New fire retardant aluminium crystal whisker and its production process

A new type of aluminum-based technology, applied in the direction of fire-resistant coatings, etc., can solve the problems of poor compatibility between inorganic flame-retardant whiskers and polymers, few types of flame-retardant gases released, and small whisker length/diameter ratio, etc., to achieve good Smoke suppression effect, low toxicity, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

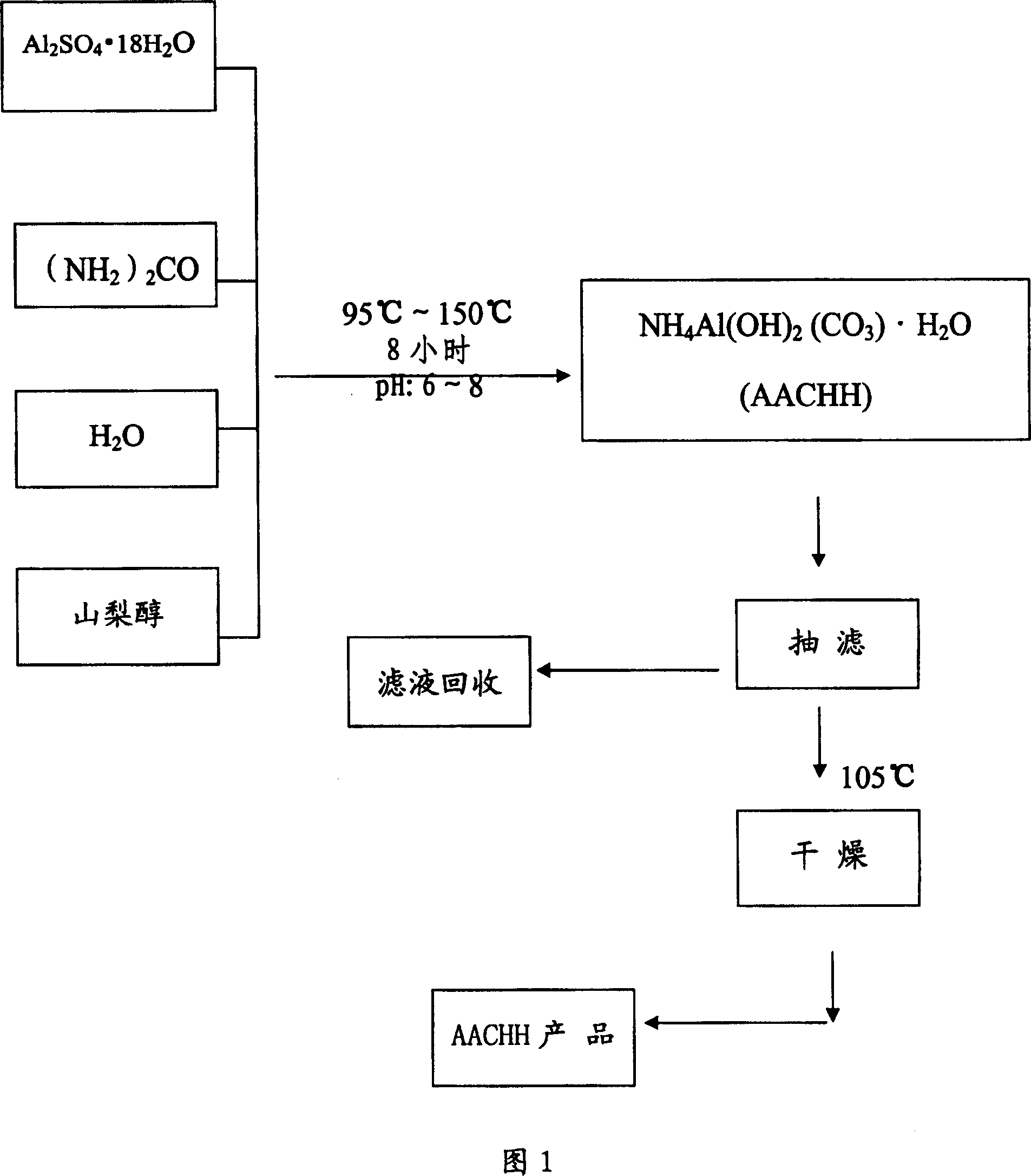

[0013] Add 1Kg Al 2 SO 4 18H 2 O and 0.254Kg urea (NH 2 ) 2 CO as raw material, add 1.1Kg water H 2 O and 0.038Kg template agent sorbitol, mix evenly, adjust the pH value to 6 with nitric acid, put the mixed solution in an autoclave, heat to 95°C-100°C, and react for 8 hours to obtain the crystal NH 4 Al(OH) 2 (CO 3 )·H 2 O, after washing with water and suction filtration, the filtrate is recycled, and the filter cake is dried at a temperature of 105°C to finally obtain 0.66Kg of novel aluminum-based flame-retardant whiskers (AACHH).

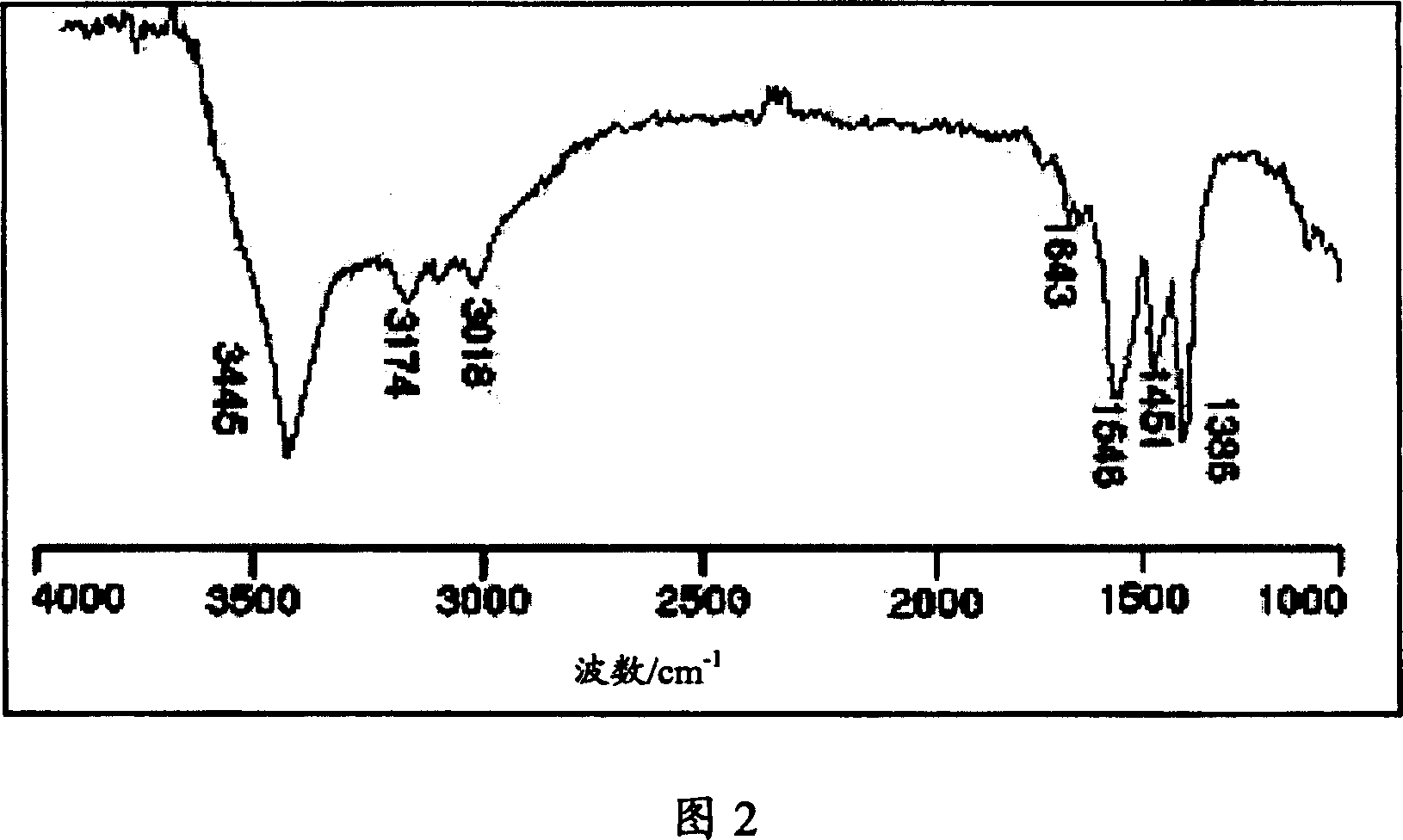

[0014] The infrared spectrum of the obtained novel aluminum-based flame-retardant whisker (AACHH) is shown in FIG. 2 .

[0015] In the figure, there are obviously three kinds of anionic groups, among which 3445cm -1 is the structural hydroxyl group (OH -1 ) symmetrical stretching vibration; 3018~3174cm -1 is the amine group (NH 4 + ), the symmetrical stretching vibration of ), 1386cm -1 is the amine group (NH 4 + ) asymmetric str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com