Method for producing a large steel tube

一种钢管、管子的技术,应用在制造钢管领域,能够解决管体不利应力状态、材料损伤、管道顶锻强度断裂稳定性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

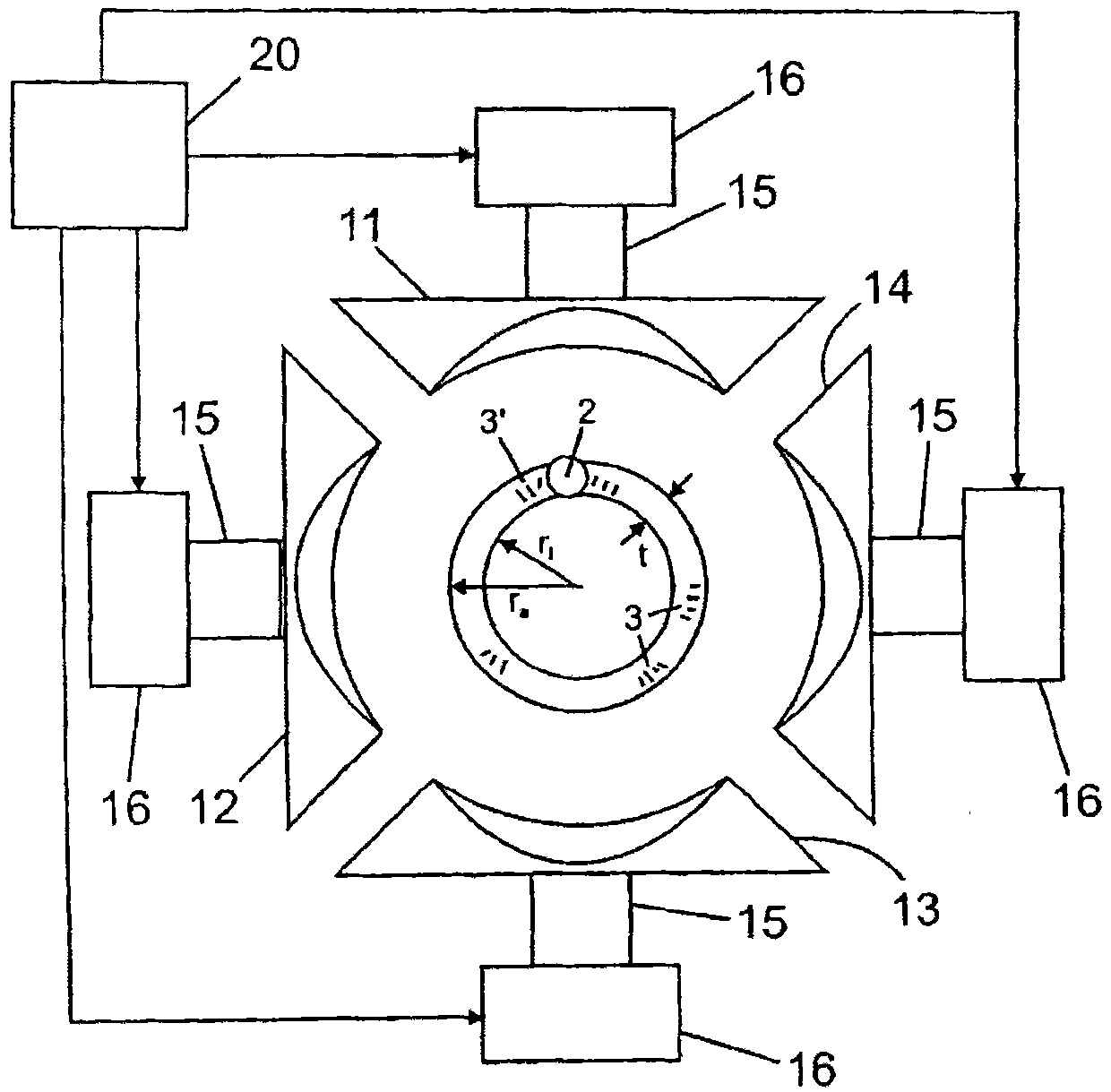

[0020] figure 1 Shows a top axial view of a tube 1 of circular cross-section having an inner diameter r i and outer diameter r a and the wall thickness t determined by the difference between the inner and outer diameters. The pipe 1 has a longitudinally extending weld seam 2 . There are mechanically or thermally stressed regions 3, 3' in the tube wall as a result of the mechanical forming process and as a result of the thermal action during welding.

[0021] Shaping machine or shaping device 10 has a plurality of shaping punches that are uniformly distributed along the circumferential direction and arranged at the same position in the axial direction, and the shaping punches have respective shaping shell molds 11, 12, 13, 14, which can be replaced are installed on the respective brackets 15, and are provided with a surface shape that matches the surface profile of the pipe 1 and extends along the surface of the pipe in the circumferential direction on its side facing the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com