Water-in-water type soundproof colorful paint and preparation method thereof

A technology of multi-color paint and water-in-water, which is applied in the direction of multi-color effect paint, coating, polyurea/polyurethane paint, etc., can solve the problems of slow construction speed, high production cost, and containing organic solvents, and achieve low cost and high specific gravity Low, high gloss retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

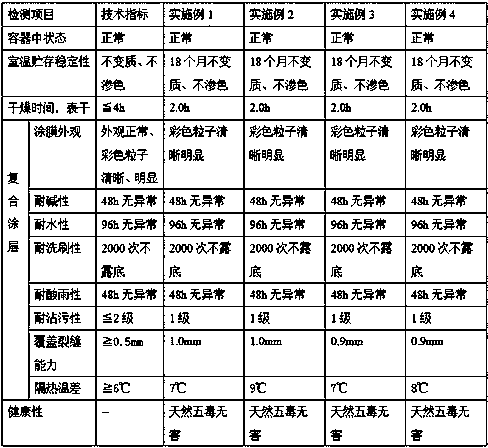

Examples

Embodiment 1

[0038] A water-in-water sound-insulating colorful paint, which is formed in three stages of colloidal solution, granulated base paint and latex finished paint; wherein, in parts by weight,

[0039] The colloid solution is composed of the following raw materials: 1 part of sodium pyrophosphate, 10 parts of lithium magnesium silicate and 90 parts of water;

[0040]The granulated base paint is composed of the following raw materials: 20 parts of polyethylene glycol, 3 parts of polyoxyethylene polyoxypropanolamine ether, 150 parts of water-based elastic polyurethane emulsion, 120 parts of colloidal solution, 30 parts of titanium dioxide, hydroxyethyl 2 parts of cellulose, 10 parts of nano-alumina, 1 part of polyester alcohol and 350 parts of water;

[0041] The latex finished paint is composed of the following raw materials: 100 parts of water-based elastic polyurethane emulsion, 10 parts of propylene glycol, 2 parts of slag fiber, 3 parts of mineral fiber, 520 parts of particle-m...

Embodiment 2

[0049] A water-in-water sound-insulating colorful paint, which is formed in three stages of colloidal solution, granulated base paint and latex finished paint; wherein, in parts by weight,

[0050] The colloidal solution is composed of the following raw materials: 5 parts of sodium pyrophosphate, 5 parts of lithium magnesium silicate and 100 parts of water;

[0051] The granulated base paint is composed of the following raw materials: 10 parts of polyethylene glycol, 8 parts of polyoxypropylene glyceryl ether, 50 parts of water-based elastic polyurethane emulsion, 150 parts of colloidal solution, 10 parts of titanium dioxide, 30 parts of environmentally friendly inorganic pigments, carboxylate 5 parts of methyl cellulose, 5 parts of nano magnesium oxide, 10 parts of polyvinyl alcohol and 350 parts of water;

[0052] The environment-friendly inorganic pigment is titanium nickel yellow;

[0053] The latex finished paint is composed of the following raw materials: 100 parts of w...

Embodiment 3

[0061] A water-in-water sound-insulating colorful paint, which is formed in three stages of colloidal solution, granulated base paint and latex finished paint; wherein, in parts by weight,

[0062] The colloidal solution is composed of the following raw materials: 3 parts of sodium pyrophosphate, 6 parts of lithium magnesium silicate and 95 parts of water;

[0063] The granulated base paint is composed of the following raw materials: 15 parts of polyethylene glycol, 5 parts of polyoxypropylene glyceryl ether, 100 parts of water-based elastic polyurethane emulsion, 130 parts of colloidal solution, 20 parts of titanium dioxide, 15 parts of environmentally friendly inorganic pigments, carboxyl 3 parts of methyl cellulose, 8 parts of nano-titanium oxide, 5 parts of polyvinyl alcohol and 325 parts of water;

[0064] The environmentally friendly inorganic pigments are titanium nickel yellow, iron zinc chrome brown, cobalt green and cobalt blue with a mass ratio of 1:1:1:1;

[0065]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com