Three-phase permanent-magnet synchronous motor rotor punching sheet suitable for both line starting and variable frequency starting

A technology of rotor punching and variable frequency starting, which is applied to synchronous machine parts, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of reduced power factor of permanent magnet motor and unreasonable rotor punching design , the permanent magnet motor has low overload capacity, etc., to achieve reasonable no-load back electromotive force, obvious power saving effect, and small vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

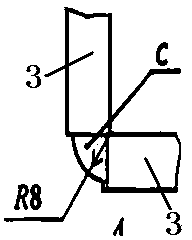

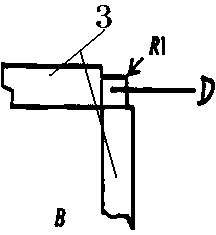

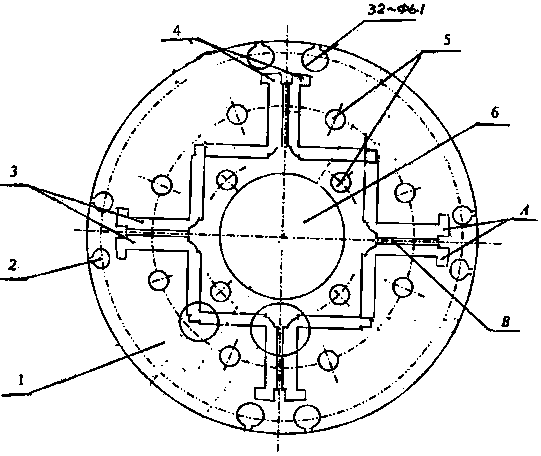

[0037] Refer to attached figure 1 , 2 , 3. The common three-phase permanent magnet synchronous motor rotor stamping structure for line start and variable frequency start has a rotor stamping body 1, and the outer circumference of the rotor stamping body 1 is evenly distributed with a starting rod hole 2, and a rotor punching plate is placed below the starting rod hole 2 The body 1 is evenly distributed with W-shaped magnetic steel slots 3. A magnetic isolation bridge A is set under the start rod hole 2 and above the magnetic steel slot 3. A magnetic isolation bridge B is set between two radial magnetic steel slots. A magnetic isolation bridge C is arranged between the magnetic steel grooves, 12 rigidity-enhancing screw holes 5 are arranged on the rotor punching body 1, a rotor shaft hole 6 is arranged in the middle of the rotor punching body 1, and the magnetic steel groove 3 is W-shaped.

[0038] The rotor punch body 1 has a diameter of Φ134-134.03mm.

[0039] The diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com