Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Control characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

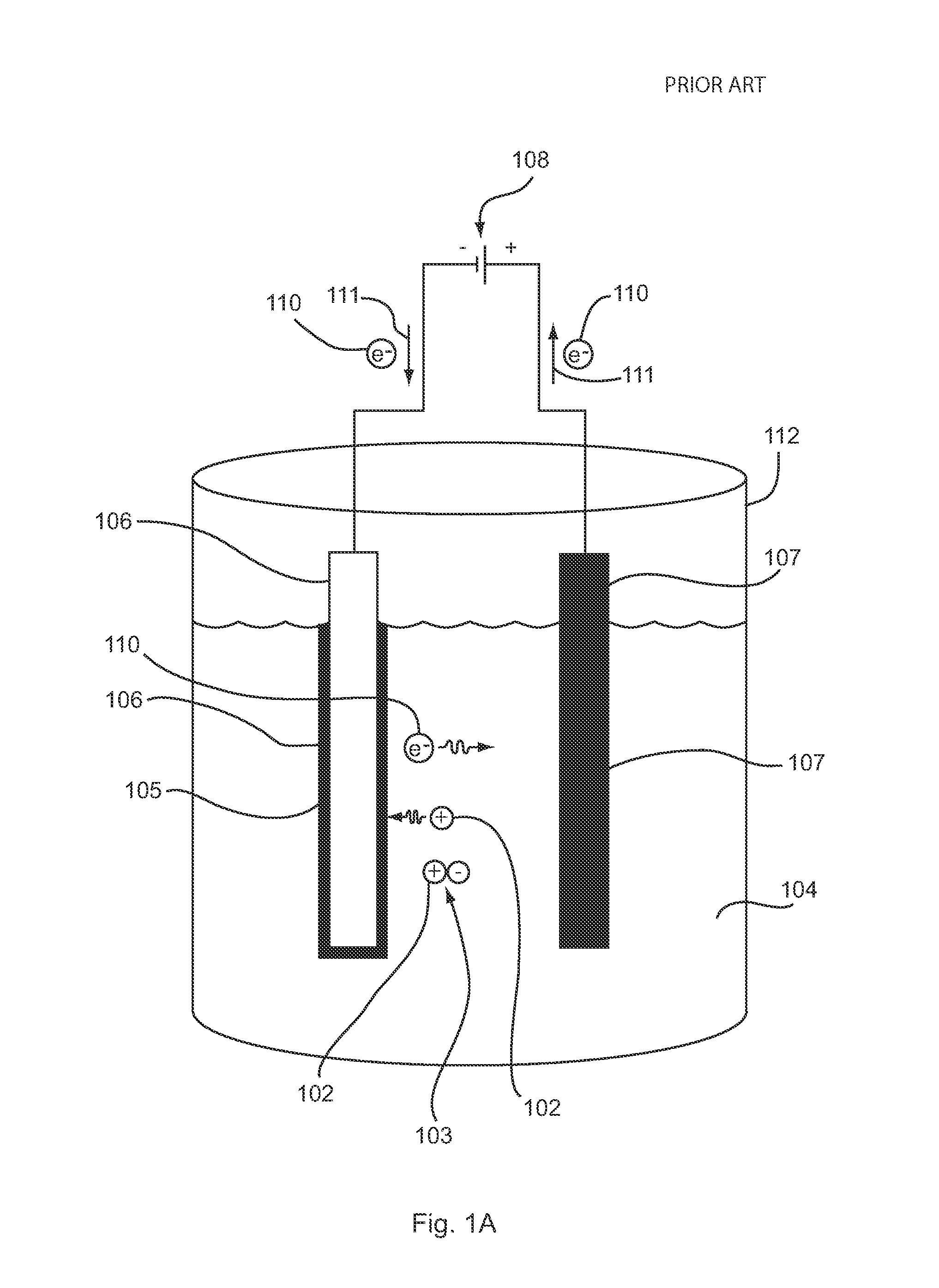

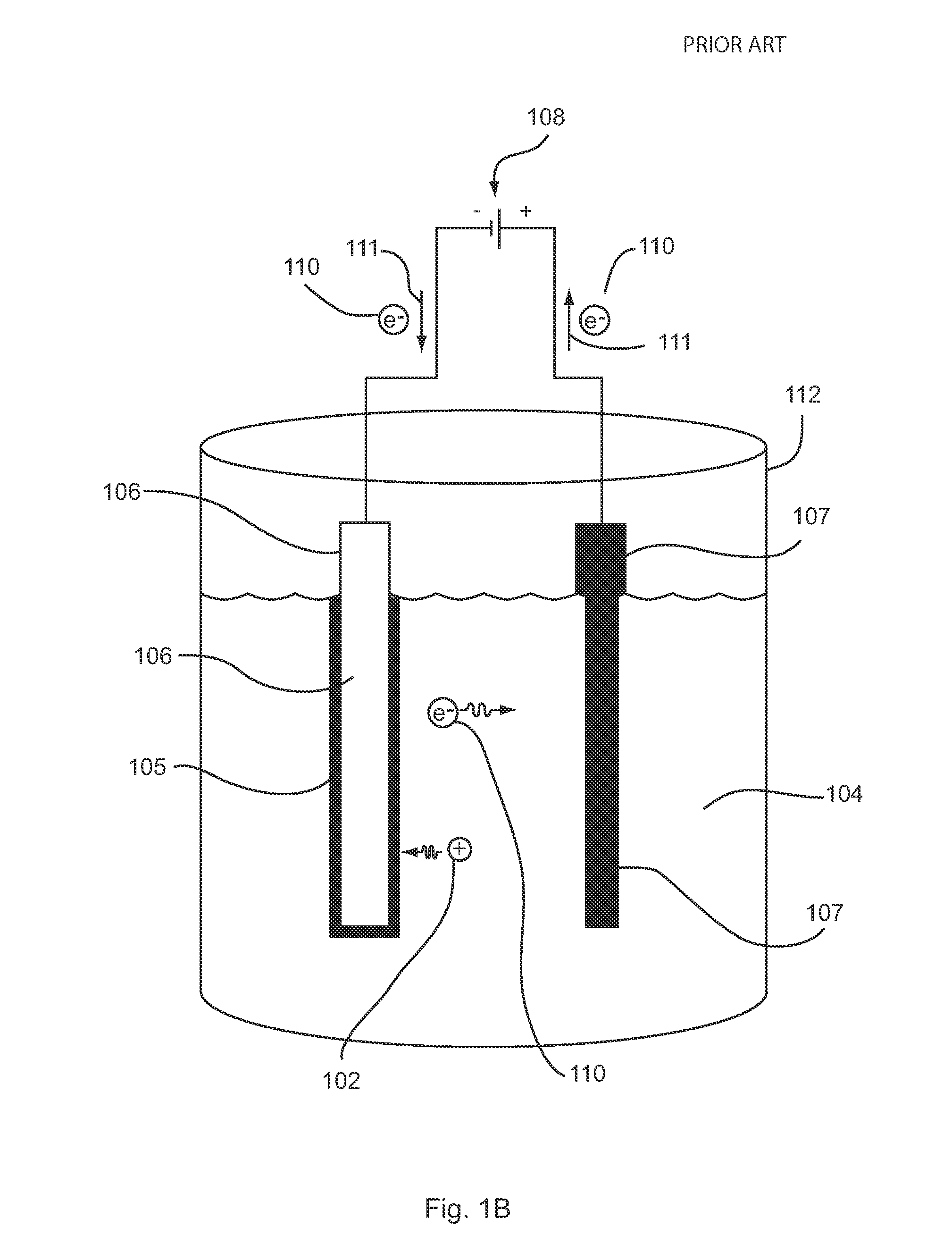

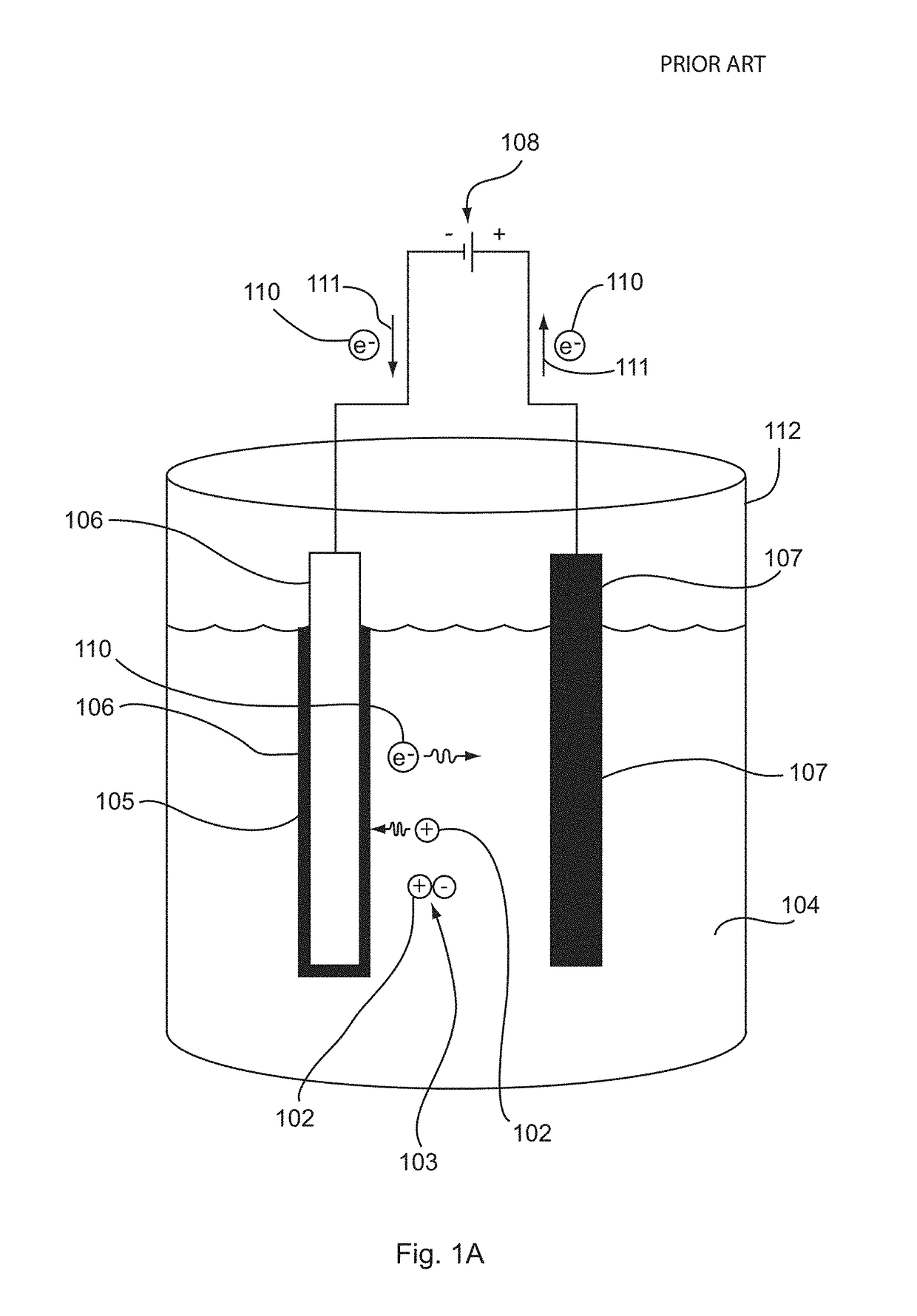

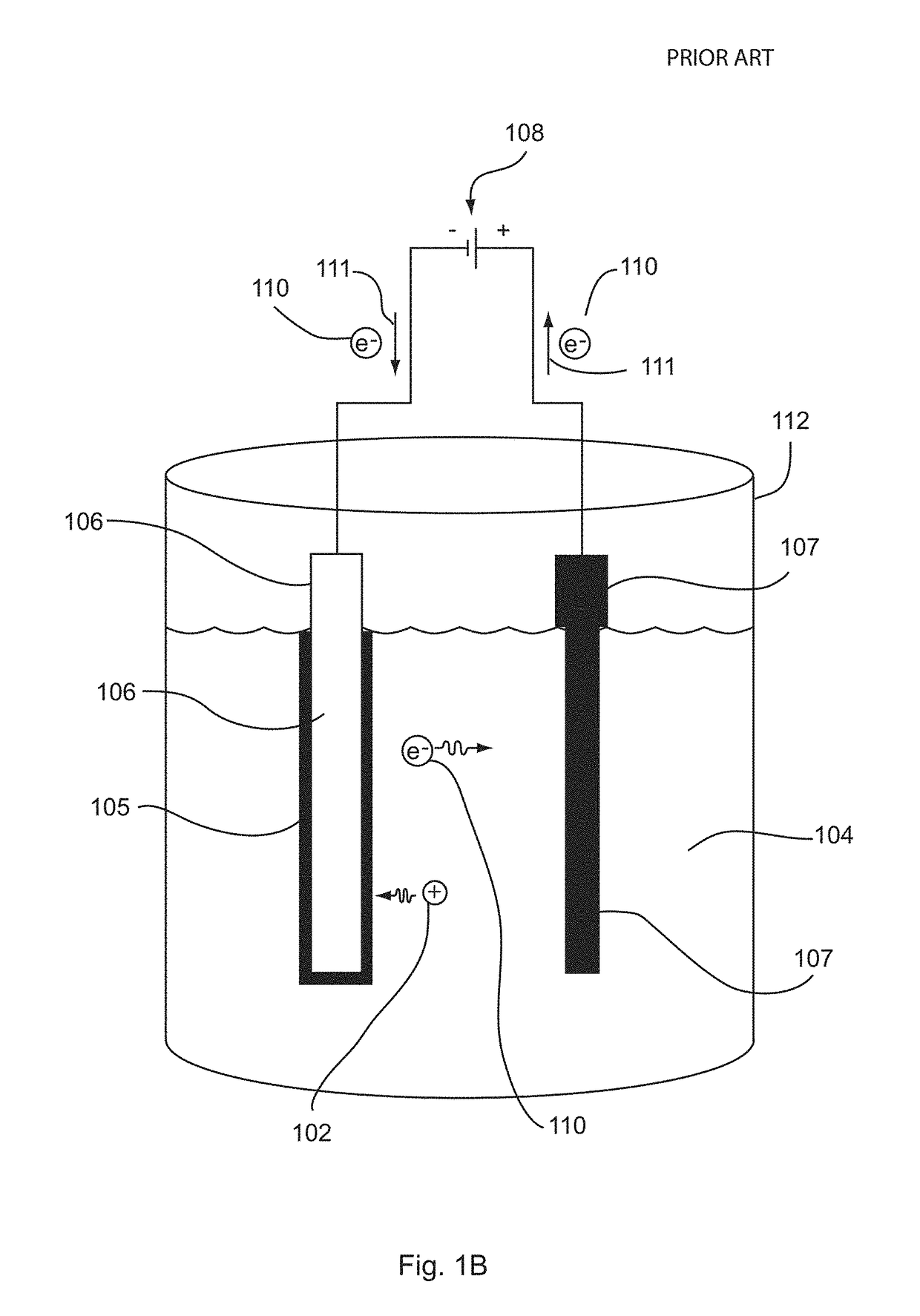

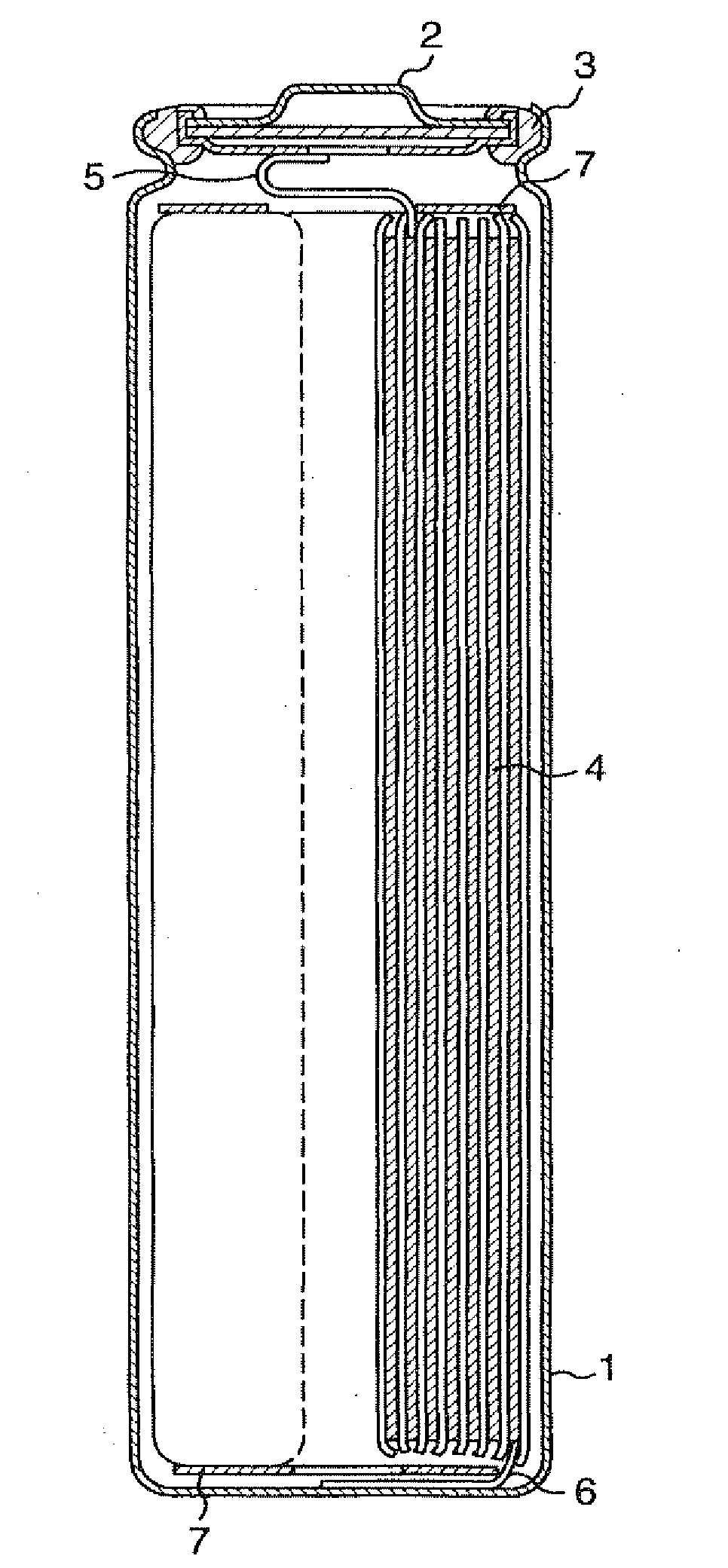

Electrolytic solution for non-aqueous type battery and non-aqueous type secondary battery

InactiveUS20030118912A1Excellent in high-temperature storage characteristicReduced responseCell electrodesOrganic electrolyte cellsNon aqueous electrolytesTerphenyl

In a rechargeable non-aqueous electrolyte secondary battery using positive electrodes, negative electrodes and a non-aqueous electrolytic solution, additives to the electrolytic solution are used in combination, preferably in combination of at least two compounds selected from o-terphenyl, triphenylene, cyclohexylbenzene and biphenyl, and thus there are provided batteries excellent in safety and storage characteristics.

Owner:PANASONIC CORP +1

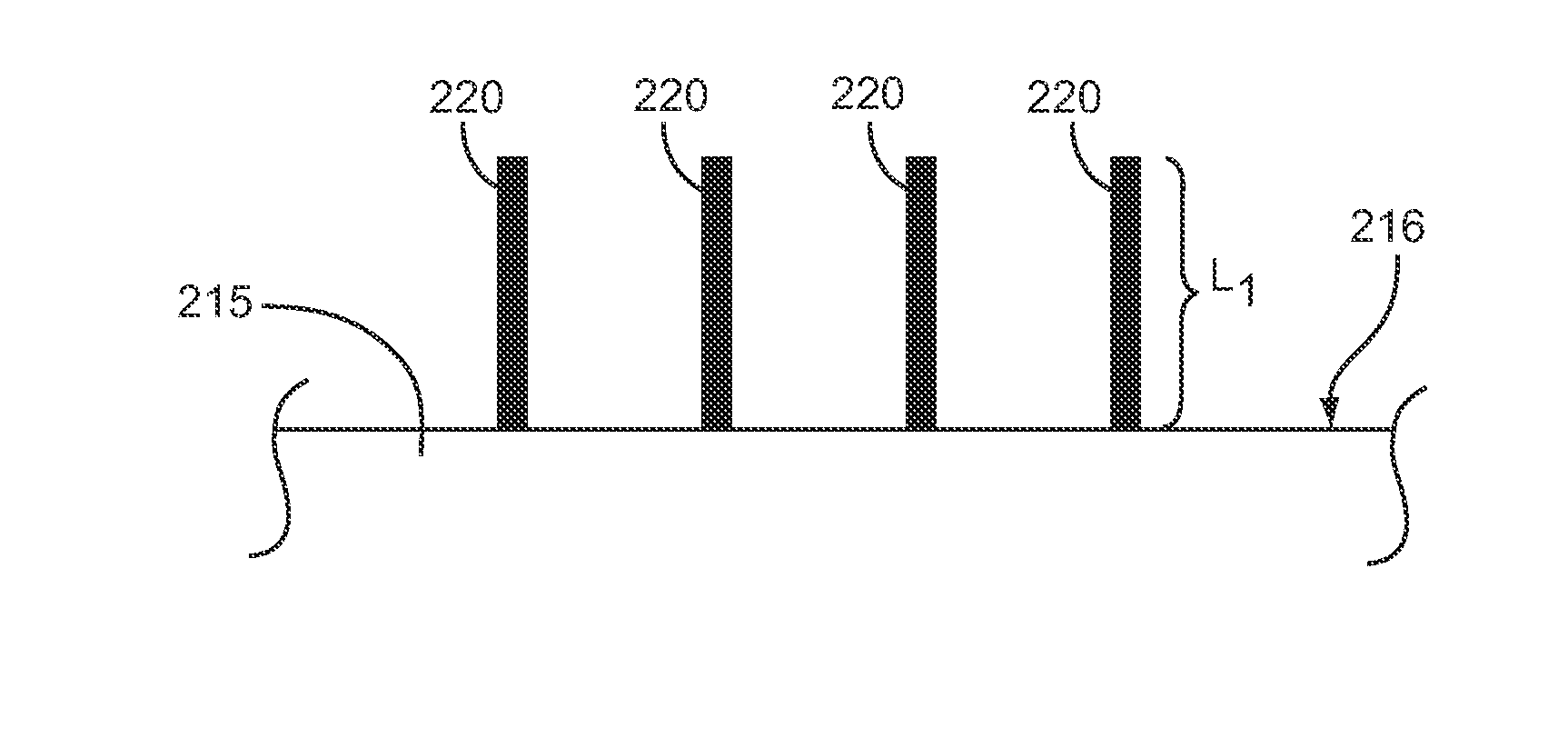

Silicon Nanostructure Active Materials for Lithium Ion Batteries and Processes, Compositions, Components and Devices Related Thereto

ActiveUS20140248543A1Highly controllableAvoid irreversibleElectrochemical processing of electrodesElectrode carriers/collectorsCopper electrodeGraphite particle

The present invention relates to nanostructured materials for use in rechargeable energy storage devices such as lithium batteries, particularly rechargeable secondary lithium batteries, or lithium-ion batteries (LIBs). The present invention includes materials, components, and devices, including nanostructured materials for use as battery active materials, and lithium ion battery (LIB) electrodes comprising such nanostructured materials, as well as manufacturing methods related thereto. Exemplary nanostructured materials include silicon-based nanostructures such as silicon nanowires and coated silicon nanowires, nanostructures disposed on substrates comprising active materials or current collectors such as silicon nanowires disposed on graphite particles or copper electrode plates, and LIB anode composites comprising high-capacity active material nanostructures formed on a porous copper and / or graphite powder substrate.

Owner:ONED MATERIAL INC

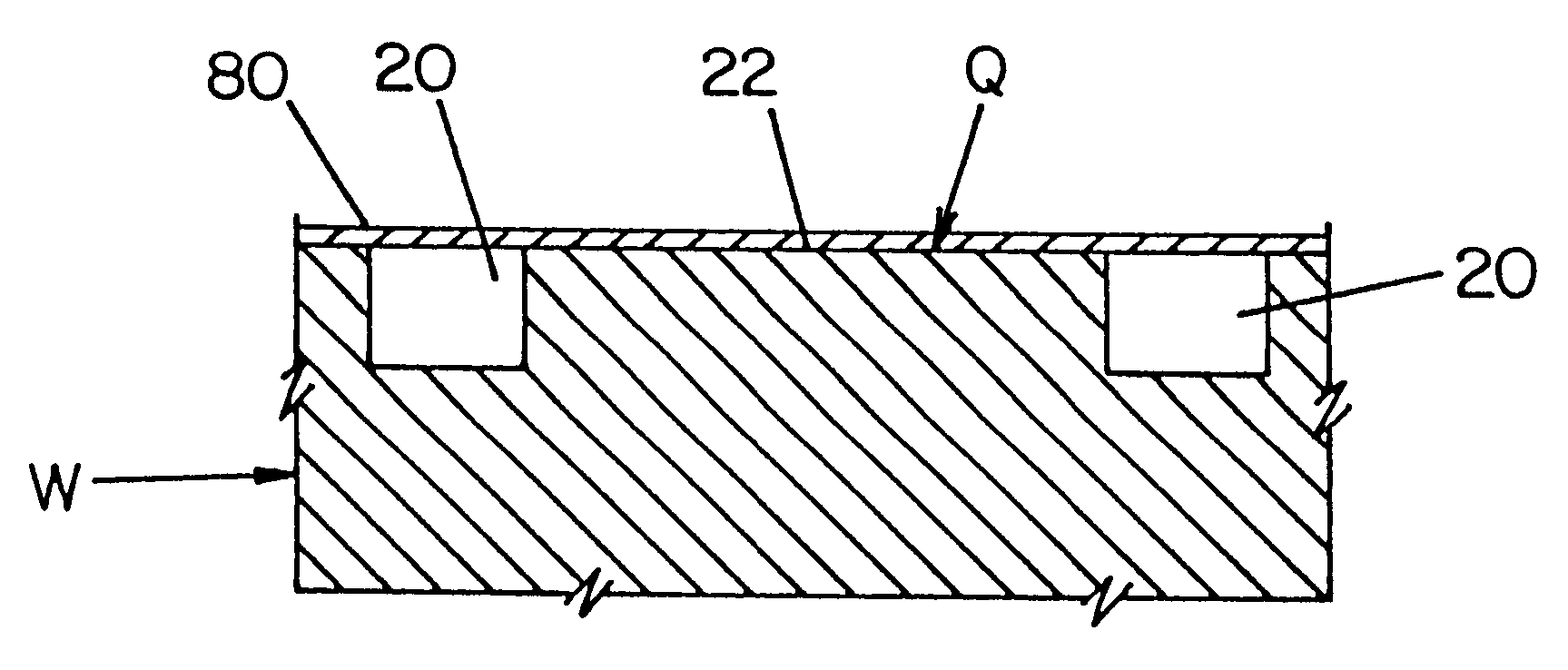

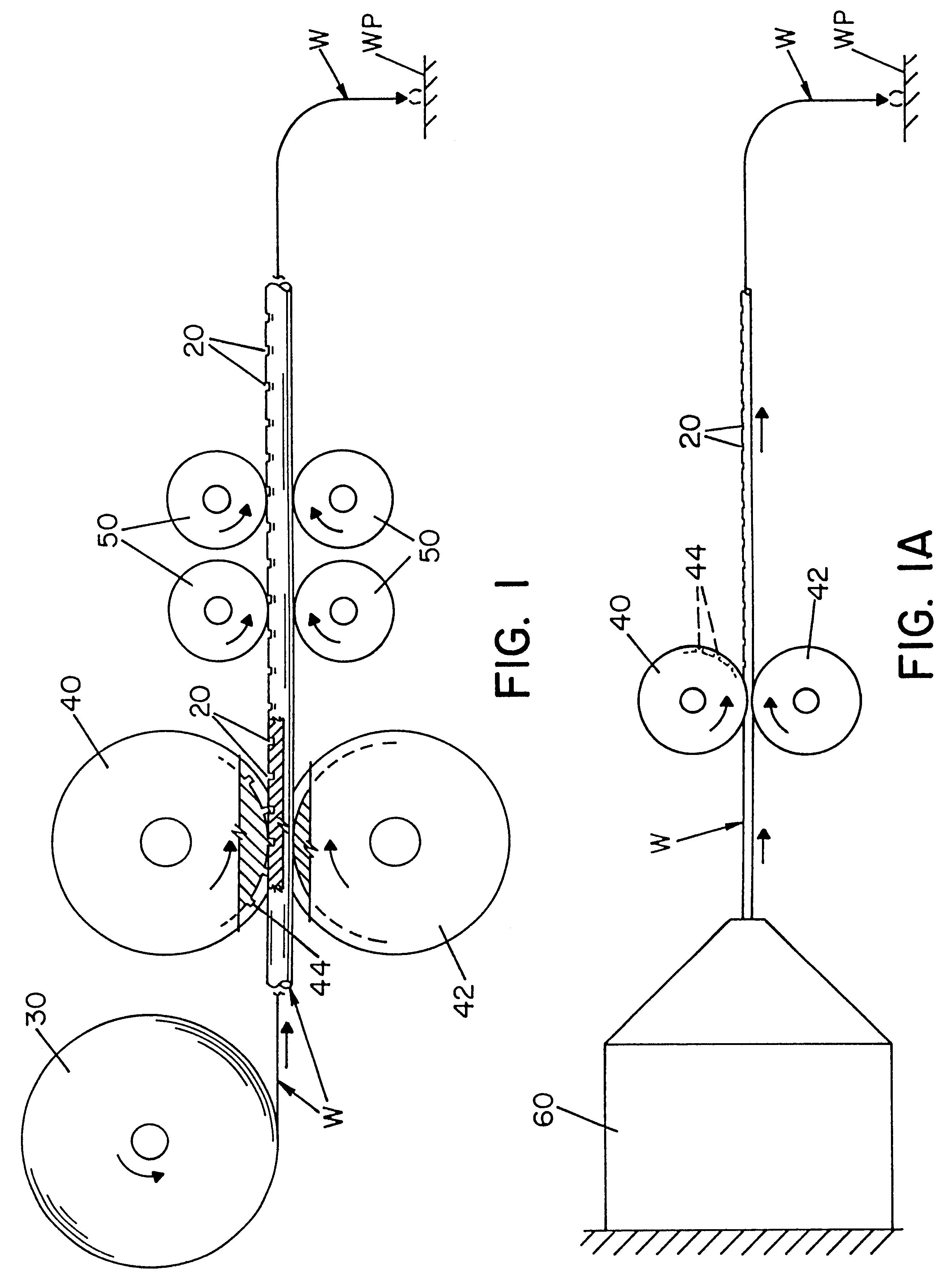

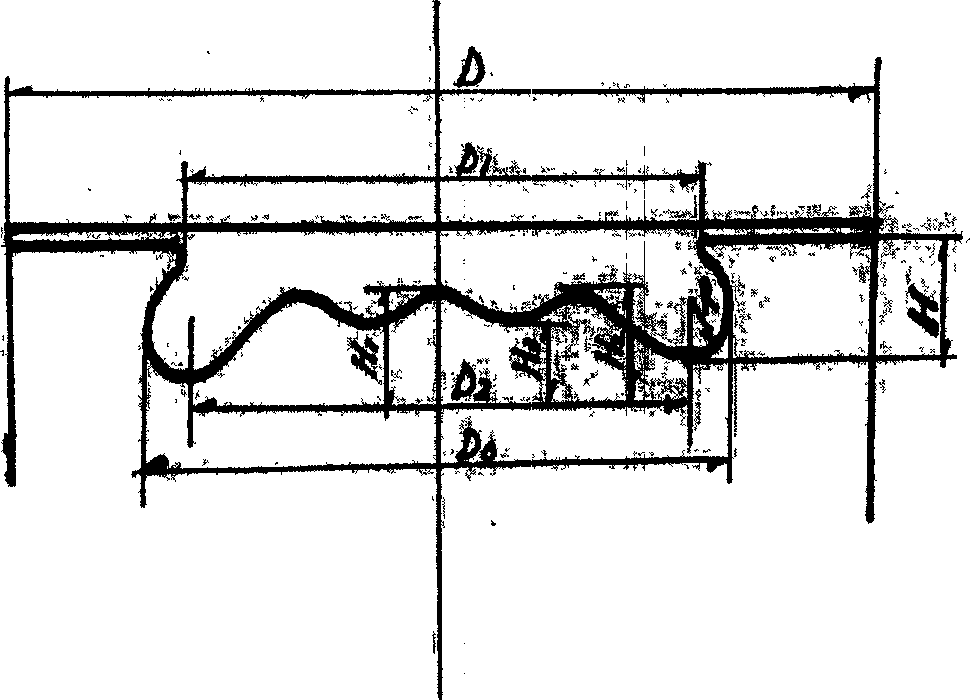

Electrode and method of making same

InactiveUS6426483B1Improve the immunityEasy to controlElectrode supporting devicesWelding/cutting media/materialsMaterials scienceSolid metal

A welding wire for use in electric arc welding and method of making same, wherein the wire has an effective outer diameter and comprises a length of solid metal formed into a series of distinct segments each having a selected volume and having an indented and non-indented region with the cross sectional area of the solid metal at said non-indented region being greater than the cross sectional area of the solid metal at the indented region.

Owner:LINCOLN GLOBAL INC

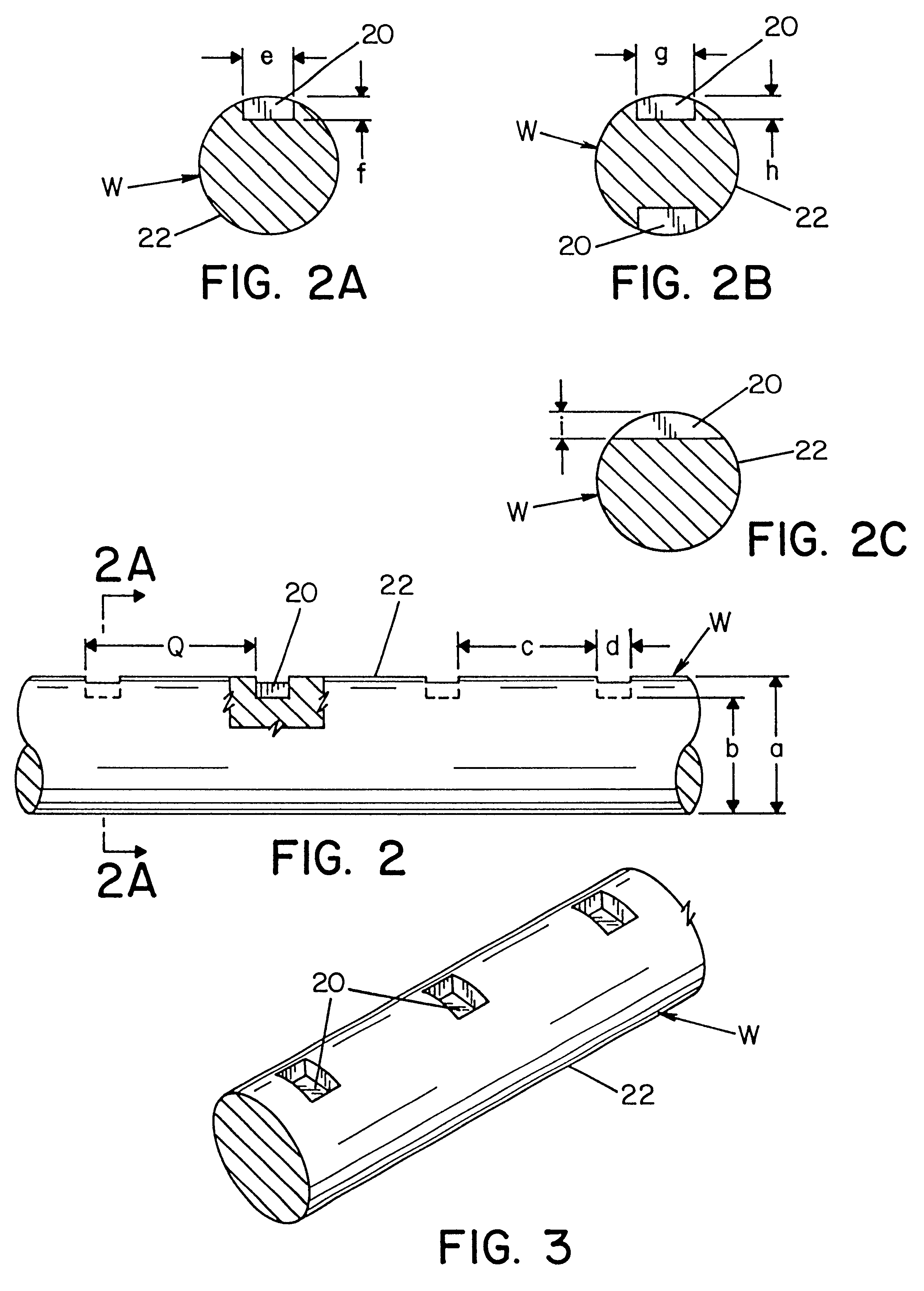

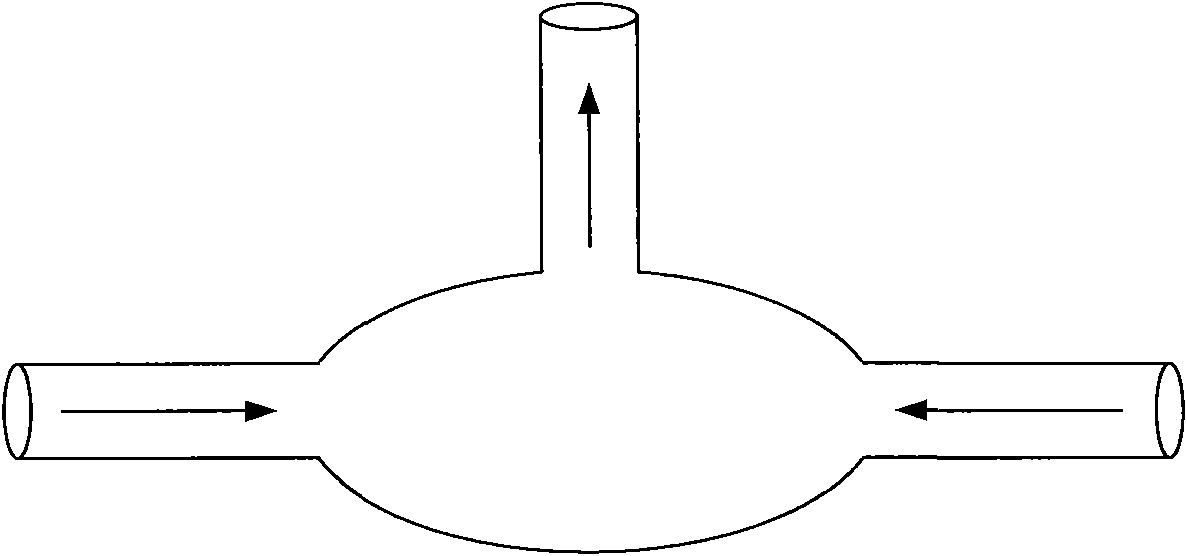

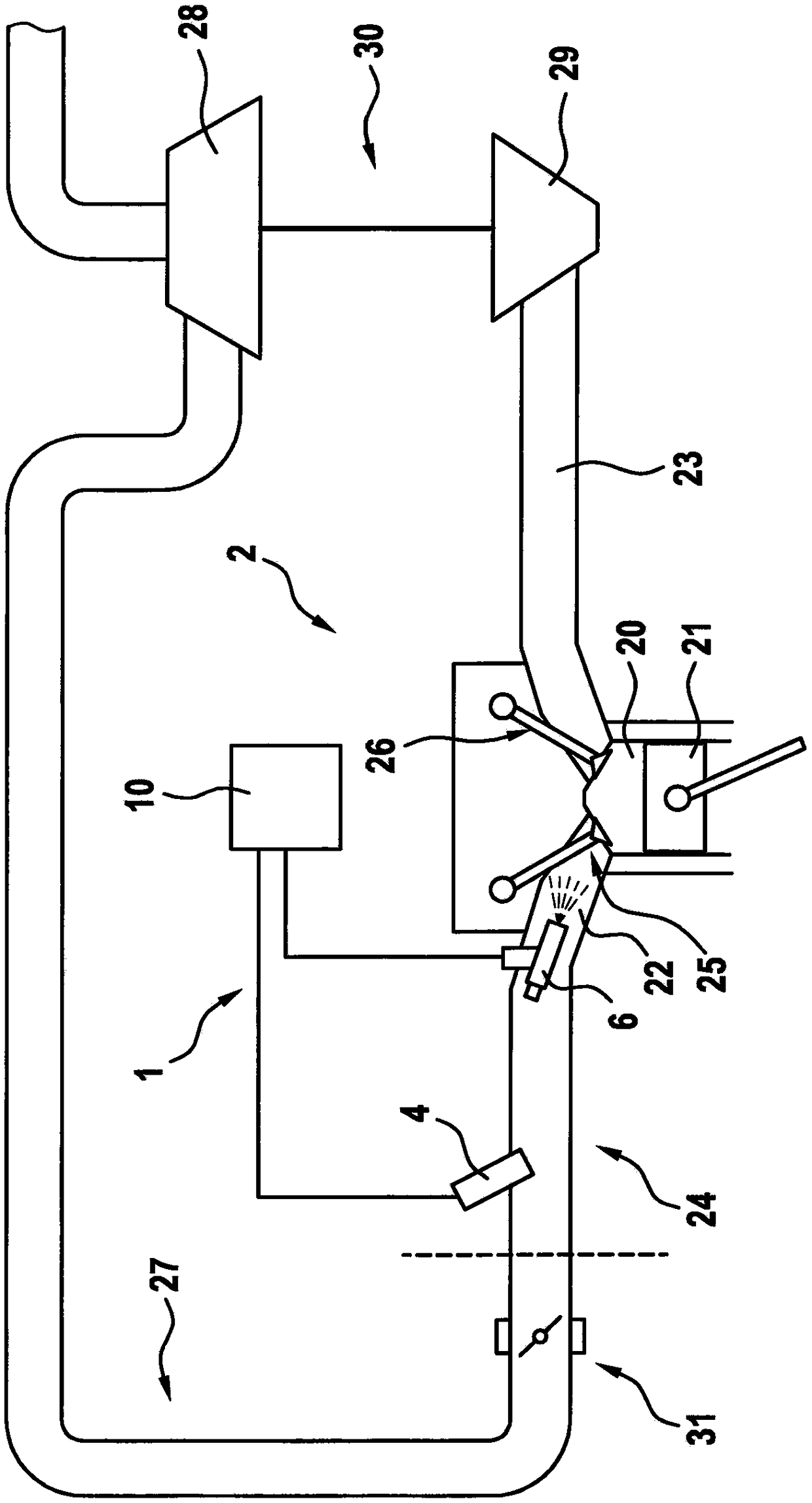

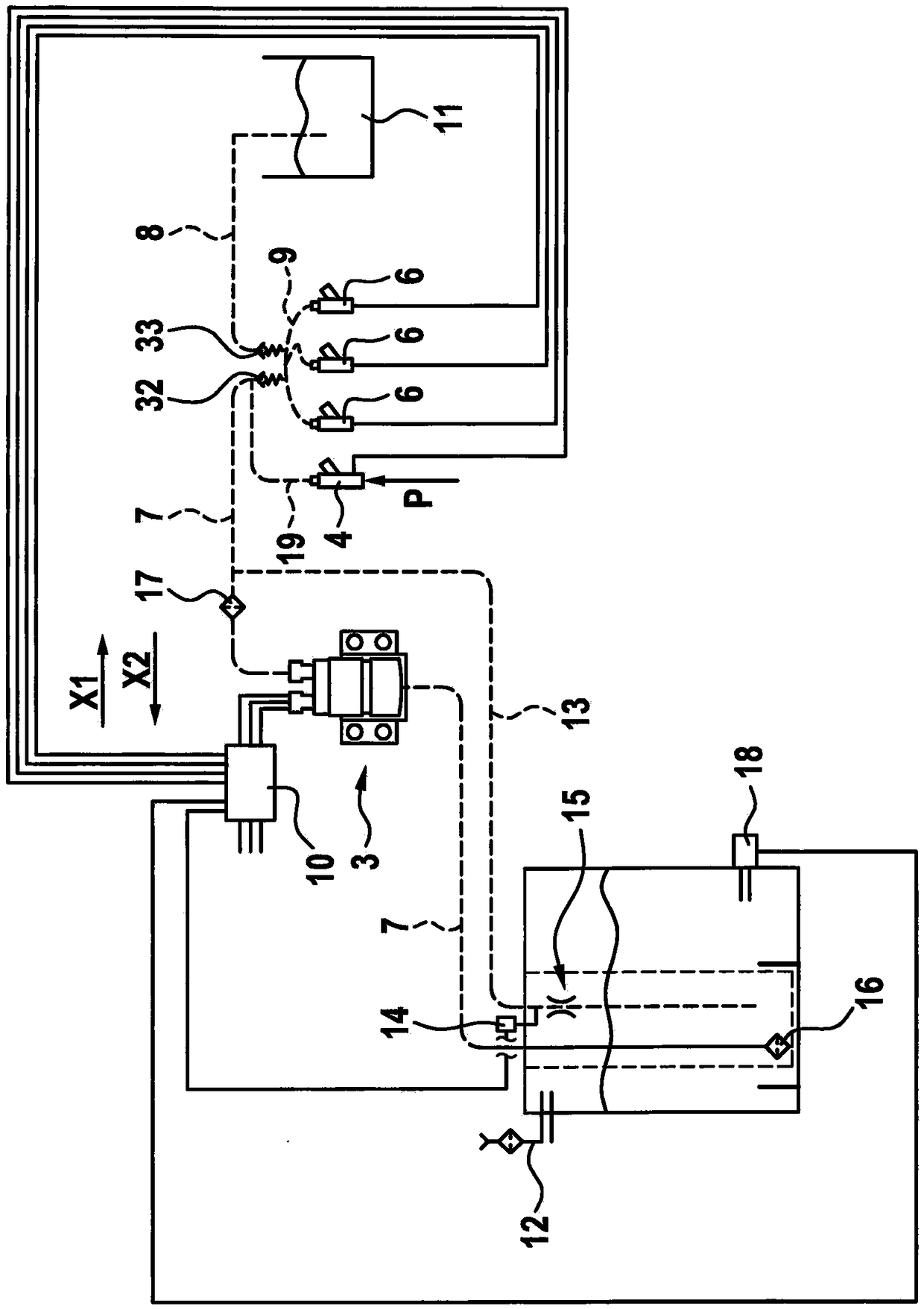

Two-staged turbocharging system testing device and testing method

ActiveCN104234820AControl characteristicsControl air intakeInternal-combustion engine testingInternal combustion piston enginesIntake pressureIntercooler

The invention discloses two-staged turbocharging system testing device and testing method. The components of an analogue turbocharging system are as follows: the outlet of an air compressor for simulating exhaust flow of an engine is sequentially connected with a filtering tank, a laminar flow meter, an intake control valve, a surge tank, a heater, an intake pressure regulating valve and high- and low-pressure turbines to empty; a branch pipe of an inlet pipe of the filtering tank is provided with a vent valve; a vortex side bypass-valve is connected between the inlet and the outlet of the high-pressure turbine; the outlet of a low-pressure gas compressor is sequentially connected with an intercooler, a high-pressure gas compressor, a second intercooler, a second surge tank, a second laminar flow meter and a back pressure regulating valve and then outputs pressurized air; a pressure side bypass valve is connected between the inlet and the outlet of the high-pressure gas compressor. The gas temperature, pressure and flow are adjusted in a plurality of manners; the pre-vortex pressure and the temperature gradient are tested by transient pressure and temperature sensors; theoretical basis and data support are provided for a transient control strategy.

Owner:成都飞擎航空科技有限公司

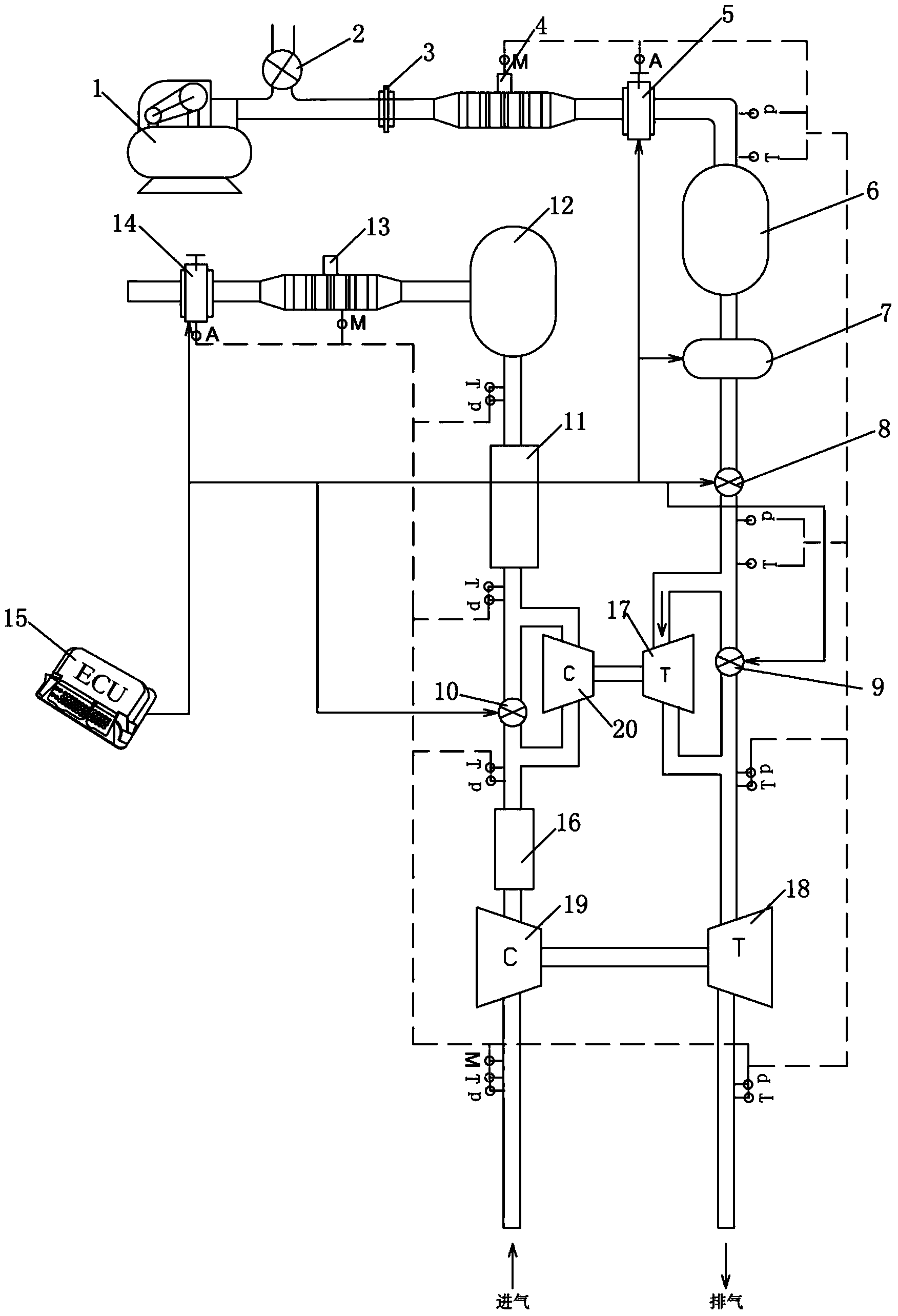

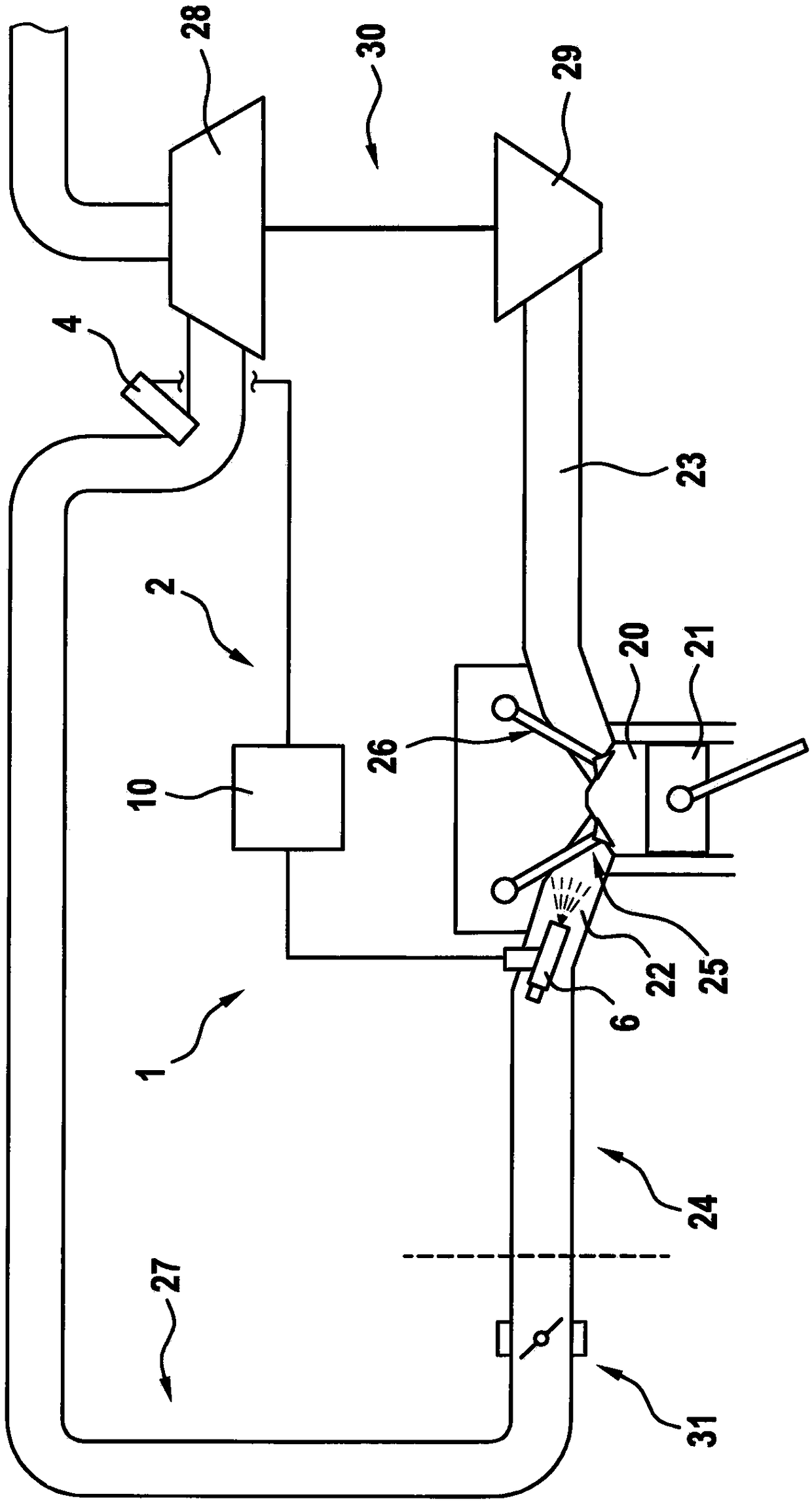

Combustion system and method for self adaption controllable heat premixing direct jet type diesel engine

InactiveCN1587660AReduce generationEffective time controlInternal combustion piston enginesFuel injection apparatusCombustion systemBurn rate

The invention discloses a kind of self-adaptnig, heat-controllable, pre-mixing and direct-spraying diesel engine burning system and its method, which belongs to the field of internal-combustion engine. The stated burning system incldues multi-hole glib talker, multi connection space burning room and inelt track. The stated multi connection space burning room consists of two or more linking space structure, it can control the transmitting way for pre-mixing burning, and when cooperatnig with the fuel spraying and timing oil support, it can effectively control the space-time distribution of combination gas and fire-starting point and burn rate under different operating modes, thus make the burning system be self-adapting and controllable. The burning room can form multi circulations to promote the forming of the homogeneous combination gas. The vortex ratio O of the stated system is 0-2, glib aperture is 50-180 mum, the oil spraying pressure is higher than 800 bar, it can reduce flame temperature notably, carbon smoke, NOX and HC, improve the combustion efficiency.

Owner:侯德洋

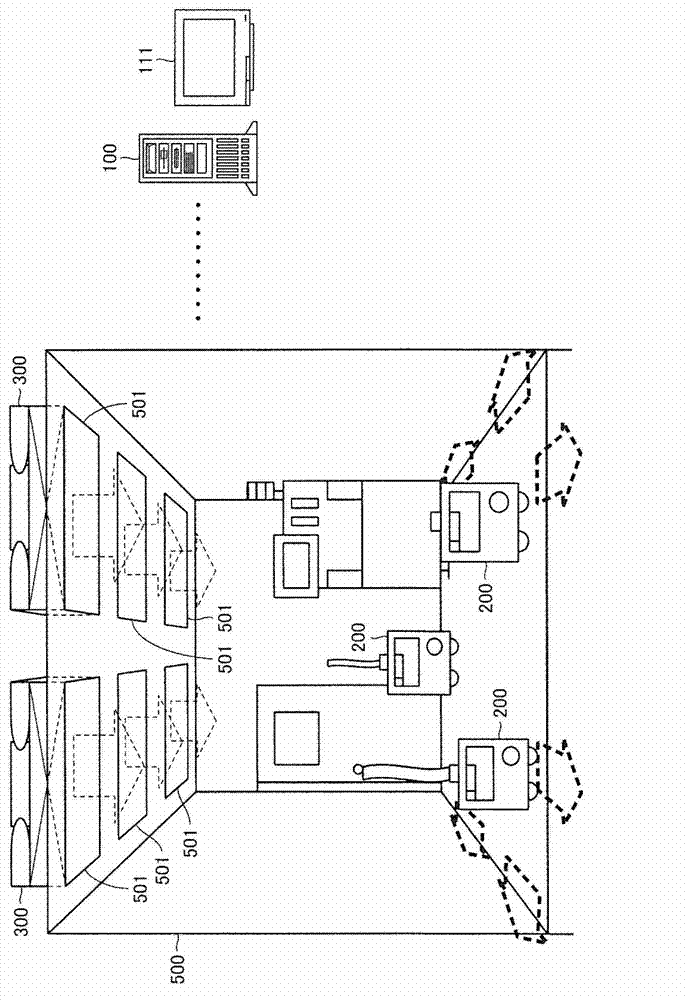

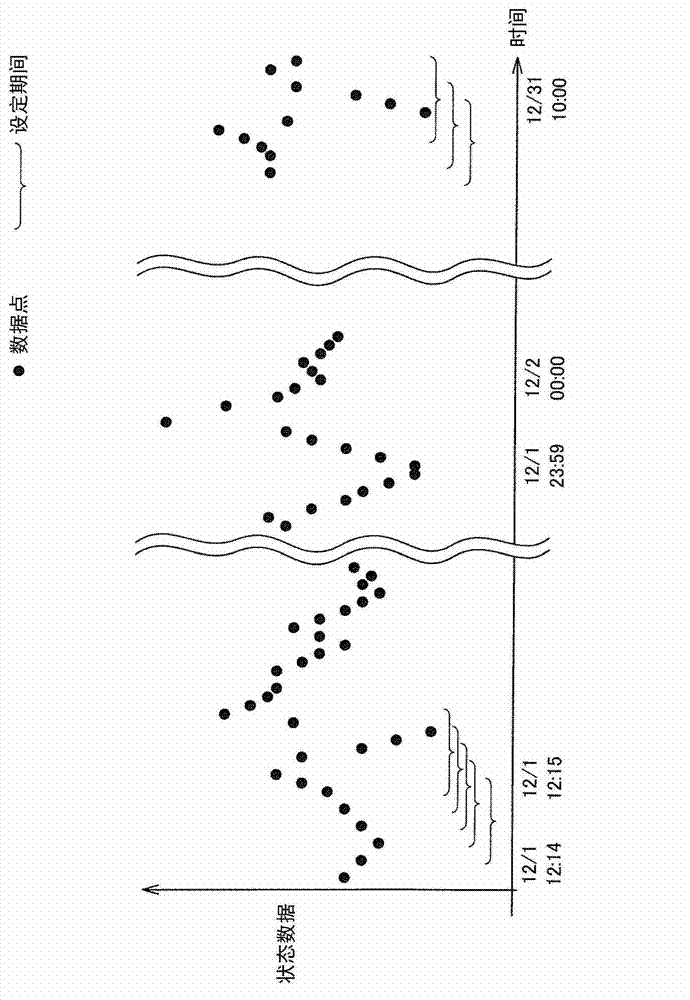

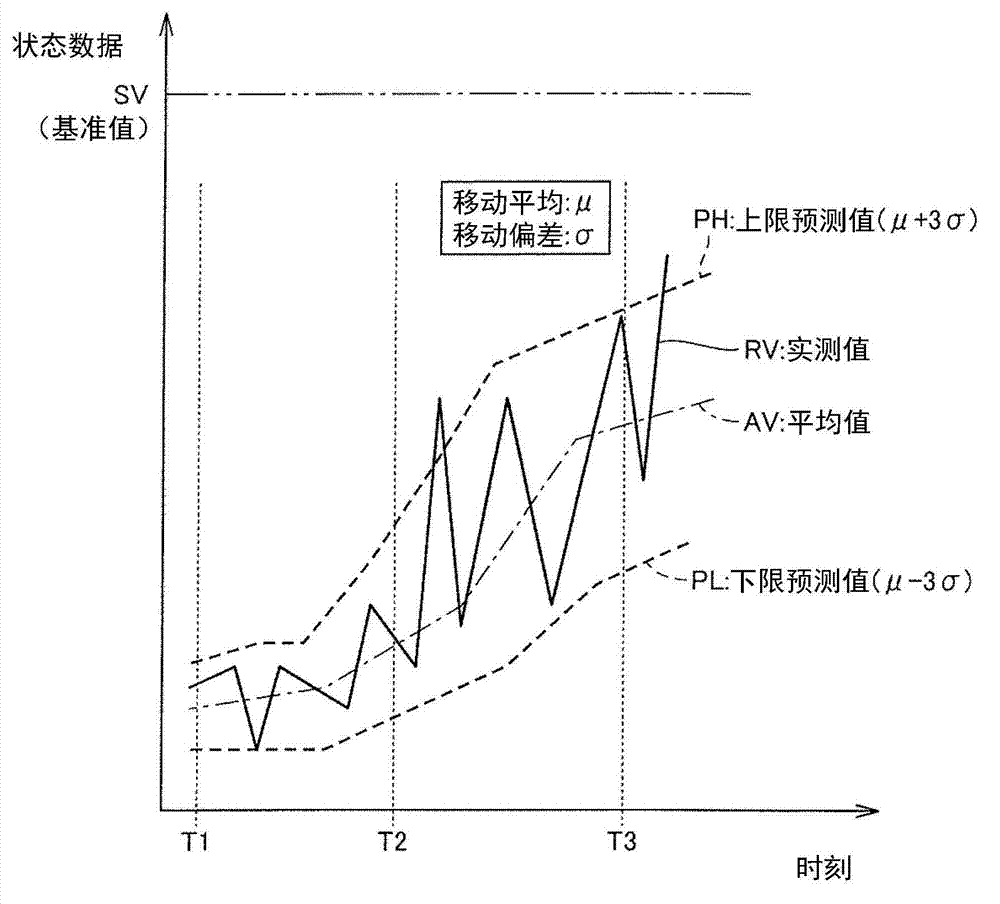

System control apparatus and system control method

InactiveCN103246212AAvoid wastingControl characteristicsMechanical apparatusSpace heating and ventilation safety systemsControl systemProcess engineering

A system control apparatus and a system control method in which, when a state of a production system is maintained at a reference value or within a reference range, a state of the production system is surely controlled while generation of useless energy is avoided and a user can recognize a degree of energy saving. In consideration of an influence of a disturbance, a prediction range is derived with respect to data ("status data") indicating the state in which quality of a product produced by the production system, and an instrument is controlled based on a relationship between the prediction range and the reference value. Therefore, the instrument can be controlled in consideration of a variation in status data due to the influence of the disturbance.

Owner:ORMON CORP

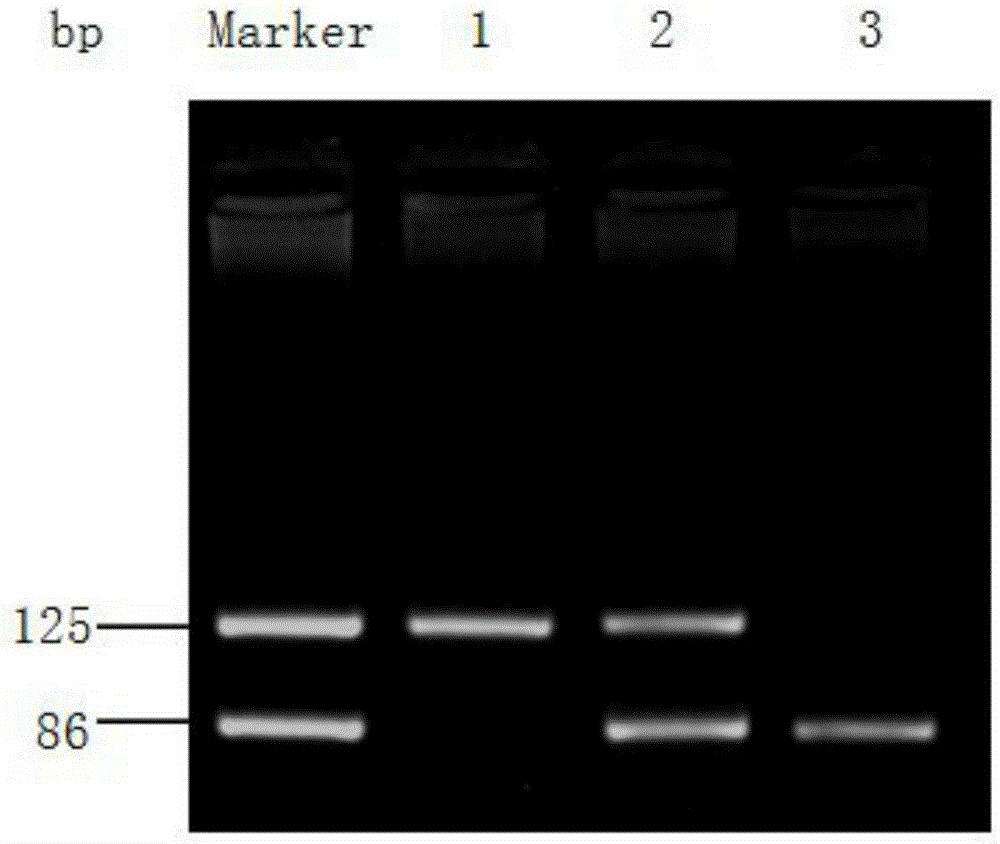

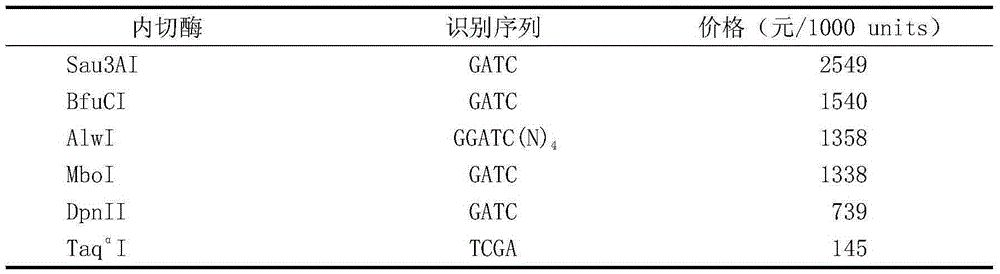

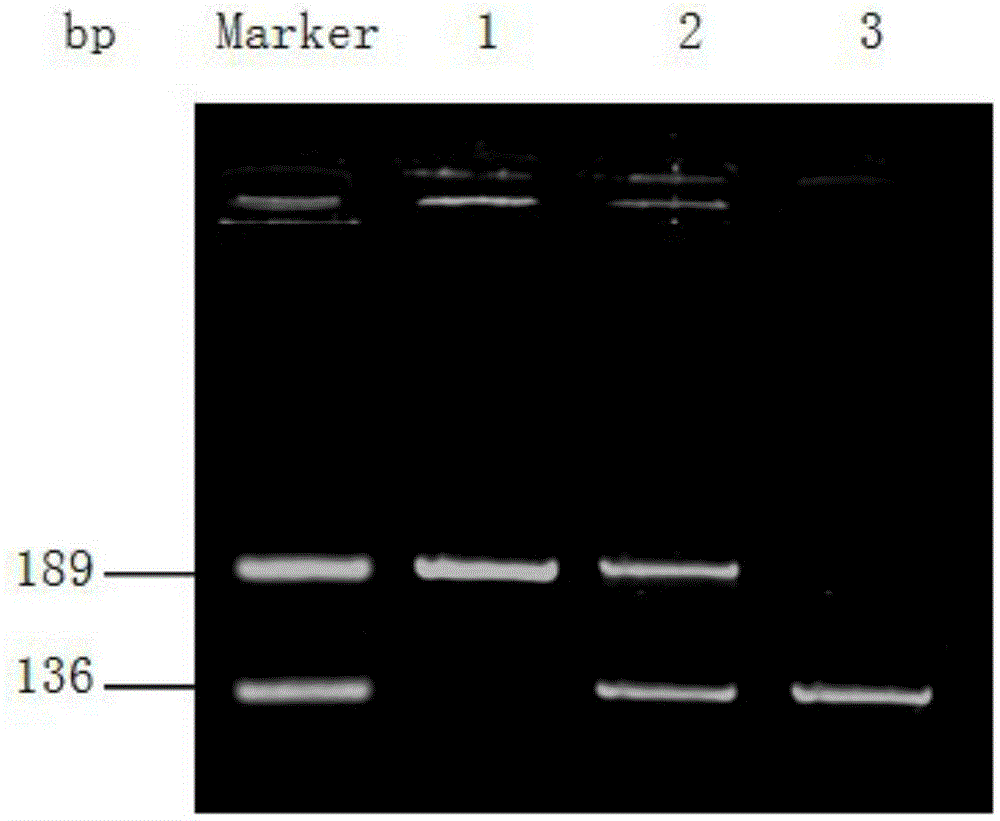

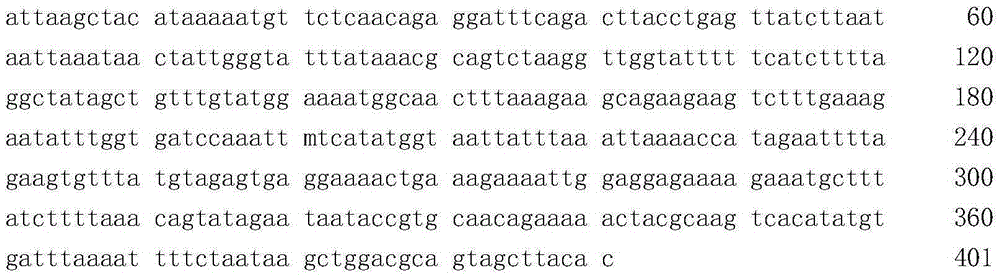

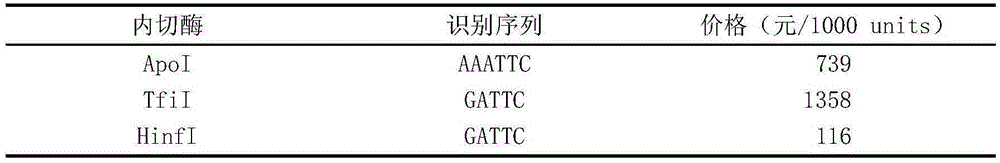

Method and kit for determination of human POT1 gene rs1034794 site polymorphism

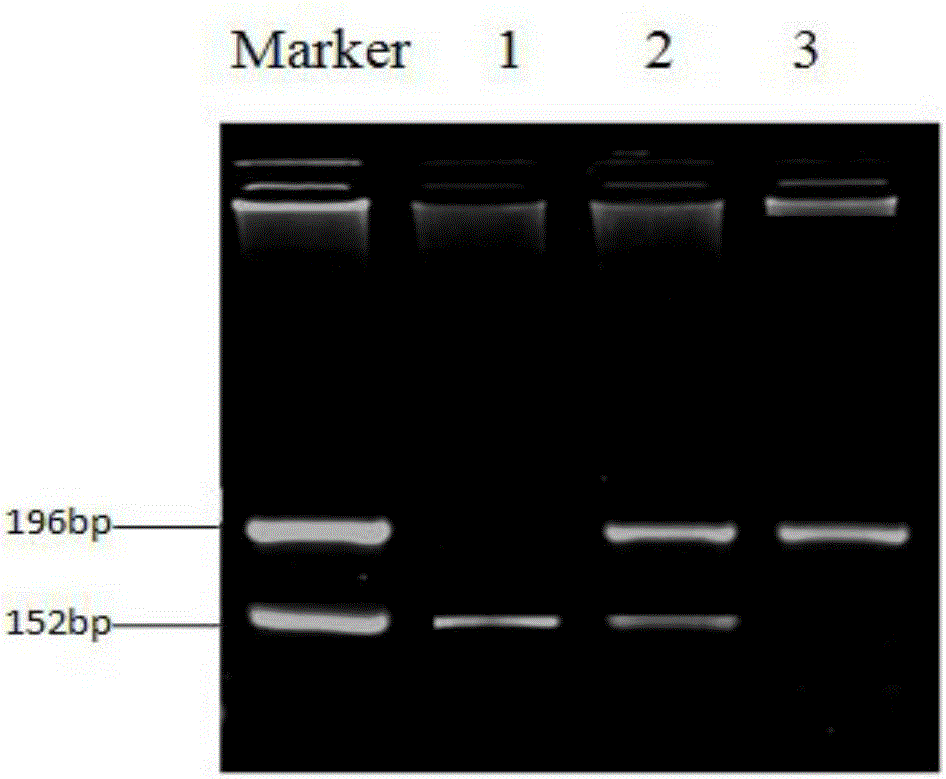

InactiveCN105274212AReduce yieldControl characteristicsMicrobiological testing/measurementEnzyme digestionGenomic DNA

The invention discloses a method and a kit for determination of human POT1 gene rs1034794 site polymorphism. The method is as follows: providing to-be-tested human genomic DNA; providing upstream and downstream primers for amplification of sequences nearby human POT1 gene rs1034794 site, wherein the upstream primer has a mismatched base A; taking the to-be-tested human genomic DNA as a template, using the upstream and downstream primers for PCR amplification reaction to obtain an amplification product containing AGCW fragment, wherein W is to be confirmed base A or T on the human POT1 gene rs1034794 site; providing a restriction endonuclease; using the restriction endonuclease for enzyme digestion of the amplification product to obtain a corresponding enzyme digestion product; and according to the resulting enzyme digestion product, determining whether the to be confirmed base W on the human POT1 gene rs1034794 site is A or T. The restriction endonuclease is restriction endonuclease which only be capable of cutting one of AGCA fragment or AGCT fragment. The determination method is fast and reliable, and can greatly reduce the determination cost.

Owner:ZHENGZHOU UNIV

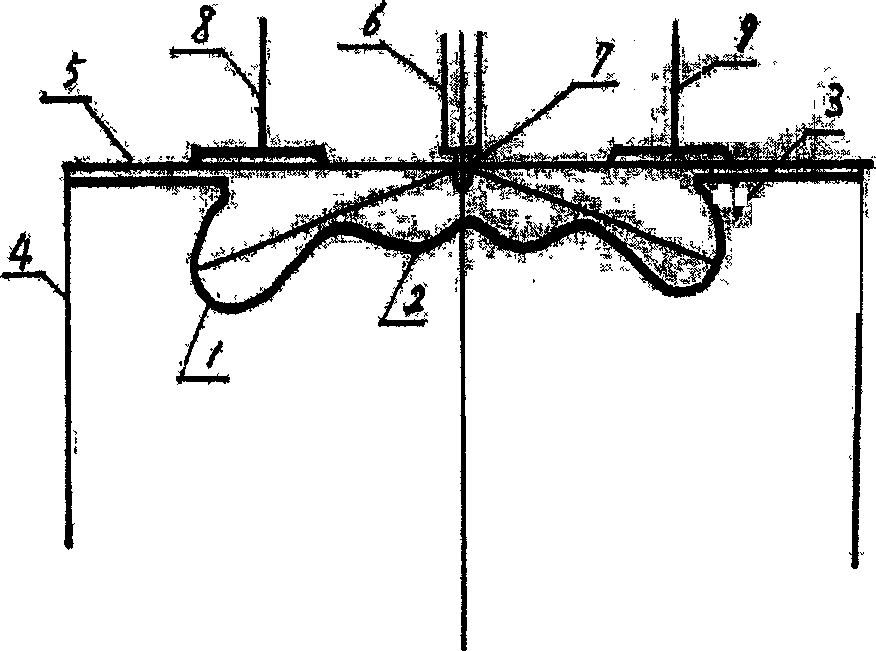

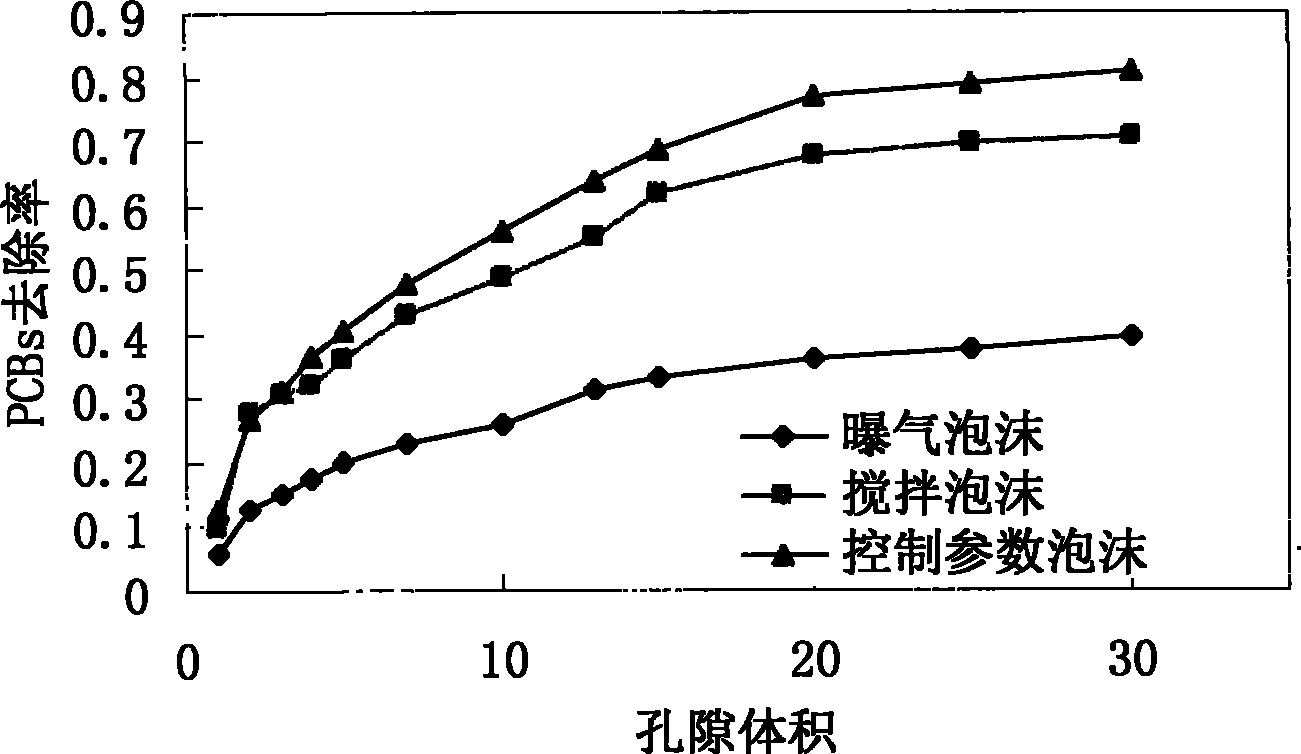

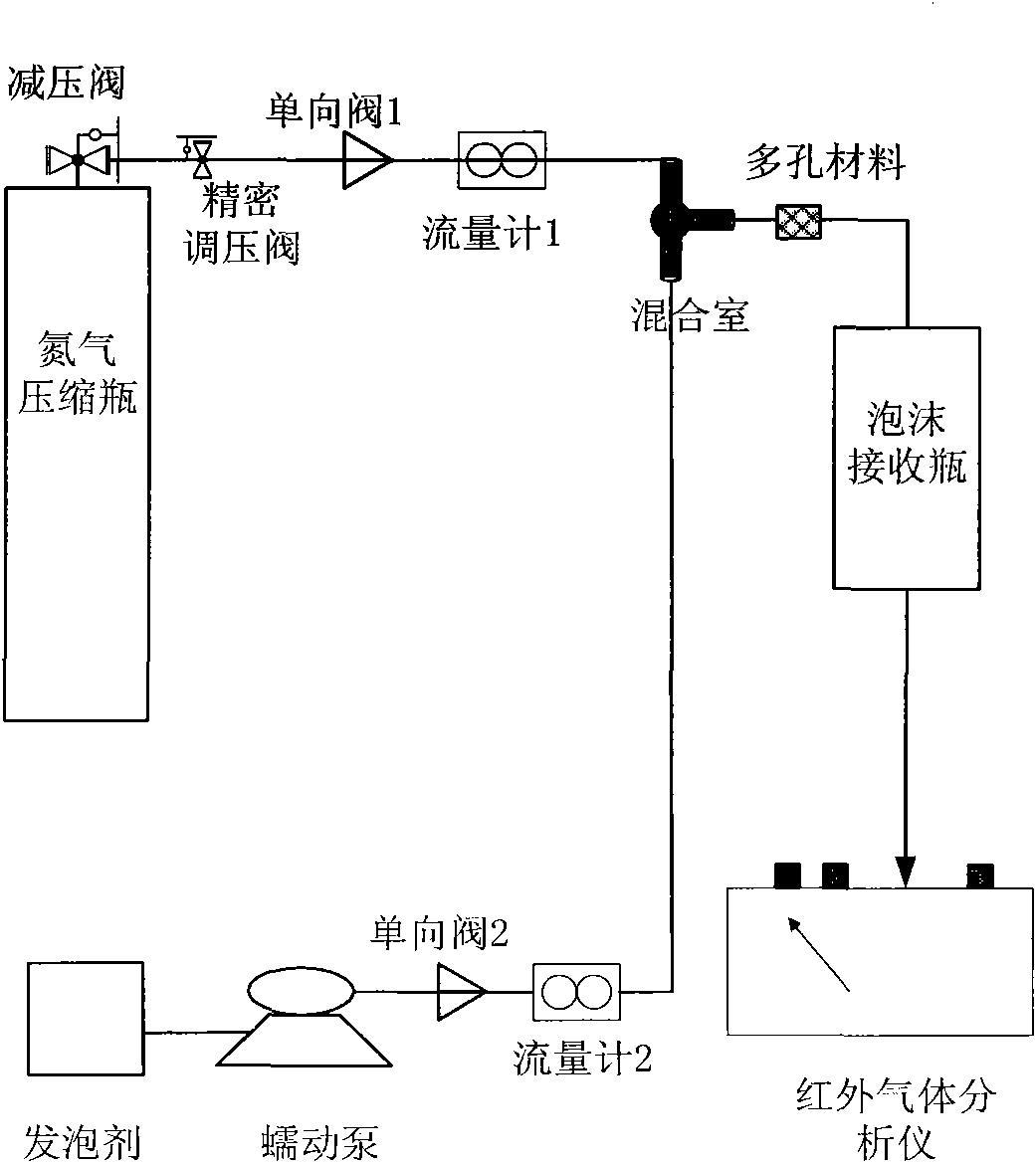

Method and device for generating ectopic foam

The invention discloses a method and a device for generating ectopic foam. The method comprises the following steps of: controlling the flow rate of a foaming agent to be 0.1-50mL / min and the flow rate of gas to be 1-500mL / min respectively by using a flowmeter, mixing the gas and liquid in a volume ratio of 100:35-100:0.2, and cutting the mixed gas and liquid by using a porous material to obtain the foam with the grain size ranging from 10 to 3,500mu m. Compared with the prior art, the invention has the advantage that: by utilizing the basic characteristic that the foam can be generated under manual control through the ectopic foam generating technology, the generated foam can be widely applied to the field of polluted soil washing.

Owner:陈家军 +2

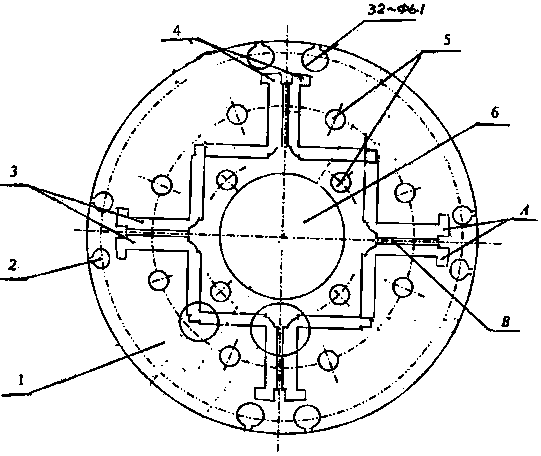

Three-phase permanent-magnet synchronous motor rotor punching sheet suitable for both line starting and variable frequency starting

InactiveCN104079095AReduce vibrationHigh out of step torqueMagnetic circuit rotating partsSynchronous machine detailsPunchingPermanent magnet synchronous motor

The invention relates to a three-phase permanent-magnet synchronous motor rotor punching sheet suitable for both line starting and variable frequency starting. The three-phase permanent-magnet synchronous motor rotor punching sheet is an iron core punching sheet which is super-ultra-high in efficiency and suitable for a rotor of a high pull-out torque three-phase rare-earth permanent magnet synchronous motor and a rotor of a variable-frequency and variable-speed motor three-phase permanent magnet synchronous motor, and is used for a permanent magnet synchronous motor with a 132 base. The three-phase permanent-magnet synchronous motor rotor punching sheet is provided with a rotor punching sheet body made of a low-loss silicon steel sheet in a punching mode. Starting rod holes are evenly distributed on the outer circumference of the rotor punching sheet body, and W-shaped magnetic steel grooves are evenly formed in the rotor punching sheet body. A magnetic isolation bridge A is arranged between the lower portions of the starting rods and the magnetic steel grooves, and a magnetic isolation bridge B and a magnetic isolation bridge C are arranged between every two adjacent magnetic steel grooves. Rigidity reinforced screw holes and rotor shaft holes are formed in the rotor punching sheet body.

Owner:JIANGSU JIUZHI MOTOR TECH

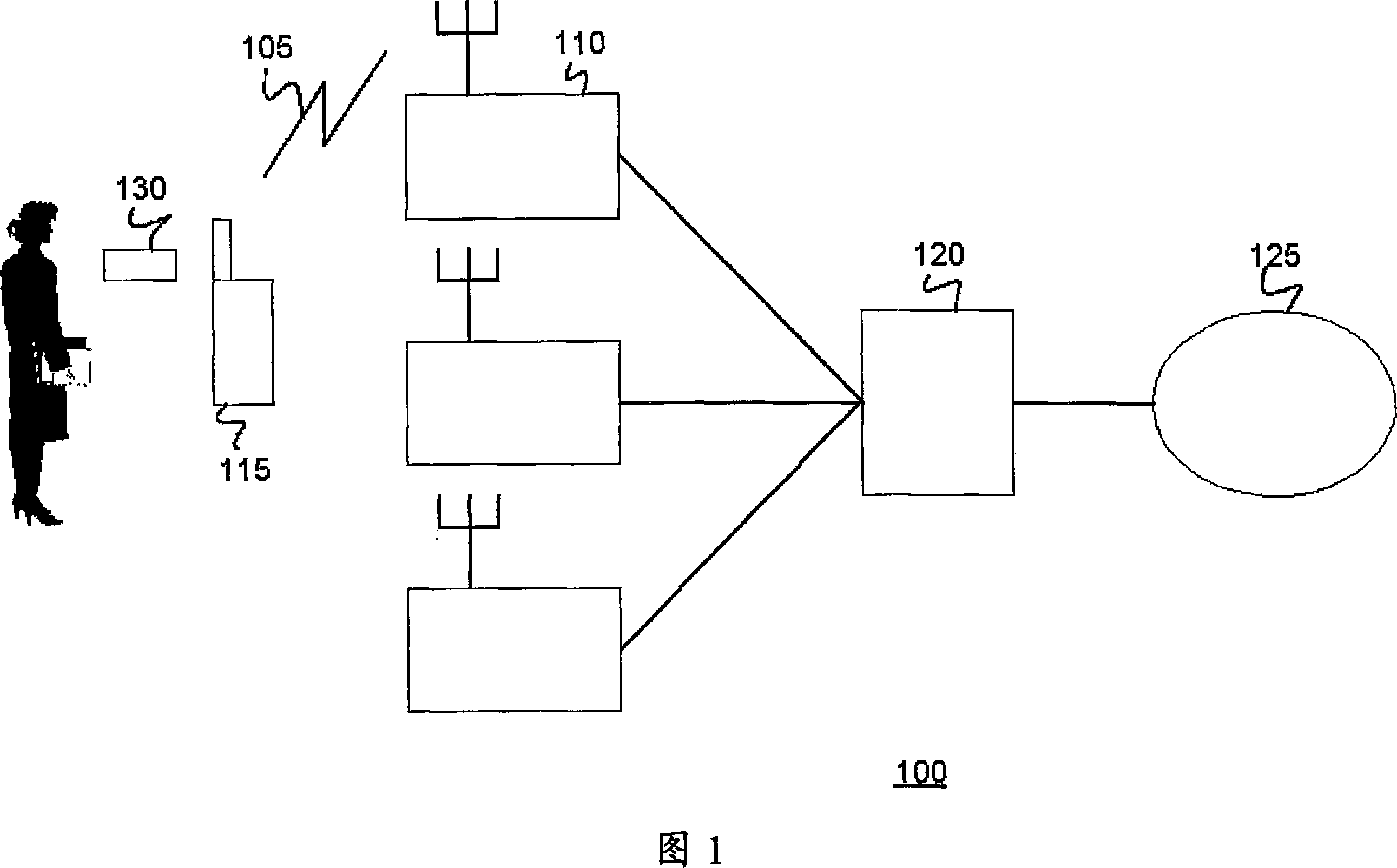

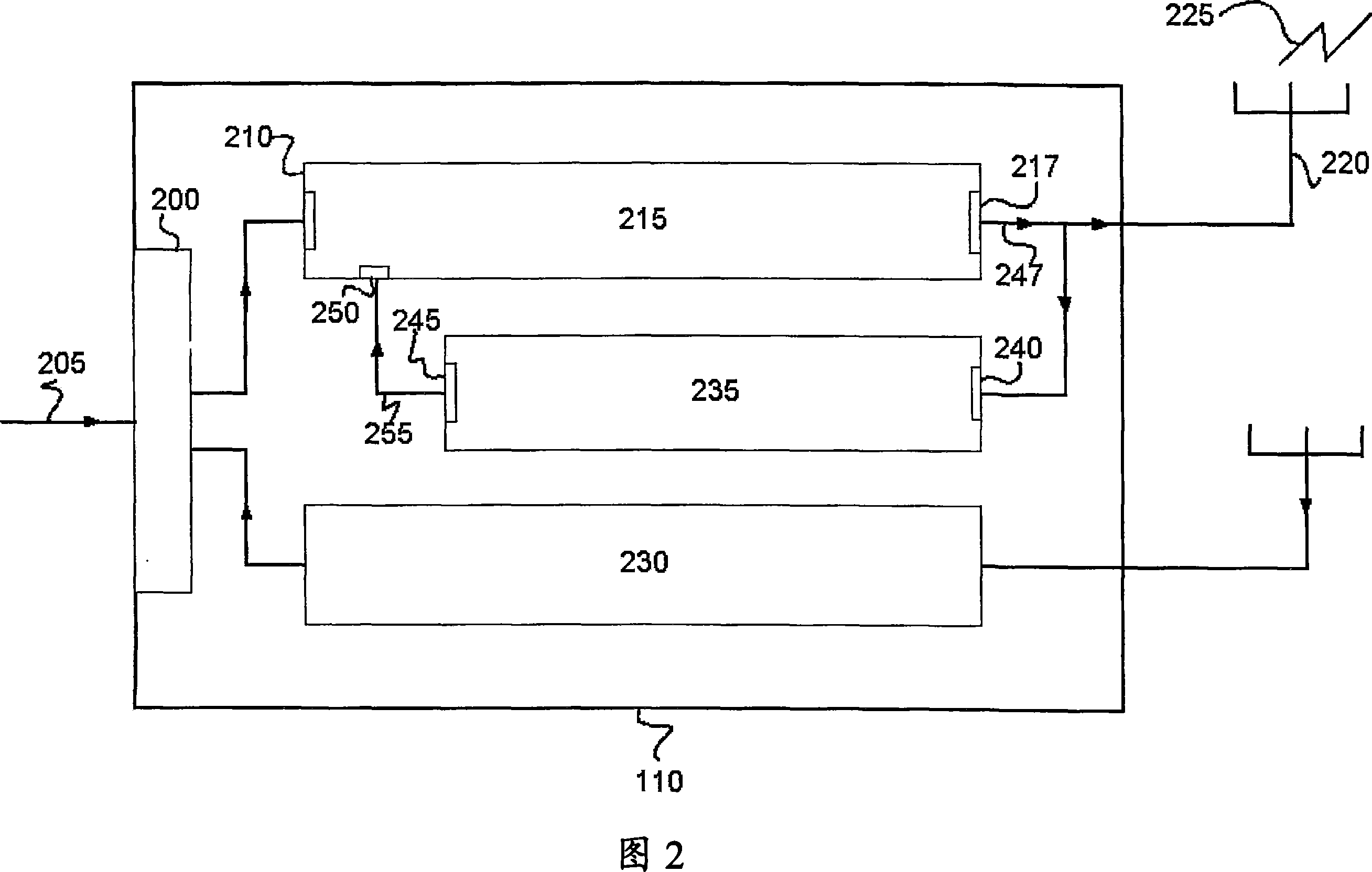

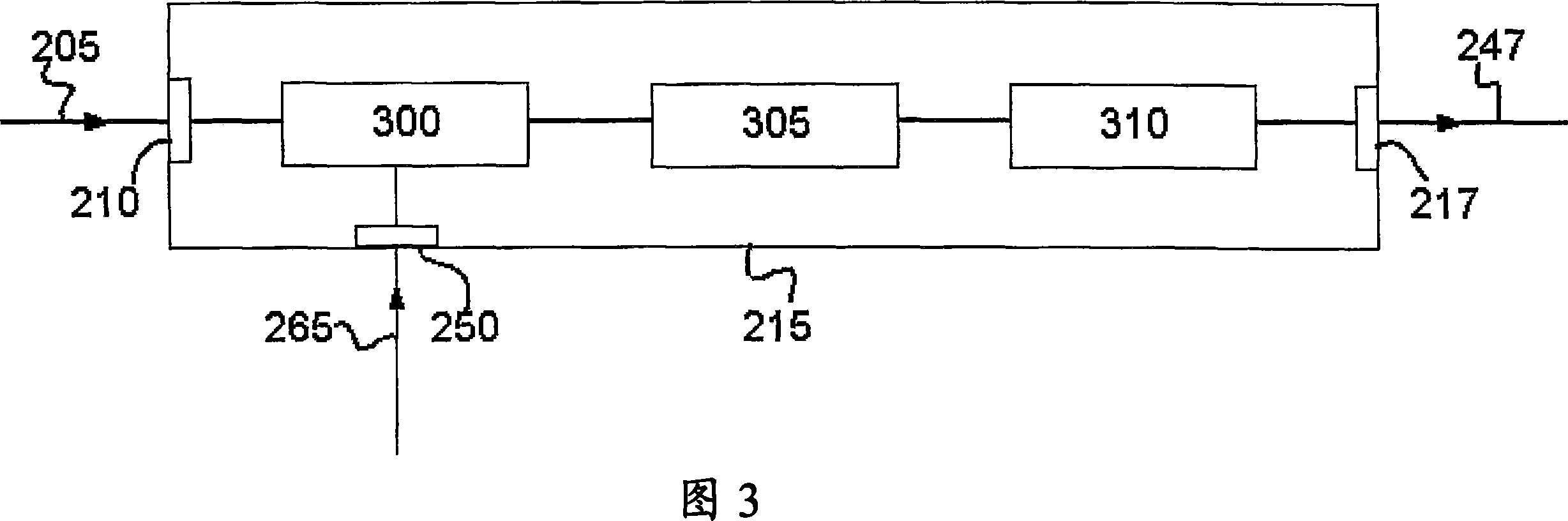

A radio transmitter and a method of operating a radio transmitter

InactiveCN101002394AControl characteristicsQuality improvementAmplifier modifications to reduce non-linear distortionPower amplifiersControl signalEngineering

By the present invention is provided an inventive radio transmitter and a method to operate a radio transmitter, by which the quality of a transmitted radio signal can be improved. The radio transmitter comprises at least one digital filter having adjustable parameters. Via a control signal input the transmitter can receive a feedback signal being indicative of the output signal from the transmitter. The radio transmitter comprises programmable digital circuitry adapted to analyzing the feedback signal and to generating an analysis result. The programmable digital circuitry is further adapted to adjusting the adjustable parameters of the digital filter in accordance with the analysis result.

Owner:ANDREW CORP

Silicon nanostructure active materials for lithium ion batteries and processes, compositions, components and devices related thereto

ActiveUS9812699B2Cost-effectiveHighly controllableElectrochemical processing of electrodesElectrode carriers/collectorsCopper electrodeLithium-ion battery

The present invention relates to nanostructured materials for use in rechargeable energy storage devices such as lithium batteries, particularly rechargeable secondary lithium batteries, or lithium-ion batteries (LIBs). The present invention includes materials, components, and devices, including nanostructured materials for use as battery active materials, and lithium ion battery (LIB) electrodes comprising such nanostructured materials, as well as manufacturing methods related thereto. Exemplary nanostructured materials include silicon-based nanostructures such as silicon nanowires and coated silicon nanowires, nanostructures disposed on substrates comprising active materials or current collectors such as silicon nanowires disposed on graphite particles or copper electrode plates, and LIB anode composites comprising high-capacity active material nanostructures formed on a porous copper and / or graphite powder substrate.

Owner:ONED MATERIAL INC

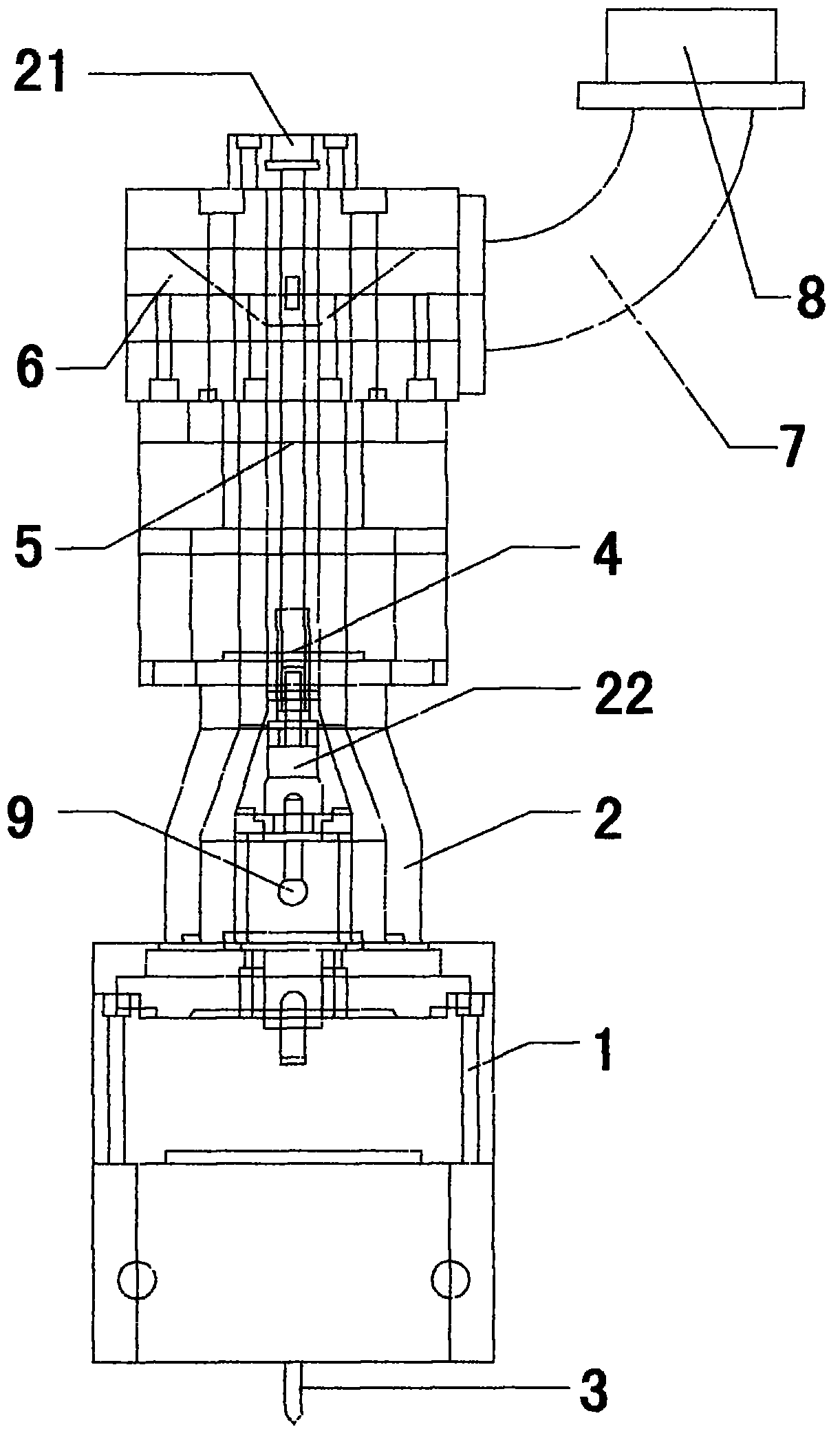

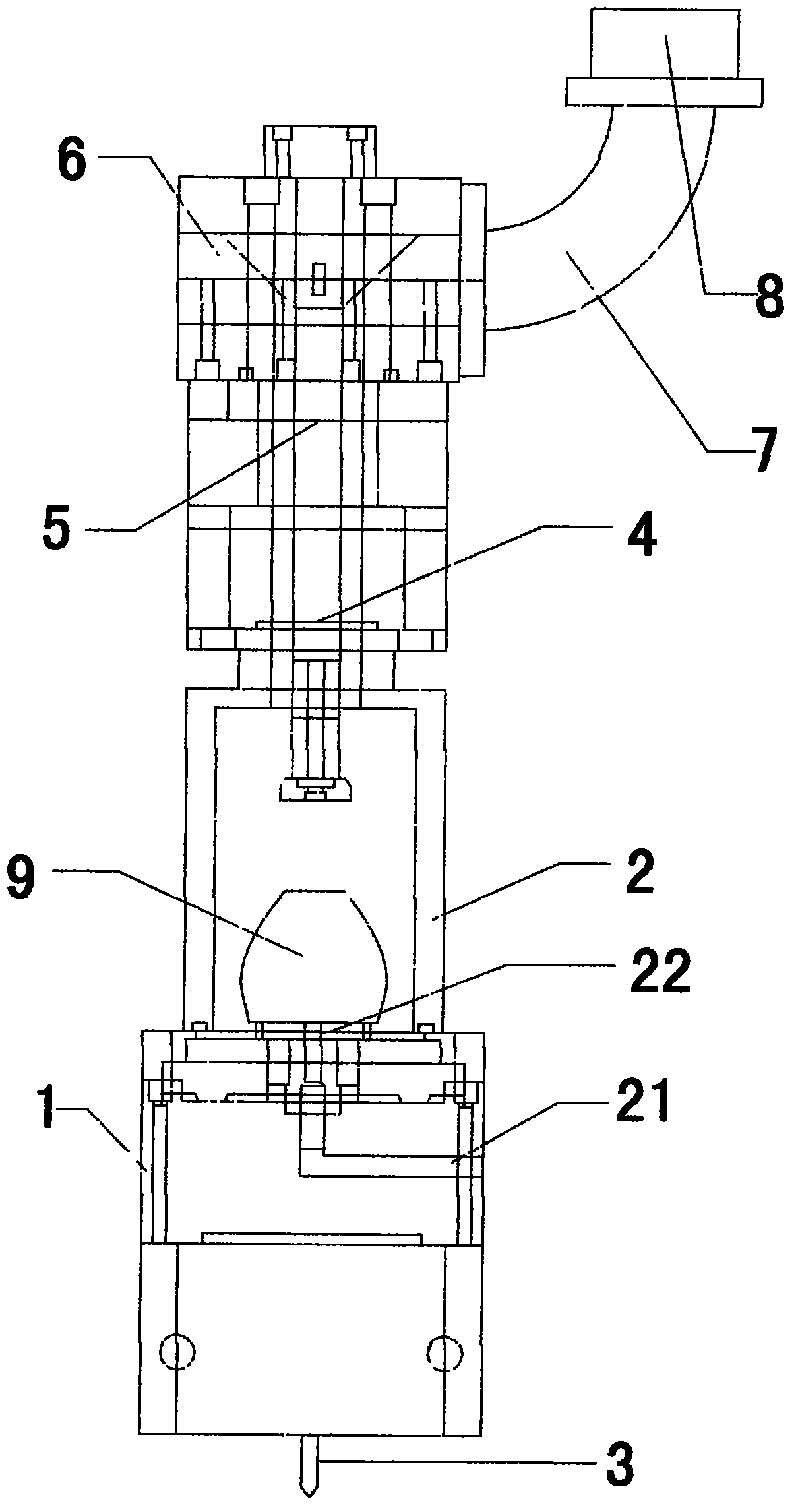

Method and equipment for forming optical films on workpiece

ActiveCN104233235AProcess equipment is compactImprove deposition efficiencyChemical vapor deposition coatingPulse microwaveEngineering

The invention relates to a method and equipment for forming optical films with various functions on a workpiece. A pulse plasma chemical vapor deposition method is adopted as the method. The method comprises the following steps that a, the workpiece is fixedly arranged in a sealed microwave cover, and the sealed microwave cover is vacuumized; b, oxygen is led into the sealed microwave cover, pulse microwaves are guided into the sealed microwave cover, and reaction is carried out for a certain time; c, gas containing film-forming component elements is led into the sealed microwave cover, the oxygen is continued to be led into the sealed microwave cover, the pulse microwaves are continued to be guided into the sealed microwave cover, reaction is carried out for a certain time, then, the gas is stopped from being led into the sealed microwave cover, and the pulse microwaves are stopped from being guided into the sealed microwave cover. The pulse plasma chemical vapor deposition method has the high deposition efficiency, the whole process only needs few minutes, and therefore the production efficiency is quite high; plasmas of the oxygen perform plasma cleaning and surface activation treatment on the surface of the workpiece before film forming, and therefore film adhesion is greatly improved; therefore, the product quality is improved.

Owner:HUIZHOU OBOLAND OPTOELECTRONICS TECH

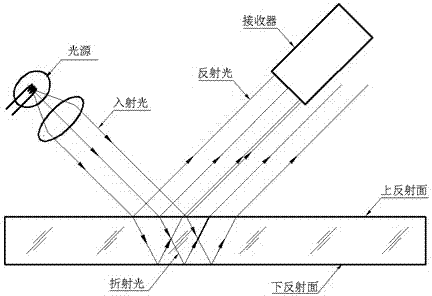

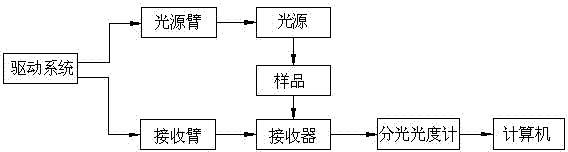

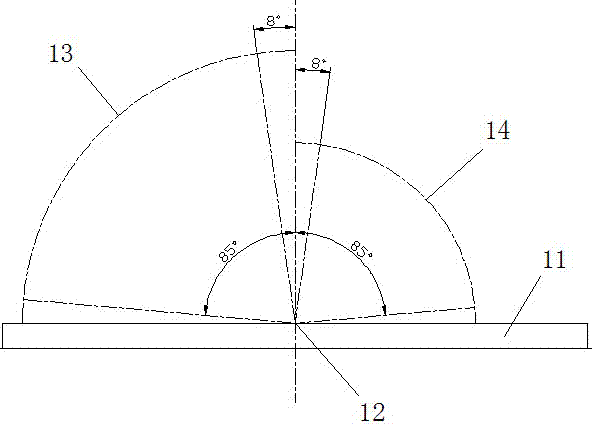

Variable-angle glass reflecting measurement device and method

InactiveCN102564740AControl thicknessControl characteristicsTesting optical propertiesOptical propertyMeasurement device

The invention relates to a variable-angle glass reflecting measurement device and a method. The method comprises the steps of measuring incident light flux to perform absolute calibration when no sample exists, changing the angle of the incident light illuminating a sample when the sample exists, collecting the total reflection light flux from an upper reflecting surface and a lower reflecting surface of the sample according to the corresponding angle variation of reflection light, and calculating the ratio of the total reflection light flux to the incident light flux, so as to obtain the total reflectance of the sample. According to the invention, the thicknesses and the optical characteristics of thin layers can be effectively controlled, angle color change data required by glass film layers and similar industries can be provided, and a basis for the quality control of the glass film layers can also be provided.

Owner:BEIJING AOPTEK SCI

Water injection device of a combustion engine and method for operating same

InactiveCN108286480AAvoid damageReduce layoutNon-fuel substance addition to fuelInternal combustion piston enginesCombustionInternal combustion engine

The invention relates to a water injection device. The water injection device comprises the components of a water tank for storing water; at least one water-fuel injector which is connected with the water tank by means of a water pipeline and can be supplied with fuel through a fuel pipeline, wherein the water-fuel injector is used for spraying water and / or fuel; and at least one water injecting device which is connected with the tank and is set for injecting water. The water injection device further comprises a conveying element which is used for conveying water from the water tank to the water injector and / or water-fuel injector and further comprises a control unit. The control unit is set for opening the water injector. The conveying element is set for sucking water in an area between the water injector and the water tank and supplying to the water tank when the water injecting device is open. Furthermore the invention relates to an internal combustion engine with the water injection device and a method for operating the water injection device.

Owner:ROBERT BOSCH GMBH

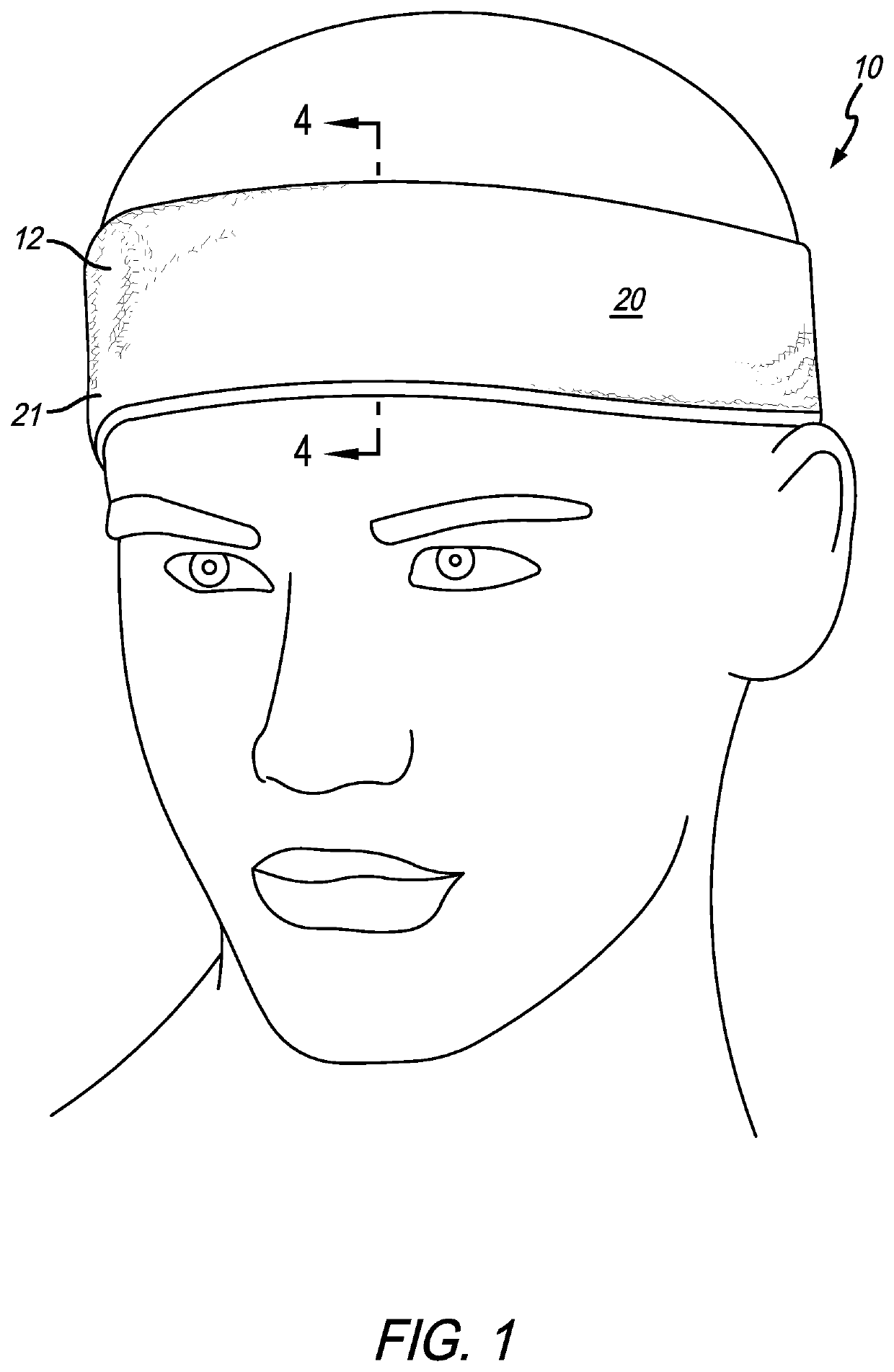

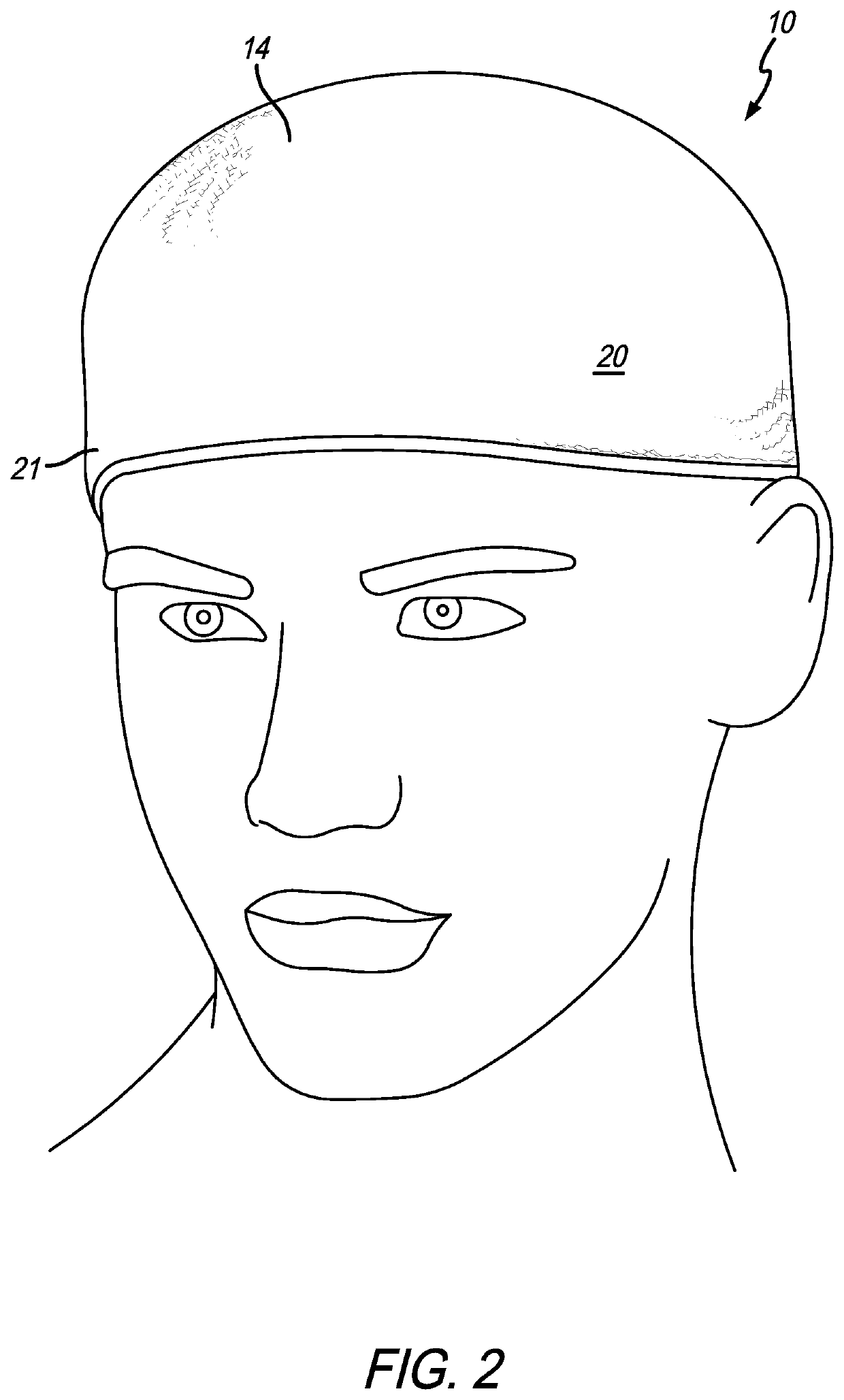

Article of headwear including non-newtonian fluid

InactiveUS20200221804A1Non toxicLittle strengthHatsHeadwear capsMechanical engineeringNon-Newtonian fluid

An article of headwear that includes at least a first bladder member that defines a bladder interior that includes a non-Newtonian fluid disposed therein, and a fabric member that surrounds the first bladder member. The fabric member includes an outer layer and an inner layer. The inner layer is configured to be positioned adjacent a wearer's head when the article of headwear is worn.

Owner:TATE TECH

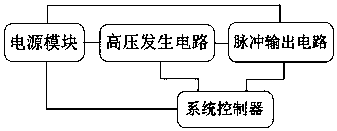

Medical low-frequency electric pulse therapeutic instrument

ActiveCN107693942AMeet the safety of useMeet self-adjusting pulse characteristicsElectrotherapyArtificial respirationControl signalPulse characteristics

The invention creatively discloses a medical low-frequency electric pulse therapeutic instrument, which comprises a power supply module, a high-voltage generating circuit used for generating a high voltage, a pulse output circuit used for generating a pulse waveform, and a system controller. The control signal output end of the system controller is respectively connected with the control signal input end of the high-voltage generating circuit and the control signal input end of the pulse output circuit. The high-voltage output end of the high-voltage generating circuit is connected with the high-voltage power supply end of the pulse output circuit. The power supply module supplies the power to the high-voltage generating circuit, the pulse output circuit and the system controller respectively. The medical low-frequency electric pulse therapeutic instrument adopts the system controller to control the voltage value of the high-voltage generating circuit and the pulse characteristics of the pulse output circuit. Therefore, the use safety of a user is ensured. Meanwhile, the pulse characteristics can be automatically adjusted by the user according to the requirement of the user. The usage comfort of the user is enhanced.

Owner:南京春之象电子技术有限公司

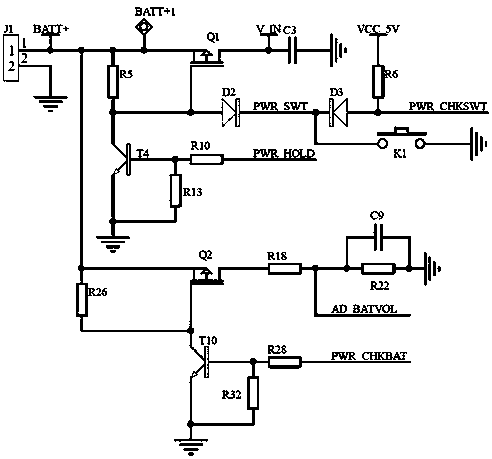

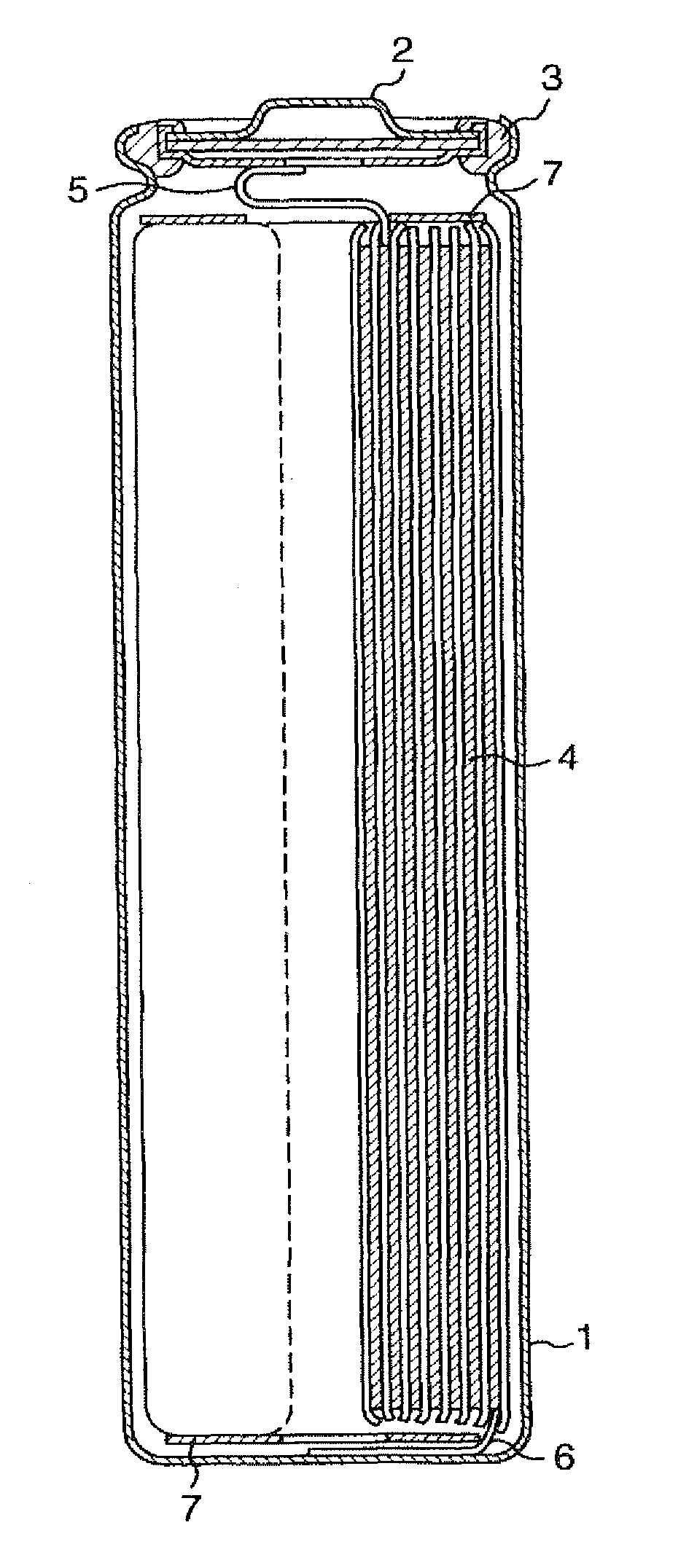

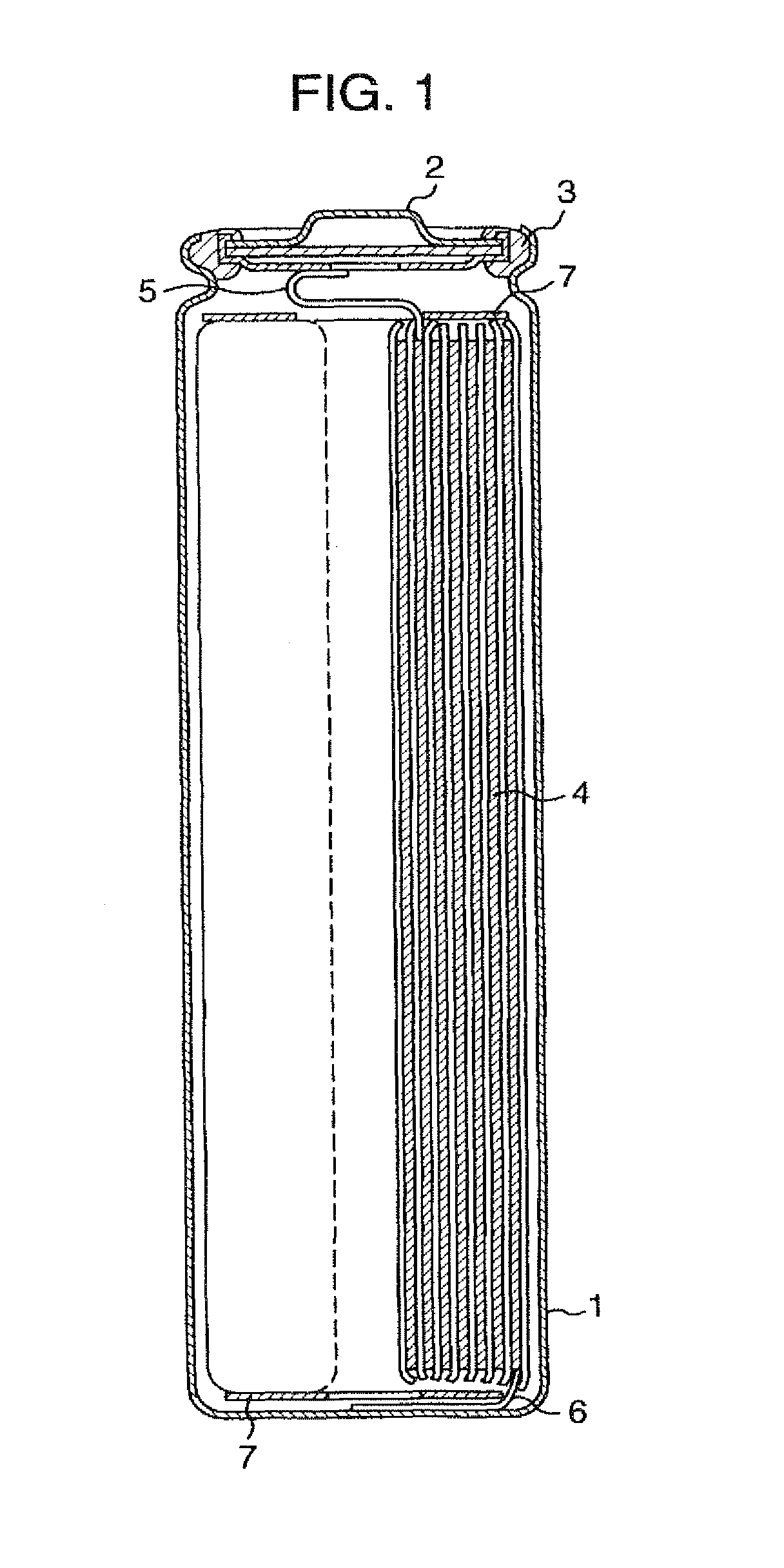

Electrolyte for non-aqueous cell and non-aqueous secondary cell

InactiveUS20100119953A1Improve securityExcellent in high-temperature storage characteristicOrganic electrolyte cellsElectrolytesPhysical chemistryNon aqueous electrolytes

In a rechargeable non-aqueous electrolyte secondary battery using positive electrodes, negative electrodes and a non-aqueous electrolytic solution, additives to the electrolytic solution are used in combination, preferably in combination of at least two compounds selected from o-terphenyl, triphenylene, cyclohexylbenzene and biphenyl, and thus there are provided batteries excellent in safety and storage characteristics.

Owner:PANASONIC CORP +1

Method and kit used for determining human PON1 gene rs662 site polymorphism

InactiveCN105256008AReduce yieldControl characteristicsMicrobiological testing/measurementHuman DNA sequencingEnzyme digestion

The invention discloses a method and a kit used for determining human PON1 gene rs662 site polymorphism. The method comprises following steps: human genome DNA to be determined is provided; upstream primers and downstream primers used for amplification of sequences near human PON1 gene rs662 site are provided, wherein the upstream primers possess mismatched base T; the human genome DNA to be determined is taken as a template, and the upstream primers and the downstream primers are used for PCR amplification so as to obtain amplification products containing TCRA segments, wherein R is used for representing base A or G to be determined on human PON1 gene rs662 site; a restriction enzyme is provided; the restriction enzyme is used for enzyme digestion of the amplification products so as to obtain corresponding enzyme-digested products; and it is determined that R is used for representing base A or G based on the enzyme-digested products. The restriction enzyme is a restriction enzyme only used for realizing restriction digestion of one segment selected from TCGA and TCAA. The method is rapid and reliable, and determination cost is reduced greatly.

Owner:ZHENGZHOU UNIV

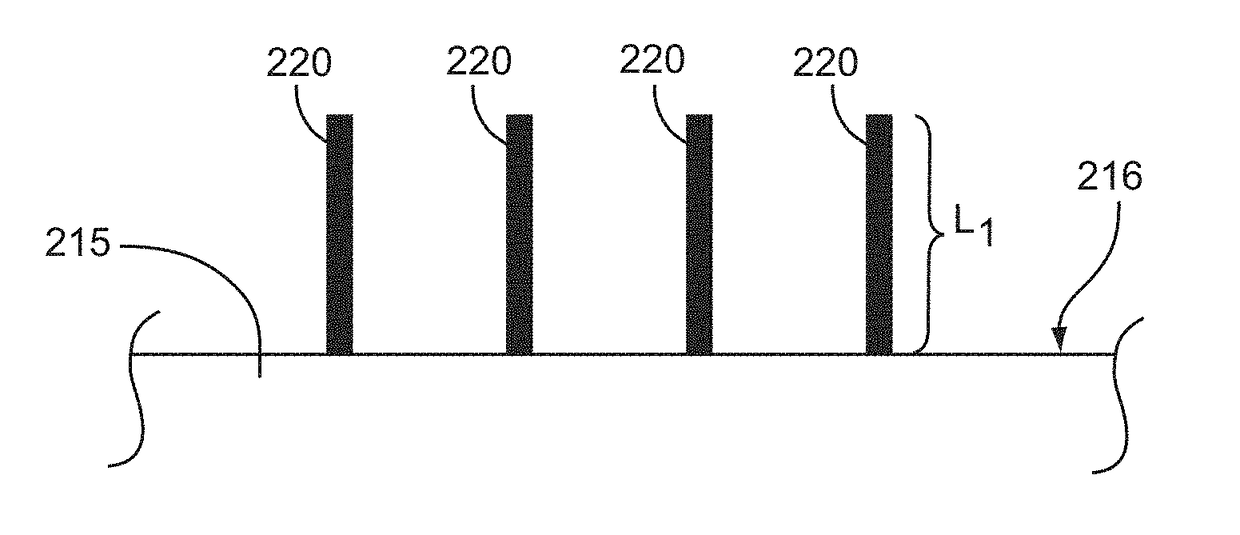

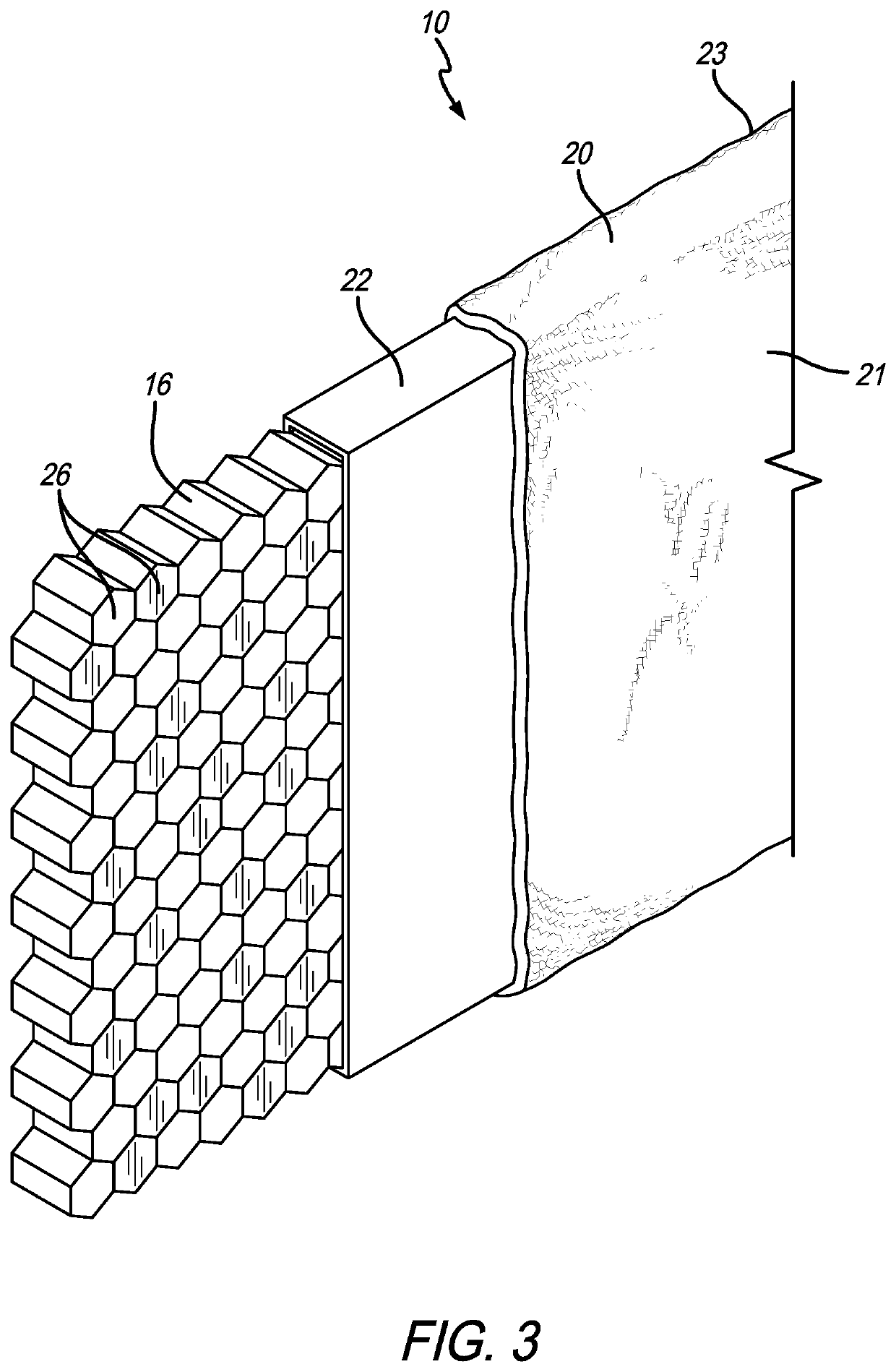

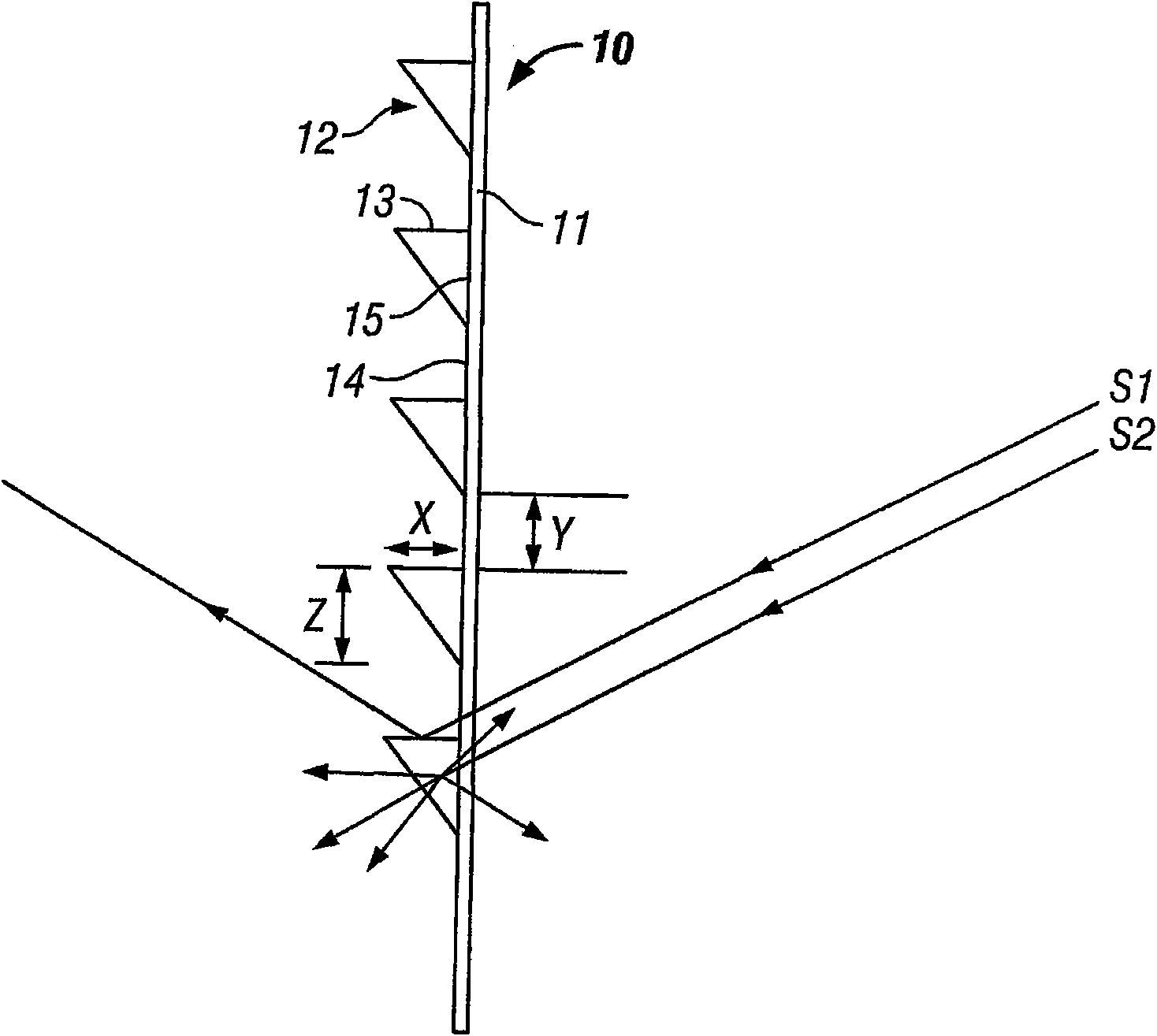

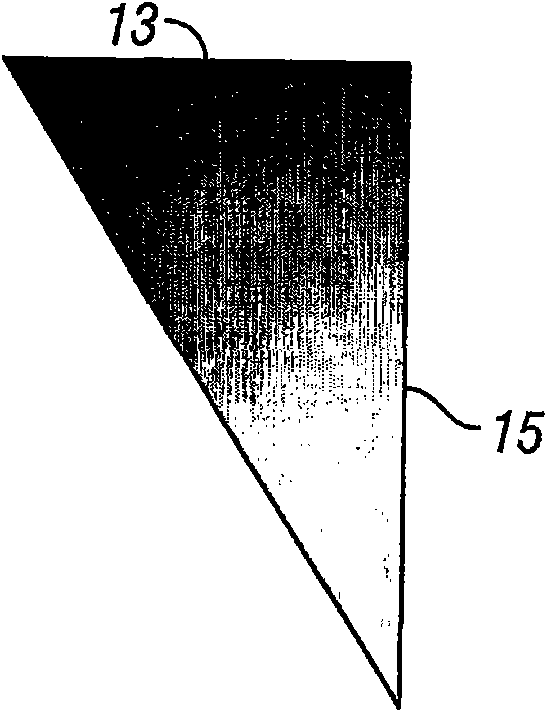

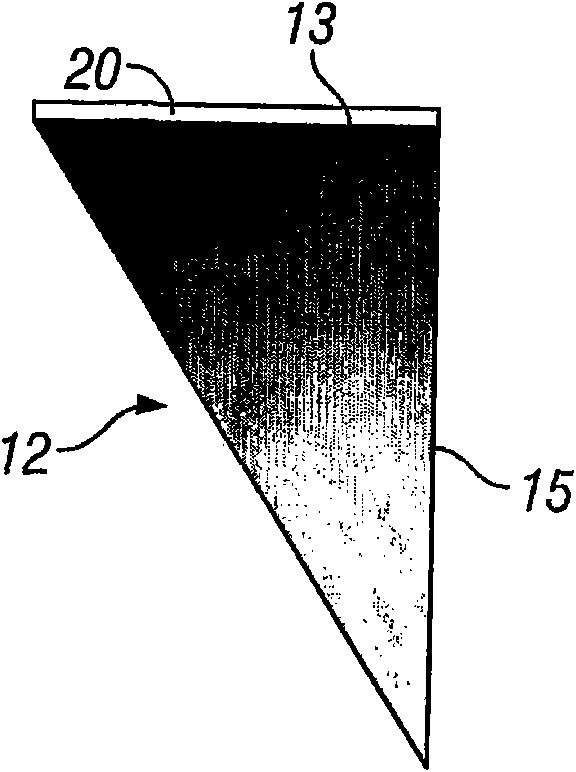

Glazing panel

InactiveCN101688428AControl characteristicsSolar heating energySolar heat collector controllersTransmission coefficientThin sheet

A glazing panel comprises sheet of glass (11) and a series of spatially separated optical elements (12) disposed on a major face of the glass. Each element (12) has an upwardly-facing reflective surface 13 which extends out of the plane of the glass. A region (15) of a material, having an optical transmission coefficient which varies across its width, is disposed below the surface (13). Light incident on the upwardly facing reflective side surfaces (13) is reflected upwardly into the area on the other side of the glazing panel. Light entering the area through the region (15) is attenuated anddiffused. The elements (12) may be printed onto the glass or onto a film that is applied to the glass. Alternatively, the elements may comprise profiled formations which are adhered to the glass.

Owner:SOLIPCO

Electrolyte for non-aqueous cell and non-aqueous secondary cell

InactiveUS7824809B2Improve securityExcellent in high-temperature storage characteristicOrganic electrolyte cellsElectrolytesNon aqueous electrolytesTerphenyl

In a rechargeable non-aqueous electrolyte secondary battery using positive electrodes, negative electrodes and a non-aqueous electrolytic solution, additives to the electrolytic solution are used in combination, preferably in combination of at least two compounds selected from o-terphenyl, triphenylene, cyclohexylbenzene and biphenyl, and thus there are provided batteries excellent in safety and storage characteristics.

Owner:PANASONIC CORP +1

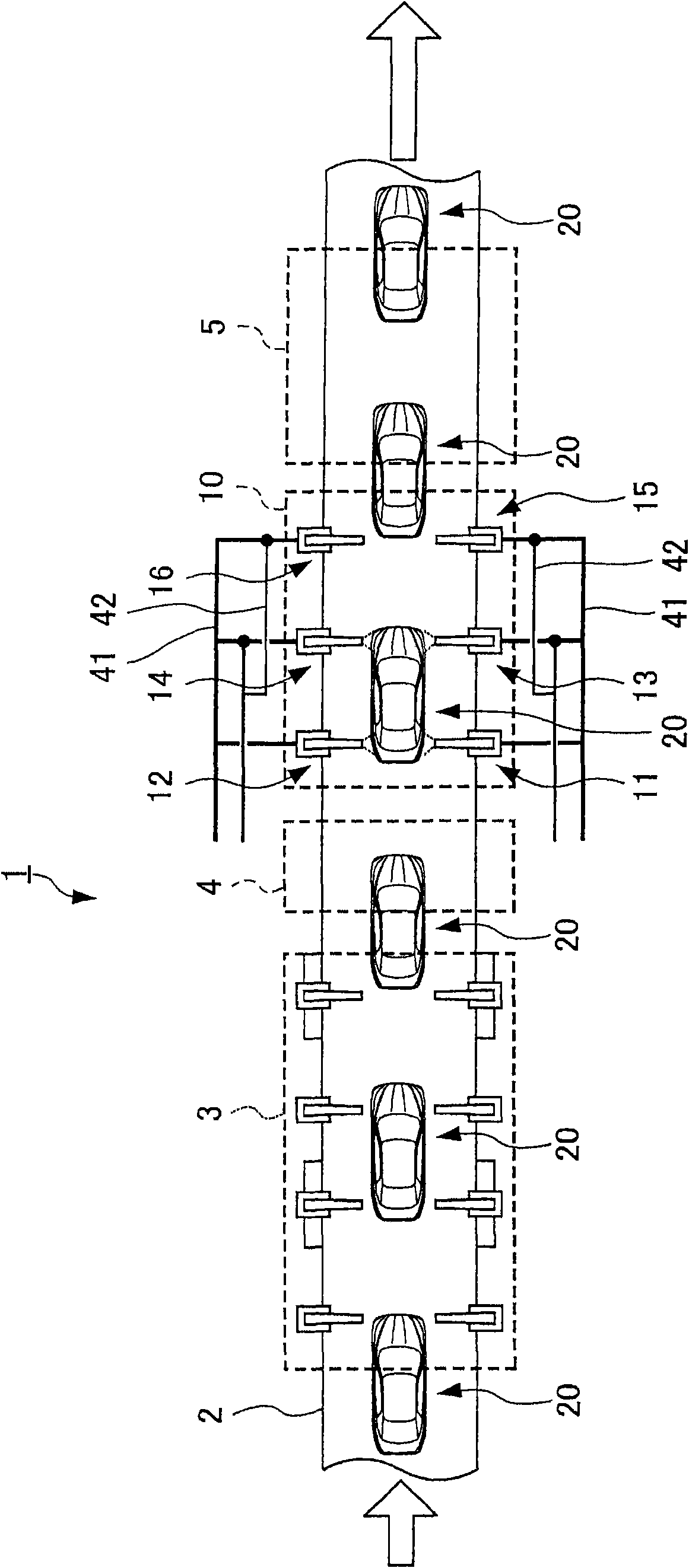

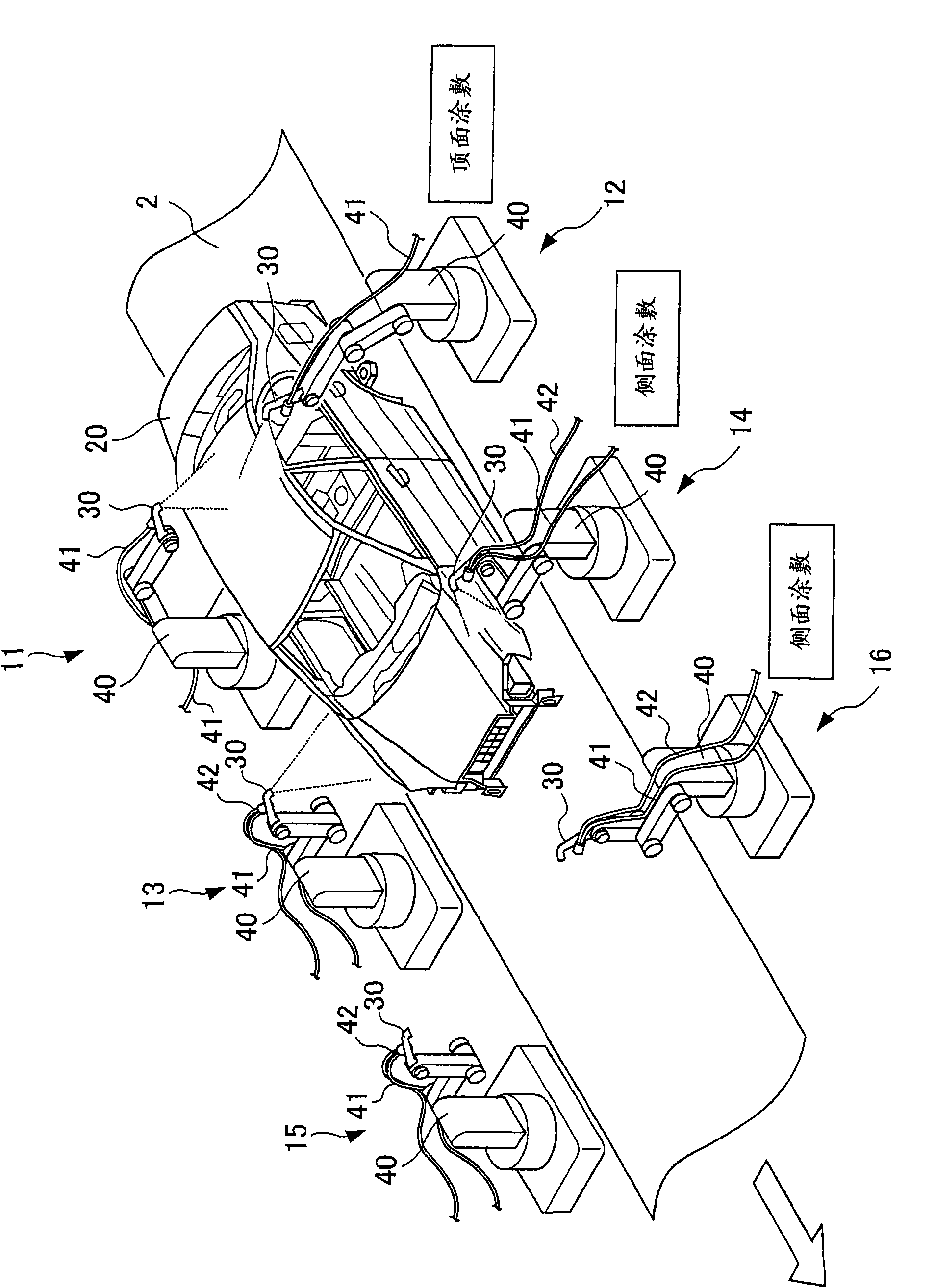

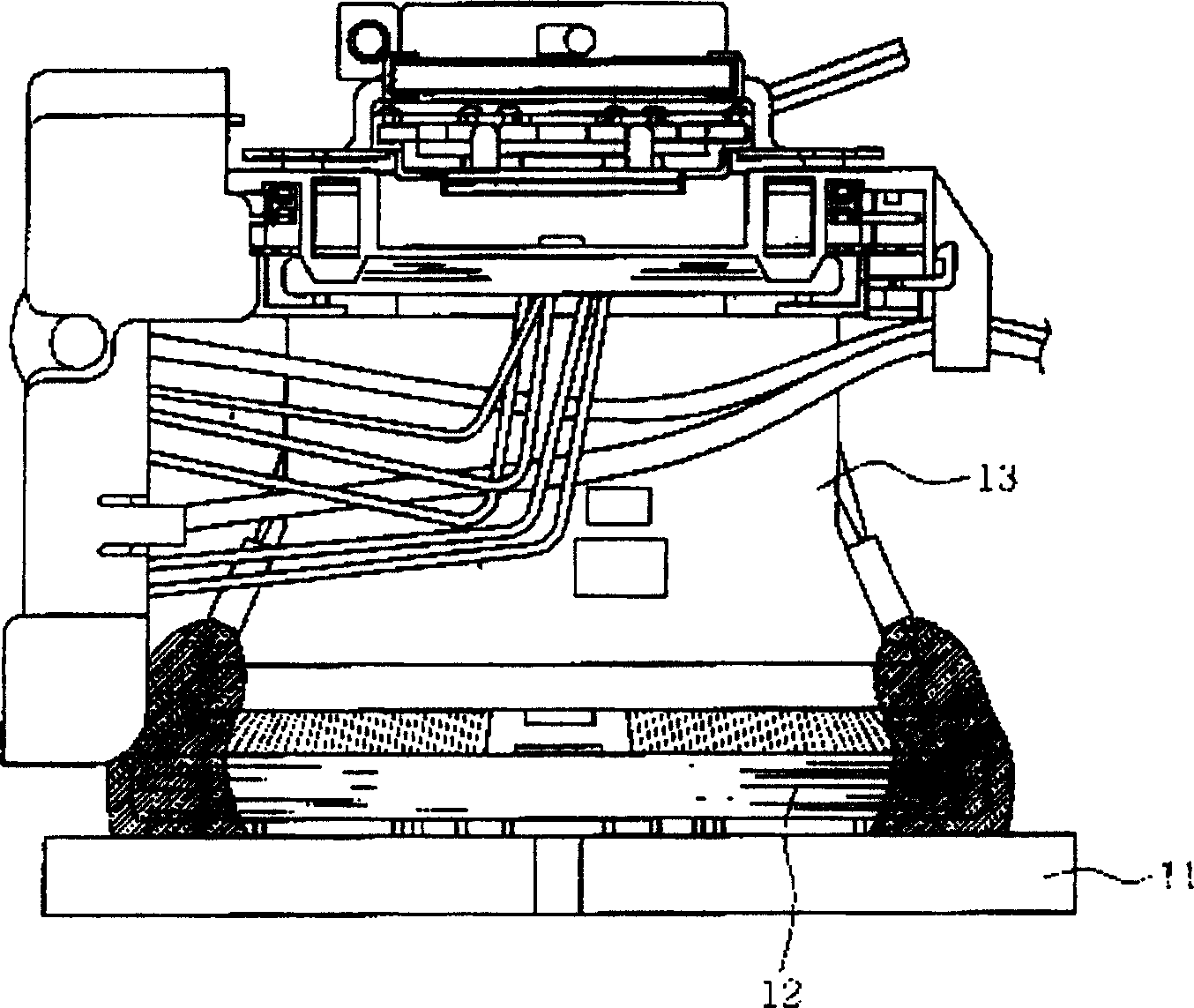

Electrostatic coating method and electrostatic coating apparatus

InactiveCN101862717AImprove smoothnessControl characteristicsLiquid spraying plantsLiquid surface applicatorsCoated surfaceElectrostatic coating

The invention relates to an electrostatic coating method and an electrostatic coating apparatus. The electrostatic coating method includes: providing a rotary atomization type coating apparatus; supplying a coating material to a rotary atomization head of the rotary atomization type coating apparatus; changing the number of rotations of the rotary atomization head to change a particle diameter of particles of the coating material; adding a solvent to the coating material so that a NV value of a coated film formed on a coated surface of a workpiece falls within a predetermined range; and electrostatically coating the coated surface with the coating material and solvent.

Owner:HONDA MOTOR CO LTD

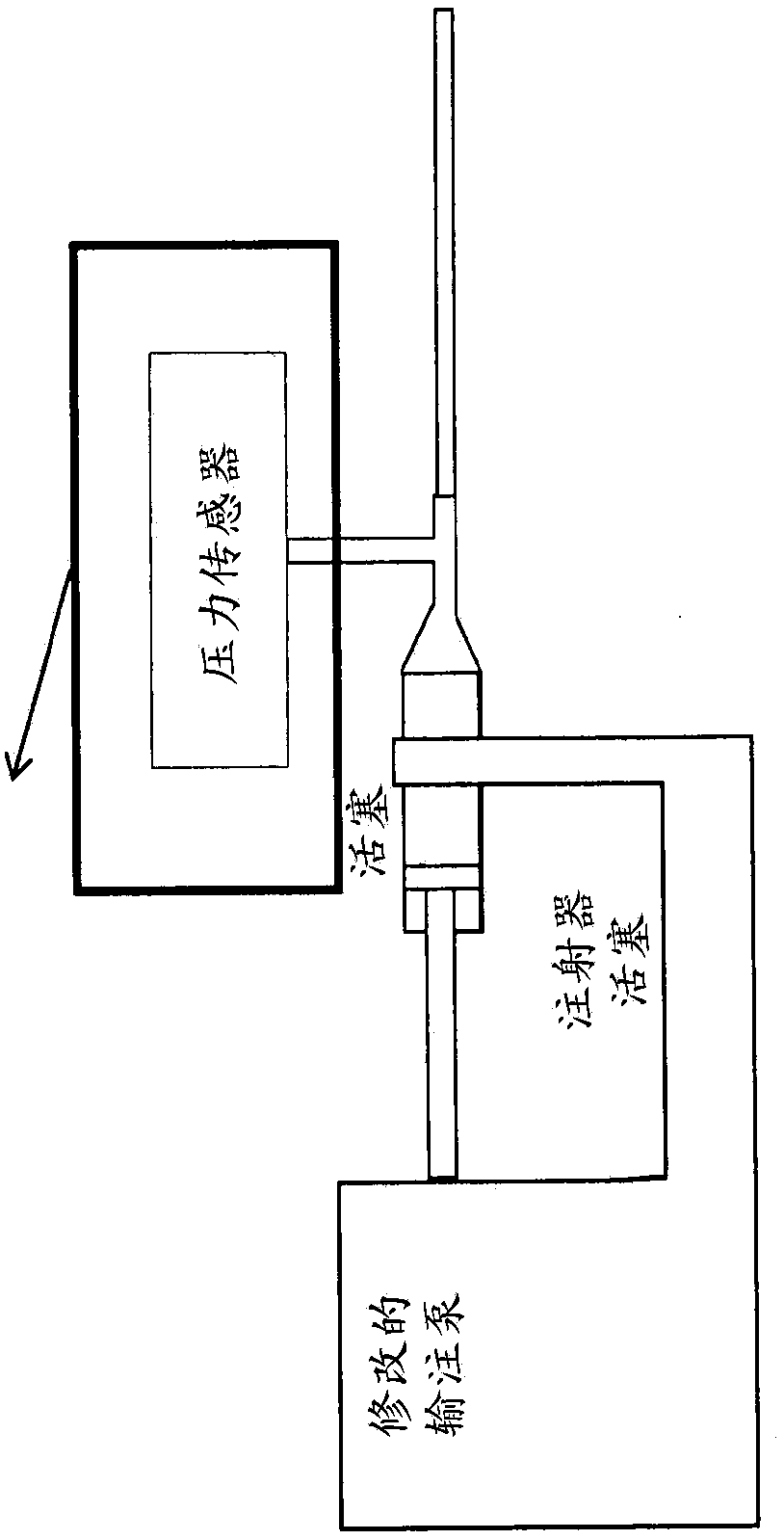

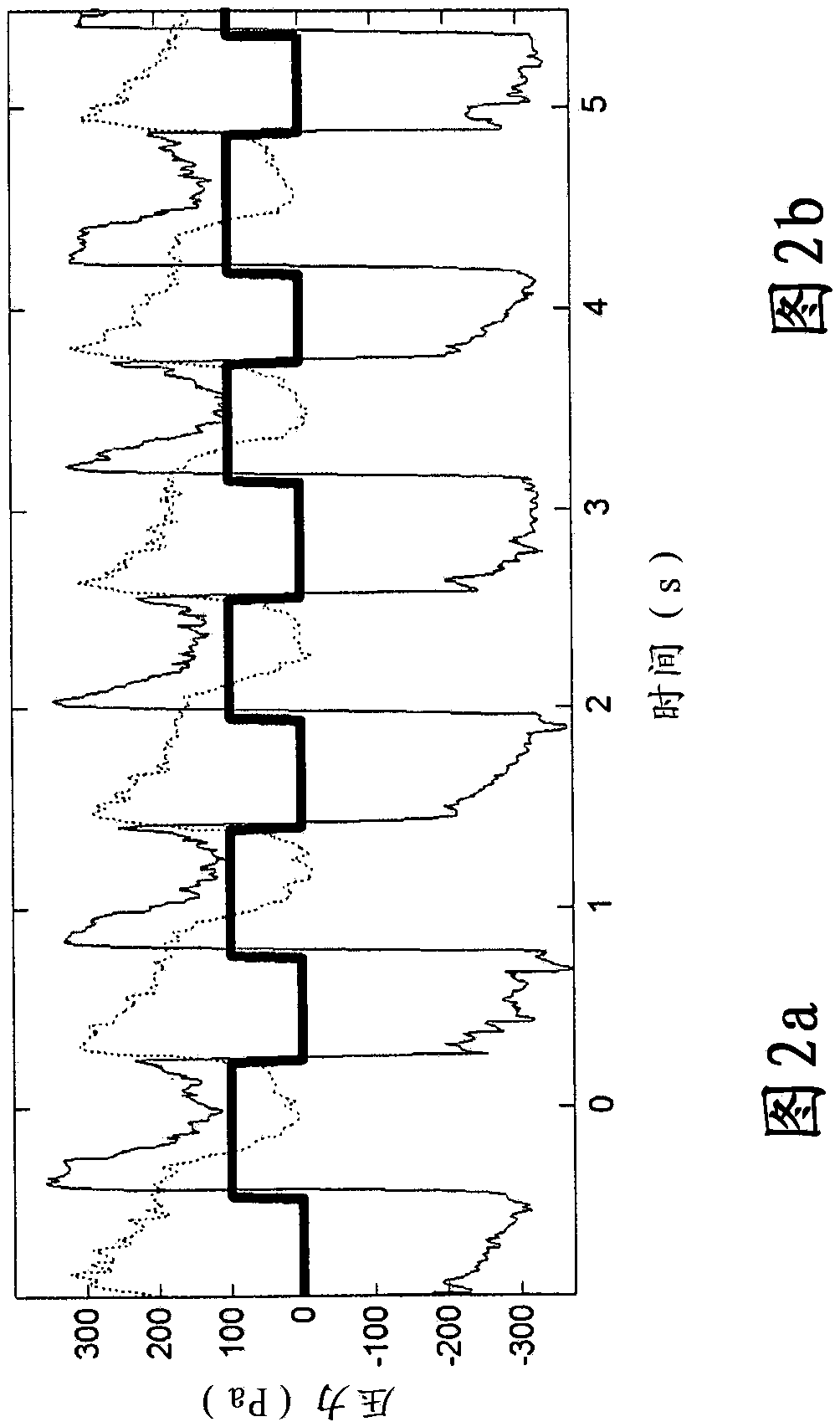

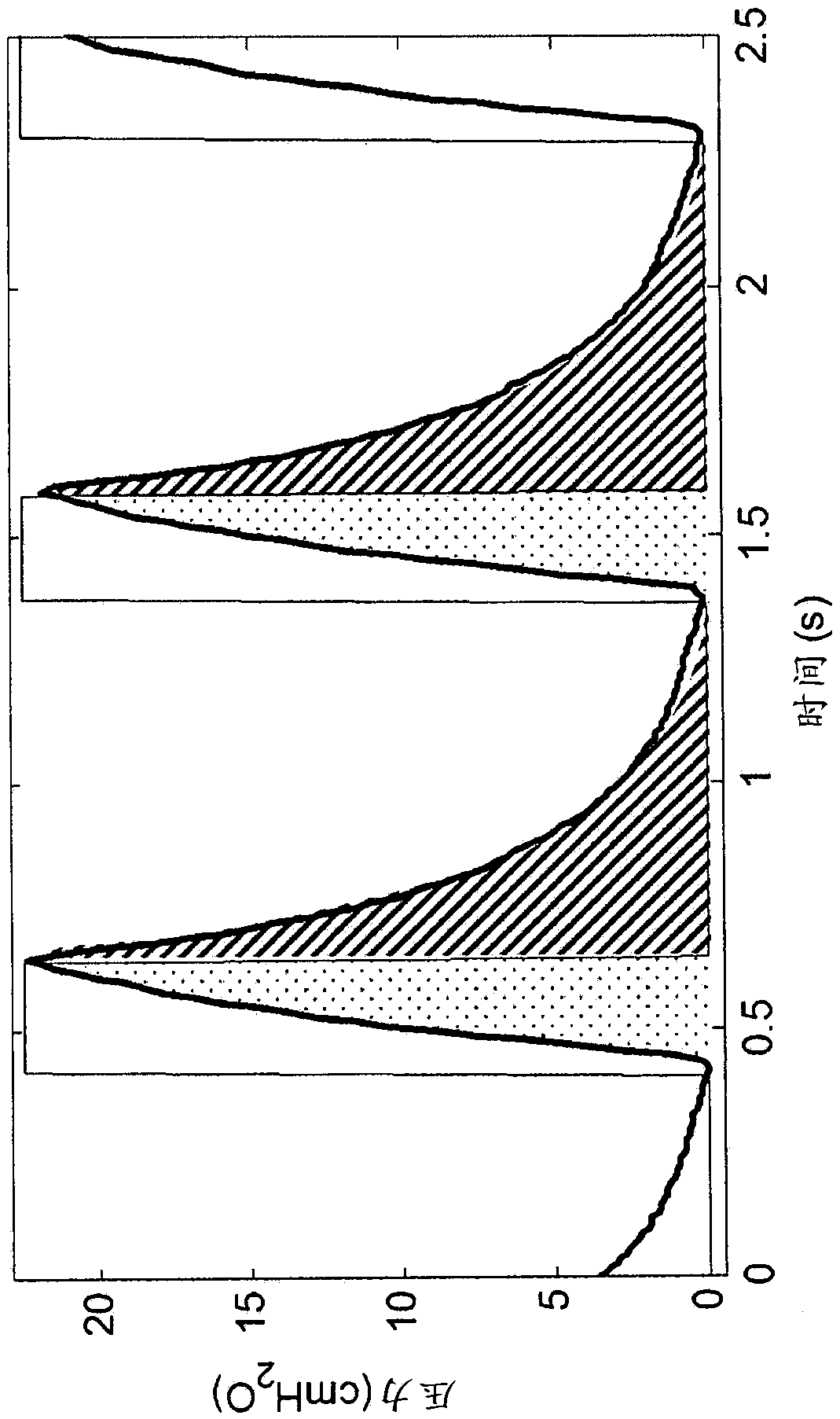

Method and system for effective breath-synchronized delivery of medicament to the lungs

InactiveCN107666933AControl characteristicsLow costTracheal tubesMedical devicesDecreased surfactantIntensive care medicine

The method and system according to preferred embodiments of the present invention allows an effective breath-synchronized delivery of atomized liquid medicament (e.g. a pulmonary surfactant) to the patient's lungs. According to a preferred embodiment, the method of the present invention provides an efficient delivery of the aerosol medicament, controlling the behavior of the infusion pump to makethe rising and falling time faster even though the intrinsic time constant of the system is long. Additionally, in an embodiment of the present invention, at the same time the information about the breathing activity contained either directly on the surfactant line or stored in the controller action can be used to extrapolate the breathing pattern.

Owner:CHIESI FARM SPA

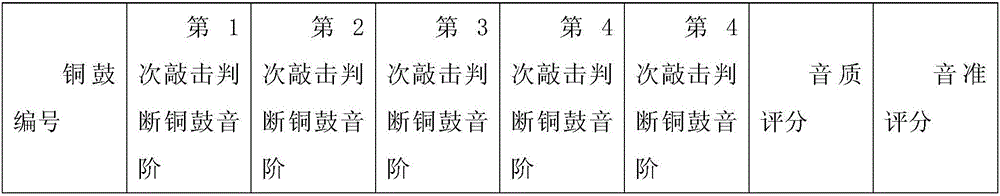

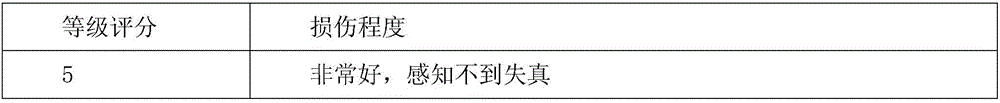

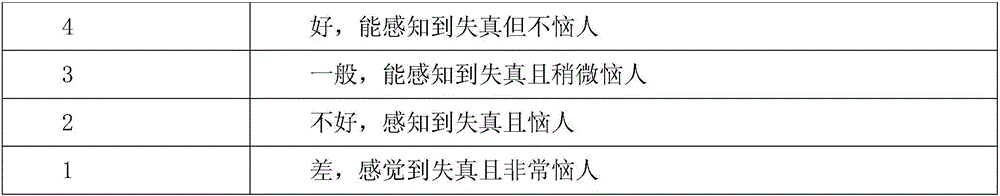

Method for manufacturing mean tone scale music bronze drum

ActiveCN106345971AControl hardnessControl characteristicsPercussion musical instrumentsFoundry mouldsZincMetallic Nickel

The invention relates to the technical field of bronze drum manufacturing, and in particular to a method for manufacturing a mean tone scale music bronze drum. The method for manufacturing the mean tone scale music bronze drum specifically comprises the following steps: a, manufacturing a bronze drum cast mold, wherein the surface of the bronze drum cast mold is 1.5-2.0mm in thickness, and the diameter of the surface is 20-22cm; b, melting a bronze drum raw material, wherein the bronze drum raw material contains the following metal elements in percentage: 8.3-10.2% of zinc, 3.2-3.6% of tin, 5.3-5.4% of aluminum, 1.7-1.84% of beryllium, 5.0-6.2% of iron, 3.5-3.9% of nickel and the balance of copper; and c, performing casting molding. By adopting the method for manufacturing the mean tone scale music bronze drum, a scale 4(fa) can be generated from the bronze drum, accurate toning can be achieved, the scales of the bronze drum can be enriched, and the bronze drum culture can be well carried forward and inherited.

Owner:DONGLAN MUSIC TONGGU CULTURAL COMM

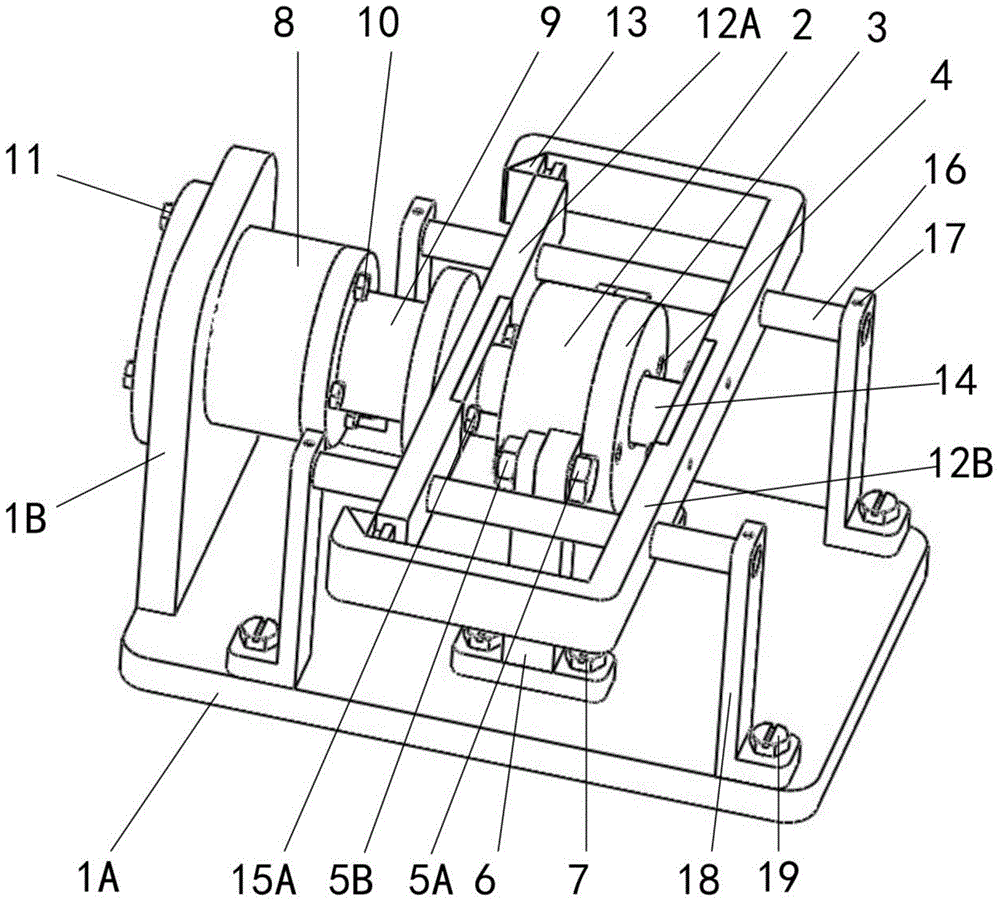

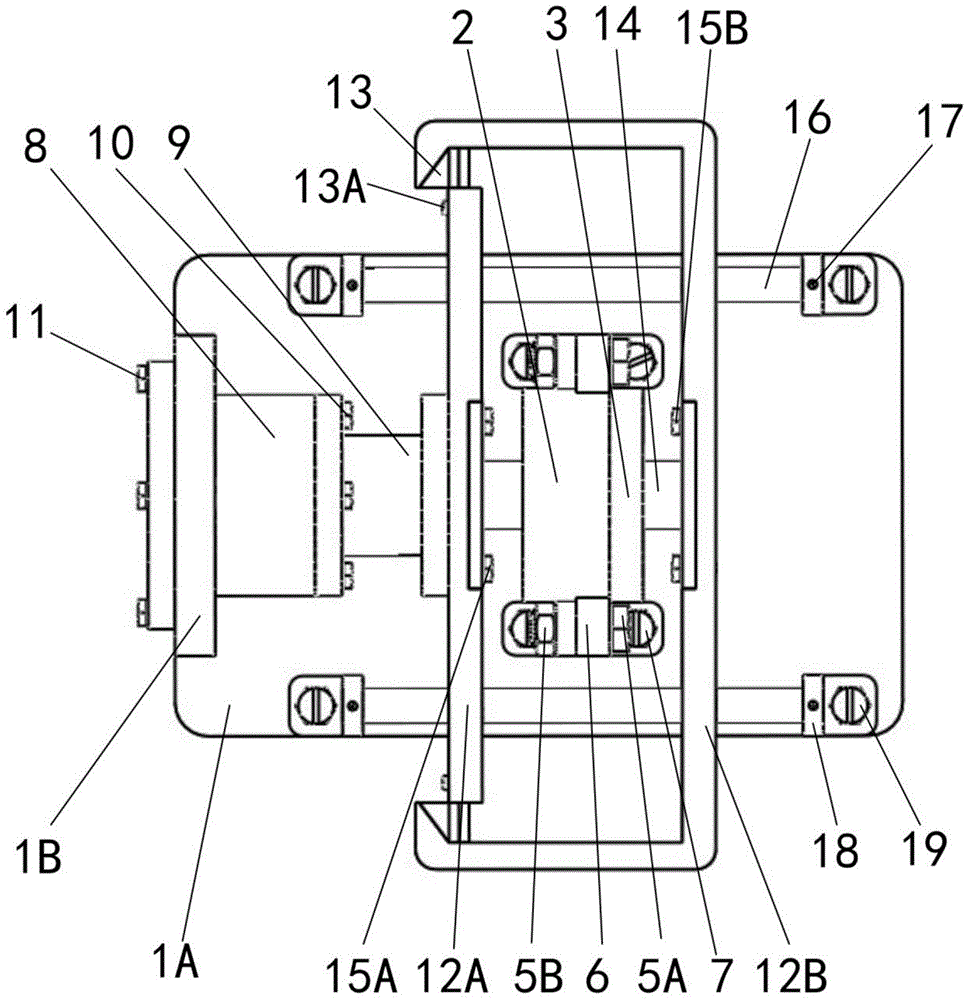

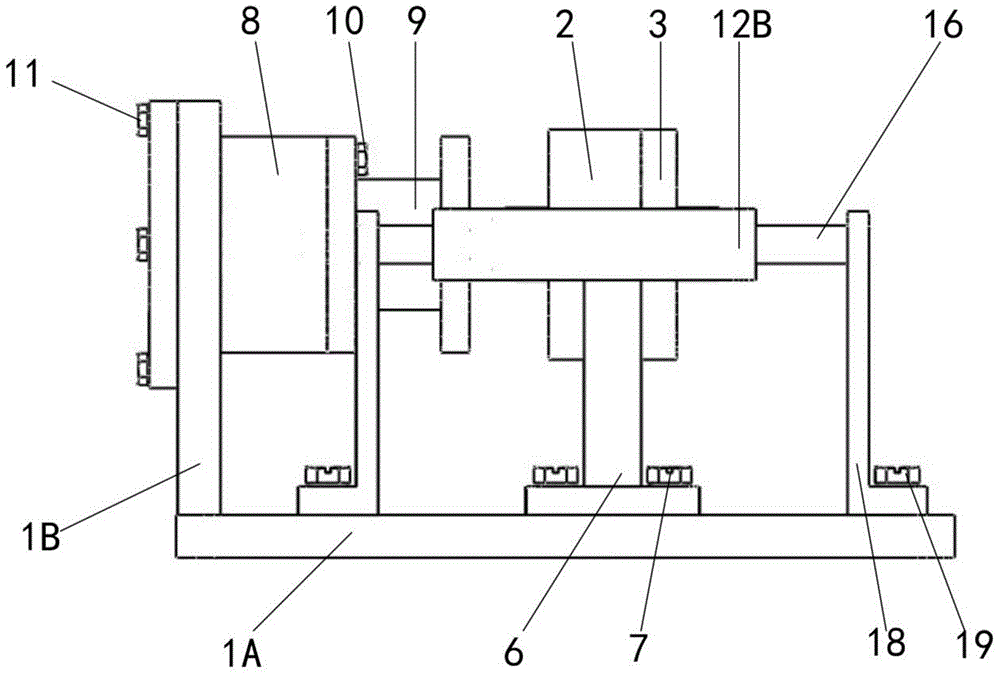

Controllable intelligent surface auxiliary energy transmission device and transmission method thereof

ActiveCN110932419AControl reflexControl characteristicsCircuit arrangementsRadio transmissionPrecodingTransmission technology

The invention belongs to the technical field of wireless energy transmission, and provides a controllable intelligent surface auxiliary energy transmission device and a transmission method thereof. Firstly, all the receiving terminals transmit orthogonal pilot signals, and each controllable intelligent surface estimates channel information from all the receiving terminals to the controllable intelligent surface; all the controllable intelligent surfaces send orthogonal pilot signals, and the energy station can estimate channels from all the controllable intelligent surfaces to each antenna ofthe energy station; secondly, all the controllable intelligent surfaces and the energy station exchange large-scale channel information, and the controllable intelligent surfaces calculate required phase angles and precoding coefficients required by the energy station by using the estimated channel information; and finally, the energy station radiates signals to the controllable intelligent surface by using the constructed precoding, and all receiving terminals collect energy. According to the invention, the controllable intelligent surfaces are used to change the transmission path of the signal, and energy transmission of the user is shielded.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Surface strength testing apparatus

ActiveCN104865141AControl movementControl characteristicsMaterial strength using repeated/pulsating forcesData acquisitionEngineering

A surface strength testing apparatus comprises a base, a film fixing portion, a stamping portion and a stamping drive portion. A film fixing mechanism is connected to the base through a bracket and a film is clamped between a left clamp and a right clamp. The head of a stamping head is designed to be a cylinder. One end surface in contact with a thin test workpiece during stamping, of the cylinder is an arc surface. The stamping mode is that two stamping heads are fixedly connected to a stamping frame to repeatedly and alternatively stamp the front and the back surfaces of the film. The stamping drive portion uses an electromagnetic actuator for driving. The actuator is connected to the stamping portion through a telescopic cylinder. A force sensor is arranged on the telescopic cylinder. The actuator and the force sensor are electrically connected to a data acquisition system. The fatigue testing machine is mainly used for testing film test workpiece fatigue properties and is short in operation cycle, low in energy consumption and capable of effectively improving the efficiency of the fatigue life test.

Owner:BEIHANG UNIV

Method and kit used for determining human TERF1 gene rs201882345 site polymorphism

InactiveCN105256006AReduce yieldControl characteristicsMicrobiological testing/measurementHuman DNA sequencingEnzyme digestion

The invention discloses a method and a kit used for determining human TERF1 gene rs201882345 site polymorphism. The method comprises following steps: human genome DNA to be determined is provided; upstream primers and downstream primers used for amplification of sequences near human TERF1 gene rs201882345 site are provided, wherein the upstream primers possess mismatched base G; the human genome DNA to be determined is taken as a template, and the upstream primers and the downstream primers are used for PCR amplification so as to obtain amplification products containing GATTM segments, wherein M is used for representing base A or C to be determined on human TERF1 gene rs201882345 site; a restriction enzyme is provided; the restriction enzyme is used for enzyme digestion of the amplification products so as to obtain corresponding enzyme-digested products; and it is determined that M is used for representing base A or C based on the enzyme-digested products. The restriction enzyme is a restriction enzyme only used for realizing restriction digestion of one segment of GATTA or GATTC. The method is rapid and reliable, and determination cost is reduced greatly.

Owner:ZHENGZHOU UNIV

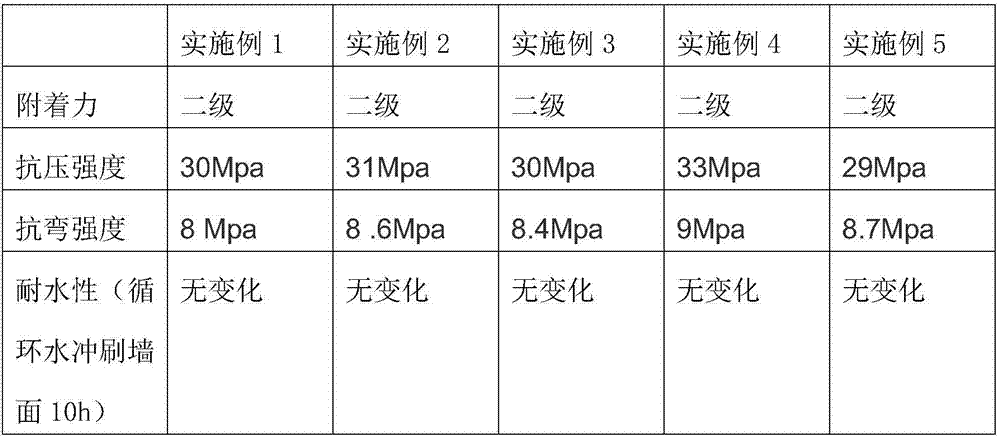

Coating embossing process

InactiveCN106965612ASimple requirementsEasy to operateDecorative surface effectsSand-paperEngineering

The invention belongs to the field of coating embossing and particularly relates to a coating embossing process. The coating embossing process comprises the following steps that first, wall peels of the wall face to be coated are removed through a scraper knife to guarantee smoothness and cleanliness of the wall face; second, primer is painted on the wall face to be coated in a rolling mode; third, gypsum is interspersed on the wall face through the scraper knife, water mist is sprayed on a film of the primer, the coverage rate of the water mist to the wall face is controlled within 50%-65%, and the gypsum is flatten through a spatula; fourth, when the gypsum is dried to 60%-80%, a mould plate with hollow patterns is placed on an area needing to be embossed of the wall face, and the mould plate is filled with gypsum to print embossed patterns; fifth, after the gypsum poured in the mould plate is solidified completely, the whole wall face is polished through sand paper, the smooth embossed pattern surfaces are guaranteed; and sixth, the wall face is coated with pigment through a sponge cloth. According to the coating embossing process, the decoration wall face can show three-dimensional embossment at the time of indoor coating, so that the artistic effect of indoor decoration is improved.

Owner:广东易涂得装饰材料有限公司

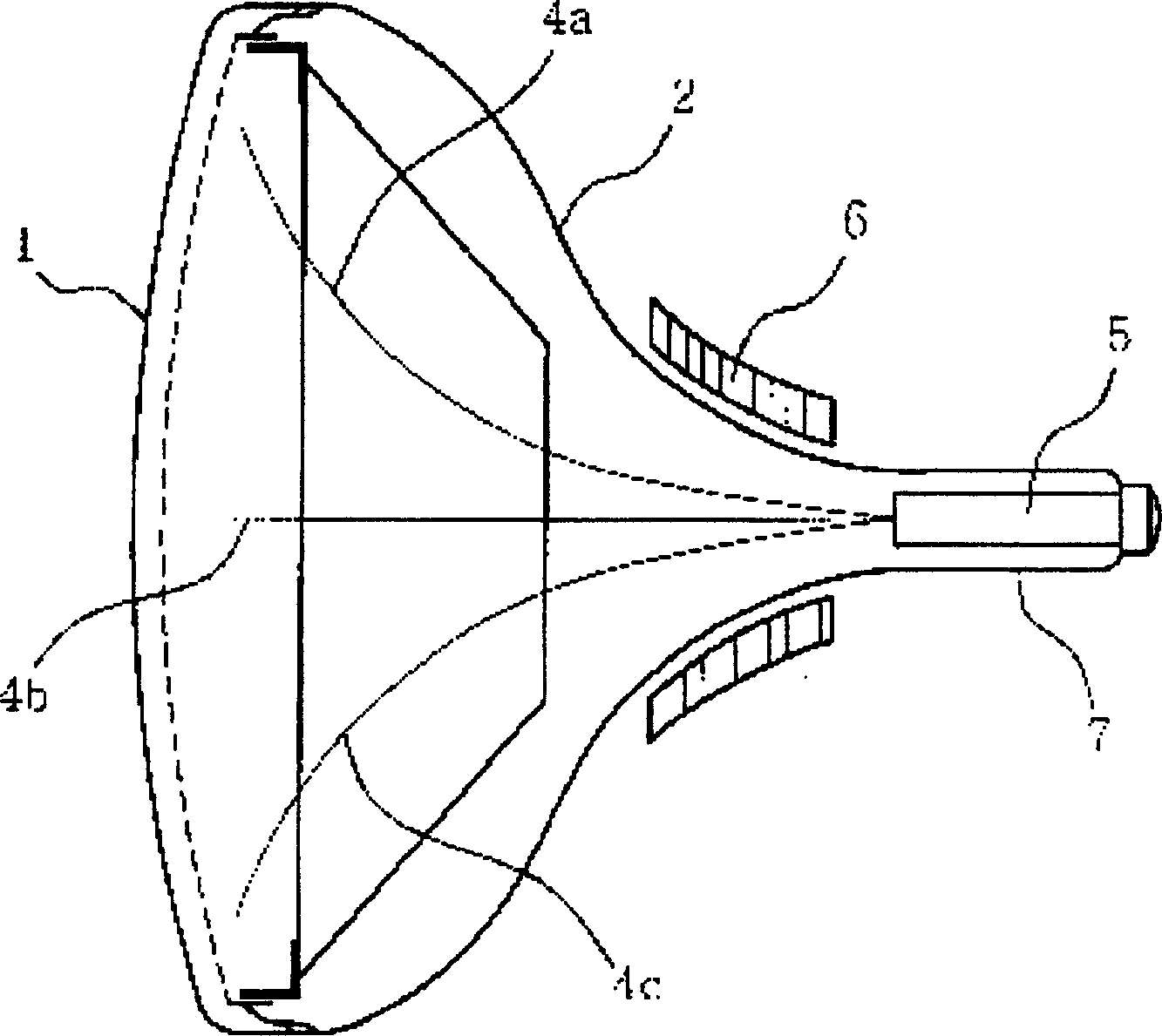

Deflection coil for deflector

InactiveCN1532882ADeformation MinimizationReduce assembly inconsistenciesElectrode and associated part arrangementsEngineeringColor television

The present invention relates generally to a deflection yoke for a color television, and more particularly to a deflection yoke, in which an auxiliary coil provided to a deflection coil that is a part of a deflection yoke is stably supported, thereby reducing the non-uniformity of assembly and controlling picture characteristics, thus greatly improving the quality of a cathode ray tube. The deflection coil includes a main coil comprising a screen portion, a neck portion and a body portion for connecting the screen portion to the neck portion, an auxiliary coil positioned at a center of the main coil, and connected to the neck portion at its lower ends to form a closed shape, and bridges for connecting an upper end of the auxiliary coil to the main coil to prevent movement of the auxiliary coil.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

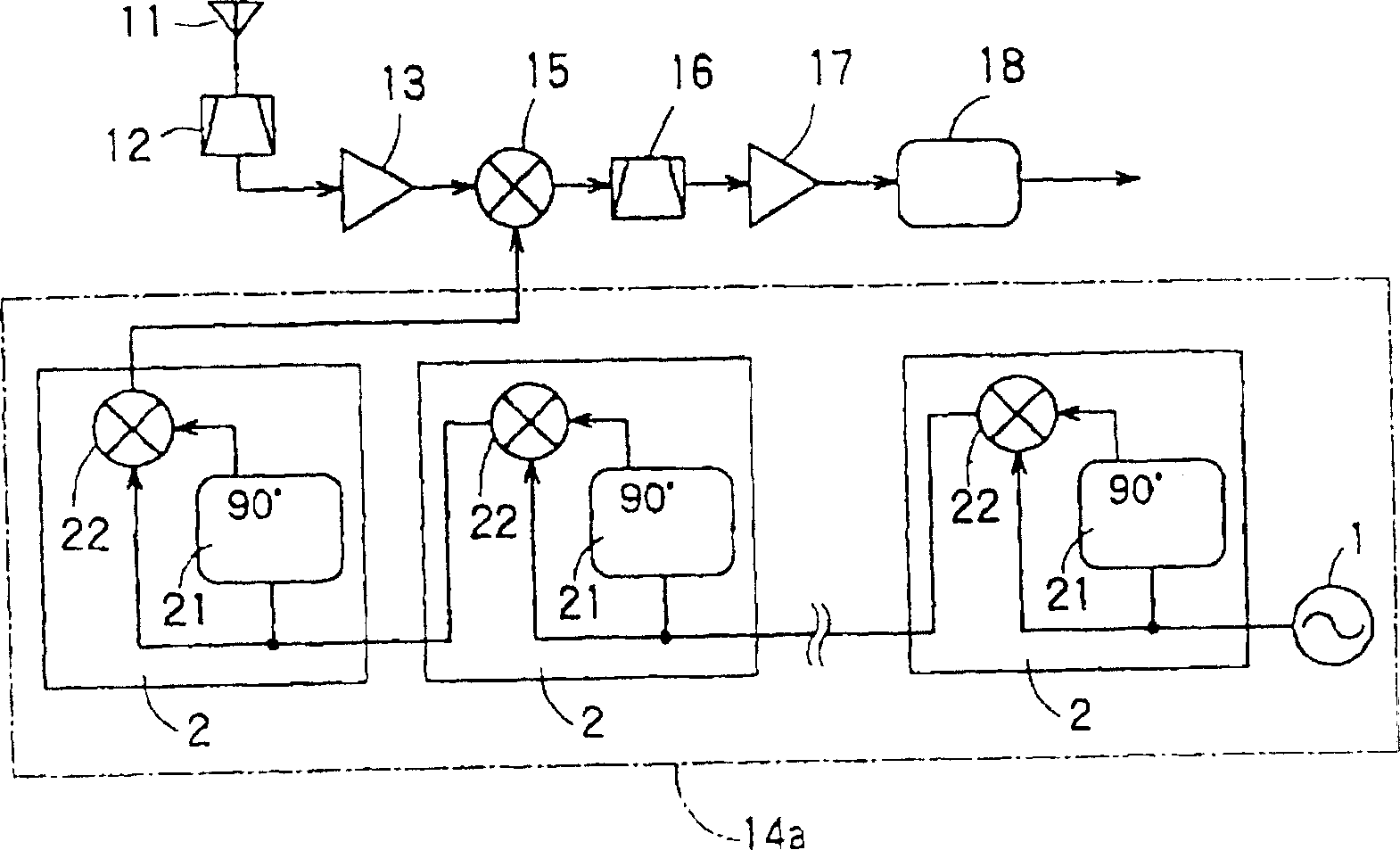

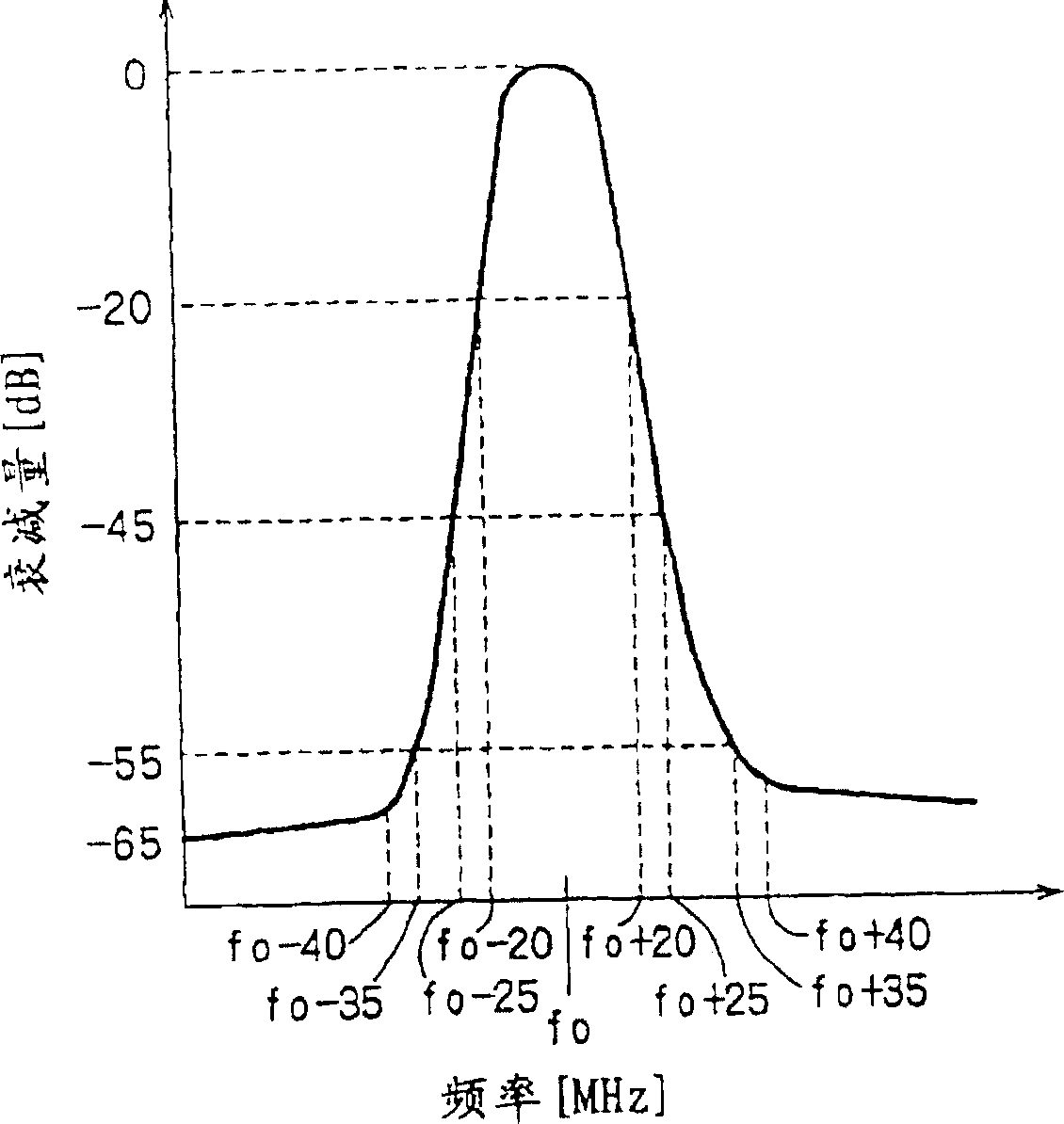

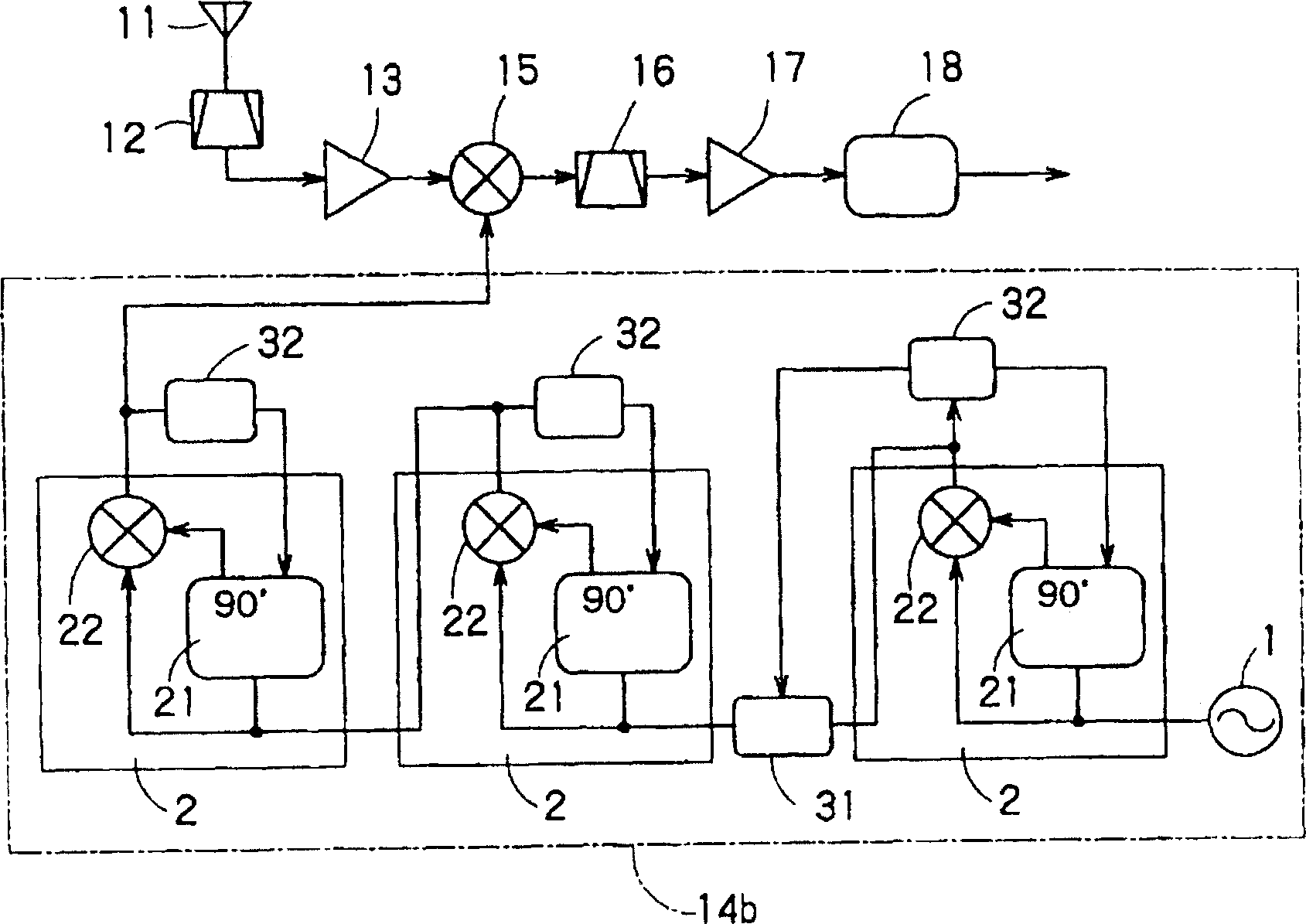

Frequency multiplier and semiconductor integrated circuit

InactiveCN1168198CSimple designStable characteristicsAmplitude modulationOscillations generatorsPhase shiftedThree stage

A frequency multiplication circuit with simple structure capable of surely removing unwanted higher harmonics. Inside the oscillation circuit 14a, cascade-connected three stages of 2-multiplication circuits 2 are provided. Since an 8-multiplied local oscillation signal is generated by supplying the source oscillation signal of the crystal oscillator to the 2-multiplication circuit 2 of the first stage, even when a source oscillation frequency is low, the local oscillation signal of a sufficiently high frequency can be generated. By providing a filter circuit 31 between the stages of the frequency multiplication circuit 2, a fixed phase shift quantity generated by a limiter amplifier 26 of the 90 deg. phase shift circuit 21a can be canceled by resistors R6-R8 inserted to the filter circuit 31, so that generation of unwanted higher harmonics is surely suppressed.

Owner:KK TOSHIBA

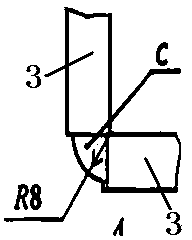

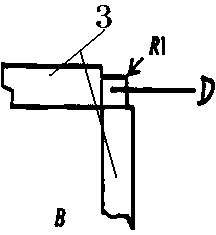

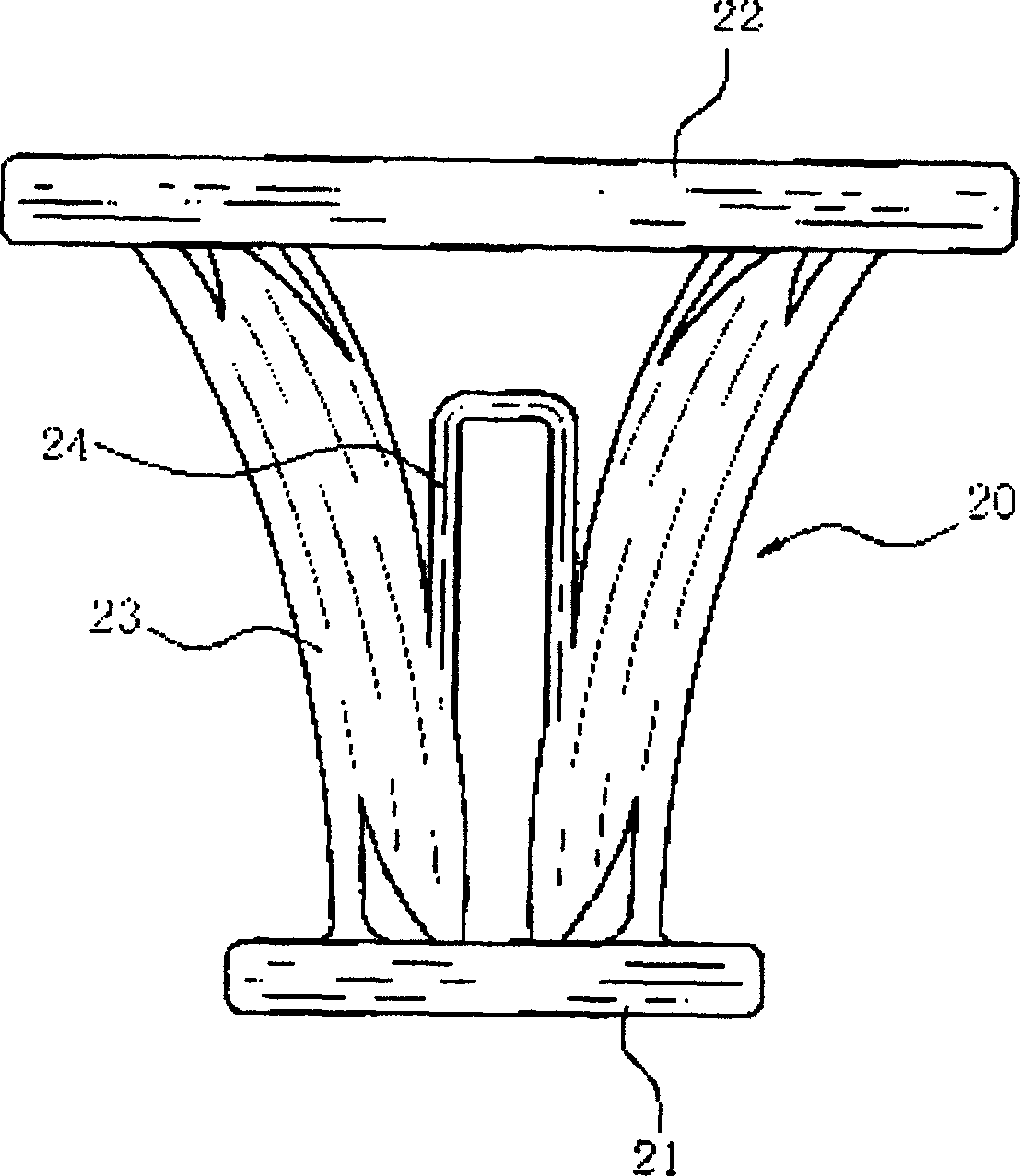

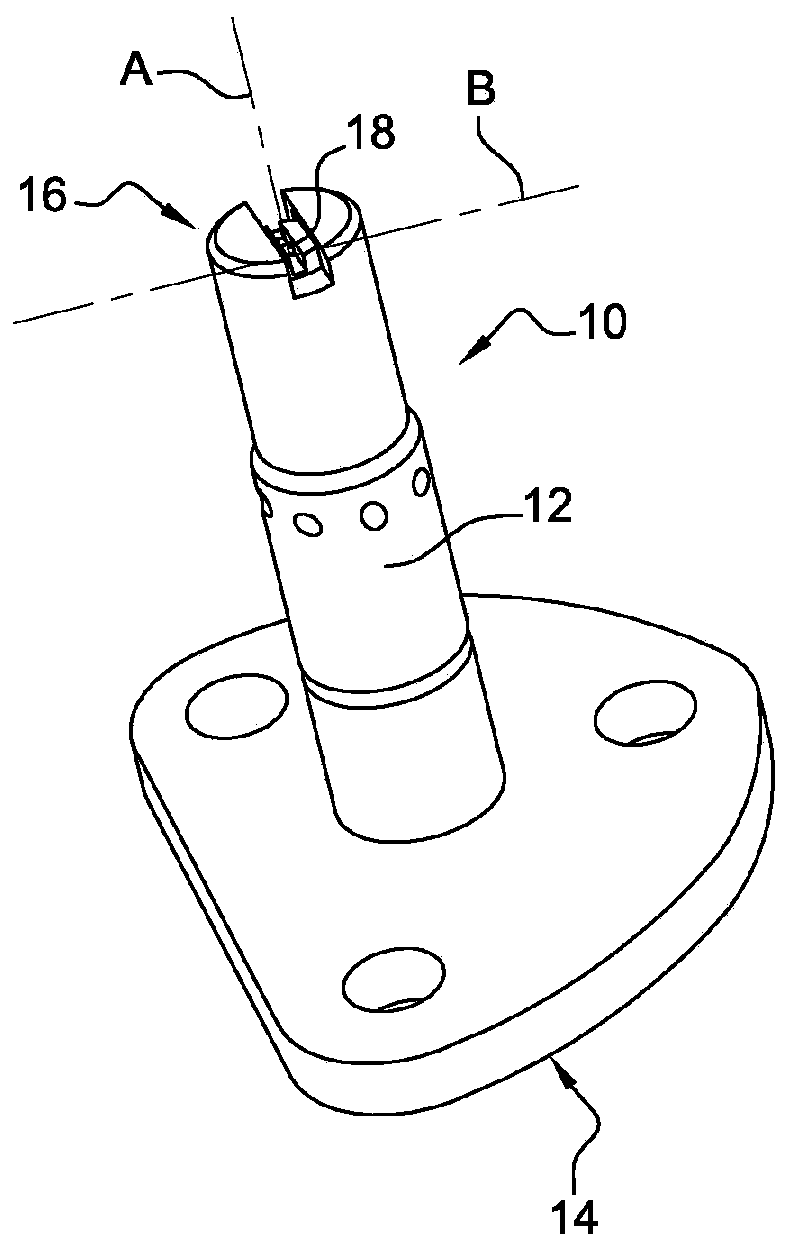

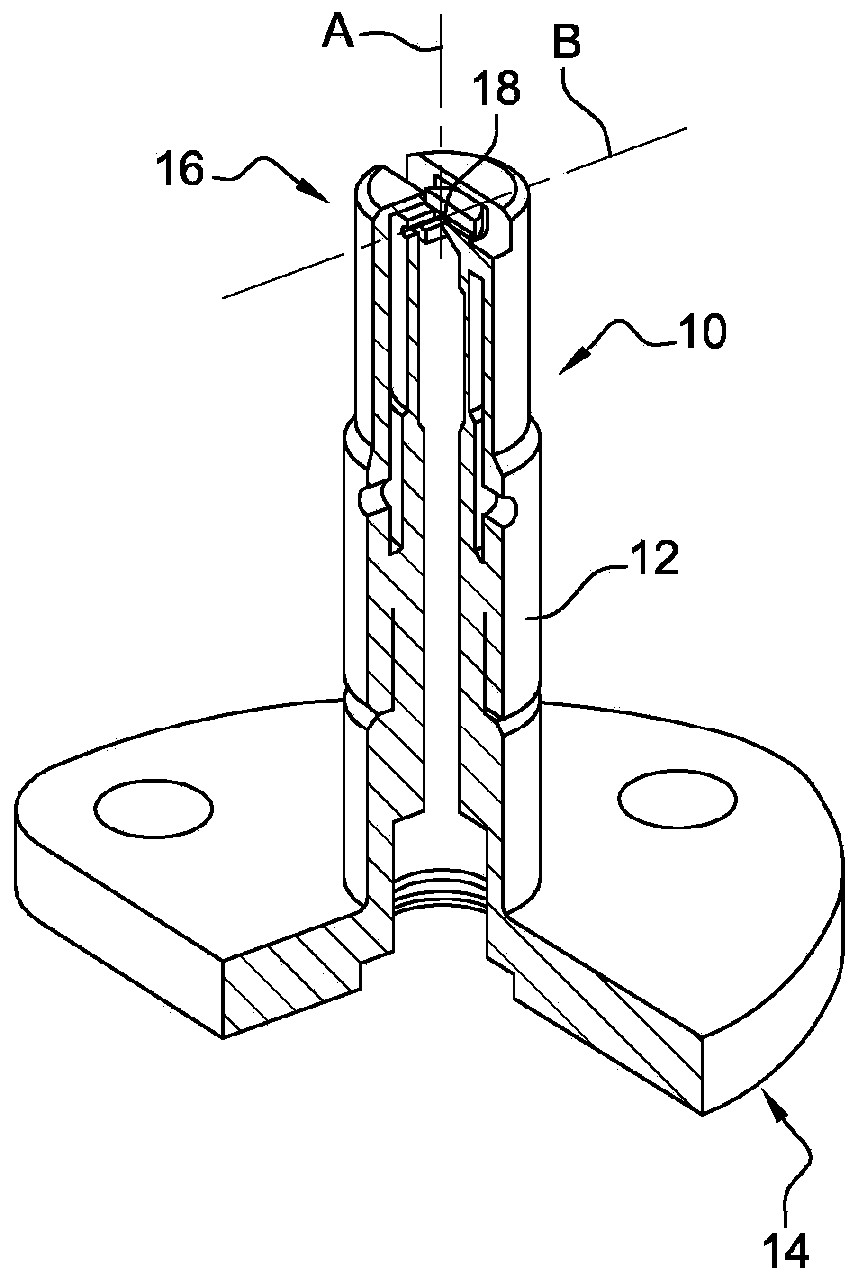

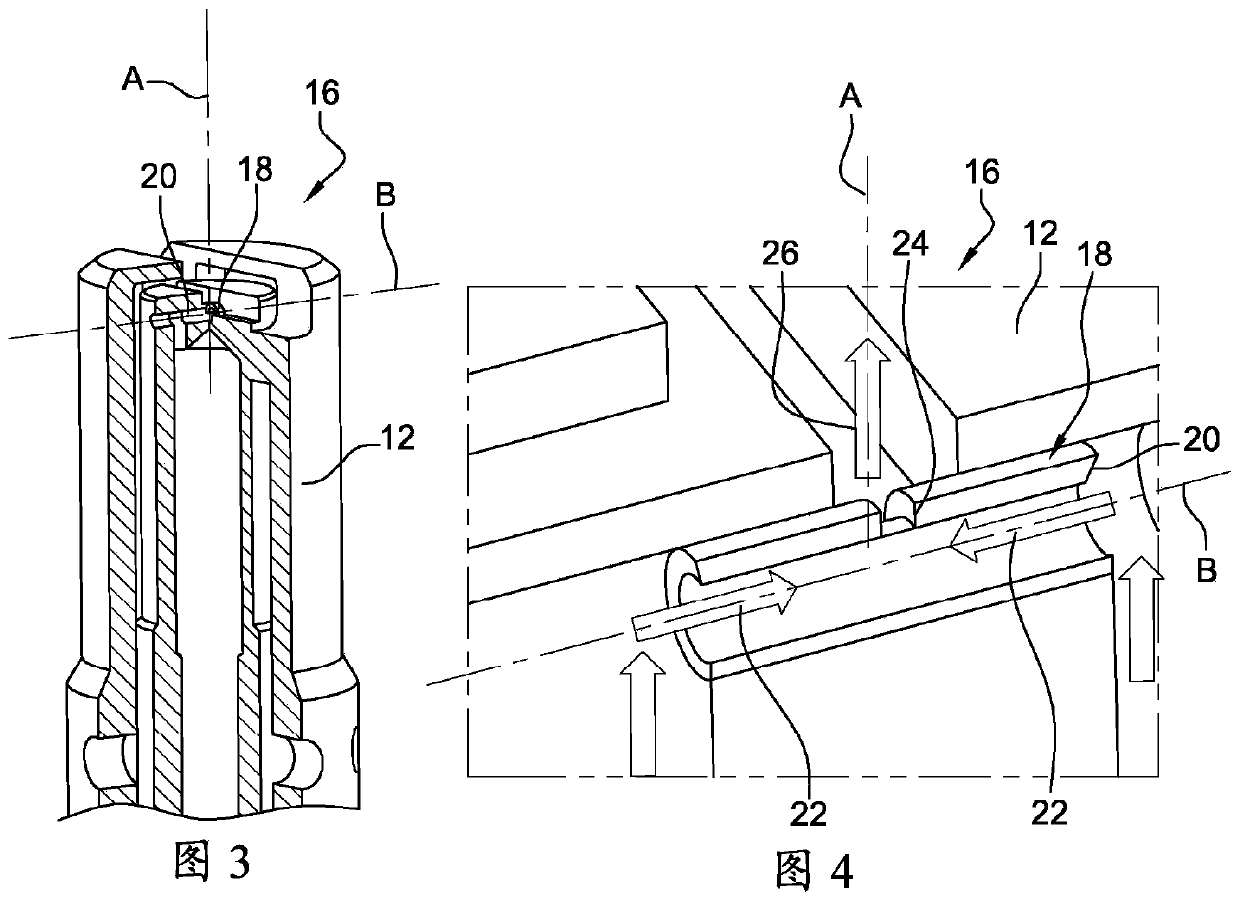

Flat-jet fuel injector for an aircraft turbine engine

ActiveCN110832255AFlow impactControl characteristicsBurnersContinuous combustion chamberJet flowFlight vehicle

A flat-jet fuel injector for an aircraft turbine engine, comprising a body (112) having a generally elongate shape having a longitudinal axis A, said body comprising a main pipe (118) having a generally elongate shape having a longitudinal axis B substantially perpendicular to said longitudinal axis A, the two longitudinal ends (120) of said main pipe being connected directly and respectively to longitudinal ends of two secondary pipes (119) having a generally elongate shape having a longitudinal axis C at least substantially parallel to said longitudinal axis A, and being configured to form,respectively, two separate fuel flow inlets intended to meet substantially at the middle of said main pipe which comprises at least one ejection slot (124) for ejecting said fuel jet, characterised inthat at least one of said main and secondary pipes defines a flow area, at least one geometric parameter of which, such as the shape or a dimension, varies along said pipe and / or is different from the same geometric parameter defined by a flow area of another of said pipes.

Owner:SAFRAN HELICOPTER ENGINES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com