Linkage type board defect cutting device

A linkage type, plank technology, applied in the direction of sawing equipment, wood processing equipment, other plywood/plywood appliances, etc., can solve the problems of affecting the quality of thin raw wood boards, uneven quality of raw wood boards, and low processing efficiency, and achieve improvement Defect removal efficiency, device compactness, and quality improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

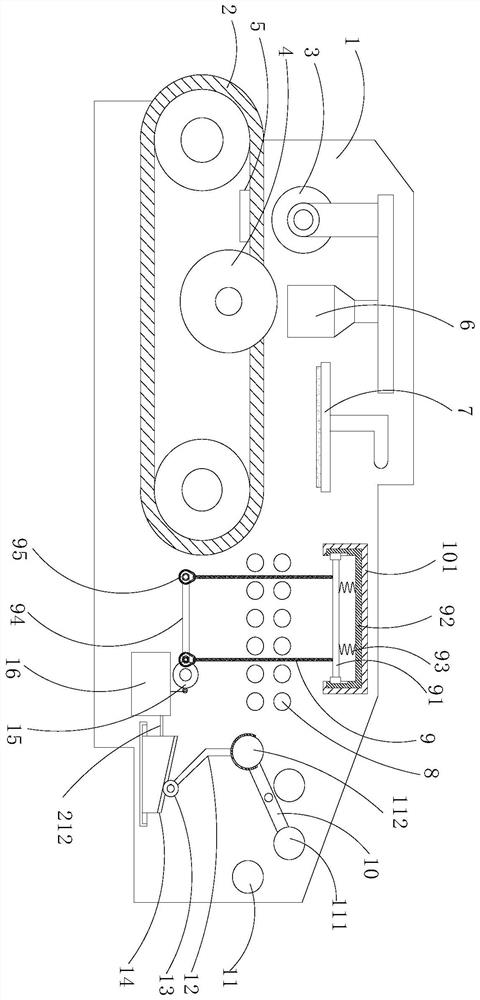

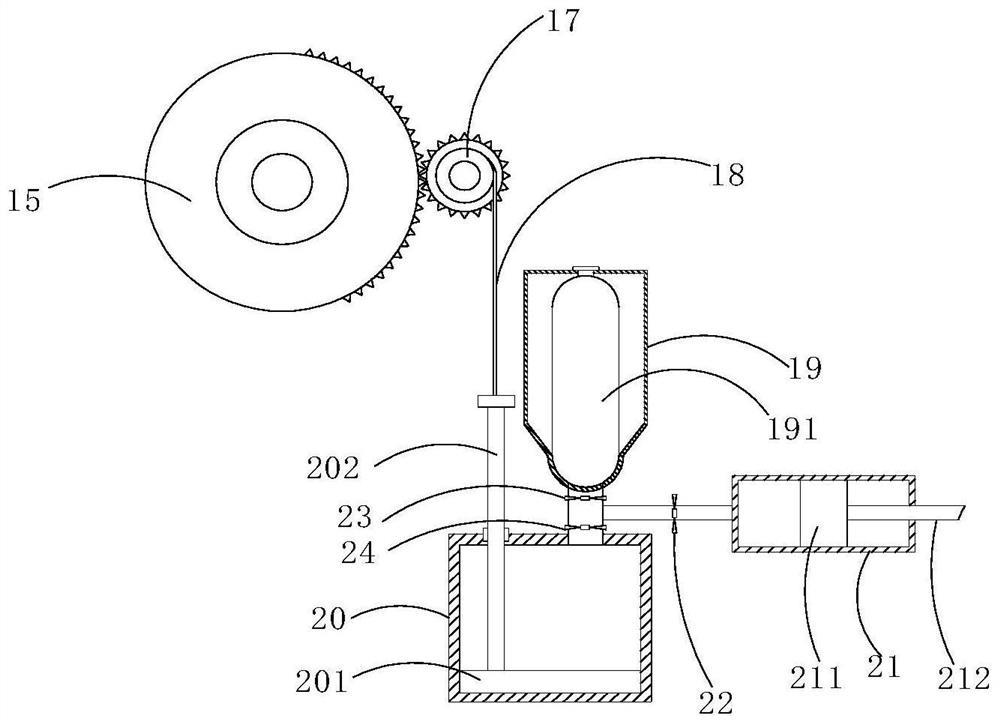

[0031] refer to Figure 1-2 The interlocking plank defect removal device comprises a frame 1, the frame 1 is provided with a plurality of parallel conveyor belts 2, a cutting blade 4 positioned between the conveyor belts 2, a detection plate 7 for detecting plank defects above the conveyor belt 2, a feed roller 8 and Limit roller group 11. The conveyor belt 2 has original power. After the raw wood board enters the conveyor belt 2, it passes through the cutting blade 4 and the inspection board 7 in sequence. The cutting blade 4 is used to cut the raw board into strips of equal width, and the inspection board 7 is used to detect the defect of the raw boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com