Lens polishing machine and lens processing equipment

A polishing machine and polishing mechanism technology, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of low polishing quality of workpieces, increased enterprise costs, high scrap rate, etc., to achieve fast and efficient polishing, Easy to manufacture, process, install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

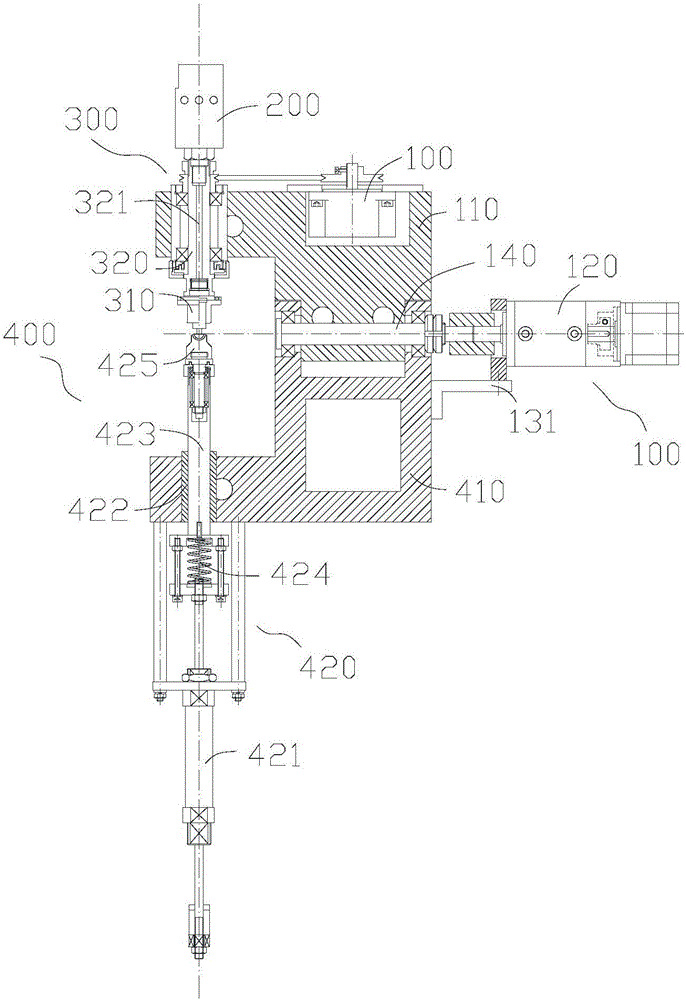

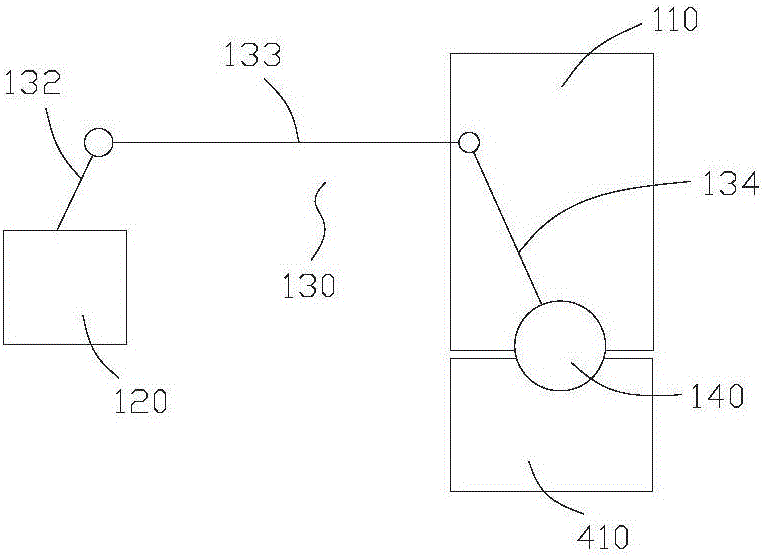

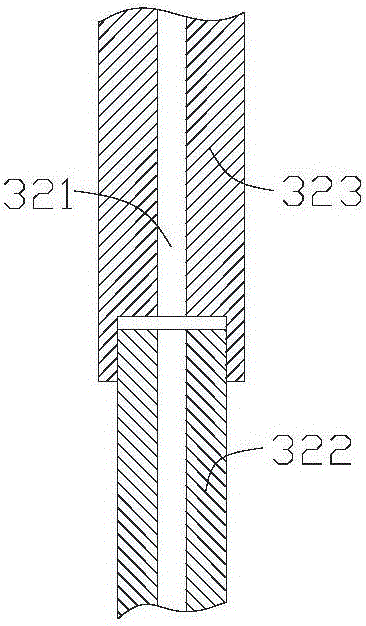

[0029] The traditional polishing method for concave workpieces in traditional optical lenses is to use top-swing or bottom-swing polishing machines for processing. The polishing die rotates at a high speed with the main shaft at the bottom, and the upper pressure head presses the workpiece and rotates with the main shaft; the upper pressure head swings or the polishing die and the main shaft swing together; the concave surface of the workpiece is downward, matching the polishing die to achieve polishing. During the processing, the grinding fluid cannot enter the concave grinding part, which may easily cause insufficient polishing, poor workpiece surface shape, traces, and low efficiency, thereby increasing the probability of rework, resulting in an increase in the scrap rate of the workpiece and an increase in the production cost of the enterprise.

[0030] In view of this, the designer of the present invention has designed a kind of lens polishing machine and lens processing e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com