Metal ageing resisting type enhanced nylon material and preparation method thereof

A technology of nylon and metal, which is applied in the field of preparation of metal aging-resistant reinforced nylon materials, to achieve the effects of good compatibility, good oil extraction and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

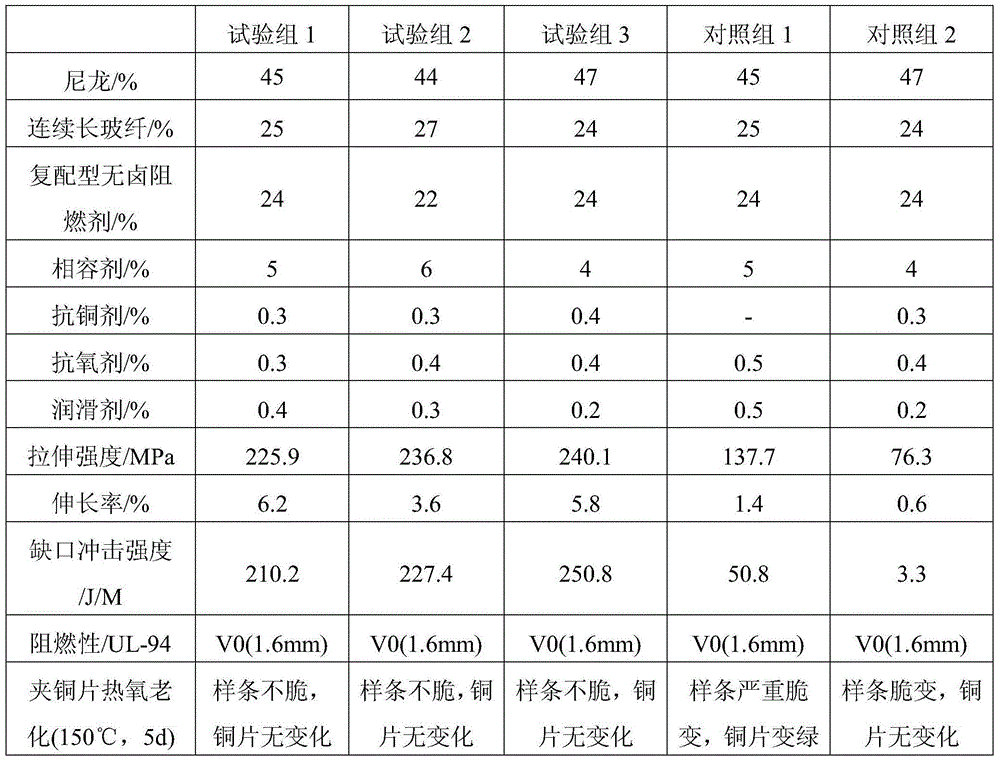

Embodiment 1

[0022] Example 1 Preparation of a Metal Aging Resistant Reinforced Nylon Material of the Present Invention (1)

[0023] The raw materials were weighed according to the following weight ratio: 45% nylon, 25% continuous long glass fiber, 24% compound halogen-free flame retardant, 0.3% antioxidant, 0.3% anti-copper agent, 5% compatibilizer, Lubricant 0.4%.

[0024] Add nylon, compound type halogen-free flame retardant, antioxidant, anti-copper agent and compatibilizer into the three-screw extruder in proportion. The body is calendered and infiltrated into the mold, the mold temperature is 280°C, and the temperature of the three-screw extruder is 270°C; then the continuous long glass fiber is drawn into the mold at a speed of 150m / min, and the length of the mold is 4m. After full calendering and infiltration, cool , pelletized, you can get metal aging-resistant reinforced nylon material.

Embodiment 2

[0025] Example 2 Preparation of a Metal Aging Resistant Reinforced Nylon Material of the Present Invention (2)

[0026] The raw materials were weighed according to the following weight ratio: nylon 49%, continuous long glass fiber 23%, compound halogen-free flame retardant 22%, antioxidant 0.3%, anti-copper agent 0.3%, compatibilizer 5%, Lubricant 0.4%.

[0027] Add nylon, compound type halogen-free flame retardant, antioxidant, anti-copper agent and compatibilizer into the three-screw extruder in proportion. The body is calendered and infiltrated into the mold, the temperature of the mold is 270°C, and the temperature of the three-screw extruder is 270°C; then the continuous long glass fiber is drawn into the mold at a speed of 130m / min, and the length of the mold is 4m. After full calendering and infiltration, cool , pelletized, you can get metal aging-resistant reinforced nylon material.

Embodiment 3

[0028] Example 3 Preparation of a Metal Aging Resistant Reinforced Nylon Material of the Present Invention (3)

[0029] The raw materials were weighed according to the following weight ratio: 44% nylon, 27% continuous long glass fiber, 22% compound halogen-free flame retardant, 0.4% antioxidant, 0.3% anti-copper agent, 6% compatibilizer, Lubricant 0.3%.

[0030] Add nylon, compound type halogen-free flame retardant, antioxidant, anti-copper agent and compatibilizer into the three-screw extruder in proportion. The body is calendered and infiltrated into the mold, the temperature of the mold is 300°C, and the temperature of the three-screw extruder is 280°C; then the continuous long glass fiber is drawn into the mold at a speed of 150m / min, and the length of the mold is 5m. After full calendering and infiltration, cool , pelletized, you can get metal aging-resistant reinforced nylon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com