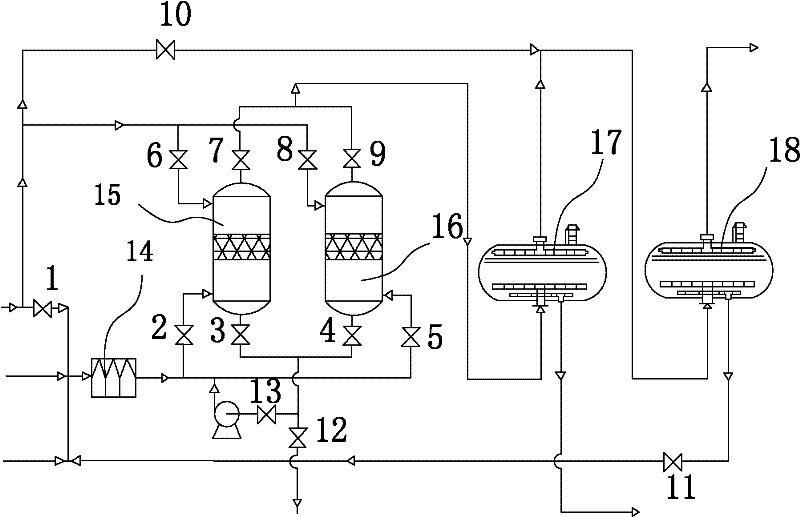

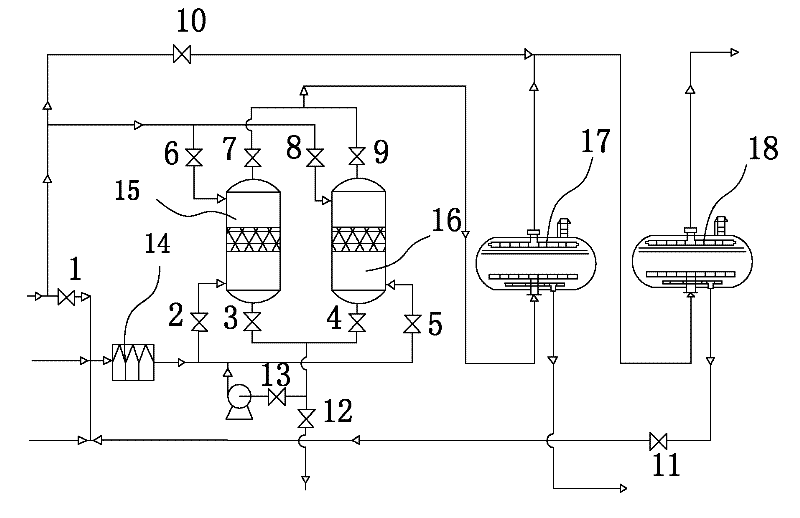

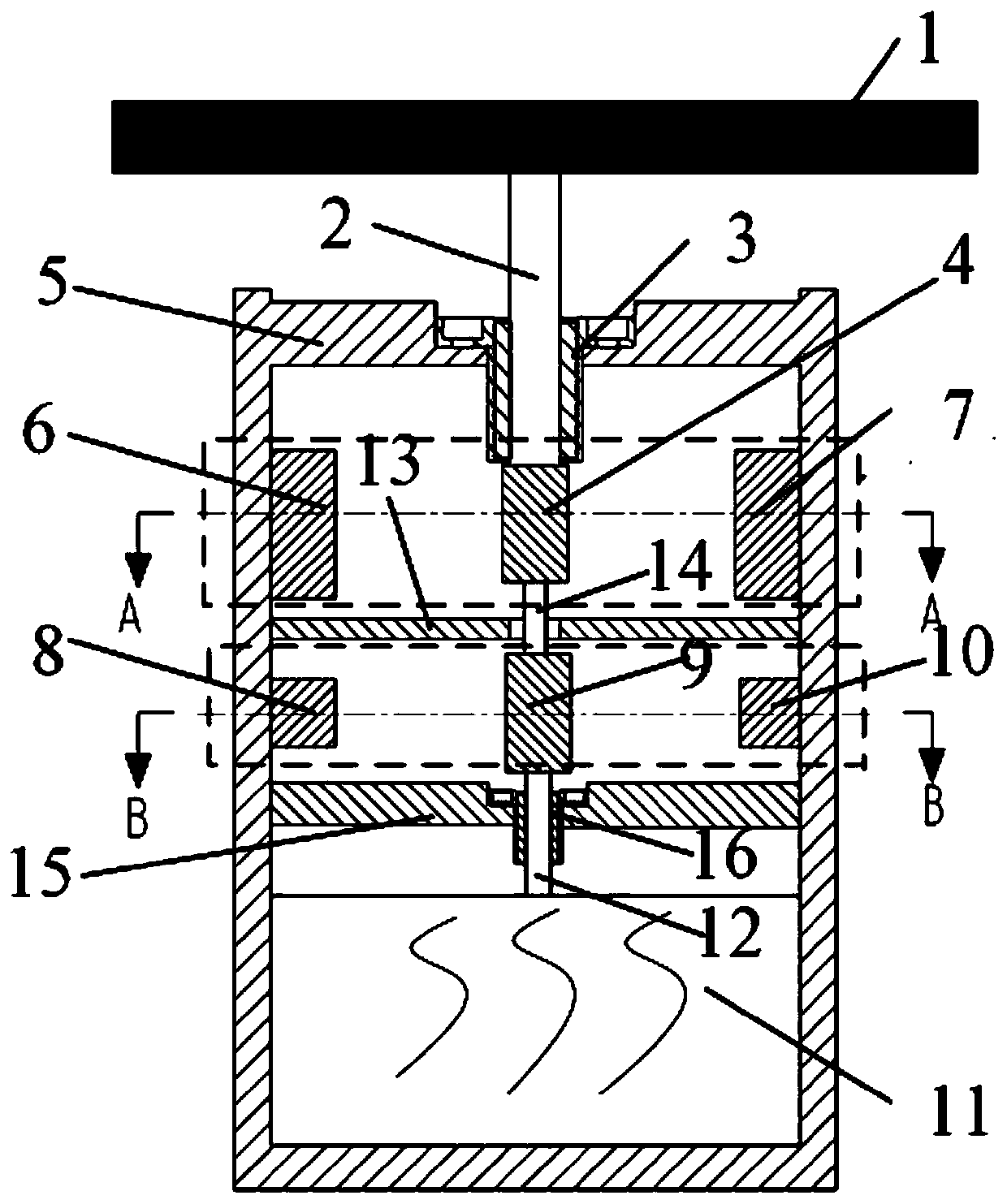

Method and apparatus for high-efficient crude oil desalination / dehydration

InactiveCN102226100AReduce difficultyReduce the water content of crude oilRefining by water treatmentTreatment with plural serial refining stagesChemistryElectric field

The invention belongs to the technical field of petrochemical industry, and particularly relates to a method and an apparatus for high-efficient crude oil desalination / dehydration by a combined filtration-electric field coalescence method. The apparatus for high-efficient crude oil desalination / dehydration of the invention comprises a raw material conveying system, a mixing device, a dehydration filtration device, and an electrical desalting device which are connected in order. The method for high-efficient crude oil desalination / dehydration of the invention is realized by using the apparatus for high-efficient crude oil desalination / dehydration of the invention and through the steps of raw material preheating, mixing, preliminary demulsification, and electrical desalination / dehydration. The invention adopts a combined filtration-electric field coalescence method for crude oil desalination / dehydration, which can overcome respective disadvantages of performing desalination / dehydration process by a filtration method or an electric field coalescence method, decrease running severity of both the two methods, not only improves the adaptability of the crude oil desalination process, the desalination / dehydration rate, and the stable running rate, but also reaches the purposes of energy saving and consumption reduction.

Owner:GUANGZHOU BOXENERGY TECH

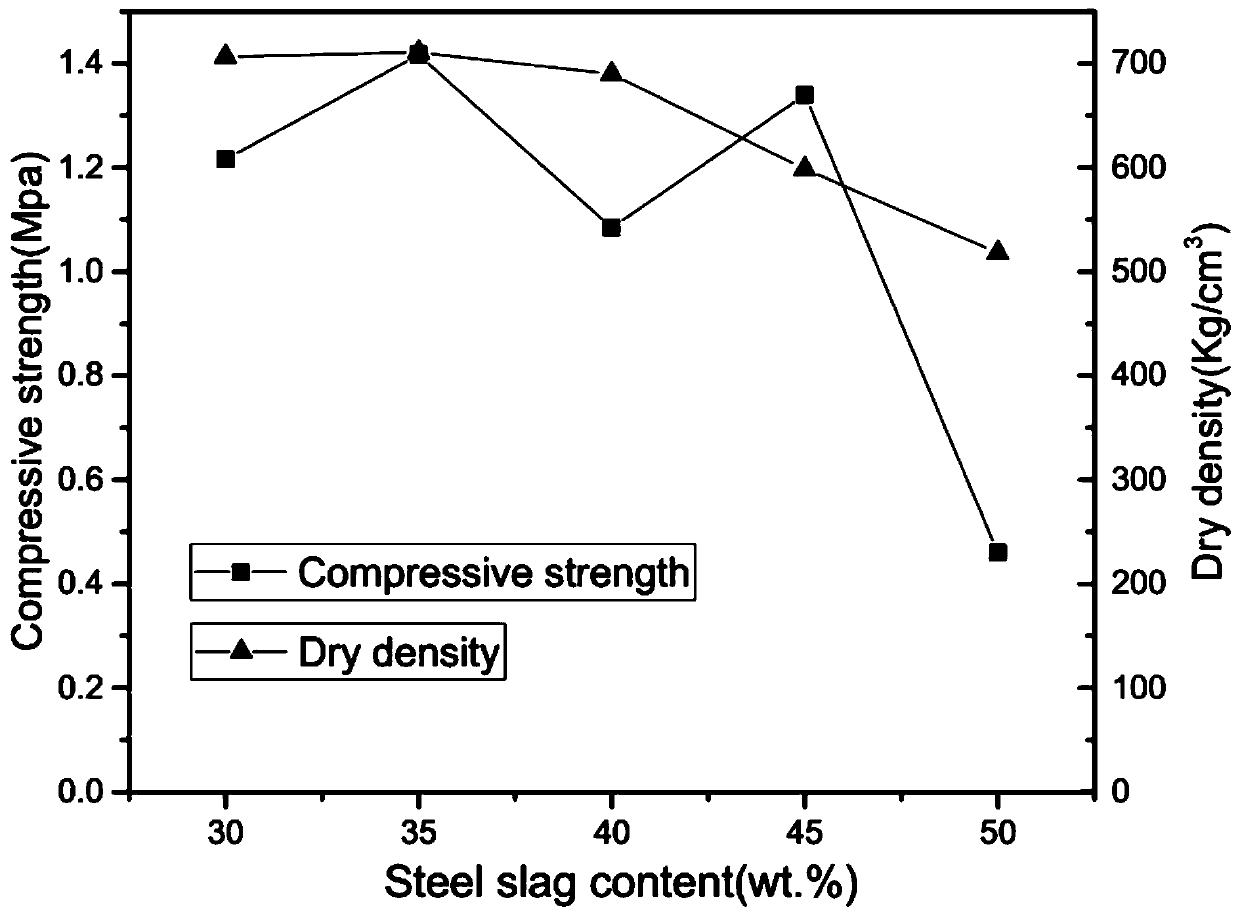

Aerated concrete block and preparation process thereof

PendingCN110734300ASolve the problem of accumulation and damage to the environmentElicit activityCeramicwareCompressive resistanceSlag

The invention discloses an aerated concrete block which is prepared from a cementing material, an additive and water by adopting an autoclaving-free process. The cementing material mainly comprises the following raw materials: steel slag, mineral slag and cement. The invention also discloses a preparation process of the aerated concrete block. The preparation process comprises the following steps:a, selecting steel slag, quick lime, gypsum, fly ash, cement, slag, aluminum powder paste, sodium sulfate, a foam stabilizer, water glass and sodium hydroxide as raw materials; b, carrying out dry mixing on the cementing material to prepare a mixture; c, adding water into the aluminum powder paste, the foam stabilizer and a curing agent to prepare a suspension; d, dissolving water glass and sodium hydroxide into water, and carrying out uniform mixing under stirring; e, pouring a solution obtained in the step d into the mixture obtained in the step b to obtain slurry; f, adding the obtained suspension into the slurry, and carrying out stirring to form paste; g, pouring the paste into a mold, carrying out casting molding, performing demolding after pre-curing, and carrying out hot and wet maintenance on a demolded green body to obtain the finished block. The block prepared by the autoclaving-free preparation process has the advantage of high compressive strength.

Owner:HUNAN INSTITUTE OF ENGINEERING

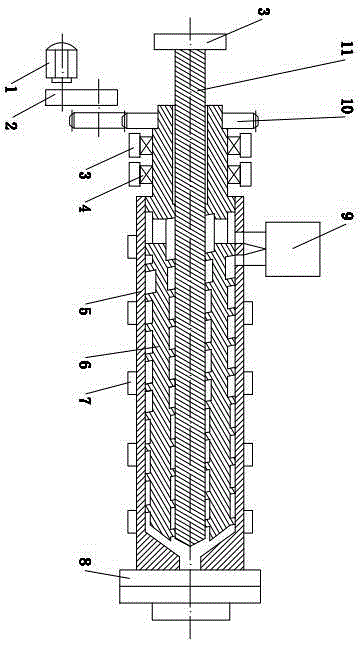

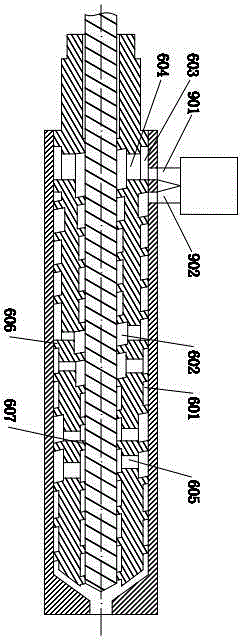

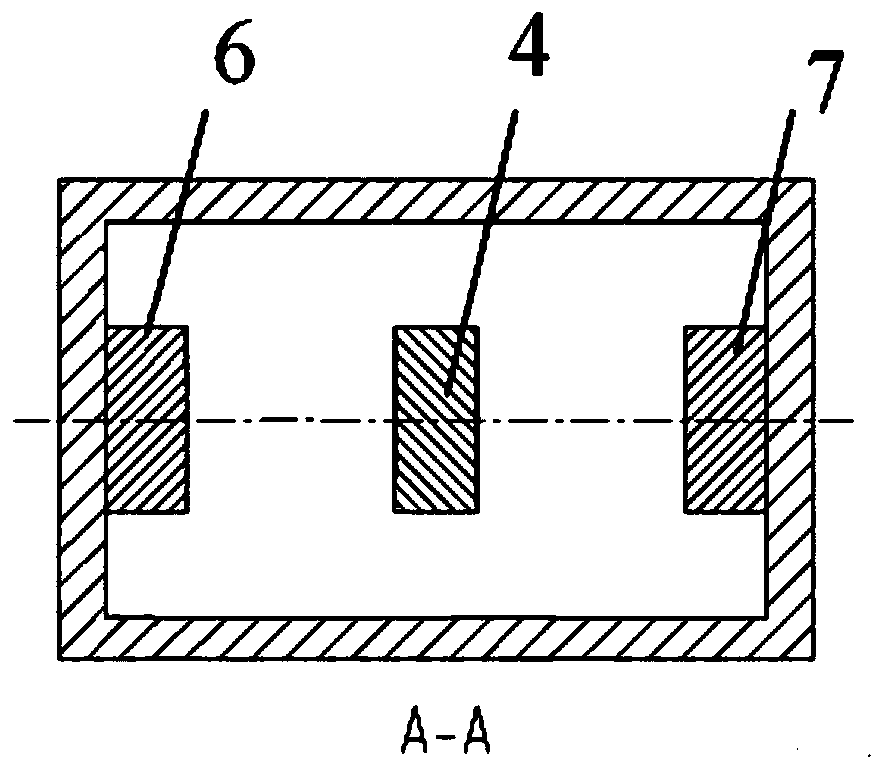

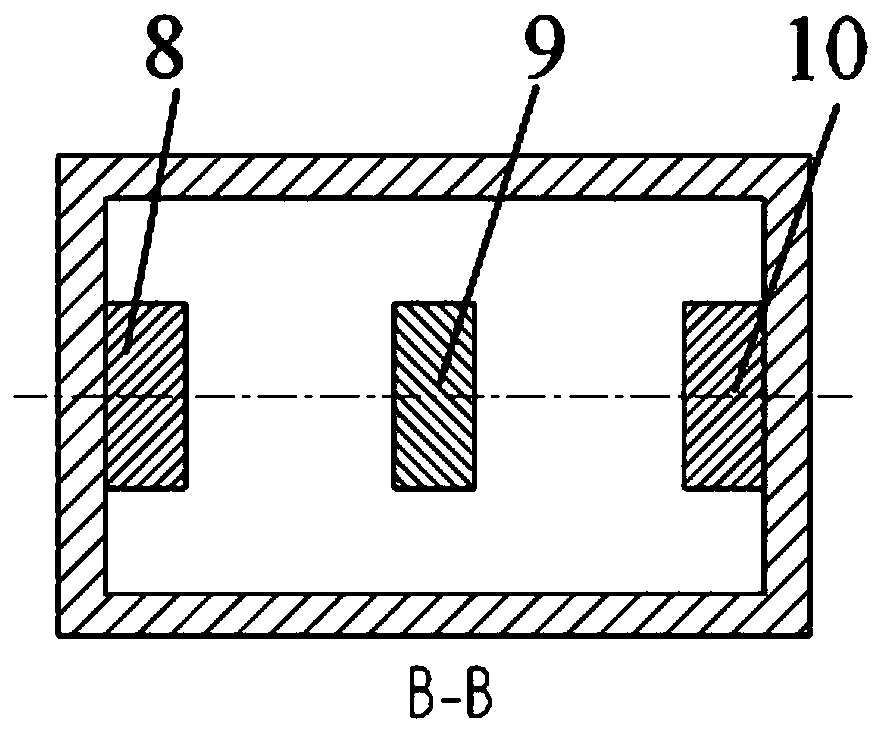

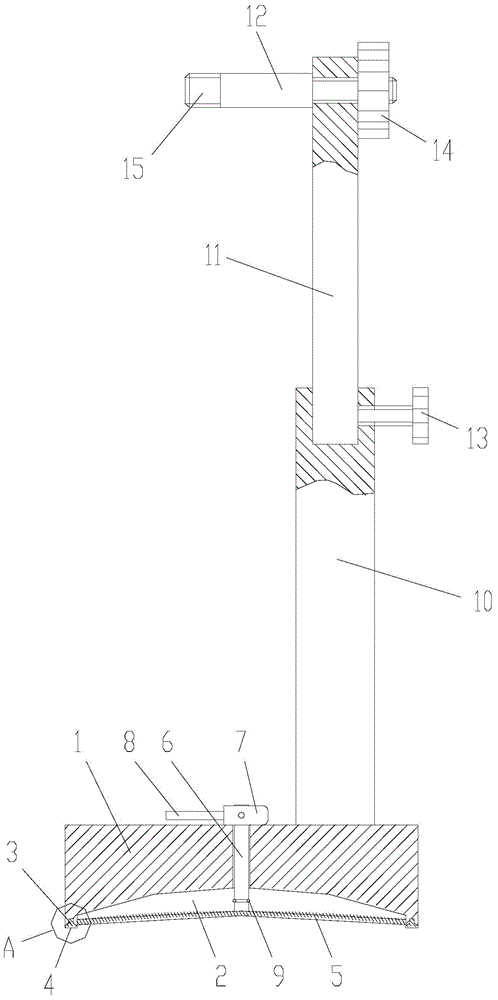

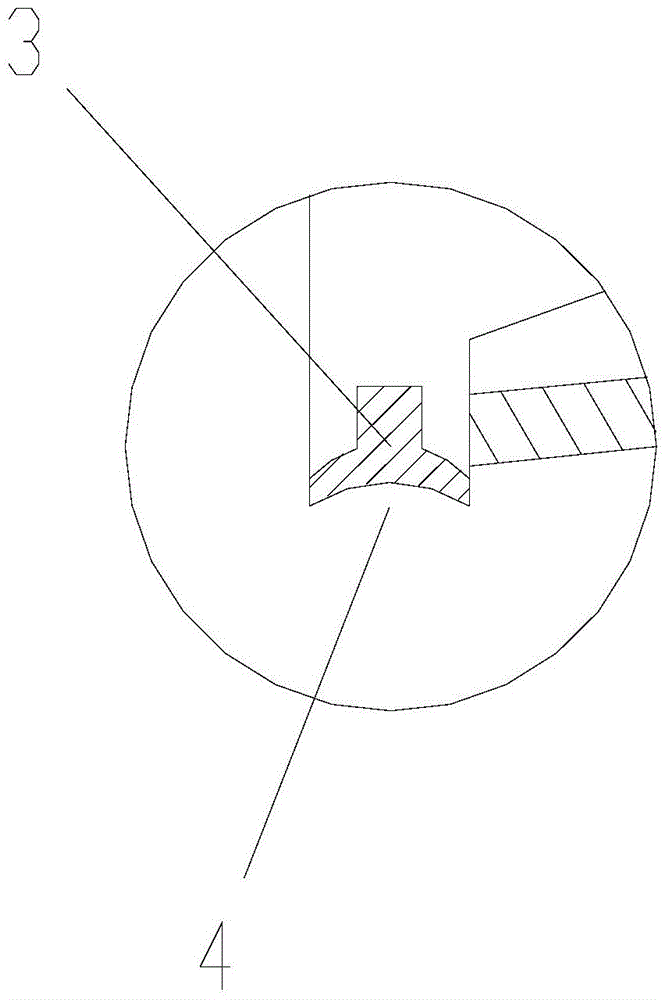

Hollow single screw extruder with spiral grooves in double sides

The invention relates to a hollow single screw extruder with spiral grooves in double sides. The hollow single screw extruder comprises a motor, a transmission mechanism, a base, a radial thrust bearing pack, a machine barrel, a hollow screw, an electric heating coil, an extruder head, a hopper, a gear and a central shaft. The motor drives the hollow screw to rotate through the transmission mechanism and the gear, and the extruder head is arranged at the discharge end of the machine barrel. The hollow single screw extruder is characterized in that the hollow screw is located in the machine barrel, and the central shaft is located in the hollow screw; the hollow screw is coaxial with the machine barrel and the central shaft and can rotate relative to the machine barrel and the central shaft; the outer spiral groove is formed in the outer circular surface of the hollow screw, and the inner spiral groove is formed in an inner circular hole of the hollow screw; a first discharge outlet and a second discharge outlet of the hopper are communicated with the left end of the inner spiral groove and the left end of the outer spiral groove respectively, and the right end of the outer spiral groove and the right end of the inner spiral groove are communicated with the extruder head. According to the hollow single screw extruder provided with the hollow screw, the length of the screw can be greatly reduced, the requirement of a material extrusion molding process for the relative length of a flow channel of the screw can be met sufficiently, the residence time of materials in the spiral grooves is shortened, decomposition of the high molecular materials is reduced, and product quality is guaranteed; besides, the service life of the machine can be prolonged, the productivity of the machine can be improved significantly, and the heat efficiency is improved.

Owner:SHUNDE POLYTECHNIC

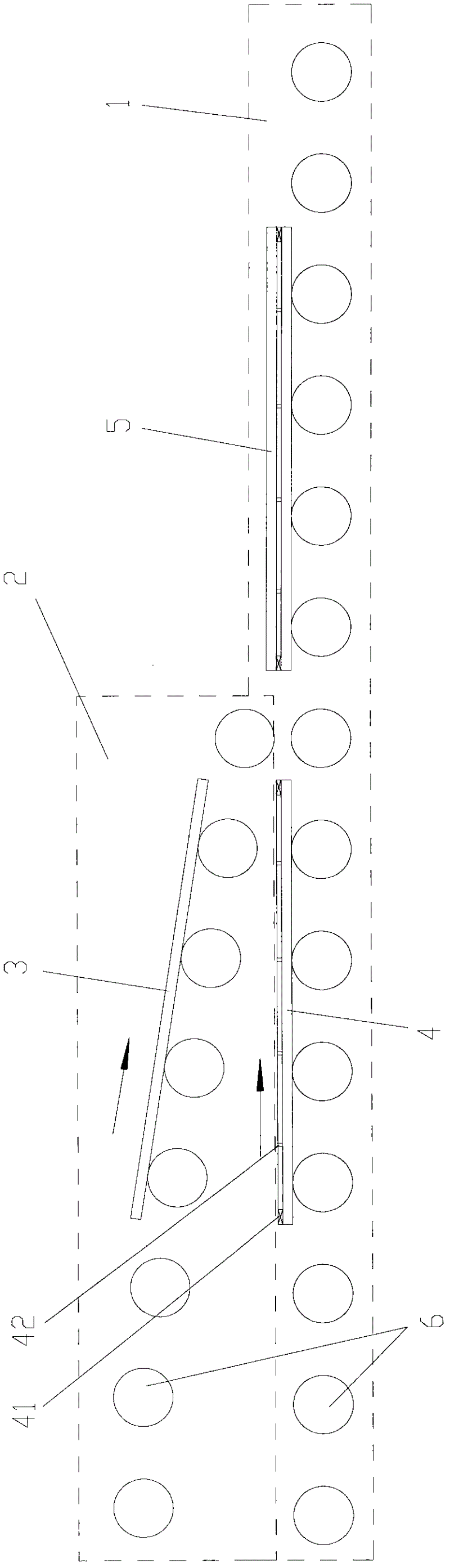

Glass plate combining apparatus used for making multilayer structure glass member

ActiveCN102617051AImprove the efficiency of laminationReduce labor intensityLamination plant layoutLamination ancillary operationsMechanical engineeringPoor quality

The invention discloses a glass plate combining apparatus, which comprises at least two glass plate conveying mechanisms, and the combining apparatus uses a mode that the glass plate conveyed by a conveying mechanism is send out and then automatically dropped on the another conveying mechanism to automatically assemble the glass plates conveyed by each conveying mechanism together. The combining apparatus realizes the automatic assembly of glass plates before sealing, so that the problems of large labor intensity of workers and poor quality stability of glass plate combination can be eliminated, the combination efficiency of the multi-sheet can be enhanced and the condition of the high efficiency production for the multilayer structure glass member can be created.

Owner:洛阳兰迪真空玻璃科技有限公司

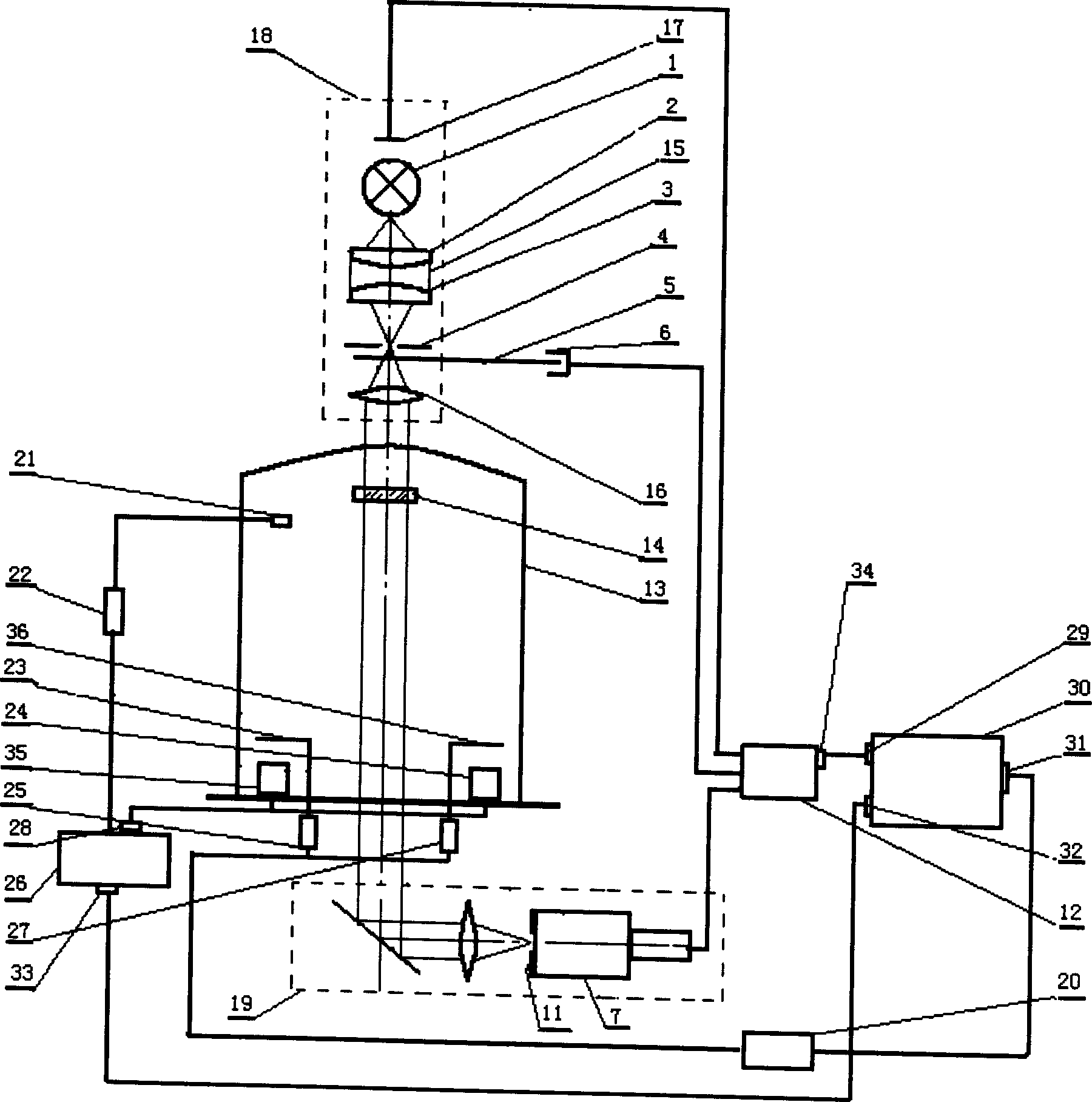

Computer controlled filming device

InactiveCN1696336AEasy to analyzeEliminate Stability IssuesVacuum evaporation coatingSputtering coatingLight sourceEngineering

A computer controlled plating apparatus is composed of an optical film thickness monitor system consisting of light source and emitting system, monitor chip, signal receiver system and phase-locked amplifier, the computer with control program consisting of parameter setting-up module and data processing module, crystal controller, and barrier switch controller.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

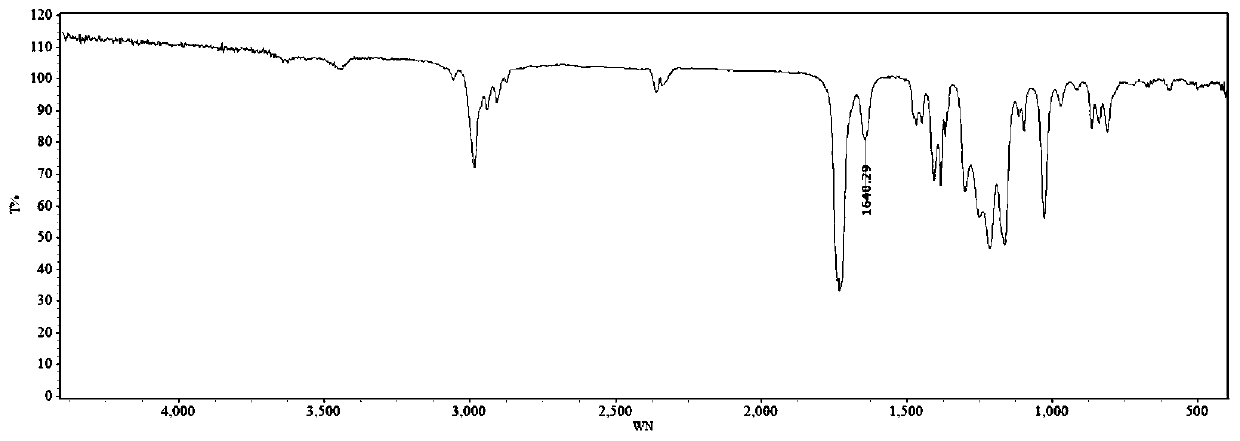

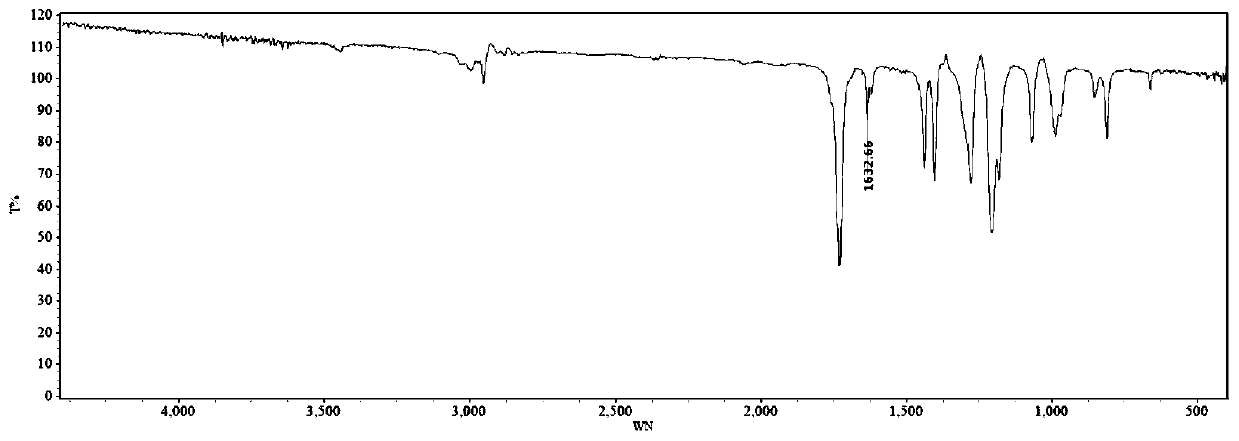

Aspartate resin of novel structure, polyurea coating as well as preparation method and application of polyurea coating

ActiveCN109912442AAvoid formingEliminate Stability IssuesOrganic compound preparationAmino-carboxyl compound preparationRoom temperatureHardness

The invention provides aspartate resin of a novel structure and a preparation method of a polyurea coating containing the aspartate resin. According to a synthesis method of the aspartate resin of thenovel structure, unsaturated binary carboxylic ester and unsaturated monocarboxylic ester are used in the aspartate resin of the novel structure to have a Michael addition reaction with a primary amino compound, wherein the unsaturated binary carboxylic ester is alkyl acrylate or alkyl methacrylate. The novel polyurea coating is characterized in that the coating is cured and formed at the room temperature in a form of double components, wherein the component A is a common isocyanate curing agent, and the component B is a mixture at least containing the aspartate resin of the novel structure,which is prepared according to claim 3 or 4. Acrylate (methacrylate) with a smaller space volume is introduced into one end of a molecular chain, the internal plasticization effect after the coating is cured is reduced, and the hardness of the coating is increased.

Owner:郁维铭 +1

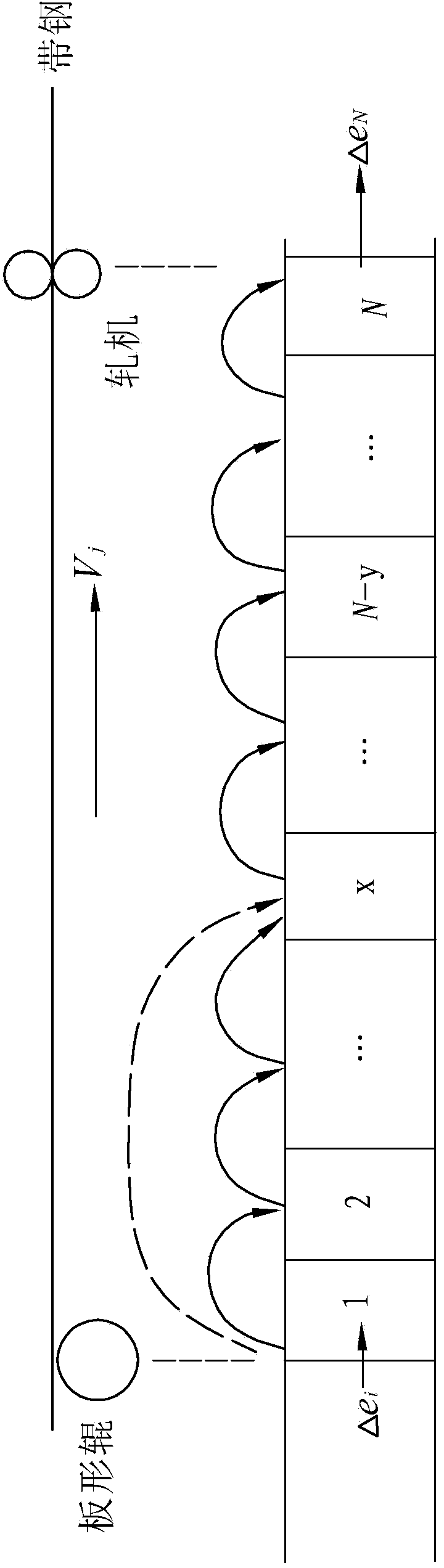

Feedforward control method for cold rolled strip shape

ActiveCN105499279AImprove stabilityIncrease production capacityRare end control deviceMeasuring devicesRolling millAdverse effect

The invention relates to a feedforward control method for a cold rolled strip shape. The control method comprises the steps of configuring a strip shape meter only at an inlet of a cold rolling mill or configuring strip shape meters both at the inlet and an outlet of the cold rolling mill to detect the shape of a strip at the inlet of the cold rolling mill in real time in order to achieve the control aims that the rolling process is stable and the shape of a strip at the outlet is favorable; regulating a strip shape regulating mechanism of the rolling mill according to the change feedforward of the shape of the strip at the inlet of the rolling mill; and eliminating the adverse effects of the shape of the strip at the inlet of the rolling mill on the stability of the rolling process and the shape of the strip at the outlet of the rolling mill in time. Compared with the prior art, the feedforward control method not only can be used for improving the stability of the cold rolling process and improving the capacity of a unit, but also can be used for ensuring the control precision of the strip shape and improving the product quality.

Owner:NINGBO BAOXIN STAINLESS STEEL

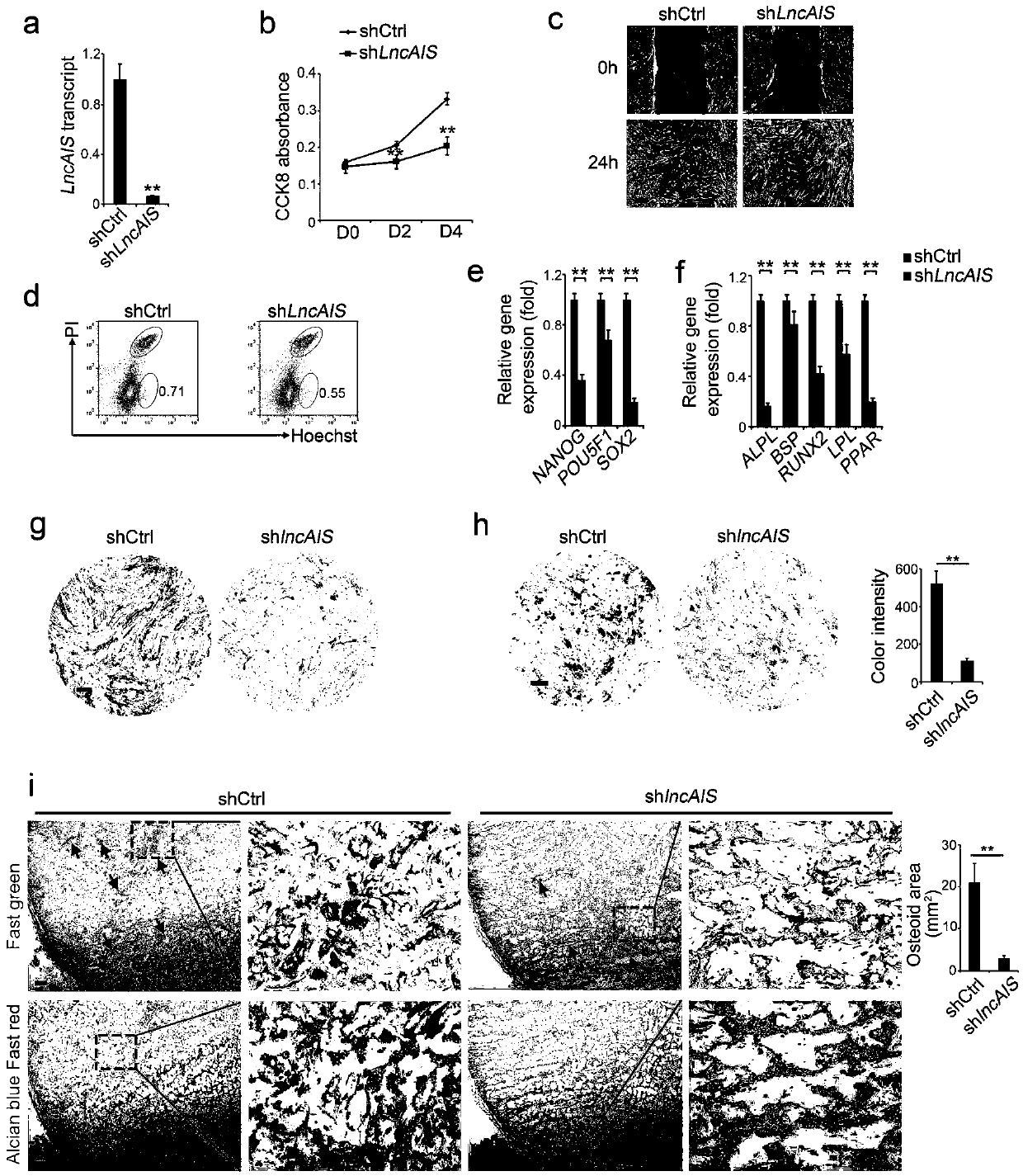

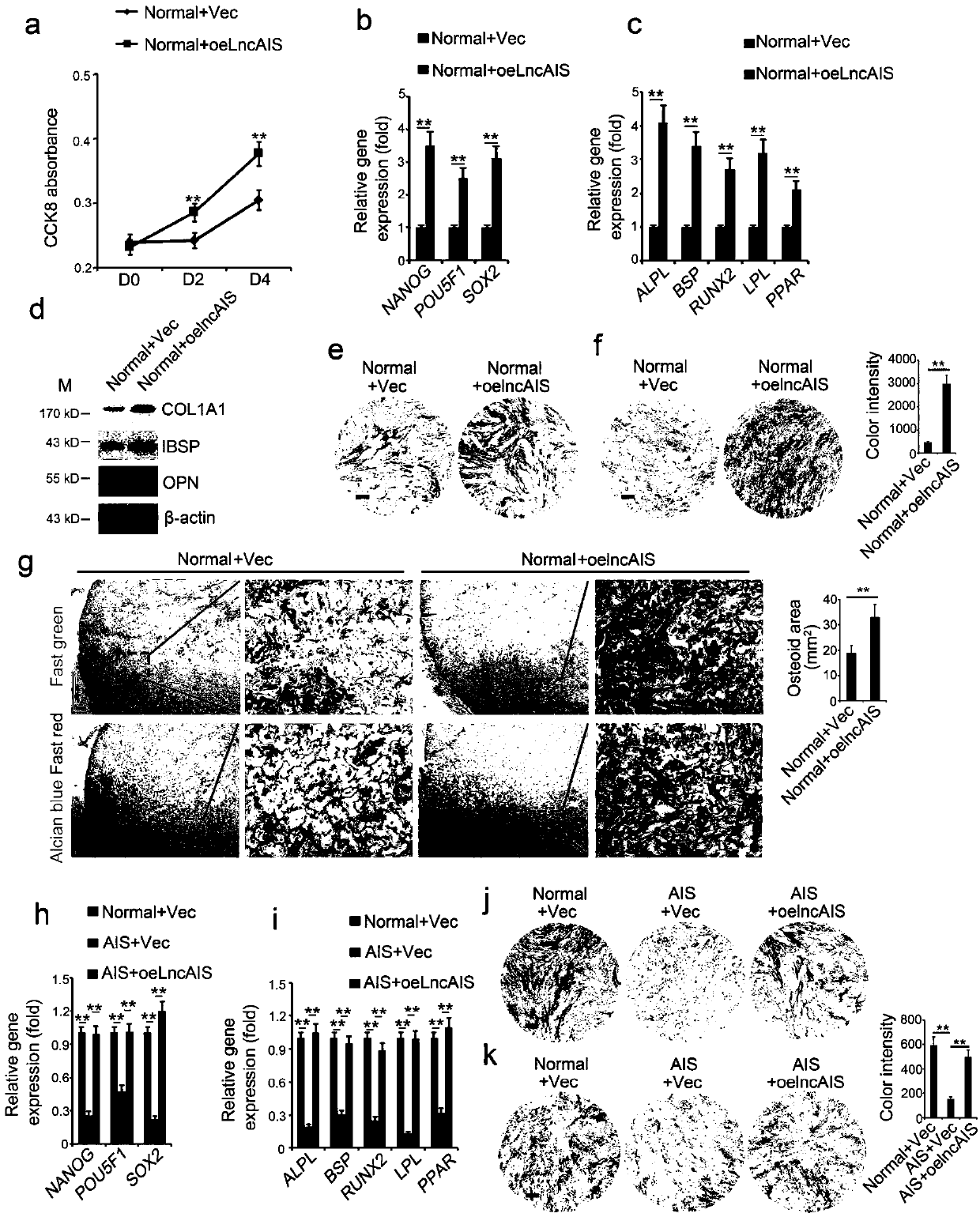

Biological agent for promoting osteogenic differentiation of bone marrow mesenchymal stem cells

ActiveCN109568343AImprove stabilityEliminate Stability IssuesSkeletal disorderUnknown materialsRUNX2Biology

The invention discloses a biological agent for promoting osteogenic differentiation of bone marrow mesenchymal stem cells (BM-MSC), and a pharmaceutical composition for prevention and / or treatment ofadolescent idiopathic scoliosis (AIS). The inventor finds that lncAIS is key lncRNA involved in progress of AIS, wherein the lncAIS interacts with NF90 to promote HOXD8mRNA stability, thus transcription of RUNX2 in the BM-MSC is enhanced, and thus osteogenic differentiation of the normal BM-MSC is caused. By contrast, the NF90 cannot be collected due to down-regulating of the lncAIS in the BM-MSCof an AIS patient , thus the HOXD8mRNA stability is eliminated, and in this way, transcription of the RUNX2 for osteogenic differentiation is hindered. Thus, the BM-MSC of overexpression lncAIS, HOXD8or the RUNX2 can be used for preparing the biological agent for promoting osteogenic differentiation of the BM-MSC and the pharmaceutical composition for prevention and / or treatment of the AIS, and thus the new means is provided for prevention and / or treatment of the AIS.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

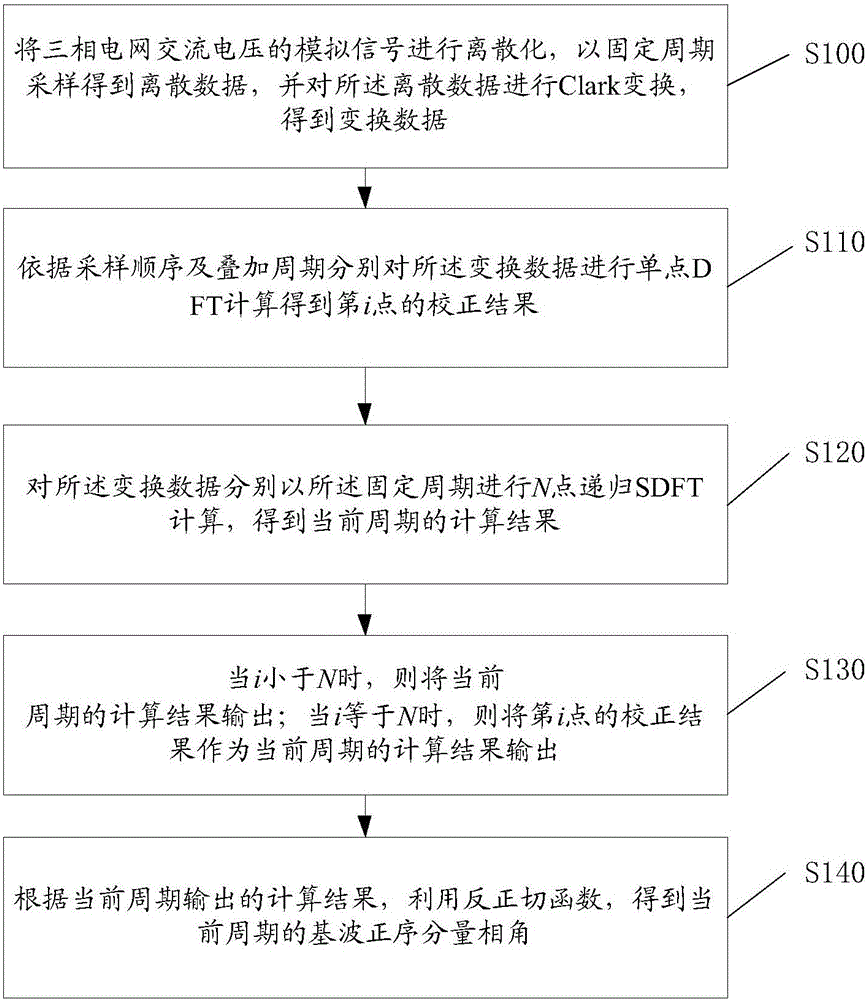

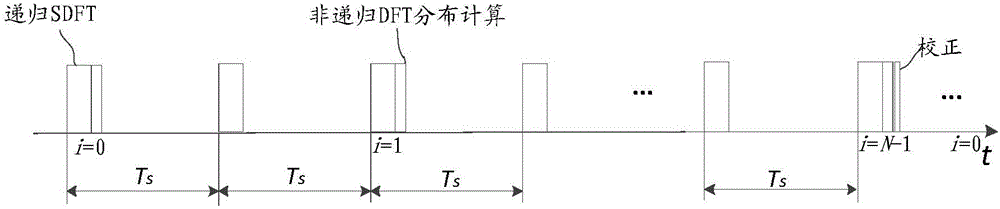

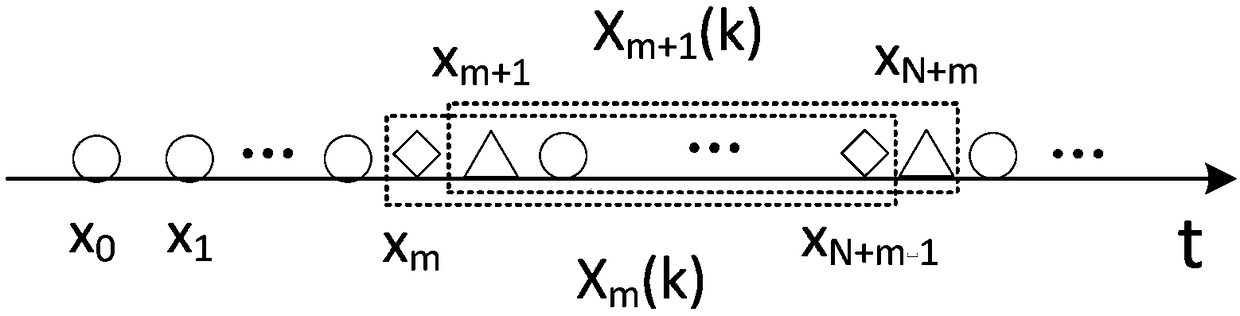

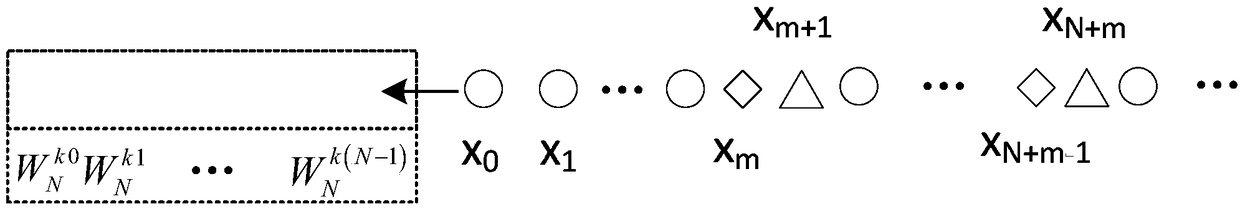

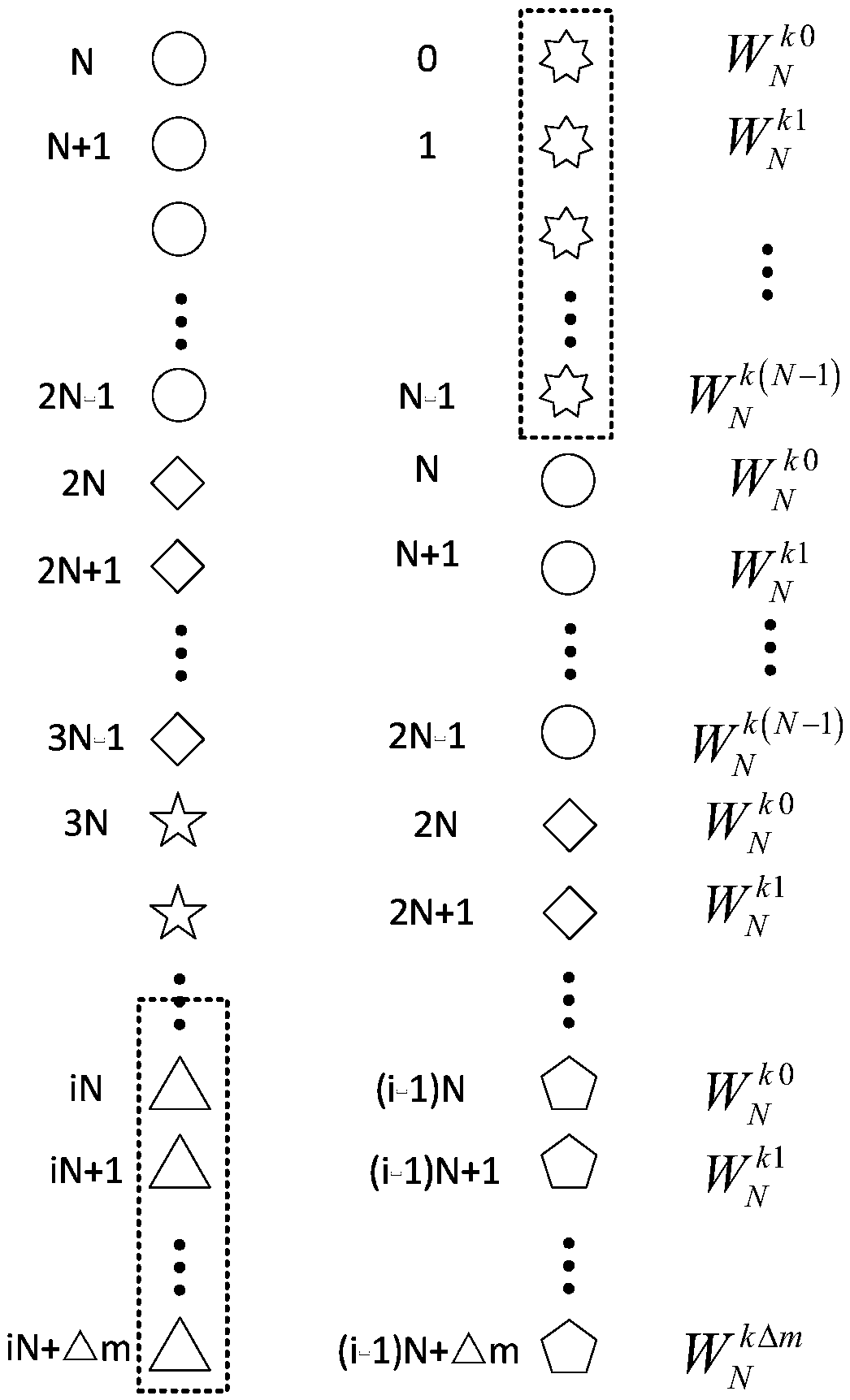

SDFT fundamental positive sequence component phase synchronization method and phase synchronization system

ActiveCN105759119AAccurate detectionEliminate Stability IssuesVoltage-current phase angleSample sequencePhase synchronization

The invention discloses an SDFT fundamental positive sequence component phase synchronization method and a phase synchronization system. The method comprises steps: analog signals for three-phase power grid AC voltage are discretized, discrete data are obtained through sampling in a fixed period, Clark transform is carried out on the discrete data, and transform data are obtained; according to a sampling sequence and an overlapped period, single-point DFT calculation is carried out on the transform data to obtain a correction result for an ith point, wherein the correction result for the ith point is the accumulated value between the DFT calculation result for the ith point and the correction result for an (i-1)th point; N-point recursive SDFT calculation is carried out on the transform data in the fixed period to obtain a calculation result in the current period; when i is smaller than N, the calculation result in the current period is outputted; when i is equal to N, the correction result for the ith point serves as the calculation result in the current period to be outputted; according to the calculation result outputted in the current period, an arc-tangent function is used for acquiring a fundamental positive sequence component phase angle. Thus, the problem of stability caused by recursive iterative cumulative errors can be eliminated.

Owner:SUZHOU UNIV

Method for producing a large steel tube

InactiveCN102056687AImproved mechanical performanceShorten production timeSheet steelStress relieving

The invention relates to a method for producing a steel tube, wherein a steel sheet (4) is formed into tubular body (1.2) having a round cross section in a bending process (a), welded in a subsequent welding process (b) along the longitudinal edges facing each other for producing a continuous longitudinal seam, and then subjected to a stress-relieving treatment. The production quality is improved, with reduced production time, in that the stress-relieving treatment is performed in a process (c) for concentrically truing along the circumference in at least one segment relative to the longitudinal axis thereof, while cold forming by compression. The mechanical technological properties of the material are also thereby improved.

Owner:EISENBAU KRAMER

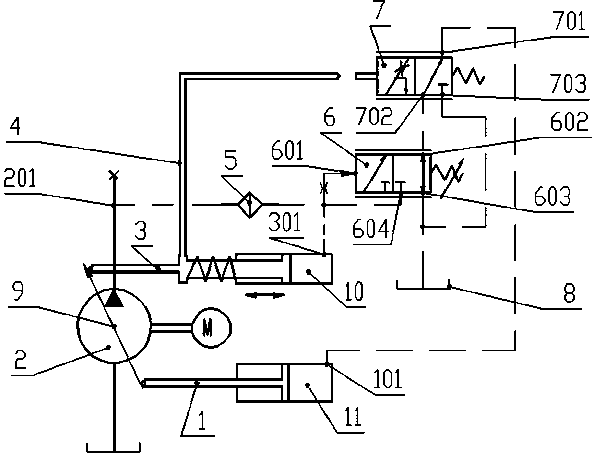

Constant-pressure control device and method for hydraulic pump

ActiveCN104179734AReduce displacementRelieve pressureServomotor componentsServomotorsFuel tankHydraulic pump

The invention discloses a constant-pressure control device and method for a hydraulic pump. An oil inlet of a fine filter is communicated with an oil discharge port of the hydraulic pump, an oil outlet of the fine filter is communicated with a constant-pressure control valve port P and a rodless cavity of a small variable piston at the same time, a constant-pressure control valve port A is communicated with a shock reducing valve port P, a constant-pressure control valve port T is communicated with a shock reducing valve port T and an oil tank at the same time, a constant-pressure control valve control port is communicated with the constant-pressure control valve port P through internal fixing damping, and a shock reducing valve port A is communicated with a rodless cavity of a large variable piston; a feedback rod is fixedly connected with the small variable piston, so that when pressure at the oil discharge port of the hydraulic pump is higher than pressure set by a proportional spring of a constant-pressure control valve, the feedback rod can be driven by the small variable piston to move to contact with a valve spool of a shock reducing valve and push the valve spool to move to the communicating station of the shock reducing valve port P and the shock reducing valve port T; when pressure at the oil discharge port of the hydraulic pump is lower than pressure set by the proportional spring of the constant-pressure control valve, the feedback rod can be separated from the valve spool of the shock reducing valve.

Owner:ZHEJIANG DETAI ELECTROMECHANICAL ENG

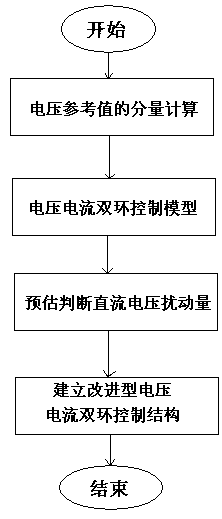

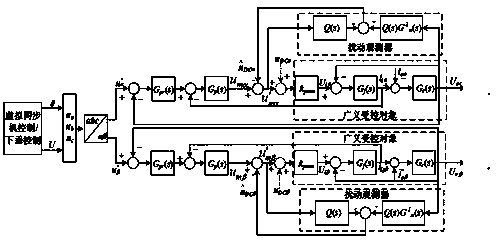

Disturbance observation suppression method for direct-current component of output voltage of photovoltaic grid-connected inverter

ActiveCN109510200ASimple methodSimple designSingle network parallel feeding arrangementsPower oscillations reduction/preventionVoltage amplitudeVoltage reference

The invention discloses a disturbance observation suppression method for the direct-current component of the output voltage of a photovoltaic grid-connected inverter. The method includes the followingsteps that: S1, the output voltage amplitude and phase angle reference instruction of the inverter are calculated according to virtual synchronous machine control or droop control, and the componentof a voltage reference value is calculated; S2, the filter capacitor voltage and filter inductor current data of the inverter are collected, a voltage loop / current loop model is established; S3, a generalized controlled object model is established, the filter capacitor voltage data of the inverter are collected, and a disturbance observer is adopted to estimate a direct-current voltage disturbancequantity; S4, a direct-current voltage disturbance estimation value is compensated to modulation voltage signals through feedforward compensation, so that an improved voltage loop / current loop control structure is formed, and the effective suppression of the direct-current component of the output voltage of the inverter is realized. The method has the advantages of parameter design simple, convenient operation, convenience in engineering realization, good suppression effect and high stability. With the method adopted, conventional voltage feedback control and outer loop voltage following performance are not affected.

Owner:SOUTHEAST UNIV +1

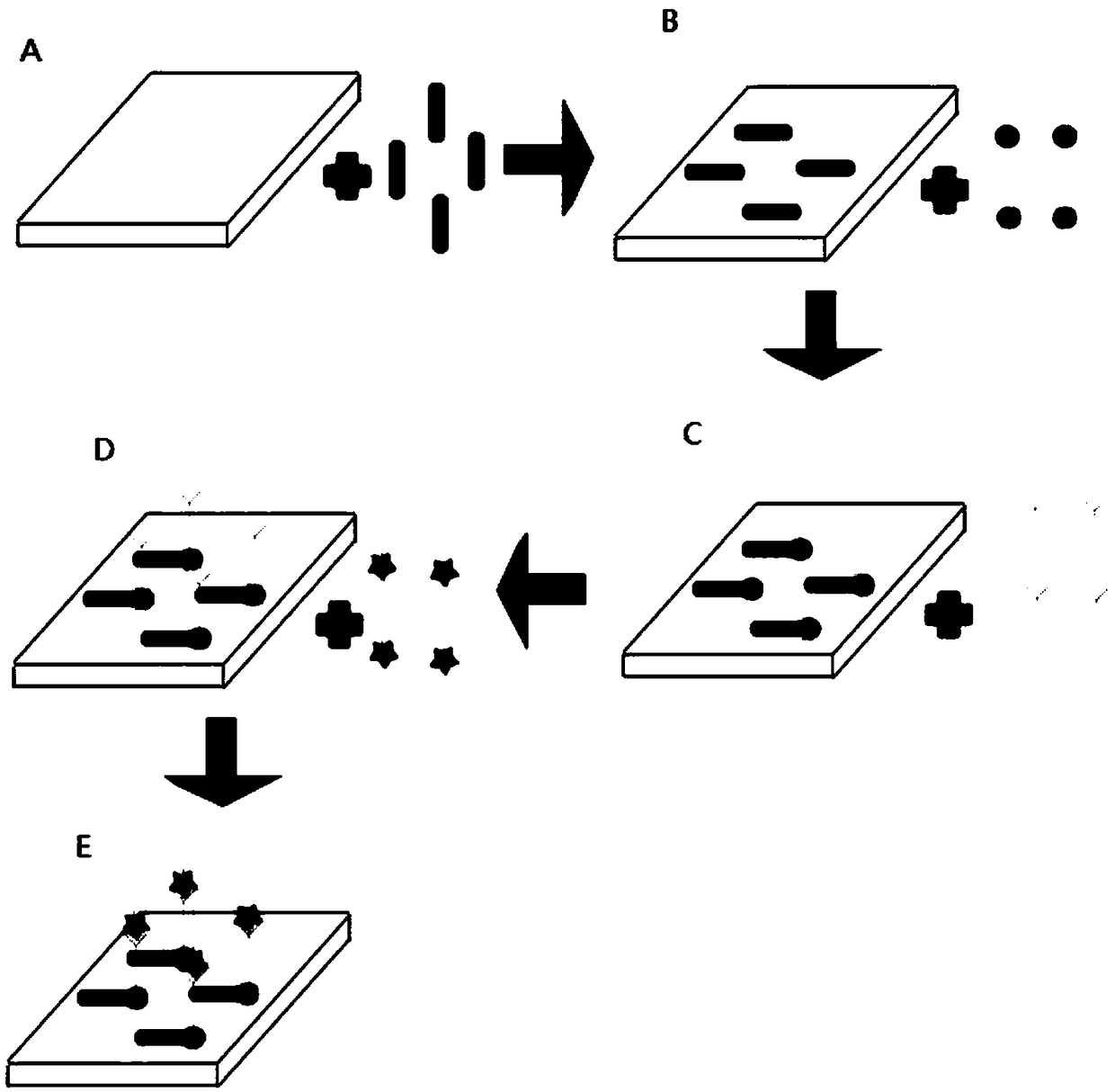

Detection method and detection device for Raman spectrum encoded liquid phase biochip

InactiveCN108896526AHigh spectral resolutionEliminate Stability IssuesRaman scatteringMicroscopic imageFluorescence

The invention discloses a detection method and a detection device for a Raman spectrum encoded liquid phase biochip. The detection method comprises the following steps: after a molecular reaction between a vector and a fluorescent probe, connecting the vector to nano metal particles to obtain a surface enhanced Raman vector with a Raman enhancing effect; reacting with a mixture of Raman to-be-detected molecules to prepare the Raman spectrum encoded liquid phase biochip; quantitively analyzing the liquid phase biochip through Raman spectrum to obtain a detection result of Raman to-be-detected molecules types; and quantitatively analyzing the liquid phase biochip through fluorescence microscopic imaging to obtain a detection result of quantity of the Raman to-be-detected molecules. The detection method has the advantages of an existing detection method of a fluorescent encoded microsphere-based liquid phase biochip, solves the problem that the existing liquid phase biochip is poor in encoding accuracy and stability fundamentally and has a very good application prospect in the fields of biomolecular analysis, clinical disease diagnosis and the like.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

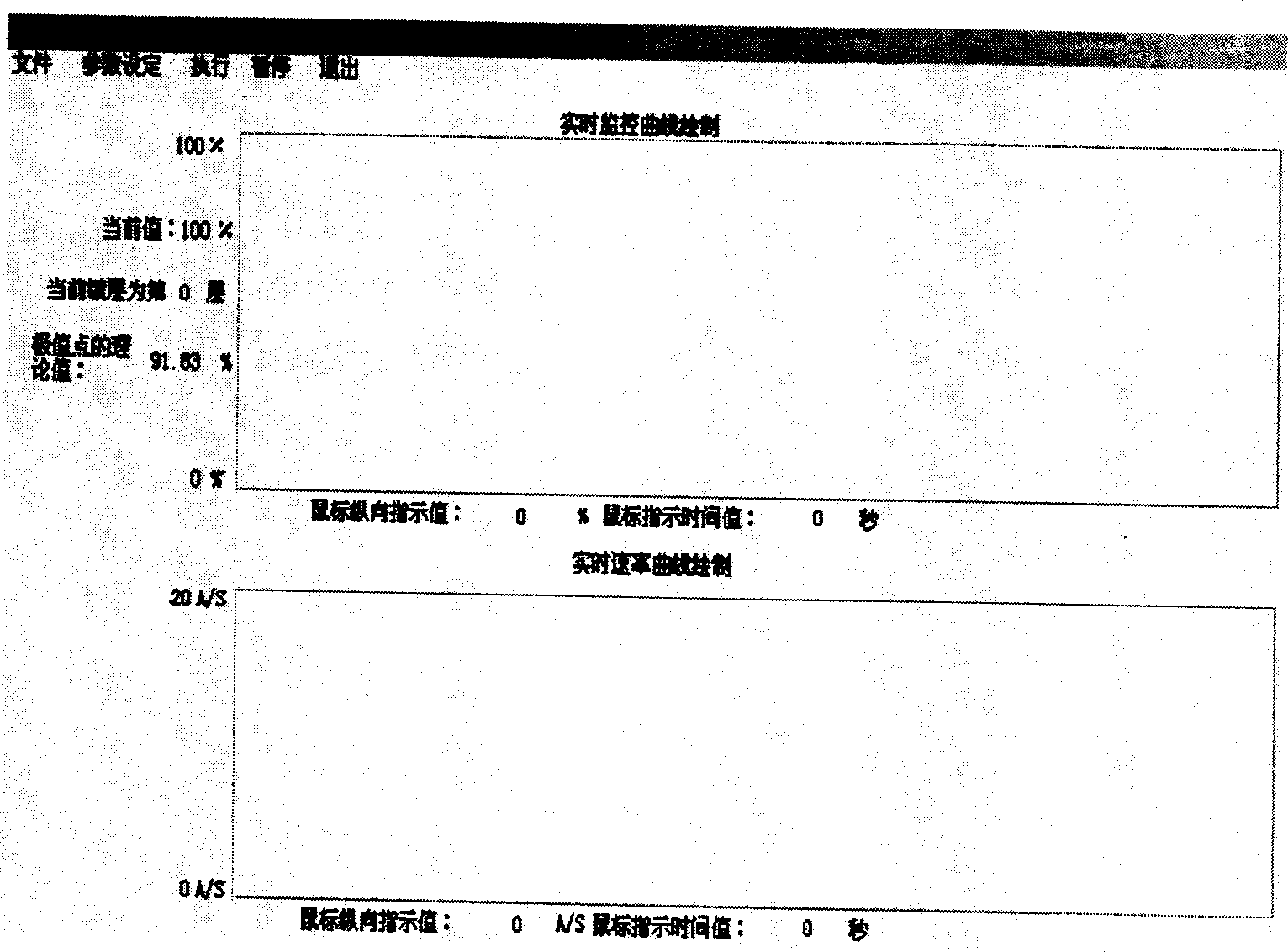

Electron beam deflection device of computer controlled coating machine and control method thereof

InactiveCN101619440AControl deflectionVersatilityVacuum evaporation coatingSputtering coatingControl dataData acquisition

The invention relates to an electron beam deflection device of a computer controlled coating machine and a control method thereof. The electron beam deflection device of the computer controlled coating machine comprises a scanning control instrument, a manual remote controller, a data collecting card and a computer. The invention has high control precision and reliability on electron beam deflection and widespread adaptability on different electron gun equipment. After carrying out the processes of data collection and data processing once, each kind of electron gun equipment can be automatically run and controlled by the computer by adjusting control data by a user.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

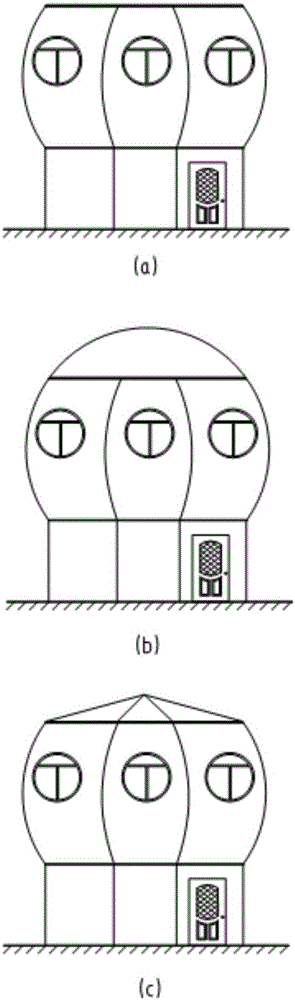

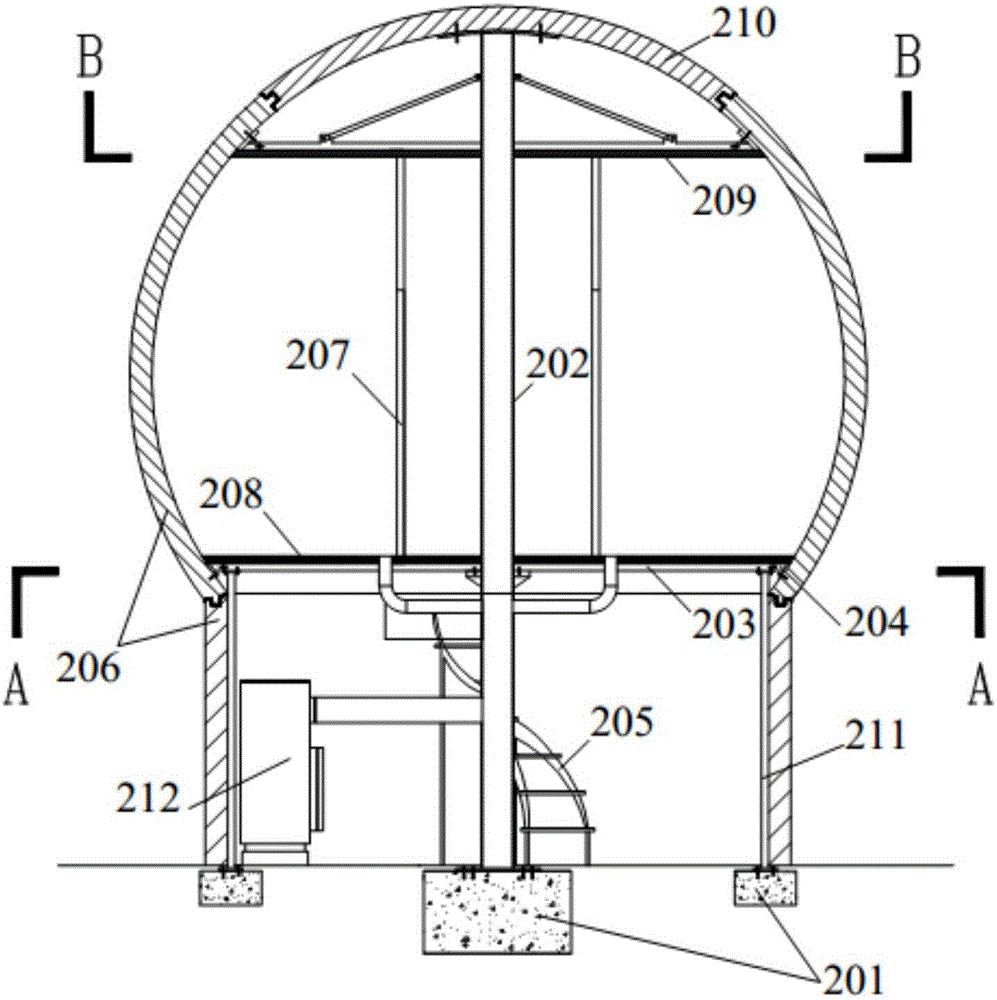

Light assembly type island living accommodation

InactiveCN105952193AUniform stressReduce construction costsSpecial buildingBuilding constructionsHigh humidityNatural disaster

The invention discloses a light-duty prefabricated sea island living cabin. The living cabin is shaped like a cylinder, a sphere or a combination thereof, and the inside of the living cabin is composed of a central column, a steel beam, a ring beam and surrounding columns. The main steel frame structure, the connection mode between the central column, steel beam, ring beam and surrounding columns is bolt connection; the central column is a hollow structure, and the main steel frame structure of the living cabin and the inner and outer wall panels are anti-corrosion light quality composite panels. The curved surface shape of the house of the present invention eliminates the adverse effects of the large wind pressure gradient at the eaves and corners of the traditional square building on the stability and wind resistance of the building, and can make the stress of each part of the house more uniform, so that the wind resistance of the building can be significantly improved Performance, and effectively resist the harsh climate environment on the island and natural disasters such as typhoons. The curved surface anti-corrosion light-weight composite plate used in the house of the invention can effectively prevent the erosion of sea salt spray and the damage of high-temperature, high-humidity and strong-wind environment.

Owner:TIANJIN UNIV

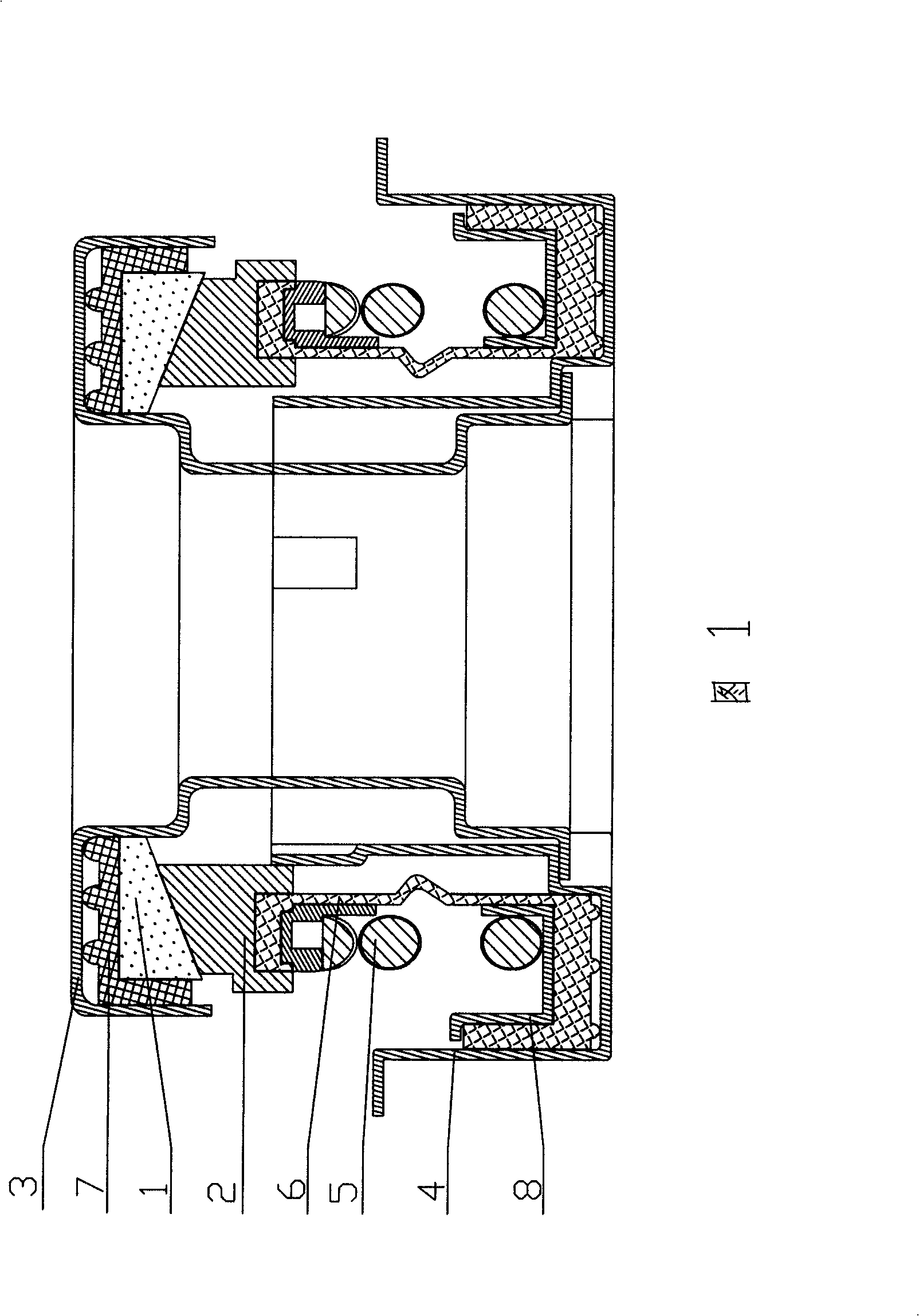

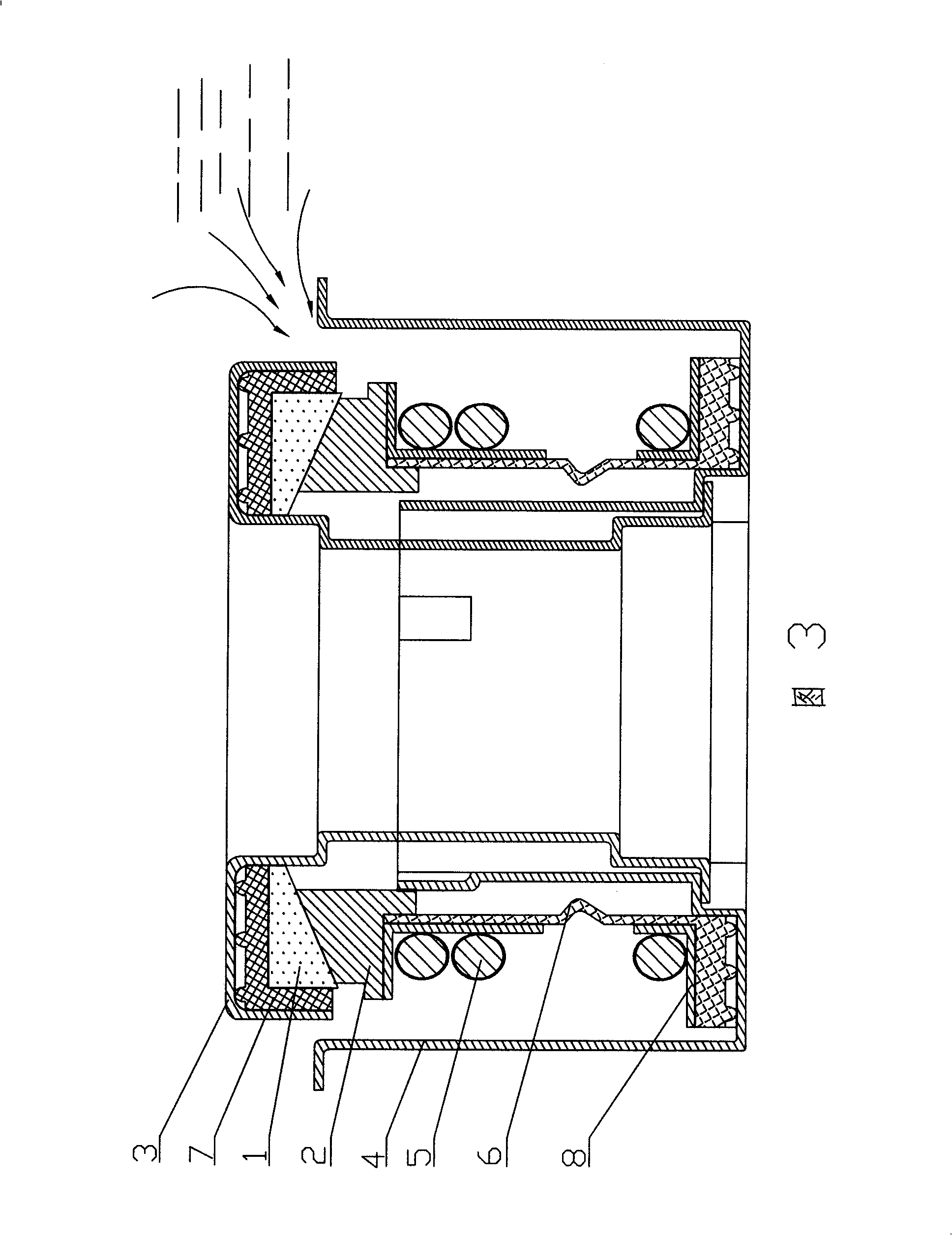

Water pump seal part assembly

InactiveCN101349280AReduce volumeLarge sealing rangeCoolant flow controlPump componentsConical surfaceEngineering

The invention provides a water pump sealing piece assembly with small volume, fine sealing effect and strong commonality, which comprises a moving ring body, a fixed ring body, a moving ring shaft housing seat, a fixed ring shaft housing seat, a moving ring sealing ring, a spring, a spring retainer and a rubber sealing sleeve, the upper portion of the rubber sealing sleeve is embedded in a groove of the fixed ring body, the lower portion is sleeved in the fixed ring shaft housing seat, the lower surface of the moving ring body is engaged with the upper surface of the fixed ring body, and engaging surfaces of the moving ring body and the fixed ring body are in conical surface engagement. The water pump sealing piece assembly can be designed as: the outer ring of the moving ring shaft housing seat extends downwards to the outer ring of the fixed ring shaft sleeve seat and has a rotating clearance with the fixed ring shaft housing seat, or the outer ring of the fixed ring shaft housing seat extends upwards to the outer ring of the moving ring shaft housing seat and has a rotating clearance with the moving ring shaft housing seat. The two structures design the sealing piece to a semi-sealing structure, thereby reducing the pressure of working medium to a sealing working surface.

Owner:江雪忠

Reactive power, unbalanced and harmonic detection method based on SDFT algorithm

ActiveCN109444515AEliminate Stability IssuesGuaranteed accuracySpectral/fourier analysisReactive/real component measurementsWave periodPhase locking

A reactive power, unbalanced and harmonic detection method based on SDFT algorithm is as follows: three-phase alternating current signals are sampled at a fixed sampling period to obtain discrete sampling data; a zero sequence component is obtained, and meanwhile a result of removing the zero sequence component is obtained; SDFT conversion is carried out on the sampling data, and the integral result of each current flow under the fundamental wave period point is obtained; according to the calculation formula of DFT, the integral value of each current flow is corrected, and the result of the SDFT operation is replaced; a fundamental wave reactive power and unbalanced component is obtained according to a calculation formula in combination with a power grid voltage phase locking result, and the instantaneous value of the harmonic component can be obtained according to the phase relation; the rotation factor is obtained through a look-up method, only a sine value table is stored, and the memory usage can be reduced; and the stability problem caused by iteration accumulation errors can be eliminated.

Owner:徐文涛 +3

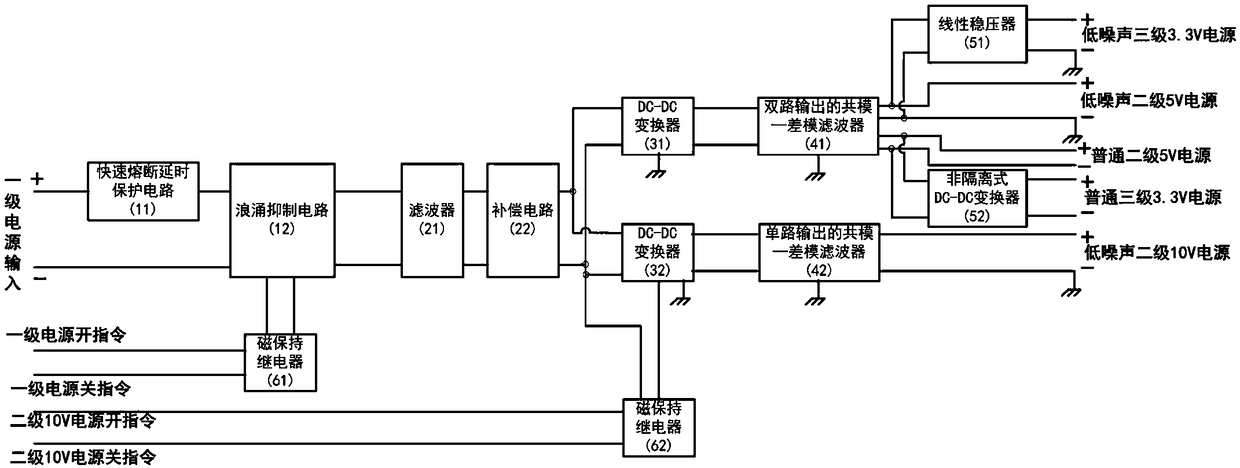

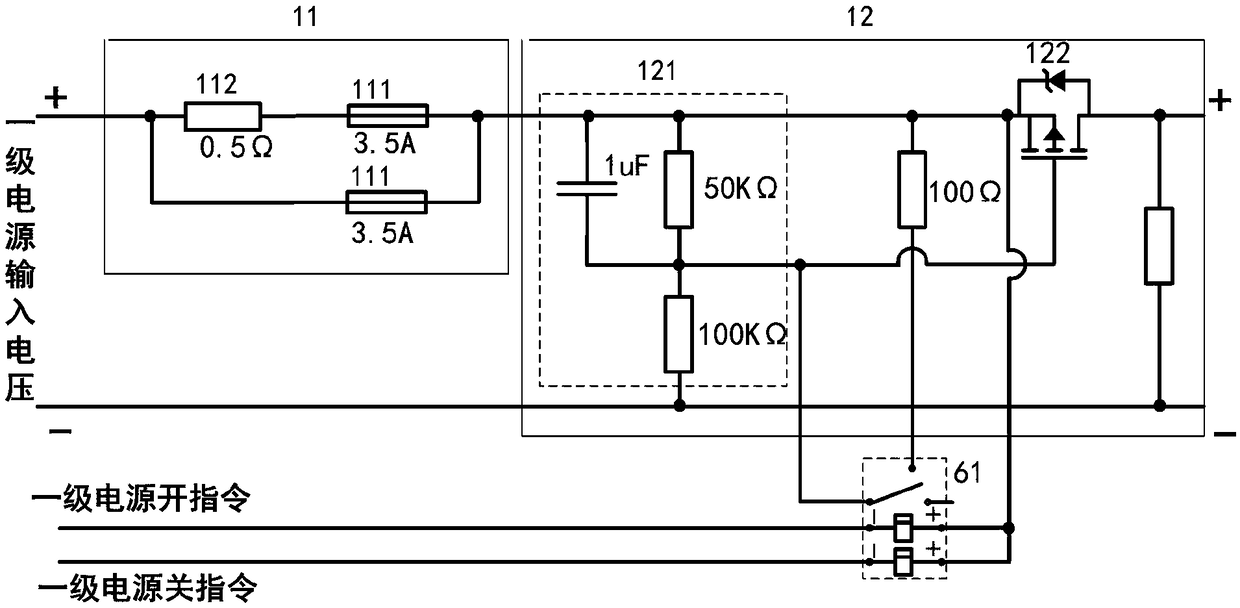

Power converting and filtering device for spaceborne wireless transceiver

ActiveCN108768166AReduce typesReduce power lossEmergency protective circuit arrangementsDc-dc conversionLow noiseWireless transceiver

The invention discloses a power converting and filtering device for a spaceborne wireless transceiver. The power converting and filtering device comprises a primary power protection module, a primarypower filtering module, a secondary power conversion module, a secondary power filtering module and a tertiary power conversion module which are connected in sequence, wherein a primary power supply sequentially passes through the primary power protection module and the primary power filtering module, generates s paths of secondary power voltage through the secondary power conversion module; the spaths of secondary power voltage enter the secondary power filtering module; the secondary power filtering module outputs n paths of low-noise secondary power voltage and m paths of common secondarypower voltage, wherein p paths of low-noise secondary power supplies and q paths of common secondary power supplies enter the tertiary power conversion module, and p paths of low-noise tertiary powersupplies and q paths of common tertiary power supplies are output; the low-noise secondary power supplies and the low-noise tertiary power supplies are used as the power supplies provided for a low-noise circuit or a linear circuit; and the common secondary power supplies and the common tertiary power supplies are used as the power supplies provided for the circuit which is insensitive to power supply noise.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

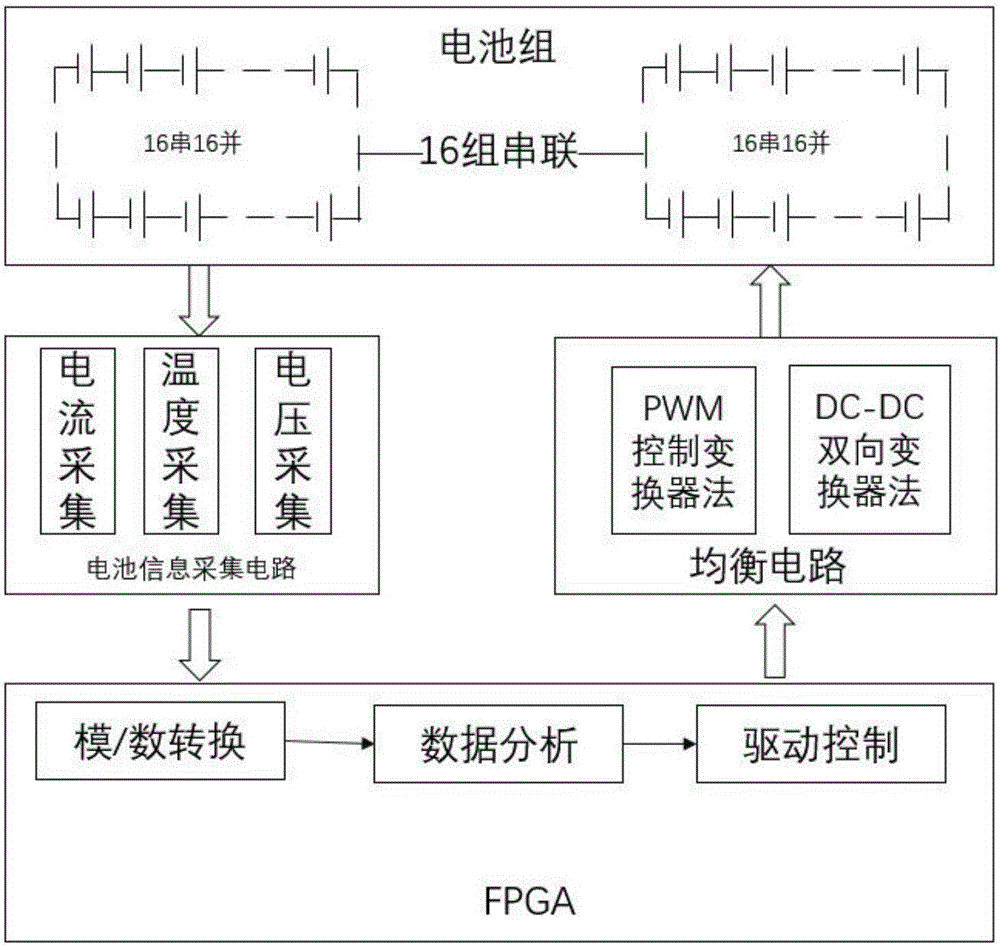

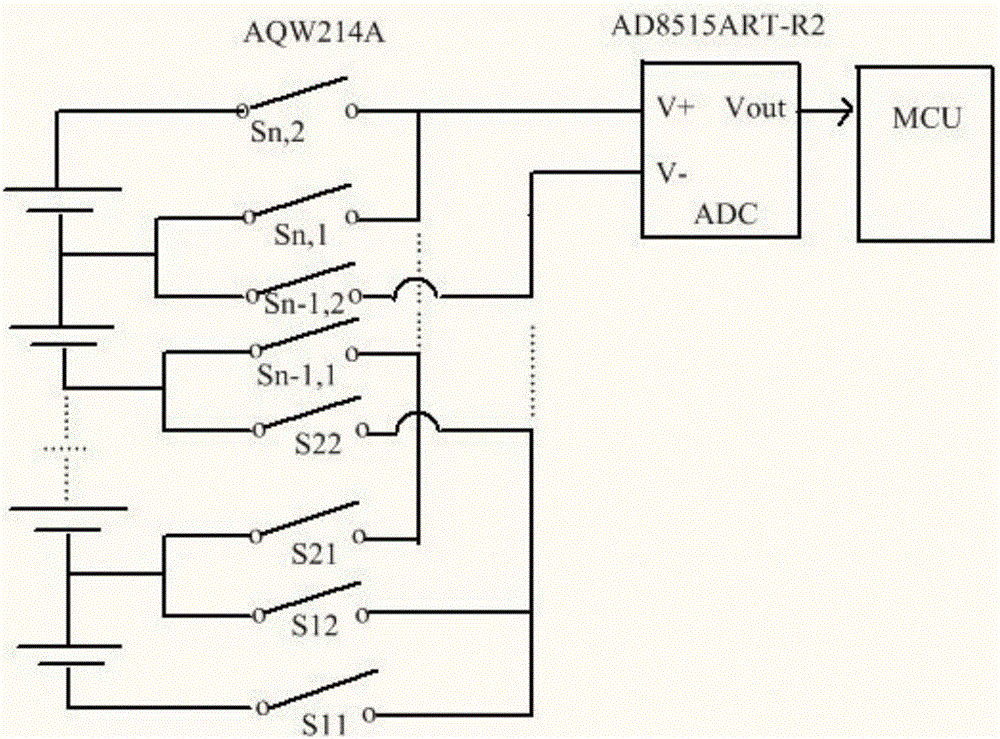

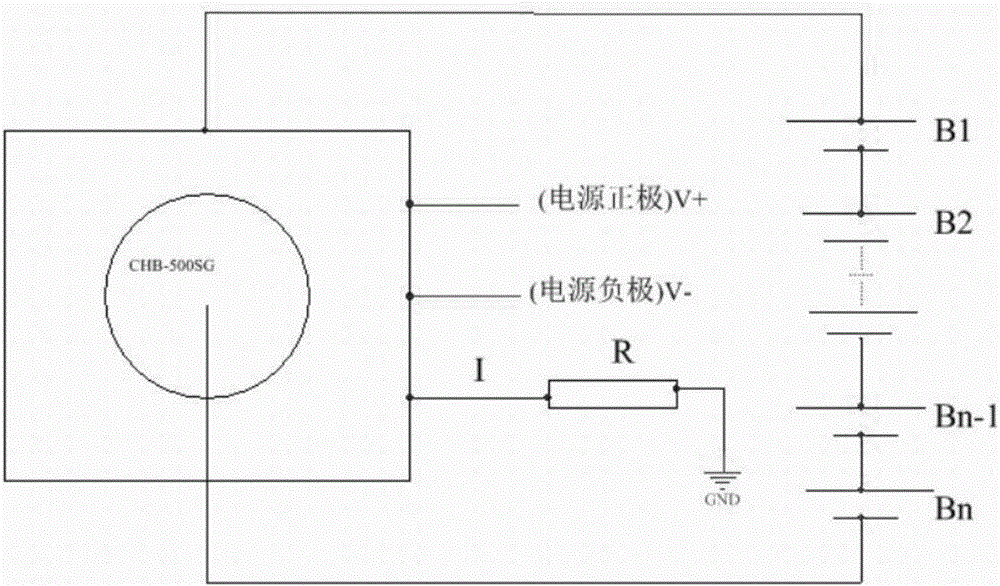

Compound active equalization circuit based on FPGA architecture

PendingCN106655317AImprove energy efficiencyAvoid wastingCharge equalisation circuitElectric powerFpga architectureEqualization

The invention discloses a compound active equalization circuit based on an FPGA architecture, comprising a battery pack, a battery information acquisition circuit, an equalization circuit, and an FPGA module. The output end of the battery pack is connected with the input end of the battery information acquisition circuit. The output end of the battery information acquisition circuit is connected with the input end of the equalization circuit through the FPGA module. The output end of the equalization circuit is connected with the input end of the battery pack. Compared with the prior art, as the compound equalization circuit is composed of a DC-DC equalization active circuit and a PWM control converter active circuit based on an FPGA architecture, the energy efficiency of batteries is improved, and the hardware cost is reduced greatly. Compared with a passive equalization method, an active equalization method avoids the waste of energy obviously, and avoids heat produced in the process of passive equalization (discharge). Thus, the safety of the system is improved.

Owner:WUHAN TEXTILE UNIV

Suction fixing and magnetic fixing combined vehicle navigation instrument

InactiveCN104512351AEasy to assemble and disassembleEasy to insertInstruments for road network navigationVehicle componentsSuction forceEngineering

The invention discloses a suction fixing and magnetic fixing combined vehicle navigation instrument. The suction fixing and magnetic fixing combined vehicle navigation instrument comprises a navigation instrument body, a suction plate and a support rod assembly. The support rod assembly comprises a vertical rod, an iron bracket, a clip, a permanent magnet block and a permanent magnet sleeve. The suction plate comprises a suction plate body, a ring-shaped seal ring, an elastic exhaust plate, a connecting rod, a cam and an O-shaped seal ring. When the suction fixing and magnetic fixing combined vehicle navigation instrument is used, the navigation instrument body is connected through the clip, and the positions of the navigation instrument body and the iron bracket are fixed through the permanent magnet block and the permanent magnet sleeve, so that the navigation instrument body is easily disassemble, assemble and adjusted in angular position to facilitate the use; and meanwhile, the suction plate is used for fixing through suction, the ring-shaped seal ring can further enhance the suction force of the suction plate, and the O-shaped seal ring can prevent the air from flowing into an arc-shaped recess in reverse, so that the suction fixing and magnetic fixing combined vehicle navigation instrument is high in suction fixing capacity and solves the problem that an existing suction fixing and magnetic fixing combined vehicle navigation instrument is poor in suction stability and easy to fall.

Owner:CHONGQING CHANGYE AUTO PARTS

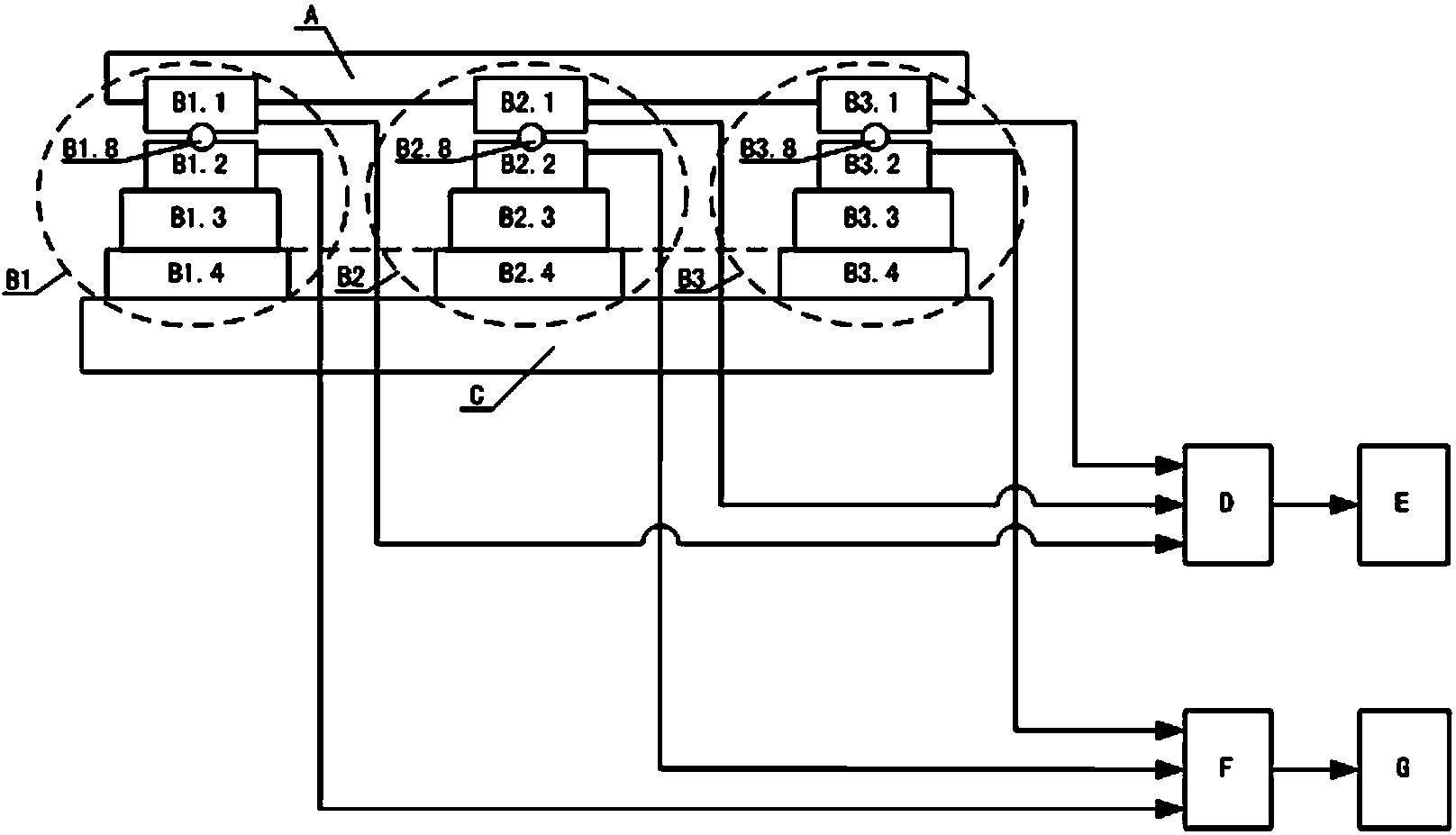

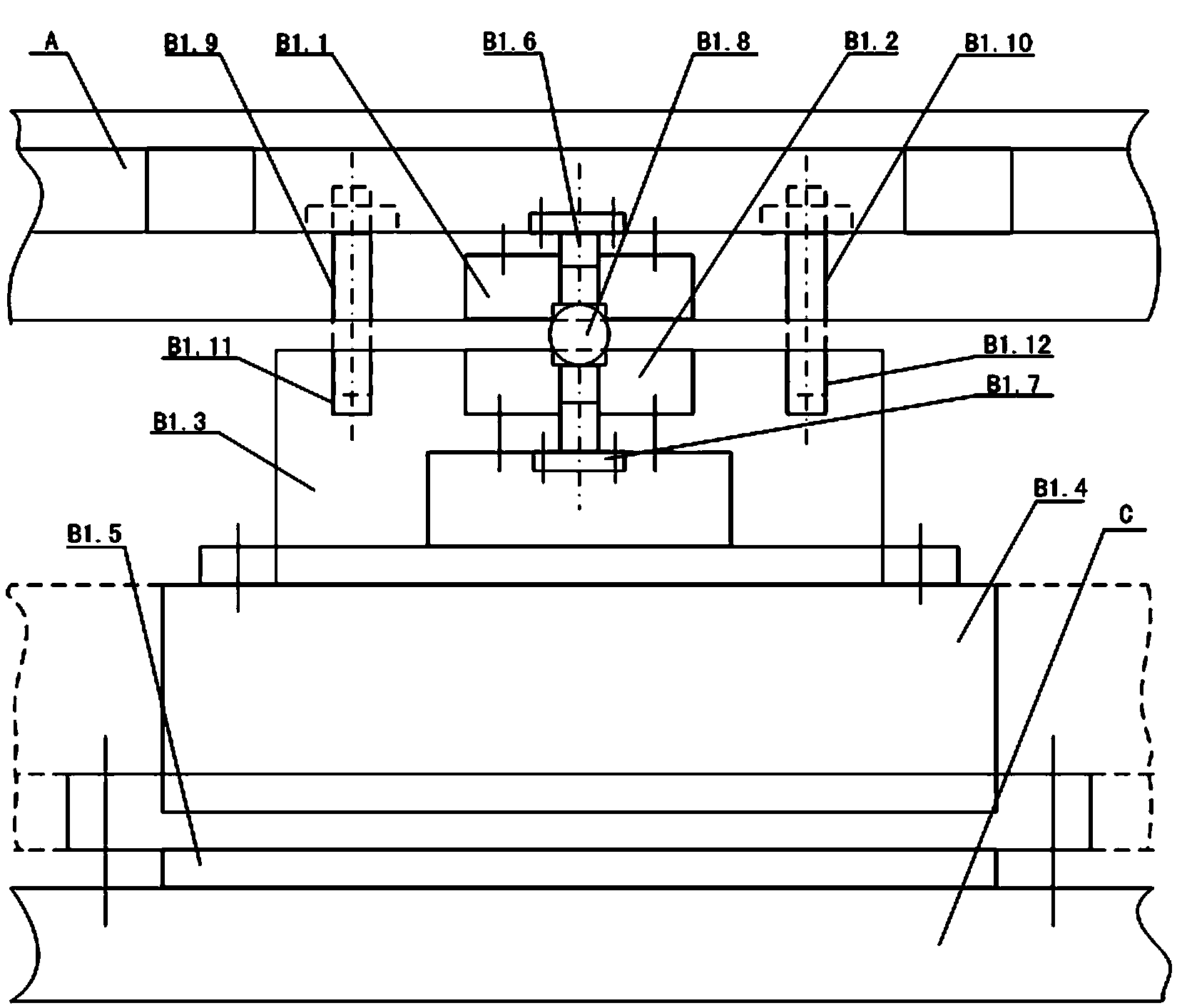

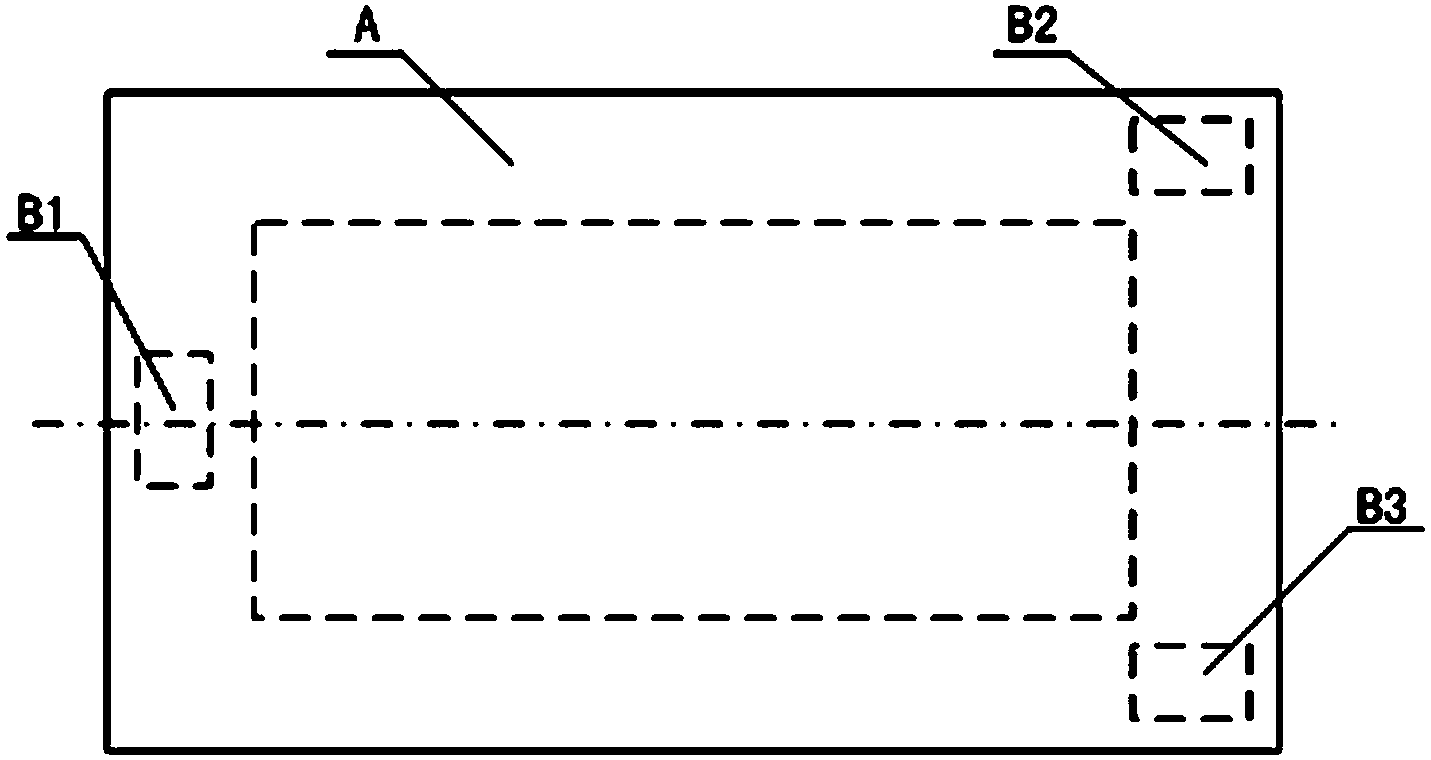

Online full-redundancy mass and mass center measurement device based on upper weighing sensor and lower weighing sensor arranged in vertical mirror image mode

InactiveCN103900643AHave rigidity requirementsGuaranteed a snug fitMeasurement devicesStable stateMeasurement device

An online full-redundancy mass and mass center measurement device based on an upper weighing sensor and a lower weighing sensor arranged in a vertical mirror image mode comprises a scale pan, weighing units which surround the scale pan and are of the same structure, two weighing sensor signal collection circuits independent of each other and a data processing and displaying system. The weighing units comprises the pair of weighing sensors, a support, a base and a support height adjustment block, wherein the weighing units are suitable for vertical mirror image positioning and installation, the base is used for fixing the support, the upper weighing sensor in the pair of weighing sensors is arranged on the scale pan, the lower weighing sensor in the pair of weighing sensors is arranged on the support, the scale pan and the support are respectively provided with standard pins and positioning pin holes, the standard pins and the positioning pin holes are used for installation of the upper weighing sensor and the lower weighing sensor, the weighing sensors are coupled together through force bearing coupling parts in a line or face tight contact mode, and the force bearing coupling part is restrained in the stable position and the stable state through force measurement parts or force measurement part transition connecting parts of the weighing sensors.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

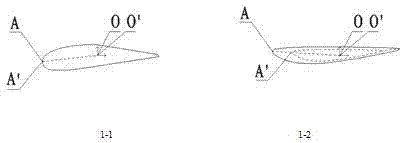

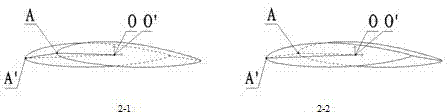

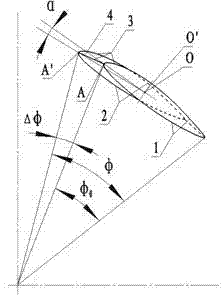

Water Pump Turbine Spatial Surface Guide Vane

InactiveCN102287307AReduce hydraulic lossImprove working efficiencyHydro energy generationReaction enginesWater turbineWater flow

The invention discloses a special curved guide vane of a pump turbine, which mainly comprises an upper end face, a lower end face and a ruled surface. The ruled surfaces is arranged between the upper end face and the lower end face and comprises a plurality of straight lines, a connecting point A of the water inlet edge of the guide vane and the upper end face and a rotating center O of the guide vane on the upper end face are connected to form a straight line OA, a connecting point A' of the water inlet edge of the guide vane and the lower end face and a rotating center O' of the guide vane on the lower end face are connected to form a straight line O'A', and the straight line OA and the straight line O'A' are not parallel and are not arranged in the same plane. Based on the same function of cutting off water flow like the traditional guide vane, hydraulic losses of a grating with double rows of vanes can be reduced, and the working condition and efficiency of the turbine can be improved. Moreover, the distribution of circulation at the inlet of a rotating wheel and the operating stability of the pump turbine can be improved.

Owner:WUHAN UNIV

Ultra-low-frequency vibration isolator with variable load and design method thereof

ActiveCN111075873AReach dynamic stiffnessReduce the lower cutoff frequency of vibration isolationMagnetic springsVibration amplitudeIsolator

The invention discloses an ultra-low-frequency vibration isolator with a variable load. The ultra-low-frequency vibration isolator comprises a rectangular shell, a vibration isolation bearing platform, a bearing rod, a first connecting rod, a second connecting rod, a first negative stiffness element, a second negative stiffness element, a fixing plate and a linear elastic element, wherein the first negative stiffness element and the second negative stiffness element are mutually matched to form double negative stiffness, and form positive and negative stiffness in parallel with the linear elastic element. According to the ultra-low-frequency vibration isolator, the ultra-low natural frequency of a vibration isolation system can be realized, the load changed within a certain range can be adapted, the working point of the vibration isolator does not need to be adjusted, the performance stability of the vibration isolator under different vibration isolation loads is maintained, and the influence, on the performance of the vibration isolation system, from the vibration degree is eliminated. In addition, the invention also provides a design method of the ultra-low-frequency vibration isolator with the variable load.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Car navigator bracket

InactiveCN104527531AStrong adsorption and fixation abilityEliminate Stability IssuesVehicle componentsSuction cupsEngineeringCam

The invention discloses a car navigator bracket. The car navigator bracket comprises a sucker and a support rod component, the sucker comprises a sucker body, an annular sealing ring, an elastic exhaust plate, a connecting bar, a cam, a handle and an O-shaped sealing ring, under the sucker detachment state, the O-shaped sealing ring is located below a connecting bar hole, and under the sucker adsorption state, the O-shaped sealing ring has seal fit with the connecting bar hole. When working, the cam pushes the elastic exhaust plate to move towards the upside so as to discharge the air in an arc-shaped cavity from the connecting bar hole, the sucker is compressed on a windshield of the car or an instrument panel shell under the atmosphere pressure effect, and the annular sealing ring further reinforces the adsorption force of the sucker; the seal fit between the O-shaped sealing ring and connecting bar hole can prevent the air reversely flowing into the arc-shaped cavity so as to further improve the adsorption ability of the sucker. The car navigator bracket is strong in adsorption fixing ability and eliminates the problems of bad adsorption stability and easiness in falling of an existing car navigator bracket.

Owner:CHONGQING CHANGYE AUTO PARTS

Anisotropic structure thermal-mechanical coupling topological optimization method based on meshless EFGM and PLSM

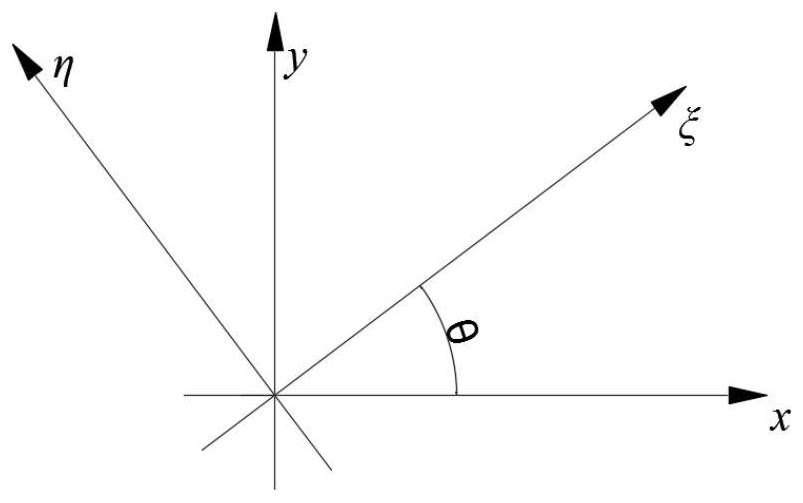

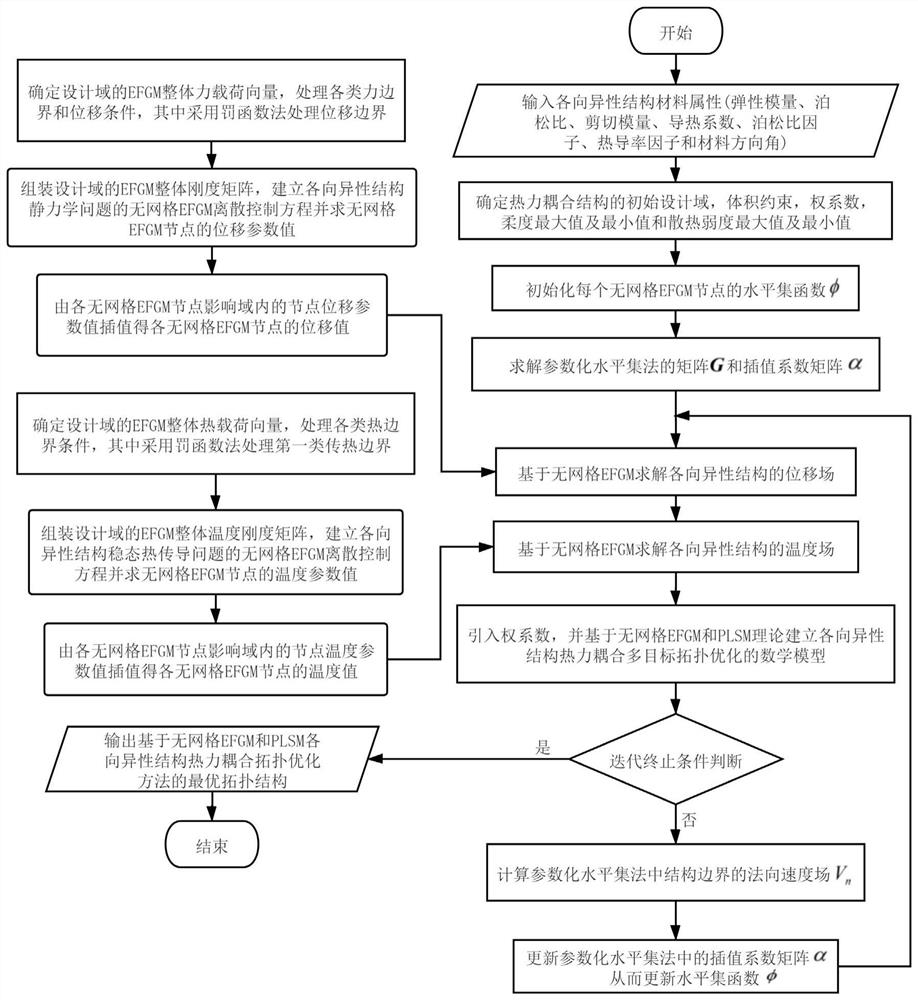

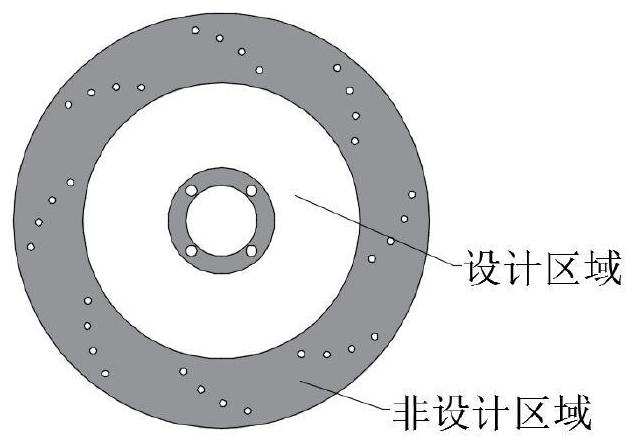

ActiveCN113821887AEliminate prone to aliasingEliminate checkerboardGeometric CADSustainable transportationMathematical modelEngineering

The invention discloses an anisotropic structure thermal-mechanical coupling multi-objective topological optimization method based on a meshless EFGM and a parameterized level set method. The method comprises the following steps: (1) inputting a Poisson's ratio factor, a thermal conductivity factor, a material direction angle and other material attributes of an anisotropic structure, and carrying out the discrete design of a domain through meshless nodes; (2) initializing a level set function of the meshless nodes; (3) interpolating a level set function by adopting a radial basis function in combination with the parameterized level set method; (4) solving a displacement field and a temperature field of the anisotropic structure based on meshless EFGM; (5) based on meshless EFGM and PLSM theories, establishing a mathematical model for thermal coupling multi-target topological optimization of the anisotropic structure; (6) inputting a termination condition, and judging whether an optimization loop is converged or not; (7) calculating a normal velocity field of a structure boundary; (8) programming, solving and optimizing the model, and updating the level set function. According to the method, thermal-mechanical coupling multi-target topological optimization of the anisotropic structure is carried out based on the meshless EFGM and PLSM, the calculation efficiency is high, the boundary of the topological structure is clear and smooth, and the method is simple and practical.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com