Method for preparing building cementing material from electrolytic manganese metal leaching residues

A technology for electrolytic manganese metal and leaching slag, which is applied in the preparation/separation of ammonia, chemical instruments and methods, applications, etc., can solve the problems of failure to effectively improve the removal of heavy metals in electrolytic manganese slag, active manganese slag, low strength, and cement mixing. Large quantity and other problems, to overcome the effect of low early strength, high compressive strength and low volume expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

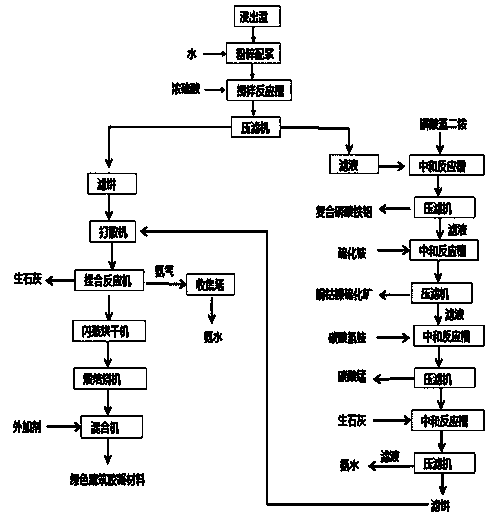

Image

Examples

Embodiment 1

[0038] A method for preparing building cementitious materials with electrolytic manganese metal leaching slag, comprising the following steps:

[0039] (1) Add a certain amount of clear water into the leaching slag of electrolytic manganese metal, stir and pulverize into pulp;

[0040] (2) Put the ore pulp in (1) into the reaction tank, slowly add a certain amount of concentrated sulfuric acid while stirring to make the pH 0.5-2, after adding the concentrated sulfuric acid, continue to stir for 1 hour, and filter the ore pulp for solidification Liquid separation, obtain filtrate A and filter residue A;

[0041] (3) Slowly add a certain amount of diammonium hydrogen phosphate to the filtrate A while stirring to adjust the pH value. Stop stirring when the pH value reaches 3.5. There is a large amount of white precipitate in the filtrate A, and then carry out suction filtration to obtain the filtrate B and filter residue B;

[0042] (4) Slowly add a certain amount of ammonium s...

Embodiment 2

[0049] A method for preparing building cementitious materials with electrolytic manganese metal leaching slag, comprising the following steps:

[0050] (1) Add a certain amount of clear water into the leaching slag of electrolytic manganese metal, stir and pulverize into pulp;

[0051] (2) Put the ore pulp in (1) into the reaction tank, slowly add a certain amount of concentrated sulfuric acid while stirring, so that the pH is 0.5-2, after adding the concentrated sulfuric acid, continue to stir for 1.5h, filter the ore pulp, and carry out Solid-liquid separation to obtain filtrate A and filter residue A;

[0052] (3) Slowly add a certain amount of diammonium hydrogen phosphate to the filtrate A while stirring to adjust the pH value. Stop stirring when the pH value reaches 4.5. There is a large amount of white precipitate in the filtrate A, and then carry out suction filtration to obtain the filtrate B and filter residue B;

[0053] (4) Slowly add a certain amount of ammonium...

Embodiment 3

[0060] A method for preparing building cementitious materials with electrolytic manganese metal leaching slag, comprising the following steps:

[0061] (1) Add a certain amount of clear water into the leaching slag of electrolytic manganese metal, stir and pulverize into pulp;

[0062] (2) Put the ore pulp in (1) into the reaction tank, slowly add a certain amount of concentrated sulfuric acid while stirring, so that the pH is 0.5-2, after adding the concentrated sulfuric acid, continue to stir for 1.2h, filter the ore pulp, and carry out Solid-liquid separation to obtain filtrate A and filter residue A;

[0063] (3) Slowly add a certain amount of diammonium hydrogen phosphate to the filtrate A while stirring to adjust the pH value. Stop stirring when the pH value reaches 4. There is a large amount of white precipitate in the filtrate A, and then carry out suction filtration to obtain the filtrate B and filter residue B;

[0064] (4) Slowly add a certain amount of ammonium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com