Method and device for generating ectopic foam

A foam, ex-situ technology, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve the problems of foam gas content, high randomness in stability, inability to control foam characteristics, and inability to solve flushing liquid and other problems, and achieve device assembly. Simple, simple design, broad market benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

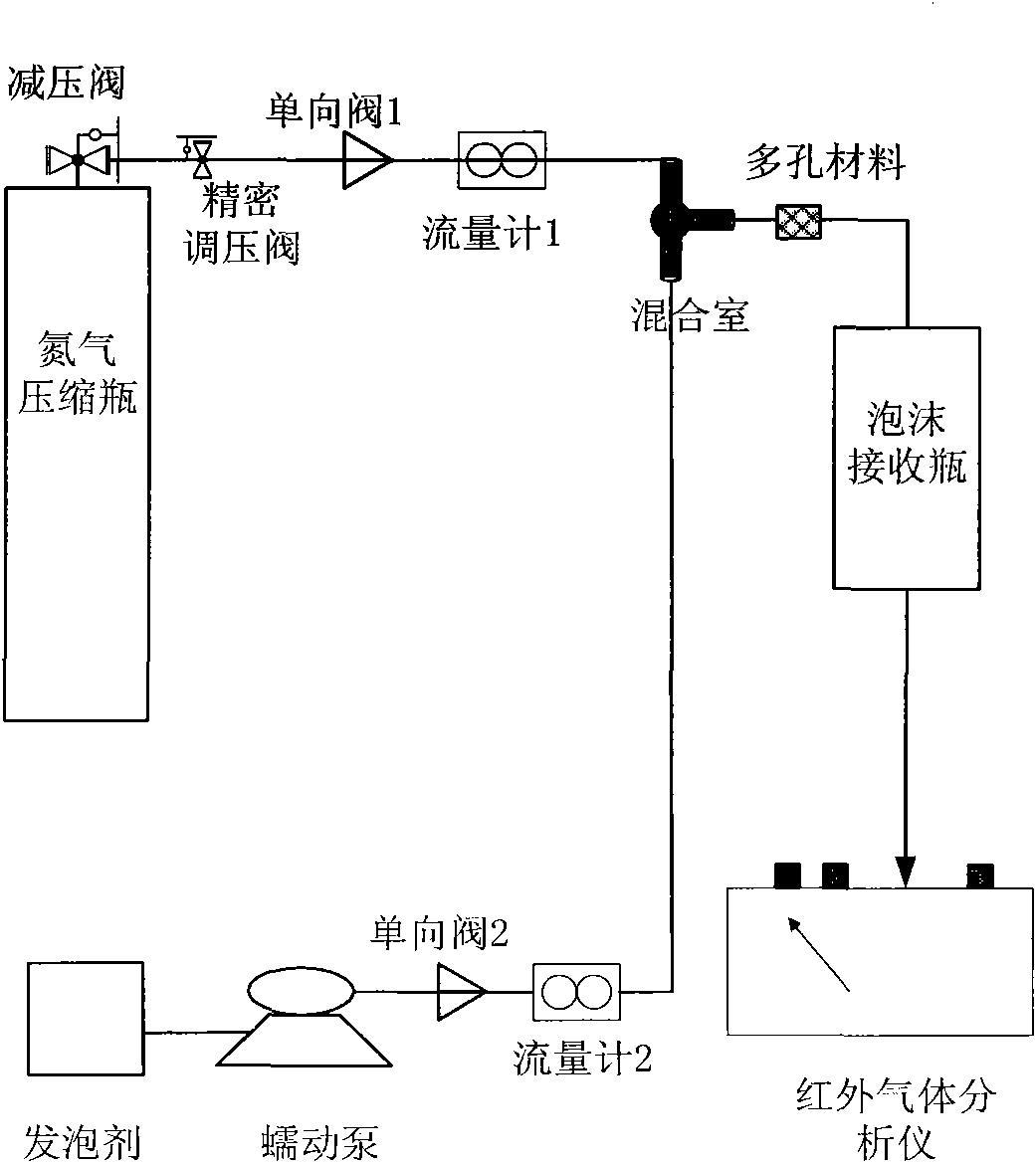

[0030] Example 1: Apparatus for Preparing Heterotopic Foam

[0031] Refer to attached figure 1 , the device for preparing heterotopic foam provided by the present invention includes a nitrogen compression bottle, a pressure reducing valve, a precision pressure regulating valve, a one-way valve, a flow meter 1, a peristaltic pump, a flow meter 2, a gas-liquid mixing chamber, and a porous material (consolidated sand core, average pore size 0.1mm), foam receiving bottle and portable infrared gas analyzer.

[0032] In the gas phase pipeline, a precision pressure regulating valve is installed after the pressure reducing valve, and then connected with the check valve 1 and the flow meter 1, and the connecting pipe is a Φ5mm hose;

[0033] In the liquid phase pipeline, the peristaltic pump is followed by a check valve 2 and a flow meter 2, and the connecting pipe is a Φ5mm hose;

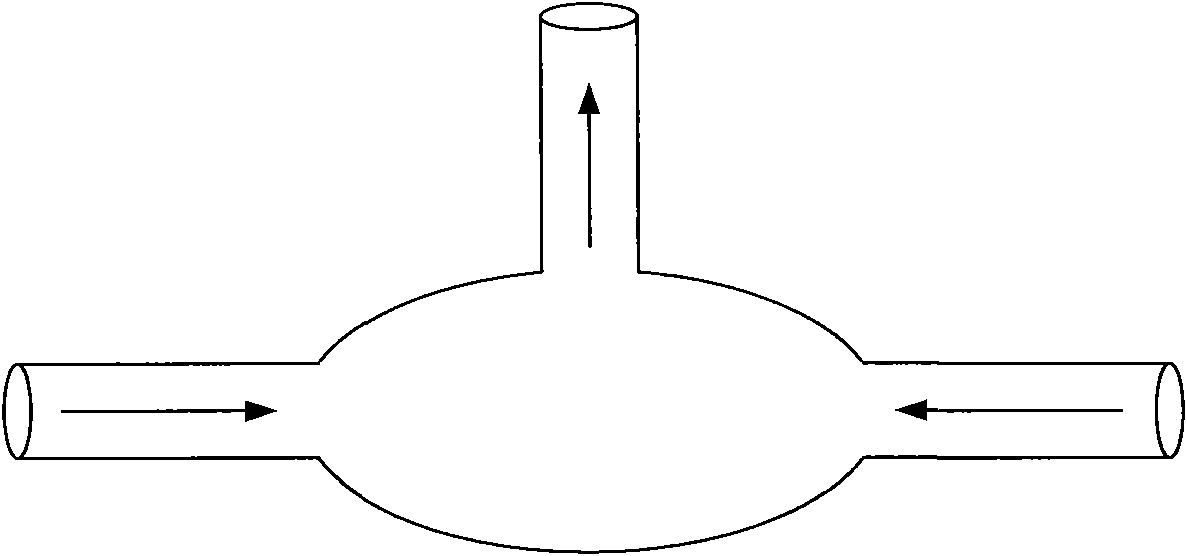

[0034] The connecting pipe between the gas-liquid phase pipe and the gas-liquid mixing chamber is a Φ5...

Embodiment 2

[0037] Example 2: Method of Preparing Heterotopic Foam

[0038] 1) Open the pressure reducing valve connected to the nitrogen compression bottle in the gas phase pipeline, adjust the precision pressure regulating valve, the pressure adjustment range is 0.1Mp~0.25Mp, and adjust the flow meter 1 to 10mL / min;

[0039] 2) Simultaneously turn on the peristaltic pump to start pumping 5000 mg / L sodium dodecyl sulfate (SDS) solution, and adjust the flow meter 2 to 100 mL / min;

[0040] 3) Gas and liquid enter the gas-liquid mixing chamber at the same time for mixing;

[0041] 4) The mixed gas and liquid enter the consolidated sand core, and the generated foam enters the foam receiving bottle;

[0042] 5) The residual gas and excess nitrogen in the system enter the infrared gas analyzer and then discharge.

[0043] In the above experiment, no liquid accumulation was found in the foam receiving bottle, and infrared monitoring showed that no nitrogen outflow was found. The particle size...

Embodiment 3

[0044] Example 3: Apparatus for Preparing Heterotopic Foam

[0045] Refer to attached figure 1 , The device and pipeline connection method for preparing ectopic foam provided by the present invention are the same as those in Example 1, and the porous material adopts metal aeration head, and the average pore diameter is about 0.98mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com