Method for improving low-activation ferrite/martensitic steel high-temperature oxidation resistance

A low-activation ferrite, high-temperature oxidation resistance technology, applied in the field of metal protection, can solve the problems of poor oxide film compactness and adhesion, weak high-temperature oxidation resistance, low Cr content, etc., to improve the high-temperature oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

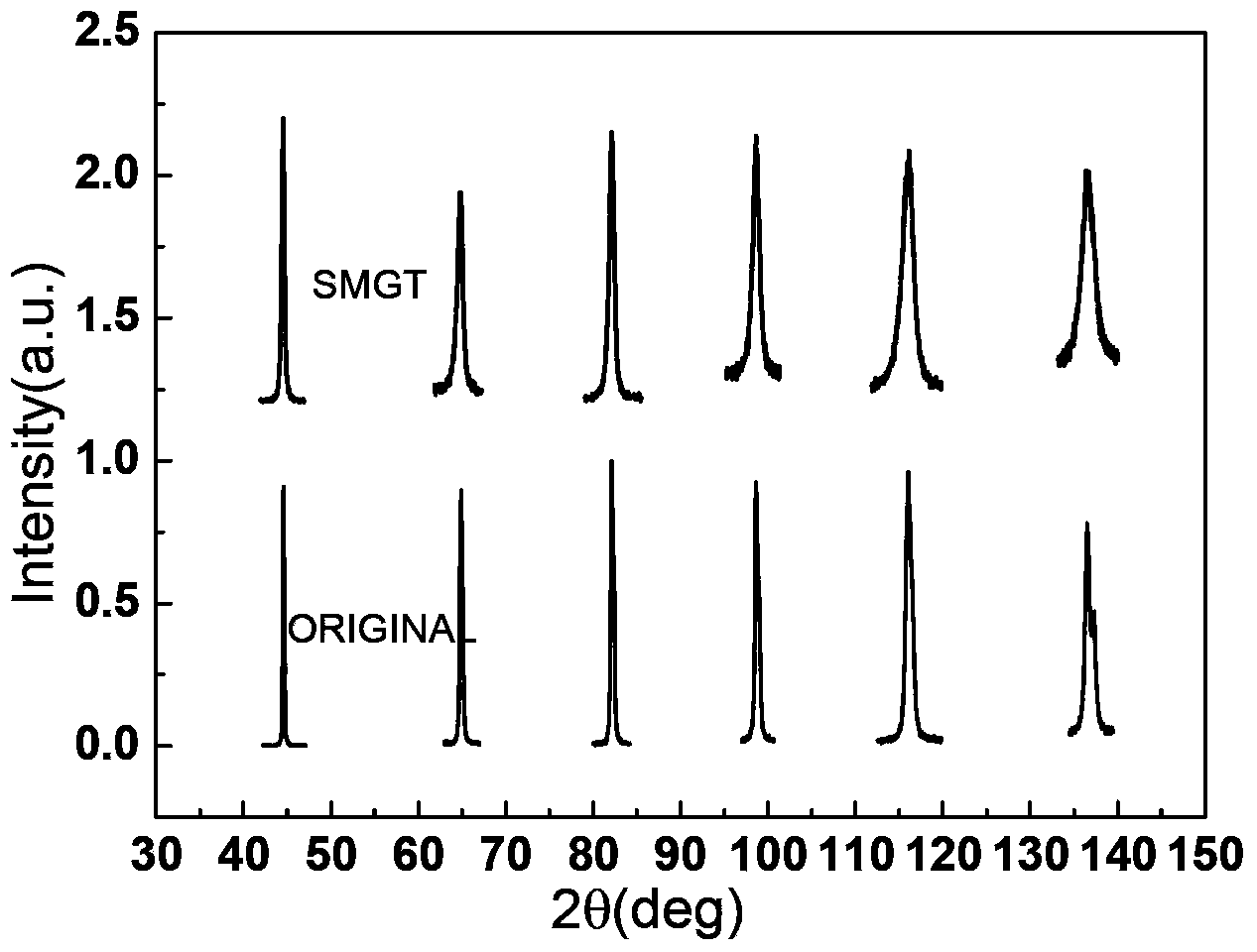

Embodiment 1

[0022] 9CrWVTa low-activation ferrite / martensitic steel is used as the research material to illustrate the effect of the present invention on the high-temperature oxidation resistance of low-activation steel, and its composition is shown in Table 1. The heat treatment system of the material before SMGT is as follows: heat preservation at 1050°C for 1 hour with water quenching, heat preservation at 750°C for 2 hours in air cooling; cut the heat-treated material into rod-shaped samples with a diameter of 20 mm and a length greater than 100 mm, and prepare a center of one end of the sample. The tip hole with a diameter of 4mm; fix the prepared sample on the machine tool, first use the turning tool to turn the rod-shaped sample to the same axis, and then use the tungsten carbide indenter to perform SMGT; the processing technology is: single feed a p =20μm, the forward speed of the indenter V 1 =6mm / min, rod rotation speed V 2 =300rpm, and the number of repeated rolling is 3 times...

Embodiment 2

[0027] The heat treatment process of raw material is the same as embodiment 1, and the SMGT treatment process is: single feed rate a p =20μm, the forward speed of the indenter V 1 =2mm / min, rod rotation speed V 2 =300rpm, the number of repeated rolling is 3 times; the grain size on the surface of the sample after nanometerization is 30nm, but the surface of the sample appears to be chipped, that is, the surface is destroyed; after oxidation at 600°C for 500h, compared with Experimental Example 1, the SMGT sample The weight gain increases, and the thickness of the oxide layer increases, and the oxide layer is looser. Therefore, under this process, SMGT has little effect on the oxidation resistance.

Embodiment 3

[0029] The heat treatment process of raw material is the same as embodiment 1, and the SMGT treatment process is: single feed rate a p =2μm indenter forward speed V 1 =15mm / min, rod rotation speed V 2 =300rpm, the number of times of repeated rolling is 1 time; after treatment, no nano-gradient structure is formed on the surface of the sample; after being oxidized at 600°C for 500h, compared with Experimental Example 1, the weight gain and oxide layer thickness of the SMGT sample and the CG sample are similar, so in this Under the process, SMGT cannot improve the oxidation resistance of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com