Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Do not migrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

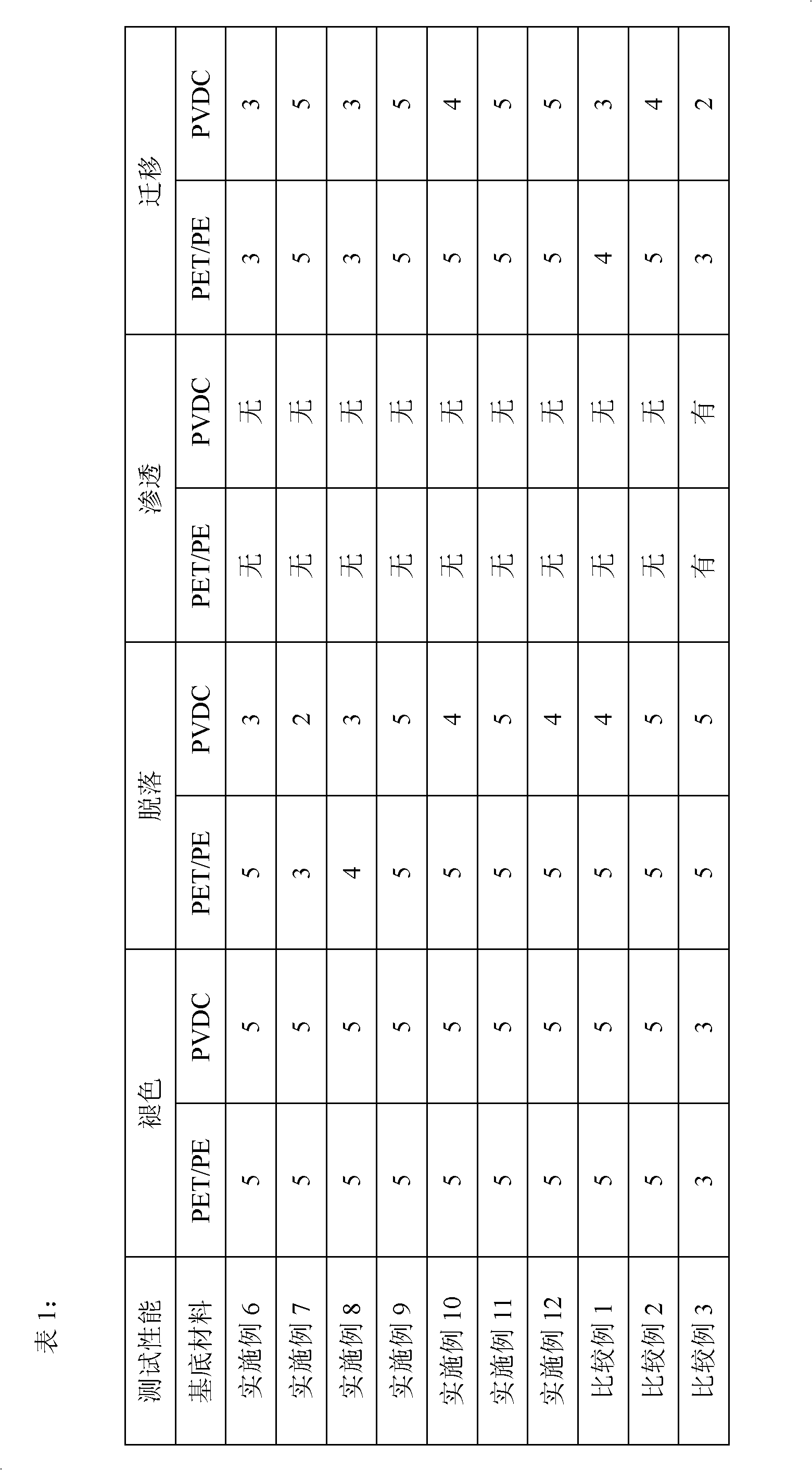

High-temperature steam endurance ink for spraying code and printing

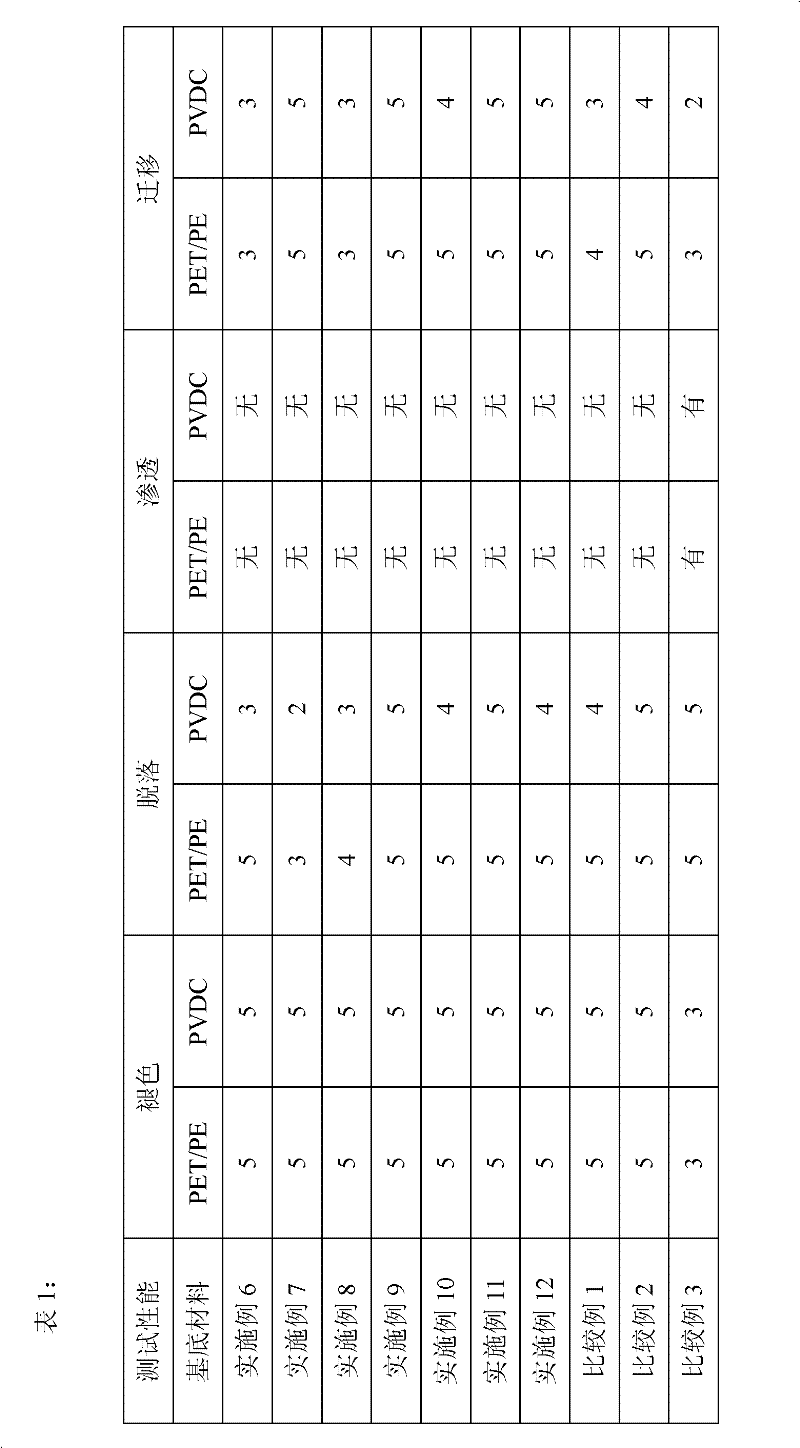

The invention relates to high-temperature steam endurance ink for spraying code and printing, containing one or more organic solvents, resin and coloring agents. In addition, the consistency of the ink is 2.8-6.2CP / 25DEG C, the conductivity is 500-1,500muS and the surface tension is 27-30Dyn / cm. The high-temperature steam endurance ink for spraying code and printing can be applied to the surfaces of various packaged objects required to be treated at high temperature. The mark and the substrate adopting the high-temperature steam endurance ink have strong adhesive force and favorable adhesiveness and cannot fade, fall off, permeate and shift after being subjected to high-temperature digestion. The dried mark can be also scraped by a cleaning agent.

Owner:北京赛腾标识系统股份公司

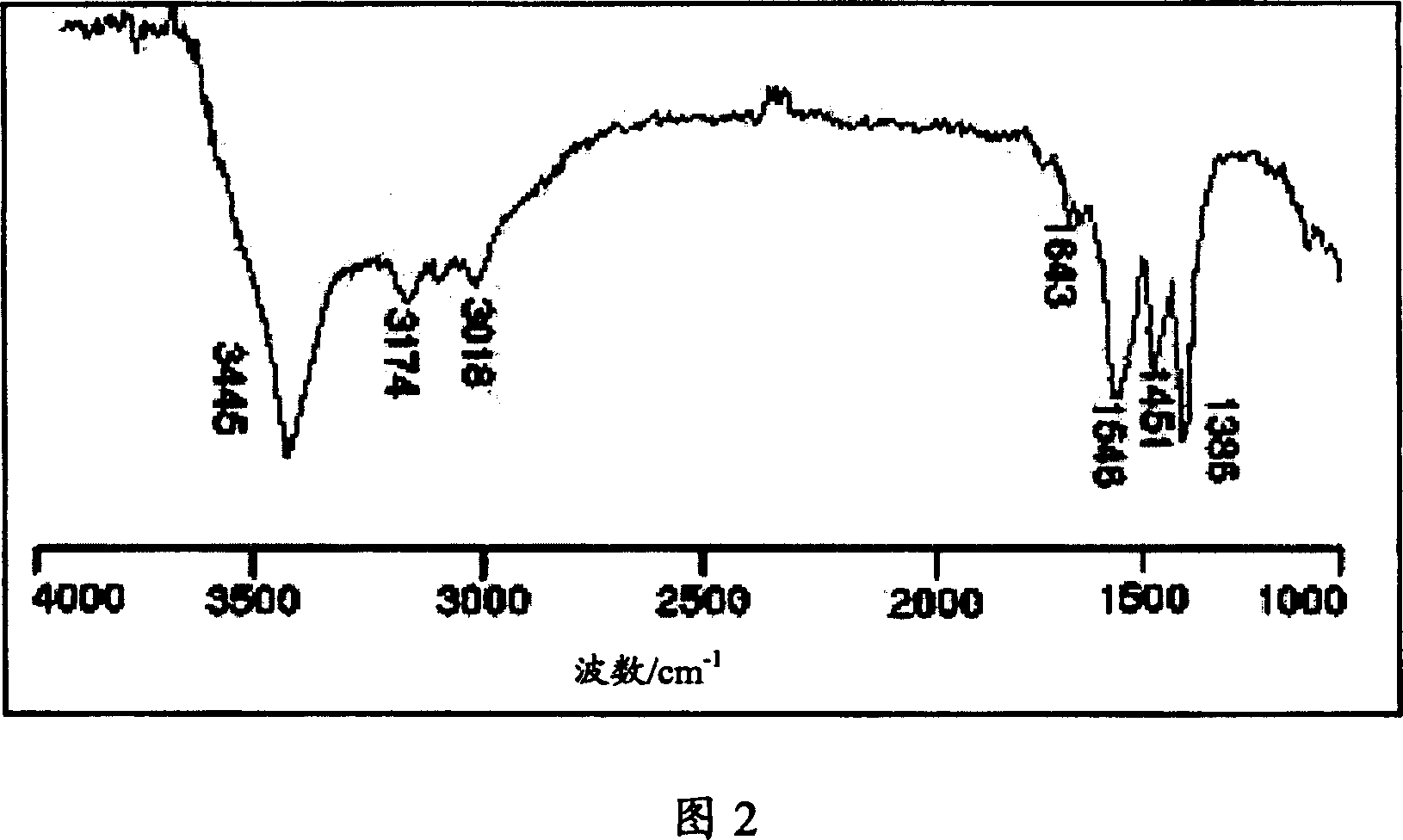

Method for preparing polyacrylate/nanometer ZnO composite coating printing binder by using Pickering emulsion polymerization method

InactiveCN103613700AImprove \"hot sticky cold crisp\"High fastnessDyeing processAmmonium sulfateAqueous dispersion

The invention discloses a method for preparing a polyacrylate / nanometer ZnO composite coating printing binder by using a Pickering emulsion polymerization method. The method comprises the steps: mixing nanometer ZnO, allyloxy nonylphenol polyoxyethylene ether ammonium sulfate and water, and then, carrying out uniform ultrasonic treatment by using an ultrasonic pulverizer to obtain an aqueous dispersion of nanometer ZnO and allyloxy nonylphenol polyoxyethylene ether ammonium sulfate; then, adding butyl acrylate and methyl methacrylate into the aqueous dispersion and emulsifying to obtain a Pickering emulsion; carrying out free radical polymerization on the Pickering emulsion by taking ammonium persulfate as an initiator to obtain the polyacrylate / nanometer ZnO composite coating printing binder. By using the method, the defects of hot sticking and cold brittleness of polyacrylate binders can be overcome; after the prepared polyacrylate / nanometer ZnO composite coating printing binder is applied to a fabric coating printing process, the phenomena including mesh clogging and crazing cannot be caused, and a coating printed fabric has favorable color fastness.

Owner:河北汇彩永泰科技有限公司

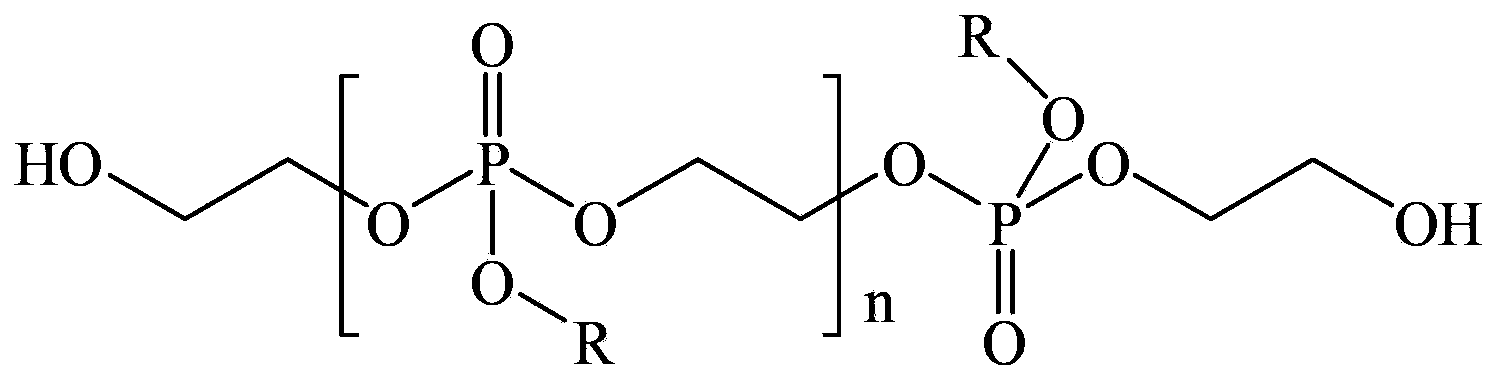

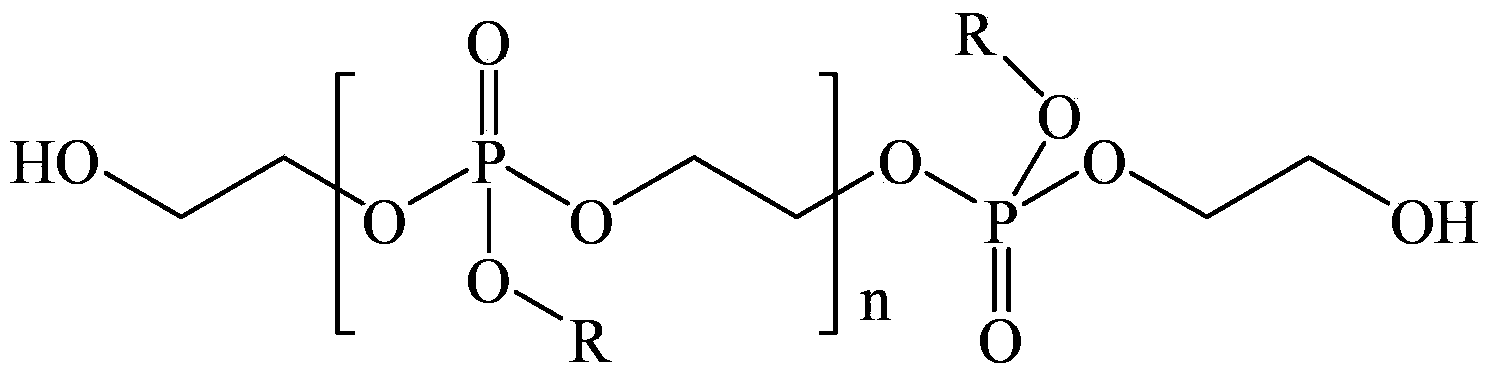

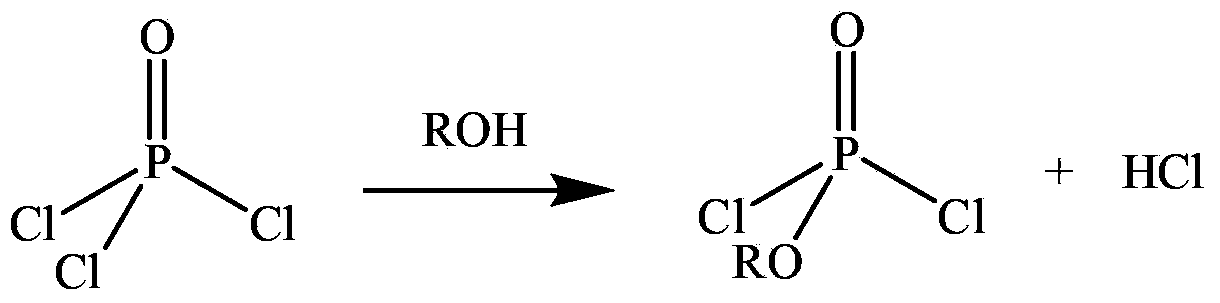

Halogen-free organophosphate fire retardant and its preparation method

ActiveCN103360606ALow costThe post-processing process is simplePhosphorus organic compoundsToxic gasHalogen

The invention relates to a halogen-free organophosphate fire retardant and its preparation method. The fire retardant contains no halogen and will not release corrosive toxic gases when combusted. Through a reaction between polycarbonate polyol and isocyanate, an inflaming retarding element is embedded into a polyurethane foamed material and will not migrate or escape when the material is heated. Thus, the material is permanently endowed with flame resistance.

Owner:常熟国和新材料有限公司

Halogen-free flame-retardant high toughness modified polycarbonate composition

InactiveCN104629285AExcellent halogen-free environmental protection flame retardant functionDroplets do notChemical industryTemperature resistance

The invention discloses a halogen-free flame-retardant high toughness modified polycarbonate composition, which comprises the following components by weight: 60%-85% of polycarbonate, 5%-15% of a complex halogen-free flame retardant, 5%-10% of a toughening agent, 2%-4% of a compatilizer, 0.1%-0.5% of an antioxidant and 0.1%-1.5% of a lubricant. The invention has the beneficial effect that compared with the prior art, halogen-free flame-retardant high toughness modified polycarbonate composition prepared by the invention has excellent halogen-free flame-retardant and environmental protection functions, and has the advantages of grade UL94V-0, no molten drop, no migration, good flame retardant durability, environment-friendliness, safety, high anti-shock efficiency, good thermal stability, processing adaptability, excellent electrical property, high temperature resistance and corrosion resistance; therefore, the composition has good application prospects in the fields of automobile, electronics, machinery, chemical industry and building materials.

Owner:殷培花

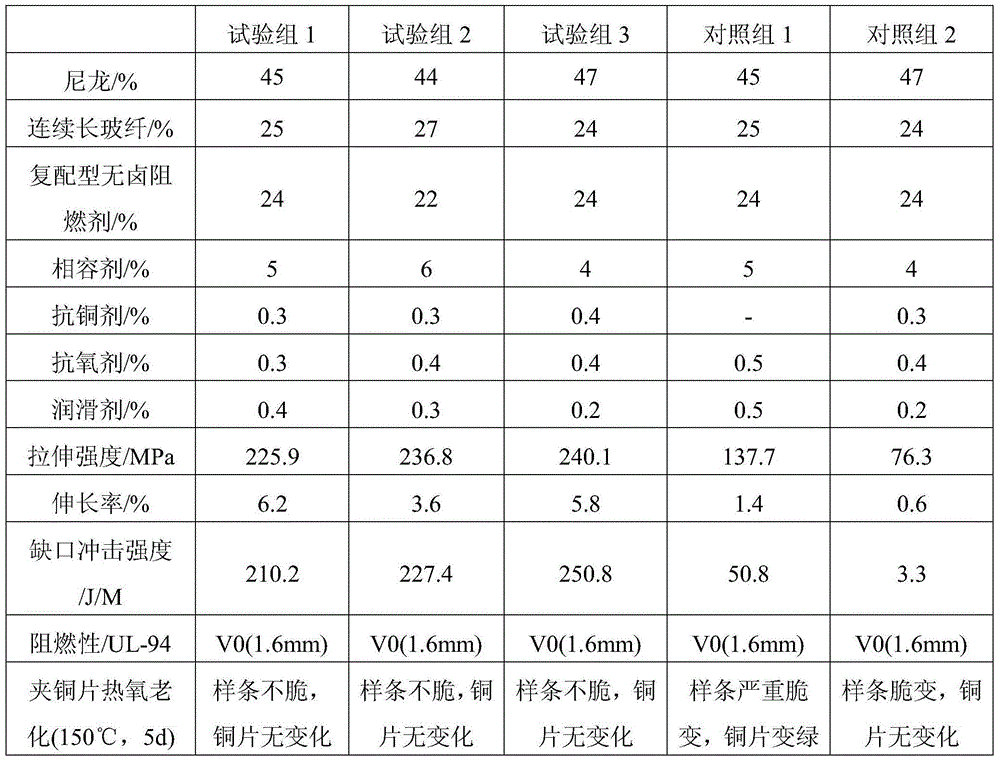

Metal ageing resisting type enhanced nylon material and preparation method thereof

The invention relates to a metal ageing resisting type enhanced nylon material. The nylon material is prepared from the following raw materials in percentage by weight: 44 to 63% of nylon, 23 to 32% of continuous long glass fibers, 22 to 26% of a complex halogen-free flame retardant, 0.3 to 0.5% of an antioxidant, 0.3 to 0.5% of an anti-copper agent, 4 to 6% of a compatilizer, and 0.1 to 0.6% of a lubricant. The invention further provides a preparation method of the metal ageing resisting type enhanced nylon material. The metal ageing resisting type enhanced nylon material has an advantage that the proper anti-copper agent is adopted, so that the copper damage resisting effect is obvious; the metal ageing resisting type enhanced nylon material further has the advantages of being high in compatibility for nylon, high in dispersing performance, free of migration, free of pollution, resistant to water, high in oil extraction performance, and free of influence on electric insulation performance and other performances of the nylon; meanwhile, a rolling and infiltration mode is adopted in production, so that the retention length of the continuous long glass fibers is more than that of the common method, and thus, the material is very high in strength.

Owner:SHANGHAI SUNNY

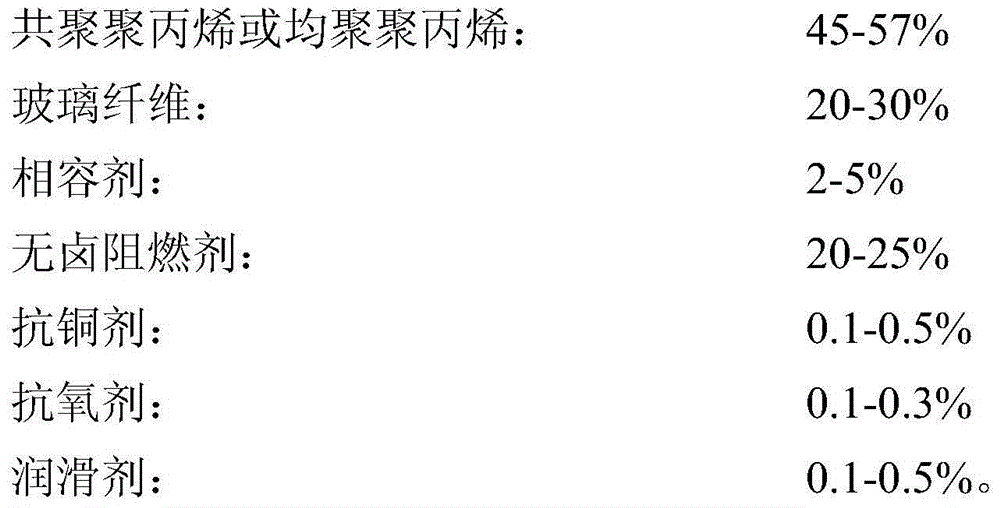

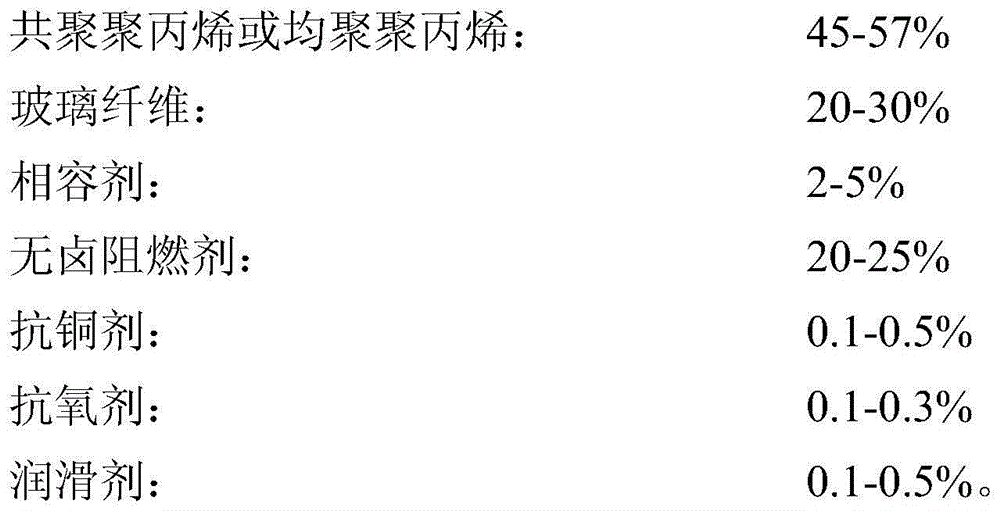

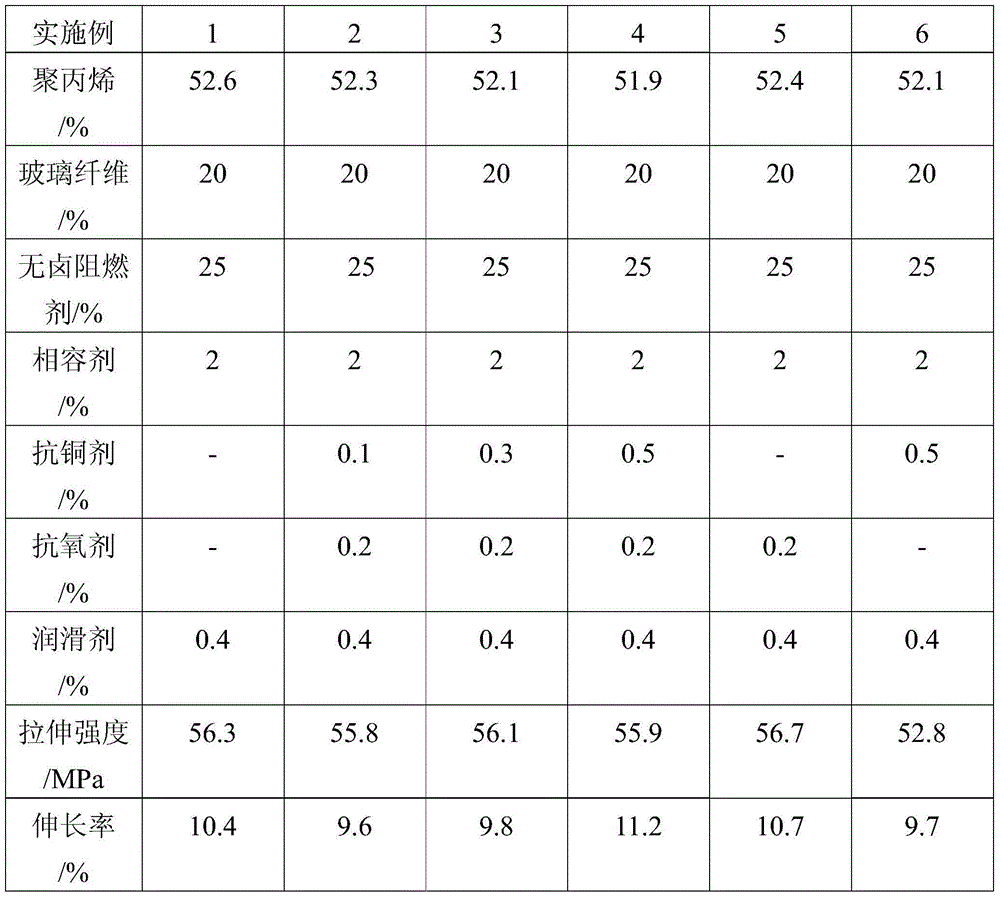

Special material for copper pollution resistant sockets and preparation method thereof

InactiveCN104592635ASignificant anti-copper damage effectGood compatibilityPolypropyleneFire resistance

The invention relates to a special material for copper pollution resistant sockets. The material is prepared from the following raw materials in percentage by weight: 45-57% of polypropylene, 20-30% of glass fiber, 20-25% of a compound halogen-free flame retardant, 0.1-0.5% of an anti-copper agent, 2-5% of a compatibilizer, 0.1-0.3% of an antioxidant and 0.1-0.5% of a lubricant. The invention further provides a preparation method of the special material for copper pollution resistant sockets. The special material for copper pollution resistant sockets provided by the invention has the advantages that the proper anti-copper agent is adopted to improve the copper ageing resistance of the special material for sockets, moreover the material has good compatibility with polypropylene, good dispersion, no migration, no pollution, water resistance and good oil extraction, and the electrical insulation property and other properties of the resin are not influenced, the special material for sockets has excellent copper pollution resistance, mechanical properties, fire resistance and processing properties, and can meet the requirements of the European Union RoHS, IEC non-halogen and Reach laws and regulations, thereby having a good application prospect in the field of sockets.

Owner:SHANGHAI SUNNY

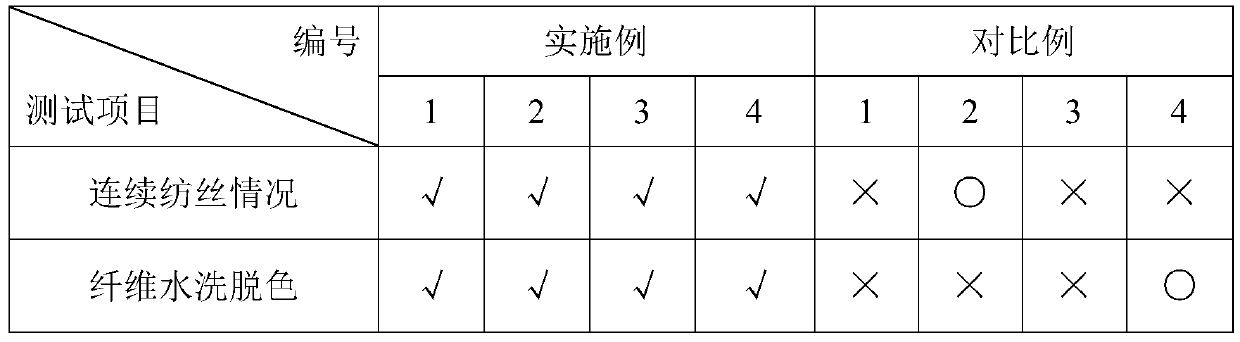

Color oil for ultra-high molecular weight polyethylene fiber and preparation method of color oil

InactiveCN109706534ADoes not fall offDo not migrateMonocomponent polyolefin artificial filamentPigment addition to spinning solutionPolymer scienceLiquid state

The invention discloses a preparation method of color oil for an ultra-high molecular weight polyethylene fiber. The method comprises the following steps that a) a dispersion agent with an anchoring structure is added to a polyethylene spinning solvent, dispersion is conducted for at least 0.1 h under the stirring state, a pigment with a modified surface is added for stirring, the mixed solution is placed for wetting, and a liquid-state color master pre-mixed solution is obtained; b) the liquid-state color master pre-mixed solution obtained in the step a) is subjected to high-speed dispersion,the temperature is controlled within 60-180 DEG C, free radical macromolecules and an initiator are added, and a modified liquid-state color master batch is obtained; c) the modified liquid-state color master batch obtained in the step b) is subjected to grinding dispersion or cutting dispersion, and the color oil for the polyethylene fiber is obtained. The fiber prepared through the color oil for the polyethylene fiber has the advantages that the fiber diameter is small, the color fastness and fastness to washing are high, and the pigment does not fall off or transfer.

Owner:SUZHOU SUNMUN TECH CO LTD

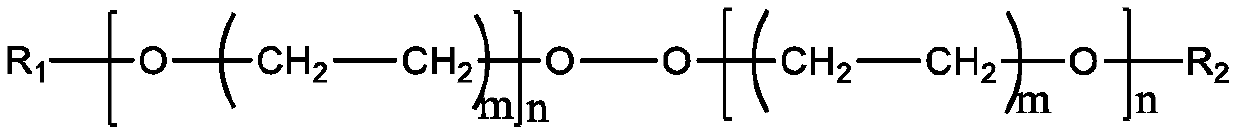

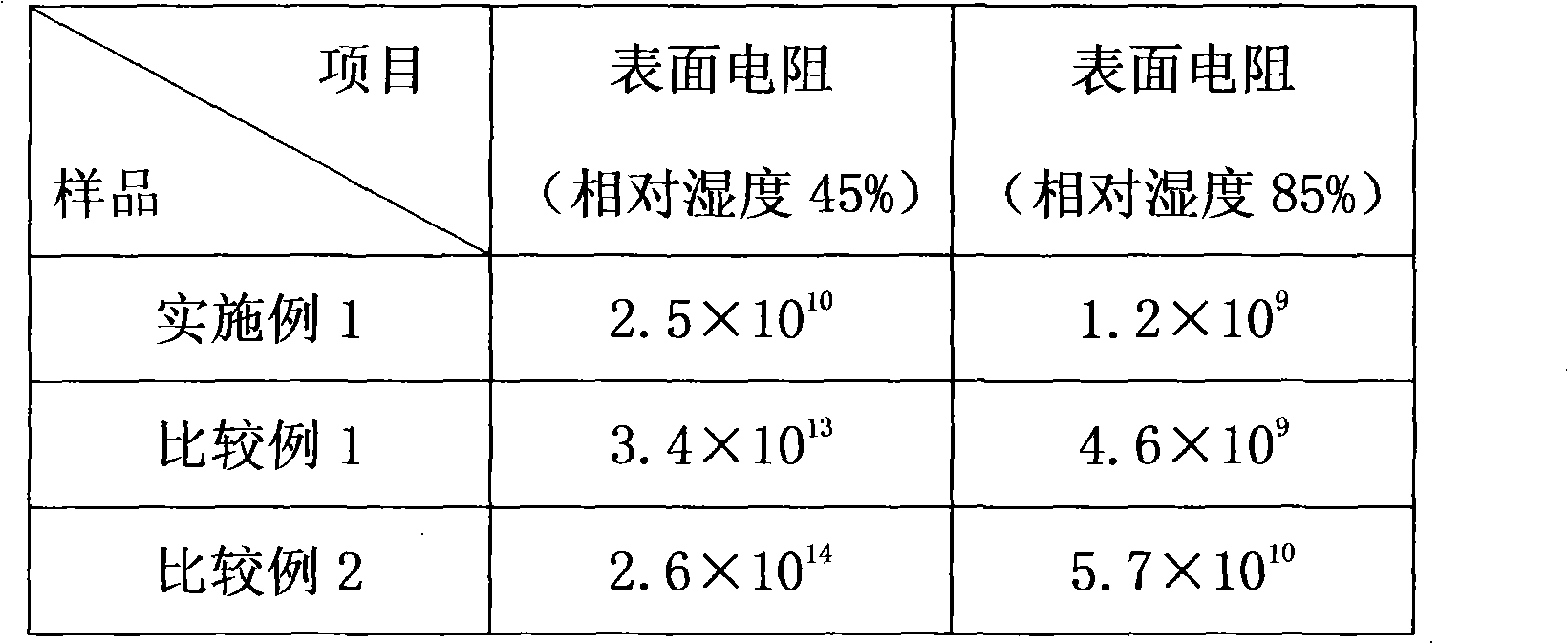

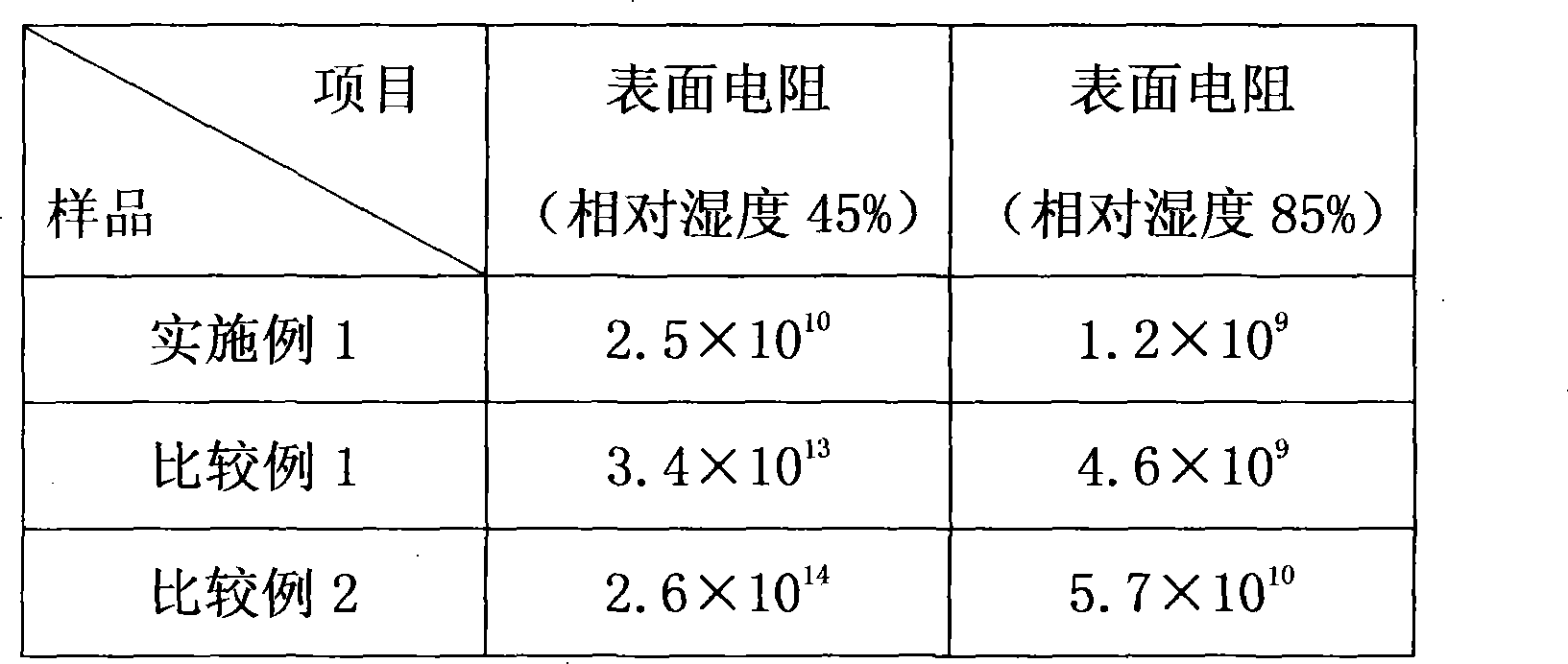

Thermal sublimation photographic paper electrostatic resistance coatings

InactiveCN101261438ANo pollutionGood adhesionPhotosensitive material auxillary/base layersPolyethylene terephthalateAntistatic agent

The invention discloses an antistatic coating of thermal dye sublimation photo paper. The antistatic coating comprises an antistatic agent, an acrylic resin and a solvent, the antistatic agent comprises a permanent antistatic agent which takes polyamide and polyether hindered anime as the basis for synthesis and a nano TiO2 conductive powder auxiliary antistatic agent which is coated by SnO2 and is carried out the Sb2O5 doping processing. As the technical proposal of the invention has excellent antistatic property, the antistatic coating can ensure the effectivity and the permanent property of the usage under the wide conditions of a relative humidity; in addition, as the polyethylene terephthalate and other plastic films have good adhesive property, the antistatic coating is applicable to the formation of the uniform and firm antistatic coating by the coating method, and the fastness of the coating is good.

Owner:江苏耐斯数码科技股份有限公司

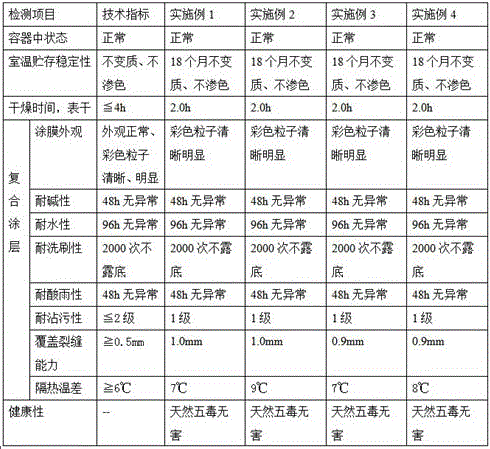

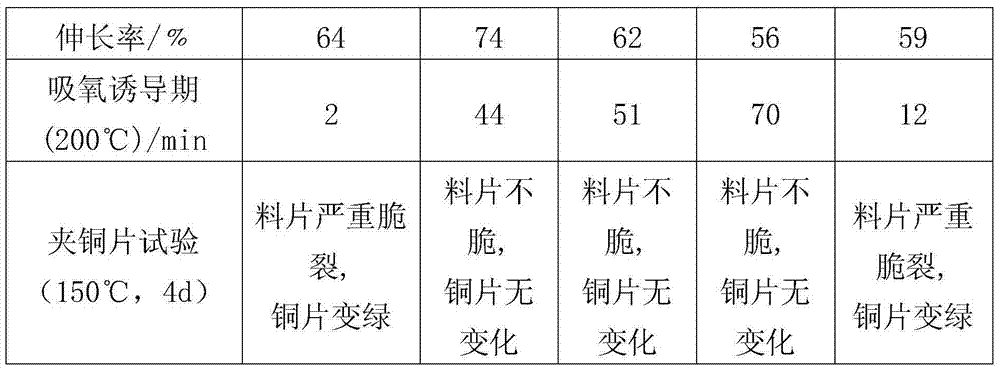

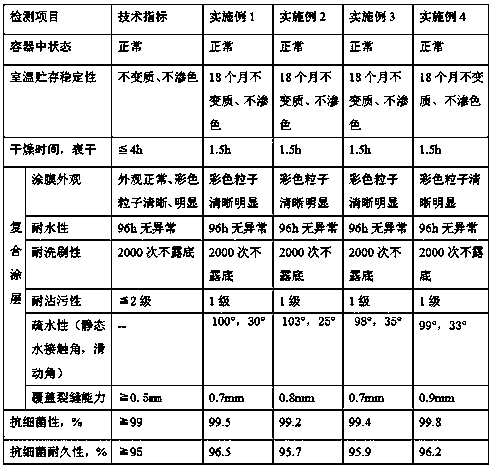

Water-in-water type sound insulation multicolor paint and preparation method thereof

ActiveCN106280959AElasticHas the effect of covering cracksPolyurea/polyurethane coatingsReflecting/signal paintsThermal insulationPolyethylene glycol

The invention discloses water-in-water type sound insulation multicolor paint. The water-in-water type sound insulation multicolor paint is formed through three phases including colloidal solution, pelletized base paint and emulsion finished paint. The colloidal solution comprises sodium pyrophosphate, lithium magnesium silicate and water; the pelletized base paint comprises polyethylene glycol, an anti-foaming agent, waterborne elastic polyurethane emulsion, colloidal solution, titanium dioxide, environment-friendly inorganic pigments, a thickening agent, a thermal insulation agent, a film coalescing aid and water; the emulsion finished paint comprises waterborne elastic polyurethane emulsion, propylene glycol, a sound absorption functional material, pelletized paint, carboxymethyl cellulose, a waterproof agent, an anti-corrosion agent and water. The invention further provides a preparation method of the multicolor paint. Once spray coating of the multicolor paint can be realized without adoption of organic solvents and various colors. In addition, the water-in-water type sound insulation multicolor paint has advantages of sound insulation, heat insulation, water resistance, pollution prevention, easiness for washing and scrubbing resistance and is available for arbitrary color matching to realize perfect patterning.

Owner:佛山中科仟合新材料有限公司

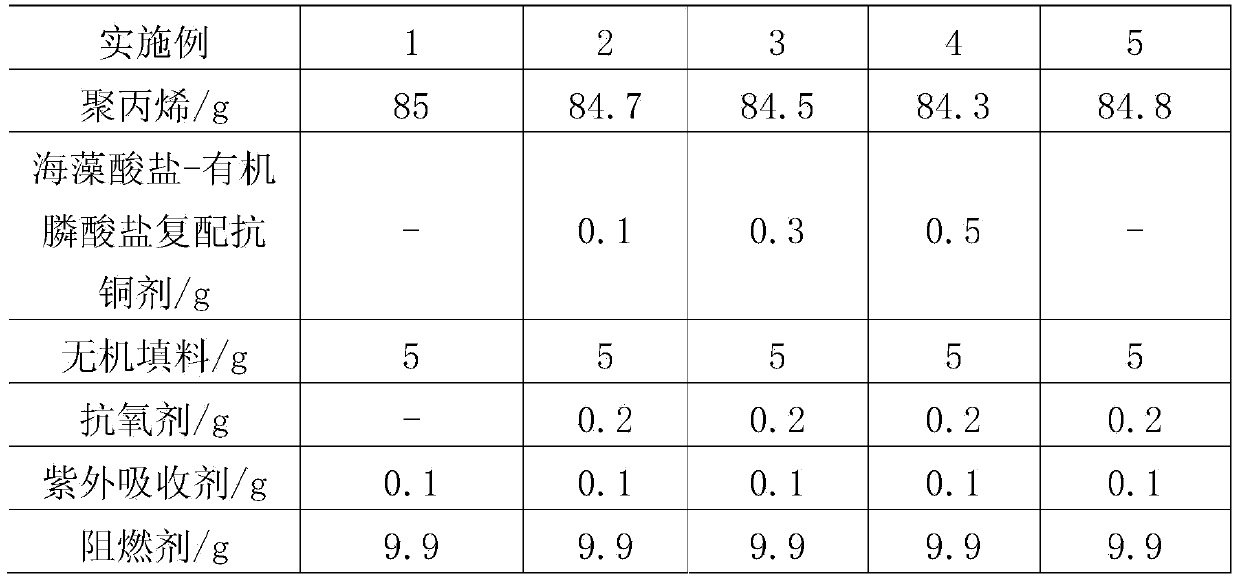

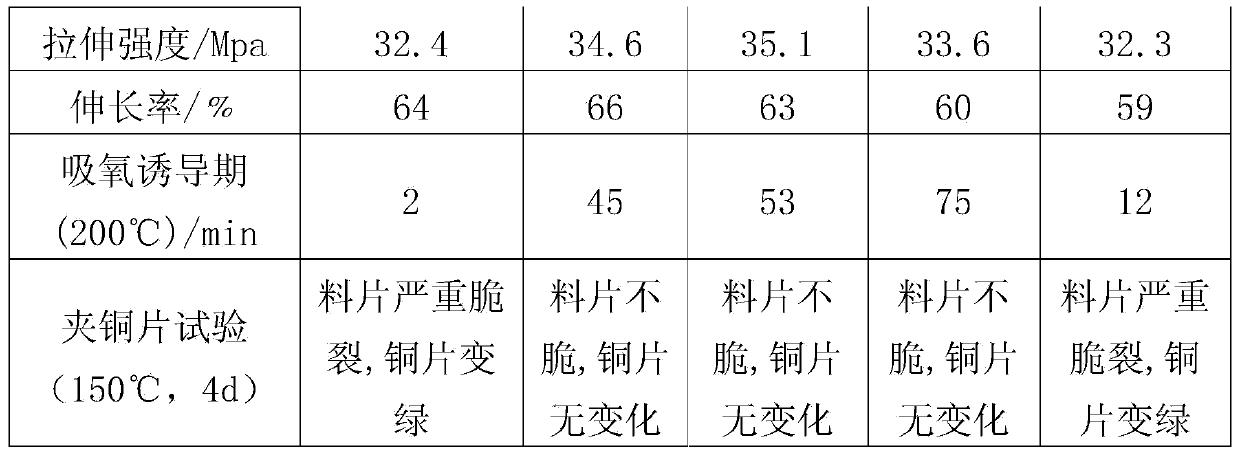

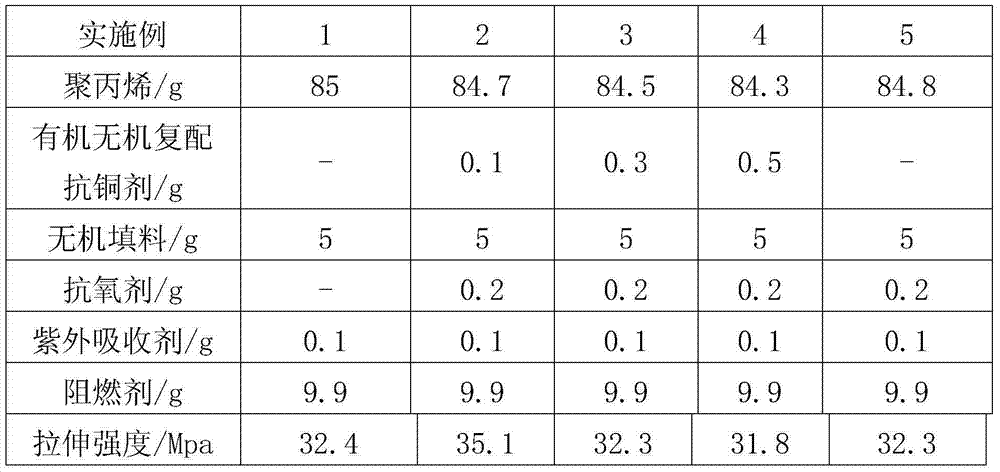

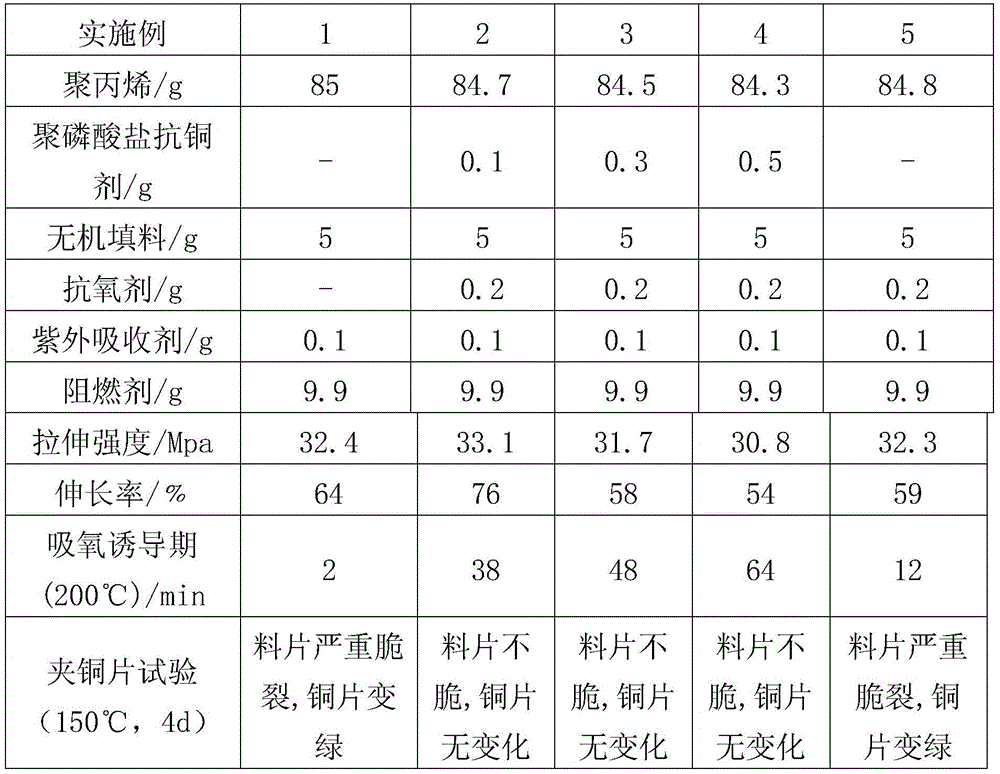

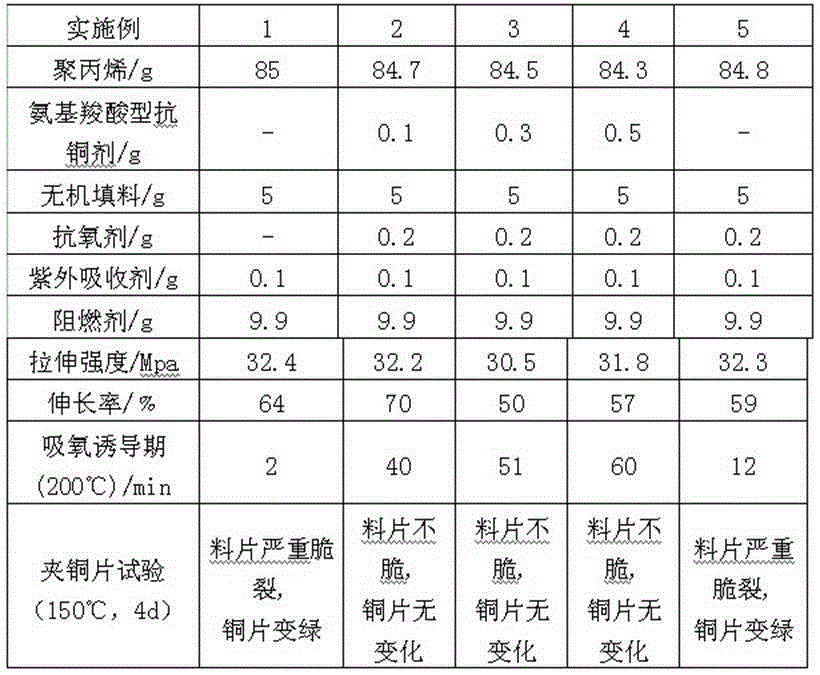

Amino carboxylic acid type copper inhibitor-containing polypropylene composite material and preparation method thereof

InactiveCN103554651ADoes not affect insulation propertiesRemarkable anti-copper damage effectPlastic/resin/waxes insulatorsBulk chemical productionAntioxidantCarboxylic acid

The invention relates to an amino carboxylic acid type copper inhibitor-containing polypropylene composite material and a preparation method thereof. The polypropylene composite material is obtained by mixing 70-90% of polypropylene, 0.01-1% of an amino carboxylic acid type copper inhibitor, 0.1-10% of an inorganic filler, 0.1-0.5% of an antioxidant, 0.1-0.3% of an ultraviolet absorbent and 5-20% of a fire retardant. The method comprises the following steps: mixing above raw materials in proportion to form a mixture, extruding the mixture through a double screw extruder, cooling with water, drafting, and carrying out cutting granulation to granules. The copper inhibitor which is an amino carboxylic acid substance forms many chelated coordination structures with copper ions to generate a chelate having a high stability, and the chelate has the advantages of strong inhibition of the ageing catalysis capability of heavy metal ions, substantial copper harm resistance, good compatibility with resins, no migration, no pollution, water resistance, good oil extraction property, and no influences on the electric insulation performance or other performances of the resins.

Owner:ZHEJIANG EXPO NEW MATERIALS CO LTD +1

Environment-friendly tire regeneration rubber softener

InactiveCN105985555AIncrease viscosityIncrease elongationBuilding insulationsHazardous substanceCottonseed oil

The invention discloses an environment-friendly tire regenerated rubber softener. In order to overcome the deficiencies of toxic and harmful substances and pungent odor in the softener used in the existing tire reclaimed rubber, the present invention mixes cottonseed oil pitch 40 and soybean oil pitch 10 in the reaction vessel in sequence, and heats up to 80°C. , 60 revolutions per minute and vacuum stirring for 30 minutes, then add slick pitch 28, fennel oil 11, and tall oil 10 to the reaction kettle in turn, and vacuum stir for 30 minutes, and finally add rosin 1 to the reaction kettle, mix, and heat to 120°C. Stirred under vacuum for one hour to obtain the product. The invention is used as a softener for environment-friendly tire regenerated rubber. It is non-toxic, tasteless, environmentally friendly, has good plasticity, does not migrate and does not change color, has good softening effect, and can increase product gloss, viscosity, plasticity and tensile strength.

Owner:怀化市华亿创新科技发展有限公司

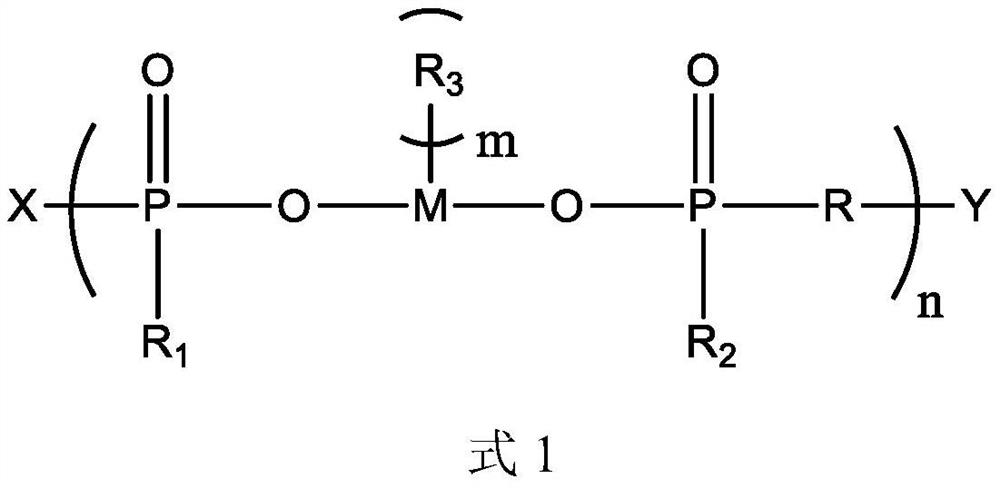

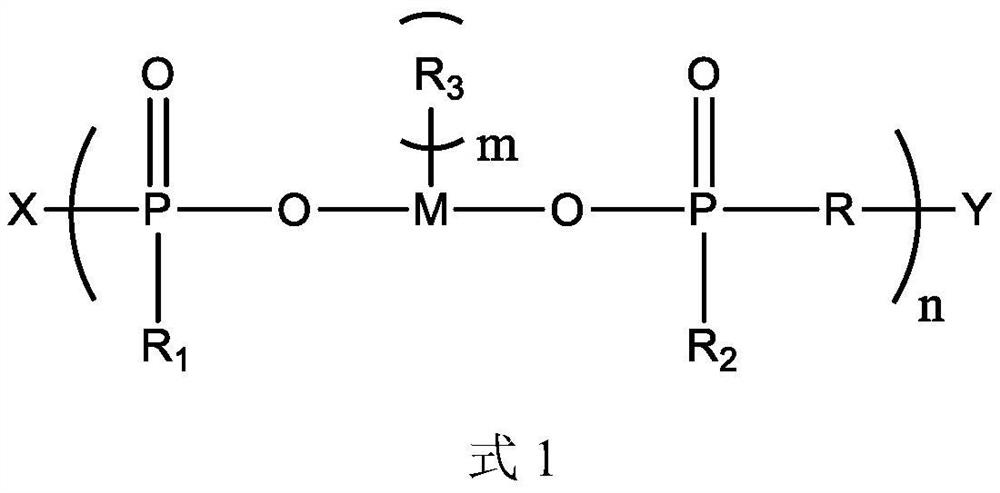

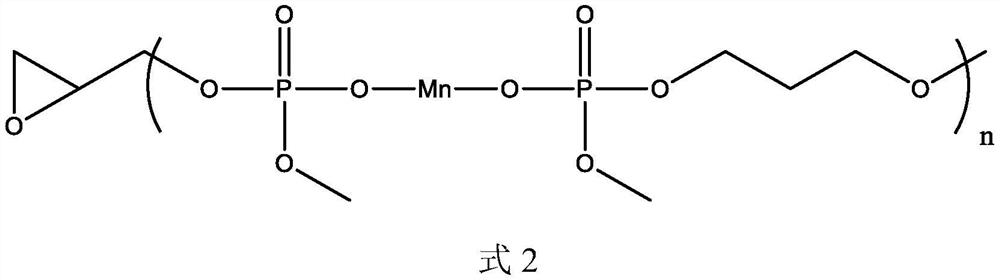

Polymeric flame retardant as well as preparation method and application thereof

The invention provides a polymeric flame retardant as well as a preparation method and application thereof. The polymeric flame retardant has excellent compatibility with an added polymer system and has excellent flame retardance, the preparation process is simple, resources are saved, and the polymeric flame retardant is environmentally friendly.

Owner:GUANGDONG GUANGSHAN NEW MATERIALS CO LTD

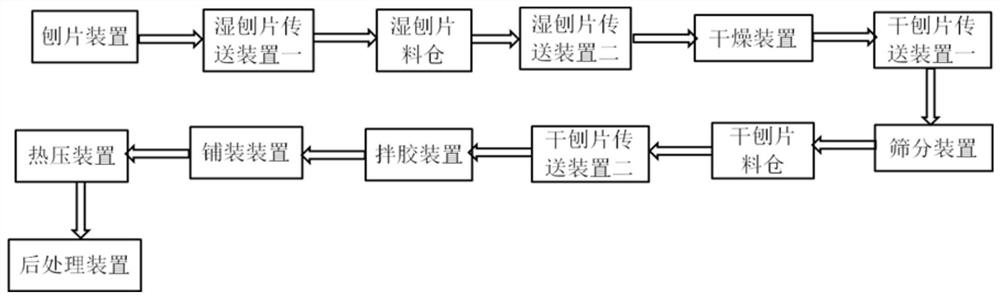

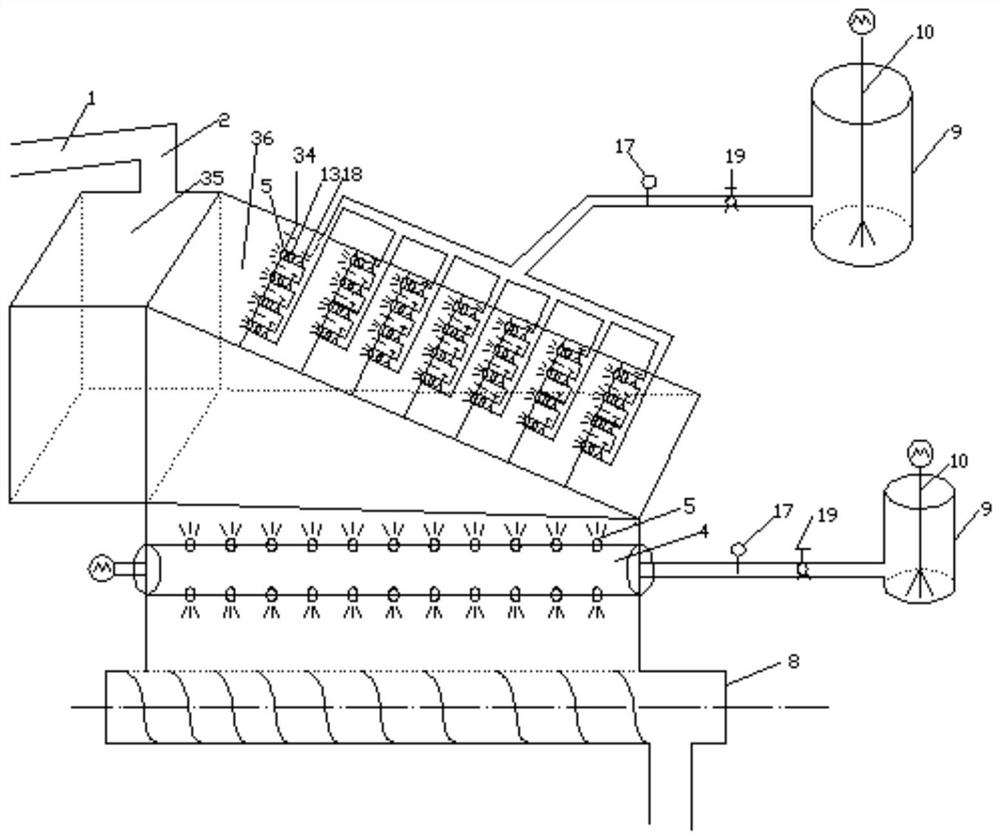

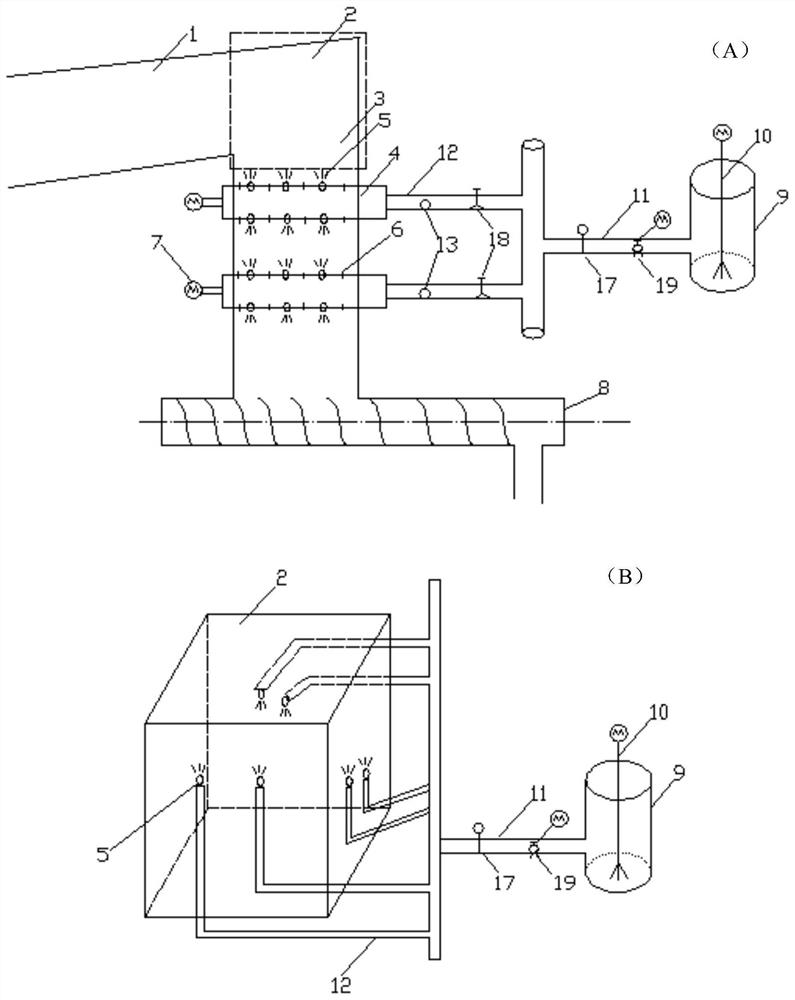

System and process for producing flame-retardant oriented strand board

ActiveCN109747019AGood adhesionIncrease coverageDomestic articlesFlat articlesAfter treatmentEngineering

The invention discloses a system and process for producing a flame-retardant oriented strand board. The system comprises a flaking device, a first wet flake conveying device, a wet flake bin, a secondwet flake conveying device, a drying device, a first dry flake conveying device, a screening device, dry flake bins (including the surface dry flake bin and the core dry flake bin), a second dry flake conveying device, glue mixing devices (including the surface dry flake glue mixing device and the core dry flake glue mixing device), a mat formation device, a hot-pressing device, and an after-treatment device and a flame retardant spraying structure used after hot-pressing. According to the system and process, a flame retardant is sprayed in multiple procedures to be sufficiently absorbed by flakes and is evenly distributed, and the flame-retardant oriented strand board obtained through the system and process has an excellent flame retardant property.

Owner:湖北宝源木业有限公司

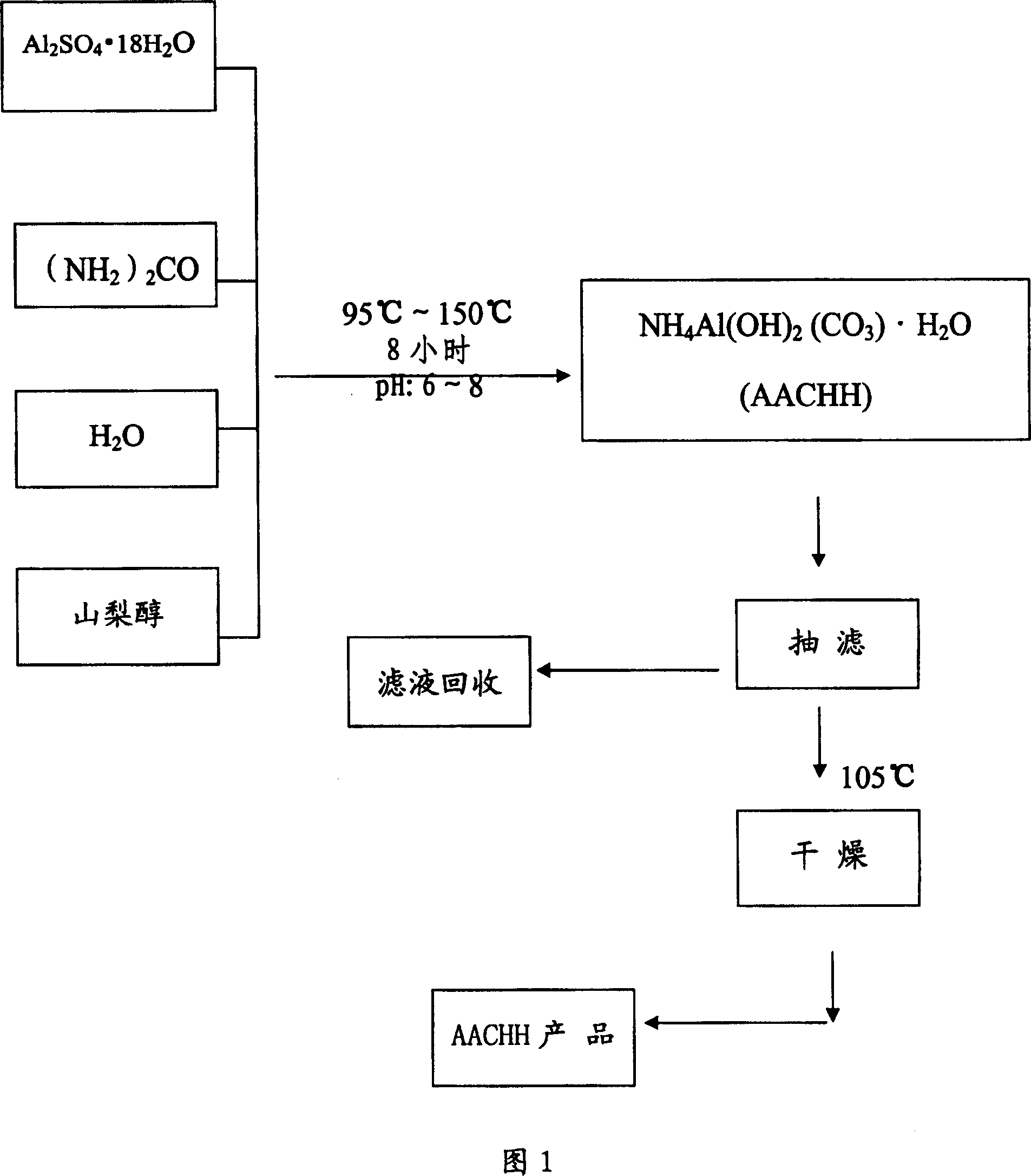

New fire retardant aluminium crystal whisker and its production process

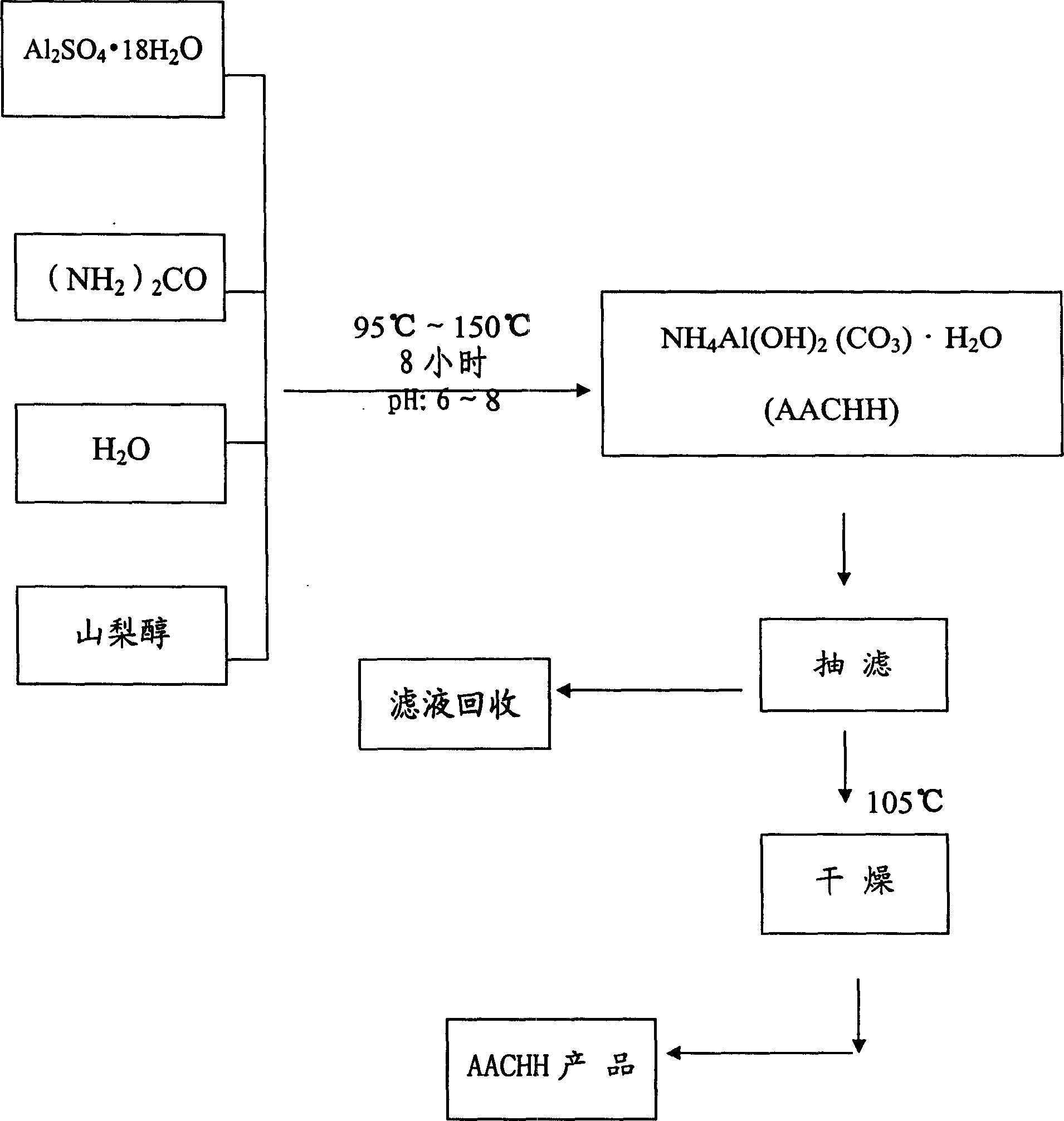

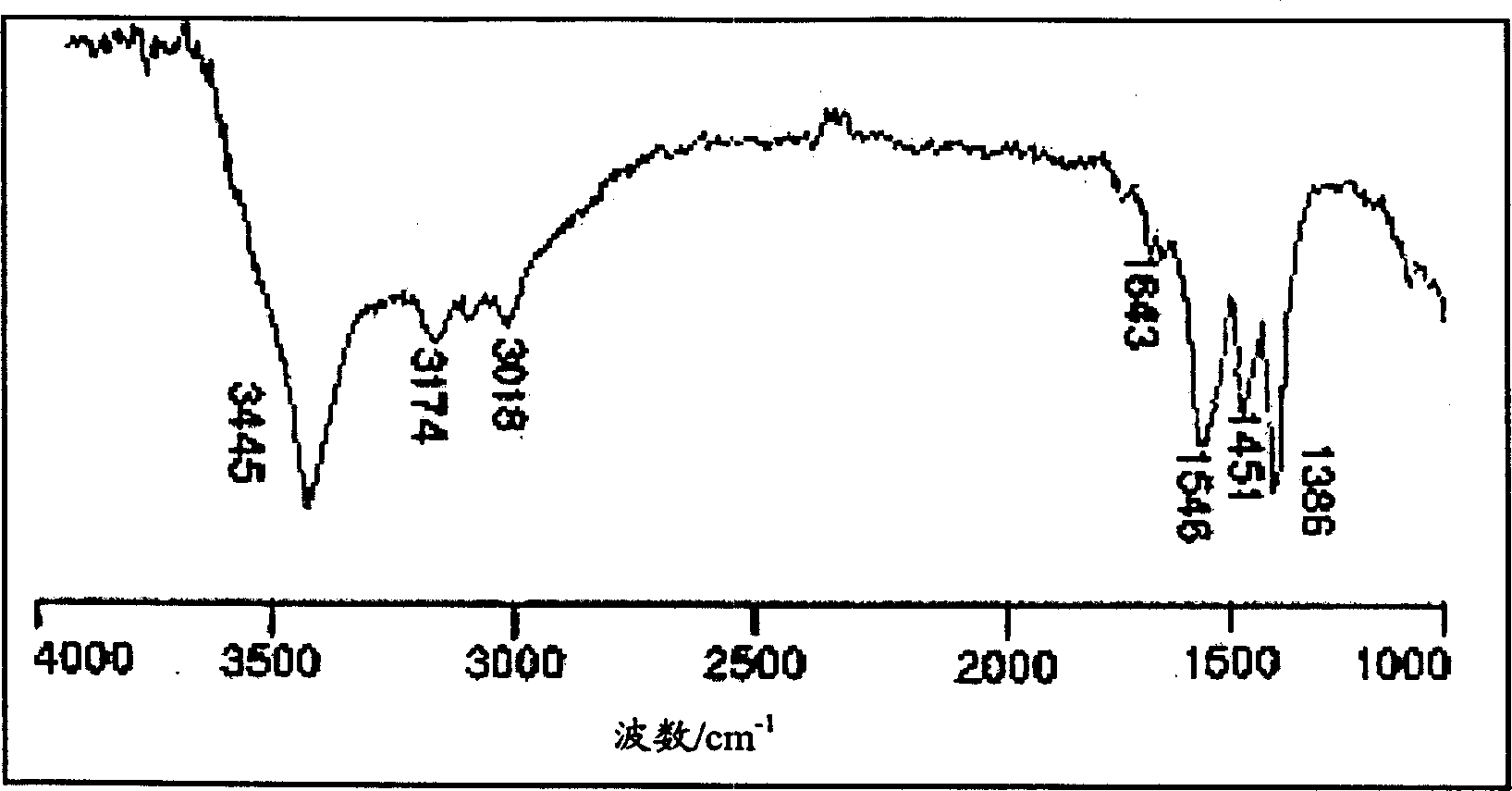

The present invention is new type fire retardant aluminum crystal whisker and its production process. The fire retardant aluminum crystal whisker has the chemical molecular expression of NH4Al(OH)2(CO3)íñH2O. It is prepared with Al2SO4íñ18H2O and urea as main material, and through mixing with sorbic alcohol and water, regulating pH to 6-8, and heating to 95-150 deg.c to react inside a high pressure reactor for 6-8 hr to obtain the crystal as the fire retardant aluminum crystal whisker. The fire retardant aluminum crystal whisker has no toxicity, less smoke produced in burning, low toxicity of the burning product, no immigration, no leaching out, no environmental pollution and low cost, as well as high compatibility with polymer, many kinds of fire retarding gases, fire retarding gas releasing amount up to 60.0-80.0 %, low fire retarding gas releasing temperature of 250-350 deg.c, whisker length / diameter ratio up to 20-40 and other features.

Owner:WUHAN CHEM COLLEGE

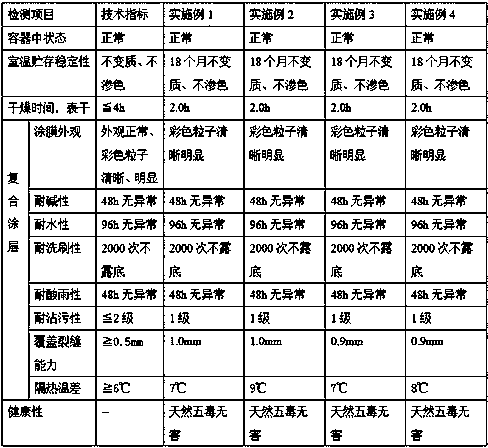

Polypropylene composite material containing alginate-organic phosphonate compound copper ion inhibitor and preparation method of polypropylene composite material

InactiveCN104212062AStrong catalytic agingStrong ability to catalyze agingPlastic/resin/waxes insulatorsBulk chemical productionPolypropylene compositesAntioxidant

The invention relates to a polypropylene composite material containing an alginate-organic phosphonate compound copper ion inhibitor and a preparation method of the polypropylene composite material. A polypropylene composite material blend disclosed by the invention comprises 70-90 percent of polypropylene, 0.01-1 percent of alginate-organic phosphonate compound copper ion inhibitor, 0.1-10 percent of inorganic filler, 0.1-0.5 percent of antioxidant, 0.1-0.3 percent of ultraviolet absorbent and 5-20 percent of fire retardant. The preparation method comprises the following steps: proportionally mixing all raw materials to obtain a mixture, then extruding by means of a double-screw extruder, and then performing drawing and cutting and pelleting by means of cold water to obtain granules. According to the preparation method disclosed by the invention, the alginate-organic phosphonate compound copper ion inhibitor is adopted for complexing copper ions to generate high-stability chelate, has strong capability of inhibiting catalytic aging of heavy metal ions and remarkable copper hazard resisting effect, and has the advantages of being good in intermiscibility with resin, being free from migration and pollution, being good in water resistance and oil extraction property, being free from influencing electrical insulation property and other properties of the resin, and the like.

Owner:宁波锦地工程塑料有限公司

Thermal sublimation photographic paper electrostatic resistance coatings

InactiveCN101261438BNo pollutionGood adhesionPhotosensitive material auxillary/base layersPolyethylene terephthalateAntistatic agent

The invention discloses an antistatic coating of thermal dye sublimation photo paper. The antistatic coating comprises an antistatic agent, an acrylic resin and a solvent, the antistatic agent comprises a permanent antistatic agent which takes polyamide and polyether hindered anime as the basis for synthesis and a nano TiO2 conductive powder auxiliary antistatic agent which is coated by SnO2 and is carried out the Sb2O5 doping processing. As the technical proposal of the invention has excellent antistatic property, the antistatic coating can ensure the effectivity and the permanent property of the usage under the wide conditions of a relative humidity; in addition, as the polyethylene terephthalate and other plastic films have good adhesive property, the antistatic coating is applicable to the formation of the uniform and firm antistatic coating by the coating method, and the fastness of the coating is good.

Owner:江苏耐斯数码科技股份有限公司

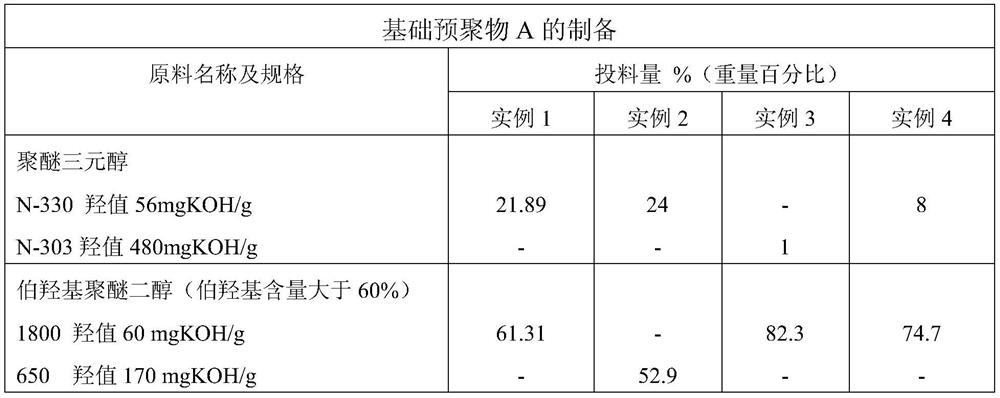

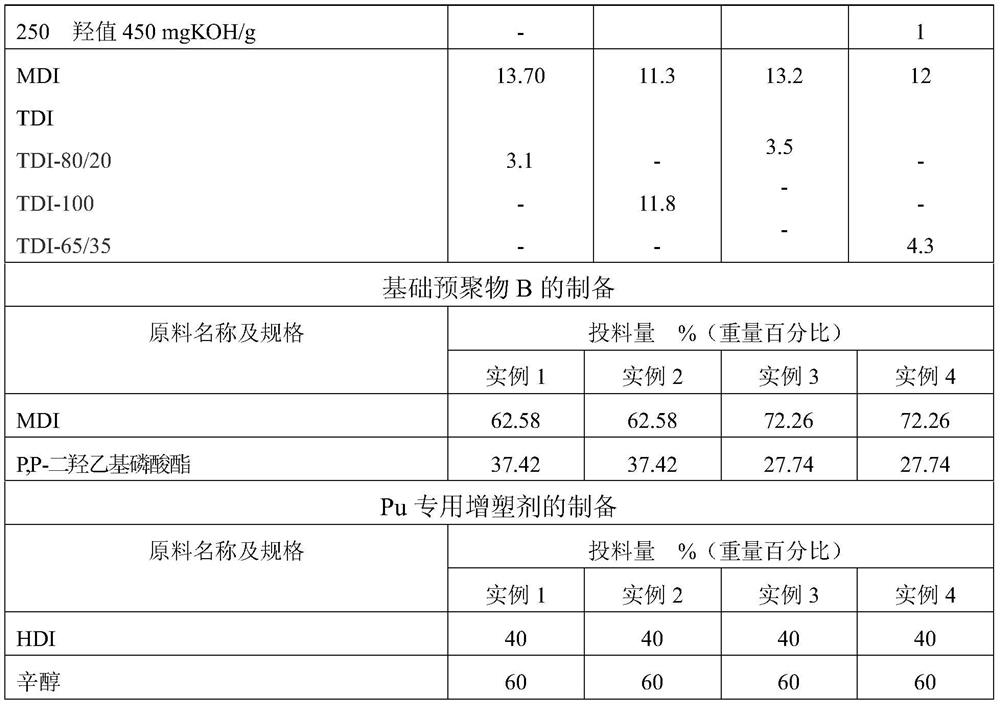

High-strength flame-retardant polyurethane sealant for high-speed rail passenger cars and preparation method thereof

ActiveCN107955576BNo pollution in the processOvercome incompatibilitiesNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePlasticizer

The invention belongs to the technical field of polymer materials, and in particular relates to a single-component high-strength flame-retardant polyurethane sealant for high-speed rail cars and a preparation method thereof. The one-component high-strength flame-retardant polyurethane sealant for high-speed rail passenger cars of the present invention uses basic prepolymers and PU plasticizers as main raw materials, supplemented by fillers and various additives, and the prepared polyurethane sealant has the following properties: It has the advantages of high strength, good flame retardancy and wide application range.

Owner:JINAN NORTH TAIHE NEW MATERIAL

A kind of polypropylene composite material containing aminocarboxylic acid type organic-inorganic composite anti-copper agent and preparation method thereof

InactiveCN103554652BStrong ability to catalyze agingDoes not affect insulation propertiesPlastic/resin/waxes insulatorsAntioxidantCarboxylic acid

The invention relates to an aminocarboxylic acid-containing organic-inorganic composite anti-copper agent polypropylene composite material and a preparation method thereof. The polypropylene composite material of the present invention is 70-90% polypropylene, 0.01-1% organic-inorganic composite anti-copper agent, 0.1-10% inorganic filler, 0.1-0.5% antioxidant, 0.1-0.3% ultraviolet absorber, 5 Blends of ~20% flame retardants. The method is to mix various raw materials in proportion to form a mixture, extrude the mixture through a twin-screw extruder, and then draw, cut and granulate into pellets through cold water. The method of the present invention uses an organic-inorganic compound anti-copper agent to complex copper ions to form a chelate with high stability, which has a strong ability to inhibit the catalytic aging of heavy metal ions, has a significant anti-copper damage effect and has compatibility with resins. Good, no migration, no pollution, water resistance, good oil extraction, does not affect the electrical insulation properties of the resin and other properties.

Owner:ZHEJIANG EXPO NEW MATERIALS CO LTD +1

Water-in-water type soundproof colorful paint and preparation method thereof

ActiveCN106280959BElasticHas the effect of covering cracksPolyurea/polyurethane coatingsReflecting/signal paintsThermal insulationPolyethylene glycol

The invention discloses water-in-water type sound insulation multicolor paint. The water-in-water type sound insulation multicolor paint is formed through three phases including colloidal solution, pelletized base paint and emulsion finished paint. The colloidal solution comprises sodium pyrophosphate, lithium magnesium silicate and water; the pelletized base paint comprises polyethylene glycol, an anti-foaming agent, waterborne elastic polyurethane emulsion, colloidal solution, titanium dioxide, environment-friendly inorganic pigments, a thickening agent, a thermal insulation agent, a film coalescing aid and water; the emulsion finished paint comprises waterborne elastic polyurethane emulsion, propylene glycol, a sound absorption functional material, pelletized paint, carboxymethyl cellulose, a waterproof agent, an anti-corrosion agent and water. The invention further provides a preparation method of the multicolor paint. Once spray coating of the multicolor paint can be realized without adoption of organic solvents and various colors. In addition, the water-in-water type sound insulation multicolor paint has advantages of sound insulation, heat insulation, water resistance, pollution prevention, easiness for washing and scrubbing resistance and is available for arbitrary color matching to realize perfect patterning.

Owner:佛山中科仟合新材料有限公司

A kind of polypropylene composite material containing polyphosphate anti-copper agent and preparation method thereof

InactiveCN103554653BAbility to inhibit catalytic agingDoes not affect insulation propertiesInsulatorsPhosphateMixed materials

The invention relates to a polypropylene composite material containing a polyphosphate copper-inhibitor and a preparation method of the polypropylene composite material. The polypropylene composite material is a blending material of the following materials in percent by mass: 70-90% of polypropylene, 0.01-1% of the polyphosphate copper inhibitor, 0.1-10% of an inorganic filling material, 0.1-0.5% of an anti-oxidant, 0.1-0.3% of a UV absorbent and 5-20% of a fire retardant. The preparation method comprises: mixing the various raw materials into a mixed material according to the ratio, extruding the mixed material by a double-screw extruder, performing cold-water drawing, cutting and granulating to form granules. The polyphosphate copper inhibitor employed by the method is strong in chelating capability with metal ions and large in chelating stability constant, metal ions are not easy to dissociate after chelated; and the polyphosphate copper inhibitor has extremely strong capability of inhibiting catalytic aging of heavy-metal ions, is substantial in copper-hazard resistant effect, and also has the advantages that the polyphosphate copper inhibitor is good in compatibility with resin, does not migrate, has no pollution, is resistant in water and good in oil extraction performance, does not influence electrical insulation property and other properties of resin, and the like.

Owner:ZHEJIANG EXPO NEW MATERIALS CO LTD +1

Shoe sole regenerated rubber environment-friendly softener

InactiveCN105985553AHigh tensile strengthHigh Mooney viscositySolesBuilding insulationsHazardous substanceEngineering

The invention discloses an environment-friendly softener for shoe sole regenerated rubber. In order to overcome the deficiencies such as the poisonous and harmful substances contained in the existing softener used for shoe sole regenerated rubber, strong odor stimulation, heavy pollution, etc., the present invention draws slick asphalt 35 and soybean oil asphalt 39 into the reaction kettle successively by weight, and heats to 60-80°C, stir in vacuum at 60 rpm for 30 minutes, then add fennel oil 25 to the reactor, stir in vacuum for 30 minutes, finally add rosin or tall oil rosin 1 into the reactor, heat up to 100-120°C, and stir in vacuum for 1 hour, get the product. The invention is used as a softener for reclaimed rubber for shoe soles. It does not contain toxic and harmful substances, has no irritating odor, does not pollute the environment, and has excellent performance. The product meets EU environmental protection standards and meets EU REACH, ROHS and other environmental regulations.

Owner:怀化市华亿创新科技发展有限公司

Method for preparing rubber-plastic anti-copper agent with cleaning effect

InactiveCN110092943ADoes not affect insulation propertiesDoes not affect other performanceWater bathsAntioxidant

A method for preparing a rubber-plastic anti-copper agent with a cleaning effect is disclosed. The method includes mixing 3,5-di-tert-butyl-4-hydroxyl phenyl compound and hydrazine hydrate in a ratioof 1-3:2-6, stirring the mixture after mixing to obtain a solution mixture, adding a first solvent and a proper amount of a reaction solution into the solution mixture, and stirring and reacting the mixture to obtain a liquid mixture; raising the temperature of the mixture obtained in the step 1 to 80-150 DEG C to evaporate the solvent, and then performing filtration, washing and drying in order to obtain a primary solid material; adding a second solvent into the primary solid material, mixing and then performing crystallization and filtration to obtain an intermediate material; adding a cosolvent, a main antioxidant, an auxiliary antioxidant and an ultraviolet absorbent into the intermediate material and mixing the mixture to obtain a material mixture; adding a lubricant into the materialmixture, mixing and stirring the mixture under a condition that a water bath temperature is 35-40 DEG C, and cooling to obtain the rubber-plastic anti-copper agent. The method has a low production cost and high yield, and the rubber-plastic anti-copper agent has a good effect of preventing damage caused by copper ions and good intermiscibility with resin.

Owner:CHIZHOU WANWEI CHEM

New fire retardant aluminium crystal whisker and its production process

InactiveCN100345938CLow release temperatureEasy to neutralizeFireproof paintsGas releaseHigh pressure

The present invention is new type fire retardant aluminum crystal whisker and its production process. The fire retardant aluminum crystal whisker has the chemical molecular expression of NH4Al(OH)2(CO3).H2O. It is prepared with Al2SO4.18H2O and urea as main material, and through mixing with sorbic alcohol and water, regulating pH to 6-8, and heating to 95-150 deg.c to react inside a high pressure reactor for 6-8 hr to obtain the crystal as the fire retardant aluminum crystal whisker. The fire retardant aluminum crystal whisker has no toxicity, less smoke produced in burning, low toxicity of the burning product, no immigration, no leaching out, no environmental pollution and low cost, as well as high compatibility with polymer, many kinds of fire retarding gases, fire retarding gas releasing amount up to 60.0-80.0 %, low fire retarding gas releasing temperature of 250-350 deg.c, whisker length / diameter ratio up to 20-40 and other features.

Owner:WUHAN CHEM COLLEGE

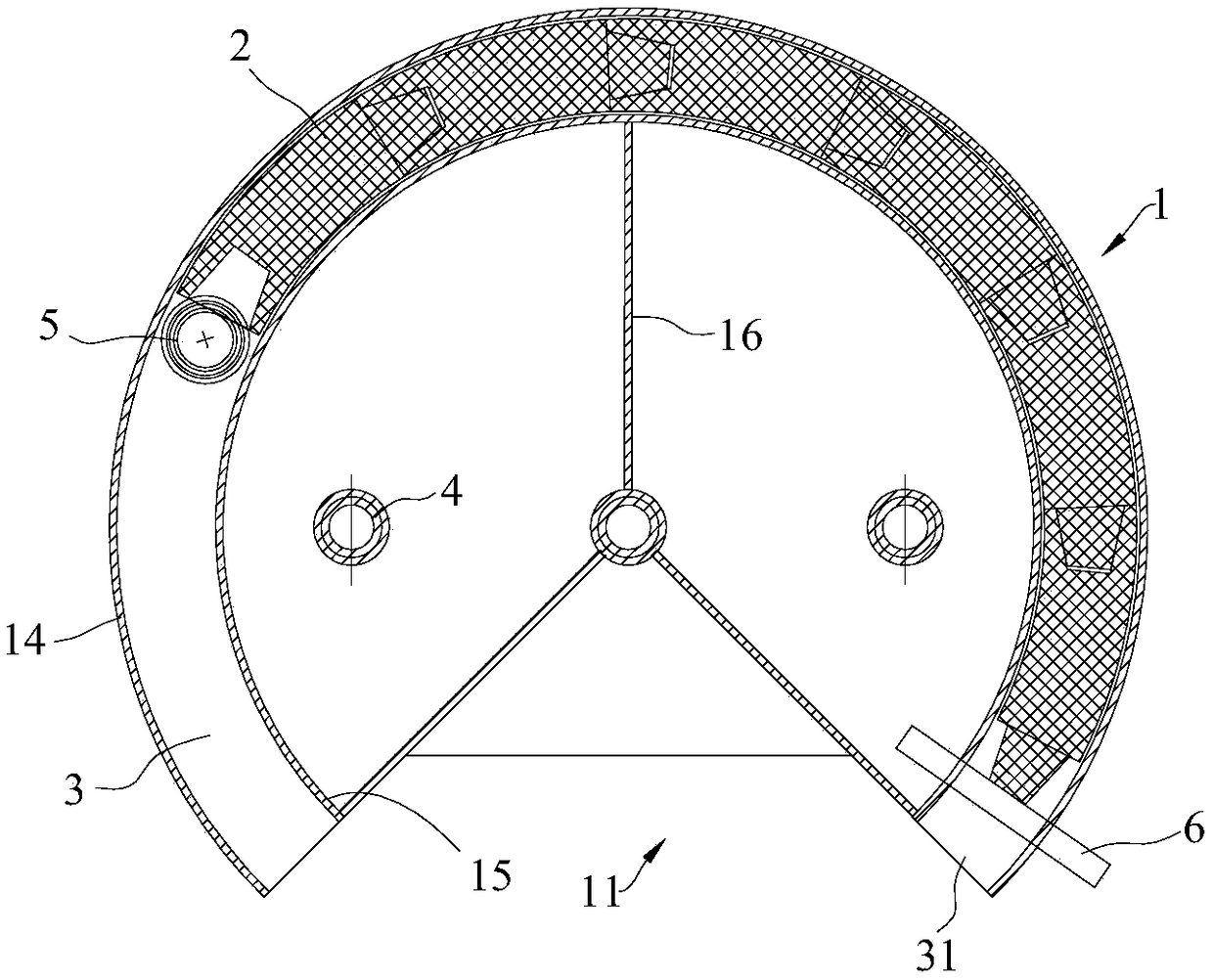

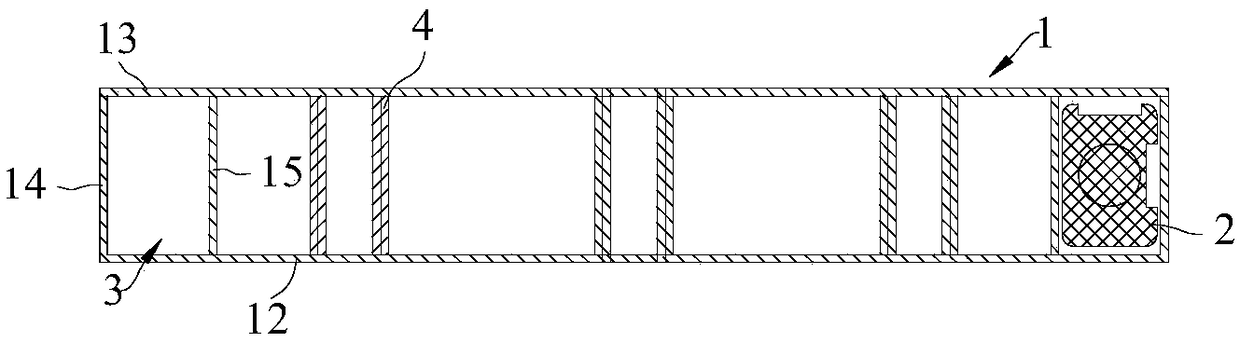

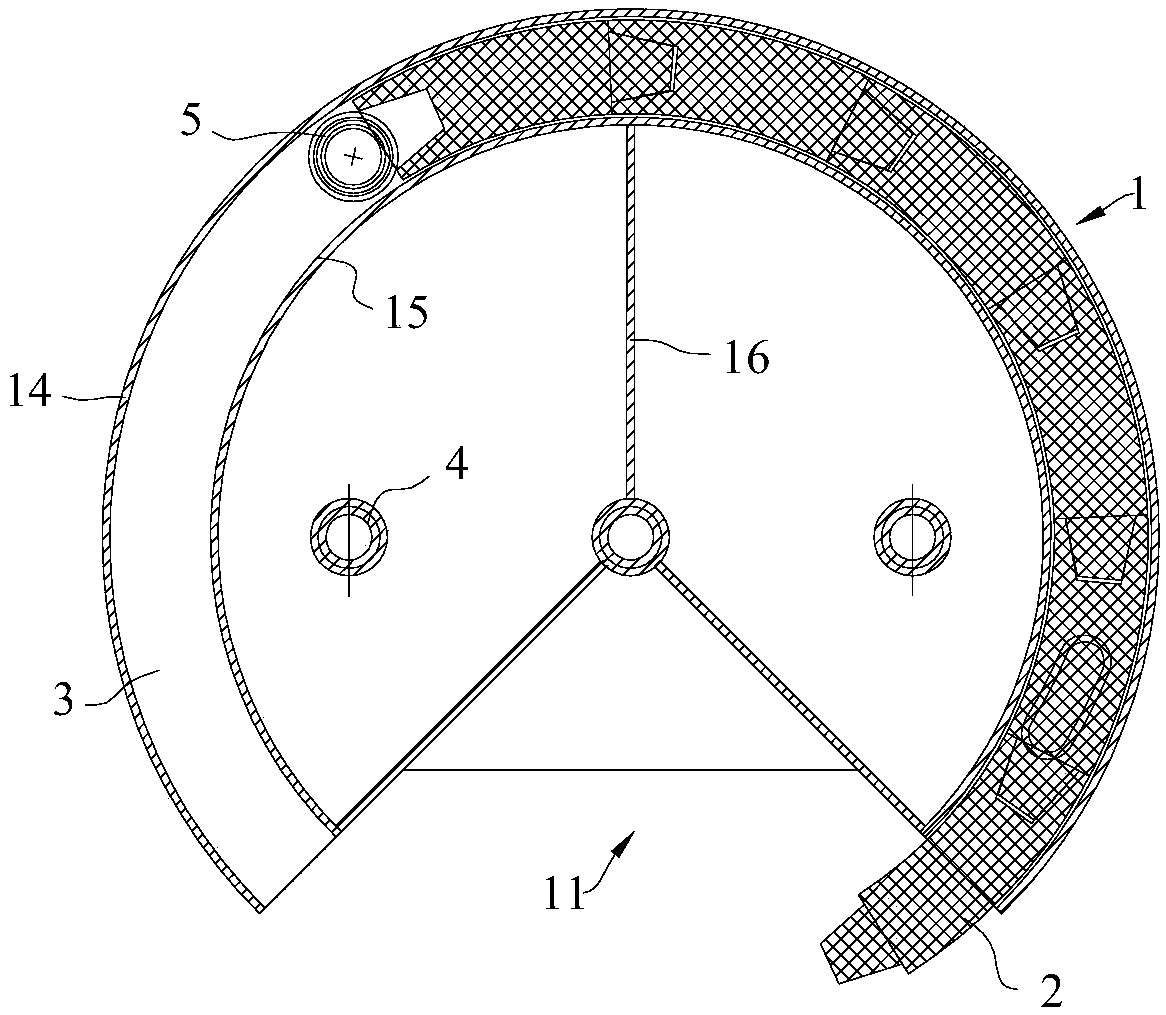

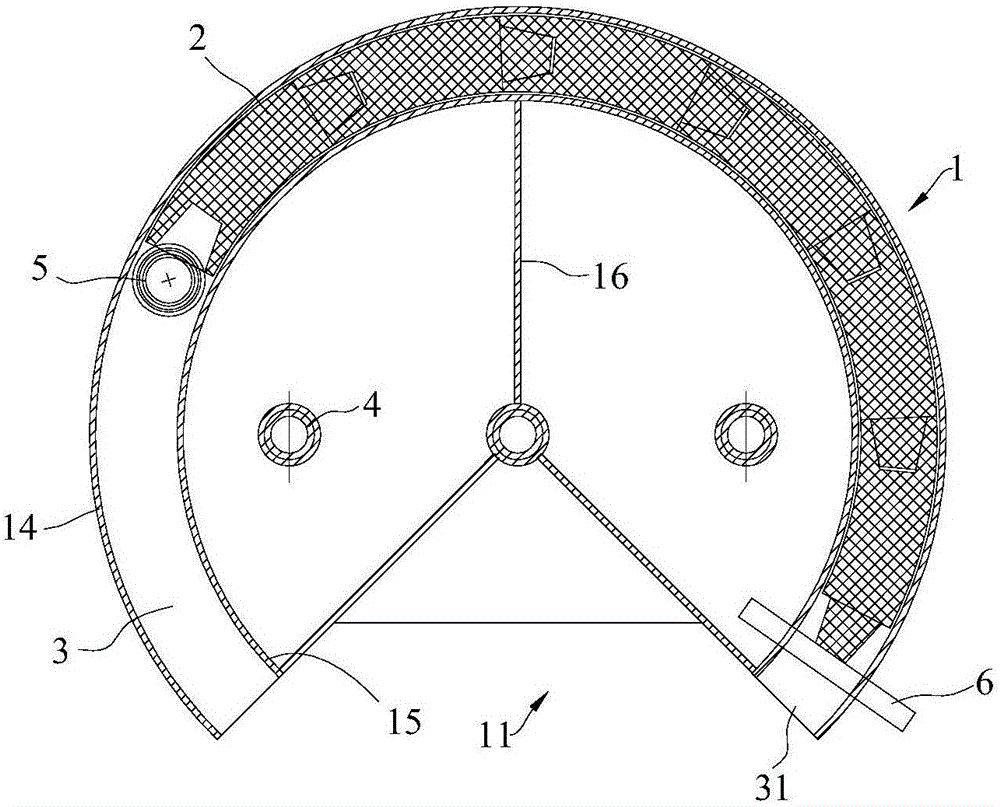

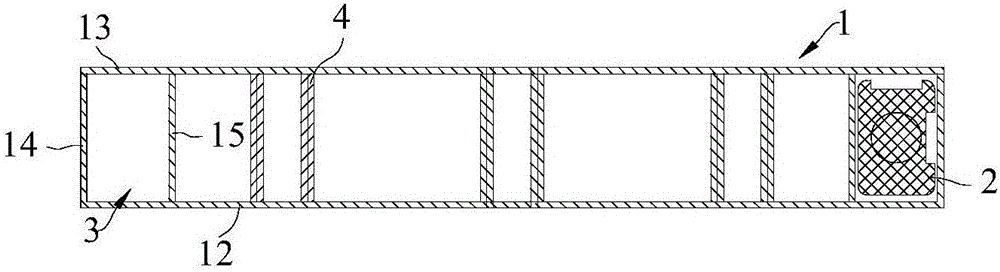

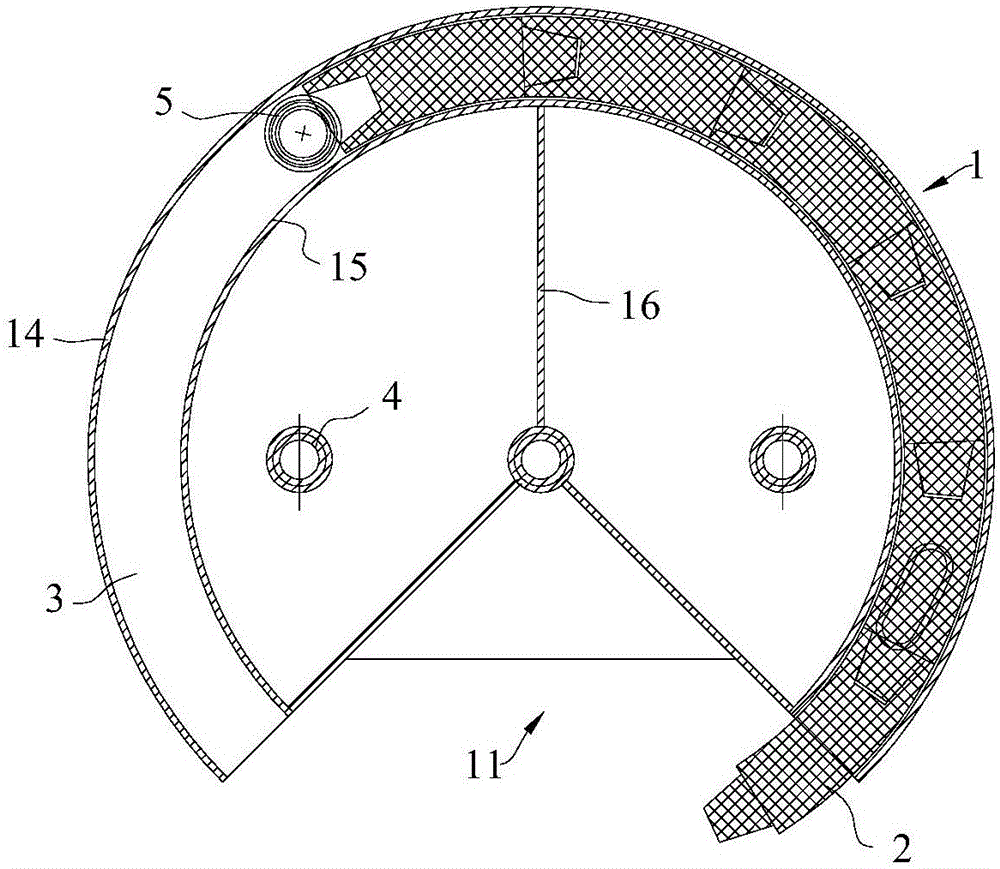

A circular dry wheel-rail lubrication system

ActiveCN106740976BEasy to controlStrong adhesionRail lubricationRail wetting/lubricationFriction effectMechanical engineering

The invention discloses a circular dry lubrication system for wheels and rails, and is applied to the field of lubrication technologies for locomotive wheel sets and rails. The circular dry lubrication system comprises lubrication blocks and a circular box. Each lubrication block is bent towards a side along a center arc to form an arc, a notch is arranged on the box, an annular guide groove for arranging the lubrication blocks is formed in the box and is provided with a lubrication block outlet which is formed in the notch, and a feeding mechanism is arranged in the box and can provide acting force for pushing the lubrication blocks arranged in the annular guide groove out of the lubrication block outlet one by one. The circular dry lubrication system has the advantages that the box can be fixedly mounted on wheel carriers of trains when the circular dry lubrication system is used, the notch of the box directly faces the edges of the wheels of the trains, the lubrication blocks in the box can slide along the annular guide groove under the effect of the feeding mechanism and can be in contact with specified locations of rims of the trains, and constant pressures can be generated; the wheels rotate when the trains run, tangential friction is carried out between the wheels and the lubrication blocks, an extremely thin lubrication film can uniformly cover each rim under friction effects of the corresponding lubrication blocks and the rim, accordingly, wheel-rail friction coefficients can be lowered to a great extent, and abrasion of the wheels and the rails can be reduced.

Owner:GUAGNZHOU WINLANE RUBBER & PLASTIC COMPONENTS

Water-in-water type antibacterial colorful paint and preparation method thereof

ActiveCN106381042BElasticHas the effect of covering cracksAntifouling/underwater paintsPaints with biocidesWater basedAdhesive

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

A system and process for producing flame-retardant oriented strand board

The invention discloses a system and process for producing flame-retardant oriented particle board. The system includes: flaking device, wet flaking conveying device one, wet flaking silo, wet flaking conveying device 2, drying device, dry flaking conveying device 1, screening device, dry flaking silo (including Surface layer dry shaving silo, core layer dry shaving silo), dry shaving transfer device 2, glue mixing device (including surface dry shaving glue mixing device and core layer dry shaving glue mixing device), paving device, Hot pressing device, post-processing device after hot pressing and flame retardant spraying structure. The invention adopts multi-process spraying, the shavings absorb fully, the flame retardant is evenly distributed, and the flame retardant particleboard obtained through the treatment has excellent flame retardant performance.

Owner:湖北宝源木业有限公司

A kind of pickering emulsion polymerization method prepares the method for polyacrylate/nanometer ZNO composite paint printing adhesive

InactiveCN103613700BSmall sizeLarge specific surface areaDyeing processAmmonium sulfateAqueous dispersion

The invention discloses a method for preparing a polyacrylate / nanometer ZnO composite coating printing binder by using a Pickering emulsion polymerization method. The method comprises the steps: mixing nanometer ZnO, allyloxy nonylphenol polyoxyethylene ether ammonium sulfate and water, and then, carrying out uniform ultrasonic treatment by using an ultrasonic pulverizer to obtain an aqueous dispersion of nanometer ZnO and allyloxy nonylphenol polyoxyethylene ether ammonium sulfate; then, adding butyl acrylate and methyl methacrylate into the aqueous dispersion and emulsifying to obtain a Pickering emulsion; carrying out free radical polymerization on the Pickering emulsion by taking ammonium persulfate as an initiator to obtain the polyacrylate / nanometer ZnO composite coating printing binder. By using the method, the defects of hot sticking and cold brittleness of polyacrylate binders can be overcome; after the prepared polyacrylate / nanometer ZnO composite coating printing binder is applied to a fabric coating printing process, the phenomena including mesh clogging and crazing cannot be caused, and a coating printed fabric has favorable color fastness.

Owner:河北汇彩永泰科技有限公司

High-temperature steam endurance ink for spraying code and printing

The invention relates to high-temperature steam endurance ink for spraying code and printing, containing one or more organic solvents, resin and coloring agents. In addition, the consistency of the ink is 2.8-6.2CP / 25DEG C, the conductivity is 500-1,500muS and the surface tension is 27-30Dyn / cm. The high-temperature steam endurance ink for spraying code and printing can be applied to the surfaces of various packaged objects required to be treated at high temperature. The mark and the substrate adopting the high-temperature steam endurance ink have strong adhesive force and favorable adhesiveness and cannot fade, fall off, permeate and shift after being subjected to high-temperature digestion. The dried mark can be also scraped by a cleaning agent.

Owner:北京赛腾标识系统股份公司

Circular dry lubrication system for wheels and rails

ActiveCN106740976AEasy to controlStrong adhesionRail lubricationRail wetting/lubricationFriction effectEngineering

The invention discloses a circular dry lubrication system for wheels and rails, and is applied to the field of lubrication technologies for locomotive wheel sets and rails. The circular dry lubrication system comprises lubrication blocks and a circular box. Each lubrication block is bent towards a side along a center arc to form an arc, a notch is arranged on the box, an annular guide groove for arranging the lubrication blocks is formed in the box and is provided with a lubrication block outlet which is formed in the notch, and a feeding mechanism is arranged in the box and can provide acting force for pushing the lubrication blocks arranged in the annular guide groove out of the lubrication block outlet one by one. The circular dry lubrication system has the advantages that the box can be fixedly mounted on wheel carriers of trains when the circular dry lubrication system is used, the notch of the box directly faces the edges of the wheels of the trains, the lubrication blocks in the box can slide along the annular guide groove under the effect of the feeding mechanism and can be in contact with specified locations of rims of the trains, and constant pressures can be generated; the wheels rotate when the trains run, tangential friction is carried out between the wheels and the lubrication blocks, an extremely thin lubrication film can uniformly cover each rim under friction effects of the corresponding lubrication blocks and the rim, accordingly, wheel-rail friction coefficients can be lowered to a great extent, and abrasion of the wheels and the rails can be reduced.

Owner:GUAGNZHOU WINLANE RUBBER & PLASTIC COMPONENTS

A kind of polypropylene composite material containing aminocarboxylic acid anti-copper agent and preparation method thereof

InactiveCN103554651BDoes not affect insulation propertiesRemarkable anti-copper damage effectPlastic/resin/waxes insulatorsBulk chemical productionAntioxidantCarboxylic acid

Owner:ZHEJIANG EXPO NEW MATERIALS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com