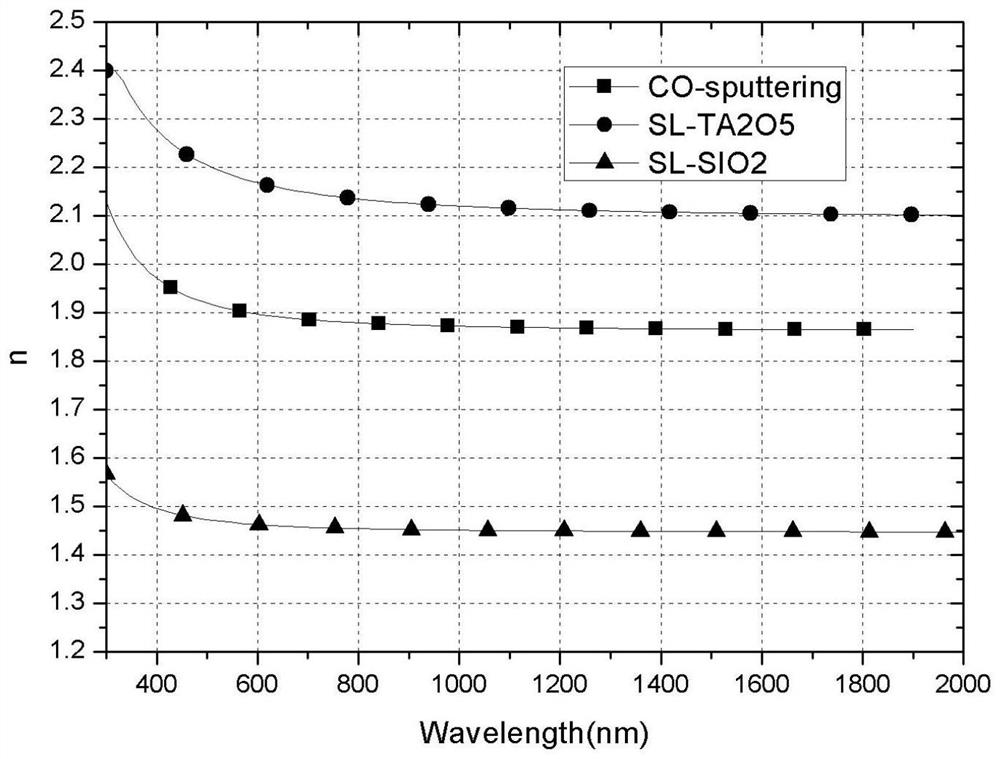

A method for preparing unconventional refractive index mixed thin films based on magnetron sputtering

A technology of magnetron sputtering and thin film preparation, which is applied in the direction of sputtering coating, metal material coating process, vacuum evaporation coating, etc., which can solve the problems of limited application and achieve the effect of excellent durability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention provides a method for preparing a non-conventional refractive index mixed film based on magnetron sputtering, comprising the following steps:

[0028] Step 1: Clean the cathode target, and install the required targets in sequence. Among them, the required target materials are as follows in order: the No. 2 target material is a tantalum target, and the No. 3 target material is a silicon target.

[0029] Step 2: Fixture treatment: In order to prevent defects such as fixture marks on the edge of the part and the fixture, sandblasting is required for the use of the fixture.

[0030] Step 3: Put the cleaned parts to be plated into the processed coating fixture, place them in the parts tray of the coating machine, press th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com