Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Efficient and stable processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

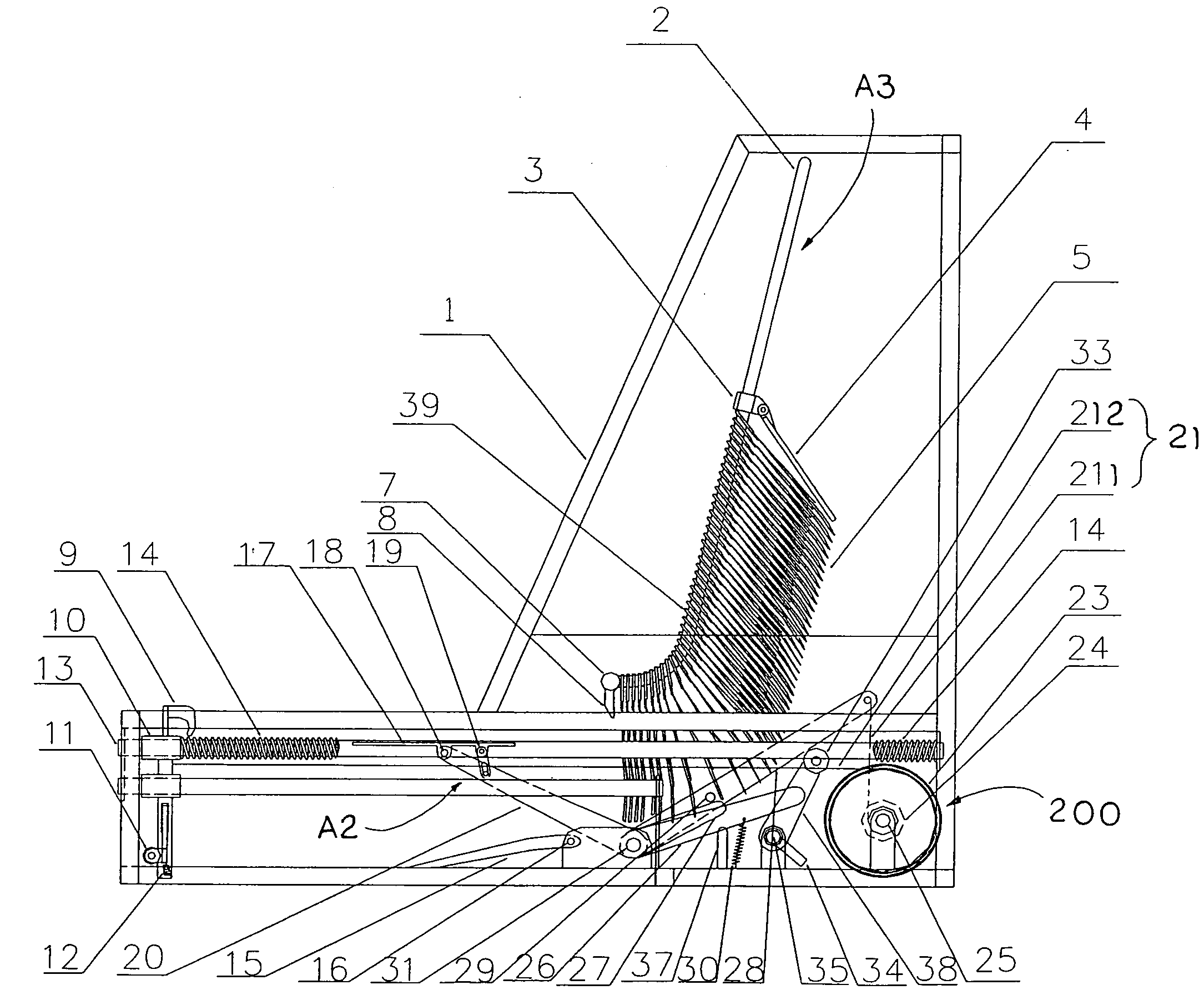

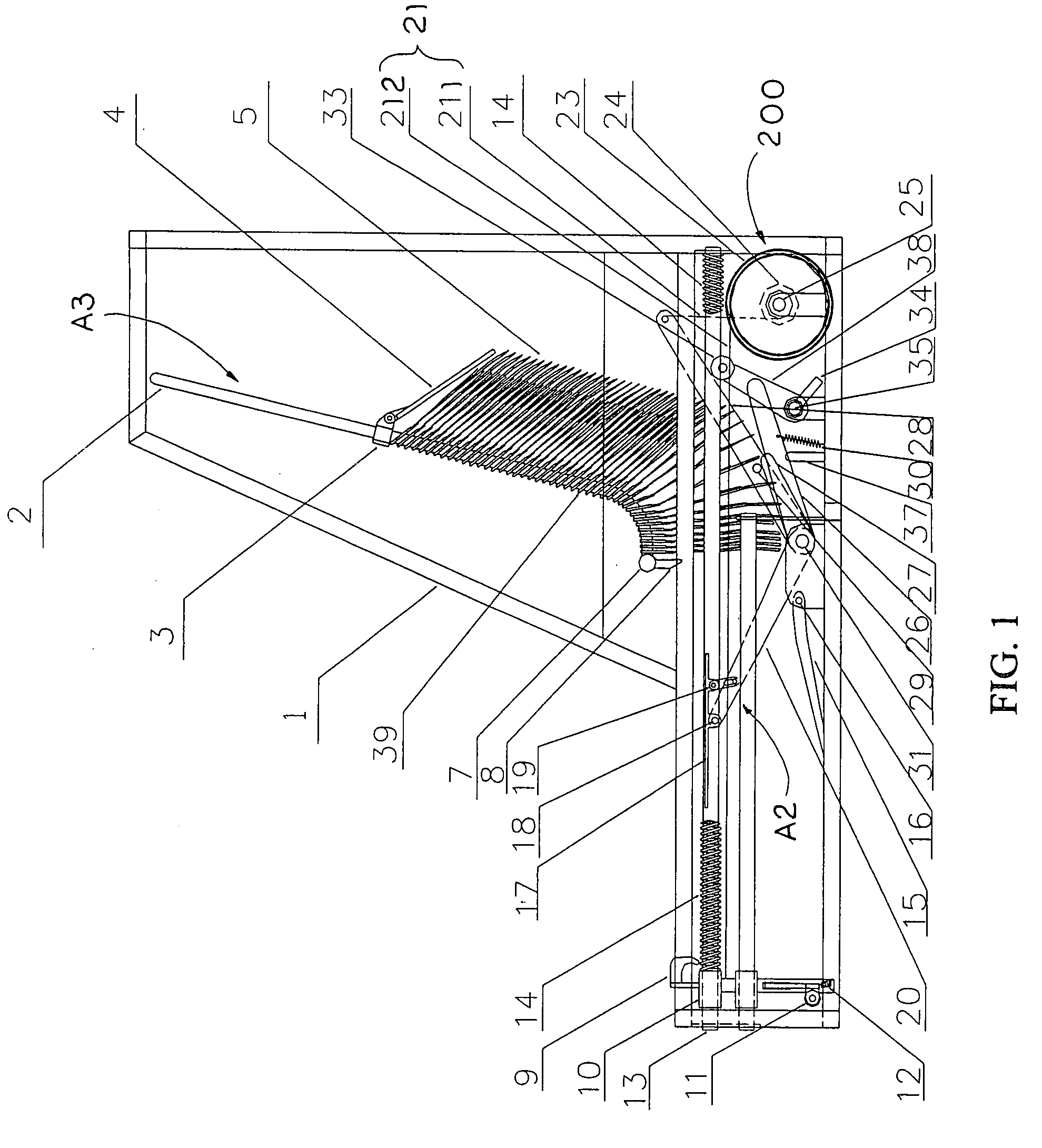

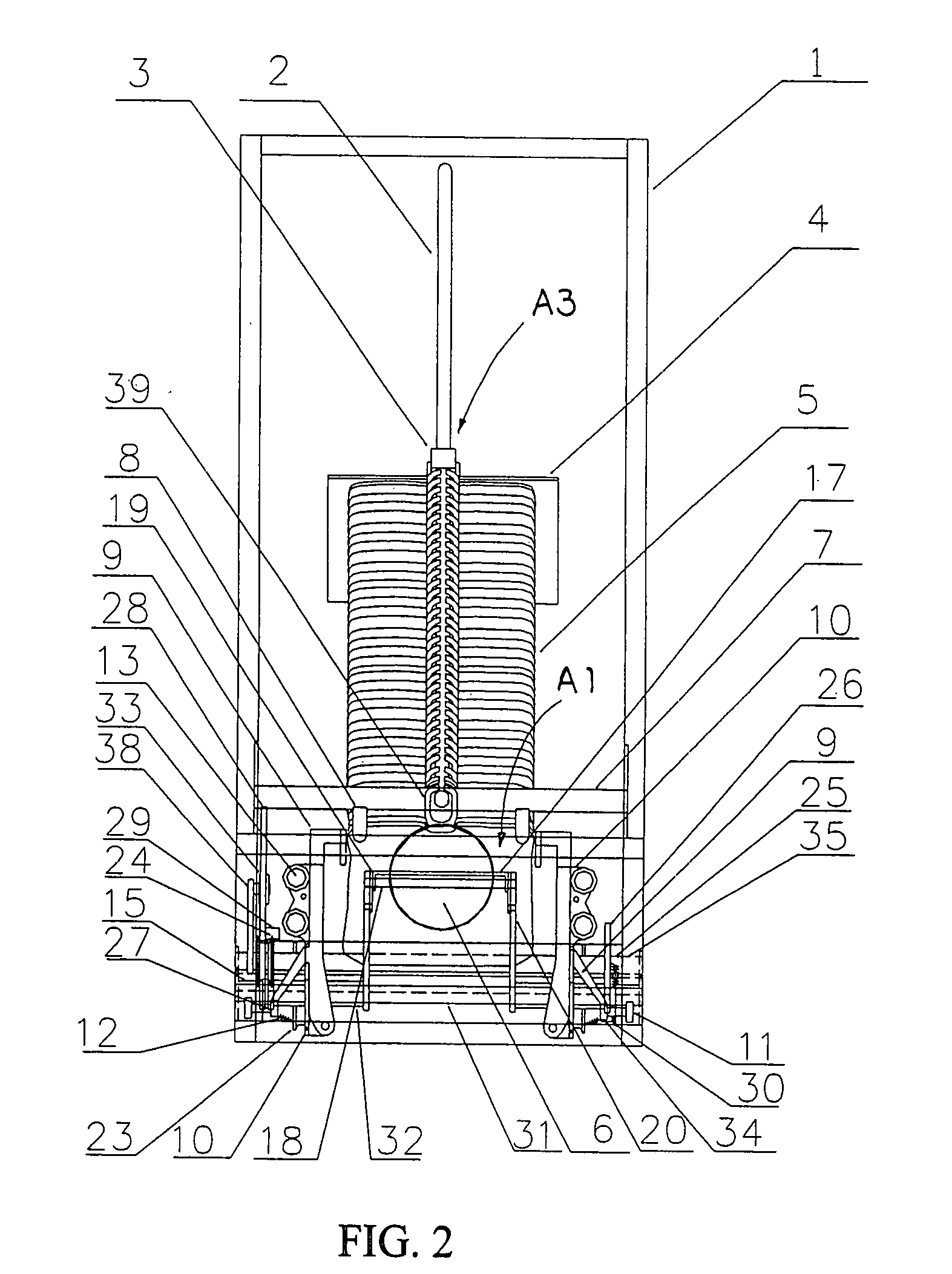

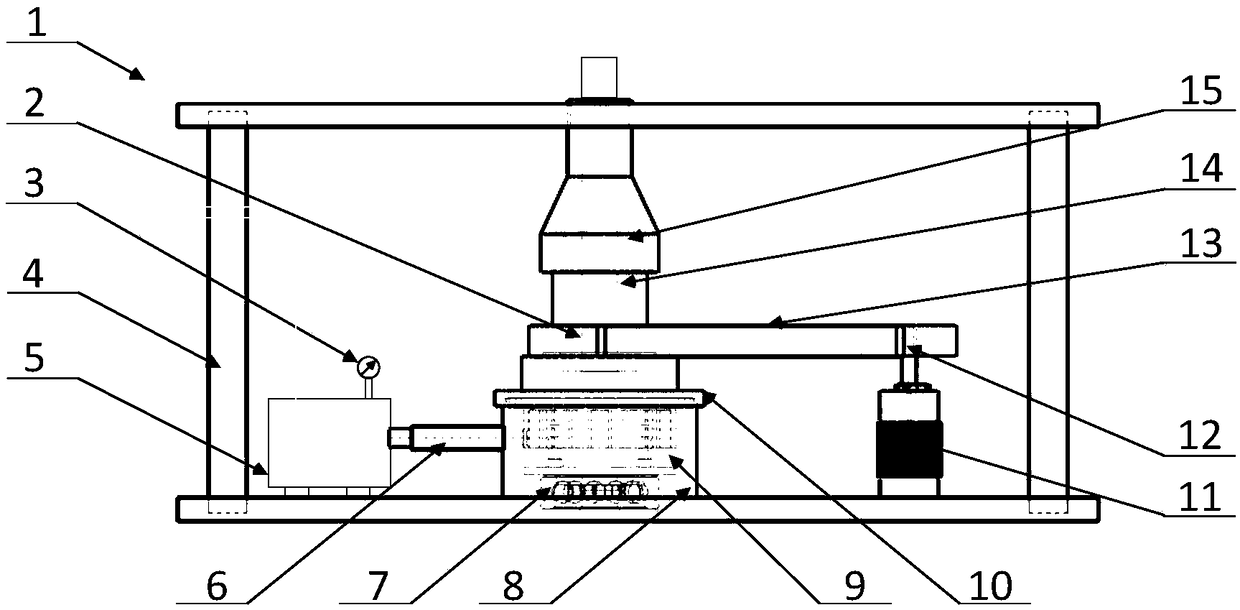

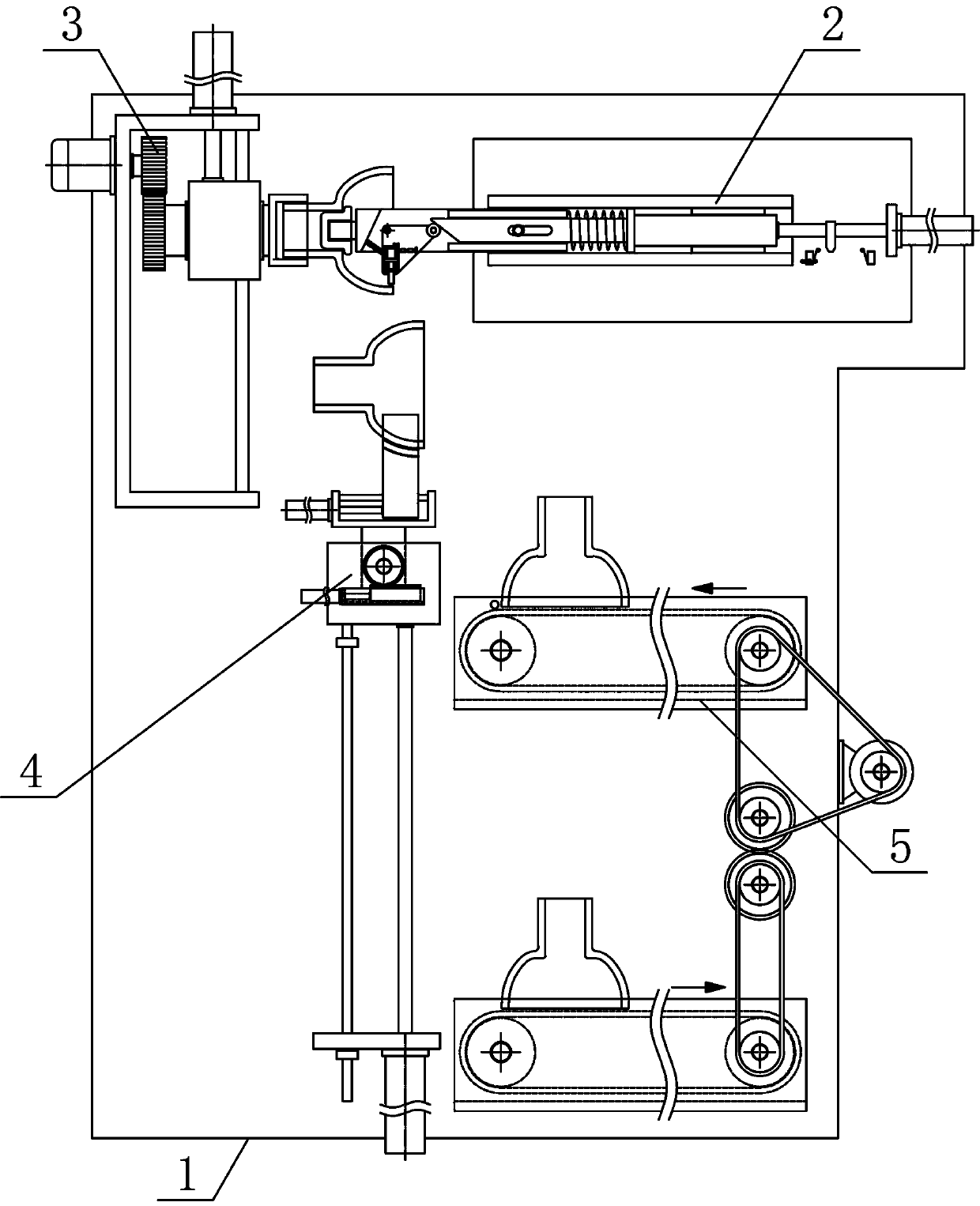

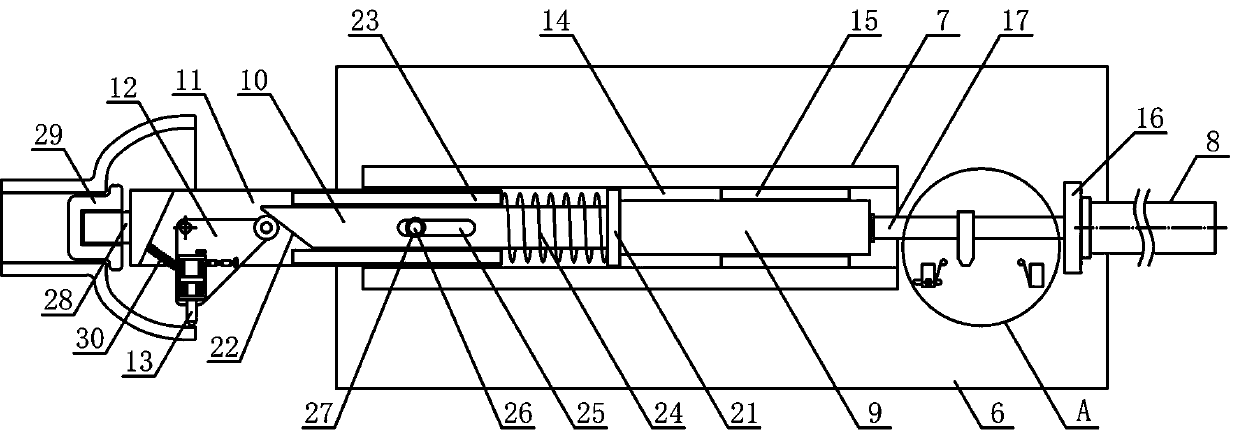

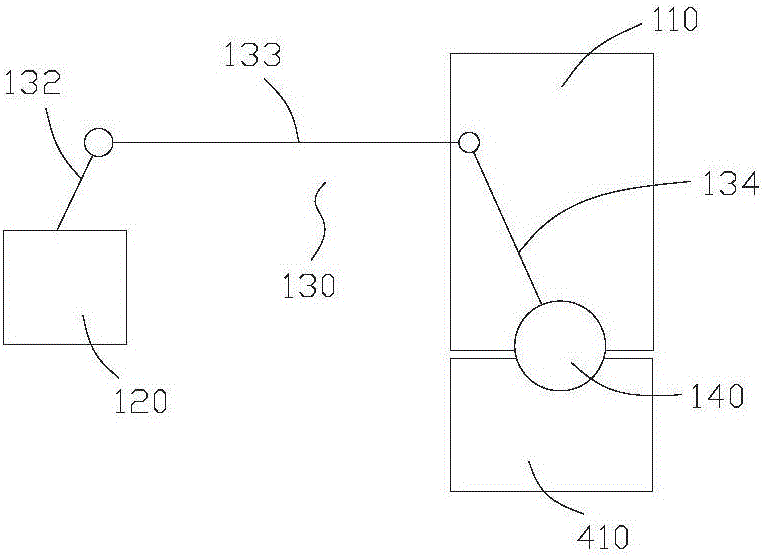

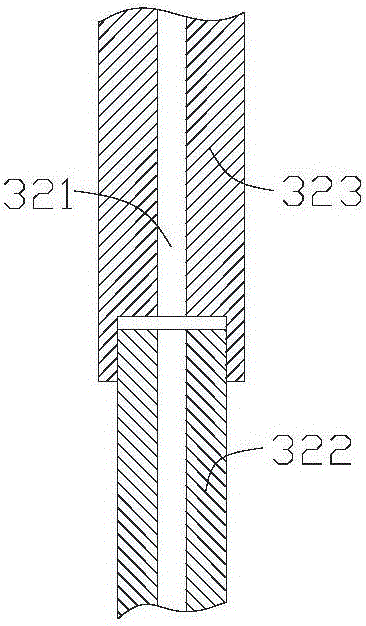

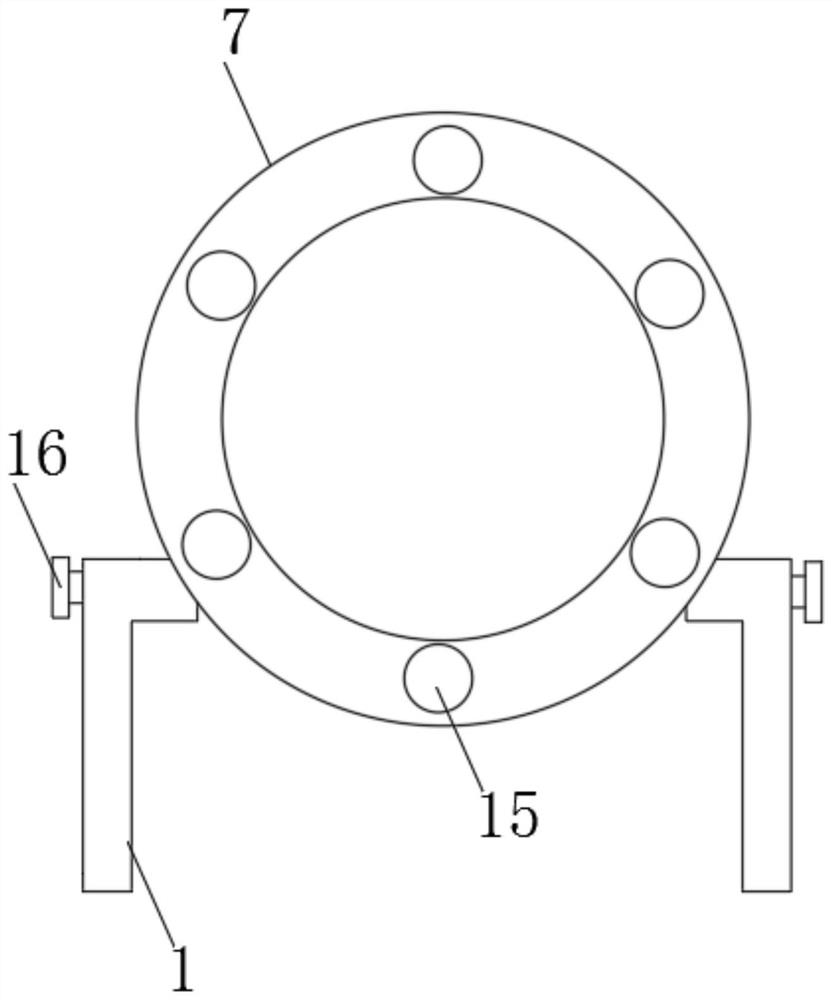

Automatic shoe cover dispenser

ActiveUS20080237277A1The process is stable and efficientEfficient and stable processingApparel holdersRegistering devicesEngineeringFootplate

Owner:XU LIANG JIE

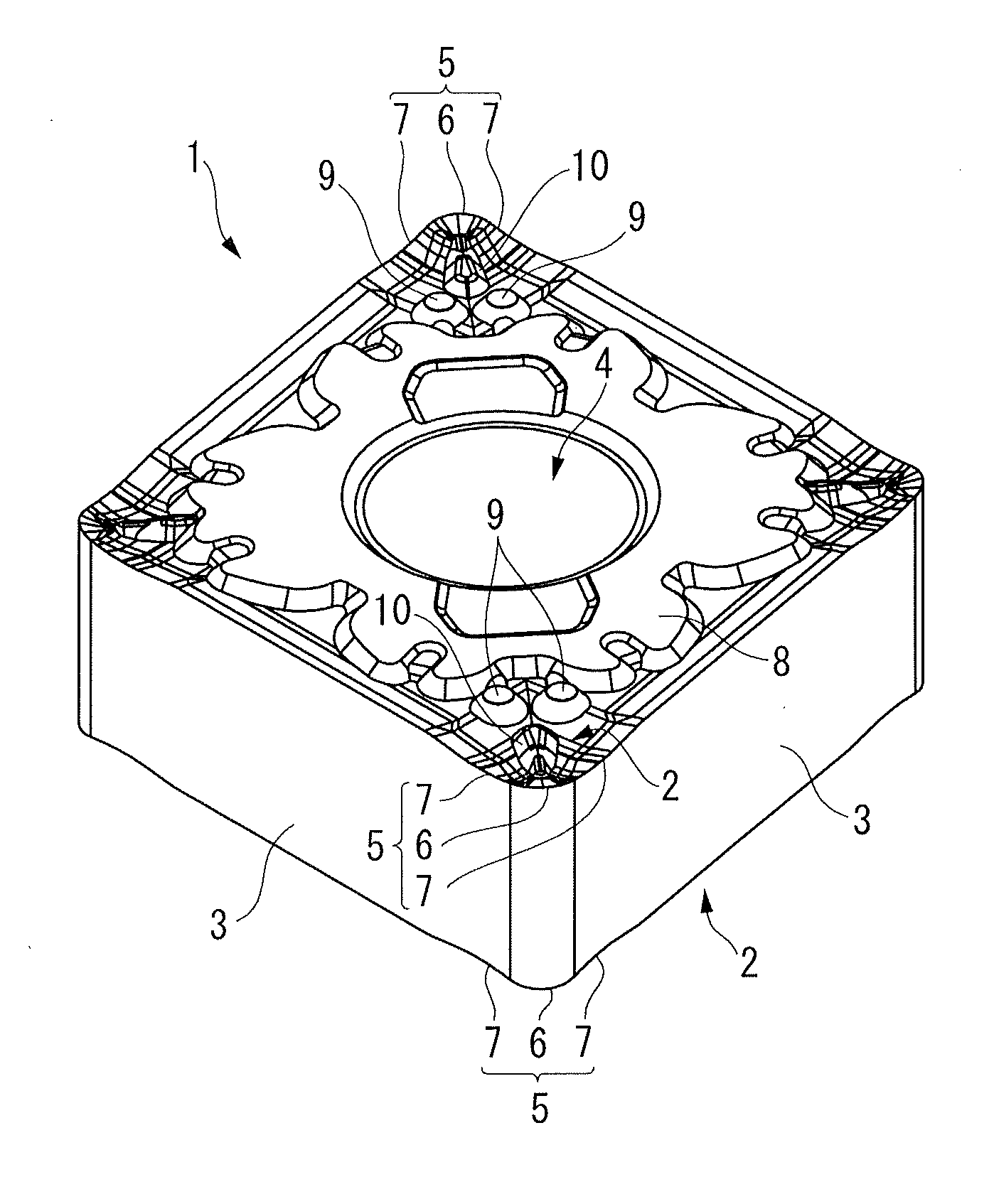

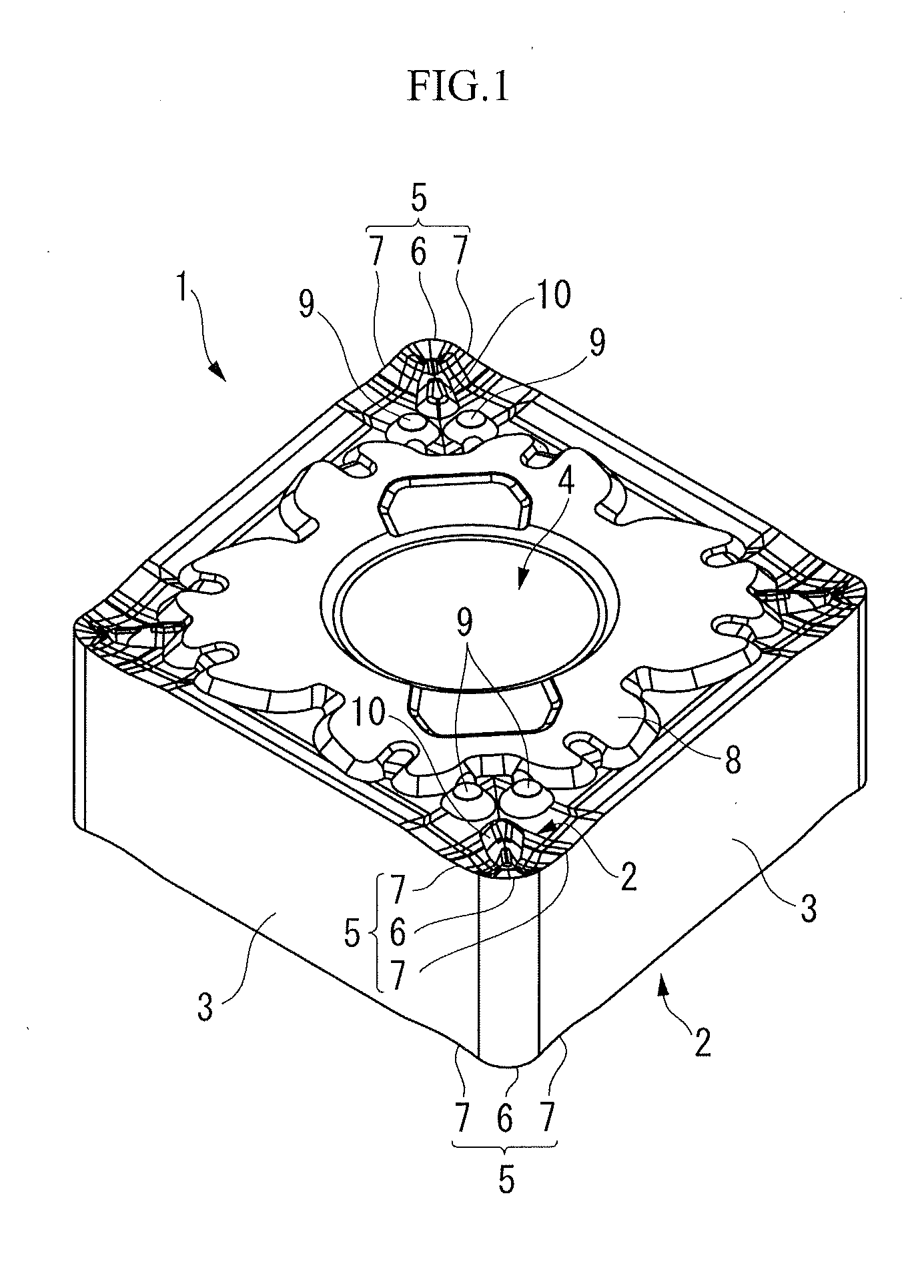

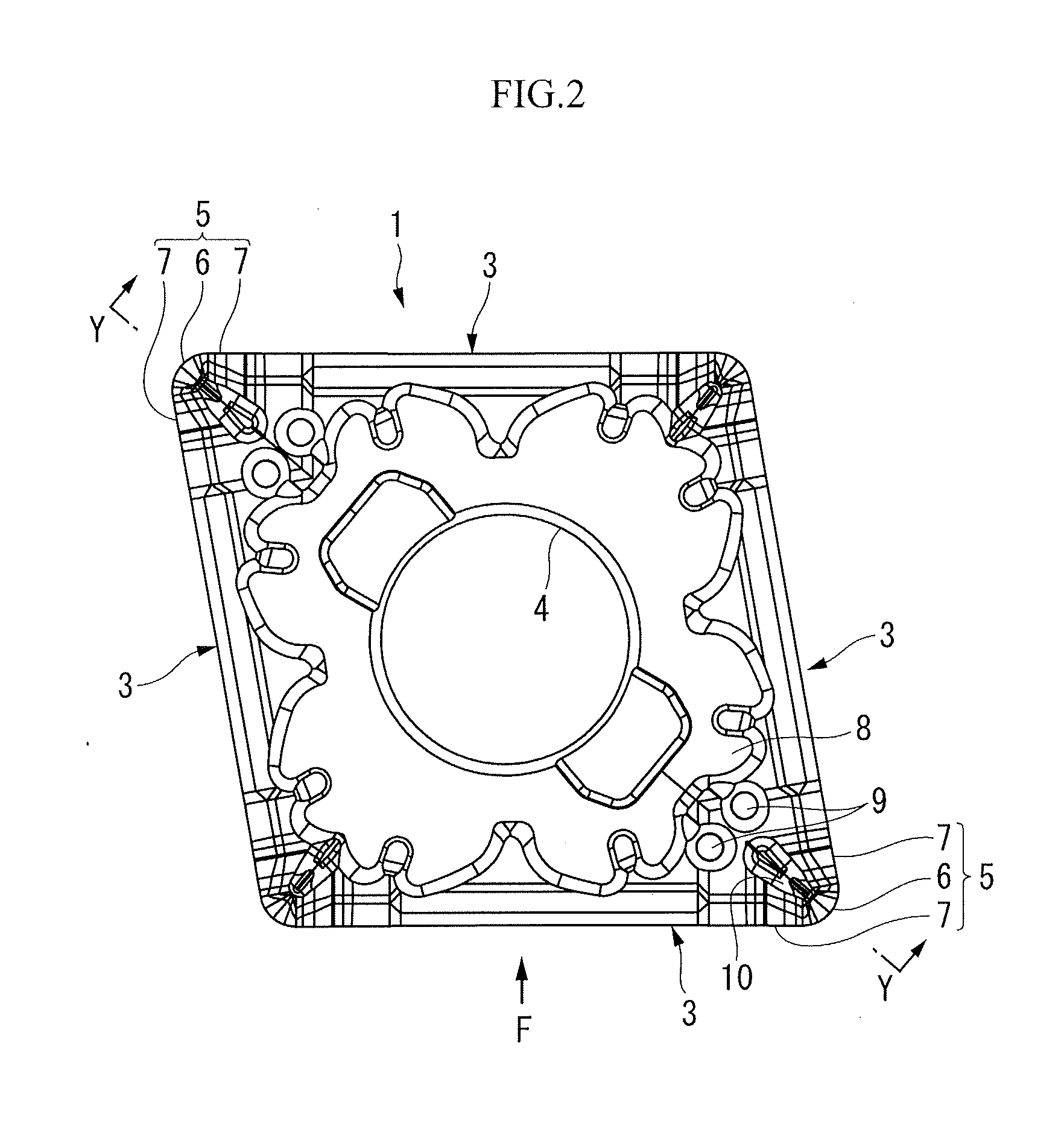

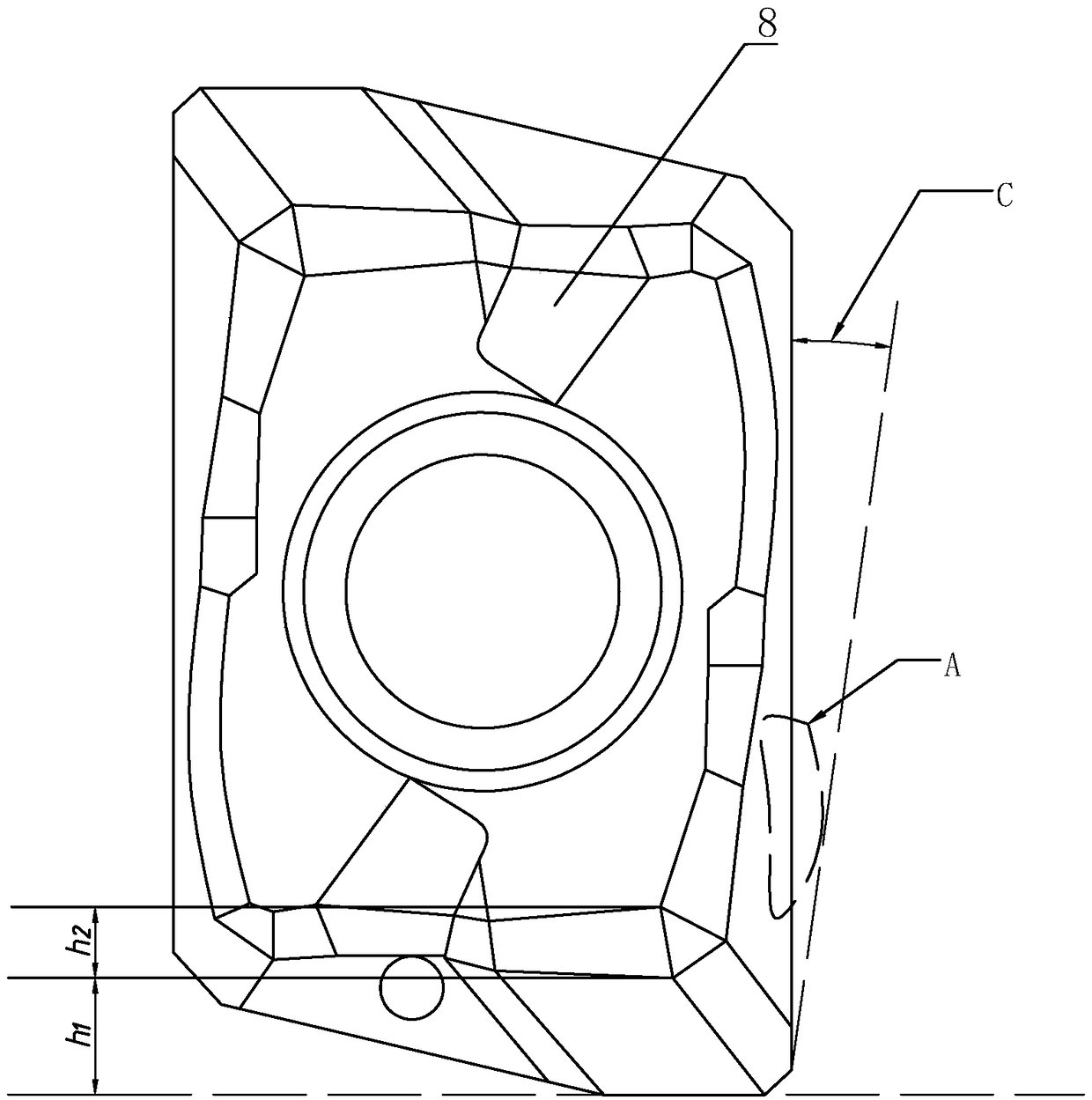

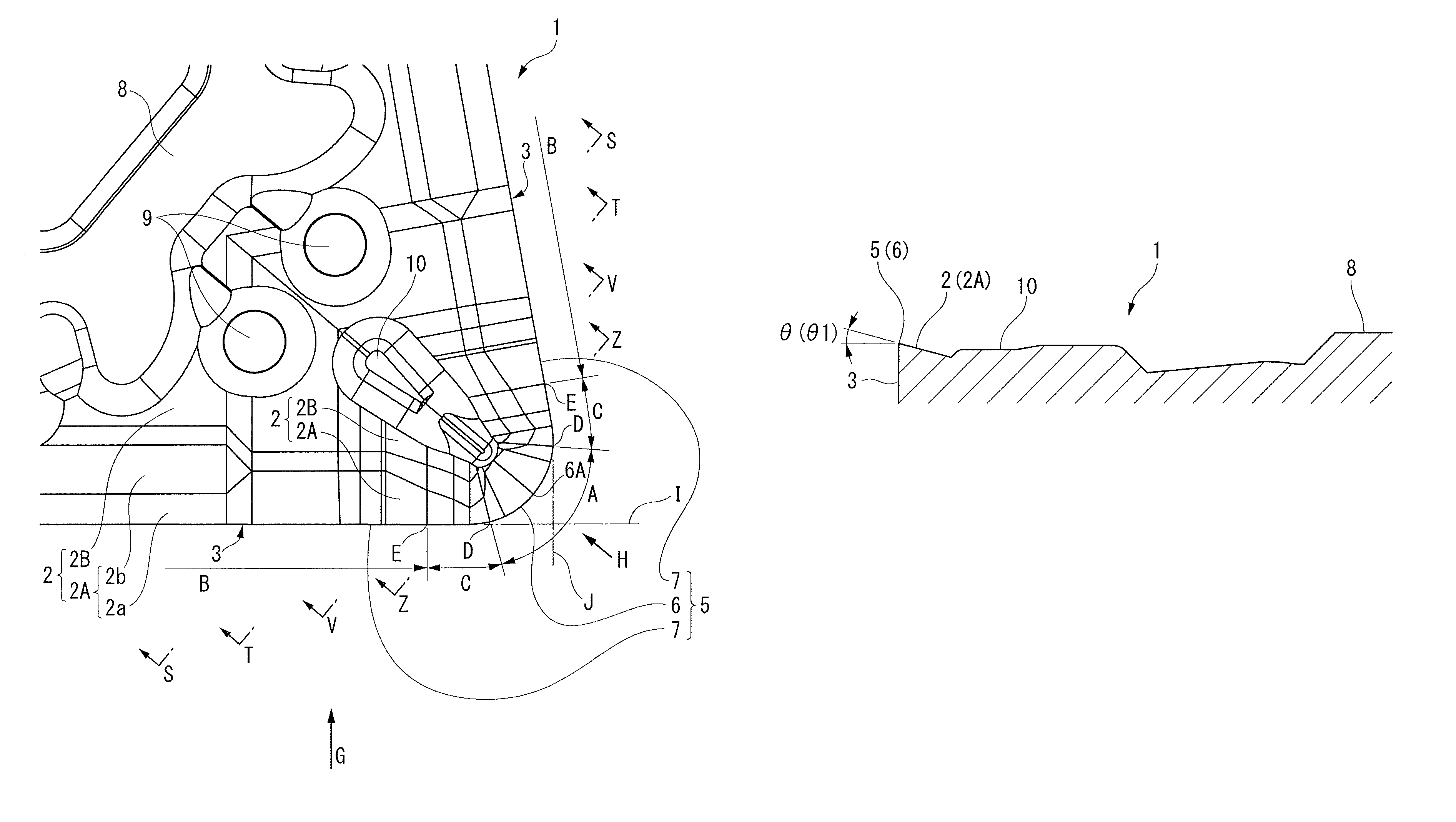

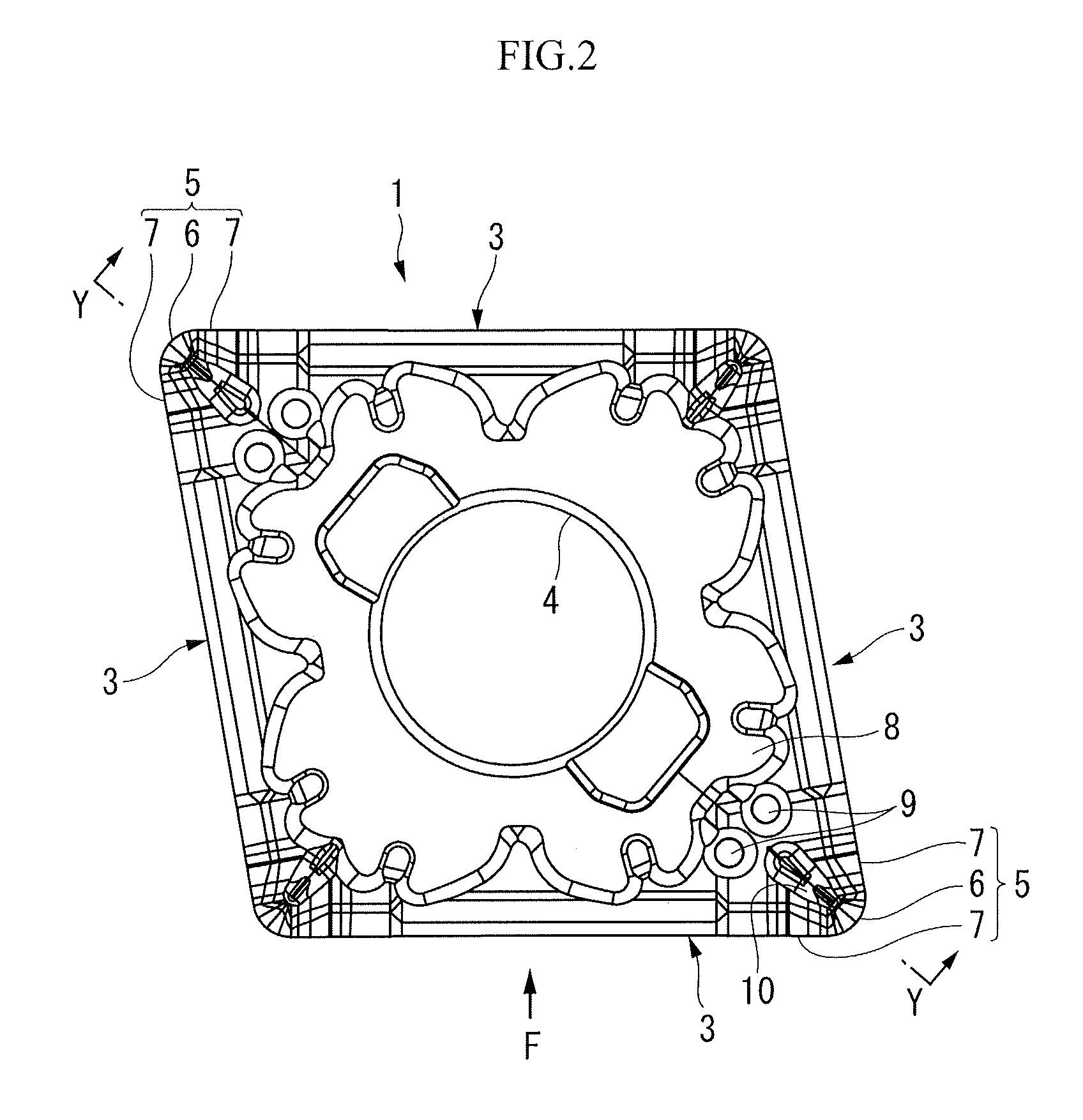

Cutting insert

ActiveUS20130236258A1Avoid fracturesAvoid chippingCutting insertsTurning toolsEngineeringMechanical engineering

The present invention relates to the cutting insert having a cutting edge which has a corner section that forms a convex arc shape when seen in a planar view from direction facing the rake face and a linear section that is in contact with the corner section at least at one end of the corner section and extends linearly. The cutting edge is provided with a first region along the corner section when seen in a planar a second region along the linear section and a third region between the first region and the second region. A rake angle of the cutting edge in the third region is made greater than rake angles of the cutting edges in the first region and the second region.

Owner:MITSUBISHI MATERIALS CORP

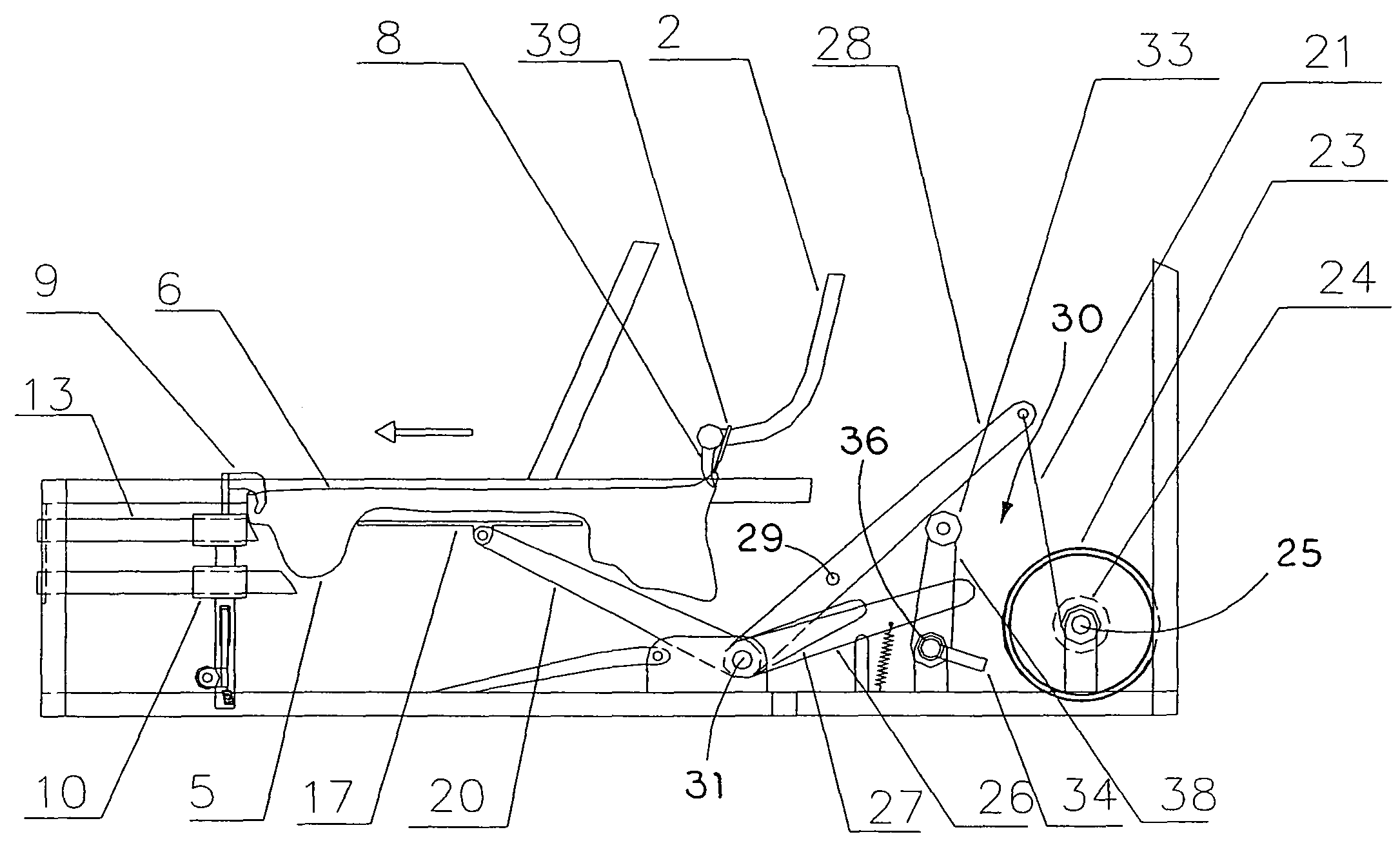

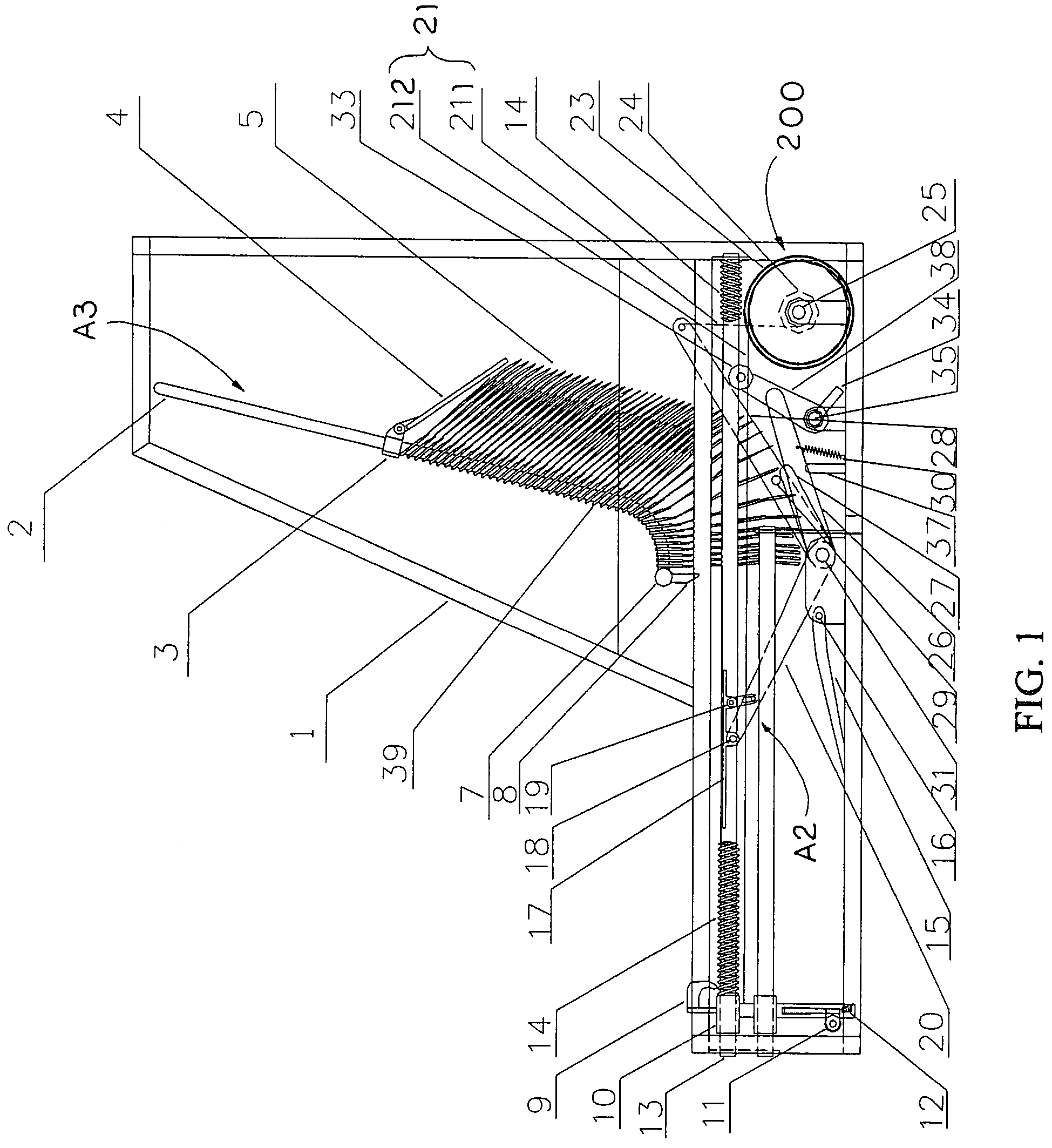

Automatic shoe cover dispenser

ActiveUS7775396B2The process is stable and efficientEfficient and stable processingApparel holdersRegistering devicesEngineeringFootplate

Owner:XU LIANG JIE

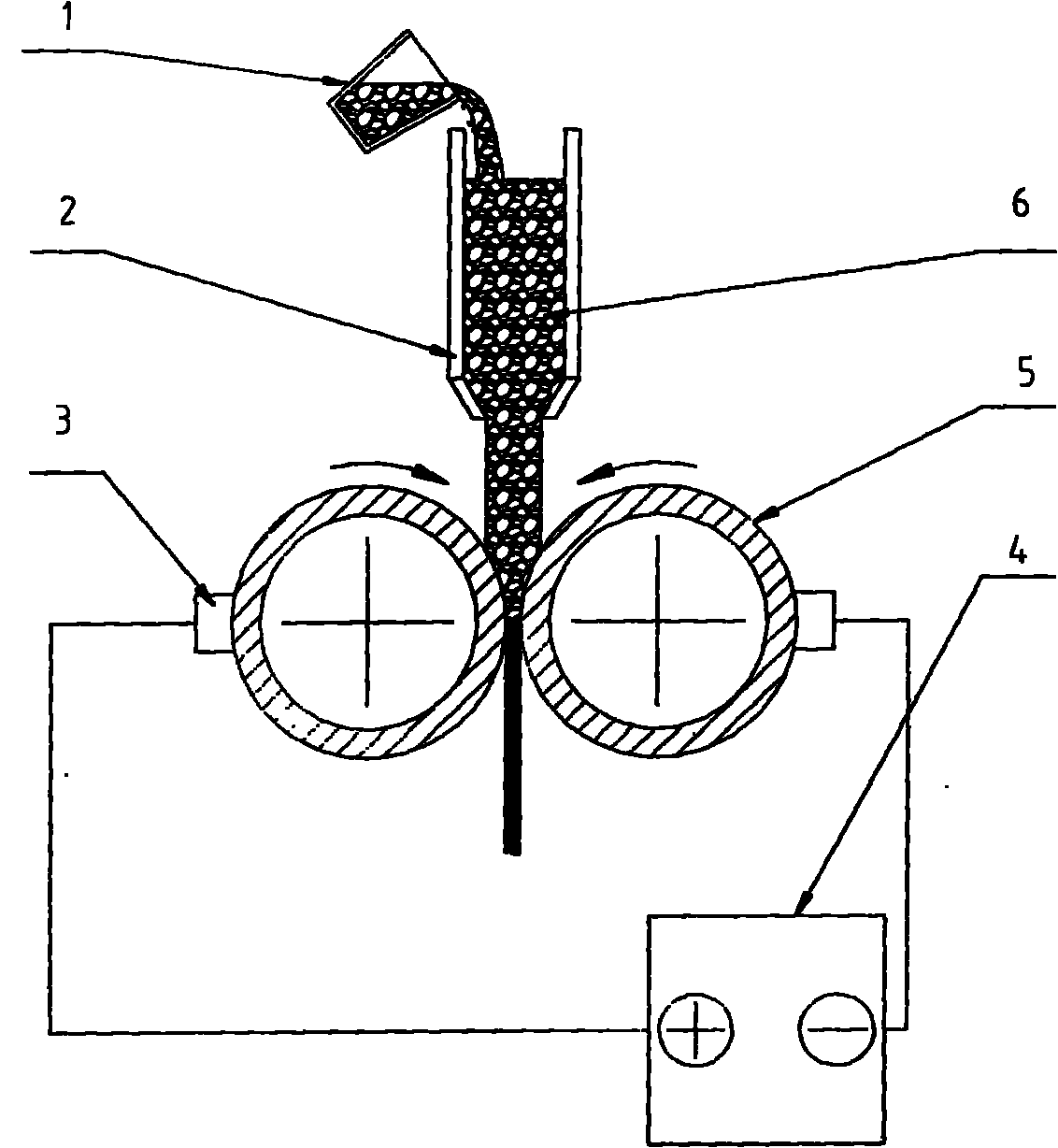

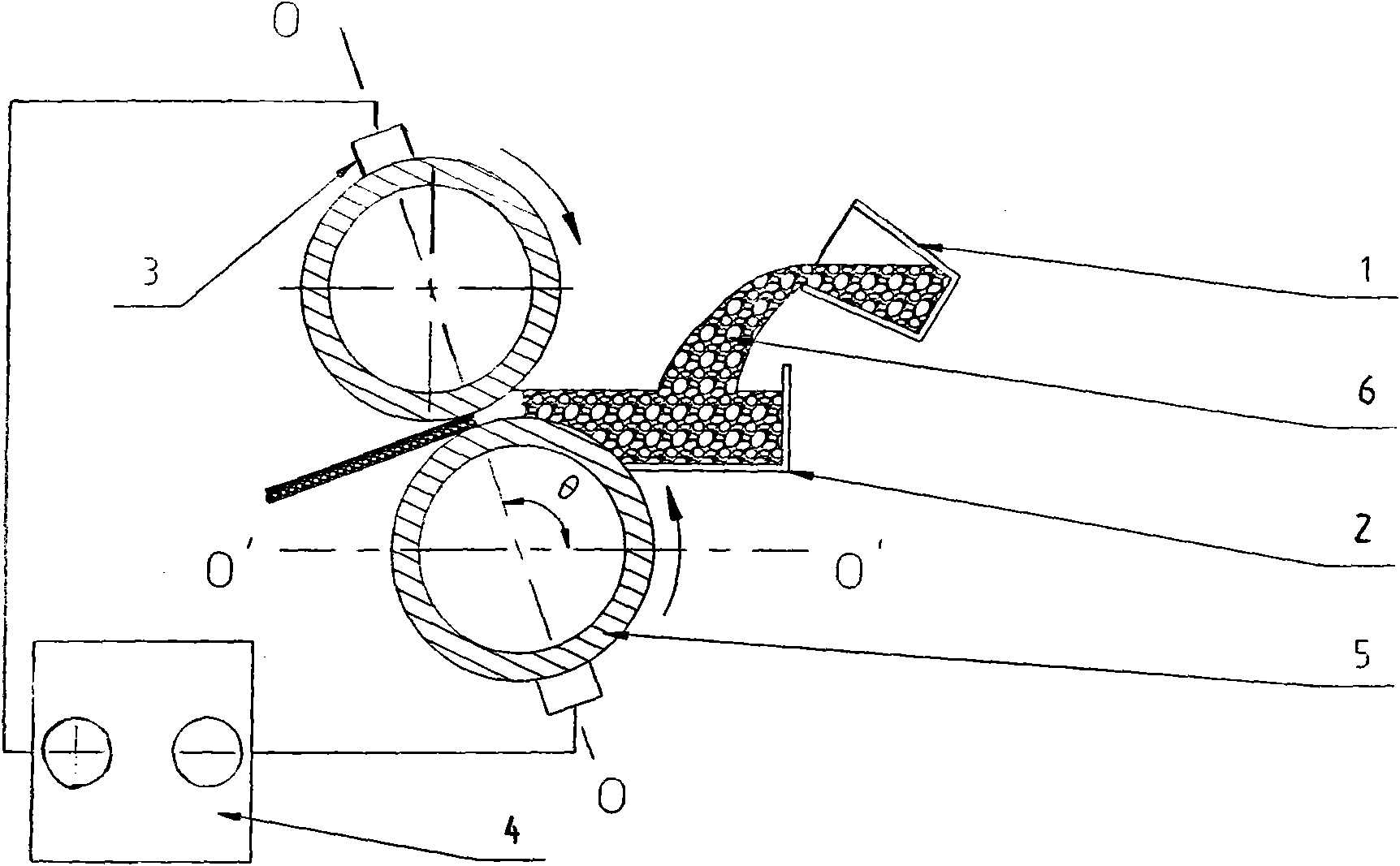

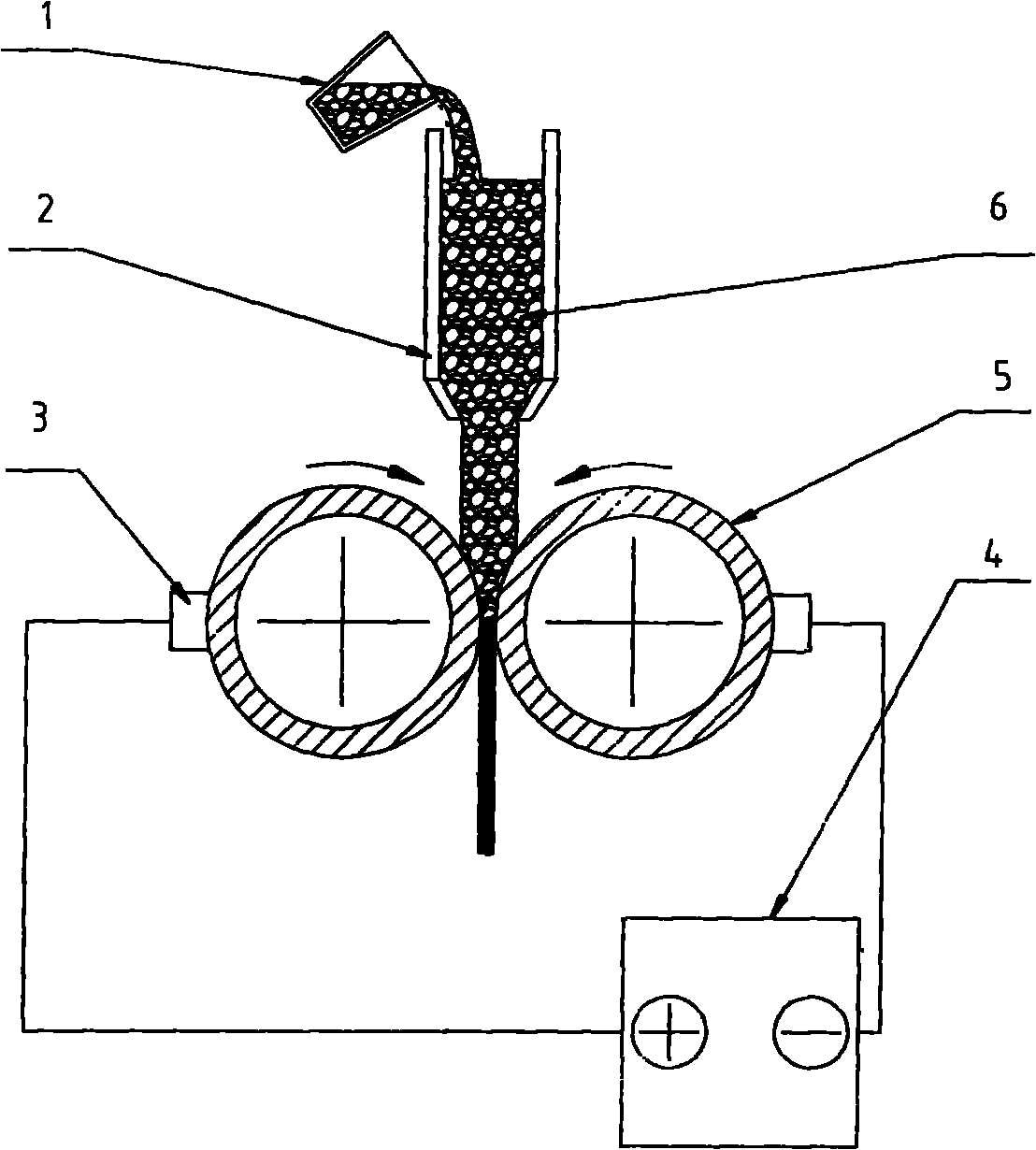

Electric pulse casting and rolling method of semi-solid alloy

The invention relates to an electric pulse casting and rolling method of a semi-solid alloy. In the method, semi-solid alloy slurry is filled between two rollers rotating in reverse directions, and is subject to flash set and plastic deformation under the action of pulse currents, thus obtaining alloy plates, thin alloy materials, alloy bars or alloy wires. The method can remarkably eliminate the segregation, refines the grains, and enhances the plastic deformation capability of the metal material, thereby improving the comprehensive mechanical properties of the material.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

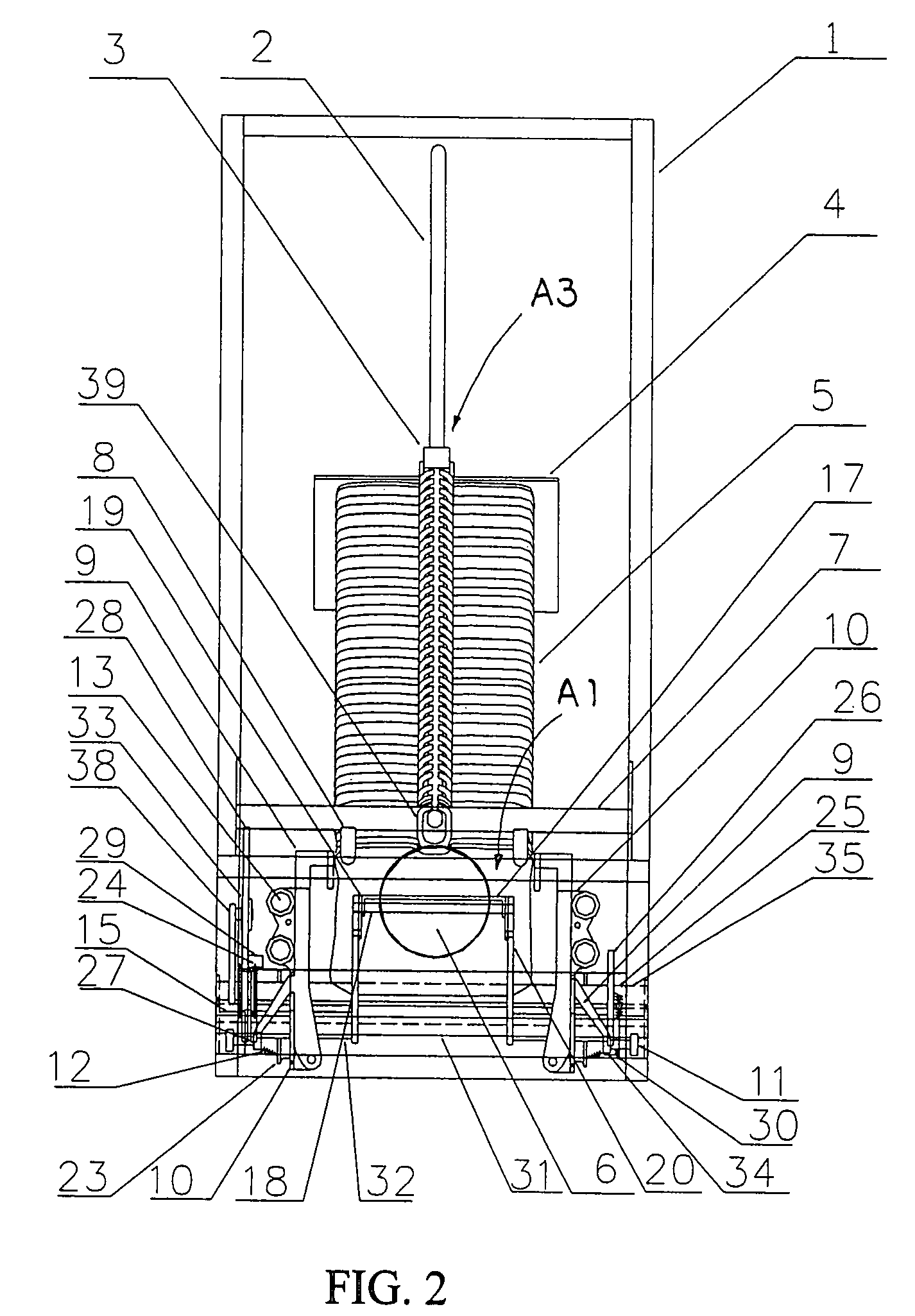

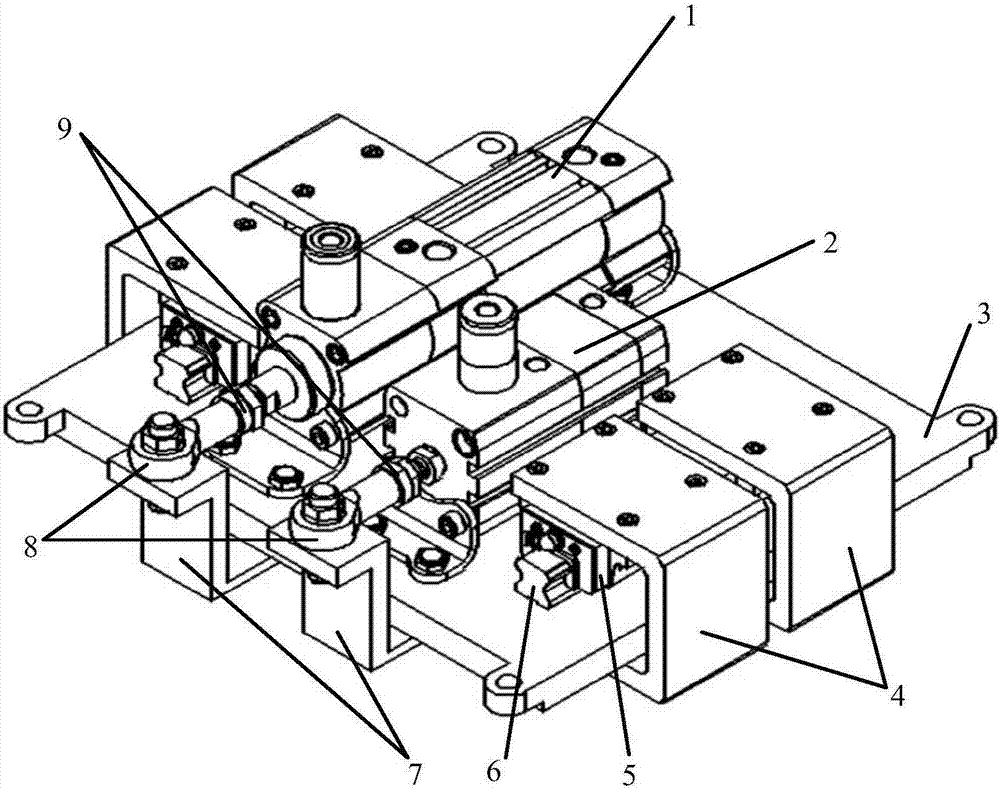

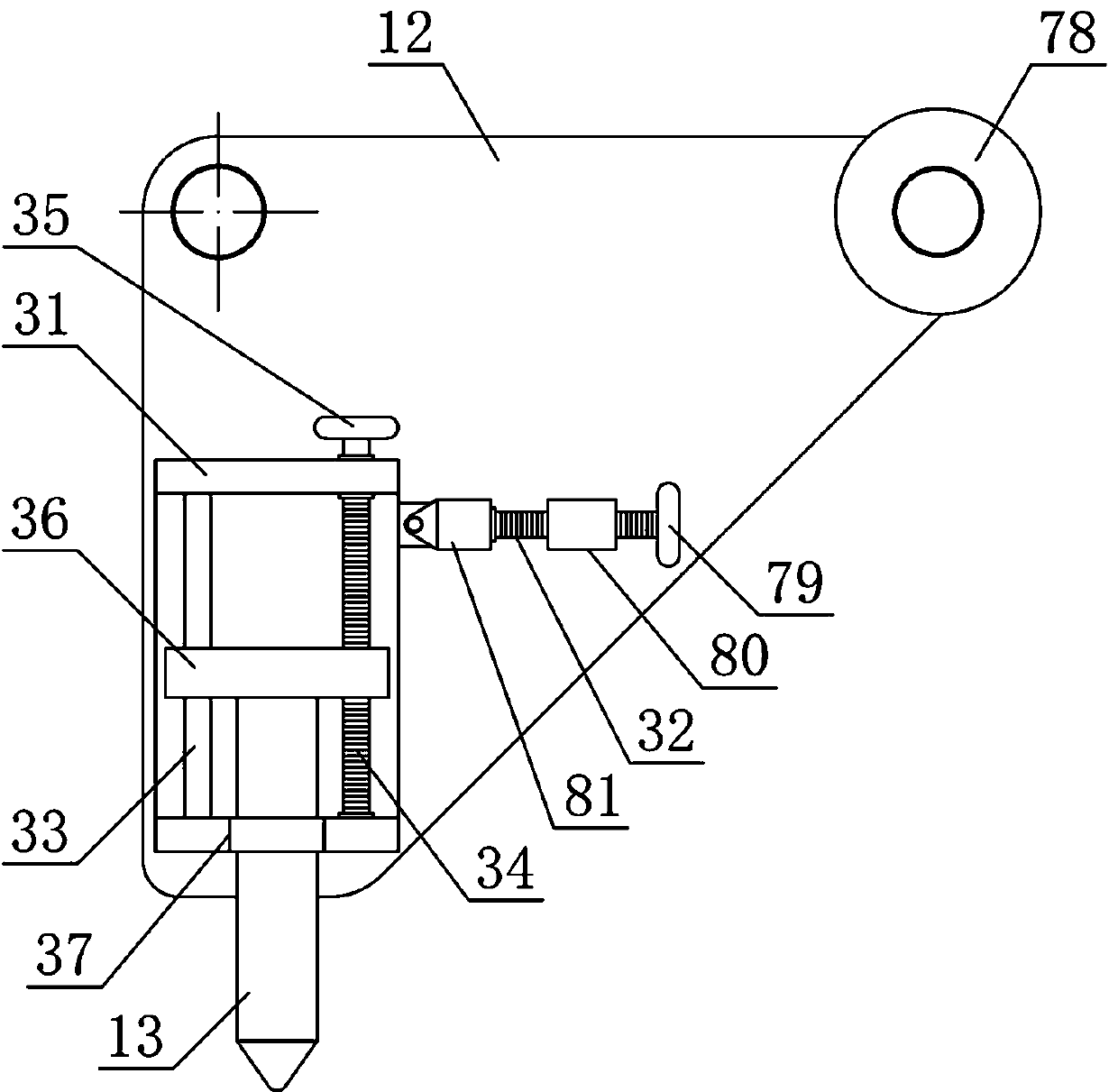

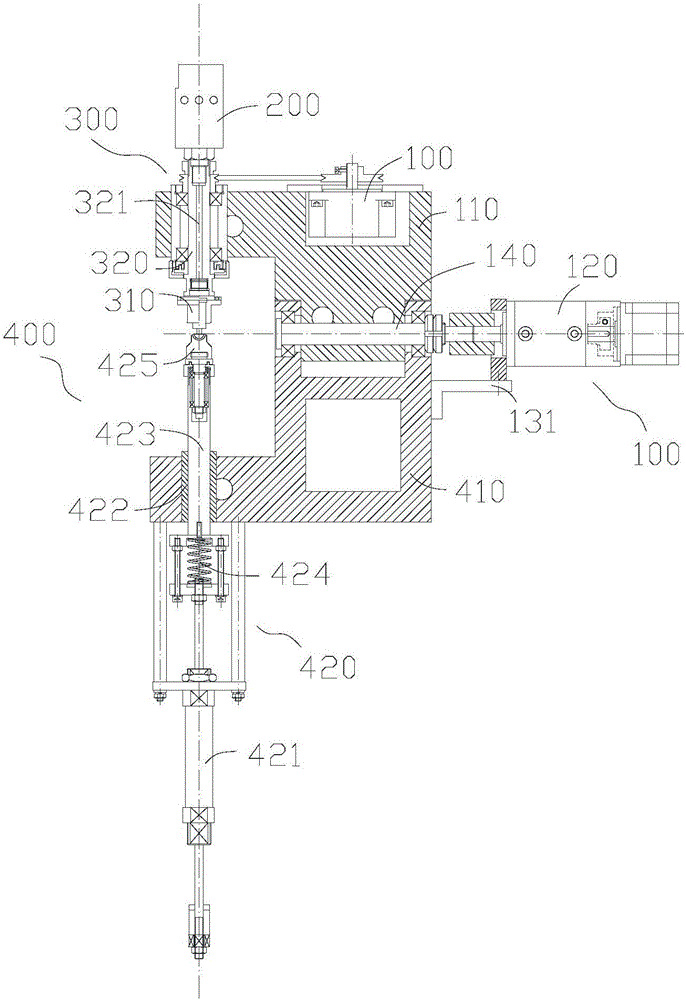

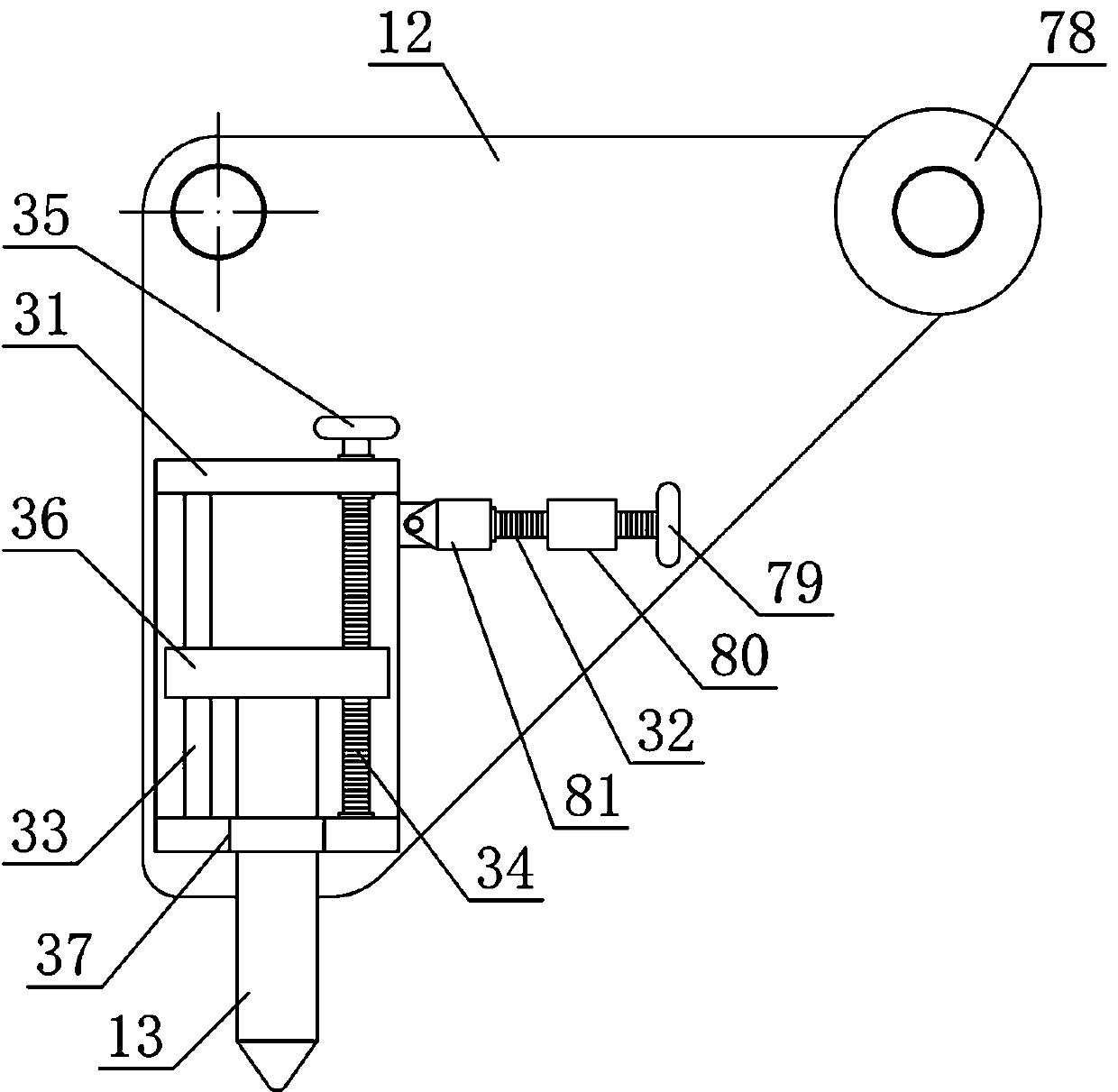

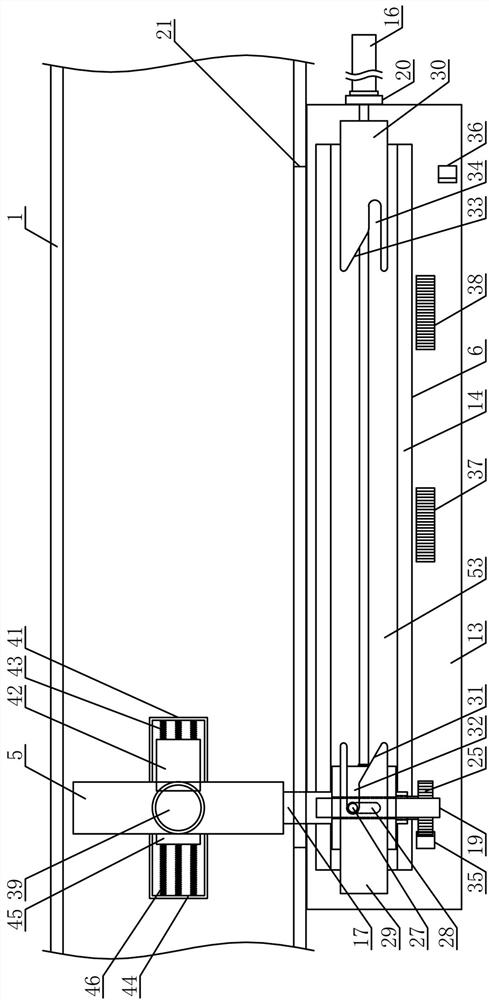

Flexible polishing constant-force control device driven by double actuators

InactiveCN106903613AHigh force adjustment accuracySmooth sandingAutomatic grinding controlPistonEngineering

A flexible polishing constant-force control device driven by double actuators comprises a base plate. A main adjusting mechanism and a fine adjusting mechanism are installed in the middle of the base plate. Linear guide rails are arranged on the two sides of the main adjusting mechanism and the fine adjusting mechanism. The linear guide rails are provided with sliding blocks. The front ends of piston rods of the main adjusting mechanism and the fine adjusting mechanism are both connected with joint bearings. Force sensors are arranged between the piston rods and the joint bearings. The joint bearings are connected with connecting racks. The flexible polishing constant-force control device driven by the double actuators is installed at the tail end of an industrial robot, and an automatic-cutter-change electric spindle on the industrial robot is connected with the flexible polishing constant-force control device driven by the double actuators through a clamping device. The automatic-cutter-change electric spindle clamps a polishing head to polish a workpiece. The main adjusting mechanism and the fine adjusting mechanism rapidly respond. The force sensors monitor the polishing force in real time, control over the polishing force is accurately guaranteed through a closed-loop system, and constant-force control is achieved. According to the flexible polishing constant-force control device driven by the double actuators, a wide force adjusting range can be obtained through the main adjusting mechanism, fine adjustment is conducted through the fine adjusting mechanism, the control precision is high, response is rapid, smooth polishing is achieved, and the polishing quality is improved.

Owner:SHANDONG UNIV

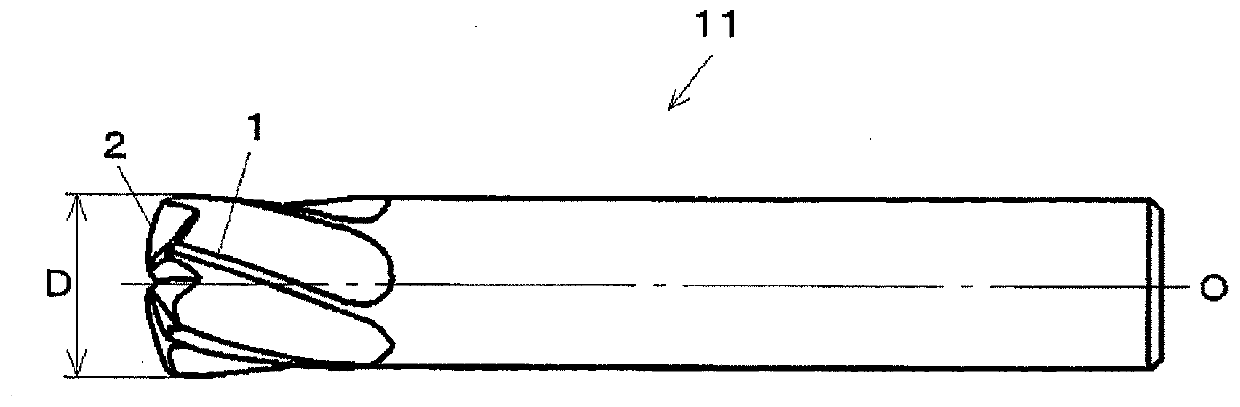

End mill for cutting of high-hardness materials

The present invention relates to an end mill having a circular cutting edge of curved shape when viewed in a direction perpendicular to the tool axis, an end cutting edge composed of a medium-to-low pitch cutting edge of linear shape or circular shape, and a peripheral cutting edge. When viewed in a direction parallel to the tool axis, the edges of the circular cutting edge and the flank face of the circular cutting edge at the rearward sides thereof with respect to rotation are curved shapes having curvature radii, and the curvature radius of the circular cutting edge is smaller than the curvature radius of the flank face of the circular cutting edge at the rearward side thereof with respect to rotation.

Owner:MOLDINO TOOL ENG LTD

Process for the separation of organic compounds

ActiveUS10730022B2Improve stabilityEfficient and stable processingAmino compound purification/separationMembranesOrganic acidSimple Organic Compounds

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

Profile translation perforating mechanism

InactiveCN108480467APunch fullyNo offset shakingPerforating toolsMetal-working feeding devicesMechanical equipmentGuide tube

The invention discloses a profile translation perforating mechanism, and belongs to the field of building material machining mechanical equipment. According to the profile translation perforating mechanism, a translation pushing mechanism is horizontally arranged on one side of a fixed support; a perforating mechanism is vertically arranged at the position, on one side of the translation pushing mechanism, of the fixed support; a lifting bearing plate is horizontally arranged in the middle of a perforating support; a perforating pressing plate slides in the vertical direction to be arranged onperforating guide rods; a lifting pressing plate is fixedly arranged at the output ends of perforating air cylinders; a clamping base is horizontally arranged on the upper side of a pushing support of the translation pushing mechanism; the output end of an adjusting air cylinder on one side of the pushing support is fixedly connected with the middle of one side of the clamping base; a clamping air cylinder is arranged at the upper end of a clamping pressing rod by inclining downwards; and a sundry suction guide pipe is vertically arranged on one side of the fixed support. The profile translation perforating mechanism is reasonable in structural design, profiles of multiple dimensions can be fast and efficiently subjected to section-by-section accurate translation feeding for perforating machining, the profile machining efficiency and quality can be improved, and the machining use requirement can be met.

Owner:沈洁

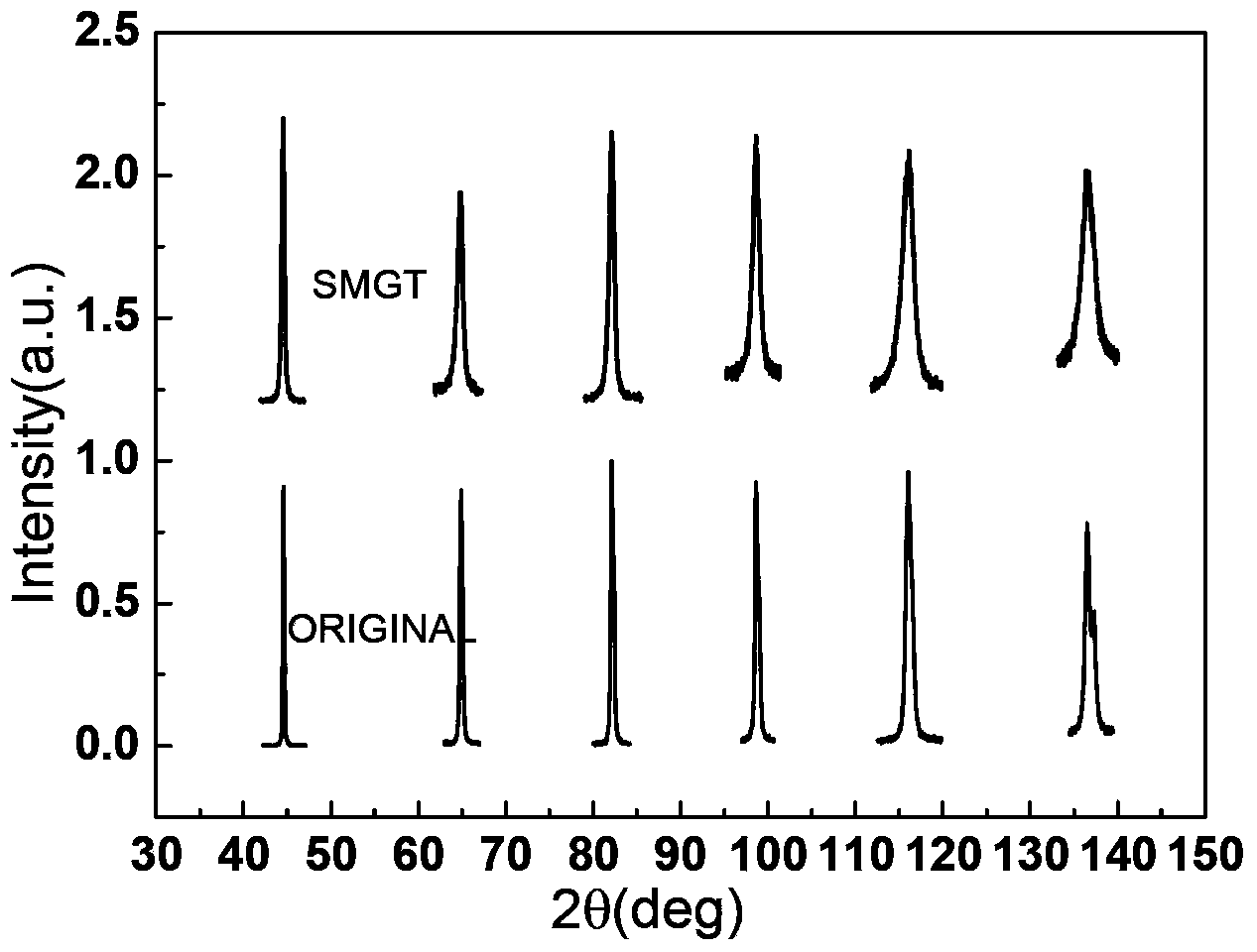

Method for improving low-activation ferrite/martensitic steel high-temperature oxidation resistance

InactiveCN104278132AImprove high temperature oxidation resistanceProtectiveSurface layerOxidation resistant

The invention aims at providing a method for improving low-activation ferrite / martensitic steel high-temperature oxidation resistance, and the method enables the ferrite / martensitic steel to satisfy service conditions. The method helps to improve the high-temperature oxidation resistance of the material by forming a nanocrystal-composed surface layer on the low-activation steel surface. Especially, by performing surface mechanical grinding treatment (SMGT) on the low-activation ferrite / martensitic steel subjected to high-temperature tempering, the crystal grain is fined, the crystal boundary ratio is increased, and the element diffusion rate is improved, and thus a protective oxidation film is rapidly formed and anti-oxidation effect is finally given play. The method is capable of substantially improving the high-temperature oxidation resistance of the material, thereby solving the problem that the usage temperature is relatively low.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-efficiency machining control method for deep hole in oil pump casing

ActiveCN109375578AEfficient and stable processingOptimizing the cutting process pathNumerical controlModal testingMachine control

The invention discloses a high-efficiency machining control method for a deep hole in an oil pump casing. The method comprises the following steps: calculating a modal transfer function of a cutting processing system and acquiring the modal transfer function; according to a processing depth, arranging one row of points successively and uniformly at intervals from a cutter point to the tail of a cutter rod, carrying out modal testing, and acquiring modal transfer functions of all joints of the cutter successively; on the basis of the modal transfer function of the cutting processing system andthe modal transfer function of each joint of the cutter, establishing cutting processing transfer functions phi1i of different joints of the cutter, and carrying out Laplace transform on the phi1i toobtain phi1i(s); according to the phi1i(s), acquiring stable regions under different joints of the cutter during cutting processing based on a method of solving a stable region by a frequency domain;and according to the cutting parameters of the stable regions, carrying out high-efficiency stable processing on a workpiece. According to the design, preferable cutting parameters are obtained accurately based on the dynamic characteristics of the cutter and the workpiece and the cutting processing path is optimized, so that high-efficiency and stable deep hole processing is realized and the machining stability of the cutting process and the surface quality of the workpiece are improved.

Owner:HUNAN INST OF TECH

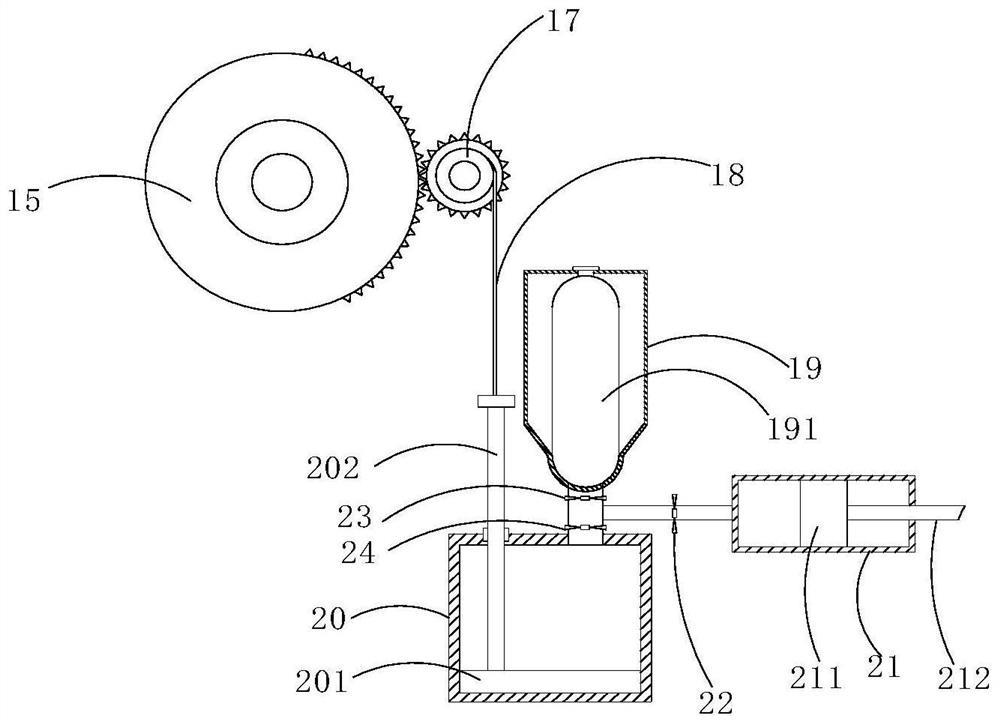

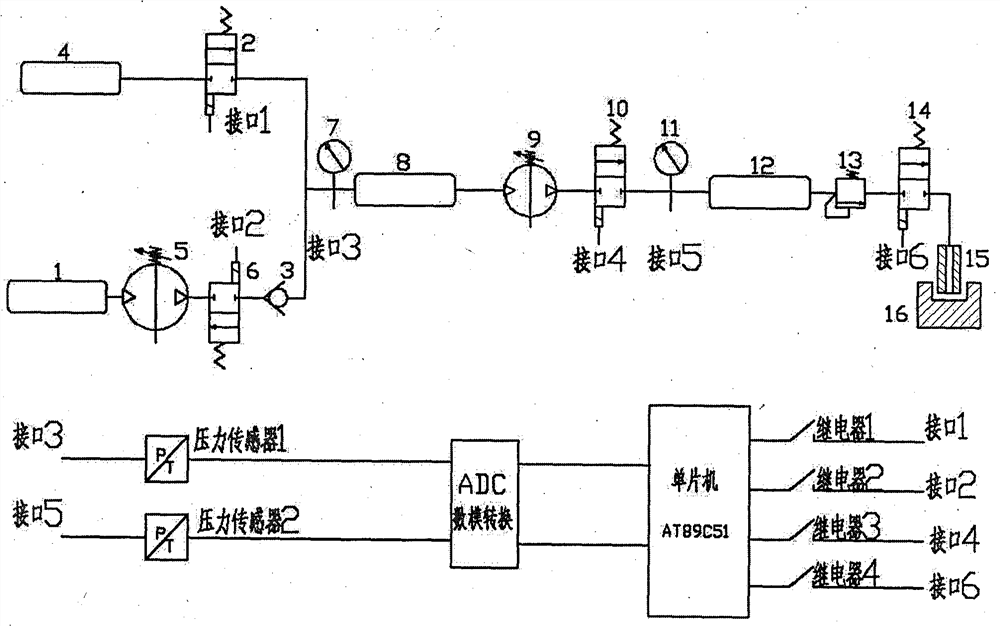

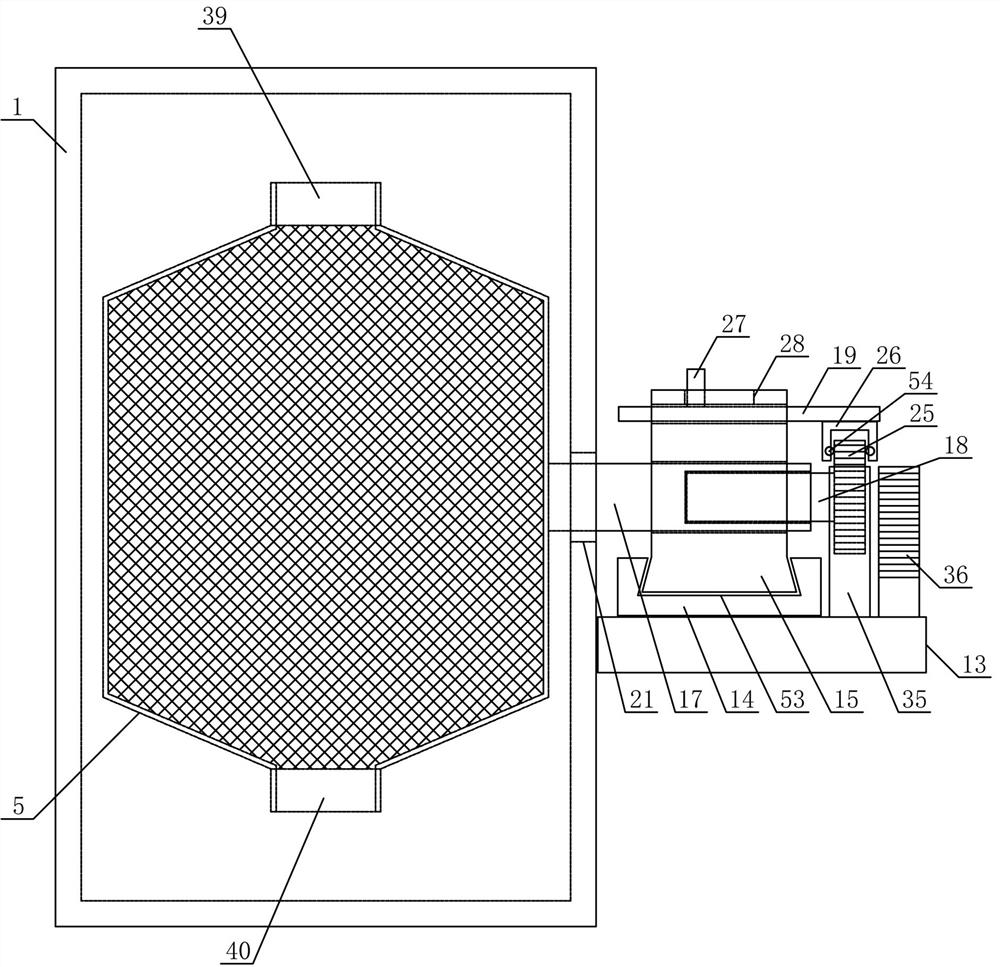

Pulsed abrasive flow polishing device and method

ActiveCN109352536AStable pressure waveLow failure rateEdge grinding machinesPolishing machinesMaterial hardnessEngineering

The invention relates to a pulsed abrasive flow polishing device and method, and provides a pulse generating device which can generate four different pressure forms. Different tooth forms and tooth spacings are designed, and different mechanical structures are used for generating stable sinusoidal pressure wave, triangular pressure wave, trapezoidal pressure wave and standard sine-cosine pressurewave, so that the effect of increasing the fluid turbulent kinetic energy is achieved, the uniform machining effect is achieved, additionally, different pressure forms are selected according to different material hardness and high-temperature oxidation effects during machining, the characteristics of different kinds of pressure wave are exerted, and the machining effects of high efficiency and economy are achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

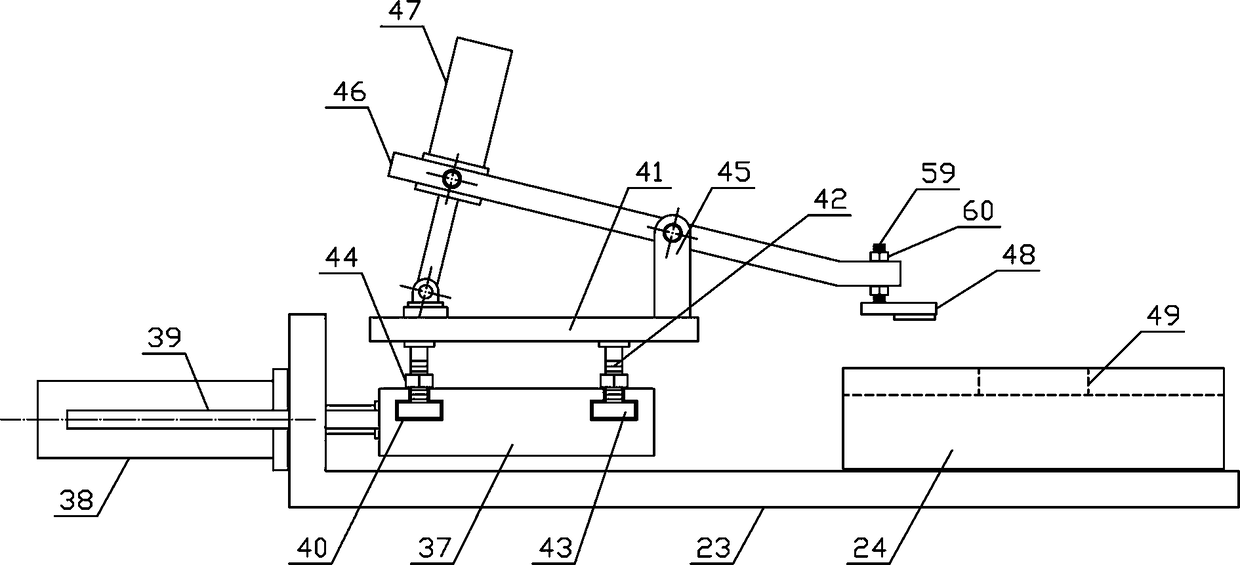

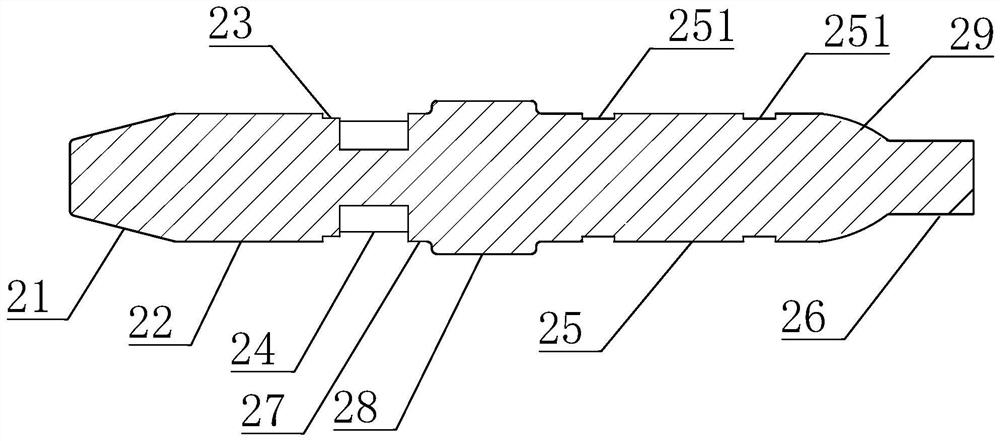

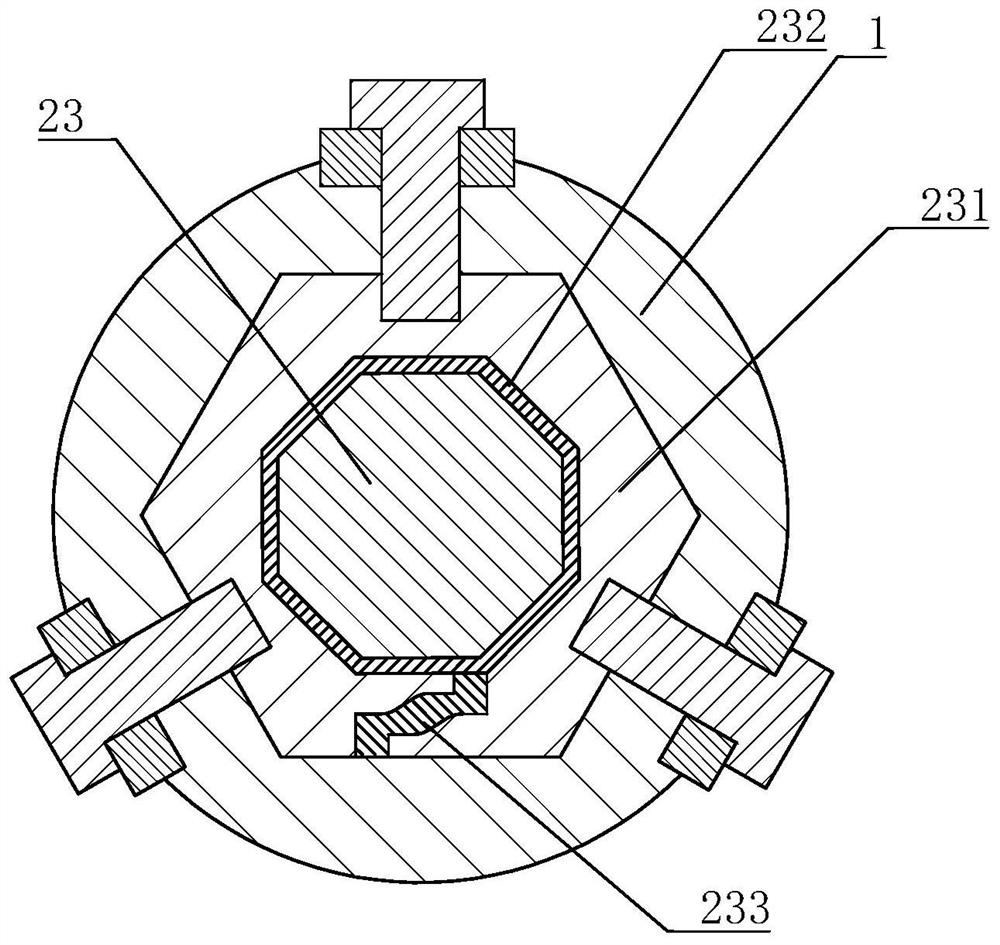

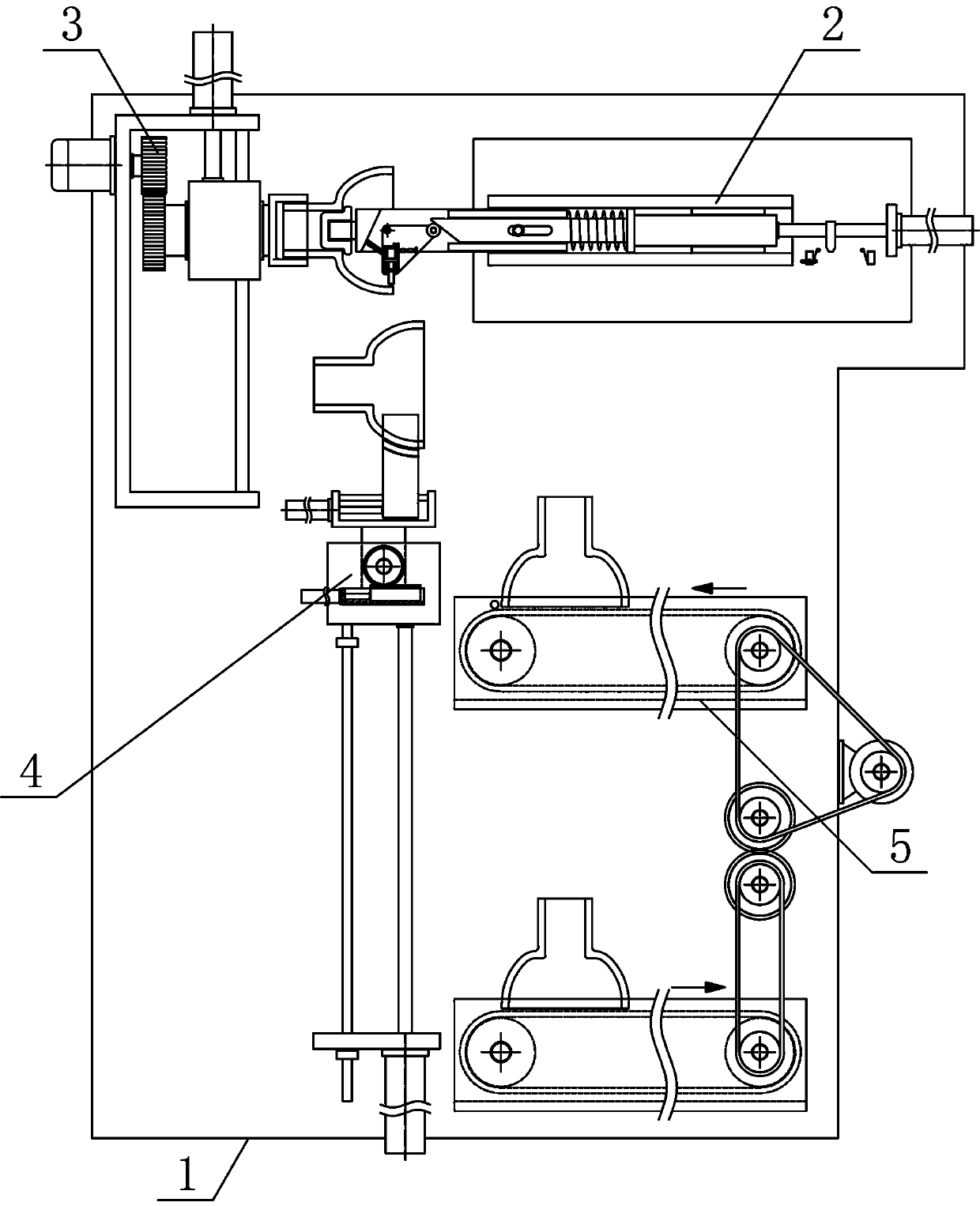

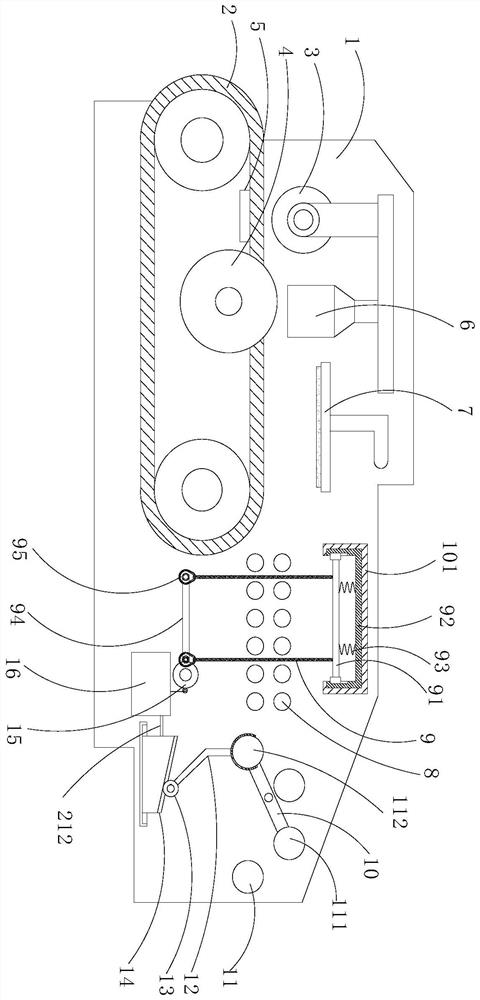

Cutting machining device for spherical-surface workpieces

ActiveCN110586962ARealize automatic transferSmooth rotationAutomatic control devicesFeeding apparatusMechanical equipmentTransfer mechanism

The invention discloses a cutting machining device for spherical-surface workpieces, and belongs to the field of workpiece machining mechanical equipment. The cutting machining device comprises a machining conveying support, a horizontal moving and cutting mechanism, a clamping and lifting mechanism, a turning and transferring mechanism and a workpiece conveying mechanism, wherein the horizontal moving and cutting mechanism is horizontally and fixedly arranged on one side above the machining conveying support, the clamping and lifting mechanism is vertically arranged at the position, on one side of the horizontal moving and cutting mechanism, of the machining conveying support, the turning and transferring mechanism is vertically arranged at the position, on one side below the clamping andlifting mechanism, of the machining conveying support, and the workpiece conveying mechanism is horizontally arranged at the position, on one side of the turning and transferring mechanism, of the machining conveying support in a mode of being adjacent to the turning and transferring mechanism. The cutting machining device has the advantages that the structural design is reasonable, the spherical-surface workpieces can be efficiently and stably cut and machined one by one, moreover, automatic transferring feeding and pushing of the spherical-surface workpieces can be achieved, the machining automation degree is high, and the workpiece machining and use requirements are met.

Owner:昆山勖盟工业科技有限公司

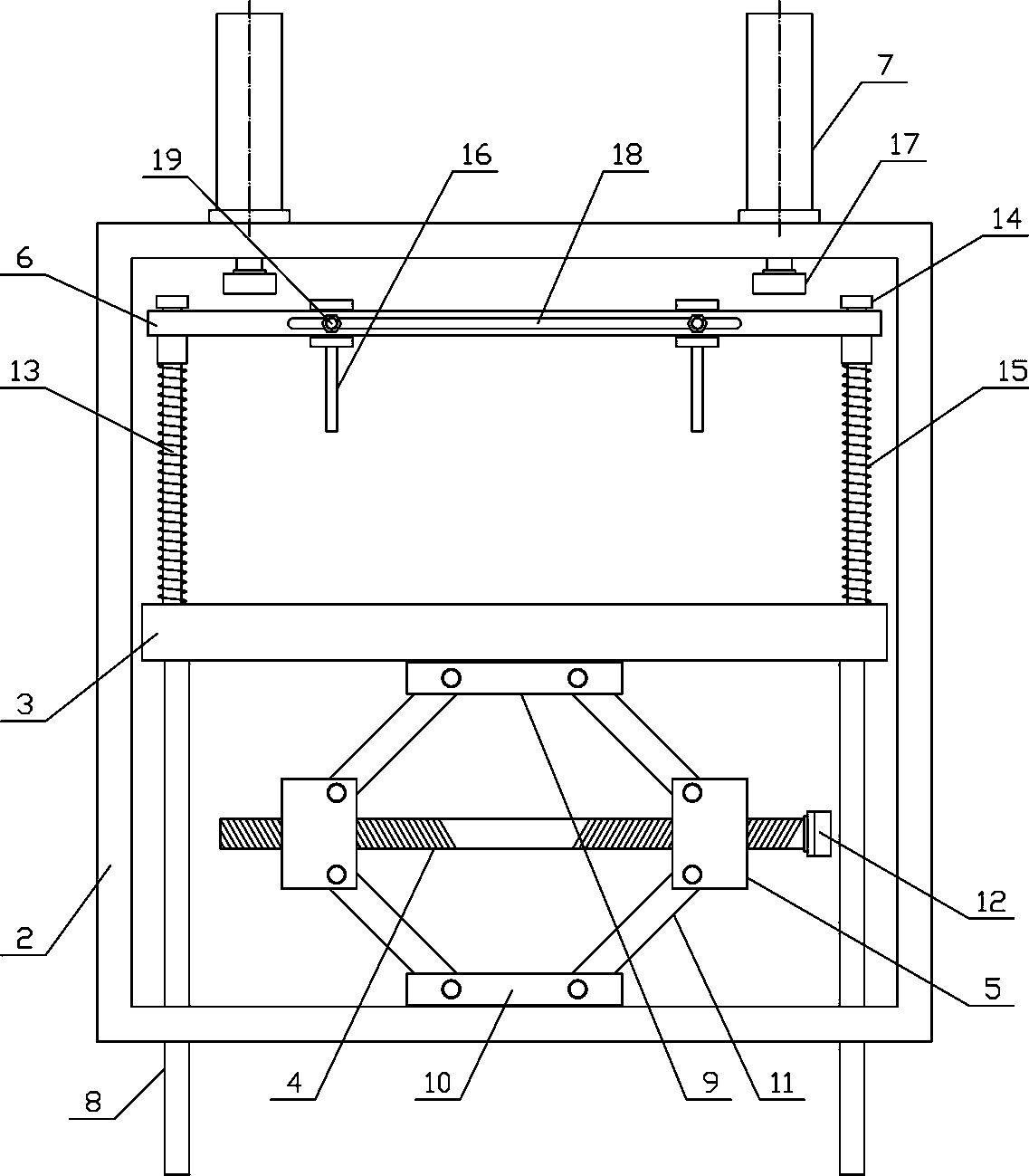

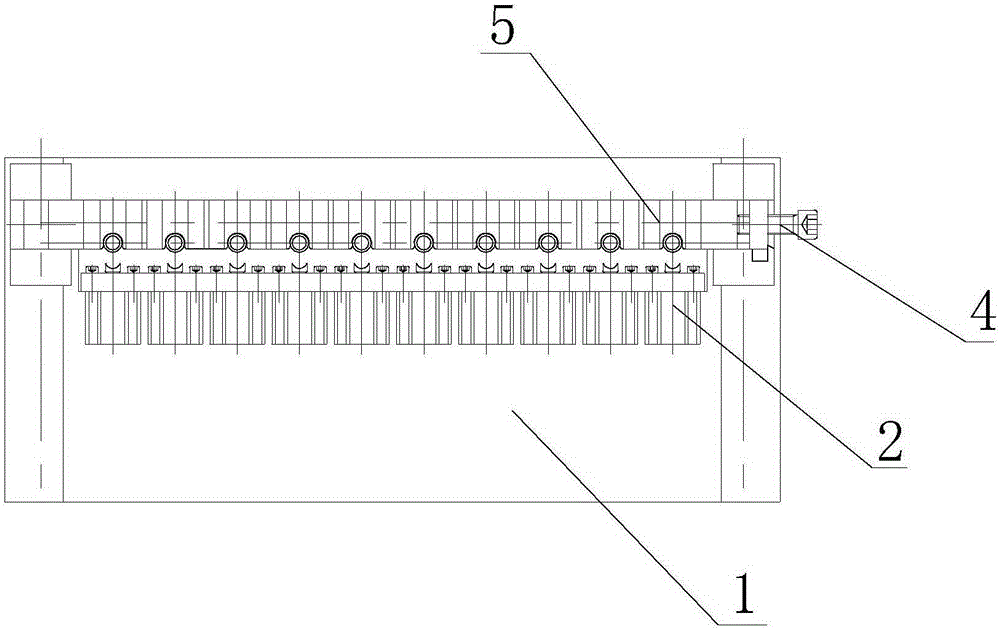

Clamping mechanism for blanking machine

InactiveCN104416084AImprove stabilityStable processingMetal-working feeding devicesPositioning devicesFixed frameInstability

The invention discloses a clamping mechanism for a blanking machine. The clamping mechanism comprises a clamping unit, a guide rail and a fixing frame, wherein the guide rail and the clamping unit are respectively arranged on the fixing frame, the clamping unit comprises a movable baffle plate and a fixed baffle plate, the movable baffle plate is glidingly arranged on the guide rail, the fixed baffle plate is arranged on the fixing frame, the clamping mechanism also comprises a hydraulic mechanism, and the hydraulic mechanism is connected with the bottom end of the movable baffle plate. During the material cutting work procedure, a workpiece is tightly attached to the inner wall of the fixed baffle plate, the movable baffle plate approaches to the fixed baffle plate under push by the output end of the hydraulic mechanism until the workpiece is tightly clamped, and finally, a cutting mechanism is used for carrying out cutting processing on the workpiece. The hydraulic mechanism is adopted, the problems of clamping instability of conventional machinery and great noise generated by the clamping of a pneumatic clamping mechanism are solved, the clamping reliability is ensured, meanwhile, good operation environment is also maintained, and the work efficiency is improved.

Owner:熊凌聪

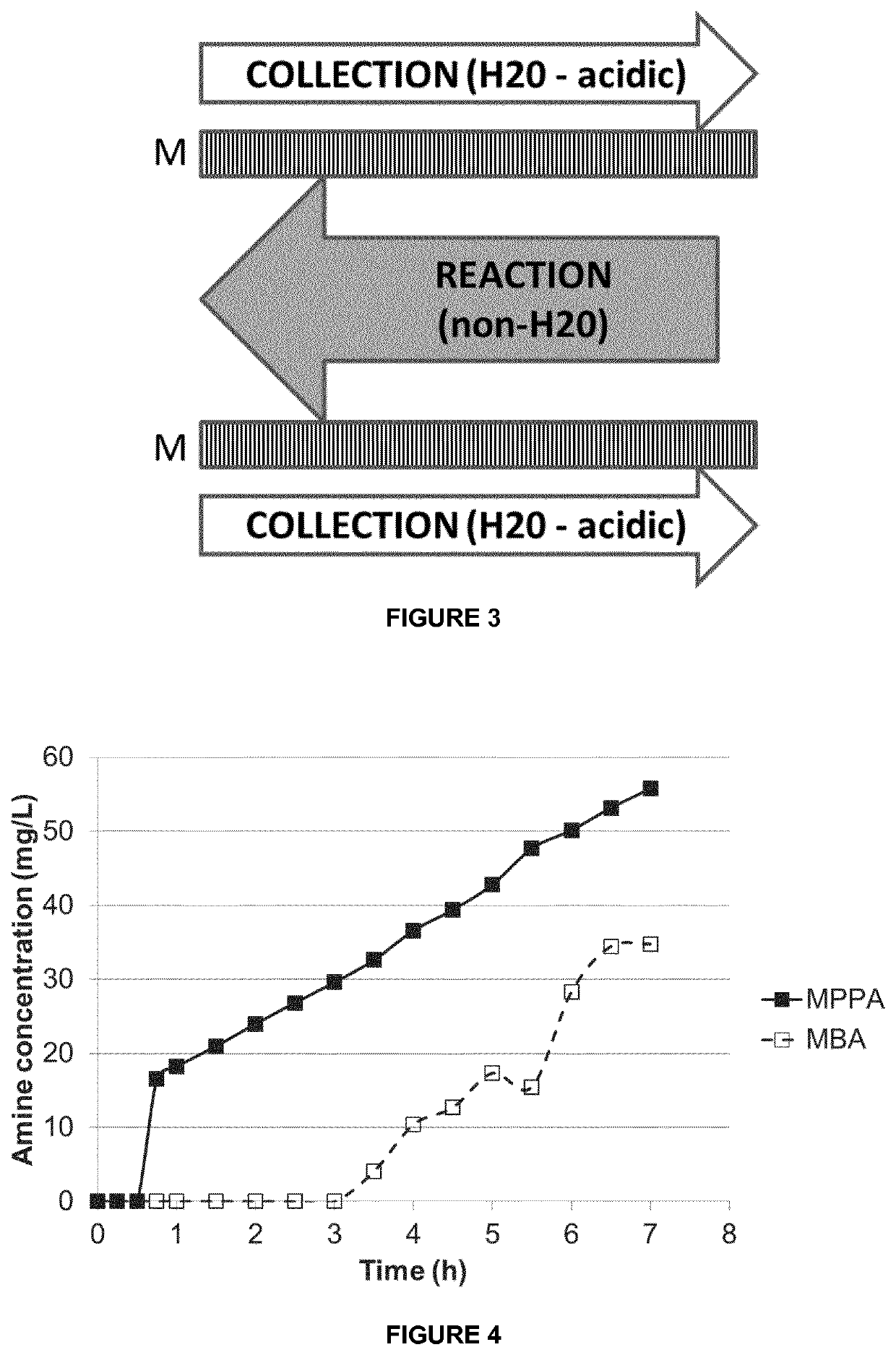

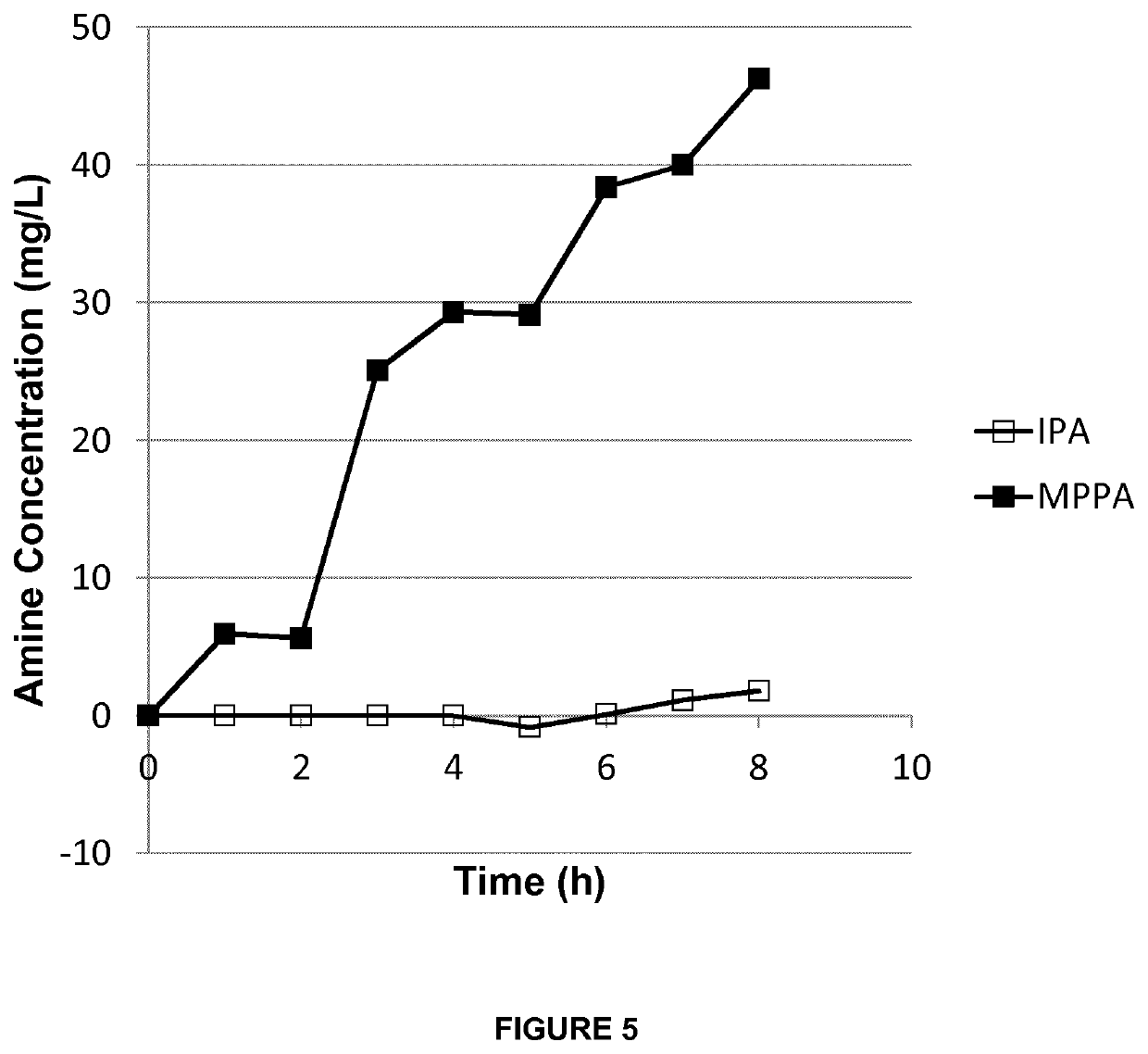

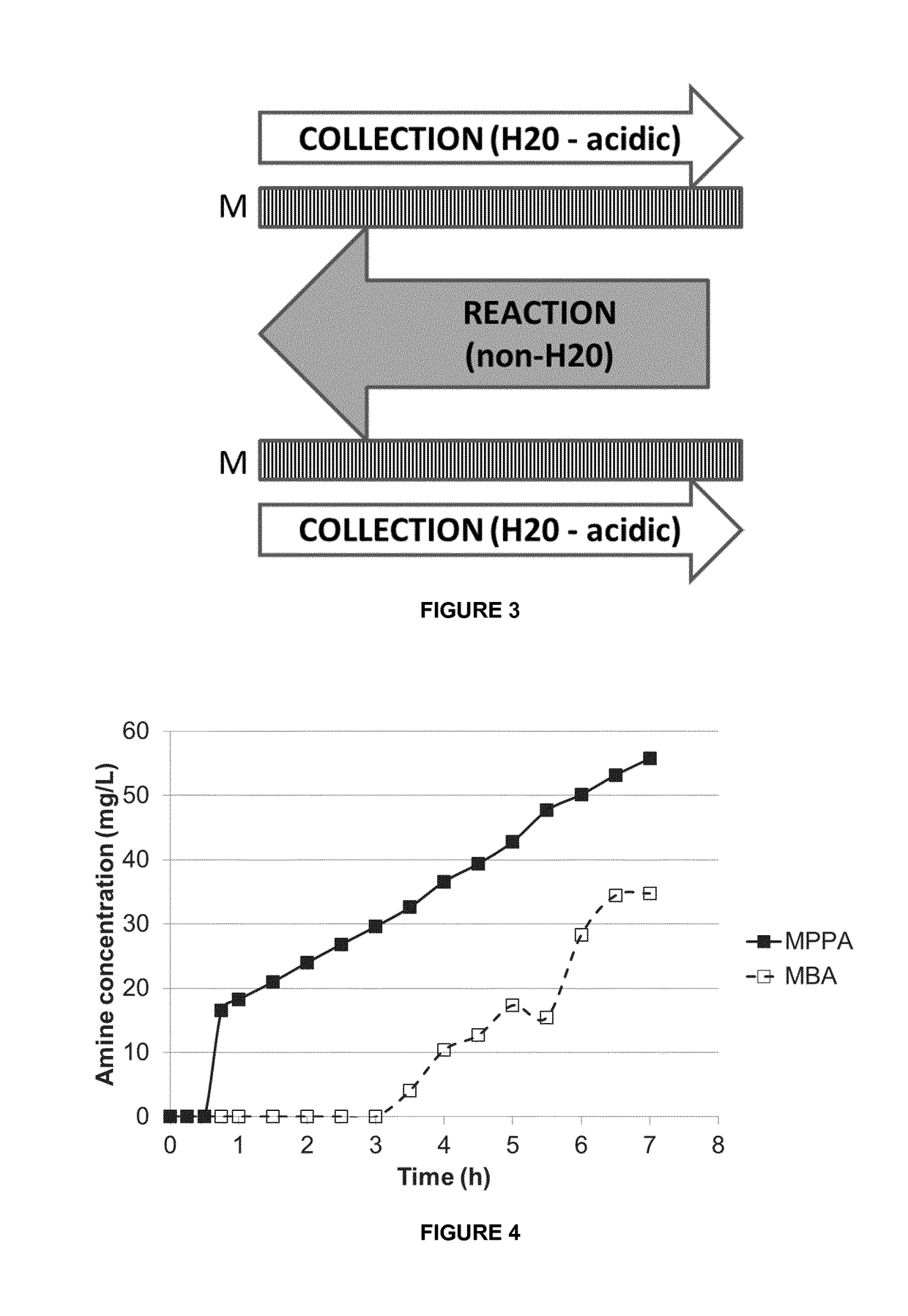

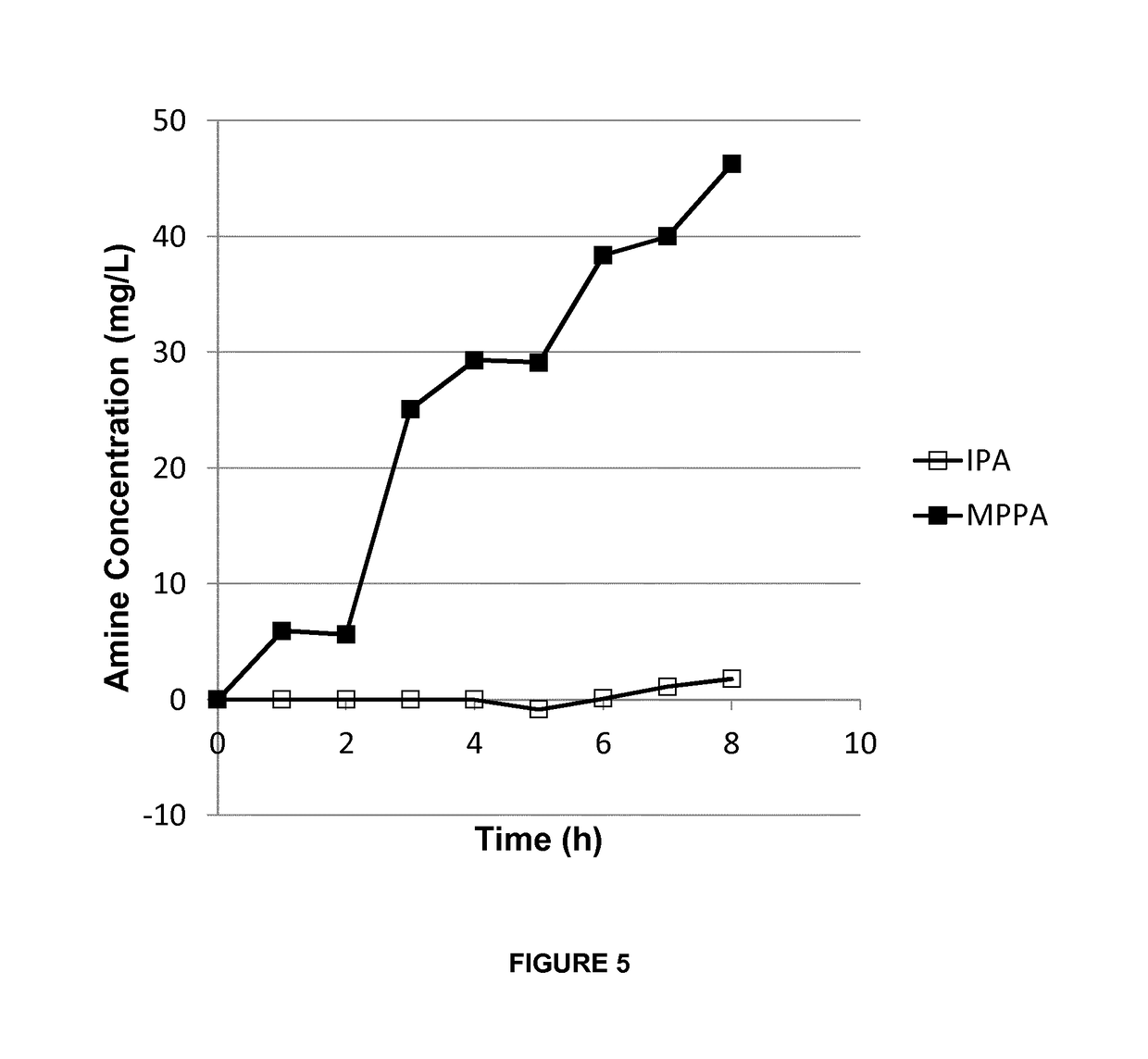

Process for the separation of organic compounds

ActiveUS20180369759A1Improve stabilityEfficient and stable processingAmino compound purification/separationMembranesOrganic acidSimple Organic Compounds

A membrane based process separates amines or organic acids from a solution containing at least one amine or at least one organic acid according to their hydrophobic properties. The more hydrophobic amine or organic acid passes the hydrophobic membrane into an acidic aqueous solution, thus selectively removing the amine or organic acid from the first solution. The process is particularly suitable to obtain chiral amines in high yield. A transaminase-catalyzed transamination of an amino donor and amino acceptor is combined with a hydrophobic membrane separation of the produced chiral amine. The selective removal of the chiral amine from the reaction mixture promotes the further transformation of the amino acceptor into the product chiral amine.

Owner:VLAAMSE INSTELLING VOOR TECHNOLOGISCH ONDERZOEK NV VITO

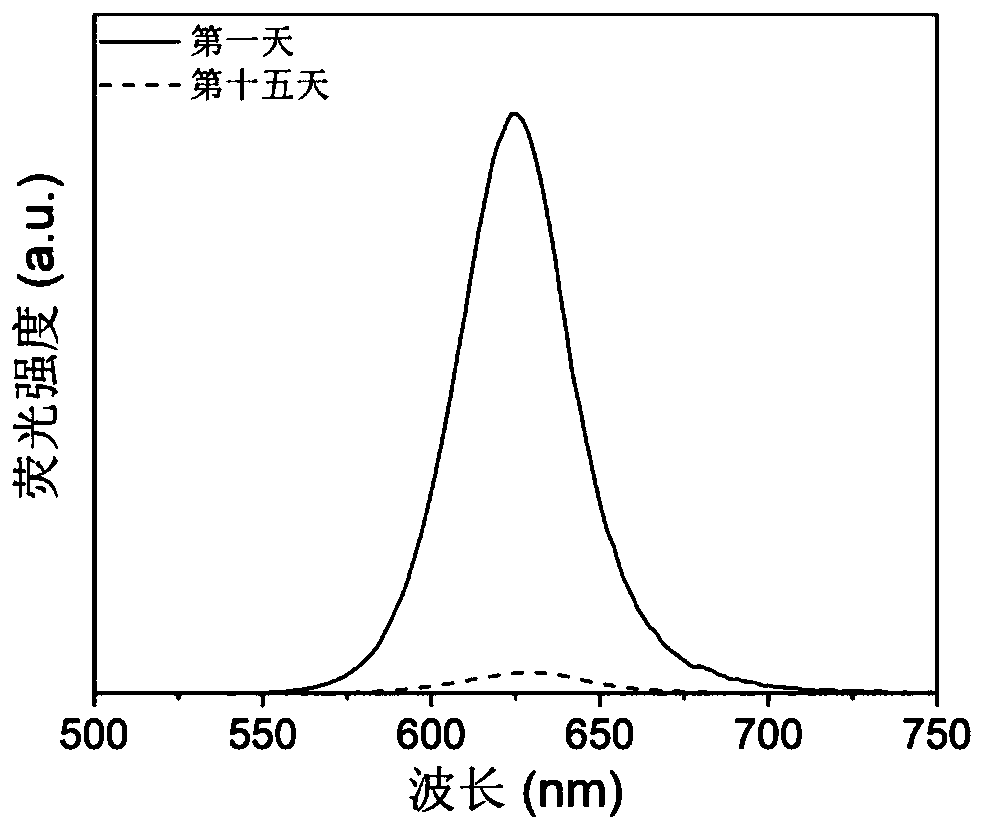

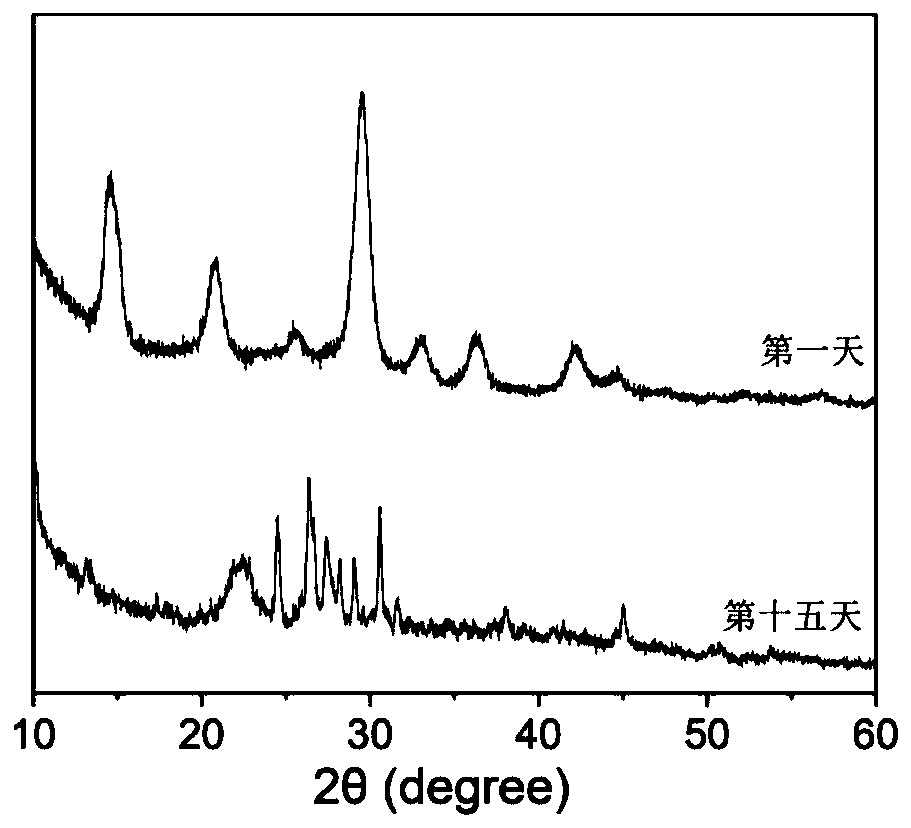

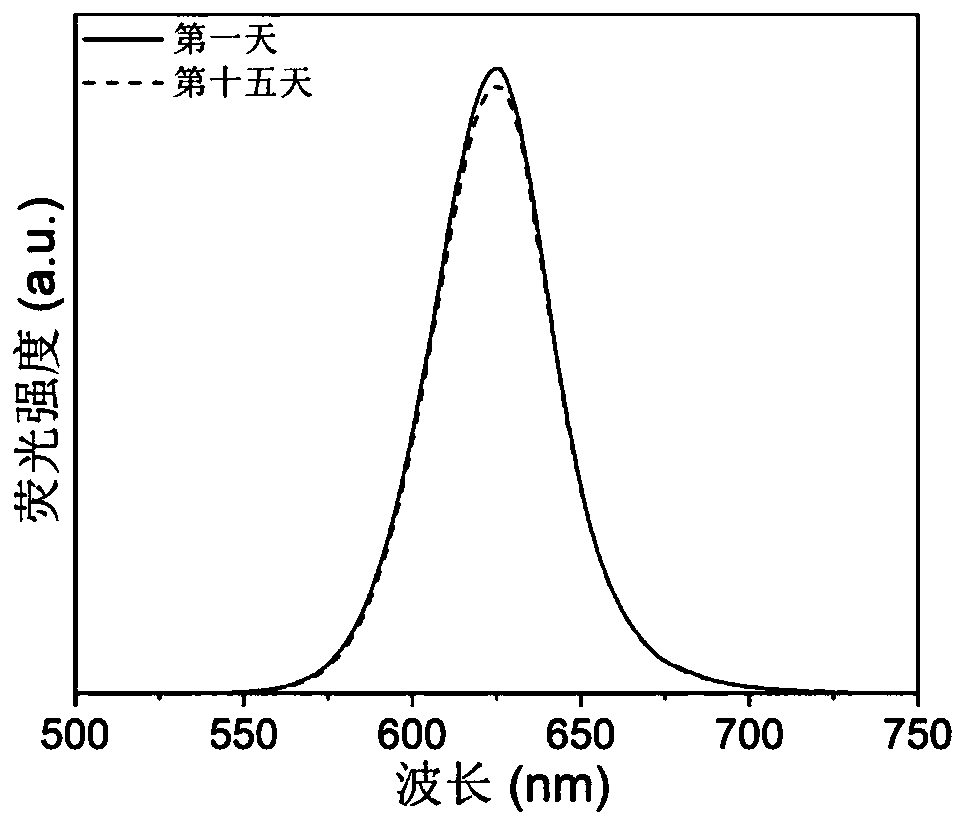

A kind of copper-doped red light perovskite quantum dot and preparation method thereof

ActiveCN109796976BImprove stabilityHigh fluorescence quantum efficiencyNanoopticsLuminescent compositionsFluorescenceSolar cell

The invention belongs to the technical field of preparation of optoelectronic materials and particularly relates to a copper-doped red-light perovskite quantum dot and a preparation method thereof. According to the method, a cesium salt or a formamidine salt, copper acetate, lead bromide and lead iodide are adopted as raw materials, organic acids and organic amine are adopted as ligands, and the stable and efficient copper-doped red-light perovskite quantum dot processable in solutions are rapidly synthesized through a thermal injection method. The stability of the red-light perovskite quantumdot is greatly improved through copper doping, and meanwhile, it is ensured that the high-fluorescence quantum efficiency of the quantum dot approaches 90%. According to the quantum dot, the absorption wavelength is increased along with the increase of the doping amount of copper, and a blue shift phenomenon of corresponding fluorescence emission wavelength of the quantum dot occurs. Obtained red-light perovskite quantum dot powder has high stability and can still be stored for more than 15 days under the condition that the air humidity is higher than 85%. The preparation method is simple andenvironmentally friendly, and the obtained red-light perovskite quantum dot can be applied to photoelectric devices such as light-emitting diodes, photoelectric detectors, laser devices and solar cells.

Owner:HUAZHONG UNIV OF SCI & TECH

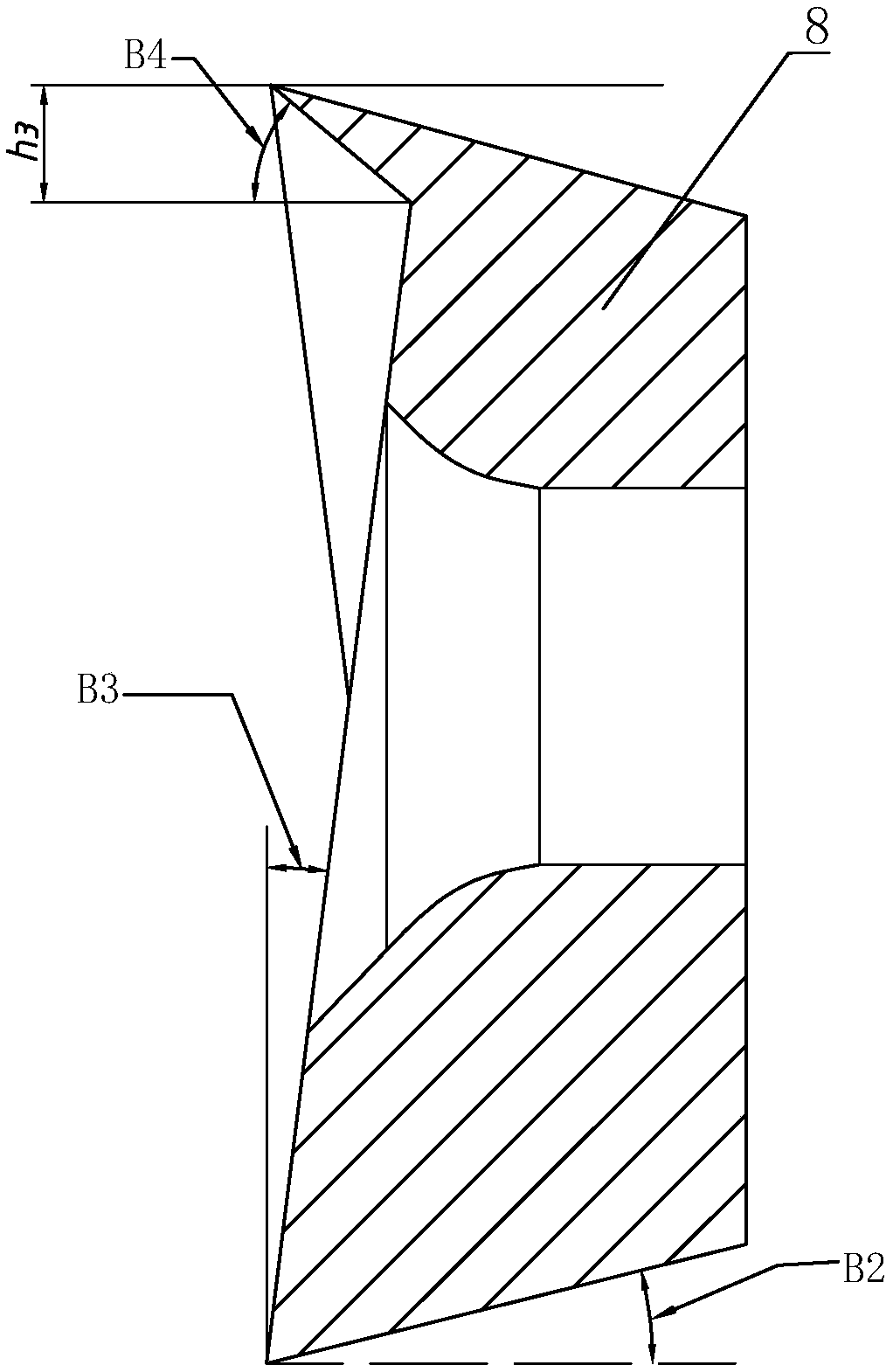

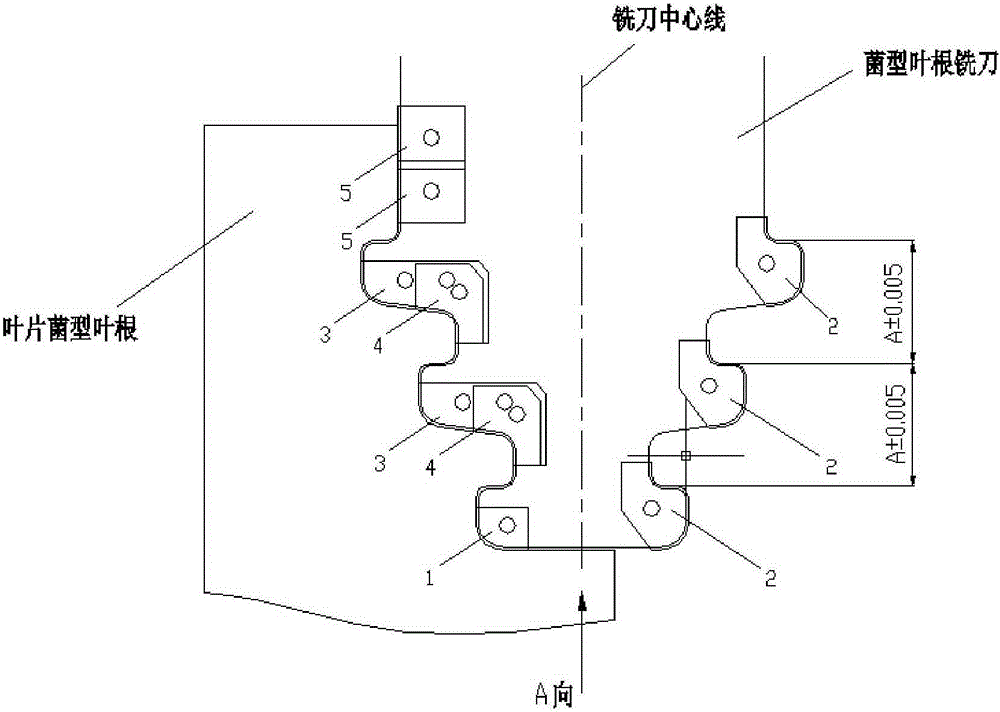

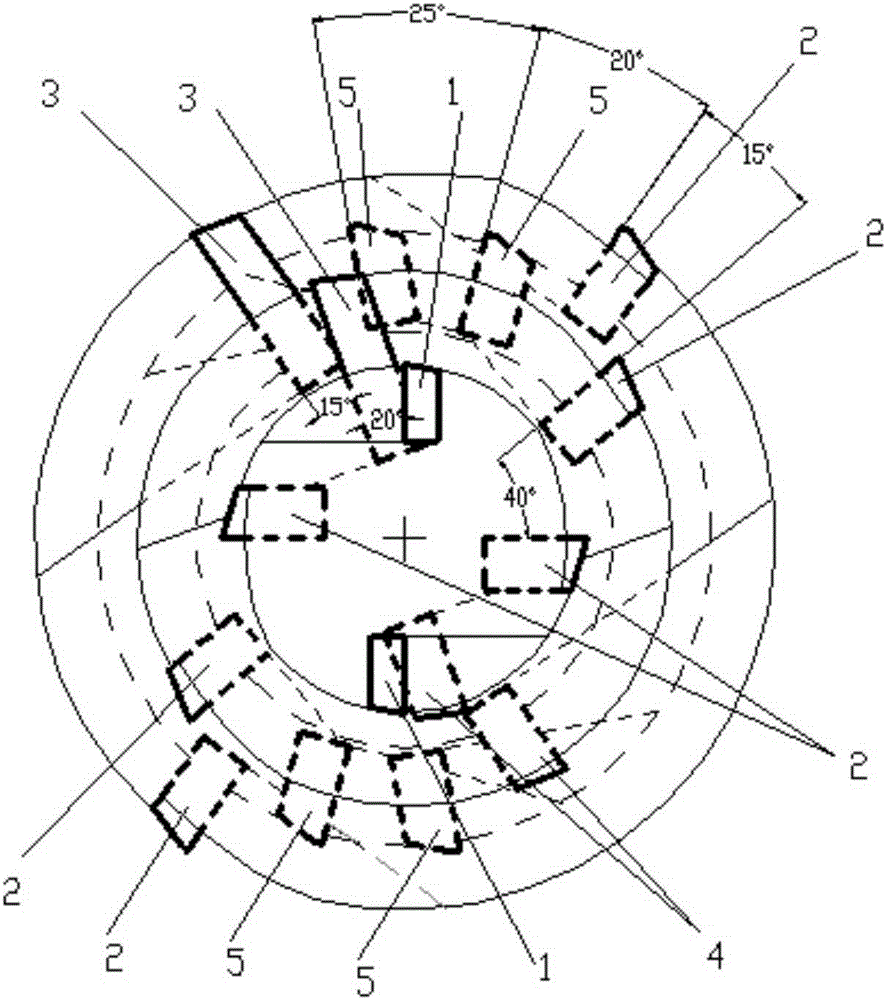

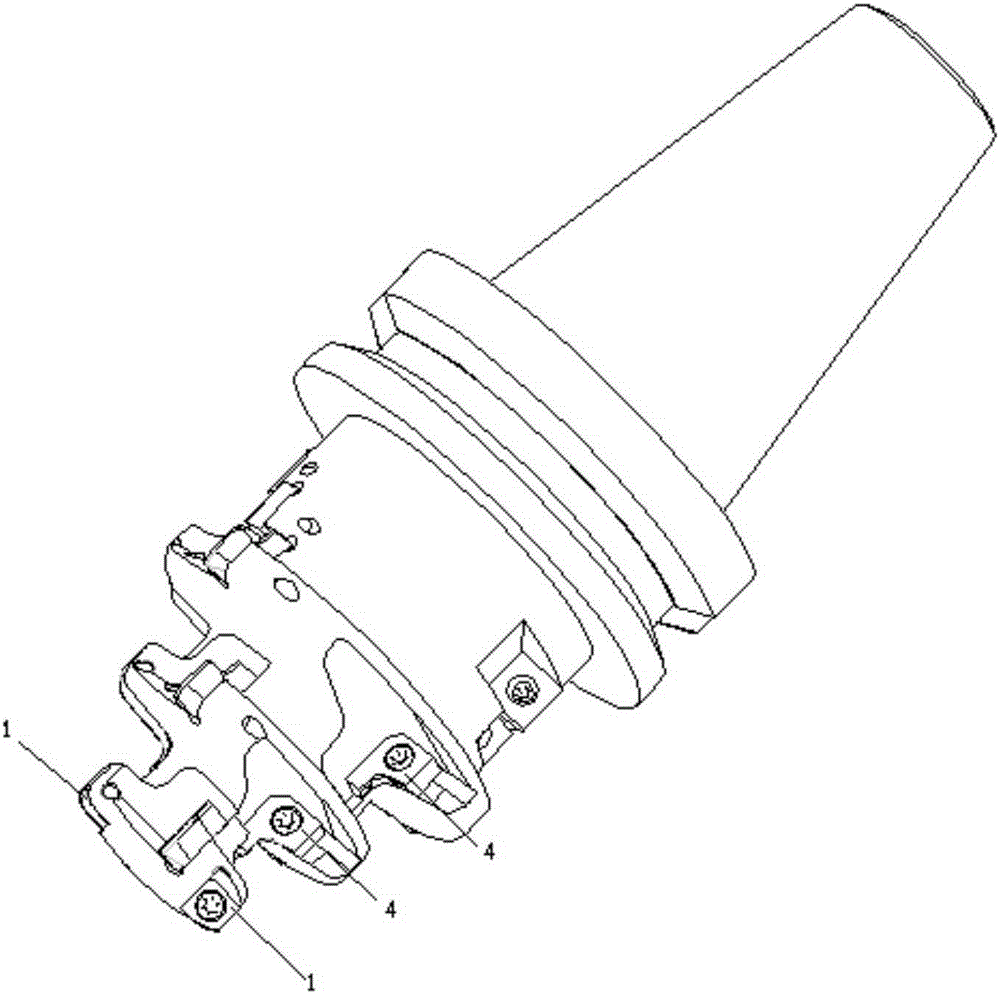

Mechanically clamped type fir tree blade-root milling cutter

ActiveCN105171083AReduce in quantityGuaranteed strength and rigidityMilling cuttersMilling cutterEngineering

The invention discloses a mechanically clamped fir tree blade-root milling cutter. The mechanically clamped fir tree blade-root milling cutter comprises a fir tree shaped cutter body and eight rows of cutter grooves which are arranged in the cutter body, wherein two first cutter blades which are symmetrically distributed with respect to the center are arranged in the first row of cutter grooves starting with the end surface, the front cutter surfaces of the first cutter blades pass through the center, and the front angles of the first cutter blades are 0 degrees; two second cutter blades which are symmetrically distributed with respect to the center are arranged in each of the second row of cutter grooves, the fourth row of cutter grooves and the sixth row of cutter grooves, the front cutter surfaces of the second cutter blades pass through the center, and the front angles of the second cutter blades are 0 degrees; third cutter blades and fourth cutter blades which are symmetrically distributed with respect to the center are arranged in the third row of cutter grooves and the fifth row of cutter grooves; and two fifth cutter blades which are symmetrically distributed with respect to the center are arranged in each of the seventh row of cutter grooves and the eighth row of cutter grooves, and the front cutter surfaces of the fifth cutter blades pass through the center, and the front angles of the fifth cutter blades are 0 degrees. The mechanically clamped fir tree blade-root milling cutter has the advantages that the quantity of the cutter blades is reduced on the premise of realizing a complete processing profile and considering specialized processing sites, and the rigidity and strength of the cutter body are ensured to the greatest extent, thereby providing a guarantee for the rigidity of the cutter in a processing process and reducing the vibration stripes of the cutter generated due to vibration.

Owner:DONGFANG TURBINE CO LTD

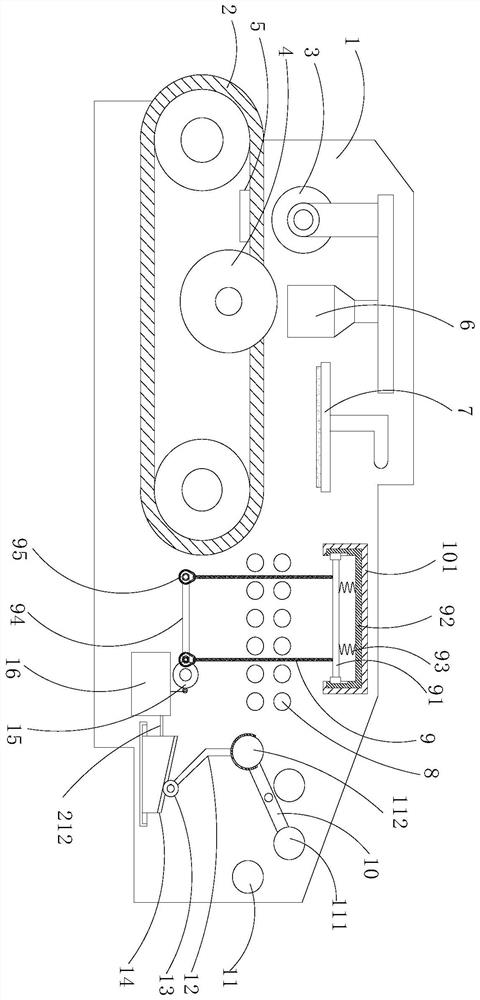

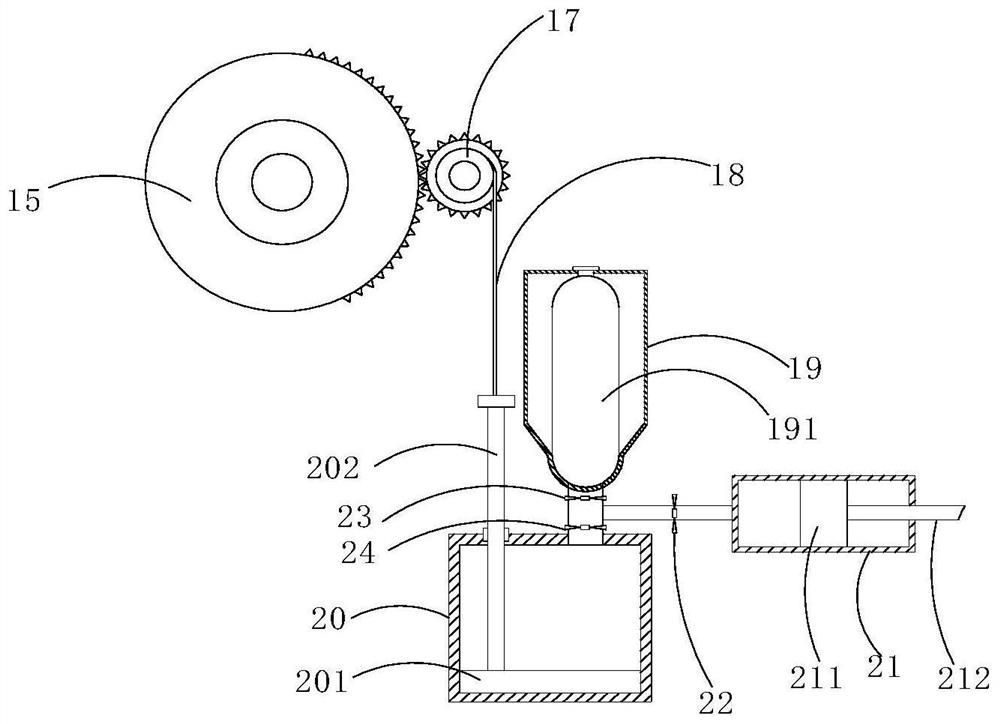

Linkage type board defect cutting device

ActiveCN112140256AQuality improvementImprove efficiencyOther plywood/veneer working apparatusProfiling/shaping machinesPower sharingKnife blades

The invention discloses a linkage type board defect cutting device which comprises a rack provided with a plurality of parallel conveying belts, cutting blades located between the conveying belts, a detection plate located above the conveying belts and used for detecting board defects of a raw material board, a feeding roller and a limiting roller set. The raw material board sequentially passes through the cutting blades, the detection plate, the feeding roller and the limiting roller set. A wood-plastic board defect removal comprehensive cutting system is used for defect cutting of the raw material board of the wood-plastic board, the quality and the defect removal efficiency of the wood-plastic board raw materials can be improved, a defect cutting piece and a defect removing piece of thewood-plastic board defect removal comprehensive cutting system can be linked and share power, the whole linkage type board defect cutting device is compact in structure, stable delay power can be formed in the power sharing process, the whole process can be accurately and effectively carried out, and efficient and stable machining can be conveniently achieved.

Owner:TAOJIANG HONGSEN WOOD IND

Lens polishing machine and lens processing equipment

InactiveCN106736995ASimple structureEasy to processGrinding carriagesPolishing machinesEngineeringContact position

The invention provides a lens polishing machine and lens processing equipment, and belongs to the technical field of lens processing. The lens polishing machine comprises an upward swing mechanism, a polishing solution inner spraying mechanism, a polishing mechanism and an installing mechanism used for installing work-pieces, wherein the upward swing mechanism and the installing mechanism are vertically arranged in a spaced mode, the upward swing mechanism is located above the installing mechanism, the polishing mechanism is installed on the upward swing mechanism, the upward swing mechanism drives the polishing mechanism to swing relative to the installing mechanism, and an inner channel for a polishing solution to flow is formed between the polishing solution inner spraying mechanism and the polishing mechanism. According to the lens polishing machine, in the process of polishing a lens, sufficient polishing solutions exist between the grinding surface of a polishing mold and the contact positions of the work-pieces, the polishing solutions can make full contact with the work-pieces in the grinding process, fast and efficient polishing of the concave optical lens is effectively realized, and processing is efficient and stable.

Owner:南阳中一光学装备有限公司

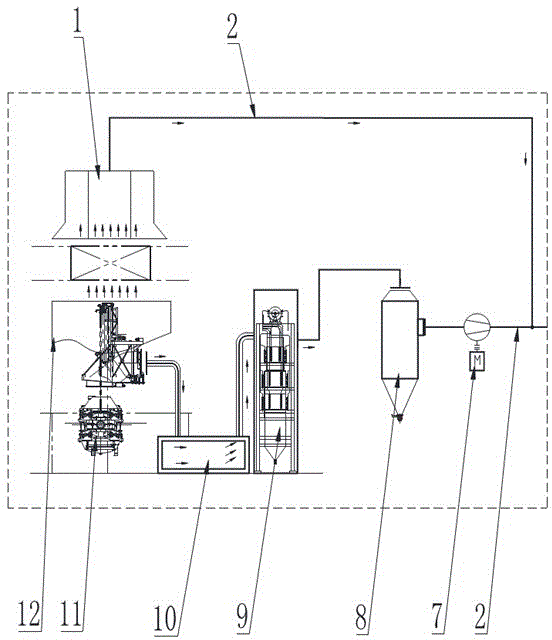

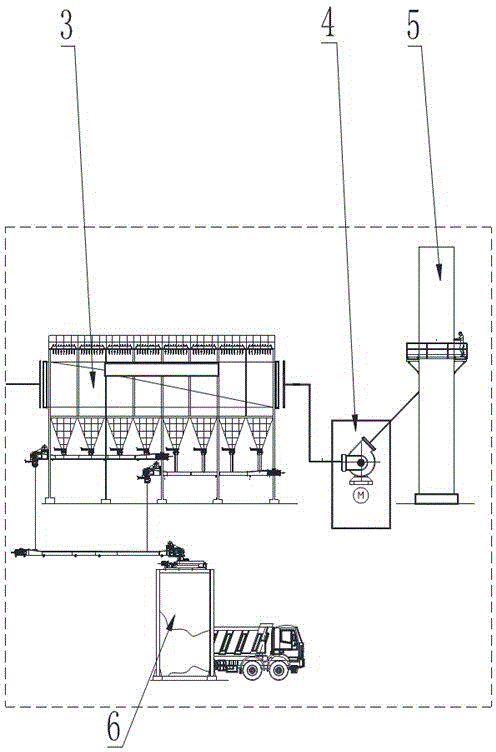

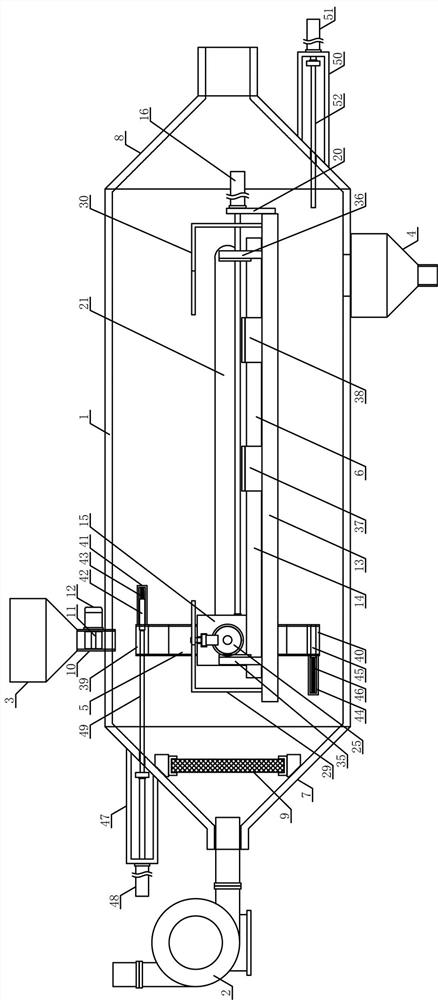

Flue gas purification and heat energy utilization system of AOD (Argon Oxygen Decarburization) refining furnace

InactiveCN104406416AEfficient use ofImprove utilization efficiencyWaste heat treatmentThermodynamicsFlue gas

The invention discloses a flue gas purification and heat energy utilization system of an AOD (Argon Oxygen Decarburization) refining furnace. The system comprises a refining furnace and a hearth flow guide hood which covers the outer side of the refining furnace, wherein the upper end of the hearth flow guide hood is communicated with a roof circulation hood; the roof circulation hood is communicated with a pulse bag type dust collector through a flue gas pipeline; a flue gas exhaust hole in the refining furnace is used for circulating the flue gas through a primary settlement chamber, a preheating recovery device, a secondary settlement chamber and the pulse bat type dust collector in sequence via the flue gas pipeline; an air outlet of the pulse bag type dust collector is communicated with an exhaust cylinder through an exhaust air pipeline. According to the system, the flue gas of the AOD refining furnace can be completely captured and purified, and the heat energy of the flue gas is efficiently utilized and converted to reduce the influence of the flue gas of the AOD refining furnace on the atmospheric environment, and the heat energy of the flue gas is fully utilized while relevant national environmental protection policies are met; the system has the characteristics of safety, effectiveness, economy and energy saving.

Owner:无锡东雄重型电炉有限公司

Cutting insert

ActiveUS9364898B2Prevent fracturing and chippingImprove clarityMilling cuttersCutting insertsEngineeringMechanical engineering

Owner:MITSUBISHI MATERIALS CORP

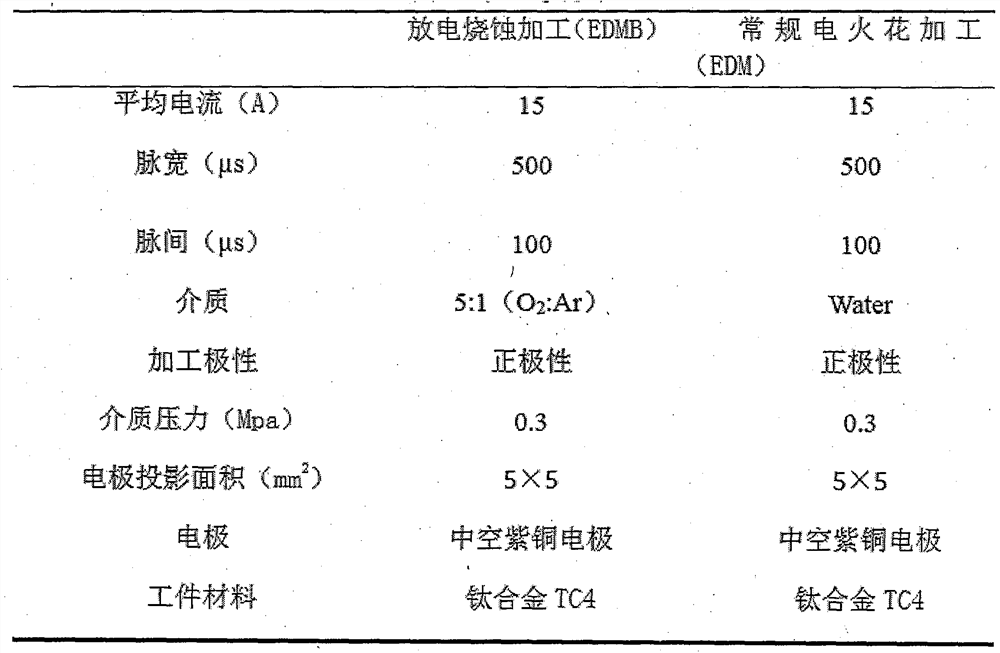

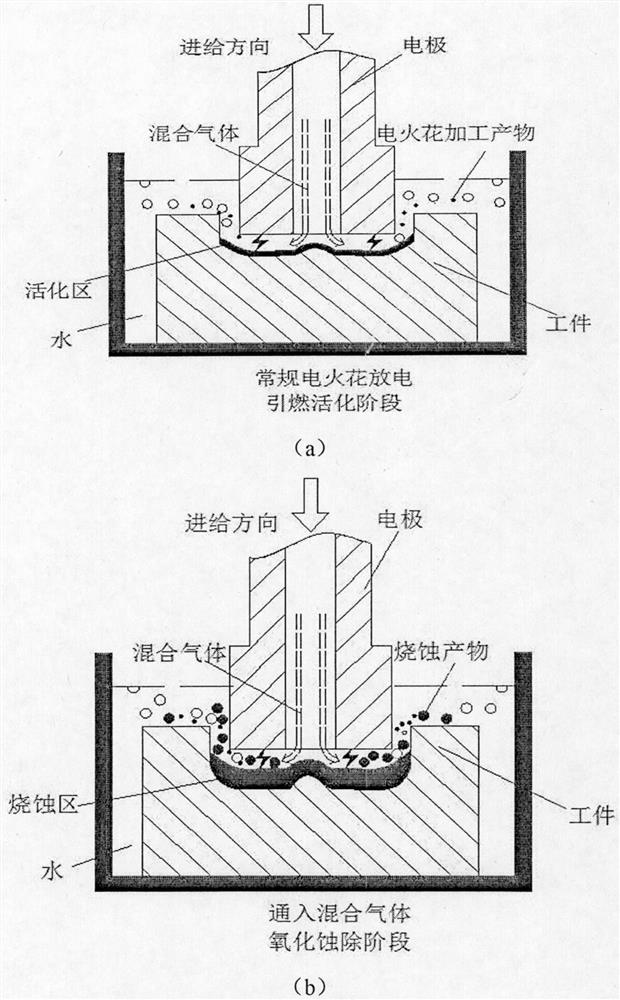

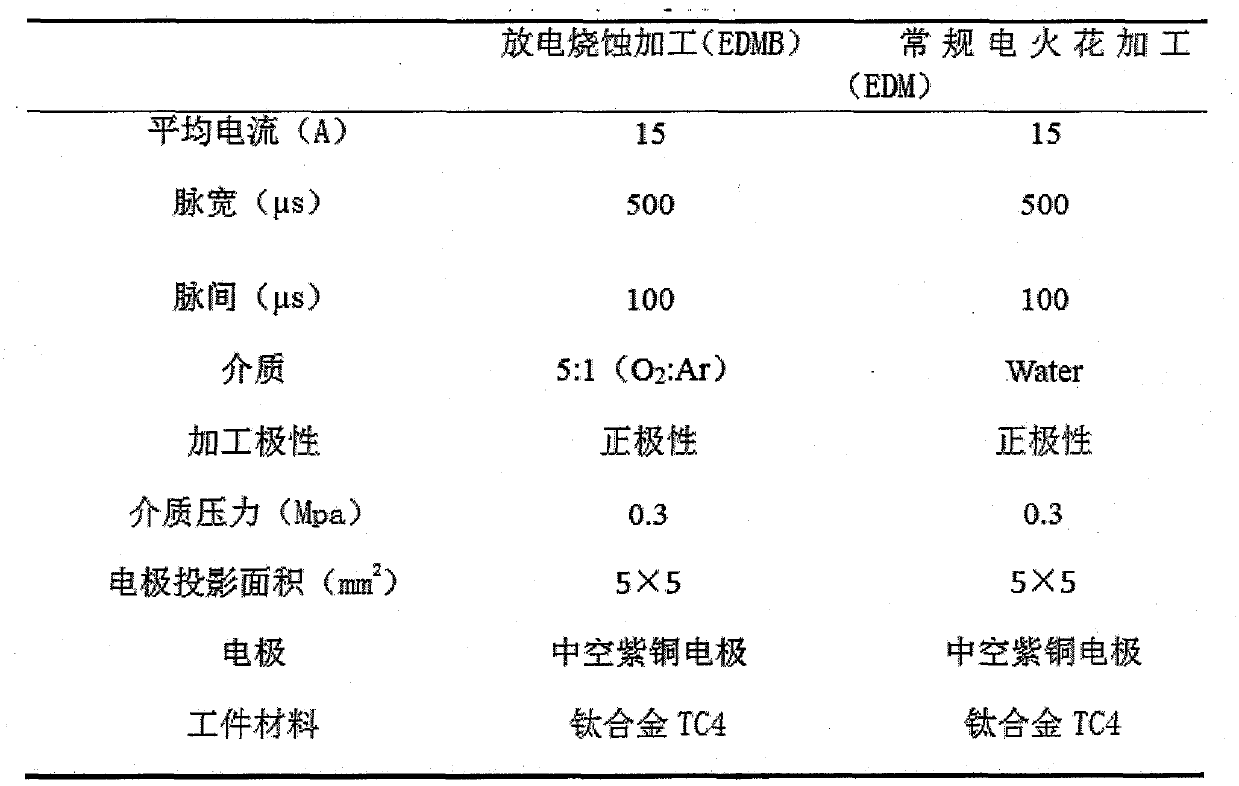

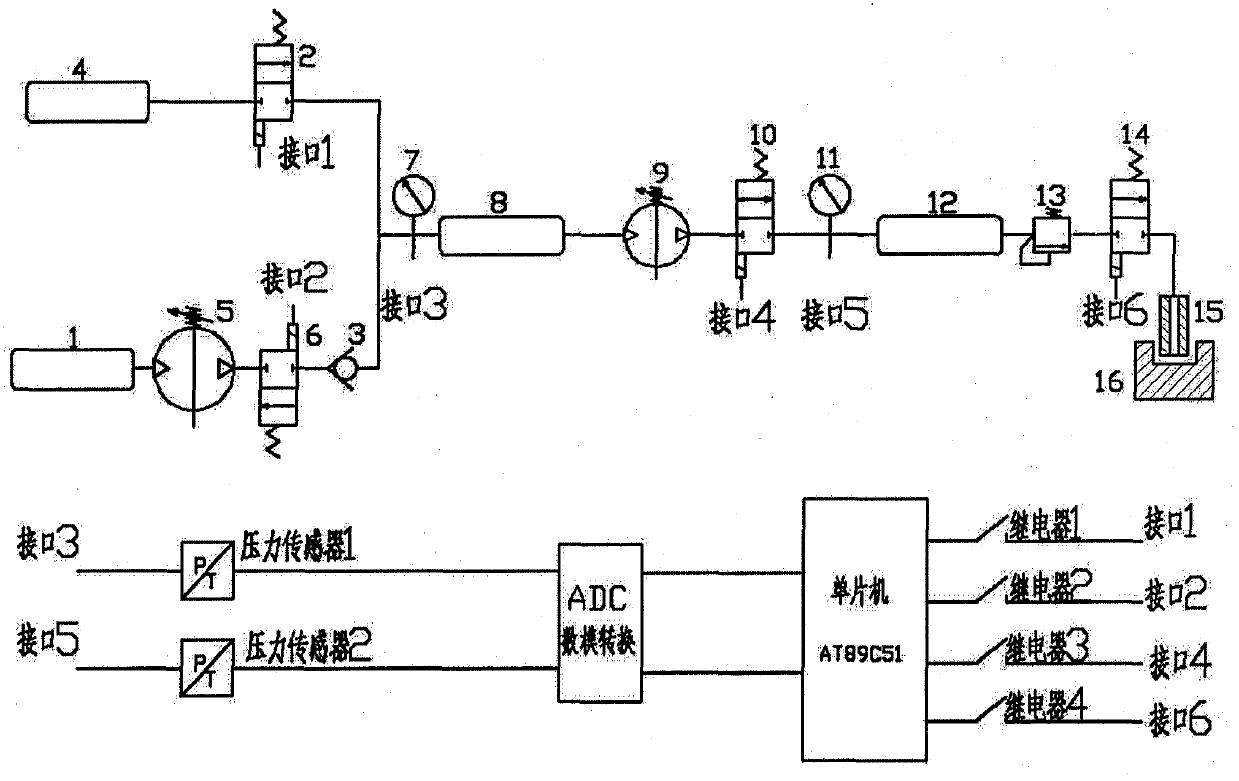

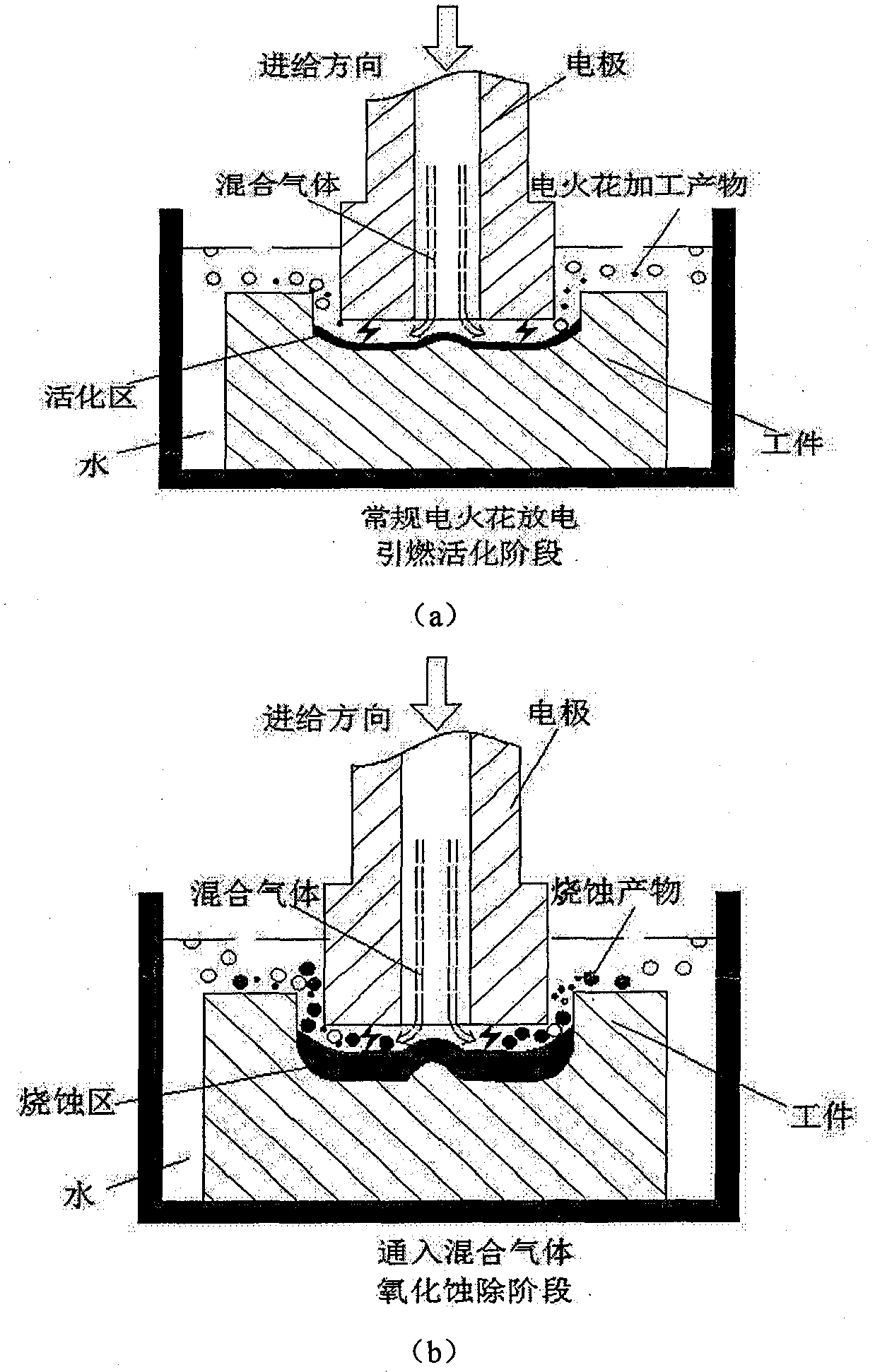

Controllable discharge ablation processing method for flammable and difficult-to-process materials with adjustable combustion-supporting gas concentration

ActiveCN110605442BPrevent uncontrollable explosionsEfficient processingElectric circuitsChemical reactionCombustion

The invention provides a controllable discharge ablation method for a combustible difficult-to-process material and with adjustable combustion-supporting gas concentration. The method is characterizedin that a mixed gas medium provided by a special combustion-supporting gas concentration adjustable gas supply device is introduced before processing; during processing, inter-pole voltage required to breakdown the mixed gas medium is supplied to two poles through a pulse power supply, and required energy is provided for melting and gasification of an inter-pole workpiece material; after a metalmaterial forms a high-temperature molten material, the high-temperature molten material and combustion-supporting gas in the mixed gas medium are subjected to a severe oxidation chemical reaction, a large amount of chemical energy is generated, extra ablation energy is introduced for efficient material ablation, and therefore the material removal rate of the combustible difficult-to-process material is improved under the condition that the discharge energy of the pulse power supply is certain. By means of the special gas supply device, the concentration of the combustion-supporting gas participating in the oxidation reaction is controlled, the explosion phenomenon caused by violent combustion in the processing process is avoided, the damage of a machined workpiece is avoided, and controllable and efficient processing of the combustible difficult-to-process material is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method of treating biomass, fuel for fuel cell, gasoline, diesel fuel, liquefied petroleum gas, and synthetic resin

In processing of biomass by catalytic cracking in a fluidized catalytic cracker having a reaction zone, a separation zone, a stripping zone, and a regeneration zone, the feedstock oil containing the biomass is processed in the reaction zone using a catalyst containing 10 to 50 mass % of ultrastable Y-type zeolite under the conditions: outlet temperature of the reaction zone 580 to 680° C., catalyst / oil ratio 10 to 40 wt / wt, reaction pressure 1 to 3 kg / cm2 G, and contact time of the feedstock oil with the catalyst in the reaction zone 0.1 to 1.0 sec, and the catalyst is then treated in the regeneration zone under the conditions: regeneration zone temperature 640 to 720° C., regeneration zone pressure 1 to 3 kg / cm2 G, and exhaust gas oxygen concentration at the regeneration zone outlet 0 to 3 mol %.

Owner:NIPPON OIL CORP

Controllable discharge ablation method for combustible difficult-to-process material and with adjustable combustion-supporting gas concentration

ActiveCN110605442APrevent uncontrollable explosionsEfficient processingElectric circuitsChemical reactionMaterial removal

The invention provides a controllable discharge ablation method for a combustible difficult-to-process material and with adjustable combustion-supporting gas concentration. The method is characterizedin that a mixed gas medium provided by a special combustion-supporting gas concentration adjustable gas supply device is introduced before processing; during processing, inter-pole voltage required to breakdown the mixed gas medium is supplied to two poles through a pulse power supply, and required energy is provided for melting and gasification of an inter-pole workpiece material; after a metalmaterial forms a high-temperature molten material, the high-temperature molten material and combustion-supporting gas in the mixed gas medium are subjected to a severe oxidation chemical reaction, a large amount of chemical energy is generated, extra ablation energy is introduced for efficient material ablation, and therefore the material removal rate of the combustible difficult-to-process material is improved under the condition that the discharge energy of the pulse power supply is certain. By means of the special gas supply device, the concentration of the combustion-supporting gas participating in the oxidation reaction is controlled, the explosion phenomenon caused by violent combustion in the processing process is avoided, the damage of a machined workpiece is avoided, and controllable and efficient processing of the combustible difficult-to-process material is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

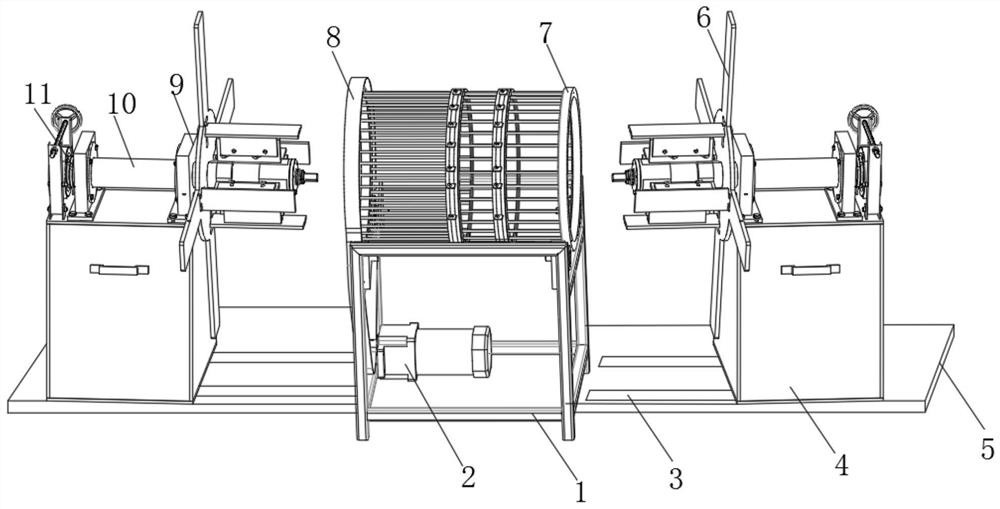

An Optimal Method for Efficient and Stable Broaching of Turbine Disc Tenon Groove

The invention discloses an optimization method for efficient and stable broaching machining of a turbine disc mortise. The optimization method comprises the following steps that a series of points areevenly arranged on the contact trace of a workpiece and a tool at intervals according to the broaching machining path, and modal transfer functions for the tool and the workpiece at all nodes are sequentially obtained through a modal test; transfer functions phi<1i> between the workpiece and the tool at the different nodes are built according to the modal transfer functions of the tool at the nodes and the modal transfer functions of the workpiece at the nodes, and transfer functions phi<1i> (s) in a Laplace mode are obtained from phi<1i> through Laplace transformation; stable areas in cutting machining of the workpiece at the different nodes are obtained according to phi<1i> (s) and the method of solving the stable areas through frequency domains; and the workpiece is efficiently and stably machined according to cutting parameters of the stable areas. According to the method, stable and efficient machining can be conducted by selecting the corresponding cutting parameters according to the different nodes, the condition that tool tipping is generated due to tool trembling is avoided, the life of the tool is prolonged, and the workpiece surface quality is improved.

Owner:CENT SOUTH UNIV

Using method of spherical workpiece cutting machining device

InactiveCN111531227AAccurate and efficient reciprocating translational movementHigh degree of processing automationAutomatic control devicesFeeding apparatusMechanical equipmentMaterial transfer

The invention discloses a using method of a spherical workpiece cutting machining device, and belongs to the field of workpiece machining mechanical equipment. The spherical workpiece cutting machining device comprises a machining material conveying support, a translation cutting mechanism, a material clamping lifting mechanism, a turnover material transferring mechanism and a workpiece conveyingmechanism; the translation cutting mechanism is horizontally and fixedly arranged on one side above the machining material conveying support, the material clamping lifting mechanism is vertically arranged on the machining material conveying support on one side of the translation cutting mechanism, the turnover material transferring mechanism is vertically arranged on the machining material conveying support on one side below the material clamping lifting mechanism, and the workpiece conveying mechanism is horizontally and adjacently arranged on the machining material conveying support on one side of the turnover material transferring mechanism. The spherical workpiece cutting machining device is reasonable in structural design, capable of efficiently and stably cutting spherical workpiecesone by one, capable of achieving automatic transferring, feeding and returning of the spherical workpieces, high in machining automation degree and capable of meeting the requirements for workpiece machining and use.

Owner:黄明珠

Welding clamp for scaffold inclined levers

InactiveCN105171317ASimple structureInnovative designWelding/cutting auxillary devicesAuxillary welding devicesMachining

The invention discloses a welding clamp for scaffold inclined levers. The welding clamp comprises a frame body; the structures of the left end and the right end of the frame body are the same; a plurality of sets of material returning air valves are arranged on the end face of the left-end structure in parallel and are provided with a plurality of clamping air valves corresponding to the material returning air valves; the lower ends of the material returning air valves are driven by a material returning air cylinder; one ends of the clamping air valves are clamped by a clamping air cylinder; the material returning air valves and the clamping air valves clamp workpieces through engagement of the air cylinders. The welding clamp for the scaffold inclined levers is simple in structure, effectively masters the key machining sizes, efficiently and stably completes machining and saves time and labor.

Owner:ANHUI ZULIN NEW MATERIALS

Linkage plank defect removal device

ActiveCN112140256BQuality improvementImprove efficiencyOther plywood/veneer working apparatusProfiling/shaping machinesPower sharingConveyor belt

The invention discloses a linkage type plank defect cutting device, which comprises a frame, which is provided with a plurality of parallel conveyor belts, a cutting blade located between the conveyor belts, a detection plate for detecting defects of the raw wood planks above the conveyor belts, a feeding roller and The limit roller group, the raw wood board passes through the cutting blade, the detection plate, the feeding roller and the limit roller group in sequence. The wood glue board defect removal comprehensive cutting system in the present invention is used for the defect removal of the wood glue board raw material board, which can improve the wood glue. The quality of the board raw material and the efficiency of defect removal, and the defect cutting parts and defect removal parts of the comprehensive cutting system for wood glue board defect removal can be linked and share power. Power, the whole process can be carried out accurately and effectively, which is convenient for efficient and stable processing.

Owner:TAOJIANG HONGSEN WOOD IND

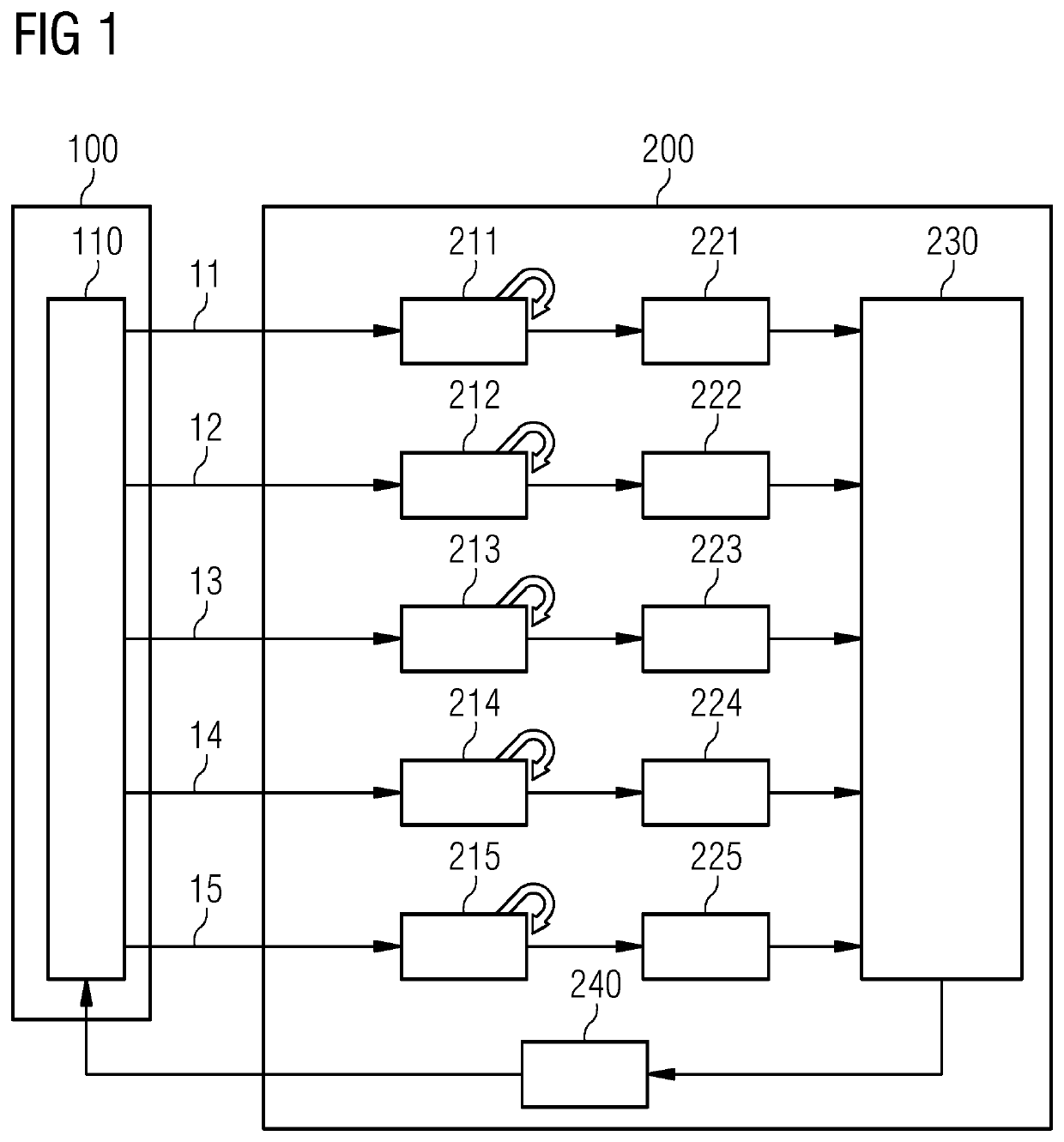

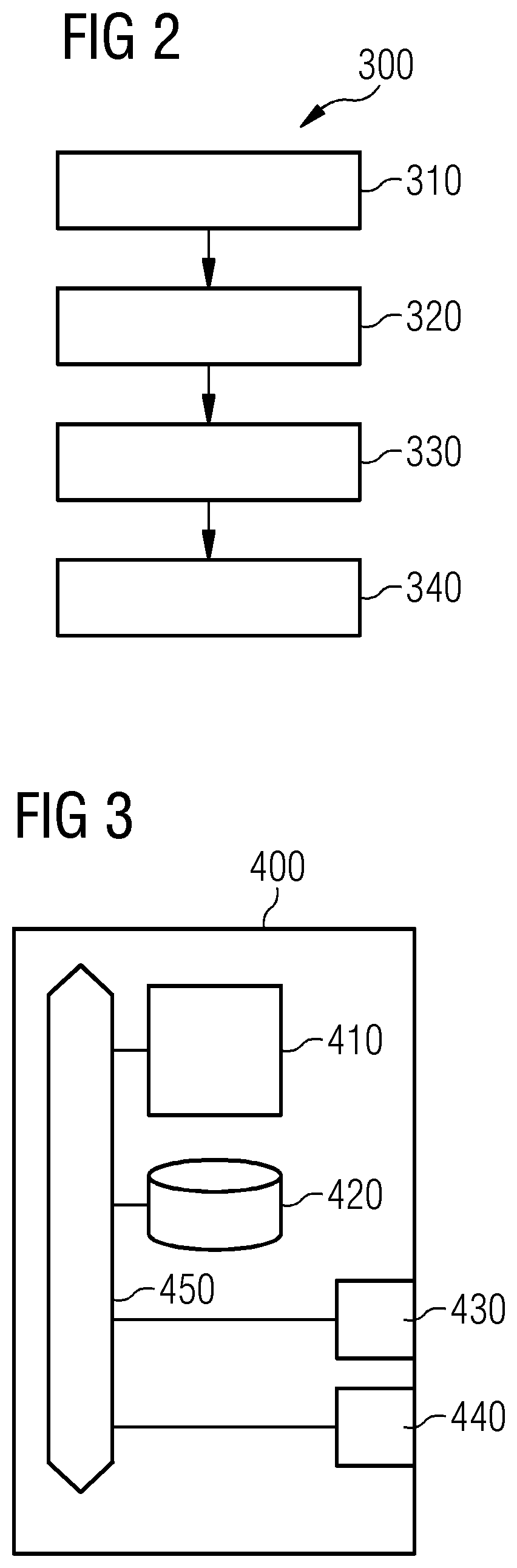

Machine Control Based on Automated Learning of Subordinate Control Skills

PendingUS20220171348A1Complete efficientlyEfficiently determinedGas turbine plantsEngine controlMachine controlControl objective

Method and device for controlling a machine in accordance with to multiple control objectives in which machine control is based on automated learning of subordinate control skills, wherein the device provides multiple subordinate control skills which are each assigned to a different one of the multiple control objectives, the device provides multiple learning processes that are reinforcement learning processes that are each assigned to a different one of the multiple control objectives and are configured to optimize the corresponding subordinate control skill based on input data received from the machine, and where the device is configured to determine a superordinate control skill based on the subordinate control skills and to control the machine based on the superordinate control skill.

Owner:SIEMENS AG

A kind of preparation method of high-strength pump valve

ActiveCN109894945BEasy to fixFixed card connection is stableEdge grinding machinesPositive displacement pump componentsMechanical engineeringMaterials science

The invention discloses a high-strength pump valve. The high-strength pump valve is prepared from 3.5-5 parts of C, 1.5-2 parts of Mn, 0.5-1 part of Si, 12-14 parts of Cr, 3-5 parts of CU, 0.3-1 partof Sn and 30-40 parts of Fe. A preparation method of the high-strength pump valve includes the following steps that 1, the raw materials are put in a heating container to be heated to 1,500-1,900 DEGC, all the raw materials are melted into solutions, the solutions are mixed to be uniform, pouring liquid is formed, and finally the pouring liquid is poured into a forming die; 2, the forming die issealed and does not make contact with external objects, the forming die is taken out after being naturally cooled, and the pump valve has a preliminary appearance; and 3, the prepared pump valve appearance is put in a grinding forming device to be ground, leftover materials outside the pump valve appearance are removed, and the joint of the die is smooth. The grinding forming device is convenientto use, easy to operate, suitable for pump valves with different sizes and shapes, convenient to adjust and high in grinding efficiency during use.

Owner:长沙集智创新工业设计有限公司

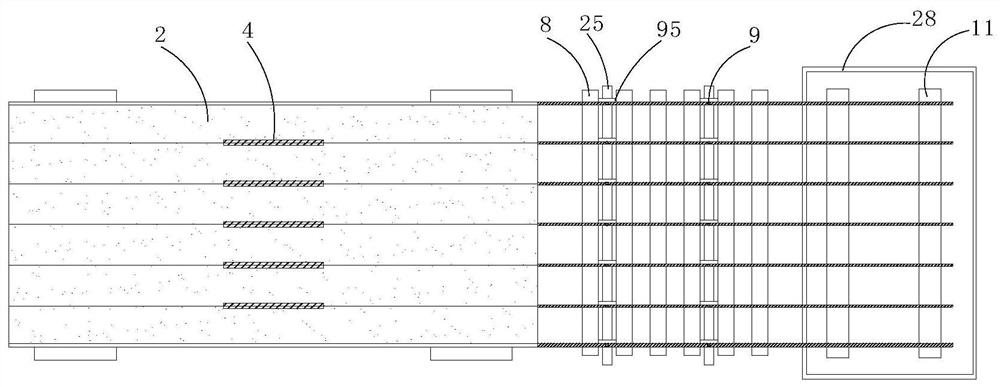

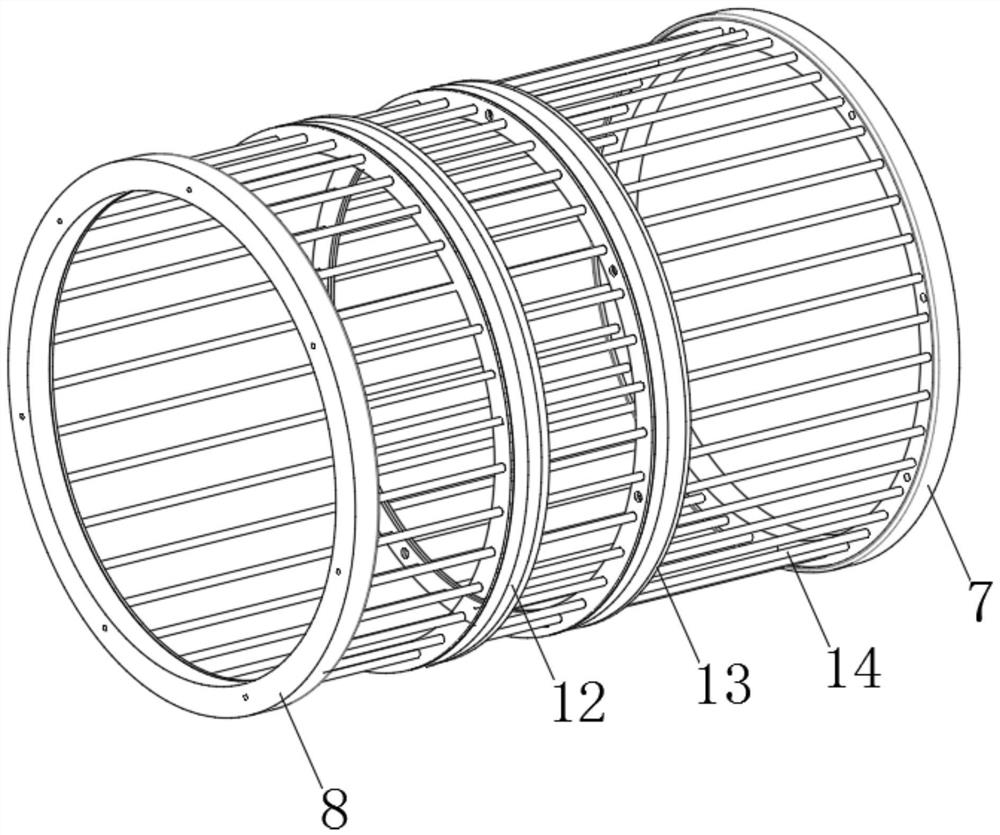

Reciprocating type seed drying device

InactiveCN113267017AControl the amount of feedGuaranteed feed amountDrying gas arrangementsDrying chambers/containersAgricultural scienceAgricultural engineering

The invention discloses a reciprocating type seed drying device, and belongs to the technical field of seed processing mechanical equipment. The reciprocating type seed drying device is characterized in that the two ends of a seed drying pipeline are fixedly communicated with a material drying air inlet hopper and a material drying air exhaust hopper respectively; a material drying air blower is fixedly communicated with one side of the material drying air inlet hopper; an electric heating material drying grid plate is vertically and fixedly arranged on the inner side of the material drying air inlet hopper; a seed feeding hopper is vertically and fixedly communicated with the upper side of the seed drying pipeline along the material drying air inlet hopper end; a seed discharging hopper is vertically and fixedly communicated with the lower side of the seed drying pipeline along the material drying air outlet hopper end; a material drying reciprocating mechanism is horizontally and fixedly arranged on one side of the seed drying pipeline; a material drying reciprocating guide plate is slidably arranged on a material drying translation rail in the horizontal direction; and the middle of one side of a material drying storage container is fixedly connected to the end portion of a seed material drying rotating shaft. The reciprocating type seed drying device is reasonable in structural design, seeds can be efficiently, stably, continuously and quantitatively dried and processed, the seed processing automation degree is improved, and the processing and using requirements are met.

Owner:桐乡绿禾农业科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com