Electric pulse casting and rolling method of semi-solid alloy

A semi-solid, electric pulse technology, applied in the field of casting and rolling forming of metal alloy materials, can solve the problems of low processing yield, high deformation resistance and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

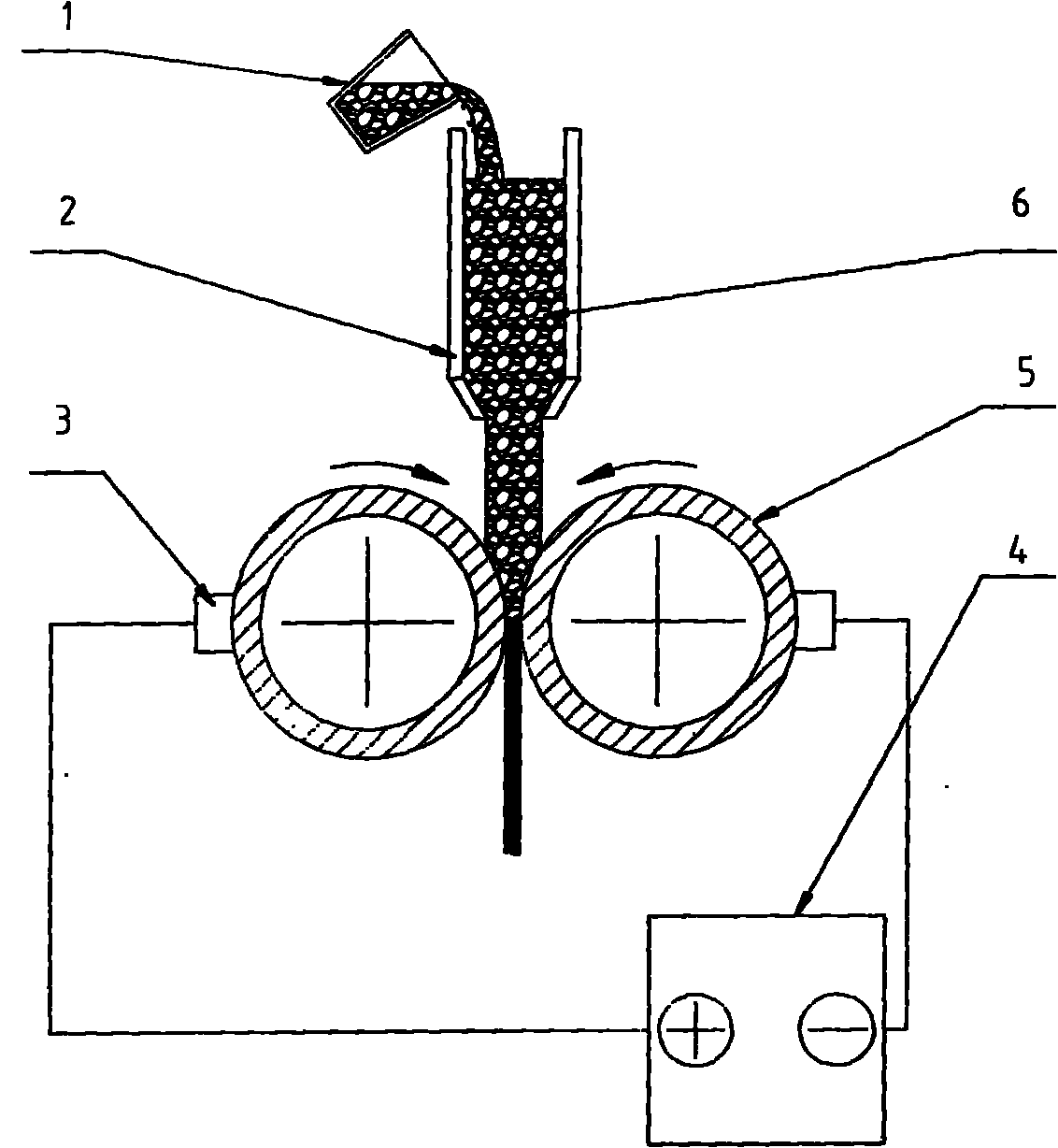

[0010] Embodiment 1: AZ31B magnesium alloy

[0011] use as figure 1 In the vertical casting and rolling process shown, the diameter of the roll is 210mm, and the rolling speed is controlled by a frequency converter, and the casting and rolling speed is 0.8-1.0m min -1 , adjust the roll gap to 2mm, keep the temperature of the semi-solid slurry in the insulating crucible between 560 and 570°C, carry out casting and rolling, and cool it with water, the cooling rate is 550°C / S-600°C / S, and the frequency is 50Hz, the current When the duty ratio is 200A and the duty cycle is 10%, the magnesium alloy thin strip with neat edges and good surface quality can be obtained. The grain structure of the cast-rolled strip is equiaxed grain with fine texture, the grain size is not very uniform, and the average grain size It is 15μm-25μm, which greatly eliminates segregation, improves the plastic deformation ability of metal materials, and improves the comprehensive mechanical properties of mat...

Embodiment 2

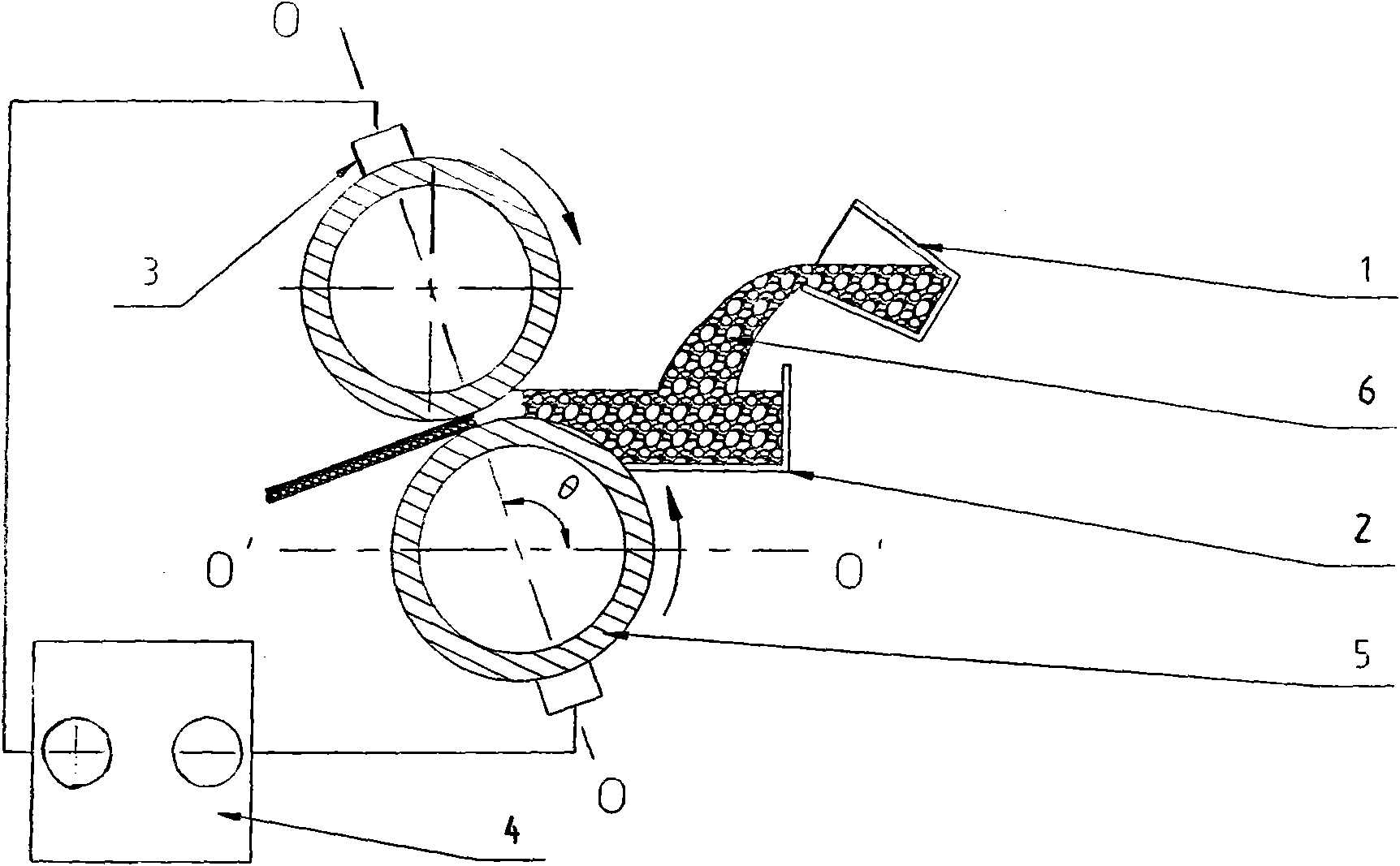

[0012] Embodiment 2: 5754 aluminum alloy

[0013] Due to the poor fluidity of the 5754 aluminum alloy melt, such as figure 2 The vertical casting and rolling scheme, the roll diameter is 210mm, the roll gap is 3.0mm, the holding crucible temperature is 670-685°C, and the casting-rolling speed is 0.7-0.8m·min -1 , water cooling, cooling rate 600℃ / S~650℃ / S, when the frequency is 100Hz, the current is 400A, and the duty cycle is 20%, the tensile strength is 210~215N·mm -2 , The elongation rate is 24-26%, and the crystal grain is finer than ordinary casting and rolling. Composed of α-phase and β-phase, the β-phase is granular and strip-shaped, and the distribution, size, position and structure of the precipitated intermetallic compounds are microstructures with good deformability.

Embodiment 3

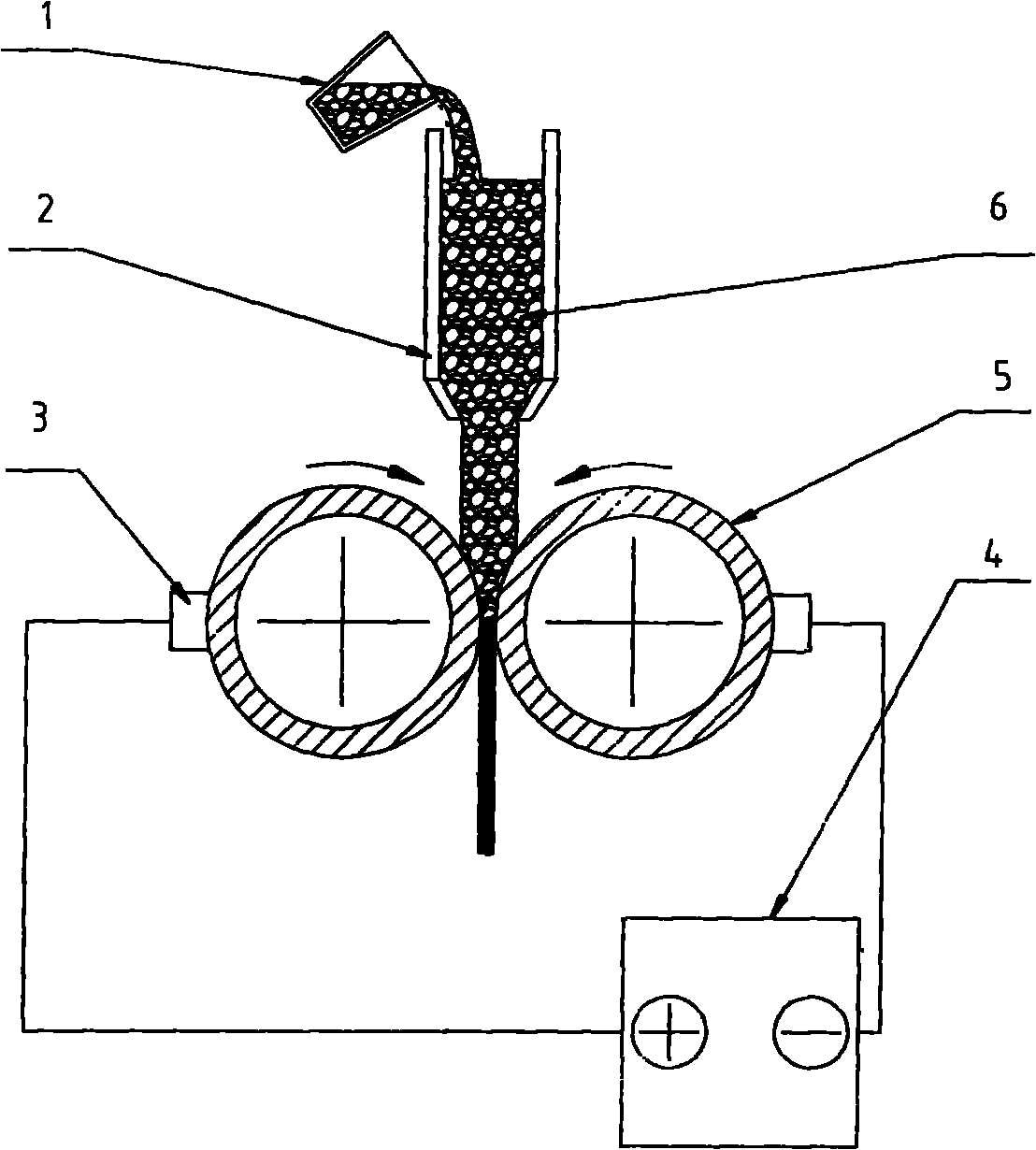

[0014] Embodiment 3: A356 aluminum alloy

[0015] Adopt the inclined casting and rolling scheme as shown in Figure 3, the diameter of the roll is 210mm, the roll gap is 3.0mm, the temperature of the molten pool is between 595~615℃, and the casting and rolling speed is 0.7~0.8m·min -1 , with cold water passed into the water-cooled hollow roll for cooling, the flow rate is controlled, the cooling rate is 580 ° C / S ~ 630 ° C / S, when the frequency is 180 Hz, the current is 600 A, and the duty ratio is 20%, a fine-grained structure is obtained. The grain size is 10-50 μm, and the performance test shows that the tensile strength reaches 280MPa, and the elongation is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com