High-temperature steam endurance ink for spraying code and printing

A technology of steaming ink and high temperature resistance, which is applied in the direction of ink, application, household utensils, etc., can solve the problems of fading, penetration, falling off, etc., and achieve the effect of strong adhesion and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

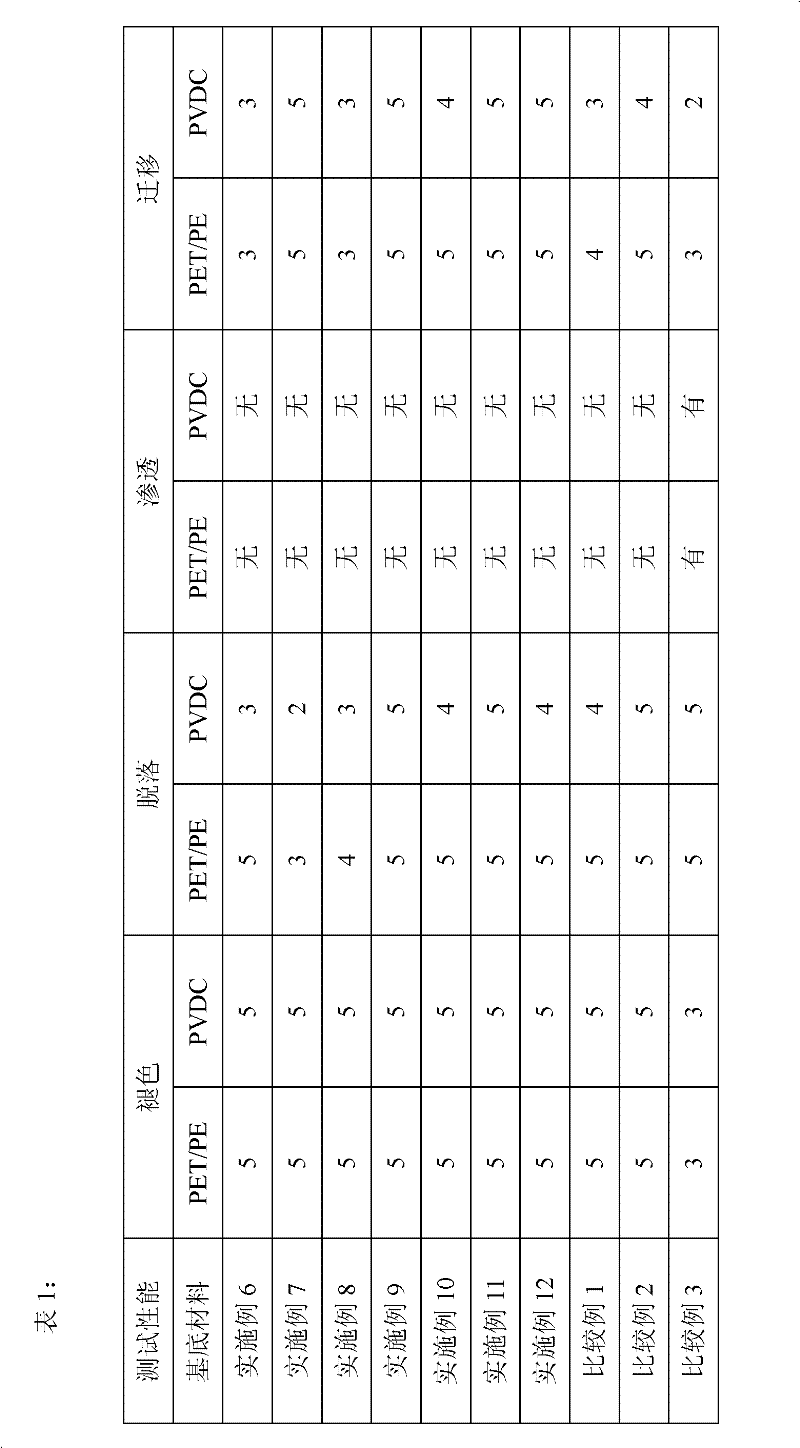

Examples

Embodiment 1

[0027] The present embodiment provides a kind of pigment slurry, and it has following composition (taking the gross weight of pigment slurry as 100%):

[0028] NeoCryl B-890 Acrylic Resin 32

[0029] SOLSPACE 28000 wetting and dispersing agent 8

[0030] MA100 carbon black 16

[0031] Butanone 40

[0032] Ethylene glycol butyl ether 4

[0033] Wherein, the Mw of the acrylic resin used is 12500, and the Tg is 85°C.

[0034] Preparation process: mix the above ingredients according to the proportion, and use a sand mill to grind 1mm glass beads until the particle size of the pigment is less than 1 micron to obtain the pigment slurry 1.

Embodiment 2

[0036] The present embodiment provides a kind of pigment slurry, and it has following composition (taking the gross weight of pigment slurry as 100%):

[0037] KC-101 aldehyde and ketone resin 32

[0038] IRGALITE Yellow B3RN 20

[0039] (C.I Pigment Yellow 83, Ciba Company)

[0040] BYK-161 wetting and dispersing additive 10

[0041] Butanone 34

[0042] Ethylene glycol butyl ether 4

[0043] Preparation process: mix the above ingredients according to the proportion, and use a sand mill to grind the pigment with 1 mm glass beads until the particle size of the pigment is less than 1 micron to obtain the pigment slurry II.

Embodiment 3

[0045] The present embodiment provides a kind of pigment slurry, and it has following composition (taking the gross weight of pigment slurry as 100%):

[0046] BL18 polyvinyl butyral resin 20

[0047] R930 titanium dioxide 20

[0048] BYK-110 wetting and dispersing additive 6

[0049] Butanone 30

[0050] N-methylpyrrolidone (N-methyl 2-pyrrolidone) 3

[0051] Ethanol 20

[0053] Preparation process: mix the above-mentioned ingredients according to the proportion, and use a sand mill to grind the pigment with 1 mm glass beads until the particle size of the pigment is less than 1 micron, and obtain the pigment slurry 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com