System control apparatus and system control method

A control device and manufacturing system technology, which is applied to program control, temperature control, adaptive control, etc. in sequence/logic controllers, and can solve the problems that it is difficult to consider the impact of sudden interference, it is too late to control the drive device, and the state data exceeds the benchmark Questions like value or base range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach ]

[0063]

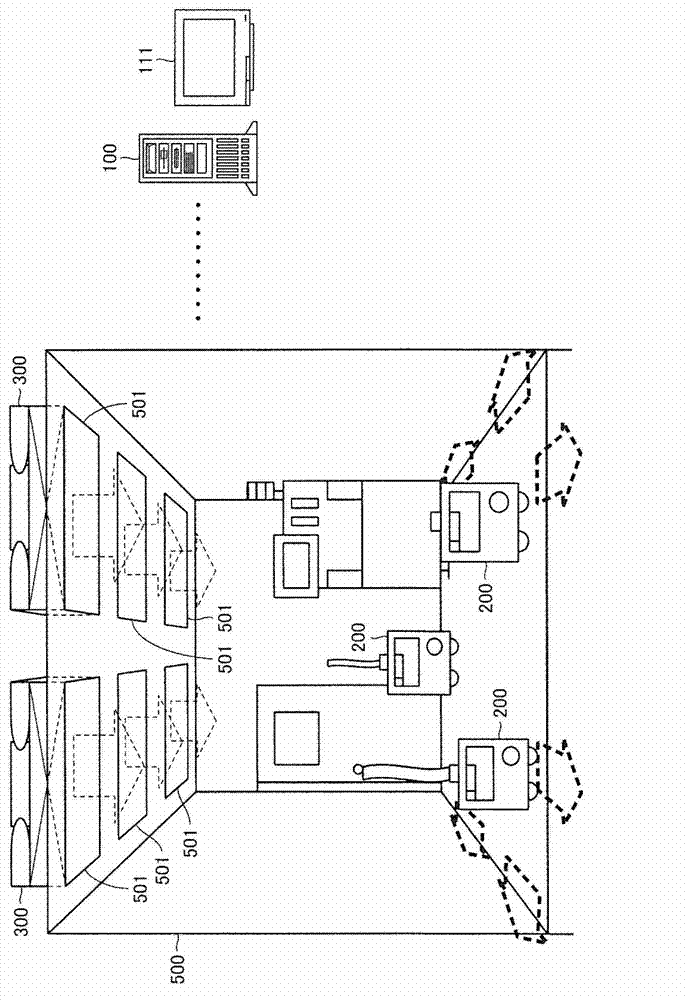

[0064] figure 1 It is a figure which schematically shows the outline structure of the manufacturing system including the system control apparatus which is 1st Embodiment of this invention.

[0065] refer to figure 1 , the manufacturing system includes a clean booth 500 as a space for manufacturing products. A particle sensor 200 for detecting the degree of cleanliness in the clean room 500 is provided in the clean room 500 . Although in figure 1 Although illustration is omitted in FIG. 1 , a production line for manufacturing products is installed in the clean room 500 , and workers who manage the production line and the like are arranged.

[0066] Frames 501 are formed on the ceiling of the clean room 500, and filter fan units (FFU) 300 are provided on each frame 501. 500 fans outside the room.

[0067] exist figure 1 In , the dotted arrows indicate the flow of air. In the clean room 500, by the operation of the fan of the filter fan unit 300 (hereinafter, so...

no. 2 approach ]

[0135]

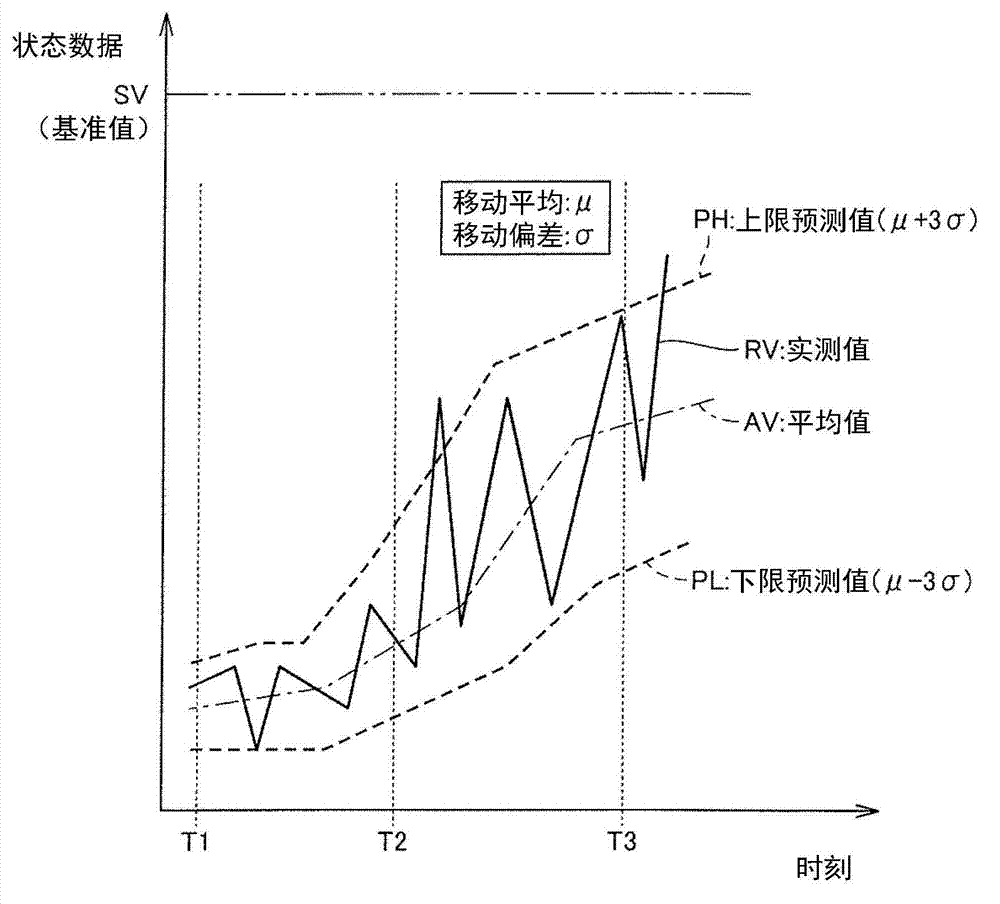

[0136] In the present embodiment, in the control of the equipment (filter fan unit 300 ) realized by the controller 100 , a plurality of estimated values are derived stepwise. Figure 13 It is a figure for demonstrating the outline|summary of the control of this embodiment.

[0137] exist Figure 13 The setting conditions of the air volume of the fan of the filter fan unit 300 and the controlled air volume of the fan are shown in . In addition, in Figure 13 Herein, regarding the reference value, the case where only the reference value on the upper side is set will be described as in the first embodiment.

[0138] In the present embodiment, a plurality of predicted values calculated using the moving average μ and moving deviation σ obtained as described above are compared with the reference value, and the air volume of the filter fan unit 300 is determined based on the comparison result.

[0139] Specifically, a plurality of predicted values ("μ+6σ", "μ+5σ"...

Embodiment )

[0162] Figure 20 It is a graph showing a specific example of the temporal change of the actually measured value of the state data, the first to fourth upper limit predicted values, and the air volume level of the filter fan unit 300 . exist Figure 20 In , the temporal change of the air volume level is shown in the upper row, and the actual measurement value and predicted value of the state data are shown in the lower row.

[0163] In addition, the graph in the lower stage shows the amount of foreign matter contained per unit volume detected by the particle sensor 200 as a specific example of state data. Then, with respect to the amount of foreign matter, the actual measured value is shown by the line R, the first upper limit predicted value is shown by the line D1, the second upper limit predicted value is shown by the line D2, and the third upper limit predicted value is shown by the line D3. The fourth upper limit predicted value is represented by line D4. in addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com