Computer controlled filming device

A coating device and computer technology, applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve problems affecting stability, repeatability and monitoring accuracy, and artificial random factors, etc., to eliminate Stability and repeatability issues, easy portability, intuitive and friendly interface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

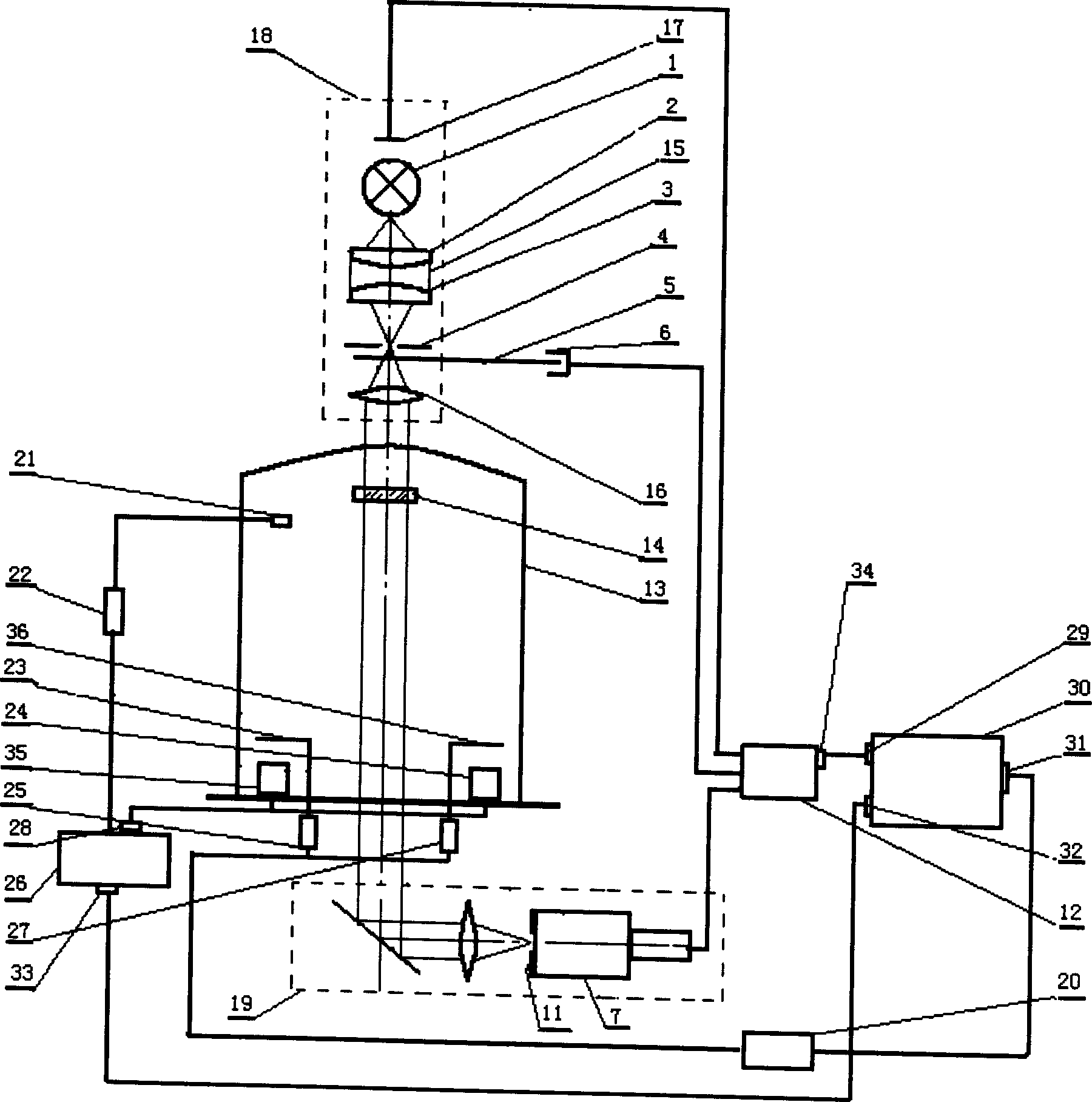

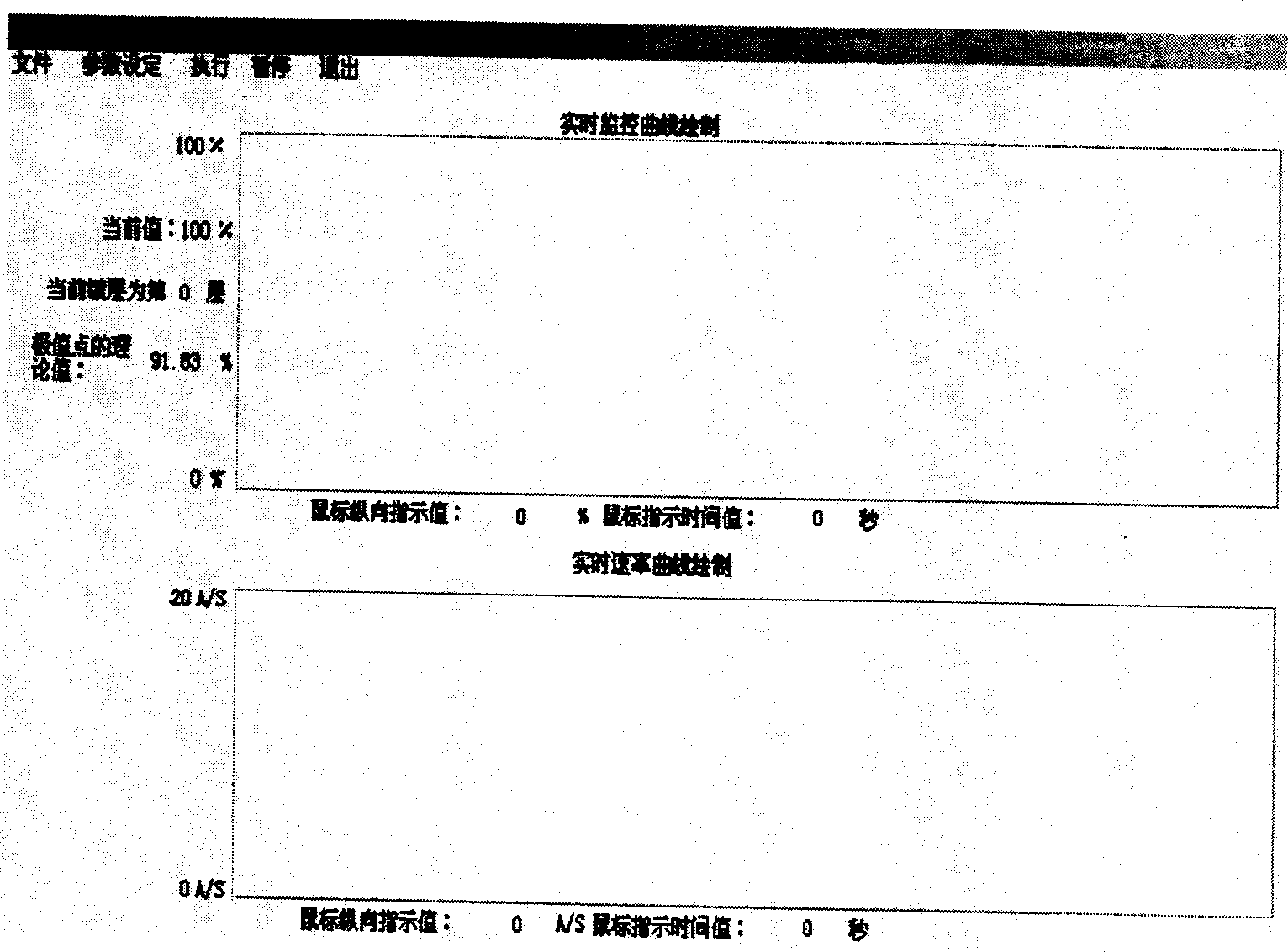

[0022] see first figure 2 , figure 2 It is a schematic structural view of the computer-controlled coating device of the present invention. As can be seen from the figure, the computer-controlled coating device of the present invention includes an optical film thickness monitoring system composed of a light source emitting system 18, a monitoring panel 14, a signal receiving system 19 and a lock-in amplifier 12. , it is characterized in that there are also: computer 30 with control program, crystal controller 26, baffle switch control circuit 20; the crystal oscillator head 21 of the crystal controller 26 is passed through the impedance matching device 22 and the crystal controller through the shielded wire 26 is connected; the evaporation source control voltage output end 28 of described crystal controller 26 is connected with the first evaporation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com