A novel regulator and its preparation method

A regulator, a new type of technology, applied in the direction of metal processing equipment, transportation and packaging, etc., can solve the problems of regulator ablation and wear, and achieve the effect of improving mechanical properties, increasing service life, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-47

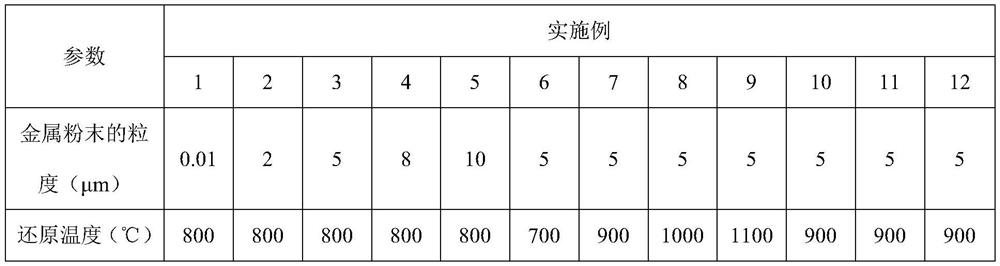

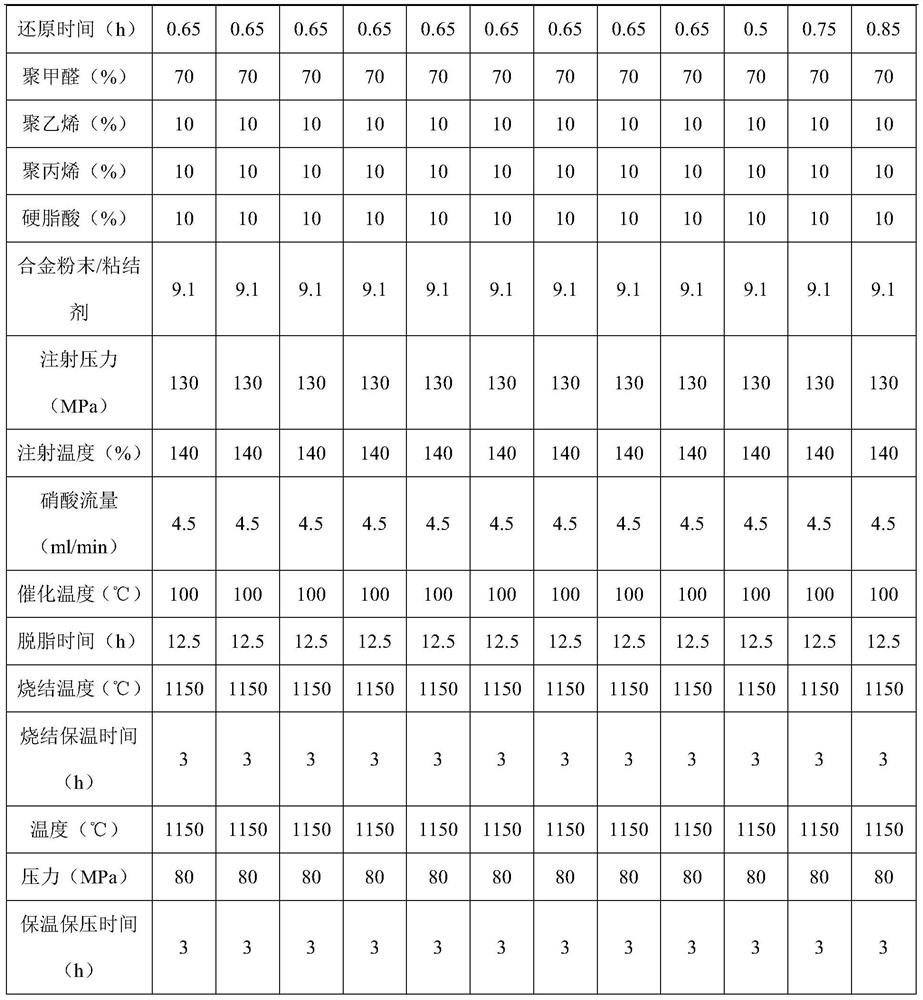

[0064] Examples 1-47 respectively provide the preparation method of the new superalloy regulator.

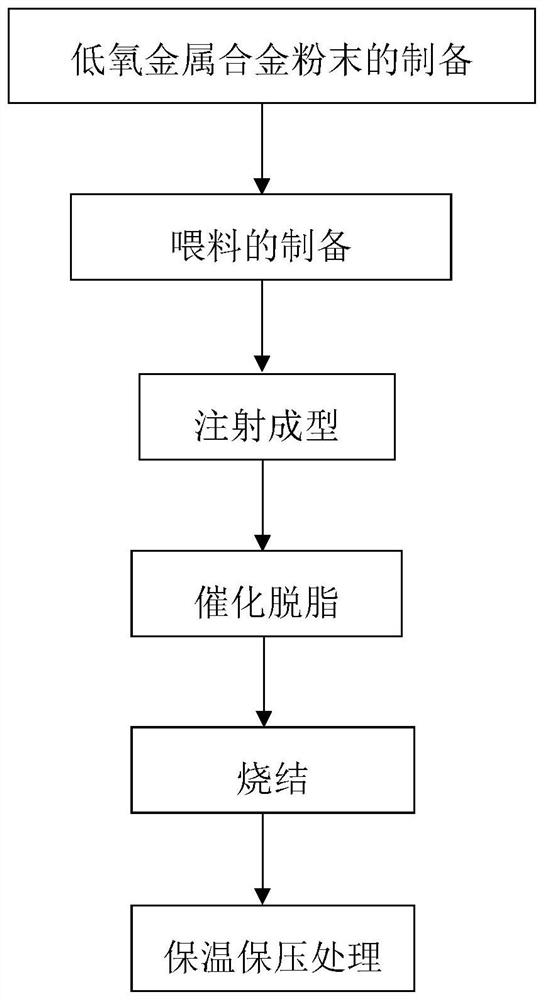

[0065] The preparation method of the novel superalloy regulator specifically comprises the following steps:

[0066] (1) Preparation of low-oxygen metal powder: using hydrogen to reduce the metal powder to obtain low-oxygen metal powder;

[0067] (2) Preparation of feeding material: uniformly mixing the low-oxygen metal powder prepared in step (1) with a binder to form feeding material;

[0068] (3) injection molding: the feeding material that step (2) is made is injected in the mold cavity, forms injection base;

[0069] (4) Catalyzed degreasing: the injection base prepared in step (3) is subjected to catalytic degreasing to form a degreased base;

[0070] (5) Sintering: sintering the degreased body prepared in step (4) in a vacuum environment or a protective atmosphere to obtain a sintered body;

[0071] (6) heat preservation and pressure preservation: the sintered billet o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com