Aerated concrete block and preparation process thereof

A technology of aerated concrete and preparation process, which is applied in the field of concrete blocks to achieve the effects of saving energy, solving damage to the environment, and improving composite reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

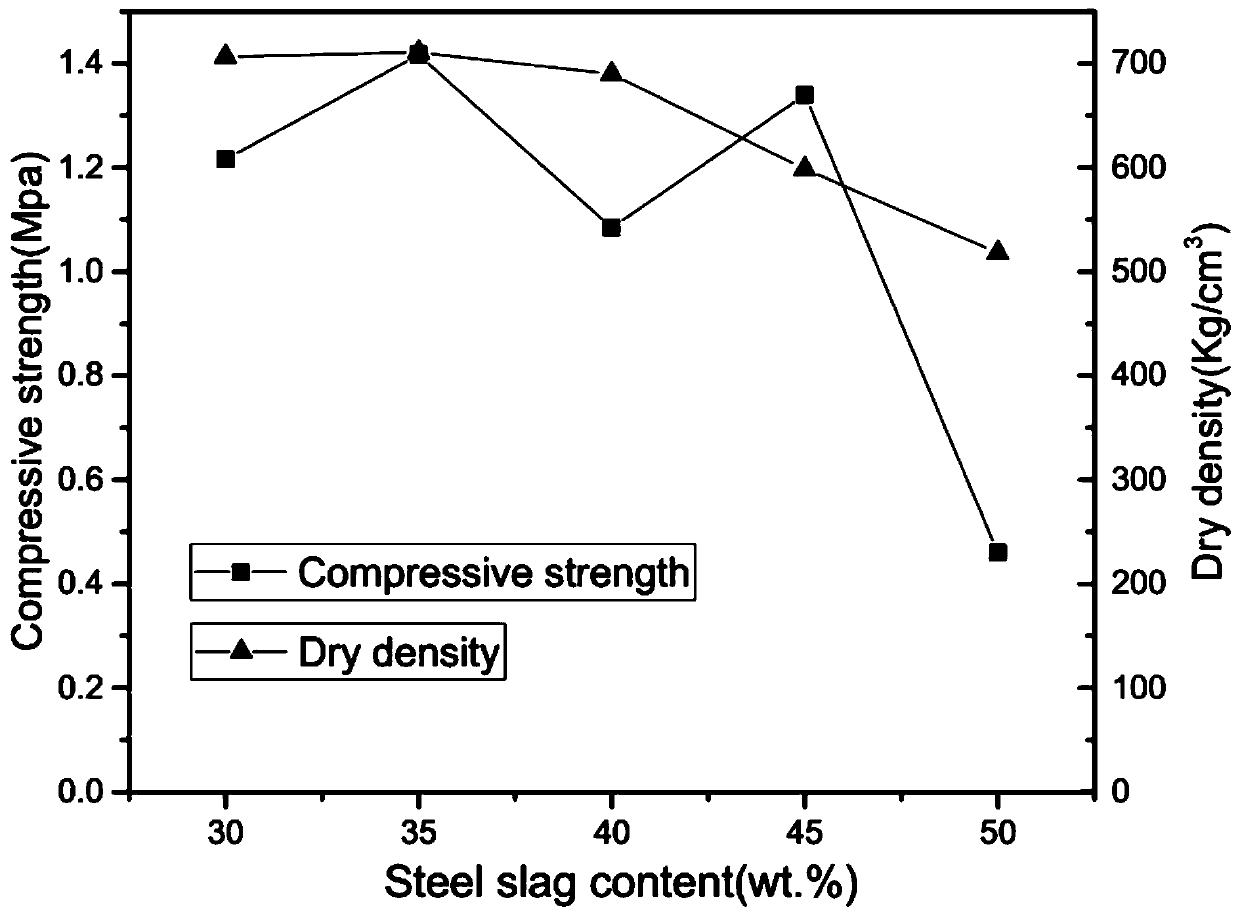

Image

Examples

Embodiment 1

[0095] a. The cementitious material and additives are selected according to the weight ratio, including steel slag 35%, slag 28%, cement 8%, fly ash 15%, alkali content 6%, water glass modulus 1.6, aluminum powder paste 0.1%, quicklime 6%, desulfurized gypsum 5%, sodium sulfate 2.8%, foam stabilizer 0.08%; the ratio of water to material in raw materials is 0.48.

[0096] b. Mix the gelling materials and stir them at a speed of 140 ± 5 r / min for rotation and 62 ± 5 r / min for revolution, and perform dry mixing for 2 minutes to make a mixture;

[0097] c. Take water accounting for 5% of the total water weight, add aluminum powder paste and foam stabilizer to 55°C water to make a suspension;

[0098] d. Dissolve water glass and sodium hydroxide into the remaining 95% of 55°C water, stir evenly, stir until no sodium hydroxide solid remains, and adjust to 48°C;

[0099] e. Pour the alkali solution added with water glass obtained in step d into the mixture obtained in step b, the st...

Embodiment 2

[0106] Such as Figure 15 shown.

[0107] a. The cementitious materials and additives are selected according to the weight ratio, including steel slag 35%, slag 28%, cement 13%, fly ash 9%, alkali content 6%, water glass modulus 1.6, aluminum powder paste 0.1%, quicklime 6%, desulfurized gypsum 5%, sodium sulfate 3%, foam stabilizer 0.08%, triethanolamine 0.08%, water reducer 0.5%; the ratio of water to material in raw materials is 0.48.

[0108] b. Mix the gelling material and the water reducer, and stir at a speed of 140±5r / min for rotation and 62±5r / min for revolution, and dry mix for 2min to make a mixture;

[0109] c. Take water accounting for 5% of the total water weight, add aluminum powder paste, foam stabilizer, and triethanolamine to 55°C water in sequence to make a suspension;

[0110] d. Dissolve water glass and sodium hydroxide into the remaining 95% of 55°C water, stir evenly, stir until no sodium hydroxide solid remains, and adjust to 48°C;

[0111] e. Pour t...

Embodiment 3

[0118] a. The cementitious materials and additives are selected according to the weight ratio of raw materials, including 35% steel slag, 28% slag, 10% cement, 12% fly ash, 6% alkali content, 1.6 water glass modulus, 0.1% aluminum powder paste, quicklime 6%, desulfurized gypsum 5%, sodium sulfate 3%, foam stabilizer 0.08%, triethanolamine 0.08%, water reducer 0.5%; the ratio of water to material in raw materials is 0.48.

[0119] b. Mix the gelling material and the water reducer, and stir at a speed of 140±5r / min for rotation and 62±5r / min for revolution, and dry mix for 2min to make a mixture;

[0120] c. Take water accounting for 5% of the total water weight, add aluminum powder paste, foam stabilizer, and triethanolamine to 55°C water in sequence to make a suspension;

[0121] d. Dissolve water glass and sodium hydroxide into the remaining 95% of 55°C water, stir evenly, stir until no sodium hydroxide solid remains, and adjust to 48°C;

[0122] e. Pour the alkali solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com