Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Control the degree of oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

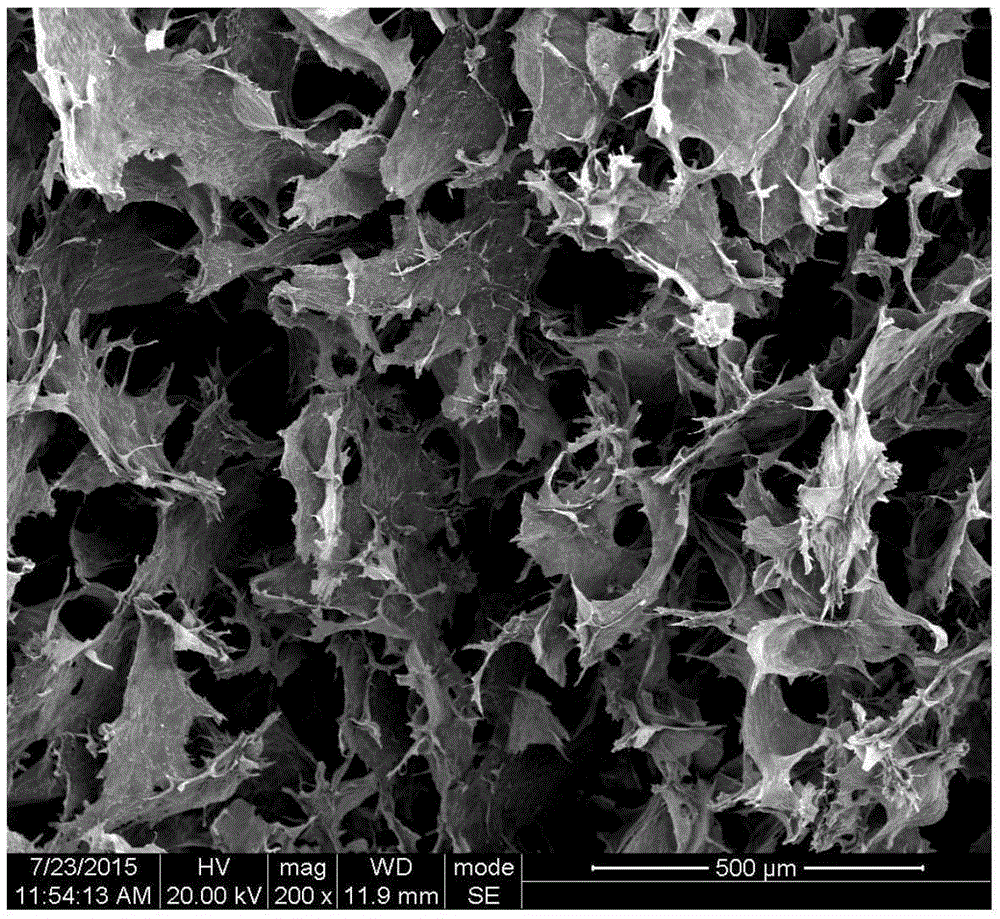

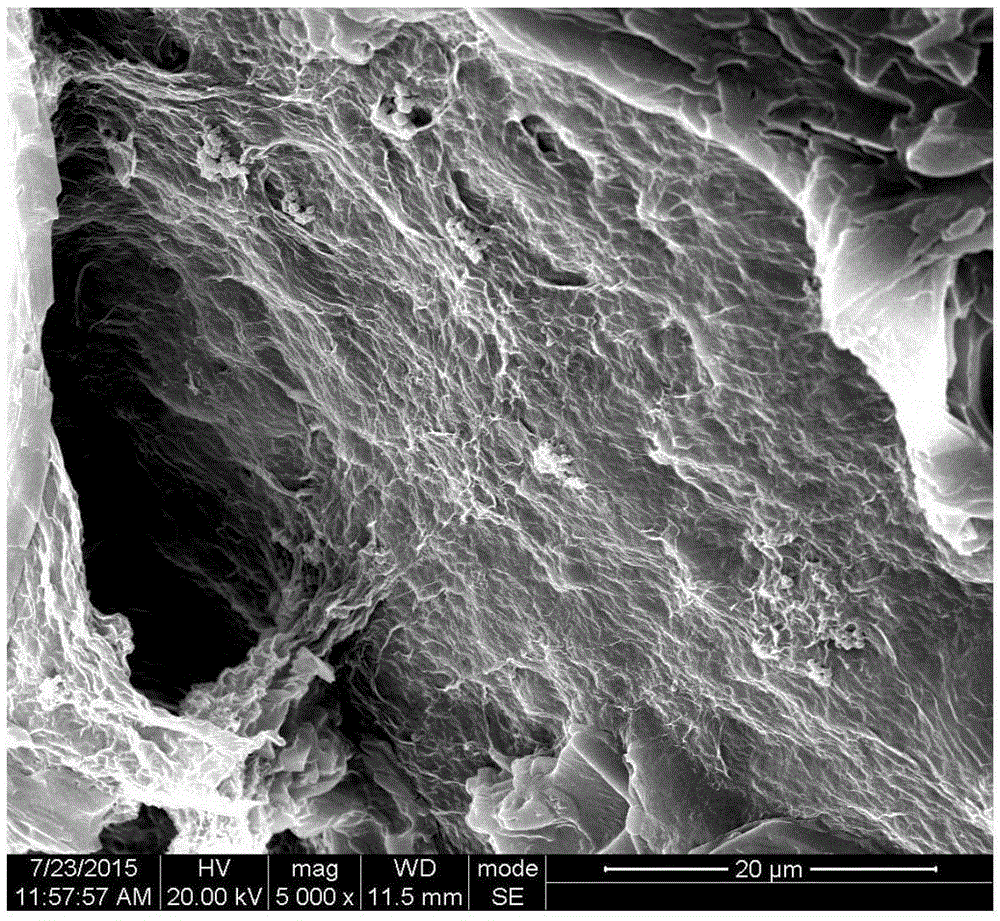

Preparation method for oxidized graphene-poly-dopamine composite aerogel

InactiveCN105254916AIntegrity guaranteedGuaranteed stabilityOther chemical processesAlkali metal oxides/hydroxidesPorosityFreeze-drying

The invention provides a preparation method for oxidized graphene-poly-dopamine composite aerogel. The preparation method comprises the following steps that 1, 0.15-0.7 g of dopamine powder is dissolved in 10-18 ml of distilled water, the dopamine aqueous solutions are mixed with 50-60 ml of oxidized graphene aqueous solutions with the concentration of 5-6 mg / ml, and stirring is performed to obtain oxidized graphene-dopamine mixed solutions; 2, 3-9 ml of tris aminomethane buffer solutions with the concentration of 0.1-0.12 mol / L are dropwise added into the mixed solutions while stirring is performed, stirring is continuously performed for 2-2.5 h, and standing is performed to enable the dopamine to be fully polymerized to obtain oxidized graphene-poly-dopamine composite aquogel; 3, after being placed in an environment with the temperature ranging from minus 20 DEG C to minus 10 DEG C to be frozen for 24-30 h, the composite aquogel is processed through freeze drying, and then the oxidized graphene-poly-dopamine composite aerogel is obtained. The method is simple in technology, and the prepared composite aerogel has the advantages of being high in porosity, excellent in adsorptivity, high in strength and the like.

Owner:SOUTHWEST JIAOTONG UNIV

Method for manufacturing silicon carbide ceramic parts through power injection molding (PIM)

InactiveCN102172959AFast degreasing rateReduced heating equipment requirementsCeramic shaping apparatusPower injectionOxide

The invention discloses a method for manufacturing silicon carbide ceramic parts through power injection molding (PIM), belonging to the field of manufacturing the silicon carbide ceramic products and aiming at solving the technical problems that the existing method is long in debinding time and high in pre-sintering temperature, and has high requirement for heating equipment, and the like. The method disclosed by the invention comprises the steps as follows: 1. adding silicon carbide ceramic powder and an oxide sintering additive in a mixer for heating, adding a binder for mixing, and pelleting to obtain a feed; 2. adding the feed in an injection-molding machine for injection molding to obtain injection blanks; 3. putting an injection-molded parts green body in an air furnace for thermal debinding and pre-sintering, and cooling along with the furnace to obtain blanks; and 4. insulating and sintering the blanks, thus obtaining the silicon carbide ceramic products. With the method, the debinding speed is fast, the parts blanks obtained at the lower pre-sintering temperature have enough strength so as to meet the transportation demand, the requirement of the process on the heating equipment is lowered, the molding efficiency is improved, and the production cost is lowered; and the method is applicable to pure carbonization and injection molding of silicon carbide taking an oxide as a sintering additive.

Owner:中硼科技(大连)有限公司

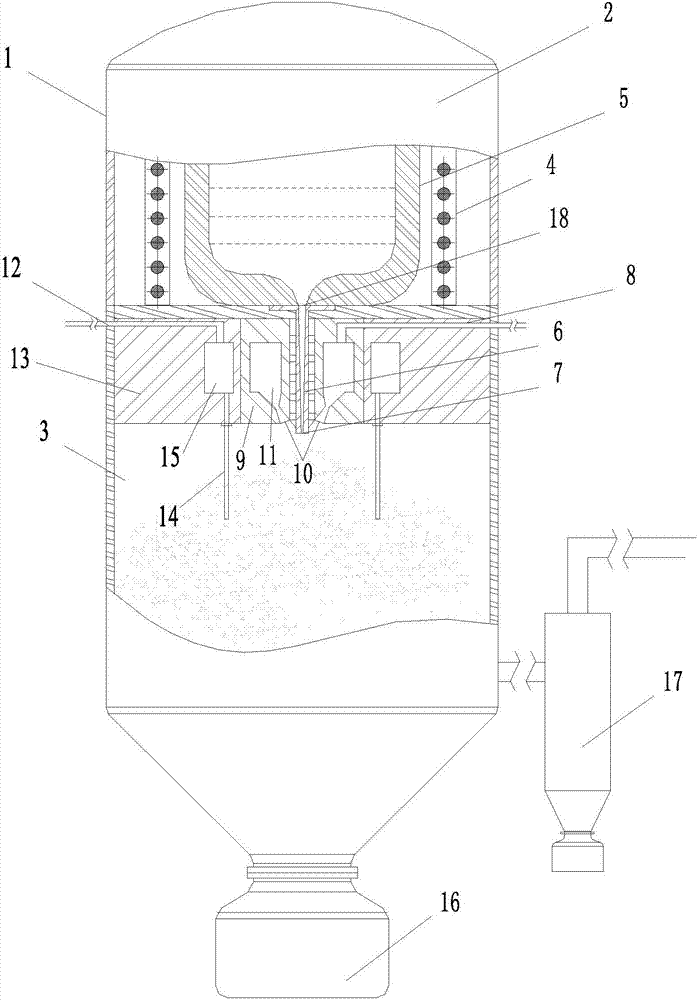

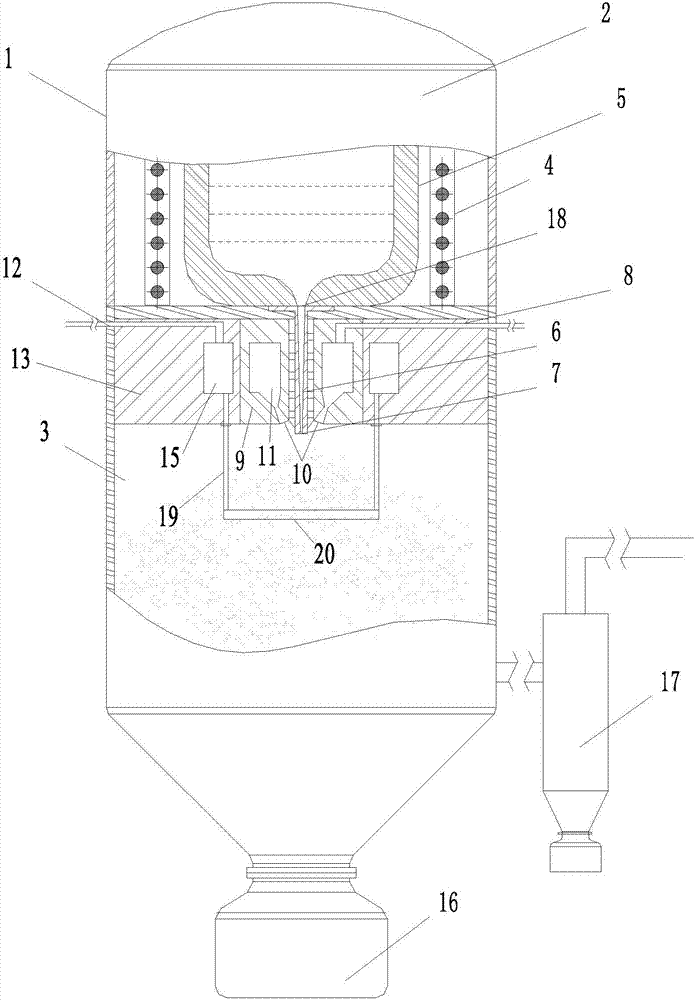

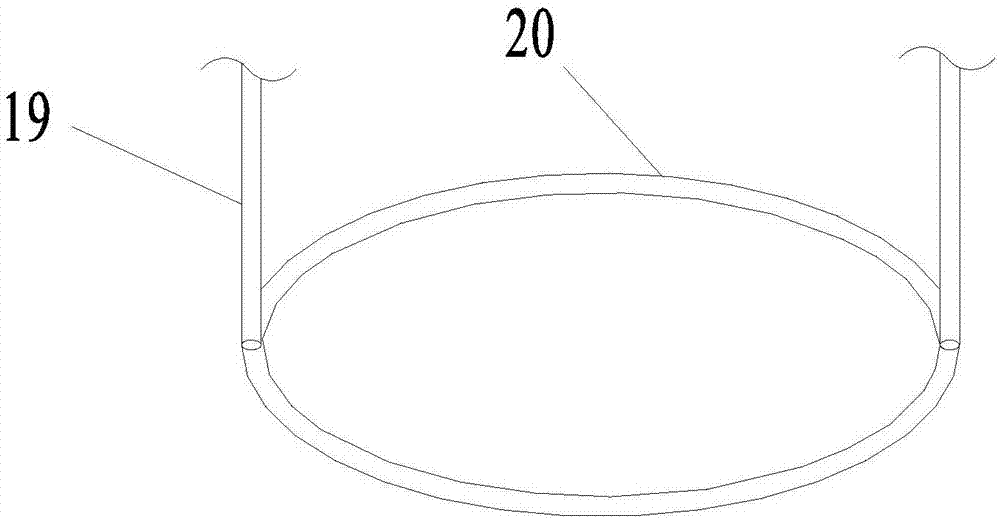

Atomization device for preparing alloy metal powder

PendingCN107377983AReduce stickingInhibition formationDispersed particle filtrationTransportation and packagingIndiumOxygen

The invention discloses an atomization device for preparing alloy metal powder. The atomization device comprises a body. A vacuum melting chamber and an atomization chamber are sequentially arranged in the body from top to bottom. A melting device and a heating device are arranged in the vacuum melting chamber. The heating device heats the melting device. The melting device comprises a liquid outlet. The liquid outlet communicates with the top of the atomization chamber through a diversion pipe. A gas spray nozzle is arranged in the atomization chamber and is connected with high-pressure inert gas through a pipeline. The gas spray nozzle sprays the high-pressure inert gas towards an outlet of the diversion pipe. An oxygen-containing gas pipeline and a gas inlet device connected with the oxygen-containing gas pipeline are arranged in the atomization chamber. The oxygen-containing gas pipeline conveys oxygen-containing gas into the atomization chamber through the gas inlet device. By means of the atomization device, the surface of the alloy metal powder can be passivated in the atomization process, and therefore the sphericity degree of copper, indium and gallium alloy powder and the phenomenon of the strong adhesion among the powder are controlled.

Owner:DONGJUN NEW ENERGY CO LTD

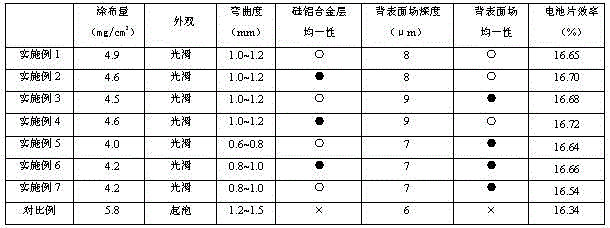

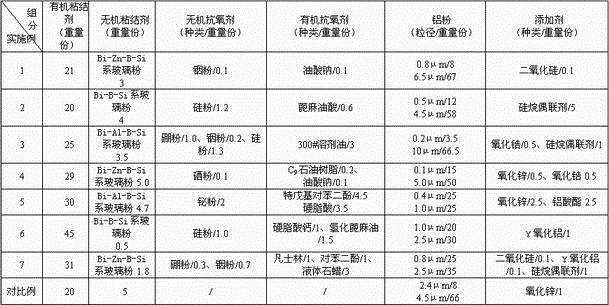

Aluminum paste for silicon solar cell

InactiveCN103065701AReduce the degree of oxidationImprove conversion efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesAntioxidantBack surface field

Provided is an aluminum paste for a silicon solar cell. The aluminum paste comprises, by composition and weight, 50 to 75 parts of aluminum powder, 20 to 45 parts of organic binder, 0.5 to 5 parts of inorganic binder, 0.1 to 5 parts of additive and 0.2 to 10 parts of antioxidants. The antioxidants are composition of inorganic antioxidants and organic antioxidants, and the weight ratio of the inorganic antioxidants and the organic antioxidants is 1:0.5 to 5.0. A product manufactured by the aluminum paste for the silicon solar cell is good in sintering adaptability, and a formed aluminum electrode is smooth in surface, and has no problems of aluminum blisters and ash generating. The aluminum paste for the silicon solar cell is particularly suitable for P-type silicon solar cell materials, a formed back surface field is deep and even, a manufactured cell piece is small in bending degree, a fragment rate is low, and photoelectric conversion efficiency is high.

Owner:乐凯胶片股份有限公司

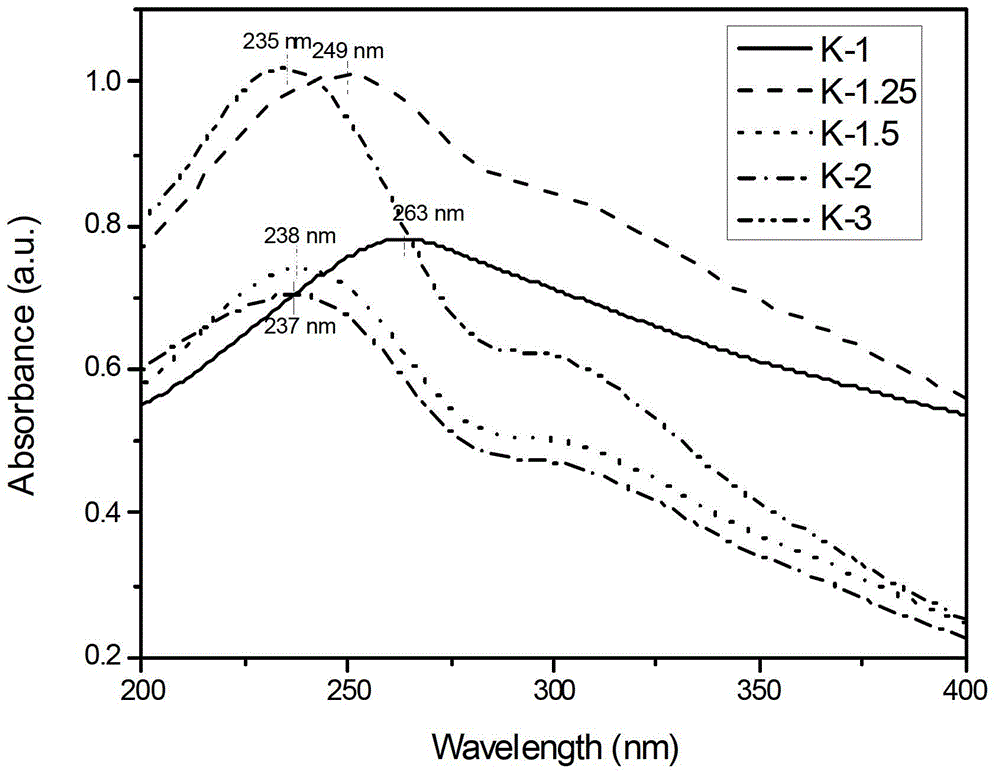

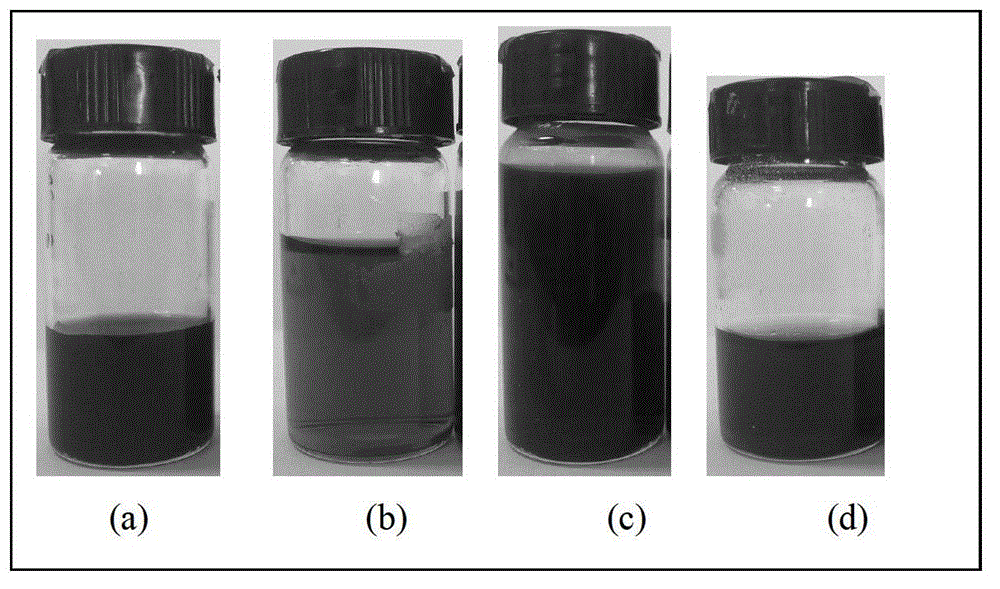

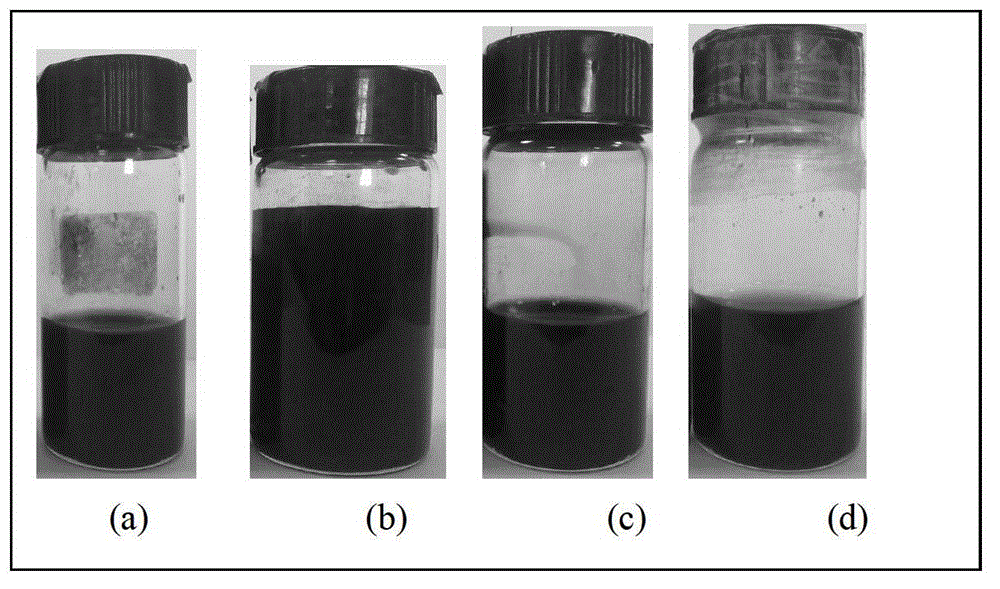

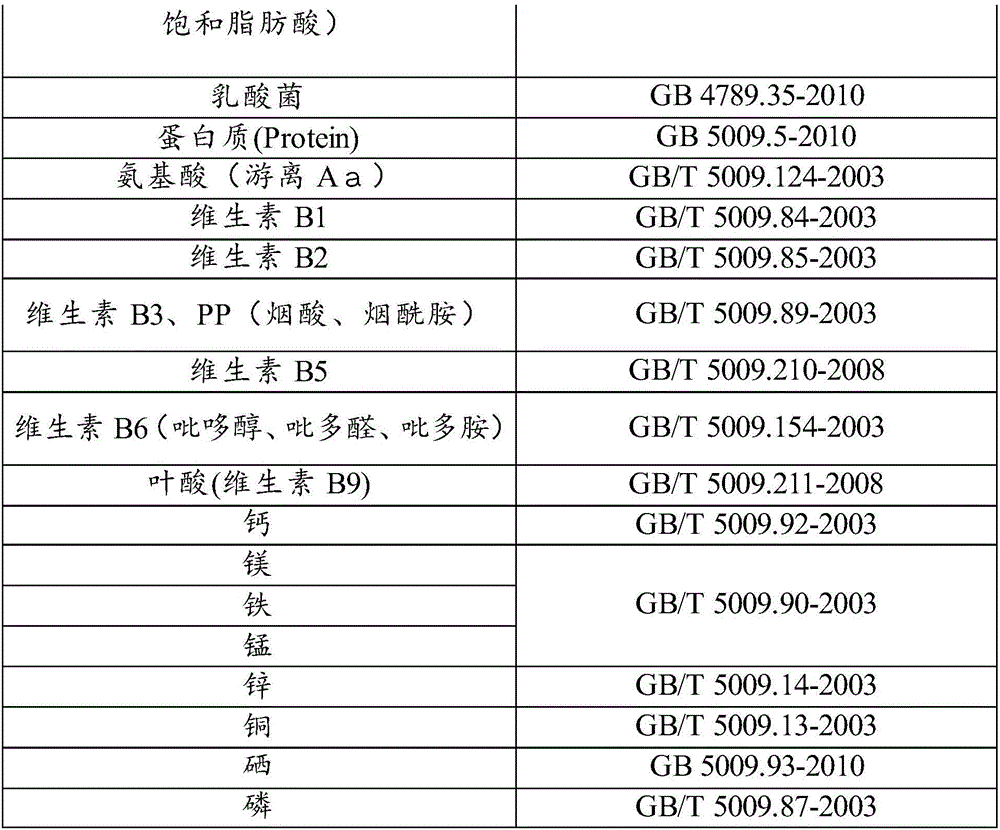

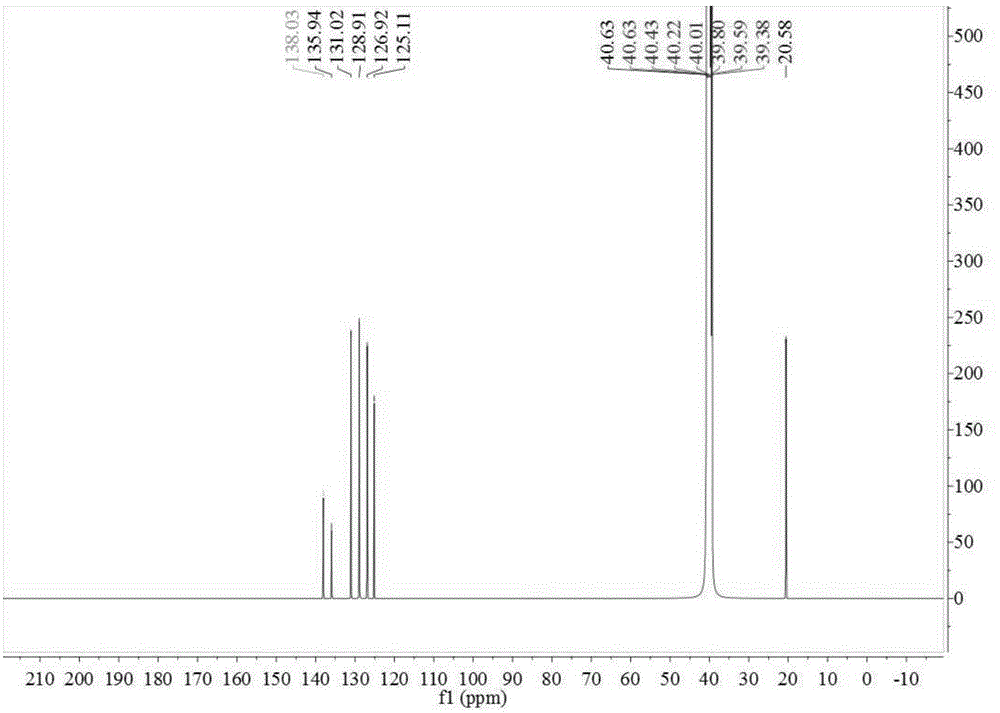

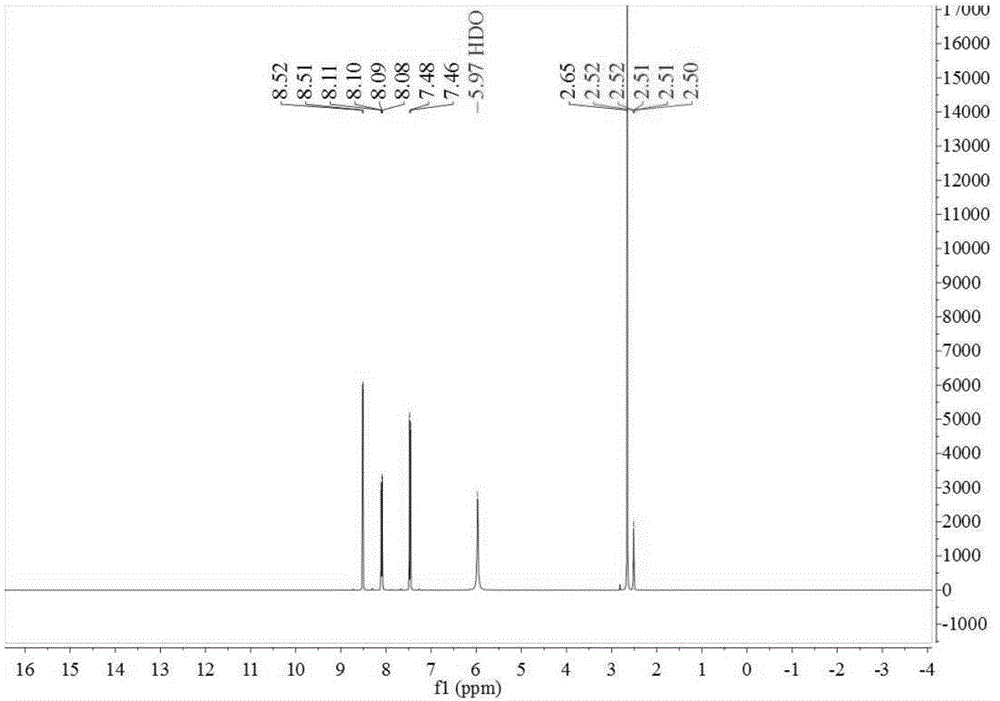

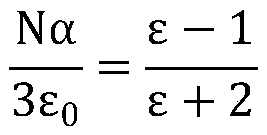

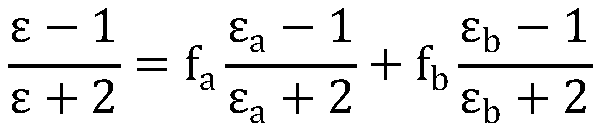

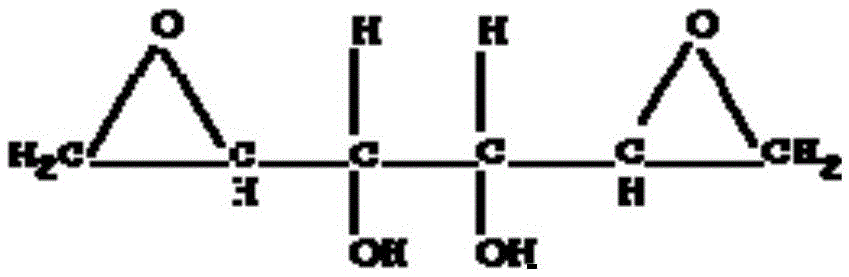

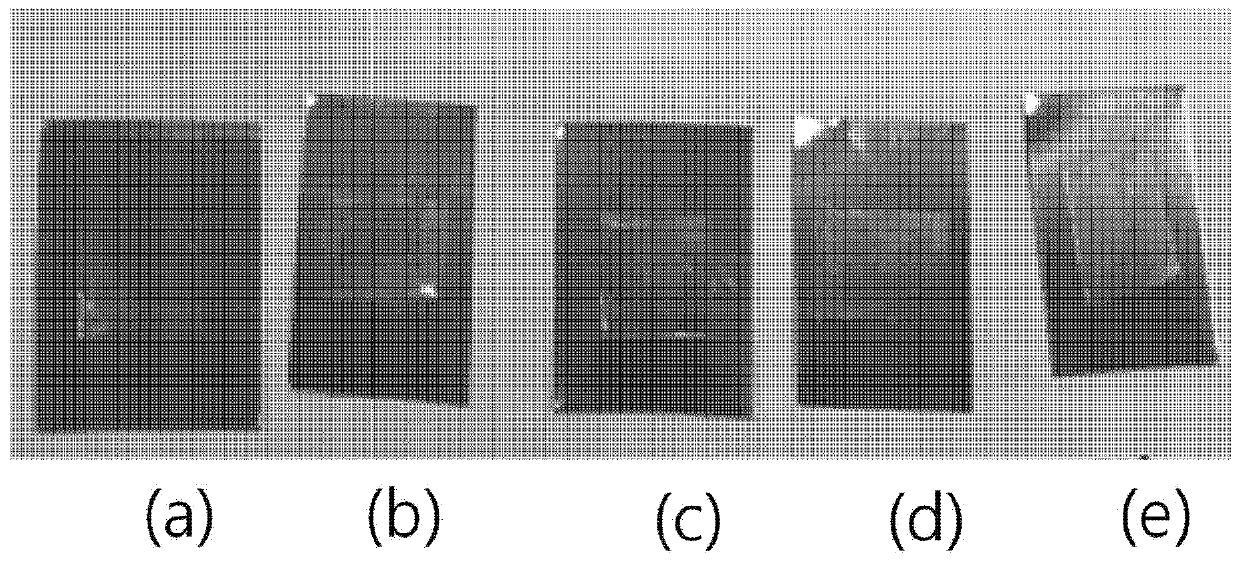

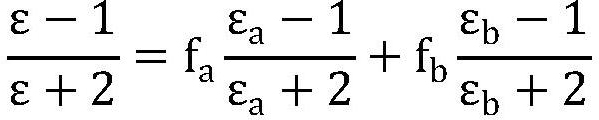

Organic thermoelectric material based on poly[Kx(Ni-ett)], preparing method for organic thermoelectric material and application of organic thermoelectric material

ActiveCN104241515AControl the degree of oxidationEasy to processThermoelectric device manufacture/treatmentThermoelectric device junction materialsPower factorCoordination polymerization

The invention discloses an organic thermoelectric material based on poly[Kx(Ni-ett)], a preparing method for the organic thermoelectric material and application of the organic thermoelectric material. The preparing method comprises the steps of dissolving potassium methoxide and 1,3,4,6-tetrathiapentalene-2,5-dione in methyl alcohol, stirring the materials in the normal temperature, then adding nickel chloride, stirring the materials in the normal temperature, filtering the materials, transferring filter liquor into an electrolytic tank and using an electrochemical constant-potential oxidizing method to adjust oxidization coordination polymerization of the poly[Kx(Ni-ett)] to obtain the organic thermoelectric material. After being subjected to different oxidation potentials, the thermoelectric performance of the material is obviously changed. When the oxidation potential is 1.6V, the power factor of the material can reach 38muW / mK2, and higher thermoelectric performance can be obtained. Meanwhile, the power factor of the film material can reach 311muW / mK2 in the room temperature, and the higher thermoelectric performance can be achieved. The film formation, the insolubility and the infusibility of the film material are favorable of the processing of thermoelectric devices and improvement of the stability. Thus, the organic thermoelectric material has good application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

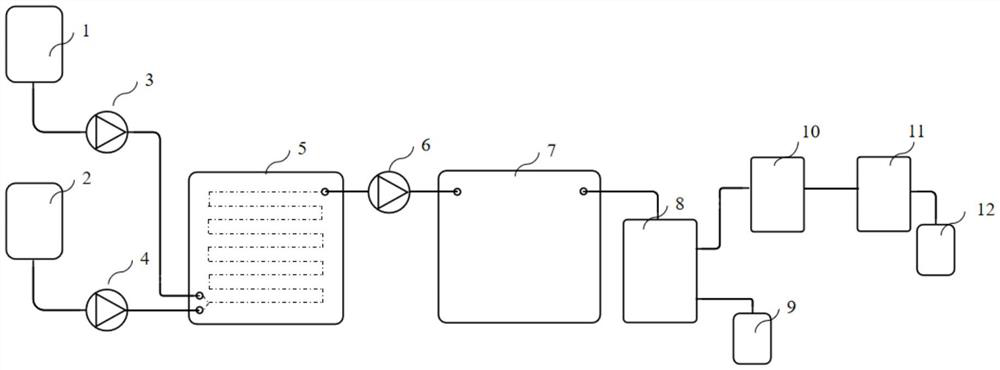

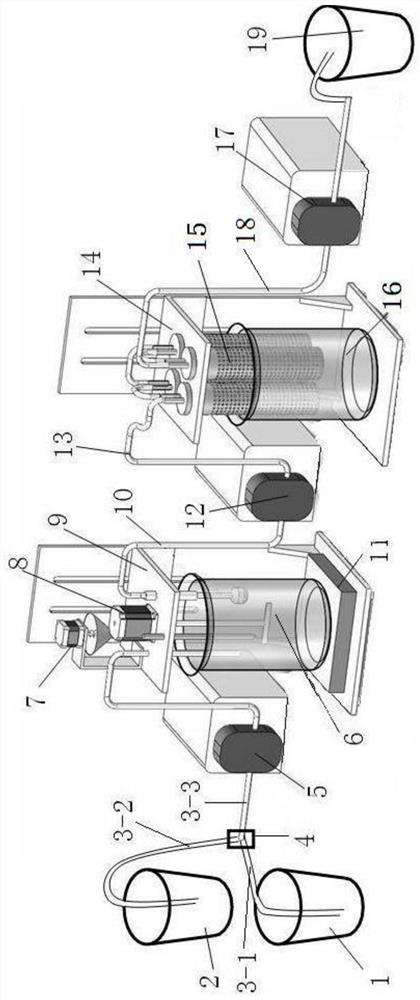

Microfluidic equipment for preparing graphene oxide

PendingCN112774596AWell mixedPrecisely control the degree of oxidationSingle layer grapheneChemical/physical/physico-chemical microreactorsPhysical chemistryEngineering

The invention discloses equipment for preparing graphene oxide through microflow control. The equipment comprises a first raw material tank, a second raw material tank, a micro-mixer, a micro-channel reactor, a separation device, a graphene oxide collection device, an acid liquor collection device and a purification device, wherein the first raw material tank and the second raw material tank are respectively connected with a feed port of the micro-mixer, a discharge port of the micro-mixer is connected with a feed port of the micro-channel reactor, a discharge port of the micro-channel reactor is connected with the separation device, the graphene oxide collection device and the acid liquor collection device are respectively connected with the separation device, and the purification device is connected with the graphene oxide collection device.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA +1

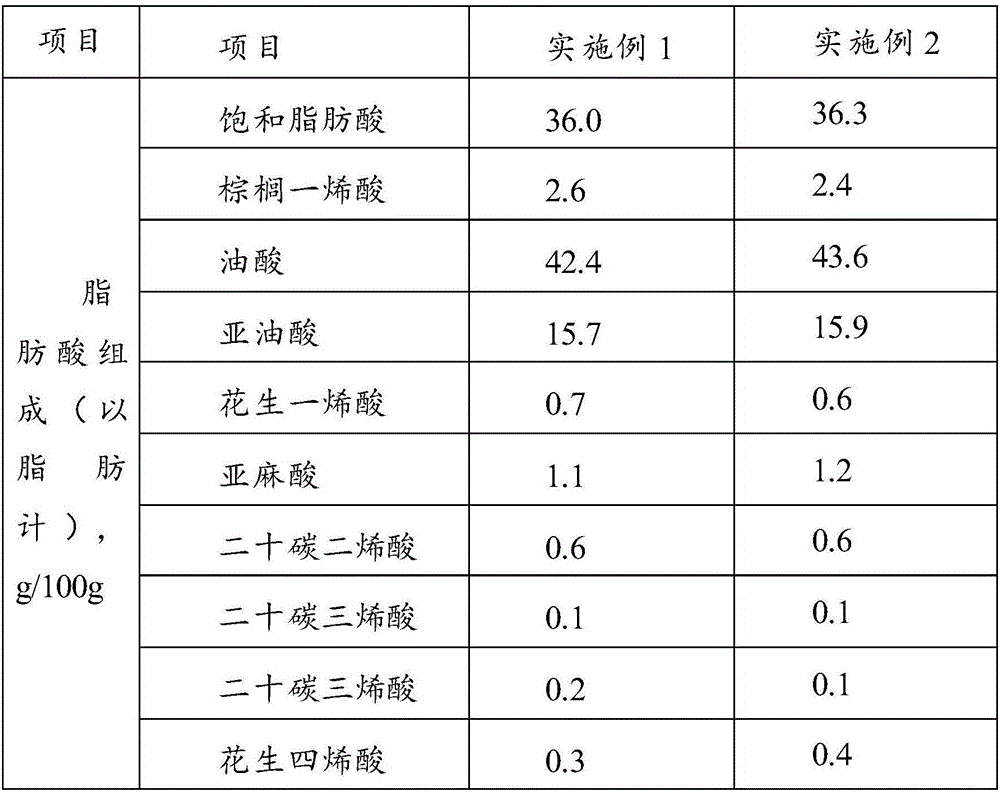

Staged oil-frying and steaming technology of Cantonese braised pork

The invention discloses a staged oil-frying and steaming technology of Cantonese braised pork. The staged oil-frying and steaming technology of the Cantonese braised pork comprises the following steps: removing hair, carrying out dicing, preparing pre-cooking soup, carrying out curing, injecting salt by puncturing, carrying out mixed oil-frying by using water and oil, carrying out mixed re-frying by using water and oil, carrying out steaming, and so on. The staged oil-frying and steaming technology of the Cantonese braised pork integrates cooking methods of traditional Chinese dishes and processing technologies of western meat products; during the oil-frying stage, the oil-frying is successively carried out at different temperature by adopting a water-oil mixed method, so that production of harmful materials can be effectively controlled during the oil-frying process so as to preserve good senses and flavors of the meat products to the maximum extent; moreover, vegetable fat, namely corn oil, is used as the oil for oil-frying in the staged oil-frying and steaming technology of the Cantonese braised pork, so that the oil-fried meat products are healthier, and better in edible properties.

Owner:GUANGXI UNIV

Method for preparing graphene oxide through microfluidics

PendingCN112811417APromote oxidation reactionPrecisely control the degree of oxidationCarbon compoundsMicrofluidicsPhysical chemistry

The invention discloses a method for preparing graphene oxide through microfluidic control, which comprises the following steps: preparation of a first premixed solution: mixing graphite powder and a first intercalator to obtain the first premixed solution; preparing a second premixed solution, namely mixing an oxidizing agent and a second intercalator to obtain the second premixed solution; performing micro-flow mixing: feeding the first premixed solution and the second premixed solution into a micro-mixer for mixing to obtain a mixed suspension of graphite, an oxidizing agent and an intercalator; performing micro-flow reaction: feeding the mixed suspension into a micro-channel reactor for reaction; performing separation: preliminarily separating graphene oxide and an acid solution containing an oxidizing agent in a reaction mixture flowing out of the microchannel reactor, collecting the graphene oxide, and carrying out quenching reaction; and performing purification: washing the collected graphene oxide to finally obtain a high-purity graphene oxide aqueous dispersion liquid or a graphene oxide filter cake.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA +1

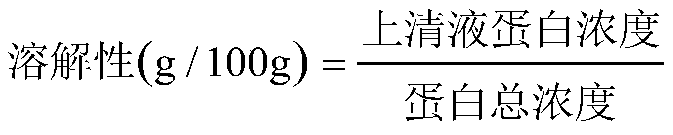

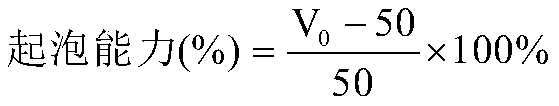

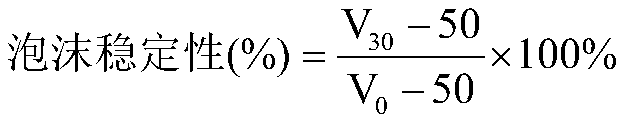

Preparation method of antioxidant soybean protein

PendingCN110050875AImprove functional propertiesEnergy savingVegetable proteins working-upChemistryFreeze dry

The invention discloses a preparation method of antioxidant soybean protein, and relates to the technical field of preparation of functional protein. The method comprises the following steps: (1) dissolving soybean protein in a buffer solution to obtain a protein solution; (2) dissolving tea polyphenol, Vc and Ve in the buffer solution together to obtain a protective agent solution; (3) mixing andhomogenizing the protein solution obtained in the step (1) with the protective agent solution obtained in the step (2) to obtain a mixed solution; (4) stirring and reacting the mixed solution homogenized in the step (3) to obtain a protective agent-protein composite solution; (5) homogenizing the protective agent-protein composite solution obtained in the step (4); and (6) freeze-drying the composite solution homogenized in the step (5) to obtain the antioxidant soybean protein. The foaming property, emulsifying property and dissolving property of the soybean protein product are effectively improved, and the sensitization of the soybean protein product is reduced.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Fermenting process of fermented ham

The invention provides a fermenting process of fermented ham, comprising: fermenting pre-preserving leg at low temperature, fermenting at medium temperature, and fermenting at high temperature to obtain a product; in low temperature fermentation, the temperature is 3-5 DEG C, humidity is 40-80%, time is 70-84 d; in medium temperature fermentation, the temperature is 14-20 DEG C, humidity is 60-80%, and time is 150-170 d; in high temperature fermentation, the temperature is 21-25 DEG C, humidity is 55-85%, and time is 45-60 d. Through precisely controlling the temperature, humidity and time for the low temperature fermentation, medium temperature fermentation and high temperature fermentation, water loss rate of the final product is controlled to 30-35%, good preservation is achieved, fat oxidation level in the product may also be effectively controlled, and harmful substances from excessive oxidation are avoided; in addition, the product fermented herein has high contents of amino acids, fatty acids and vitamins and has good flavor.

Owner:恒远食品有限公司

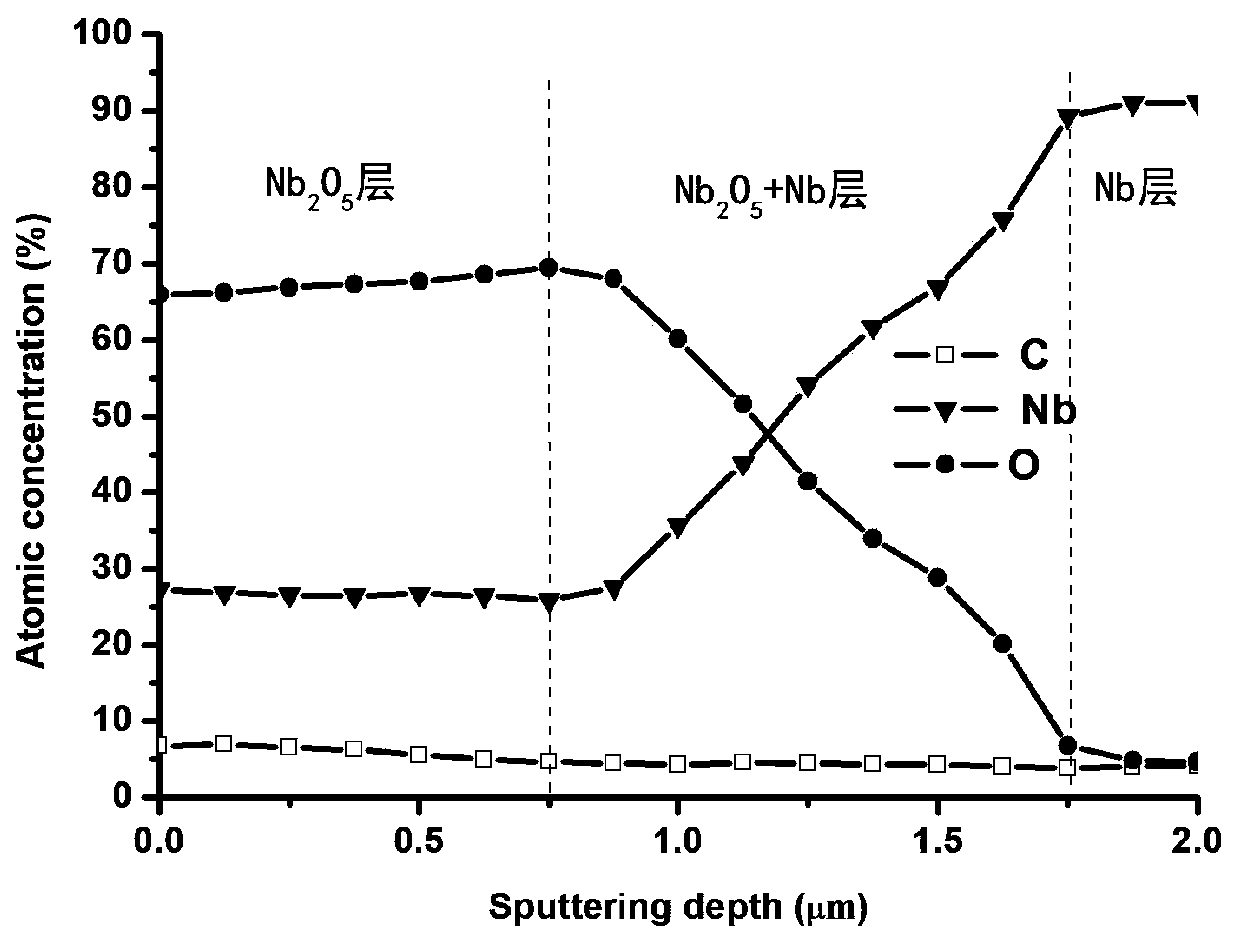

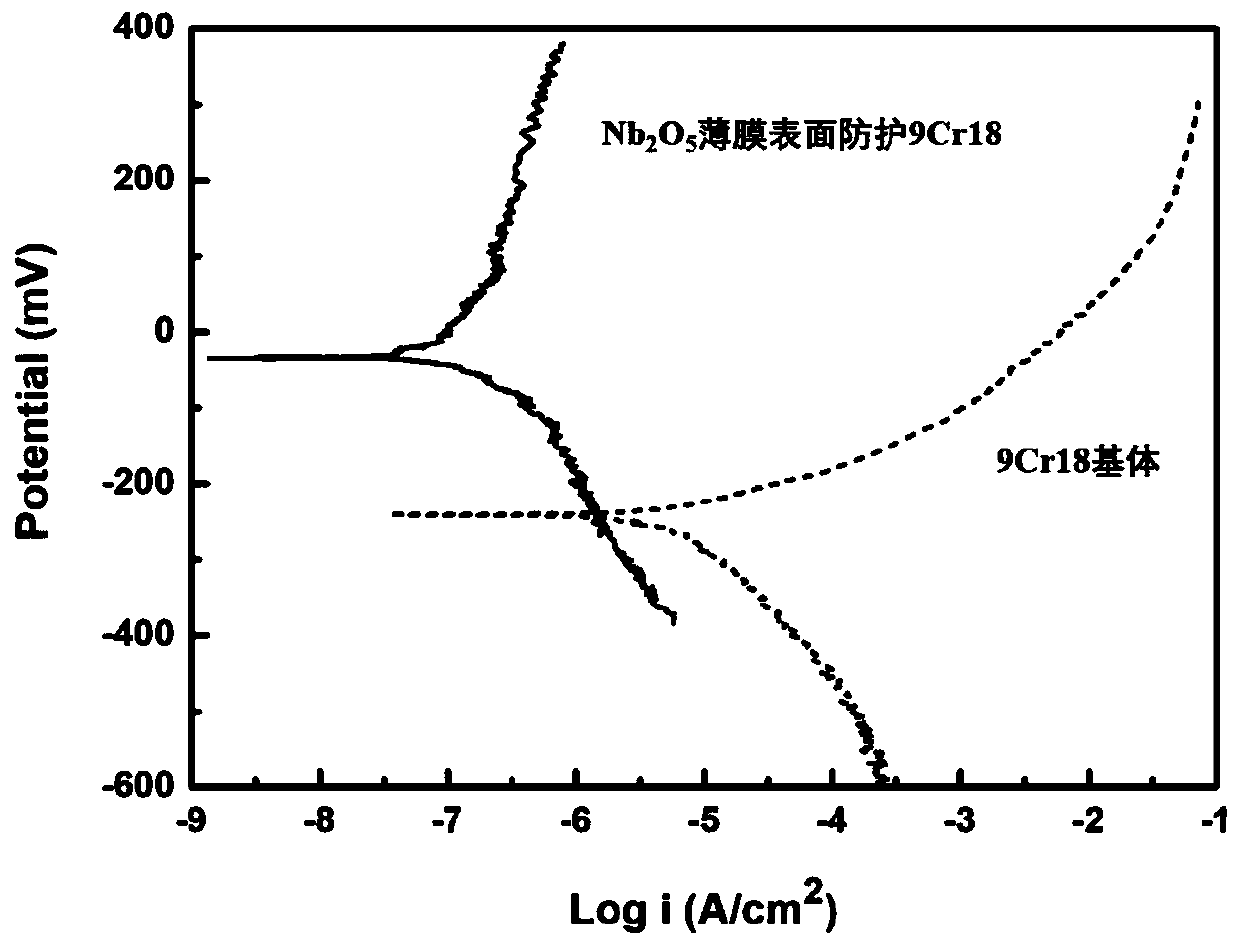

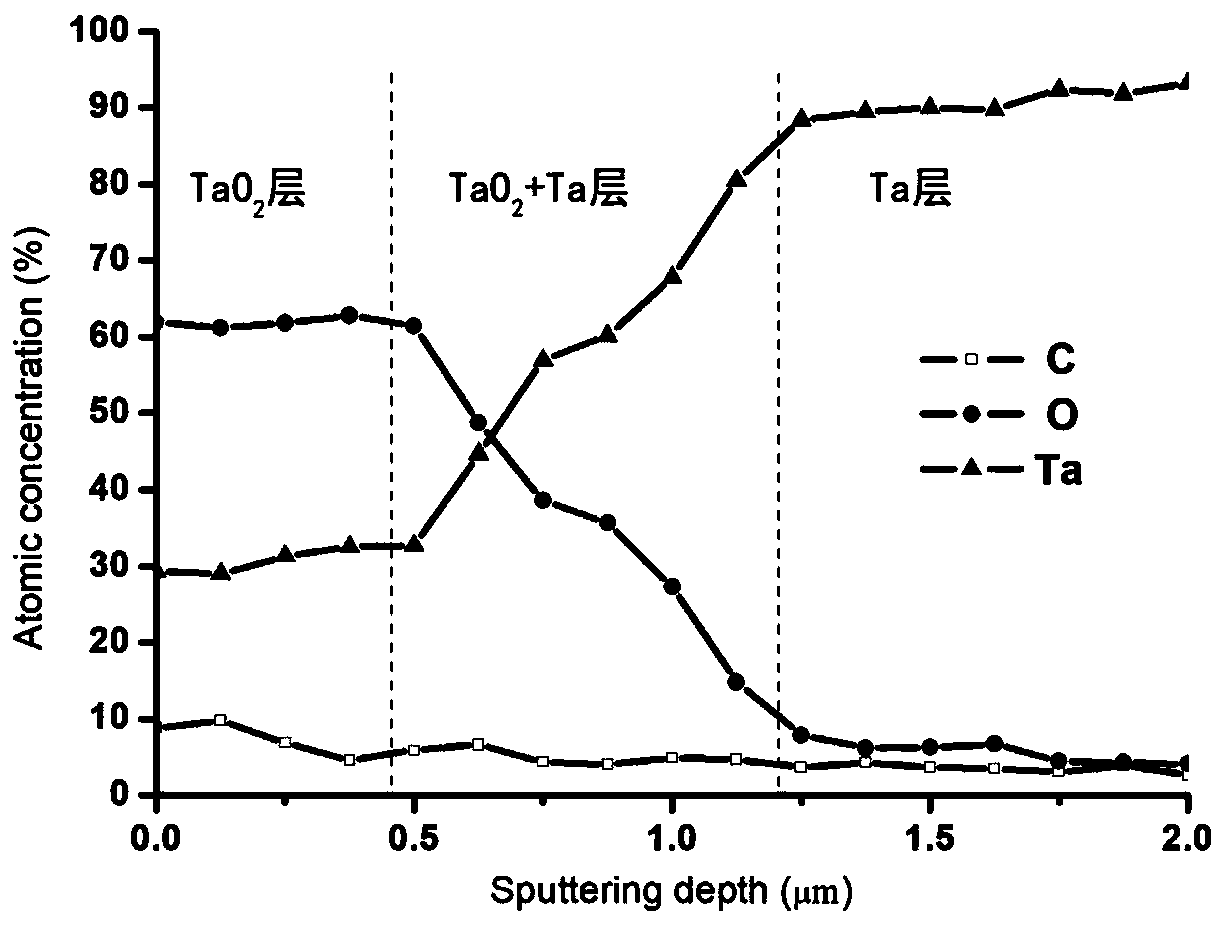

Corrosion-resistant protective thin film, and preparation method and application thereof

ActiveCN111441016AGive full play to corrosion resistanceImprove corrosion resistanceVacuum evaporation coatingSputtering coatingNiobiumPhysical chemistry

The invention provides a corrosion-resistant protective thin film, and a preparation method and application thereof, and belongs to the field of protective materials. The corrosion-resistant protective thin film provided by the invention is of a multilayer structure which includes a metal M layer, a metal M and M2O5 mixed transition layer and an M2O5 layer in sequence from the surface of a matrixand the thin film, wherein M is V, Nb or Ta. The preparation method for the corrosion-resistant protective thin film comprises the following steps of: depositing the metal M on the surface of the matrix by an ion plating method, and forming a metal thin film on the surface of the matrix, wherein M is metal vanadium, niobium or tantalum; and adopting an atomic oxygen beam to irradiate the metal thin film, and realizing the in situ formation of the corrosion-resistant protective thin film on the surface of the matrix, wherein the energy of the atomic oxygen beam is 4-10 eV, and irradiation timeis 60-180 min. The preparation method provided by the invention is simple and is easy to operate, and the prepared protective thin film can effectively improve the corrosion resistance of the matrix.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of thin-layer graphene oxide material

Owner:苏州格瑞丰纳米科技有限公司

Production process for fermented ham

The invention provides a production process for fermented ham. The production process comprises the following steps: A) subjecting a raw leg to pretreatment, salting and pickling so as to obtain a pre-pickled leg; and B) subjecting the pre-pickled leg to low-temperature fermentation, medium-temperature fermentation and high-temperature fermentation so as to obtain the fermented ham, wherein the temperature, humidity and time of low-temperature fermentation are 2 to 5 DEG C, 40 to 80% and 70 to 84 d, respectively; the temperature, humidity and time of medium-temperature fermentation are 14 to 20 DEG C, 60 to 80% and 150 to 170 d, respectively; and the temperature, humidity and time of high-temperature fermentation are 21 to 25 DEG C, 55 to 85% and 45 to 60 d, respectively. Through the procedures consisting of salting, pickling and fermentation and accurate control of the temperature, humidity and time of low-temperature, medium-temperature and high-temperature fermentation, the dehydration rate of the final fermented ham is controlled to be 30 to 35%, so good anticorrosion effect is obtained, and the oxidation degree of fat in the fermented ham can be effectively controlled so as to prevent production of harmful substances caused by excess oxidation; and the fermented ham prepared in the invention has high contents of amino acids and vitamins and good flavor.

Owner:恒远食品有限公司

Pickling process of fermented ham

InactiveCN106819880AControl the degree of oxidationImprove anti-corrosion performanceMeat/fish preservationSalt content

The invention provides a pickling process of fermented ham. The pickling process of fermented ham comprises the following steps: pretreating raw ham, rolling the raw ham for a first time, salting the raw ham for a first time, rolling the raw ham for a second time, salting the raw ham for a second time and pickling the ham to obtain pickled ham. The salt weight during salting for the first time is 2-3% of the weight of the raw ham; the temperature during salting for the first time is 2-5 DEG C; the salt weight during salting for the second time is 1.5-2.5% of the weight of the raw ham; the temperature during salting for the second time is 2-5 DEG C. Through salting, pickling and accurate controlling of salt weight and temperature of each process, the water loss rate of the final product is controlled to be 30-35%, so that a good preservative effect is achieved; the oxidation degree of fat in the product can also be effectively controlled; the fermented product is low in salt content and long in storage life.

Owner:恒远食品有限公司

A double-cylinder-cover cooking and processing process of guava-flavor fried braised pork

InactiveCN105520067AAdd flavorQuality improvementFood ingredient as mouthfeel improving agentEngineeringFood flavor

A double-cylinder-cover cooking and processing process of guava-flavor fried braised pork is disclosed. The process includes steps of removing hairs, cutting into pieces, preparing pre-cook soup, cooking, piercing to inject salt, performing water-oil-mixed type frying, performing secondary water-oil-mixed type frying, cooking, and the like. The process combines traditional Chinese dish cooking methods and a western type meat product processing technique. In a frying step, the process adopts water-oil-mixed type frying and frying is performed at difference temperatures in sequence, thus effectively controlling generation of harmful compounds in the frying step and greatly maintaining good sense and flavor of meat products. Corn coil that is vegetable type oil is adopted as oil for frying in the process so that the fried meat products are healthier and higher in edibility.

Owner:GUANGXI UNIV

Arc smelting preparation method of oxide-reinforced platinum-rhodium-based composite material

The invention discloses an arc smelting preparation method of an oxide-reinforced platinum-rhodium-based composite material. The arc smelting preparation method comprises the following steps that a platinum-rhodium alloy composite material ingot blank containing rare-earth Y powder and zirconium oxide powder is putted into an electric arc furnace to carry out electric arc smelting so as to obtaina button-shaped spindle; an X-ray fluorescence analyzer is used to measure whether the Zr content and the Y content on both sides of the spindle are uniform, wherein if the contents are not uniform, the bottom surface of the spindle is upward and arc smelting is carried out, and after smelting for many times, the Zr content and the Y content on both sides of the spindle are uniform; hot rolling iscarried out on the obtained spindle, and annealing treatment is then carried out; and then rolling, drawing and heat treatment are carried out to prepare a wire or sheet product, and an oxide-reinforced platinum-rhodium-based composite material product is obtained. The arc smelting preparation method has a simple preparation process, no pollution to the environment, controllable components of theprepared composite material, excellent comprehensive performance of the material and suitability for industrial production, and the obtained composite material can be applied to electric heating materials, electrode materials and the like.

Owner:KUNMING INST OF PRECIOUS METALS

DSD acid preparation method

ActiveCN106146357AIncrease profitReduce formationSulfonic acid preparationChemical synthesisWhitening Agents

The invention relates to the field of chemical synthesis, in particular to a DSD acid preparation method. The DSD acid preparation method includes the steps that methylbenzene is subjected to sulfonation, purification and separation to obtain OTS, wherein the byproduct is PTS; OTS is subjected to mixed acid nitration to obtain PNTS; PNTS is subjected to chlorine oxidative condensation to obtain DNS; DNS is subjected to catalyzed hydrogeneration reduction to obtain the high-quality target product, namely DSD acid which can be directly used for synthesizing a fluorescent whitening agent. The synthesis method greatly reduces dangerousness of the process, greatly reduces generation of harmful byproducts and waste, particularly, does not generate a lot of carcinogenic intermediate, namely ortho-nitrotoluene, completely solves the nitration safety problem of the old technology, and has the advantages of being simple in step, high in yield and the like.

Owner:上海合丽亚日化技术有限公司

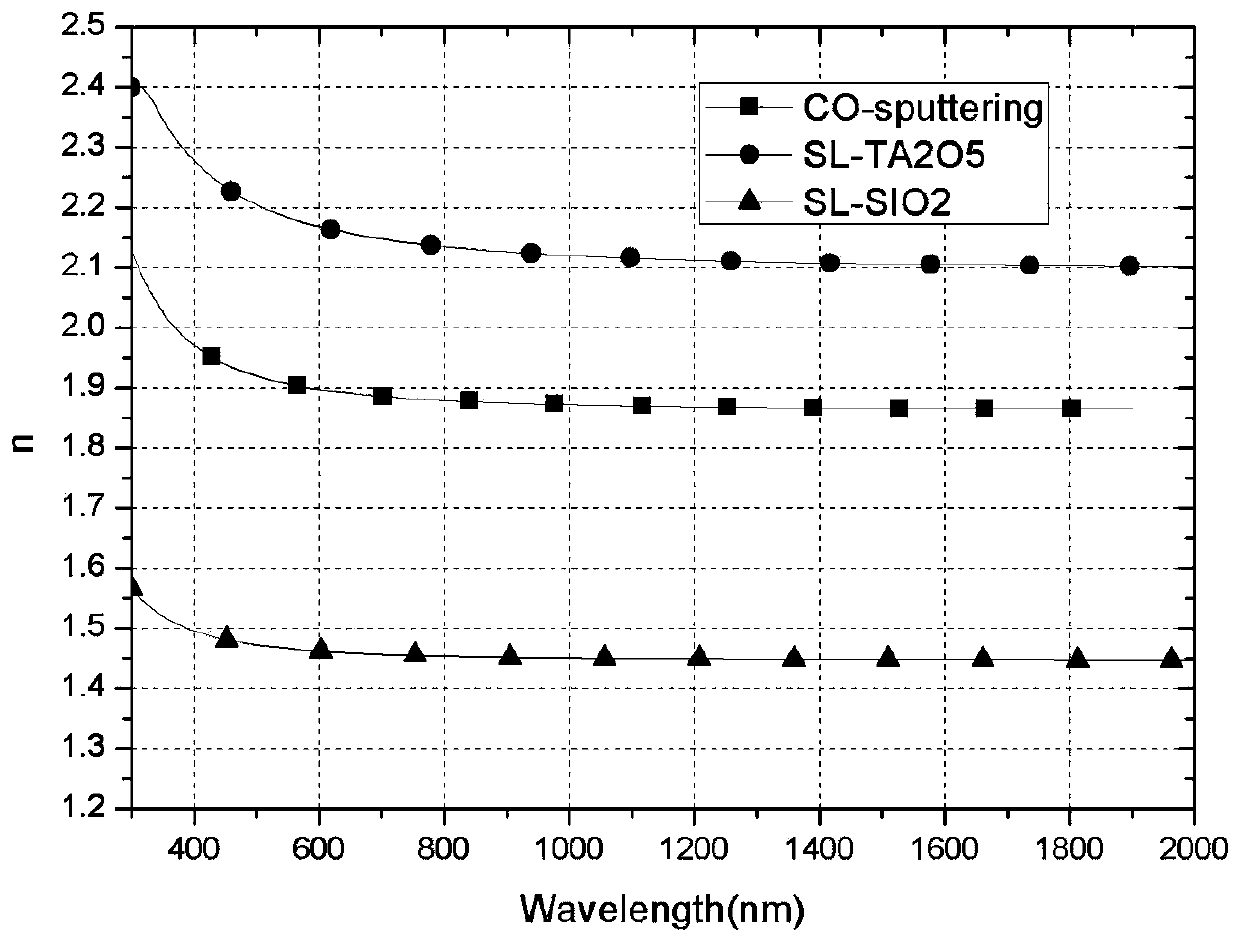

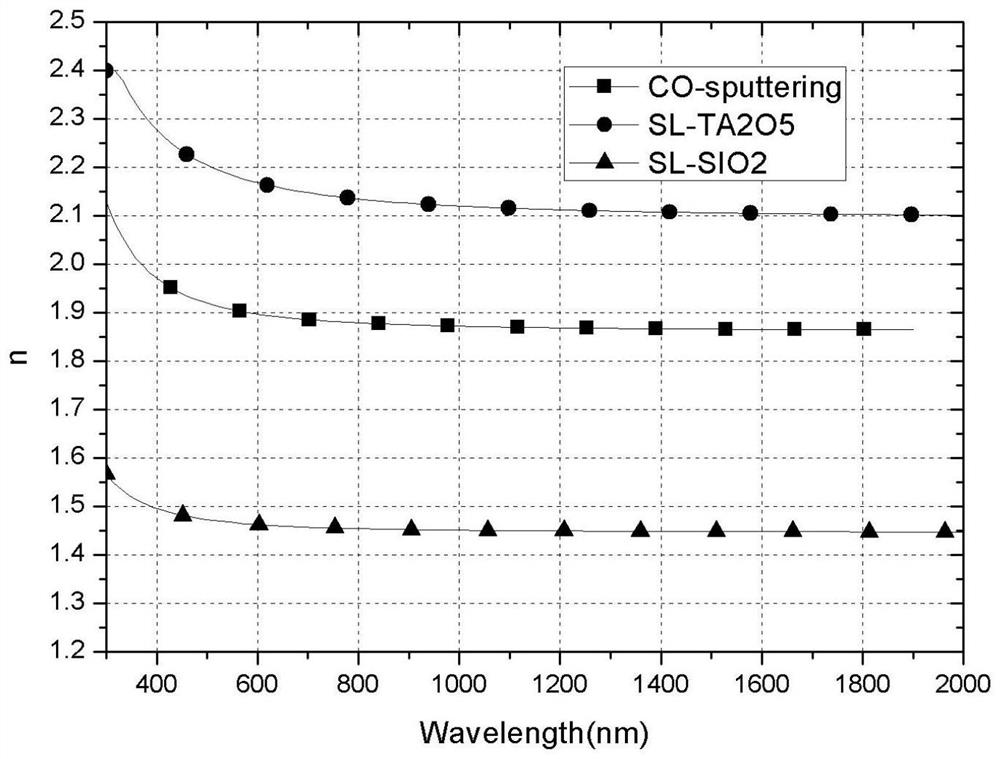

Method for preparing unconventional-refraction-index mixed film based on magnetron sputtering

ActiveCN110735121ACompact structureControl the degree of oxidationVacuum evaporation coatingSputtering coatingEvaporation (deposition)Film base

The invention provides a method for preparing unconventional-refraction-index mixed film based on magnetron sputtering and belongs to the technical field of optical film. According to the method, a unconventional-refraction-index mixed material adopts pulse direct-current magnetron sputtering deposition, specifically, joint sputtering of a tantalum target material and silicon target material is conduced with a cathode, a radio frequency ion source is used for ionizing oxygen in the same cavity, and the tantalum target material and the silicon target material are made to jointly perform a reaction on the surface of a substrate to form the film. Since the film prepared by the adoption of magnetron sputtering has a higher structure than the film prepared through thermal evaporation, the durability and stability of the film prepared by the adoption of magnetron sputtering are excellent than the film layer deposited through thermal evaporation.

Owner:江苏北方湖光光电有限公司

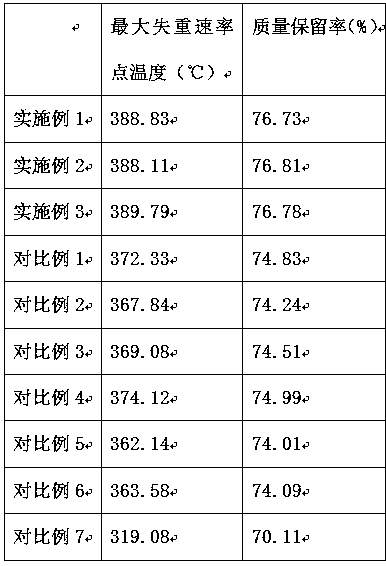

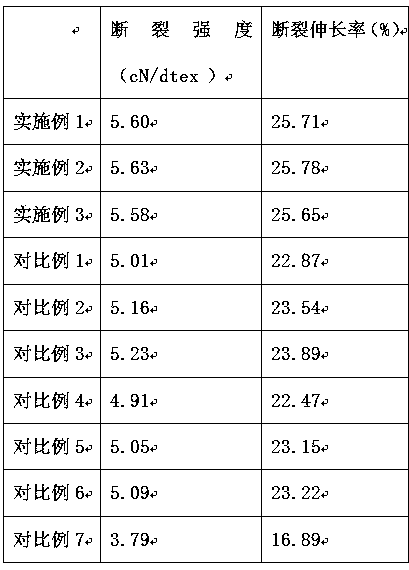

Silkworm cocoon drying method for improving mechanical properties and thermal stability of silk

InactiveCN109140906AImprove mechanical propertiesImprove thermal stabilityDrying solid materials with heatSilk filament obtainingNitrogen plasmaAlcohol sugars

The invention belongs to the technical field of silkworm cocoon drying, in particular to a silkworm cocoon drying method for improving the mechanical properties and thermal stability of silk. The methods specifically comprises the following steps that (1) fresh silkworm cocoons are arranged in an electric field for electric field treatment, immersed in a sodium alginate solution for insulation soaking, drained, fished out, drained until no drop drips and subjected to refrigerating treatment and microwave drying treatment, and pre-dried silkworm cocoons are obtained; and (2) the pre-dried silkworm cocoons are arranged in a treatment agent to be soaked, drained, fished out, drained until no drop drips and subjected to nitrogen plasma treatment and microwave drying treatment, and the dried silkworm cocoons are obtained, wherein the treatment agent is prepared from the following raw materials of fresh bamboo leaching, red sugar alcohol, aloe polysaccharide, puerarin polysaccharide, kapok polysaccharide and water. The surface of the silk is flat and smooth, the thermal stability and mechanical properties of the silk are greatly improved, the drying rate is high, the drying time is effectively shortened, the quality of the silk is greatly improved, and further development of the silk industry is effectively promoted.

Owner:ANHUI SANLI SILK GRP

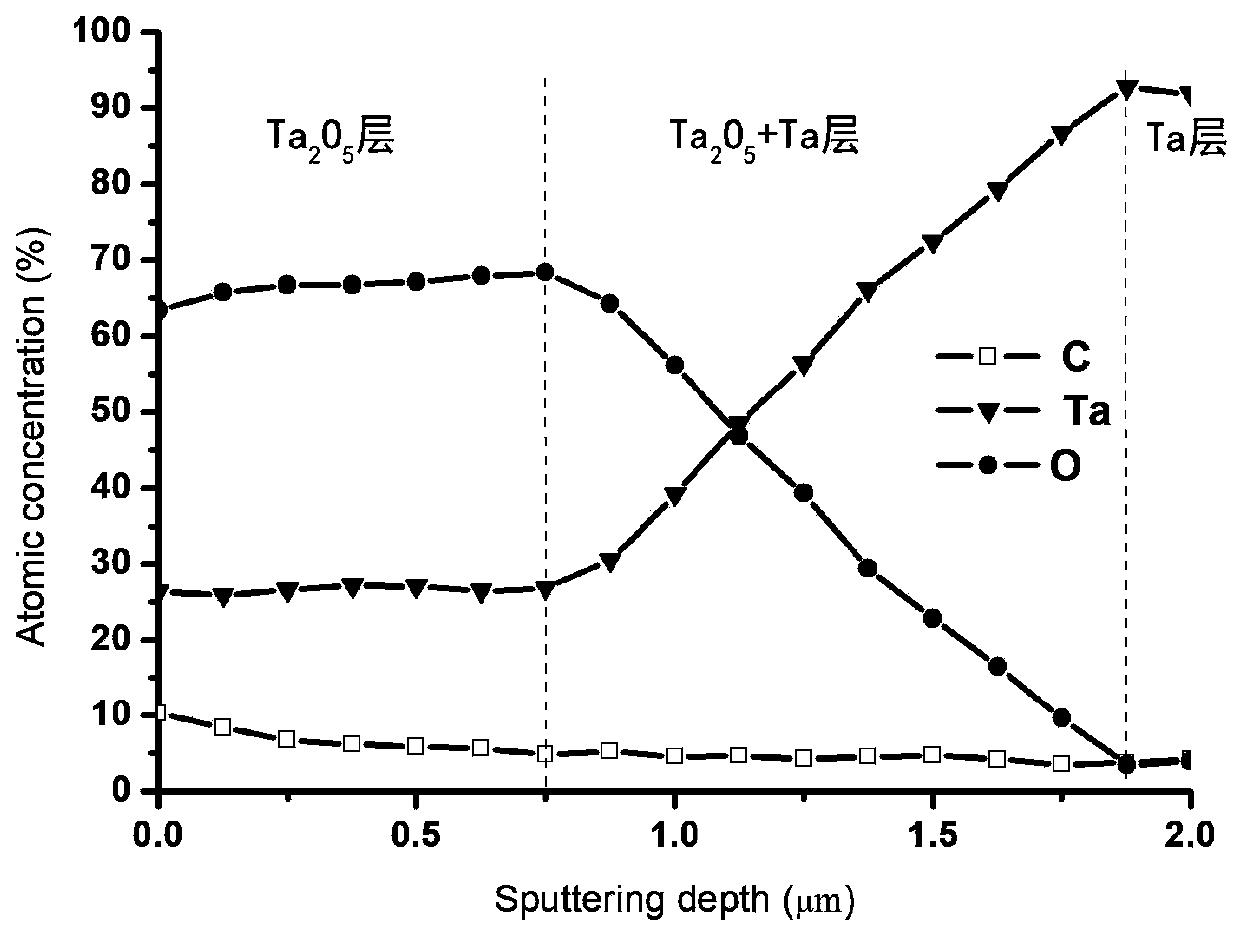

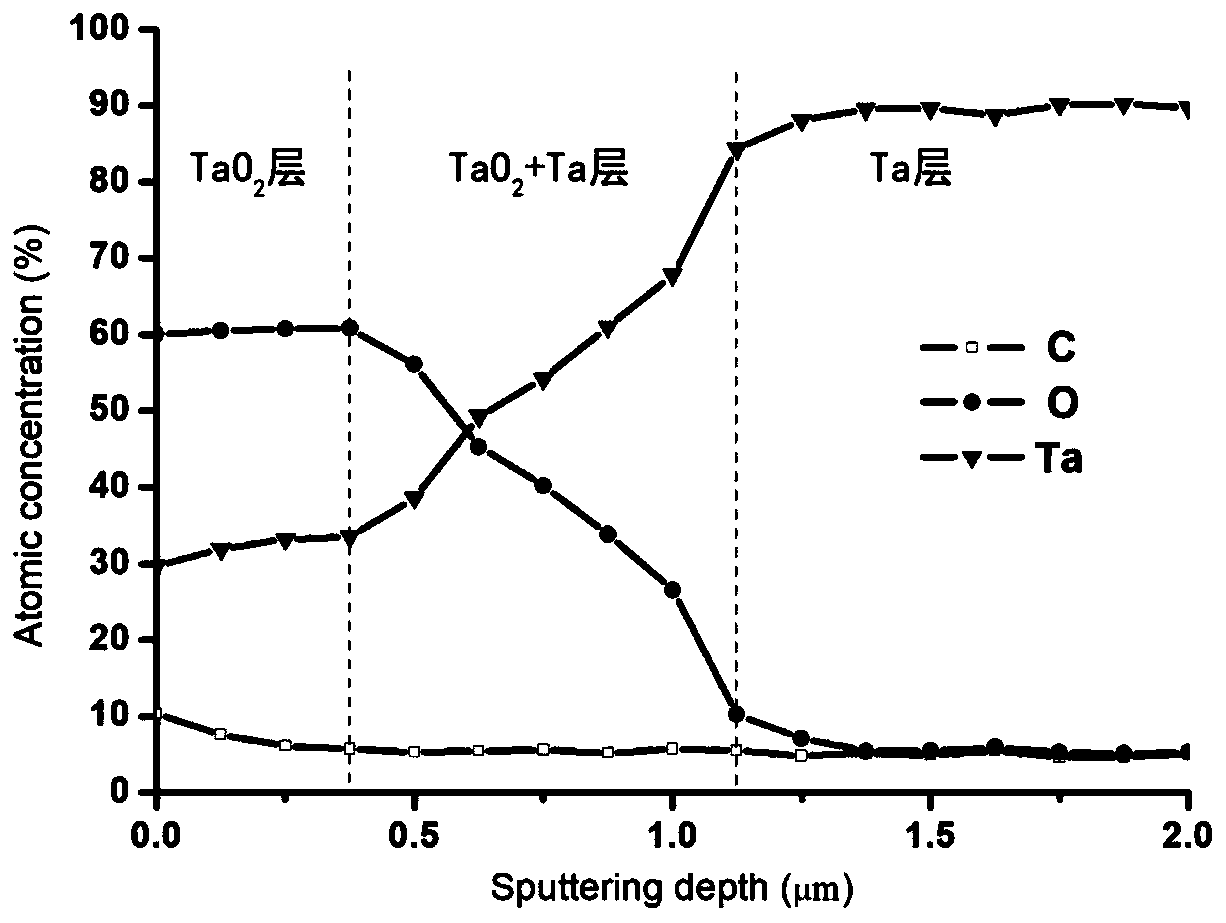

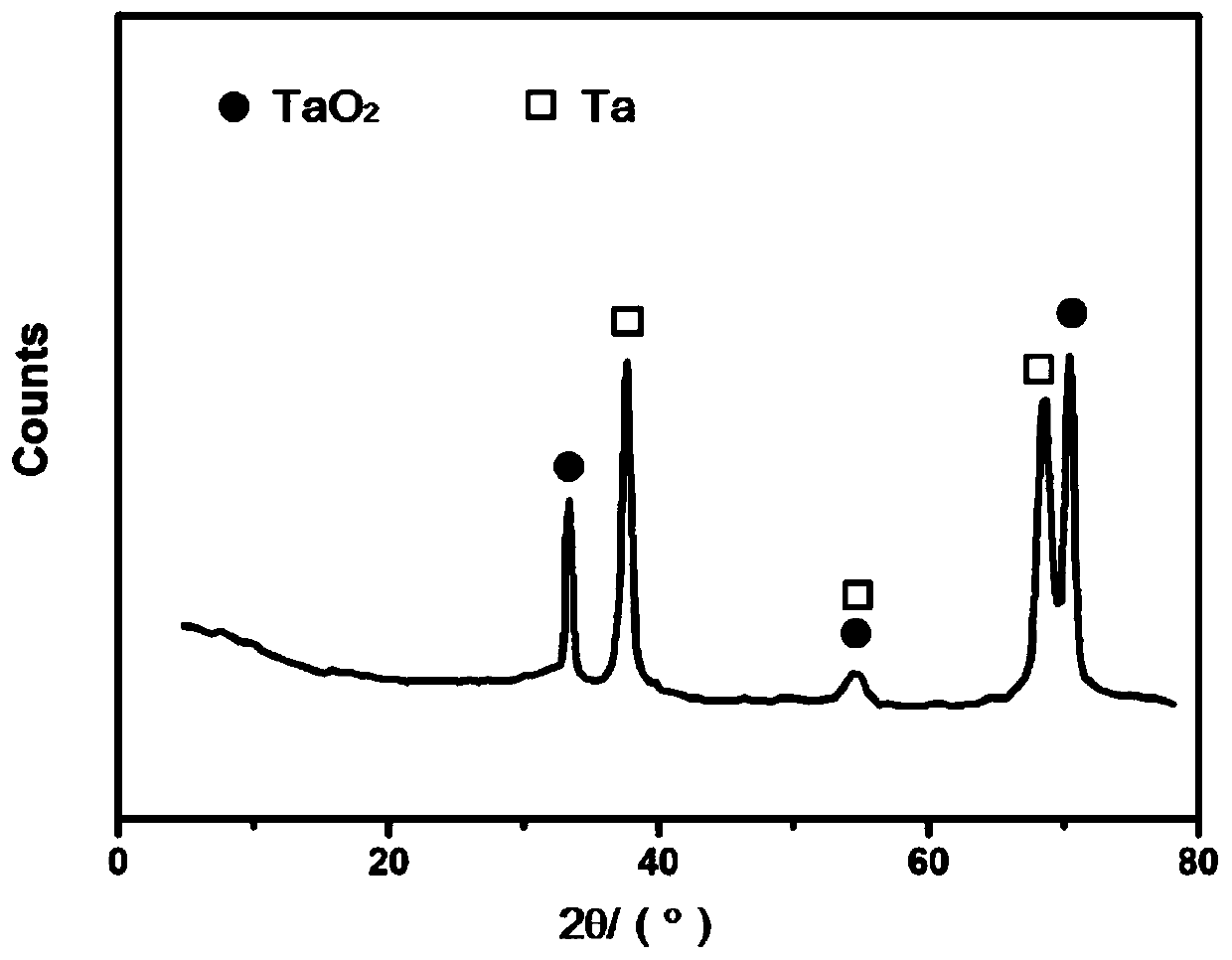

Wear-resistant and corrosion-resistant protecting film and preparation method and application thereof

ActiveCN111500989AControl the degree of oxidationEasy to prepareVacuum evaporation coatingSputtering coatingThin membraneTitanium

The invention provides a wear-resistant and corrosion-resistant protecting film and a preparation method and application thereof and belongs to the field of protecting materials. The wear-resistant and corrosion-resistant protecting film has a multilayered structure which successively comprises a metal Ta layer, a metal Ta and TaO2 mixed transitional layer and a TaO2 layer from the surface of a matrix and the surface of the film. The preparation method of the wear-resistant and corrosion-resistant protecting film comprises the following steps of depositing the metal Ta on the surface of the matrix by adopting an ion plating method to form a metal Ta film on the surface of the matrix; and irradiating the metal Ta film by adopting an atomic oxygen beam to form the wear-resistant and corrosion-resistant protecting film on the surface of the matrix, wherein energy of the atomic oxygen beam is 0.1-2 eV and the irradiation time is 30-120 min. The preparation method provided by the inventionis simple and easy to operate, and the prepared wear-resistant and corrosion-resistant protecting film has relatively good protecting performance to a titanium-based material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

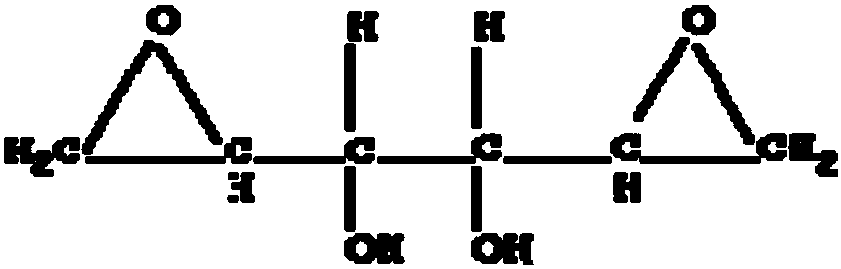

A kind of dehydrated dulcitol liposome freeze-dried powder injection and preparation method thereof

ActiveCN105663060BImprove stabilityGood membrane permeabilityOrganic active ingredientsPowder deliveryOral medicineDianhydrodulcitol

The invention relates to the field of medicinal preparations, in particular to a dianhydrodulcitol lipidosome freeze-dried powder injection and a preparation thereof. The weight ratio of dianhydrodulcitol to phospholipids to cholesterol in dianhydrodulcitol lipidosome is 1:(5-40):(2.5-15). The weight ratio of dianhydrodulcitol to phospholipids to cholesterol is preferably 1:(10-30):(5-10). The encapsulation rate of the prepared dianhydrodulcitol lipidosome can be 85% or above, and the grain diameter of the prepared dianhydrodulcitol lipidosome is smaller than 200 nm. After administration, the medicine is rapidly absorbed, takes effect rapidly, and is accurate in quantification and convenient to use, the first-pass effect of the oral medicine is avoided, and the treatment effect and bioavailability are improved.

Owner:GUANGXI WUZHOU PHARMA GRP

Anti-shrinkage polyphenylene sulfide fibre under ignition and preparation method thereof

InactiveCN110184811AImproves shrink resistanceChange temperature resistanceShrinking resistant fibresPolyacrylamideCombustion

The invention provides an anti-shrinkage polyphenylene sulfide fibre under ignition and a preparation method thereof, and belongs to the technical field of fiber materials. The preparation of the anti-shrinkage polyphenylene sulfide fibre under ignition comprises the following steps that 1, a polyphenylene sulfide fibre is added into an oxidizing agent solution for impregnation for 1-4 h under thetemperature of 180-200 DEG C, and then impregnation is performed for 0.5-1 h under the temperature of 160-180 DEG C; 2, the polyphenylene sulfide fibre is added into an anti-oxidant solution for impregnation for 1-2 h; 3, the polyphenylene sulfide fibre is subjected to washing and vacuum drying; 4, the dried polyphenylene sulfide fibre is added into a polyacrylamide solution, and impregnation isperformed for 3-5 h under the temperature of 150-180 DEG C; 5, the polyphenylene sulfide fibre is added into a 1,4-benzyl bichloride solution for cross linking for 3-5 h; 6, washing and vacuum dryingare performed on the cross linked polyphenylene sulfide fibre to obtain the anti-shrinkage polyphenylene sulfide fibre. The anti-shrinkage polyphenylene sulfide fibre has the good anti-shrinkage performance, the mechanical performance and the thermal stability, and no molten drop or shrinkage phenomenon happens during combustion.

Owner:SICHUAN UNFIRE POLYMER MATERIALS TECH

Dianhydrodulcitol lipidosome freeze-dried powder injection and preparation method thereof

ActiveCN105663060AImprove stabilityGood membrane permeabilityPowder deliveryOrganic active ingredientsOral medicineFreeze-drying

The invention relates to the field of medicinal preparations, in particular to a dianhydrodulcitol lipidosome freeze-dried powder injection and a preparation thereof. The weight ratio of dianhydrodulcitol to phospholipids to cholesterol in dianhydrodulcitol lipidosome is 1:(5-40):(2.5-15). The weight ratio of dianhydrodulcitol to phospholipids to cholesterol is preferably 1:(10-30):(5-10). The encapsulation rate of the prepared dianhydrodulcitol lipidosome can be 85% or above, and the grain diameter of the prepared dianhydrodulcitol lipidosome is smaller than 200 nm. After administration, the medicine is rapidly absorbed, takes effect rapidly, and is accurate in quantification and convenient to use, the first-pass effect of the oral medicine is avoided, and the treatment effect and bioavailability are improved.

Owner:GUANGXI WUZHOU PHARMA GRP

A preparation method of cross-linked antibacterial acellular matrix material

ActiveCN106215239BLow antigenicityIncrease the degree of cross-linkingProsthesisCross-linkAcellular matrix

The invention discloses a preparation method of a cross-linking antibacterial acellular matrix material. Oxidized chitosan quaternary ammonium salt is cross-linked with an acellular matrix material, multiple aldehyde groups on oxidized chitosan quaternary ammonium salt are cross-linked with active groups on the acellular matrix, the structural stability of the material is improved, meanwhile, chitosan quaternary ammonium salt is grafted in the acellular matrix material, and therefore excellent antibacterial and bacteriostatic performance is provided for the acellular matrix material. According to the method, cross-linking and providing of the antibacterial performance of the material are combined, the preparation method is a preparation method of the novel functional acellular matrix material, and the method can be widely applied to the field of biological materials.

Owner:SICHUAN UNIV

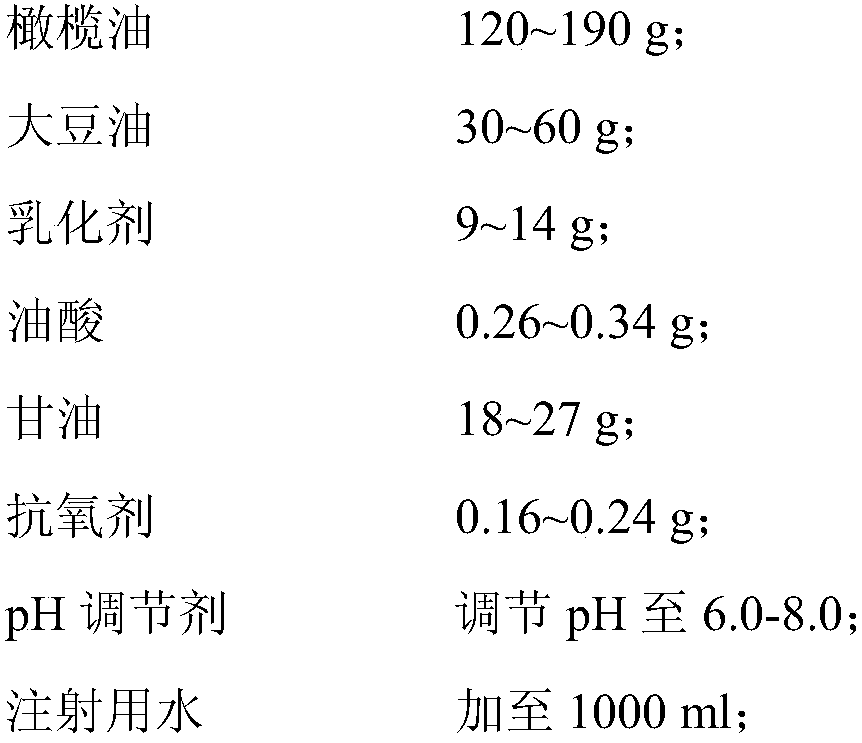

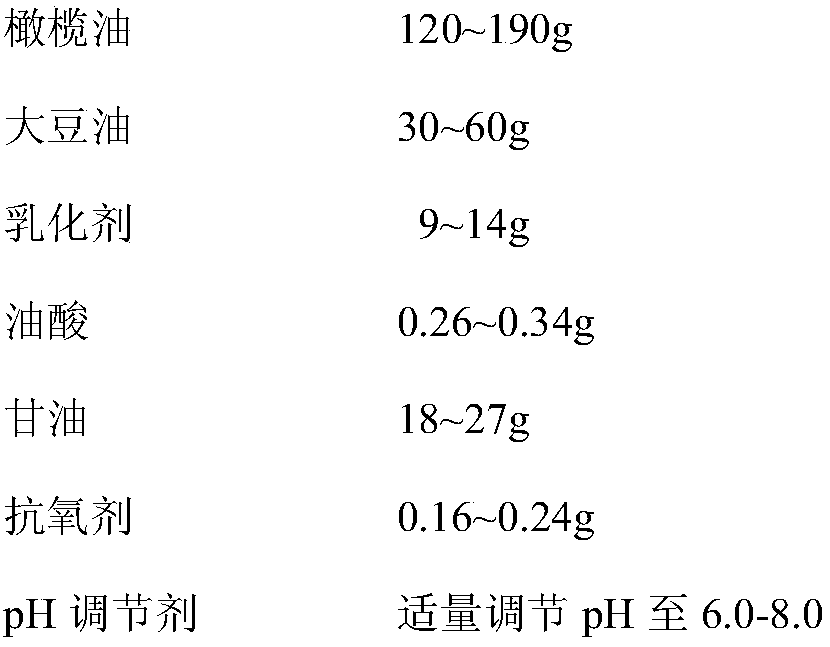

A kind of long-chain fat emulsion injection containing olive oil and preparation method thereof

InactiveCN105832667BImprove stabilityNo oil driftMetabolism disorderPharmaceutical non-active ingredientsUltrasonic emulsificationGlycerol

The invention belongs to the field of pharmaceutical preparations, in particular to a long-chain fat emulsion injection containing olive oil and a preparation method thereof. The fat emulsion comprises an oil phase composed of olive oil, soybean oil and an emulsifier, an aqueous phase composed of water for injection and glycerin, an oleic acid stabilizer, a pH regulator and a fat-soluble antioxidant; the fat emulsion injection consists of water The phase and the oil phase are prepared by ultrasonic emulsification, and the average particle size is about 280±20nm. The invention solves the problems of uneven particle size distribution and oil floating in fat emulsion, greatly reduces the residual oxygen in the emulsion and the oxidation degree of oil phase components, increases the long-term stability of fat emulsion injection, and reduces the adverse effects of patients. reaction, increasing drug safety.

Owner:JINAN KANGHE MEDICAL TECH

A kind of arc melting preparation method of oxide strengthened platinum-rhodium matrix composite material

The invention discloses an arc smelting preparation method of an oxide-reinforced platinum-rhodium-based composite material, which comprises: putting a platinum-rhodium alloy composite material ingot containing rare earth Y powder and zirconia powder into an electric arc furnace, and performing arc smelting to obtain Button-shaped ingot; use X-ray fluorescence analysis instrument to measure whether the Zr and Y content on both sides of the ingot is uniform, if not, place the bottom of the ingot upwards and perform arc melting. After several times of melting, the Zr and Y content on both sides of the ingot will be uniform; The obtained ingot is hot-rolled and then annealed; then rolled, drawn and heat-treated to prepare a wire or sheet product to obtain an oxide-reinforced platinum-rhodium-based composite product. The invention has simple preparation process, no pollution to the environment, controllable composition of the prepared composite material, excellent comprehensive performance of the material, and is suitable for industrial production. The obtained composite material can be applied to electrothermal materials, electrode materials and the like.

Owner:KUNMING INST OF PRECIOUS METALS

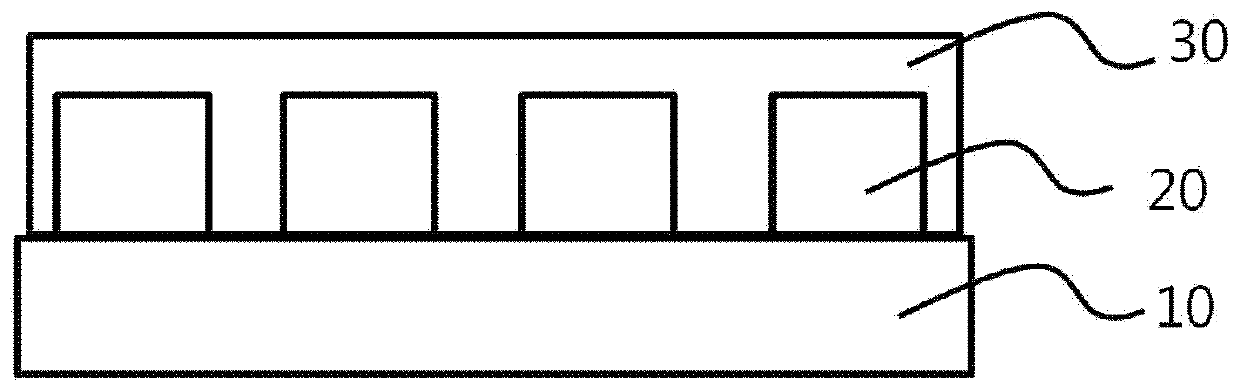

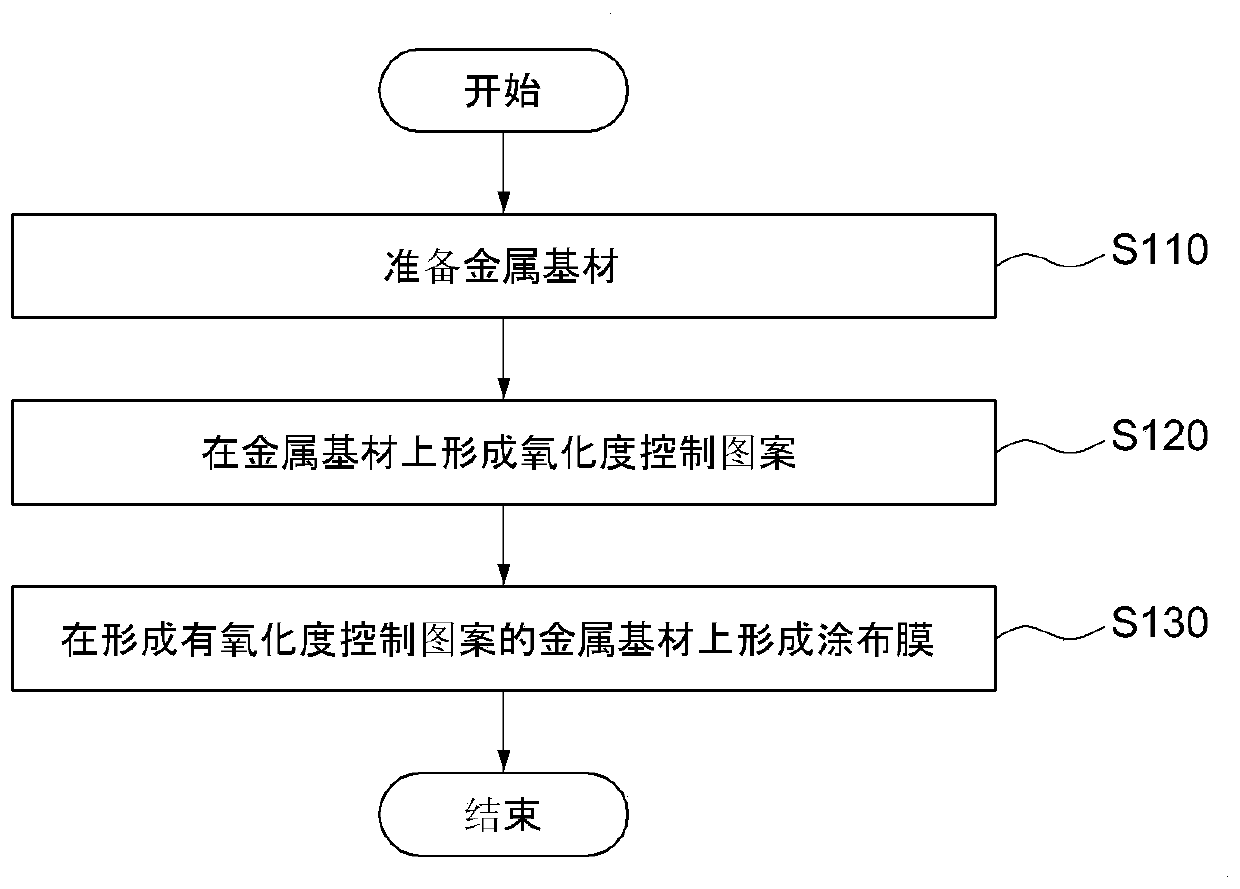

Live metal and method for preparing same

InactiveCN110062703ADifferent degrees of oxidationControl the degree of oxidationNatural patternsDecorative surface effectsMetallic substrateMetal substrate

An embodiment of the present invention provides a color metal comprising: a metal substrate comprising a first metal; an oxidation degree control pattern disposed on the metal substrate, the oxidationdegree control pattern increasing or decreasing the oxidation degree over time of the first metal; and a coating film disposed on the metal substrate on which the oxidation degree control pattern hasbeen disposed, wherein a first region of the metal substrate, on which the oxidation degree control pattern is present, and a second region of the metal substrate, on which the oxidation degree control pattern is not present, display different colors due to a difference in oxidation degree over time.

Owner:KOREA INST OF IND TECH

A kind of continuous preparation and purification device and method of graphene oxide

ActiveCN110342506BGood size uniformityRealize continuous preparationSingle layer graphenePeristaltic pumpStrong acids

The invention discloses a continuous preparation and purification device for graphene oxide, which includes a reactor, a concentrated sulfuric acid solution storage bottle and a water / hydrogen peroxide storage bottle connected to the reactor through a delivery pipe, and a three-way valve is arranged on the delivery pipe. Directly below and directly above are correspondingly equipped with an ultrasonic plate, a feeder, a stirring paddle, and a first lifting platform connected to the reactor through a discharge pipe, and the discharge pipe is connected to the filter column through a second conveying pipe provided with a second peristaltic pump. The filter column is connected to the graphene oxide storage bottle through the third conveying pipe provided with the third peristaltic pump; the invention also discloses a preparation method of graphene oxide: the strong acid and the oxidant are separately fed and oxidized with graphite, and then stripped and purification to obtain graphene oxide. The device of the present invention is provided with a concentrated sulfuric acid solution storage bottle, a feeder, a reactor and a filter, and realizes the continuous preparation and purification of graphene oxide; the method of the present invention improves the preparation and purification efficiency of graphene oxide, and realizes concentrated sulfuric acid Solution recovery and continuous utilization.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A method for preparing unconventional refractive index mixed thin films based on magnetron sputtering

ActiveCN110735121BCompact structureControl the degree of oxidationVacuum evaporation coatingSputtering coatingEvaporation (deposition)Film base

Owner:江苏北方湖光光电有限公司

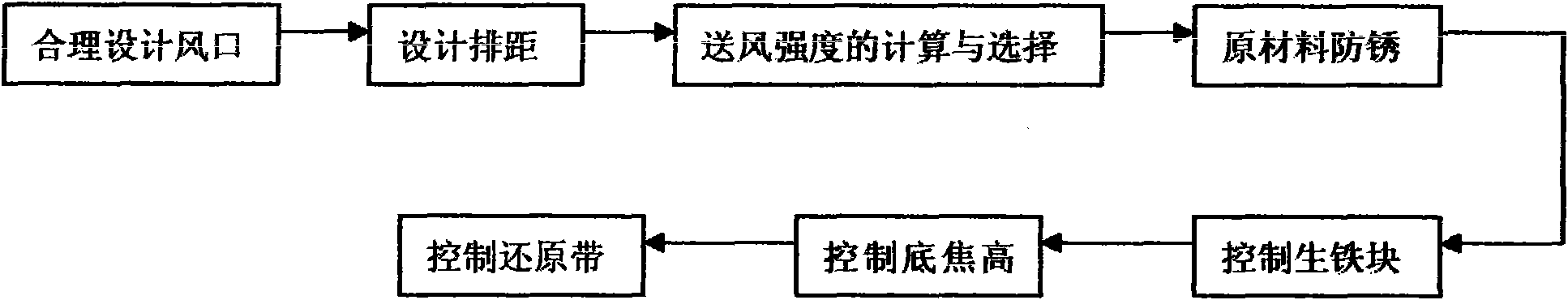

Prevention method of molten iron oxidation during smelting iron in cupola

InactiveCN101676663AReduce pollutionControl the degree of oxidationVertical furnacesCombustion chamberCupola furnace

The invention discloses a method for preventing the molten iron oxidation in a cupola, aiming to increase the liquidity of molten iron, improve the quality of molten iron, save the material and meet the demand of mass production. The design of the air port is reasonable, the upper air port is smaller than the lower air port which is 1.25 times of the upper air port, the total air port ratio is 3.0%-3.1%; the interval of the two air ports is the effective diameter of the combustion chamber at the main air port; the optimal supply air strength is 150-160m<3> / m<2>.min.

Owner:韦星野

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Organic thermoelectric material based on poly[Kx(Ni-ett)], preparing method for organic thermoelectric material and application of organic thermoelectric material Organic thermoelectric material based on poly[Kx(Ni-ett)], preparing method for organic thermoelectric material and application of organic thermoelectric material](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f63b206e-02b2-4faa-8e04-13e34b6de795/HDA0000570264330000011.PNG)

![Organic thermoelectric material based on poly[Kx(Ni-ett)], preparing method for organic thermoelectric material and application of organic thermoelectric material Organic thermoelectric material based on poly[Kx(Ni-ett)], preparing method for organic thermoelectric material and application of organic thermoelectric material](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f63b206e-02b2-4faa-8e04-13e34b6de795/HDA0000570264330000012.PNG)

![Organic thermoelectric material based on poly[Kx(Ni-ett)], preparing method for organic thermoelectric material and application of organic thermoelectric material Organic thermoelectric material based on poly[Kx(Ni-ett)], preparing method for organic thermoelectric material and application of organic thermoelectric material](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/f63b206e-02b2-4faa-8e04-13e34b6de795/HDA0000570264330000013.PNG)