Polypropylene composite material containing alginate-organic phosphonate compound copper ion inhibitor and preparation method of polypropylene composite material

An organic phosphonate and alginate technology, which is applied in the production of organic insulators, plastic/resin/wax insulators, bulk chemicals, etc. Catalytic aging, good oil extraction, and the effect of inhibiting catalytic aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

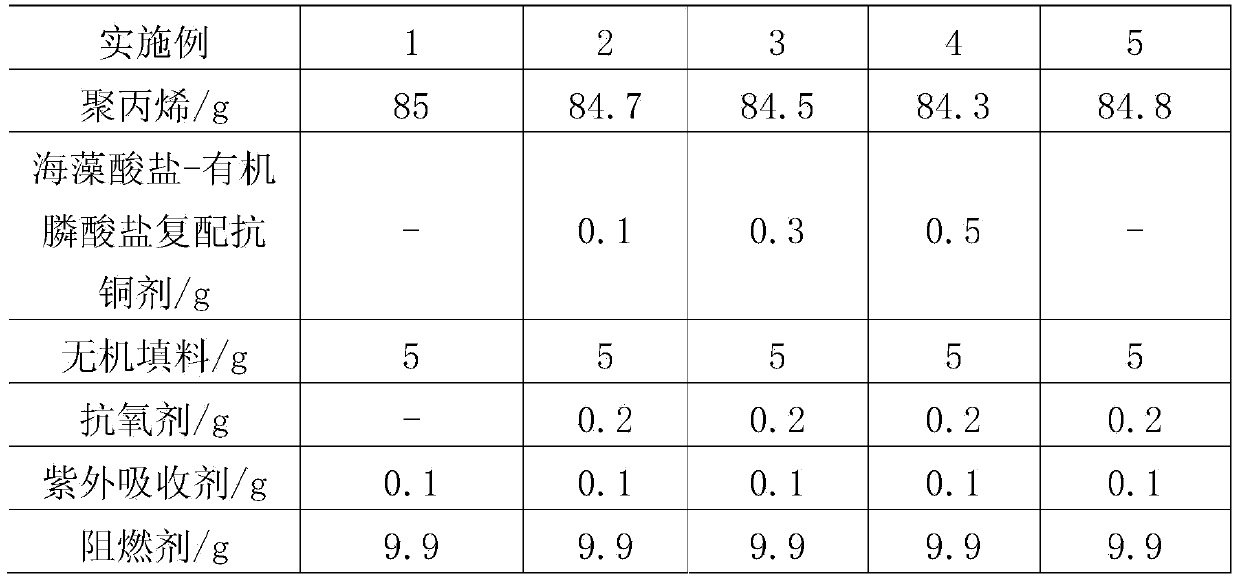

[0024] Step (1). 85g polypropylene, 5g calcium carbonate, 0.1g ultraviolet absorber UV-12, 9.9g flame retardant are mixed into 100g compound;

[0025] Step (2). Add the compound to the twin-screw extruder for extrusion. The processing temperature of the twin-screw extruder is 120°C in the feeding section, 150°C in the plasticizing section, 180°C in the homogenizing section, and the temperature of the head is 180°C ; and then draw in cold water in a water bath at 10° C., the draw ratio is 2 times, and cut and granulate with a cutting machine to obtain a polypropylene composite material.

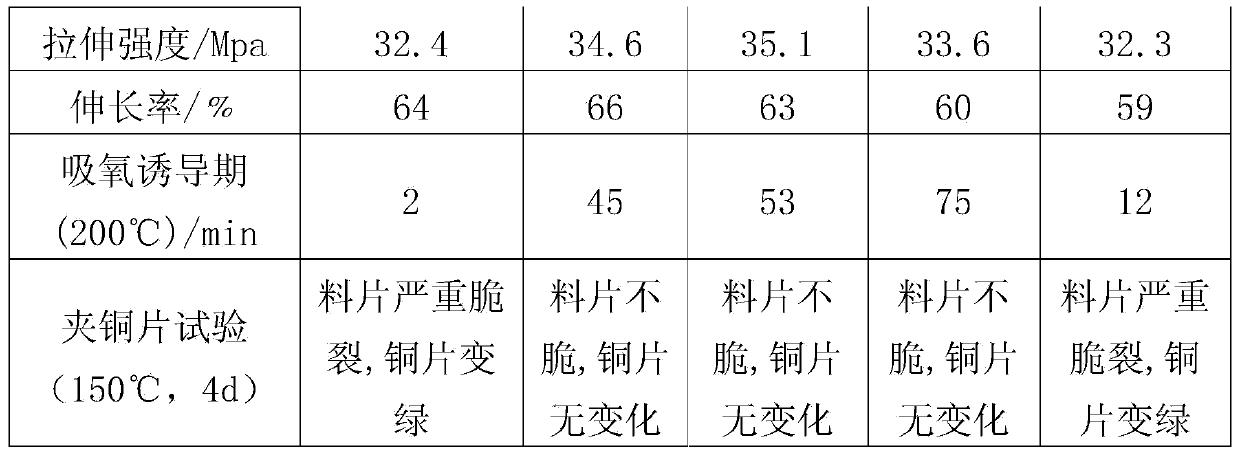

[0026] From Table 1, we can see that the polypropylene composite material prepared in Example 1 has a tensile strength of 32.4 Mpa, an elongation of 64%, an oxygen absorption induction period of 2 min at 200 °C, and a copper clamp test at 150 °C. After 4 days, the tablet was severely brittle and the copper sheet turned green.

Embodiment 2

[0028] Step (1). 84.7g polypropylene, 0.1g alginate-organic phosphonate compound anti-copper agent, 5g calcium carbonate, 0.2g antioxidant 1010, 0.1g ultraviolet absorber UV-12, 9.9g flame retardant The agent is mixed into 100g mixture;

[0029] Step (2). Add the compound to the twin-screw extruder for extrusion. The processing temperature of the twin-screw extruder is 120°C in the feeding section, 150°C in the plasticizing section, 180°C in the homogenizing section, and the temperature of the head is 180°C ; and then draw in cold water in a water bath at 10° C., the draw ratio is 2 times, and cut and granulate with a cutting machine to obtain a polypropylene composite material.

[0030] From Table 1, we can see that the polypropylene composite material prepared in Example 2 has a tensile strength of 34.6 Mpa, an elongation of 66%, an oxygen absorption induction period of 45 min at 200 °C, and a copper clamp test at 150 °C. After 4d, the tablet is not brittle, and the copper ...

Embodiment 3

[0032] Step (1). 84.5g polypropylene, 0.3g alginate-organic phosphonate compound anti-copper agent, 5g calcium carbonate, 0.2g antioxidant 1010, 0.1g ultraviolet absorber UV-12, 9.9g flame retardant The agent is mixed into 100g mixture;

[0033] Step (2). Add the compound to the twin-screw extruder for extrusion. The processing temperature of the twin-screw extruder is 120°C in the feeding section, 150°C in the plasticizing section, 180°C in the homogenizing section, and the temperature of the head is 180°C ; and then draw in cold water in a water bath at 10° C., the draw ratio is 2 times, and cut and granulate with a cutting machine to obtain a polypropylene composite material.

[0034] From Table 1, we can see that the polypropylene composite material prepared in Example 3 has a tensile strength of 35.1Mpa, an elongation of 63%, an oxygen absorption induction period of 53min at 200°C, and a copper clamp test of 4d at 150°C. The back sheet is not brittle, and the copper shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com