End mill for cutting of high-hardness materials

一种立铣刀、刀具轴的技术,应用在高硬度材料切削用立铣刀领域,能够解决无法实现寿命与稳定性、缺损、磨损快等问题,达到刚性提高、提高切削效率、排出性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0124] In order to confirm the superiority of the end mill of the present invention, a cutting test of pocket-shaped cutting was performed. In the cutting test, examples of the present invention and conventional examples were used. The specifications of each tool are as follows.

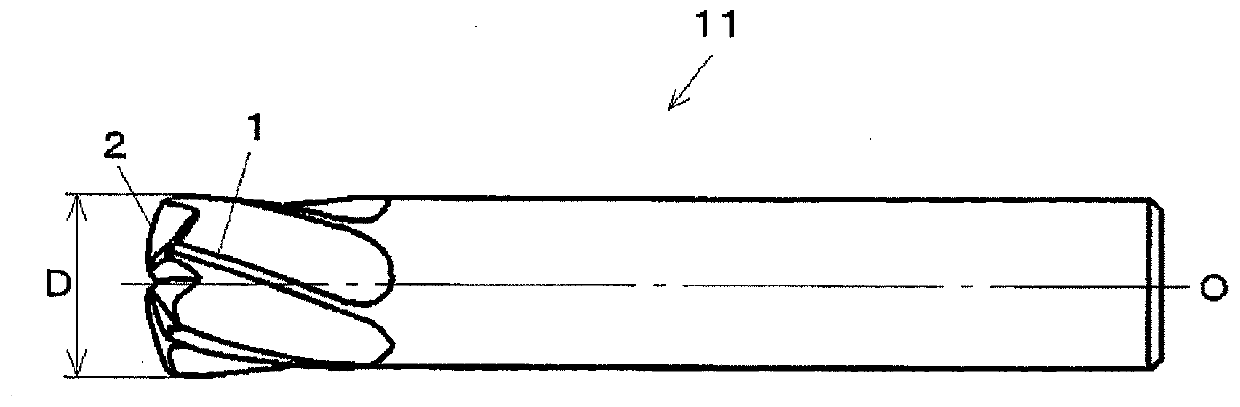

[0125] In Example 1, Example 1 of the present invention, and Conventional Examples 2 and 3 were used. As the various elements of the common end mill shape, an end mill with a tool diameter D of 10 mm, a core thickness of 7.5 mm, a twist angle of the peripheral cutting edge of 20 degrees, the number of cutting edges of 6 pieces, and a coating of The base material of TiSiN type and end mill is cemented carbide.

[0126] In Example 1 of the present invention, Examples 2 and 3 of the prior art, the radius of curvature of the edge of the clearance surface of the circular-arc cutting edge on the rear side of rotation was 13 mm, and the radius of curvature of the circular-arc cutting edge was varied.

[...

Embodiment 2)

[0137] In Example 2, in order to confirm the relationship between the radius of curvature of the circular-arc cutting edge and the radius of curvature of the edge of the circular-arc cutting edge on the rear side of the clearance surface after rotation in the example of the present invention, the pocket shape was carried out in the same manner as in Example 1. Cutting test for machining.

[0138] Embodiment 2 uses Examples 4-10 of the present invention. As in Example 1 of the present invention used in Example 1, an end mill having a tool diameter D of 10 mm, a core thickness of 7.5 mm, and a twist of the peripheral cutting edge was prepared as various elements of the common end mill shape. The angle is 20 degrees, the number of flutes is 6 pieces, the radius of curvature of the edge on the rear side of the rotation of the clearance surface of the arc cutting edge is 2.6 times the tool radius, that is, 13mm, the coating is TiSiN, and the base material of the end mill is super ...

Embodiment 3)

[0151] In Example 3, in order to confirm the relationship between the radius of curvature of the circular-arc blade and the tool radius in the example of the present invention, a cutting test of pocket-shaped cutting was performed in the same manner as in Example 1.

[0152] In Example 3, Examples 11 to 17 of the present invention were used. As in Example 1 of the present invention used in Example 1, an end mill having a tool diameter D of 10 mm, a core thickness of 7.5 mm, and a twist of the peripheral cutting edge was prepared as various elements of the common end mill shape. The angle is 20 degrees, the number of flutes is 6 pieces, the radius of curvature of the edge on the rear side of the rotation of the clearance surface of the arc cutting edge is 2.6 times the tool radius, that is, 13mm, the coating is TiSiN, and the base material of the end mill is super Hard alloy, and the bottom edge is connected with the peripheral edge.

[0153] As Example 11 of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com