Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Avoid substandard quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

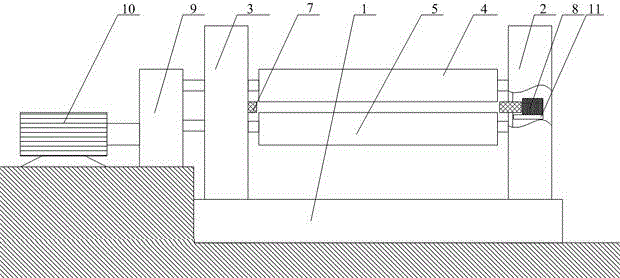

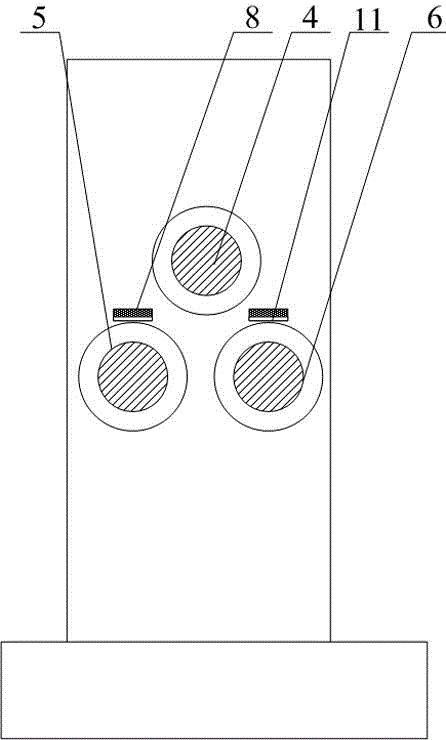

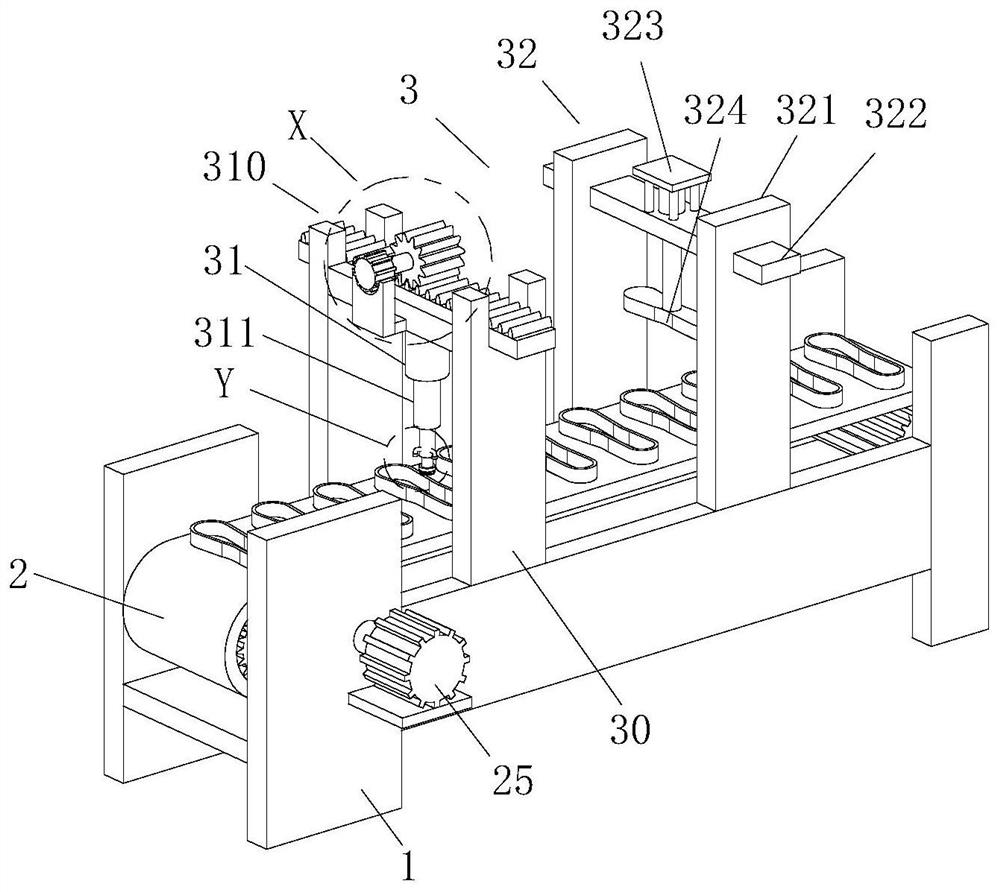

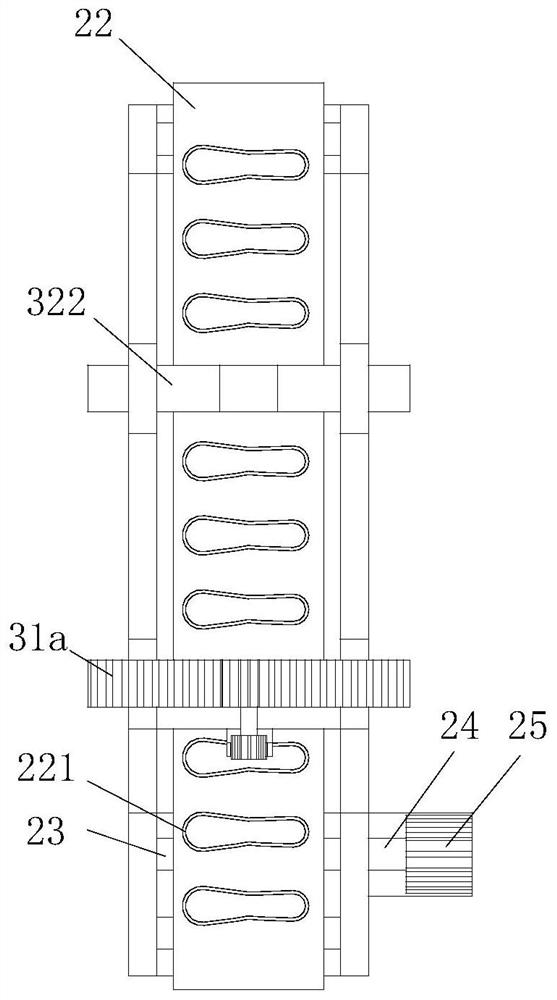

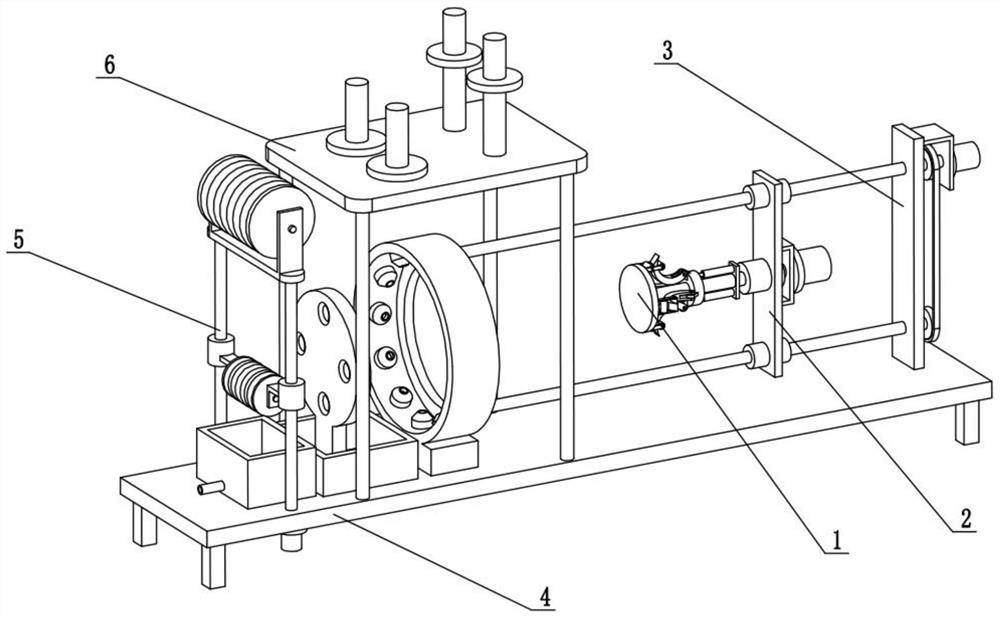

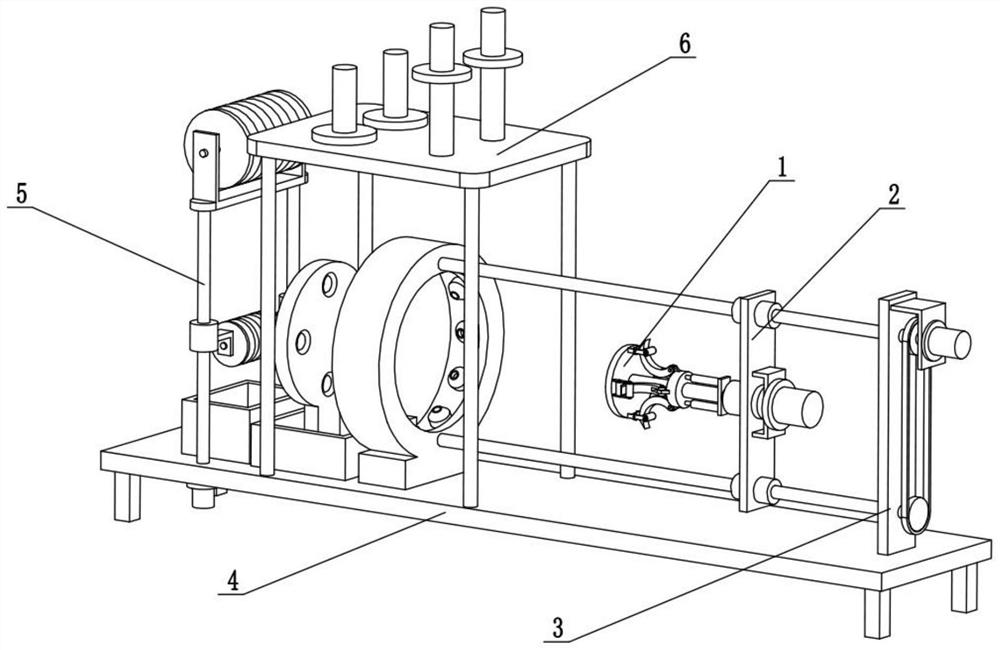

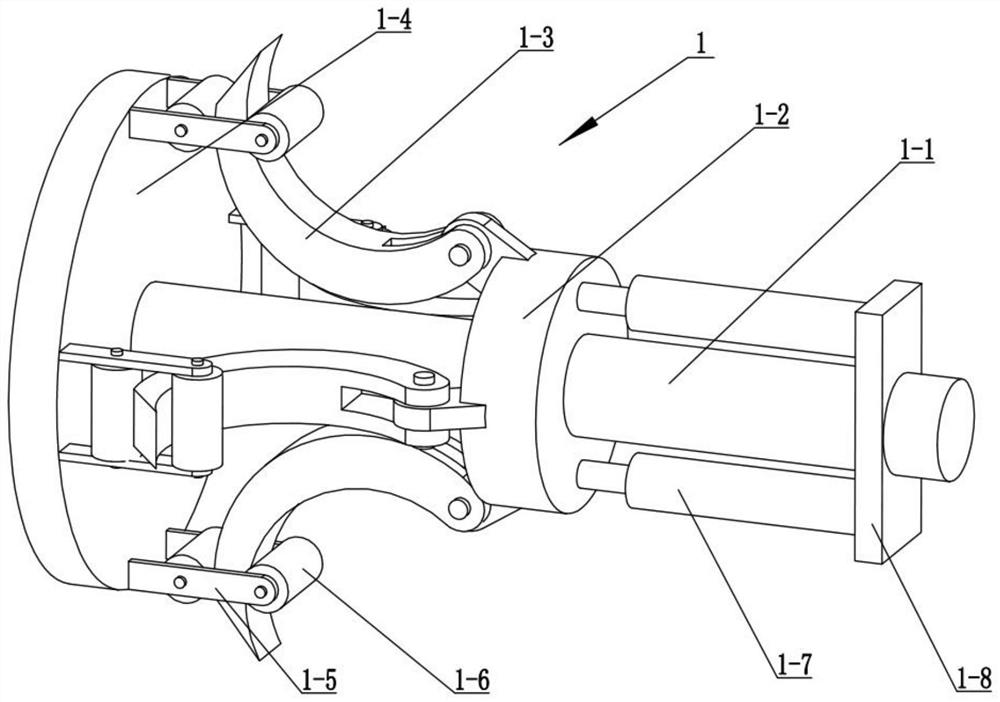

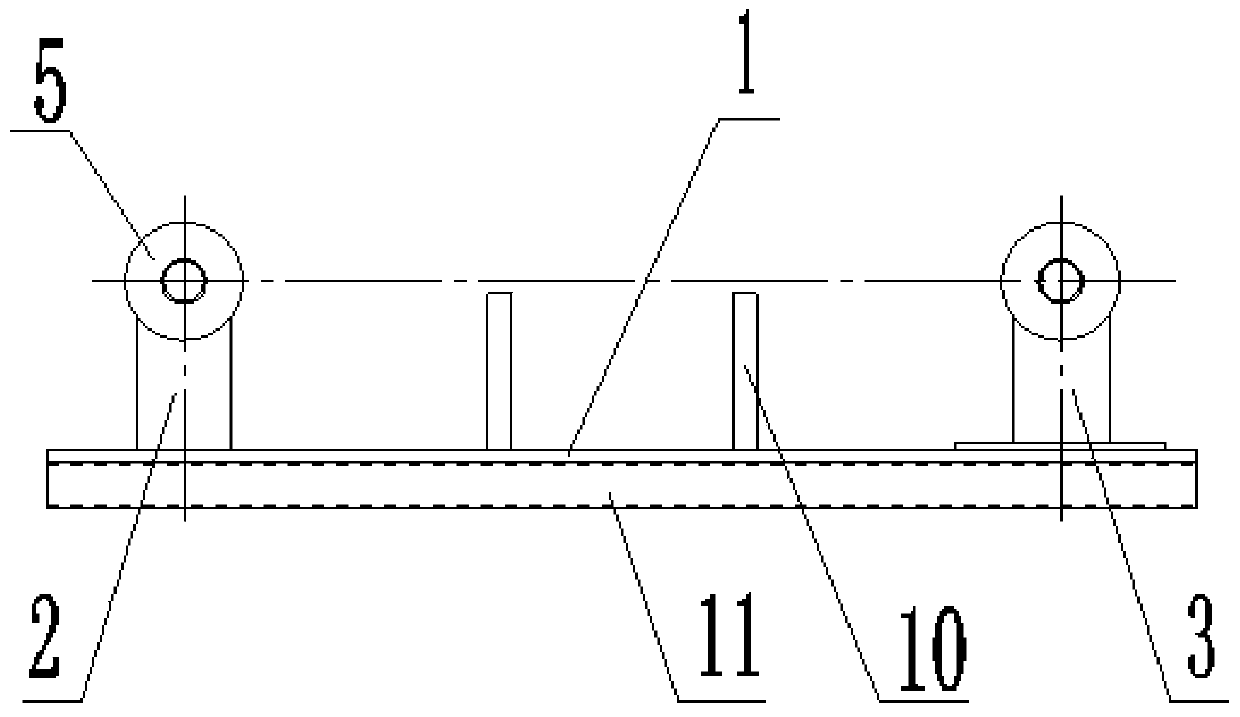

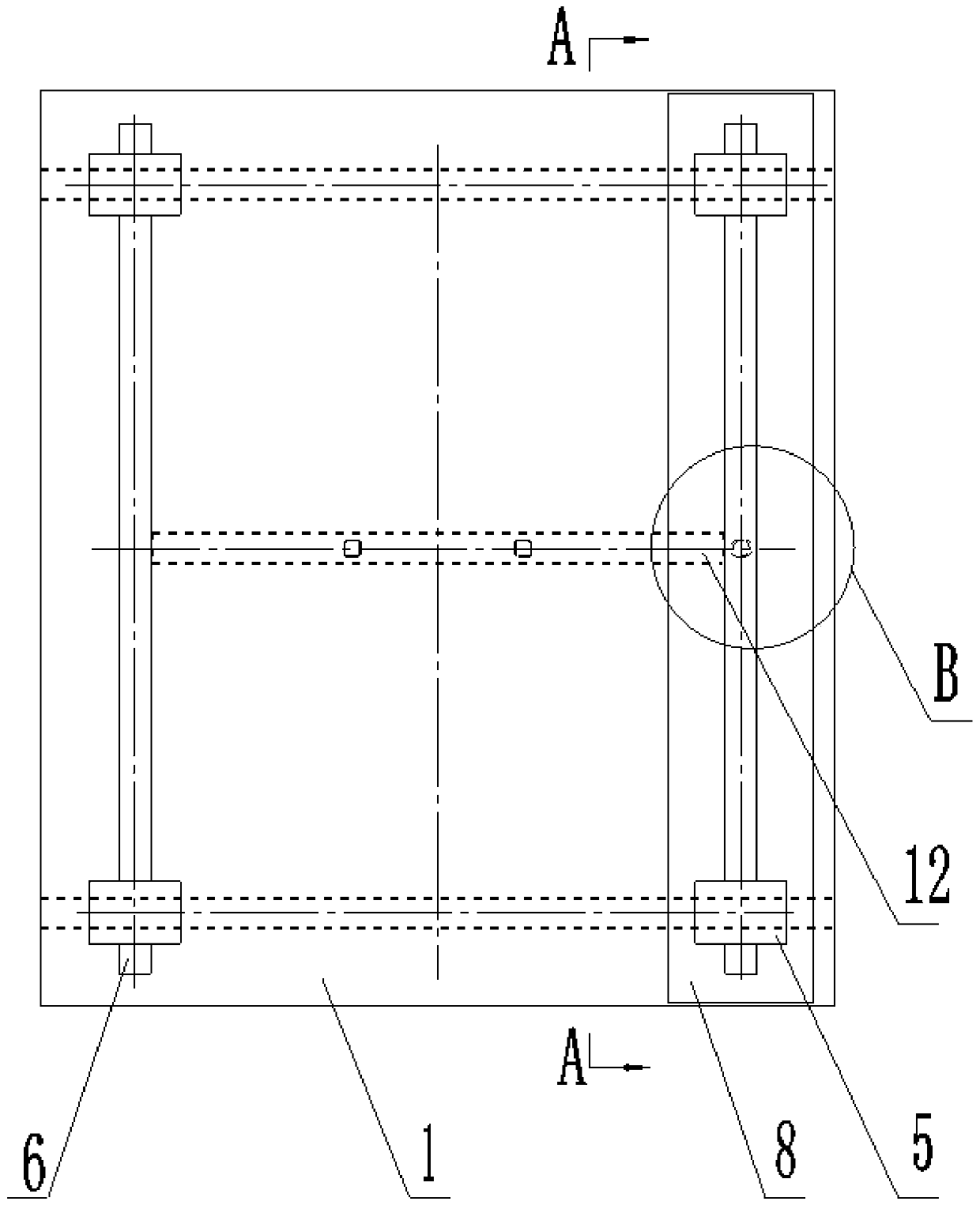

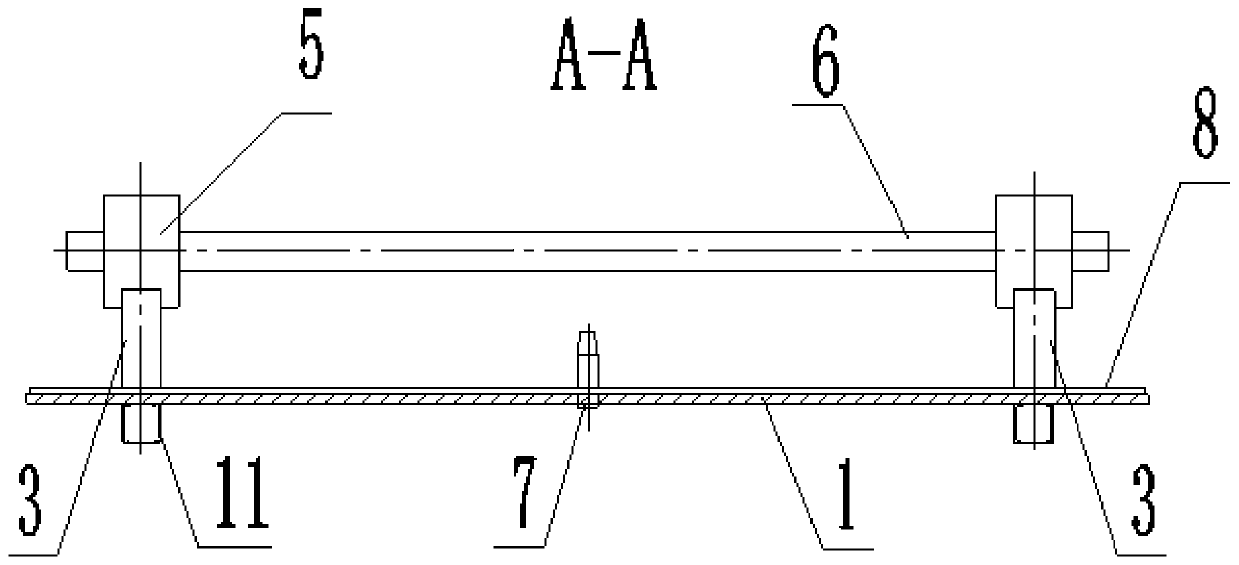

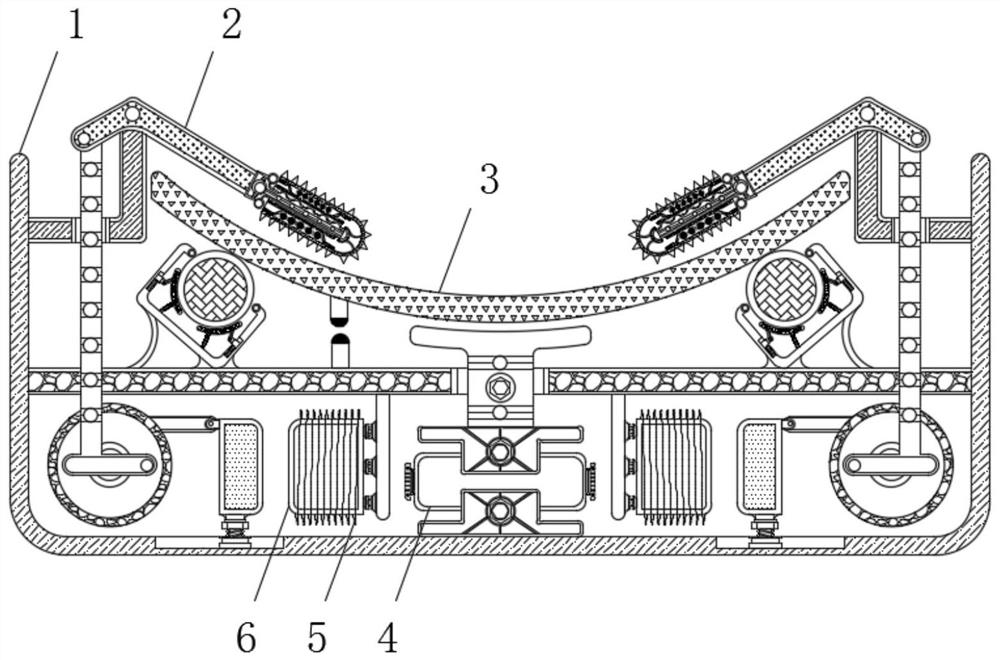

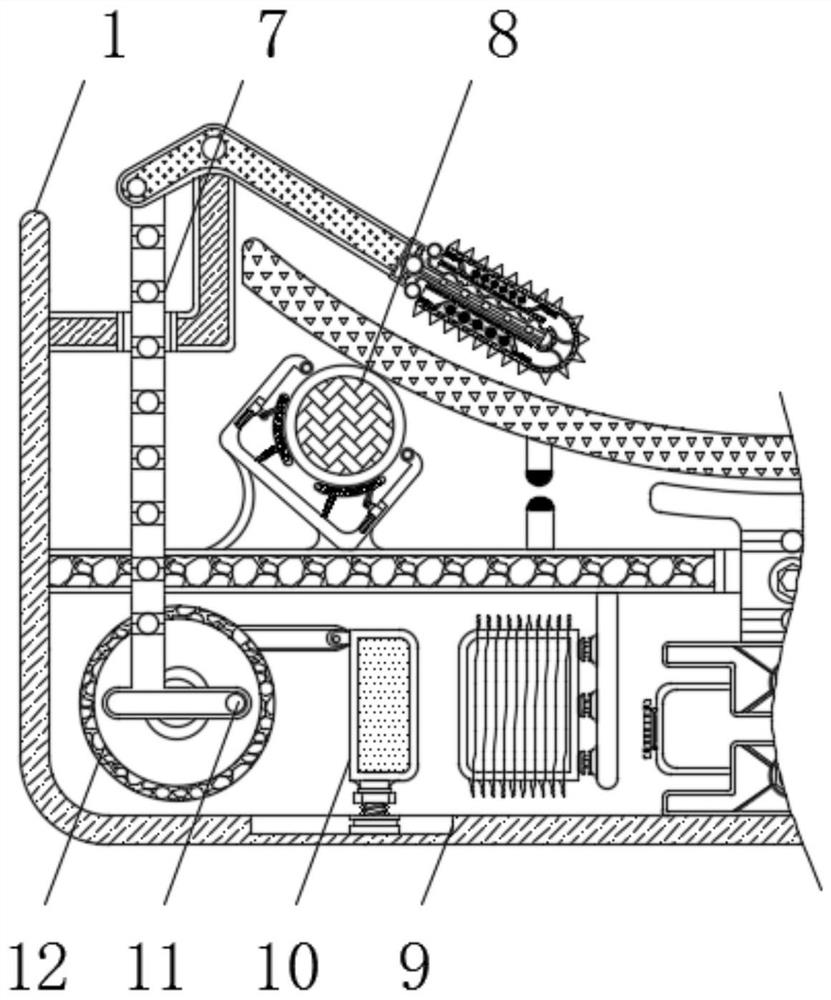

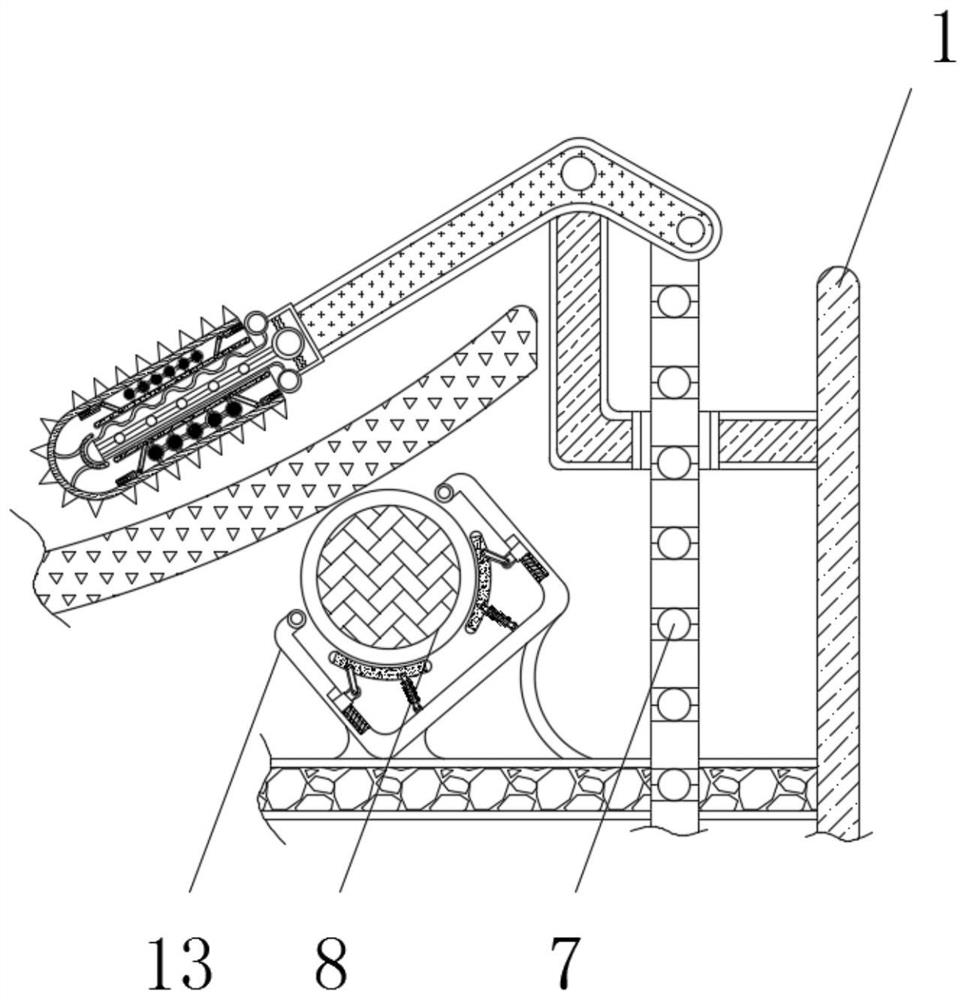

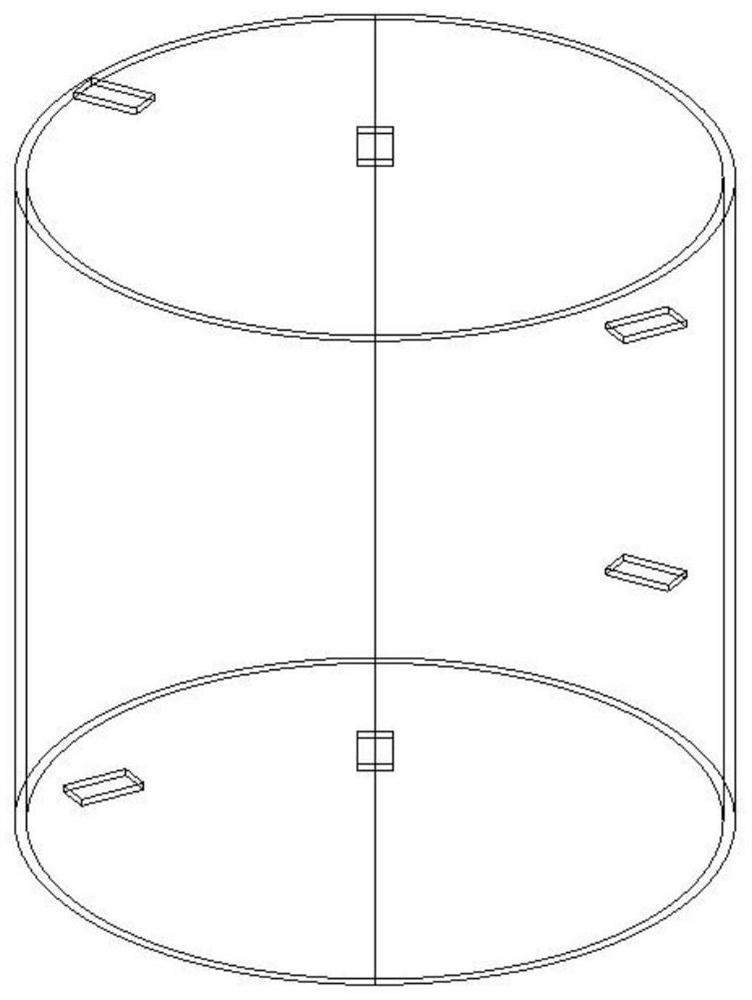

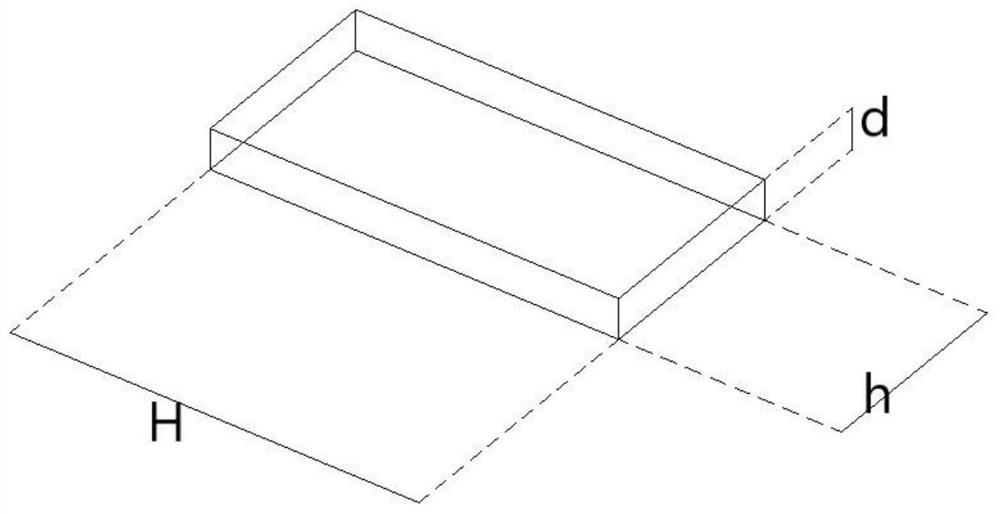

Three-roll plate- rolling machine

InactiveCN104607506AExtended service lifeAvoid wastingShaping toolsEngineeringMechanical engineering

The invention discloses a three-roll plate- rolling machine and belongs to the field of machine manufacturing. The three-roll plate-rolled machine comprises a left support, a right support, one upper roll, two lower rolls and a driving device, the upper roll and the lower rolls are arranged between the left support and the right support respectively and are connected with the driving device, four rollers are arranged on the portions, between the upper roll and the lower rolls, of the left support and the right support respectively, and the rollers make contact with a lubricating oil supply device. Four rollers are arranged on the portions, between the upper roll and the lower rolls, of the left support and the right support respectively, during the process of rolling a plate, the plate can be controlled in position in real time by rolling of the rollers, and therefore the plate can run at a normal rolling route, and the disqualification of the formed product caused by offset is avoided; the lubricating oil supply device is arranged beside the rollers and can supply the oil to the rollers and lubricate the rollers in real time in a contact mode, the friction between the rollers and the plate is reduced and the service life of the rollers can be prolonged.

Owner:NANTONG LIWANG MACHINE TOOL

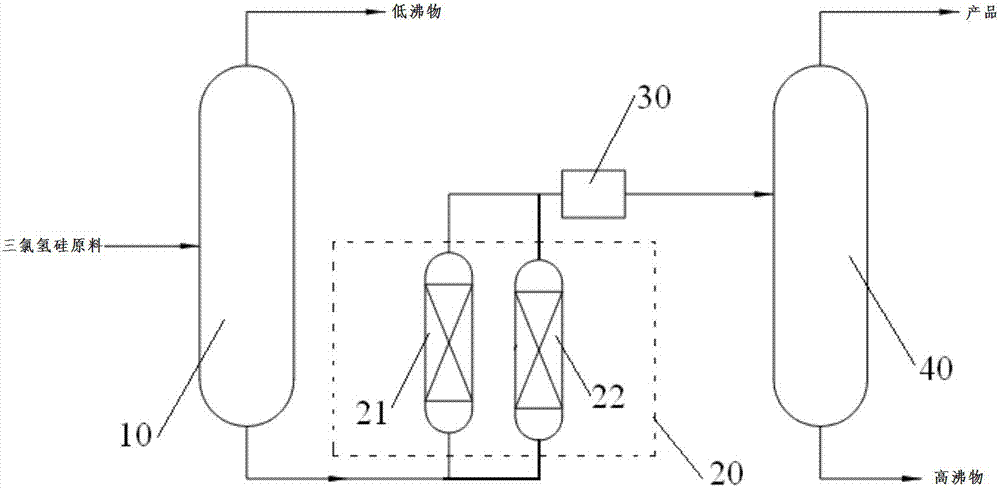

Purification method and purification system of chlorosilicate

ActiveCN106882808AMeet production requirementsAvoid substandard qualityHalogenated silanesPurification methodsSorbent

The invention provides a purification method and purification system of chlorosilicate. The chlorosilicate is dichlorosilane, trichlorosilane or silicon tetrachloride containing boron and phosphorus impurities. The purification method comprises the following steps: step S1, performing primary rectification on the chlorosilicate to obtain rectified liquid-phase chlorosilicate; step S2, processing the rectified liquid-phase chlorosilicate by utilizing an absorbent to obtain absorbed liquid-phase chlorosilicate, wherein the absorbent has free water or crystallized water, the free water or the crystallized water has hydrolytic reaction with the boron and phosphorus impurities to generate high-boiling residues, wherein a part of the high-boiling residues exist in the absorbed liquid-phase chlorosilicate; and step S3, performing secondary rectification on the absorbed liquid-phase chlorosilicate to obtain purified chlorosilicate. The water in the absorbent has hydrolytic reaction with the boron and phosphorus impurities to generate the high-boiling residues, the high-boiling residues are easily separated from the chlorosilicate, so that the separation efficiency is relatively high; and the purification method is relatively good in separation effect, and content of the boron and phosphorus impurities in the purified chlorosilicate can be 0.05 to 0.5 ppb.

Owner:CHINA SILICON CORP LTD +1

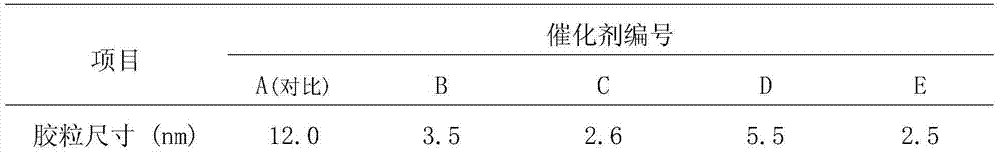

Fischer-Tropsch catalyst, as well as preparation method and application thereof

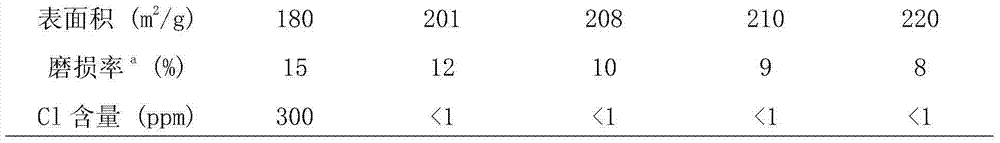

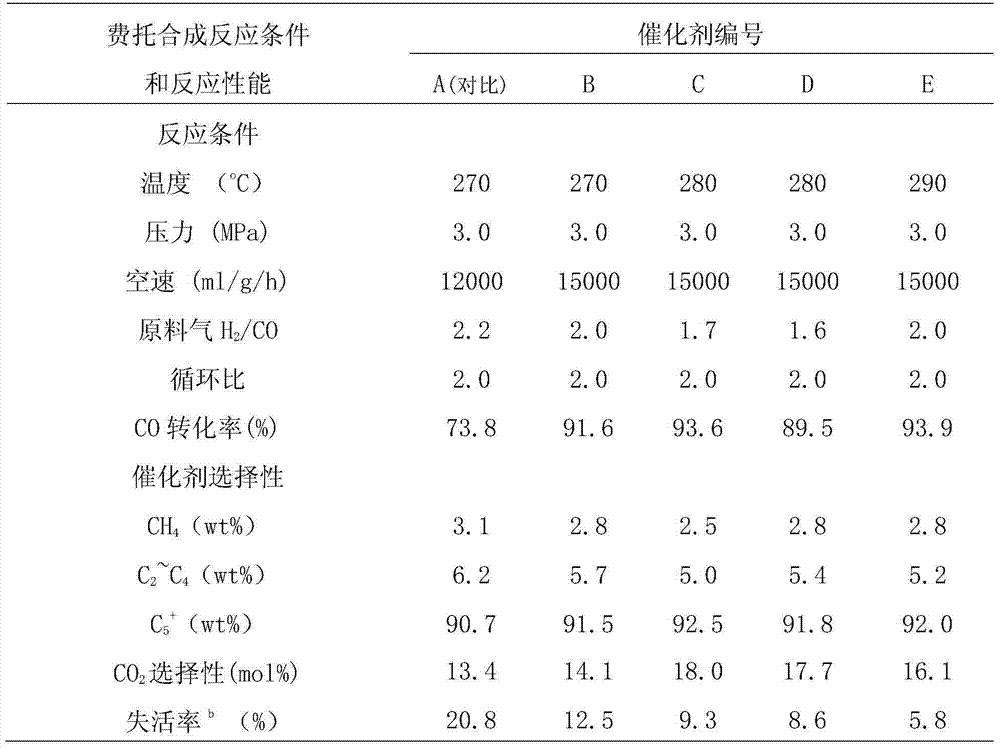

ActiveCN104707620ANovel production methodSimple processLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSilicic acidIon exchange

The invention provides a Fischer-Tropsch catalyst, as well as a preparation method and application thereof. A silicate solution is used as a raw material, a silicic acid solution is obtained through cation exchange treatment, and Cl and other anionic impurities in the silicic acid solution are then removed through anion exchange treatment, so as to obtain an activated silicic acid solution; the activated silicic acid solution can replace commercial silica gel to serve as a silicon source for Fischer-Tropsch catalyst preparation, so as to effectively solve the difficult problem of non-uniform mixing of iron species and SiO2, further enlarge the surface area of the catalyst, and improve the mechanical strength of the catalyst. The method is simple and convenient to operate, low in cost, and very applicable for the preparation of the commercialized Fischer-Tropsch catalyst.

Owner:SYNFUELS CHINA TECH CO LTD

Cement clinker prepared from low-grade limestone and preparation method thereof

The invention provides a cement clinker prepared from low-grade limestone and a preparation method thereof, and relates to the technical field of cement clinker production processes. The cement clinker comprises the following raw materials by weight: 80%-95% of low-grade limestone, 1%-10% of sandstone, 1%-5% of an iron correction material and 1%-8% of bauxite, wherein the CaO content of the limestone is 41.5%-45%; the low-grade limestone is subjected to homogenization treatment, the content of CaO in the homogenized low-grade limestone is not lower than 44.3%, the content of SiO2 is not higher than 13%, and the content of magnesium oxide is not higher than 3%; the cement clinker takes the low-grade limestone with the CaO content of 41.5-45%, sulfuric-acid slag, iron ore, steel slag, sandstone and bauxite as raw materials, so the limestone with the CaO content of lower than 45% produced by a mine is utilized, and the waste residue discharge amount of the mine is effectively reduced.

Owner:南阳中联水泥有限公司

Preparation method of decontamination type laundry detergent

InactiveCN112169610AStir wellWell mixedWater/sewage treatment by irradiationFlow mixersProcess engineeringDrive motor

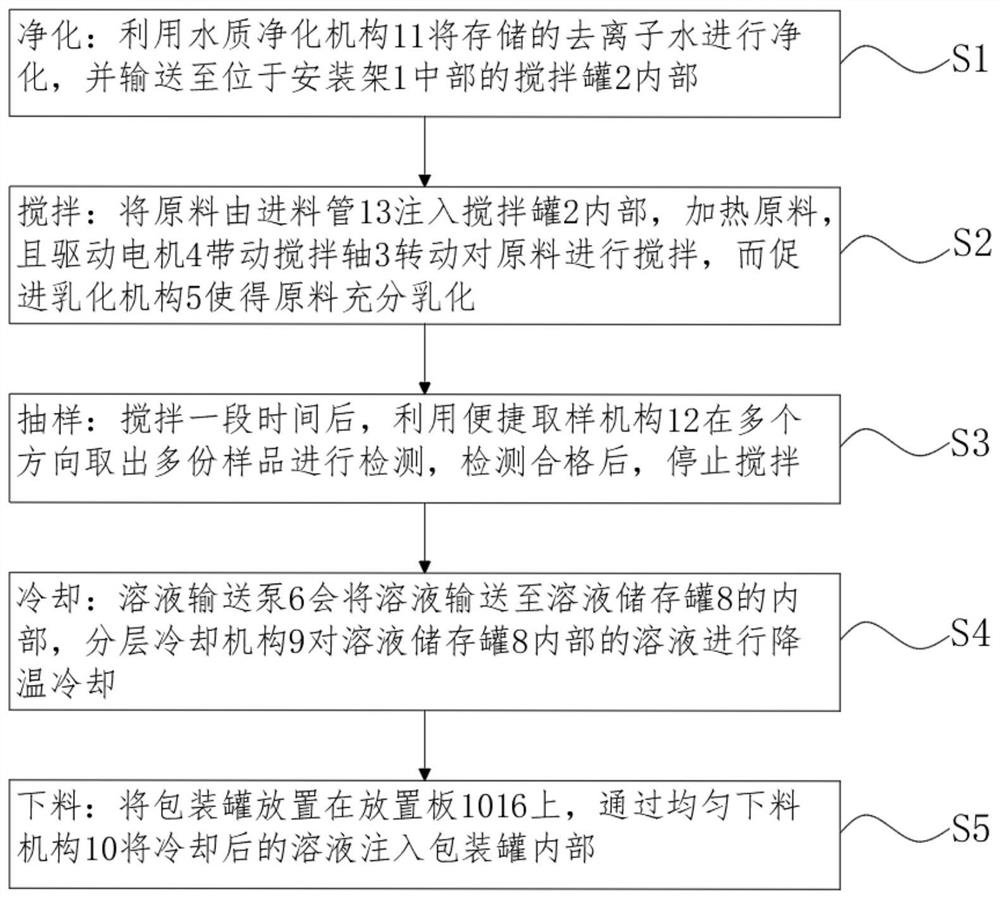

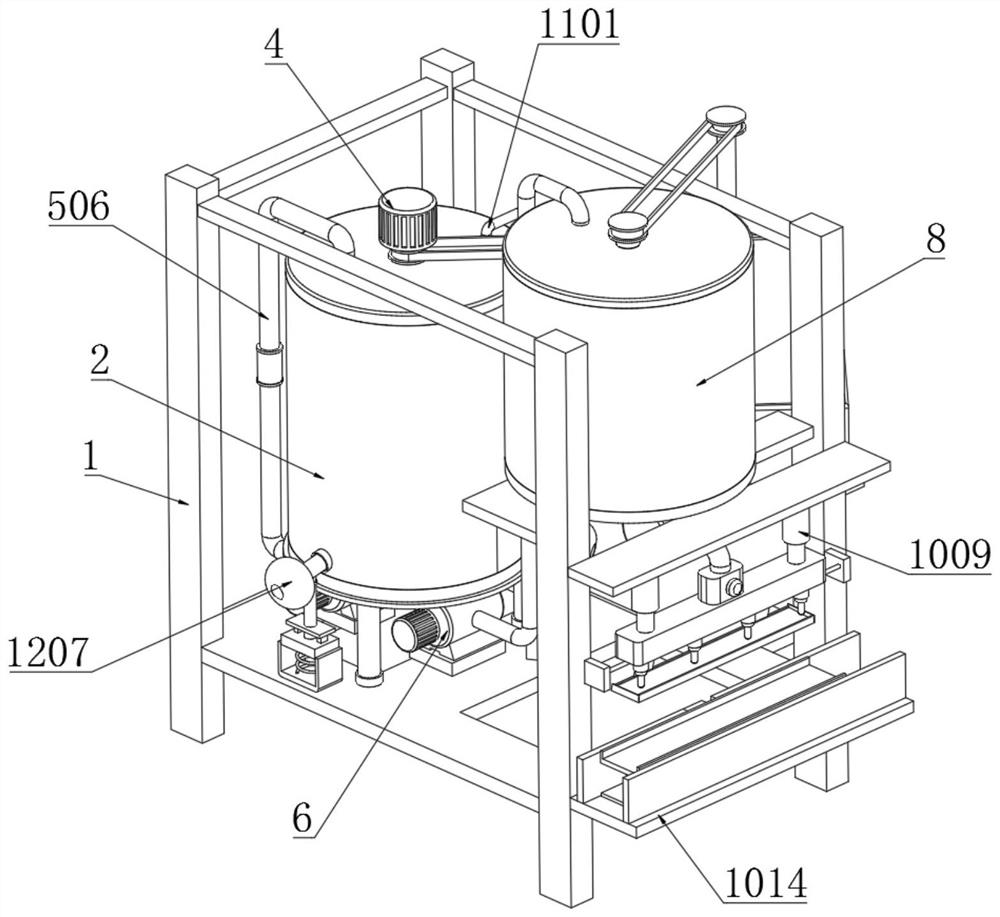

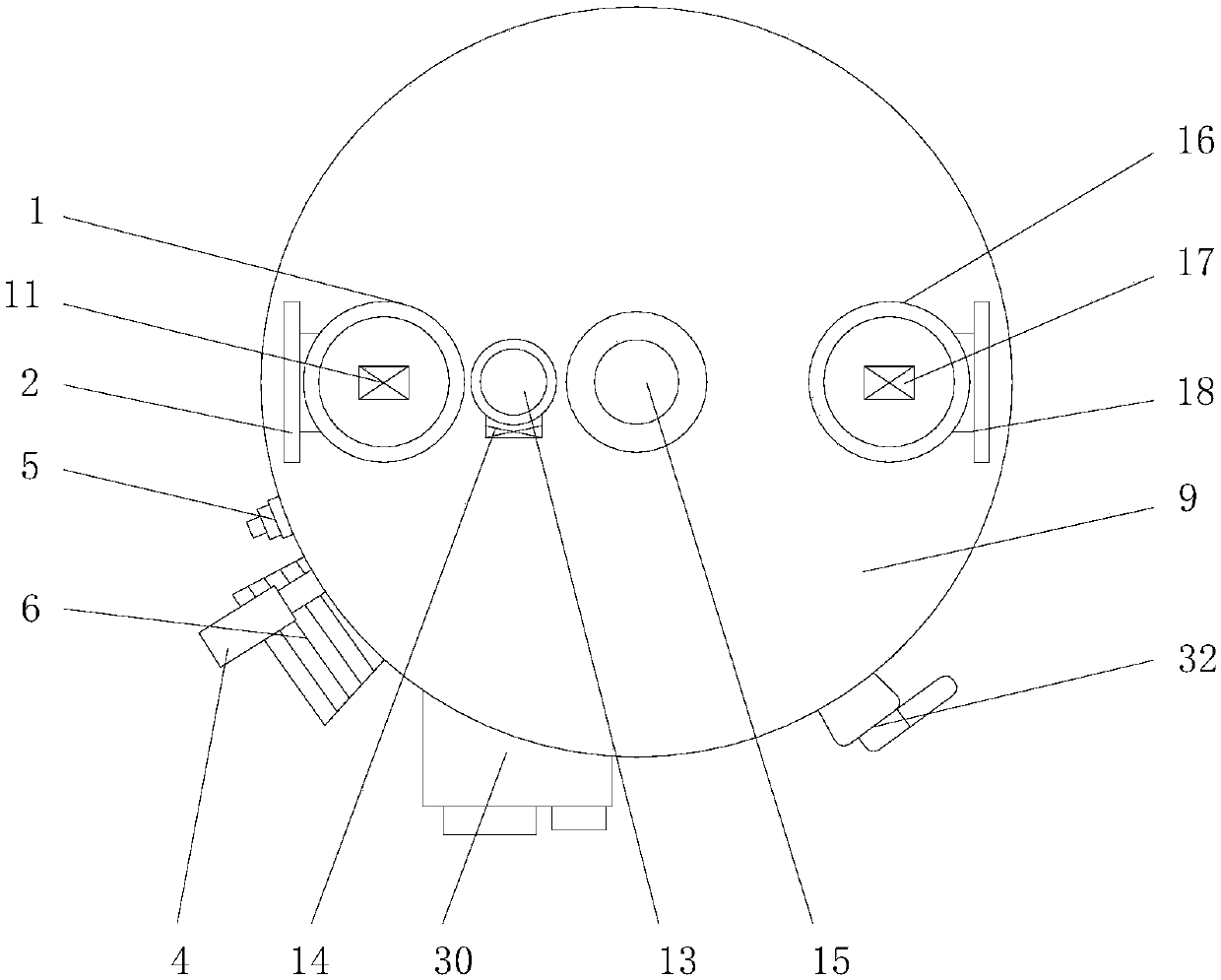

The invention discloses a preparation method of a decontamination type laundry detergent. The method comprises the following steps of: purification: purifying stored deionized water by using a water quality purification mechanism, conveying the purified deionized water into a stirring tank in the middle of a mounting frame; stirring: injecting raw materials into the stirring tank through a feedingpipe, heating the raw materials, and driving a stirring shaft to rotate by a driving motor so as to stir the raw materials, and fully stirring the raw materials through an emulsification promoting mechanism. The raw materials in the stirring tank can be fully mixed through the emulsification promoting mechanism, the raw materials can be fully mixed, and the situation that the quality of the prepared laundry detergent is unqualified due to uneven mixing of the raw materials is avoided, and meanwhile, through cooperative use of a circulating pump and a circulating conveying pipe, the mixed solution at the bottom of the stirring tank is pumped out and then re-injected into the stirring tank, the problem that the solution is deposited at the bottom of the stirring tank and cannot be fully mixed is avoided, raw materials are fully emulsified, raw material mixing is promoted, and the activity of the raw materials can be improved.

Owner:周燕芳

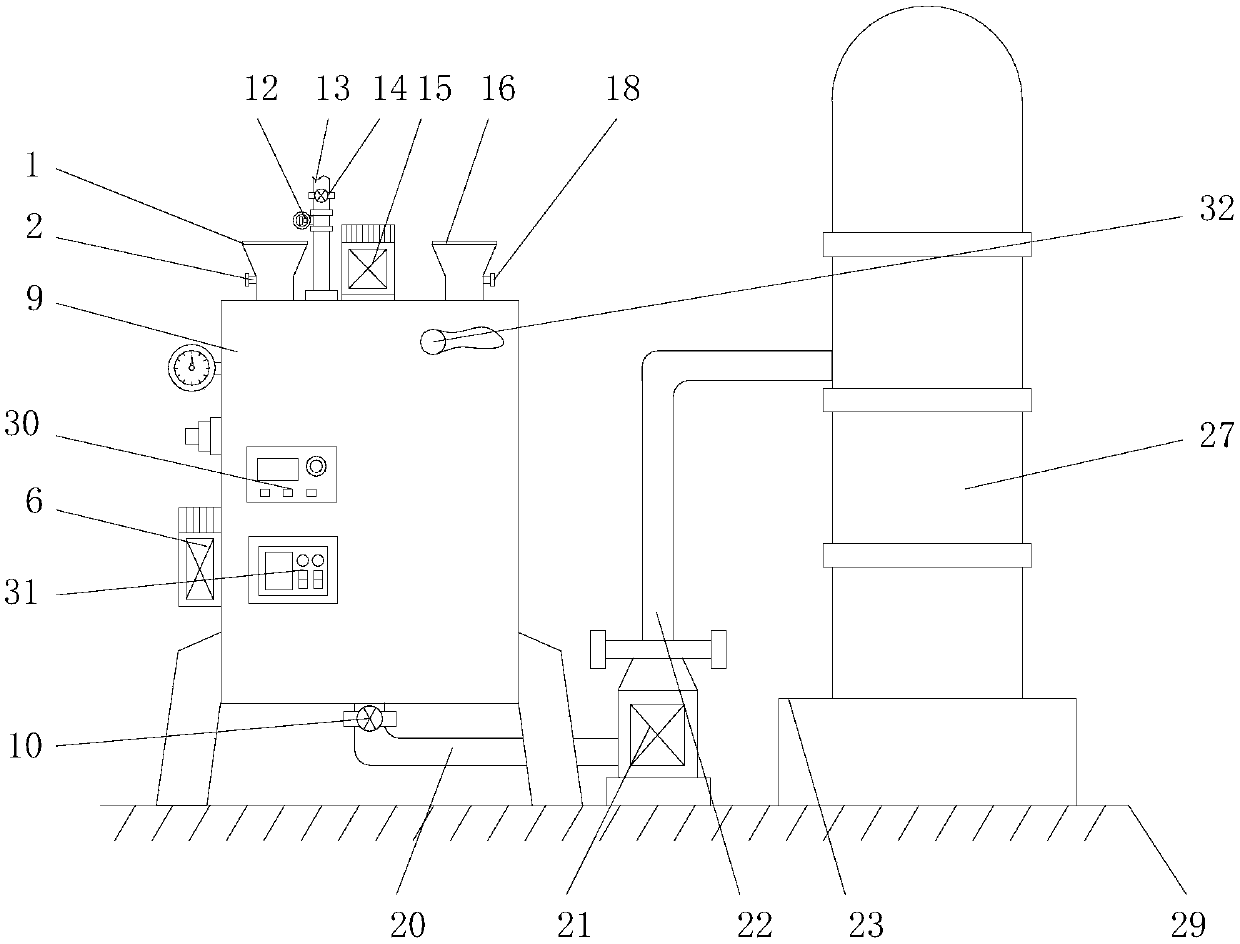

Phenyl trichlorosilane production device special for food-grade silicon resin

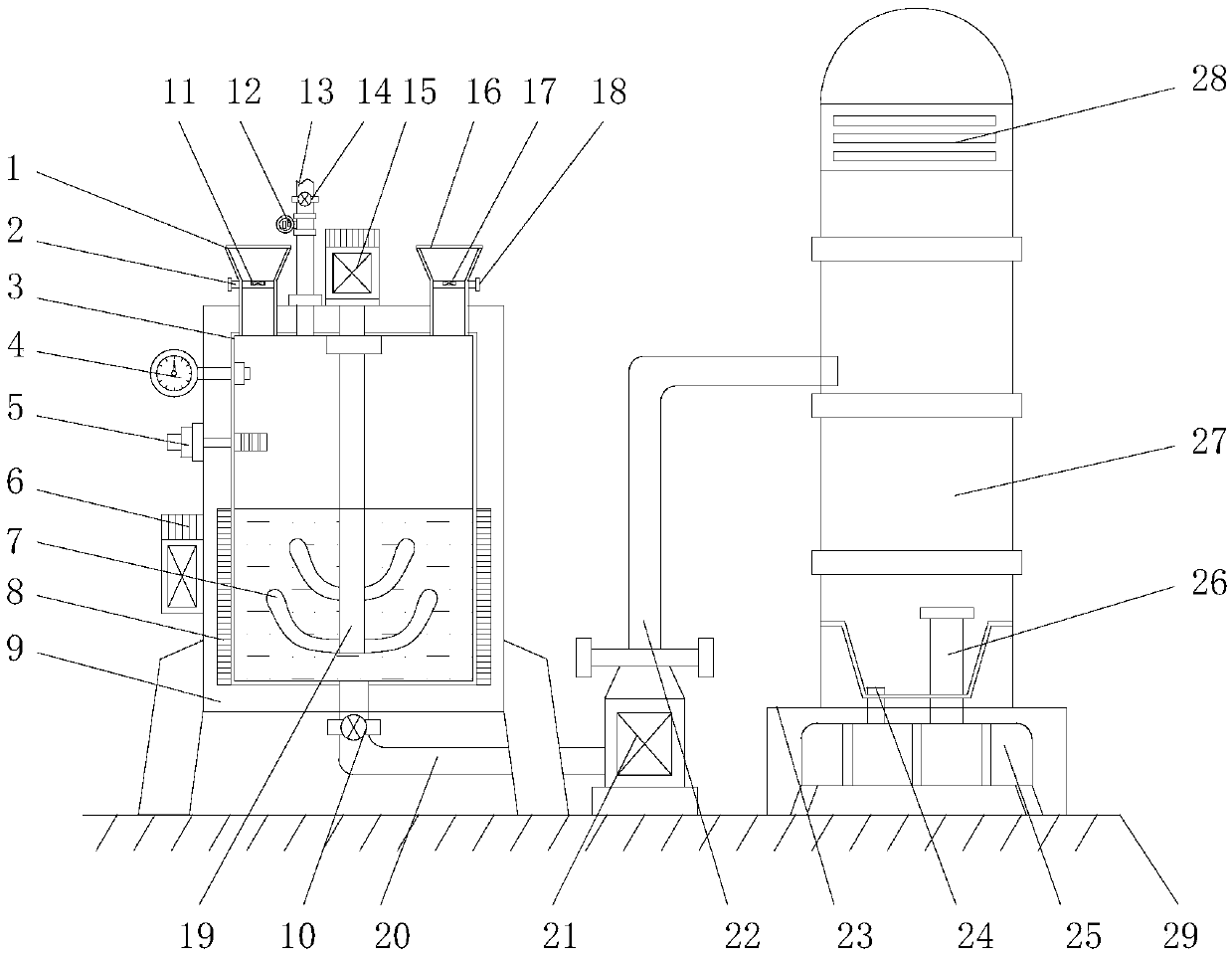

InactiveCN109663559AAvoid substandard qualityAvoid adding too muchGroup 4/14 element organic compoundsDistillation separationSurface mountingReboiler

The invention discloses a phenyl trichlorosilane production device special for food-grade silicon resin. The phenyl trichlorosilane production device special for the food-grade silicon resin comprisesa reaction kettle and a rectifying tower. The interior of the reaction kettle is provided with an inner container. A first hopper is installed above the reaction kettle. A liquid adding pipe is installed above the reaction kettle at one side of the first hopper. The surface of the liquid adding pipe is provided with a flowmeter. A motor is installed above the reaction kettle at one side of the liquid adding pipe. A second hopper is installed above the reaction kettle at one side of the motor. One side of the reaction kettle is provided with an electromagnetic heater. A circulating pump is placed at the other side of the reaction kettle. The rectifying tower is installed above a substrate. The surface of the reaction kettle is provided with a controller. The phenyl trichlorosilane production device is capable of, through installing a structure of a first weighing sensor, a second weighing sensor, the flowmeter, the controller, the electromagnetic heater, the rectifying tower, a reboiler, a condenser, and the circulating pump, solving problems that a dosing material cannot be accurately added and separation of mixed solution cannot be efficiently performed.

Owner:ZHEJIANG KAIHUA SYNTHETIC MATERIAL

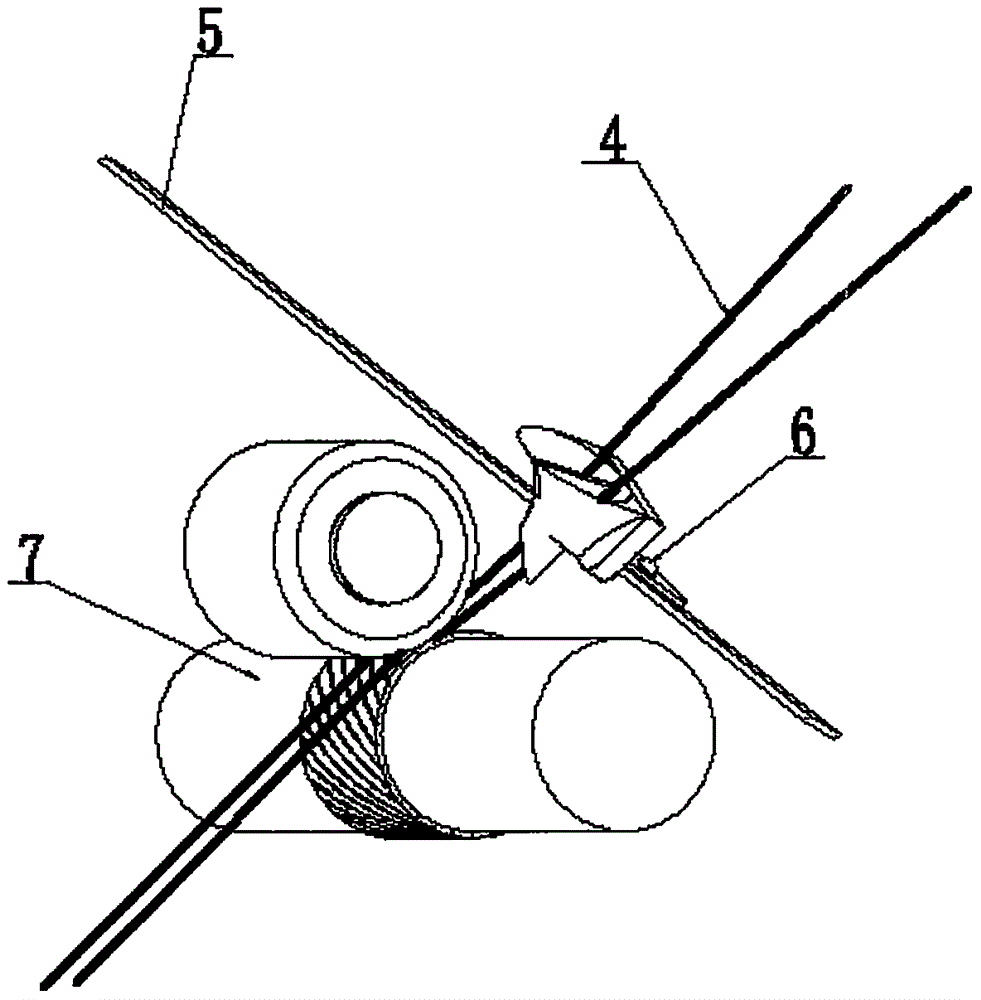

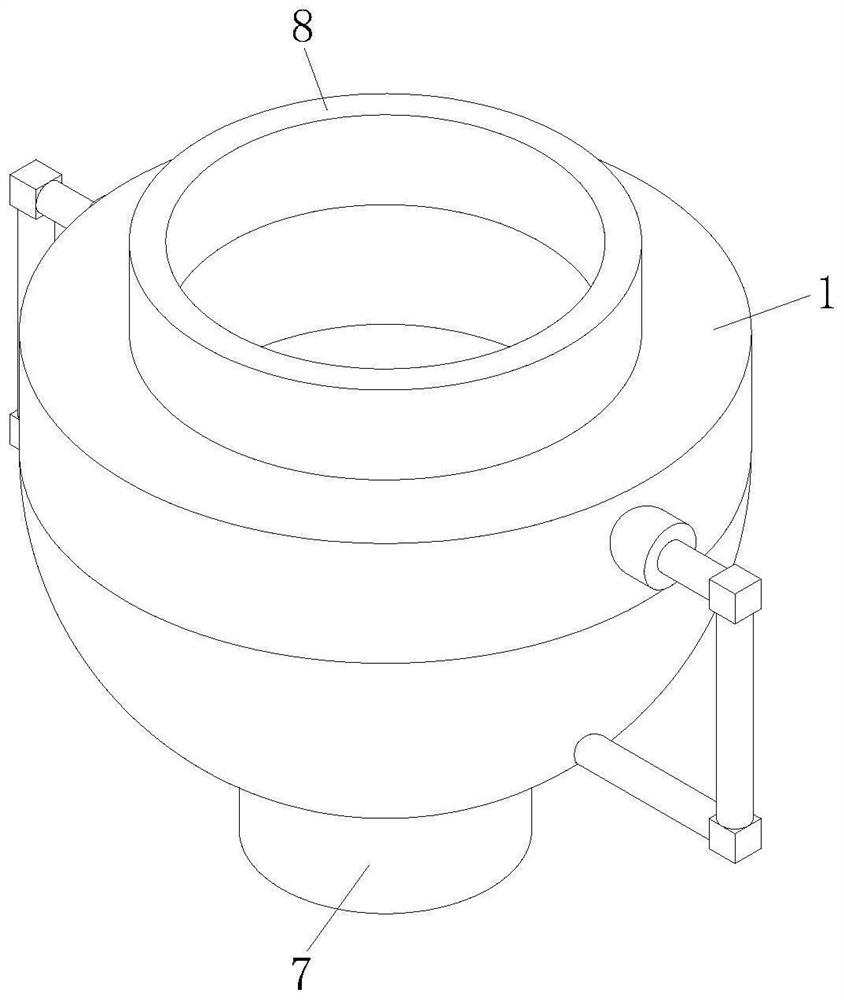

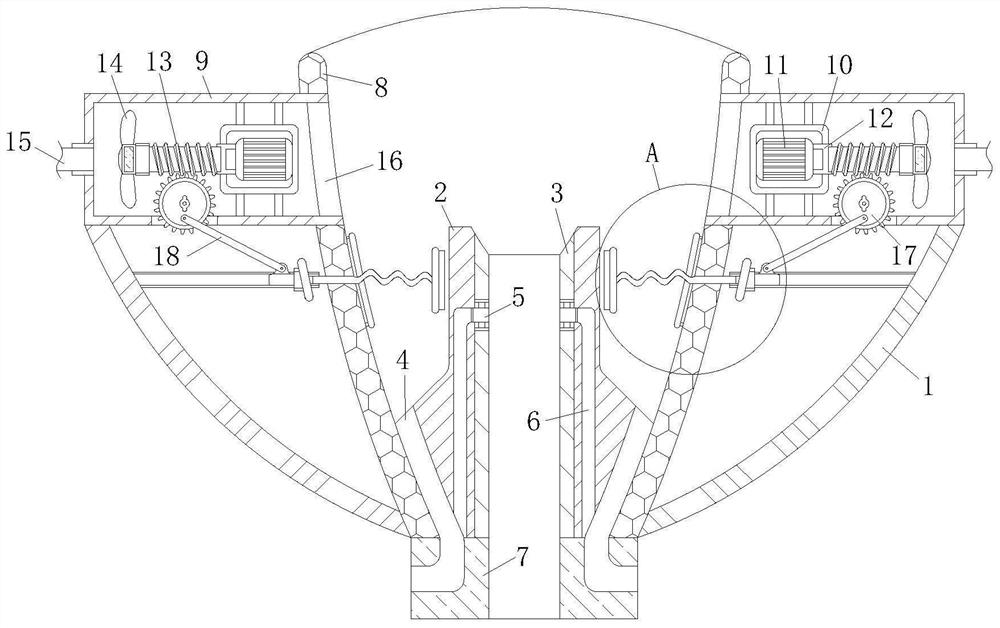

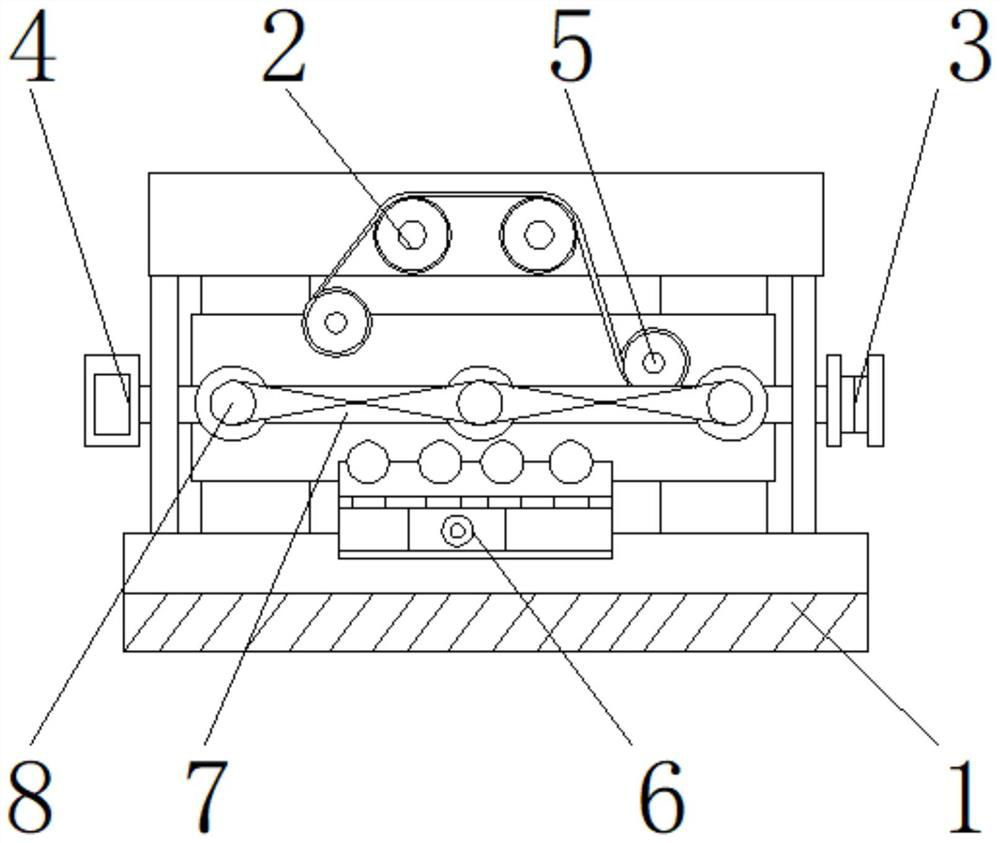

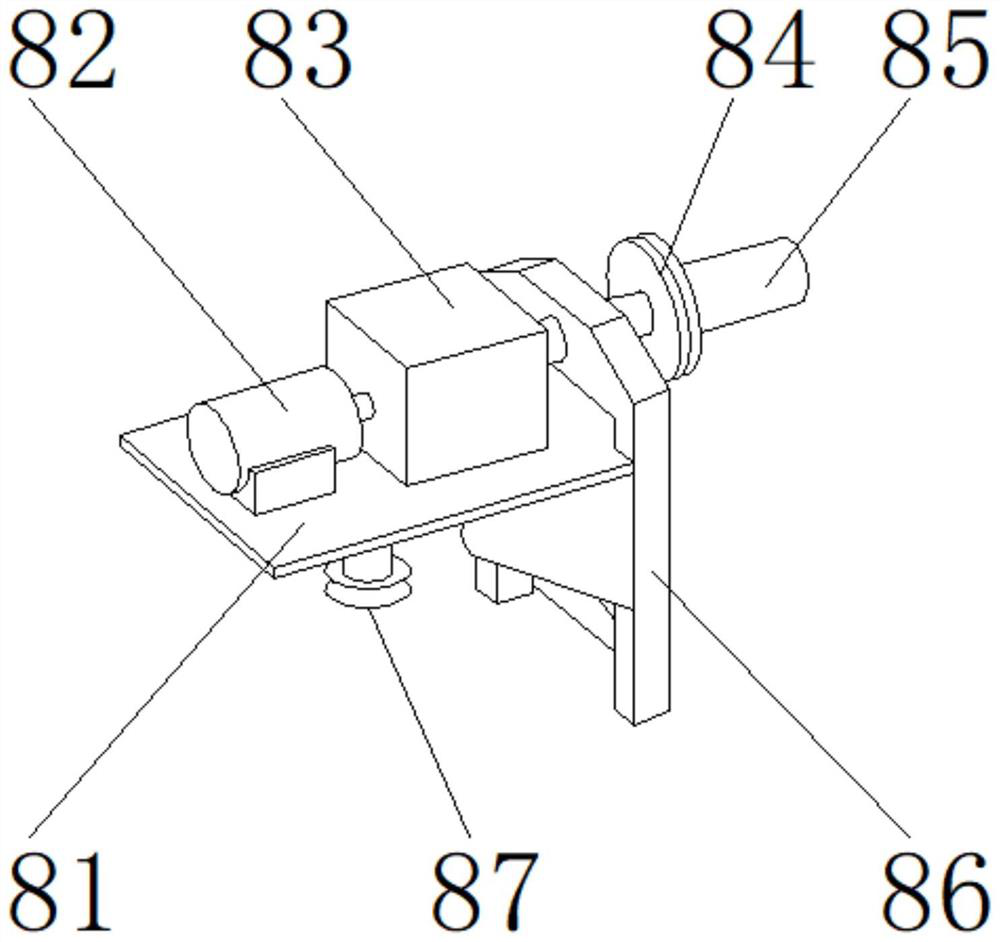

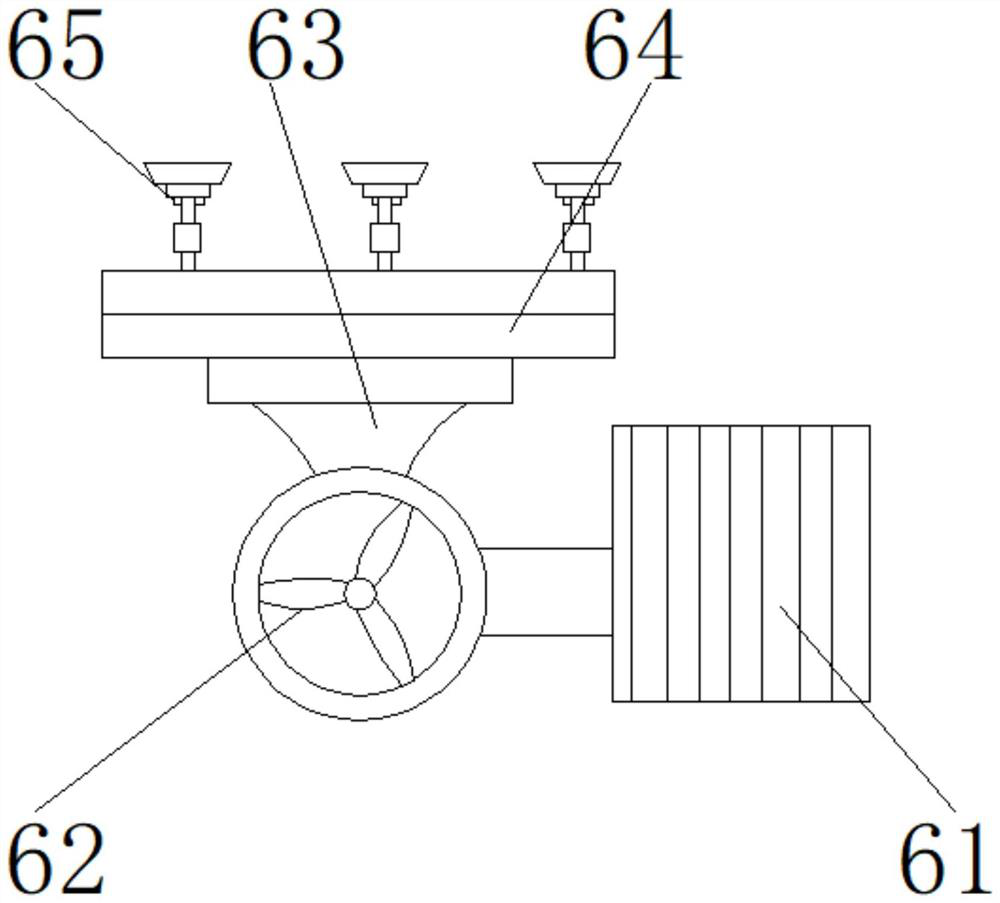

Multi-strand twisting machine

ActiveCN111945264AEvenly arrangedAvoid substandard qualityTextiles and paperEngineeringStructural engineering

The invention relates to the technical field of spinning, in particular to a multi-strand twisting machine which can evenly arrange multiple strands of fine threads for twisting operation. The multi-strand twisting machine comprises a hanging automatic telescopic mechanism, a twisting follow-up tensioning mechanism, a tensioning driving mechanism, a limiting wetting mechanism, a guiding immersionmechanism and a wire coil placing follow-up mechanism. A moving air cylinder drives a moving shaft sleeve to slide on a horizontal rotating rod, so that the moving shaft sleeve drives a plurality of arc-shaped telescopic hooks to extend out of the positions between a plurality of auxiliary limiting rollers so as to be used for hanging the multiple strands of fine threads; and meanwhile, the fine threads can be hung more uniformly, the situation that the thickness of twisted thick threads is not uniform enough in the thread twisting process is avoided, and the situation that the strength of thetwisted thick threads is not uniform is avoided.

Owner:TAIZHOU LAI & KE INTELLIGENT TECH CO LTD

Thermoplastic polyurethane masterbatch granulating device

The invention discloses a thermoplastic polyurethane masterbatch granulating device. The thermoplastic polyurethane masterbatch granulating device comprises an extrusion container and a helical blade,wherein the helical blade is transversely rotationally installed in the extrusion container, the helical blade is in transmission connection with a second driving motor fixed to the right side of theextrusion container, a cooling room is arranged on the left side of the extrusion container, three filter nets are obliquely fixedly welded to the bottom of the cooling room, copper pipes are fixed to the bottoms of the filter nets, and the copper pipes on the bottoms of the three filter nets are communicated with one another. A plurality of extrusion holes are formed in the left surface of the extrusion container. By arranging the three filter net on the bottom of the cooling room and fixing the copper pipes to the bottoms of the filter nets, circulating cooling water can be introduced intothe copper pipes during granulating work, after being well manufactured, granulates enter the cooling room and then can be quickly cooled by the filter nets with the cooperation of the cooling water in the copper pipes, and the off-specification quality caused when the granulates are stuck together is prevented.

Owner:科及士(浙江)新材料科技有限公司

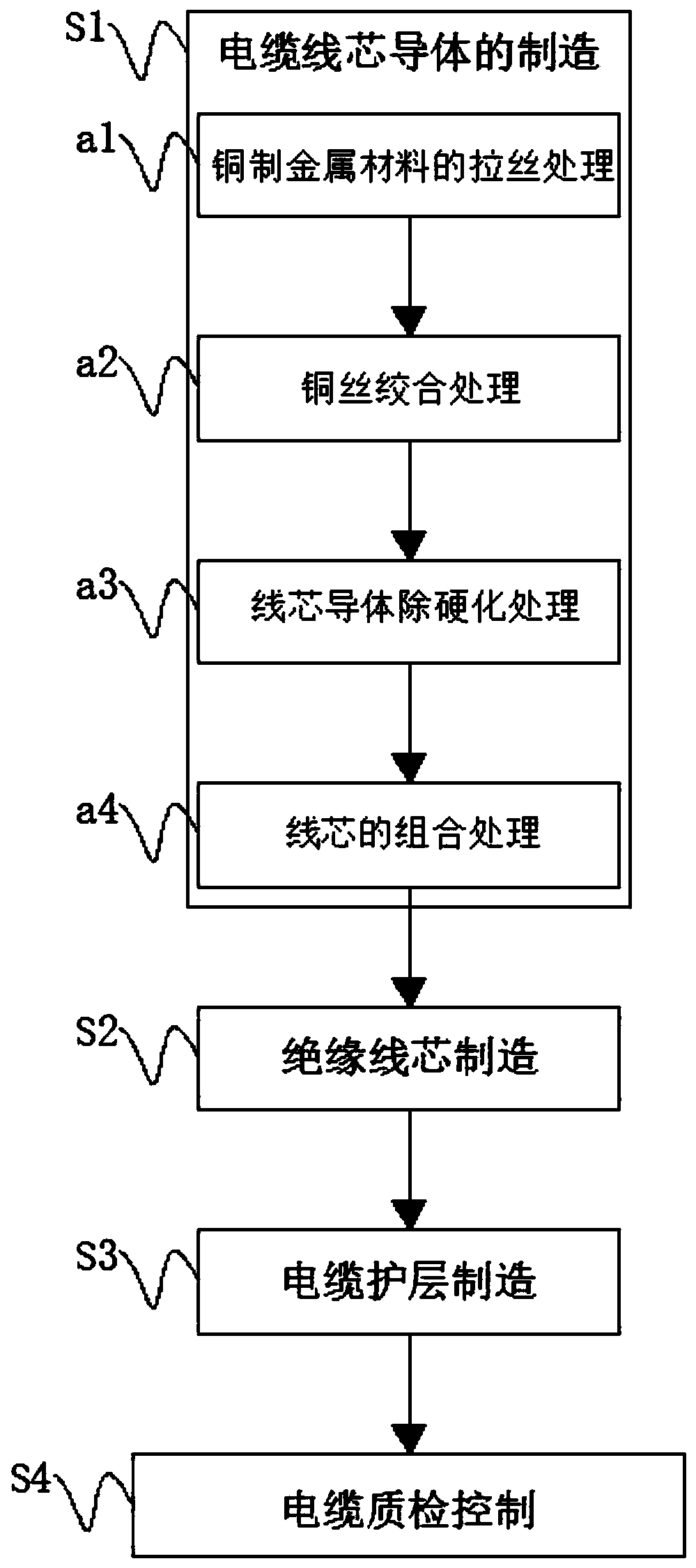

Processing method of power cable

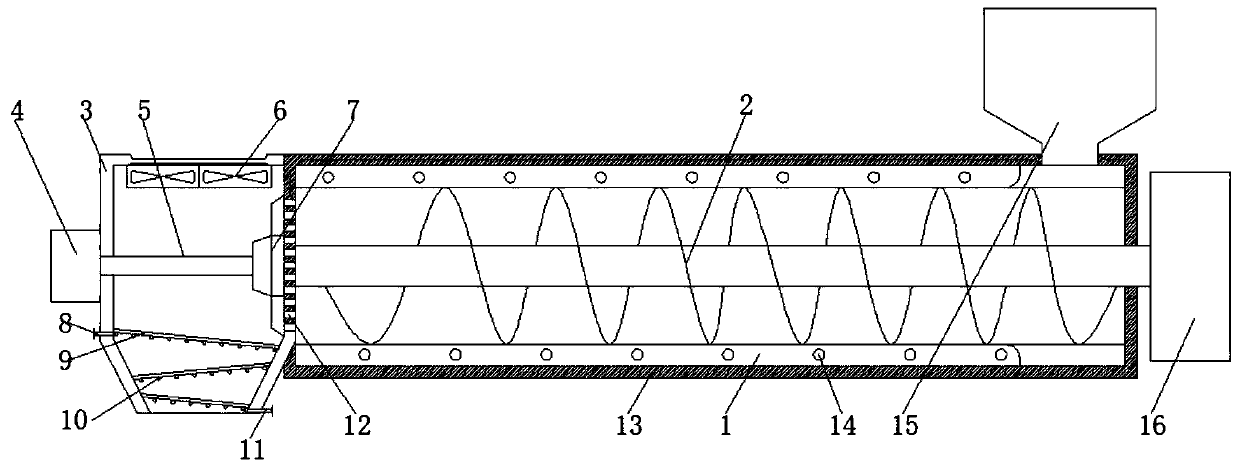

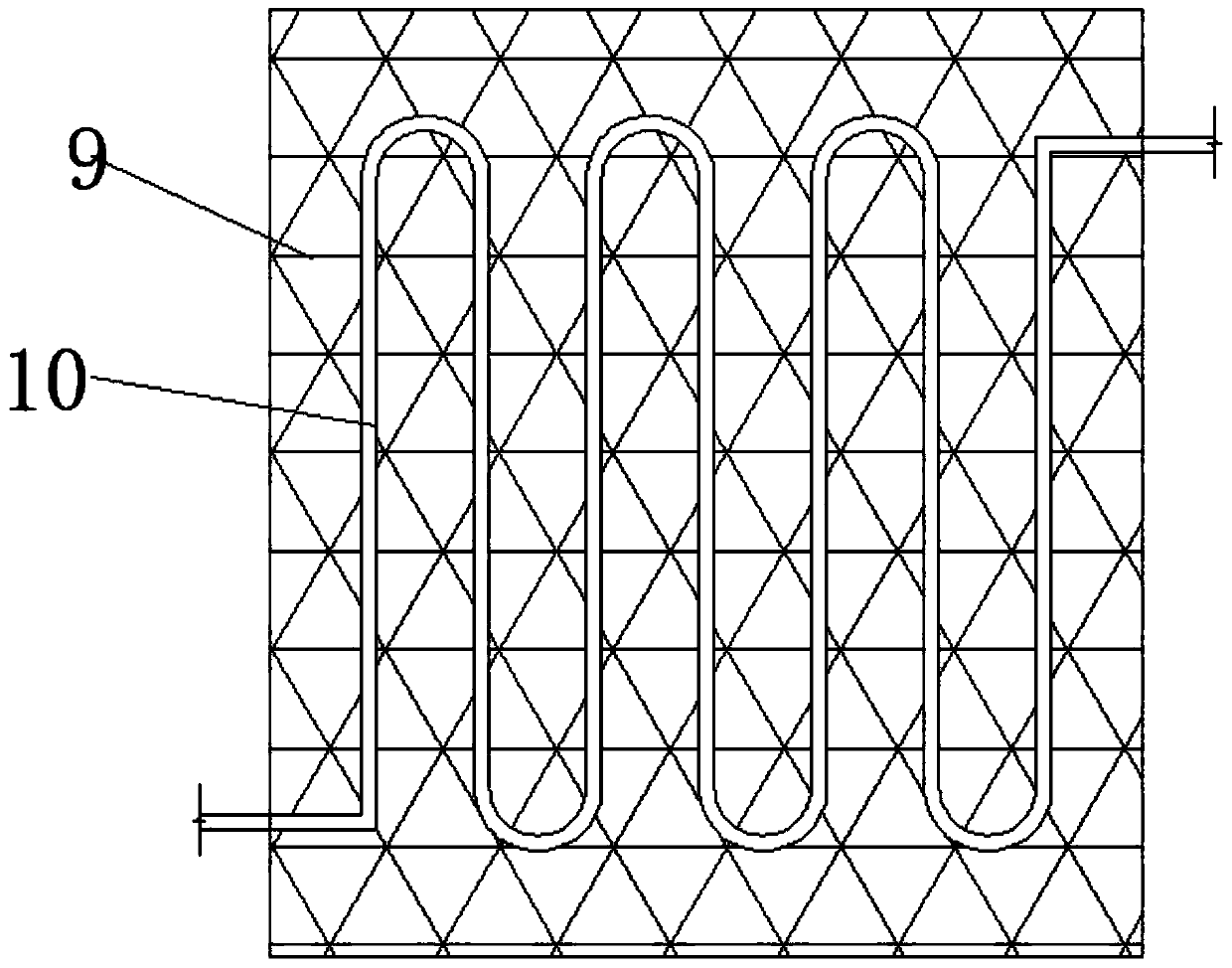

InactiveCN110233002AEasy to useAvoid damageApparatus for heat treatmentReduction of cables/conductors sizeElectrical conductorPower cable

The invention discloses a processing method of a power cable. The processing method specifically comprises the following steps of (S1) manufacturing of a wire core conductor of a cable, namely (a1) wire drawing treatment of a copper metal material, (a2) twisting treatment of copper wires, (a3) hardening removal treatment of the wire core conductor and (a4) combination treatment of a wire core; (S2) manufacturing of an insulated wire core; (S3) manufacturing of a cable sheath; and (S4) quality control of the cable. The invention relates to the technical field of power cable processing. According to the processing method of the power cable, oven heating can be replaced through induction heating on the wire core conductor, the production staff do not need to spend a lot of time to operate andmonitor, the workload of the production staff is reduced, the production efficiency of the cable is greatly improved, the target of quickly and conveniently carrying out good hardening removal treatment on the wire core conductor of the cable is well achieved, and the targets of simplifying the production procedure of the cable and reducing the production cost are achieved, thereby greatly facilitating cable production work of the production staff.

Owner:江苏双花电线电缆有限公司

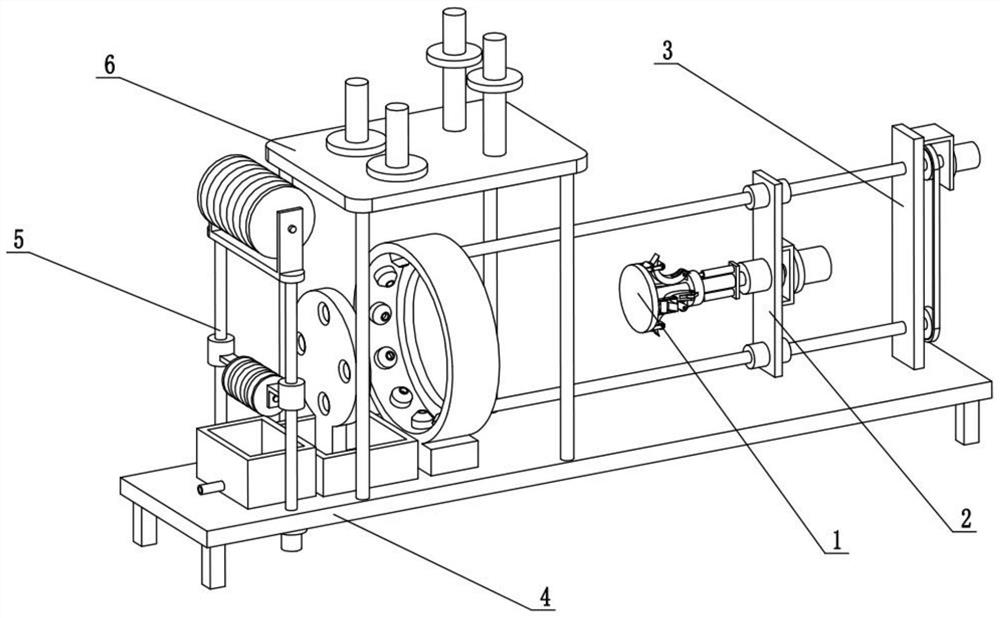

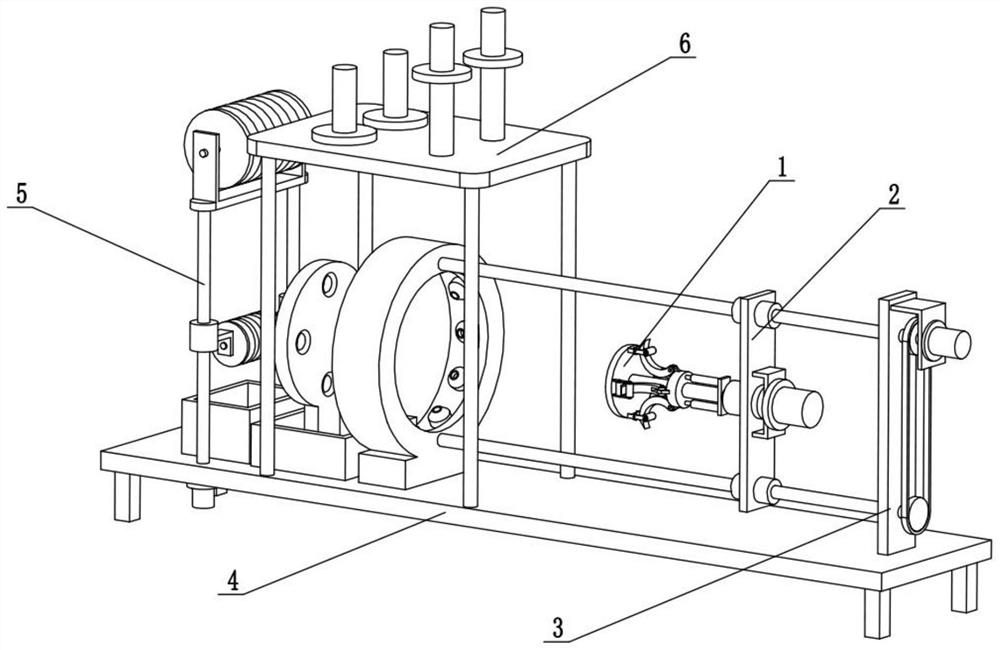

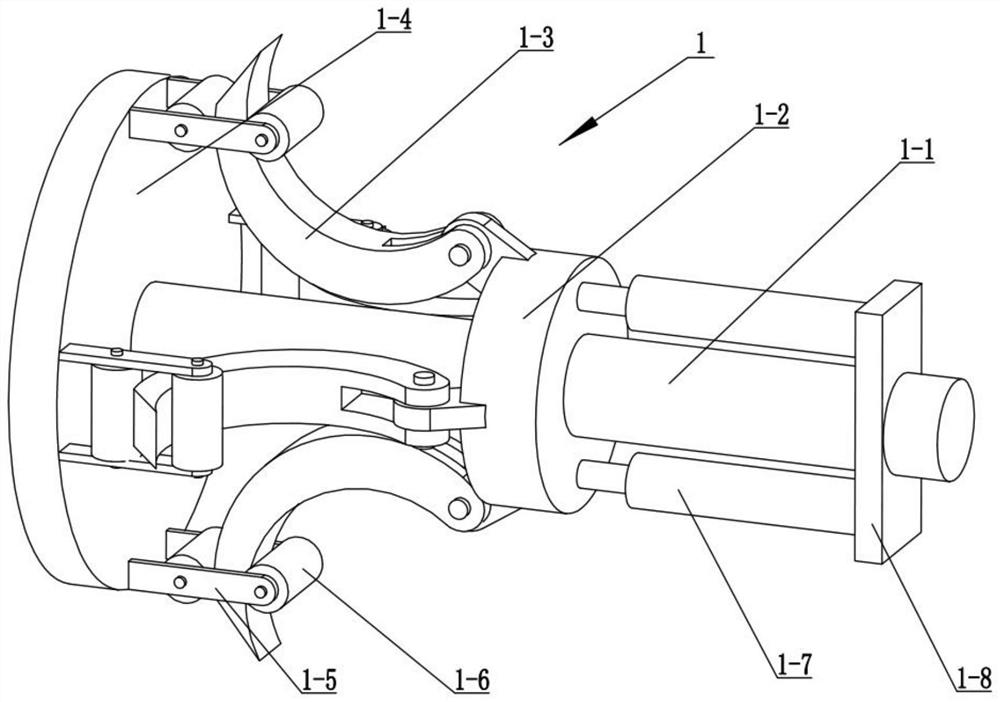

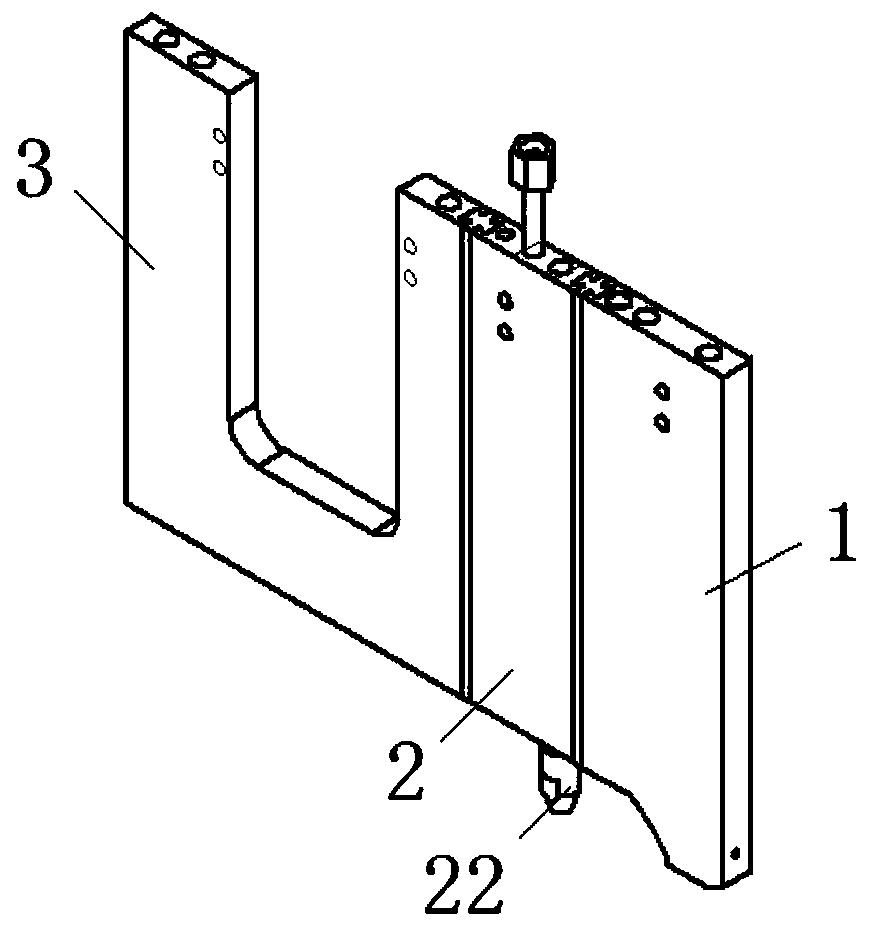

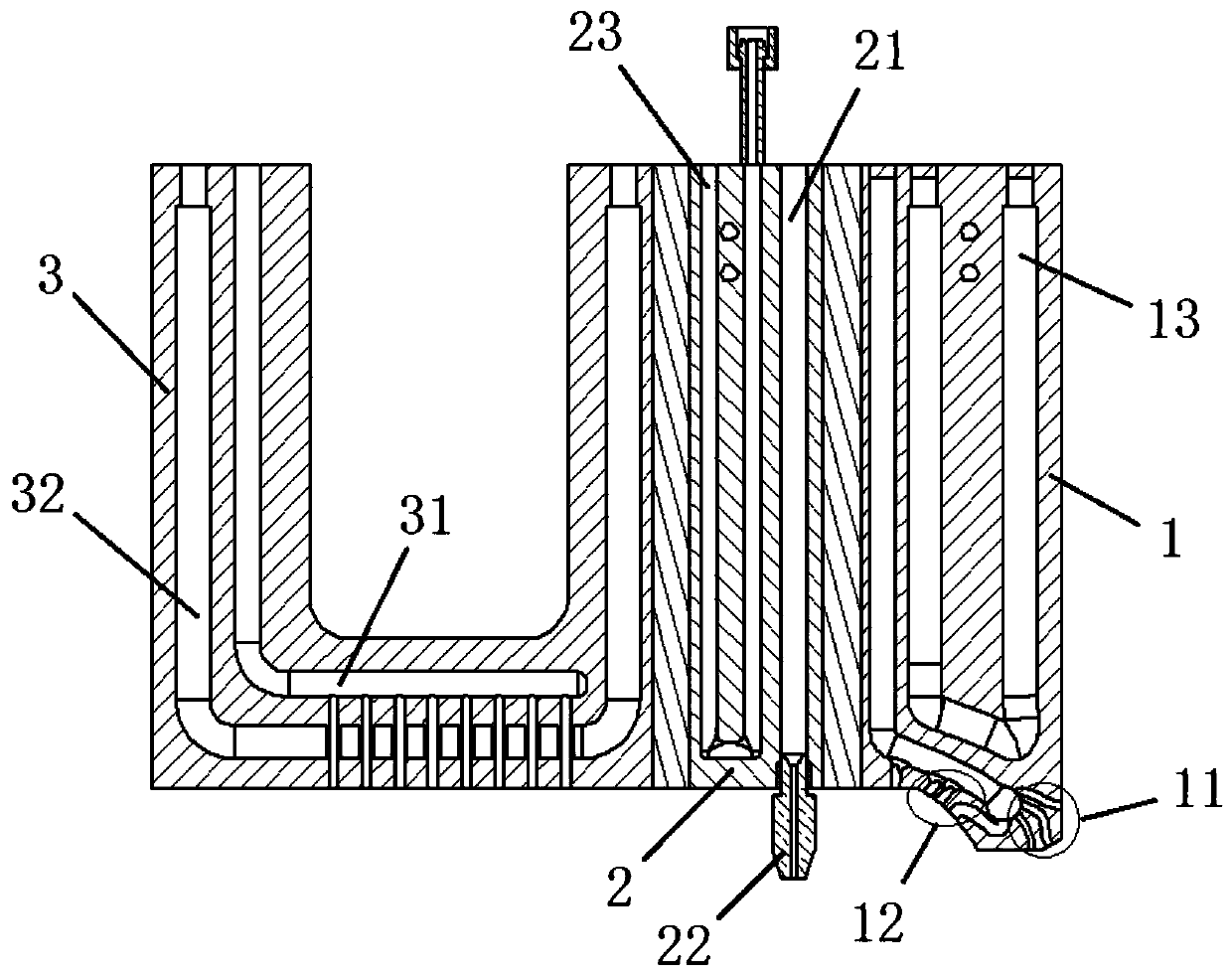

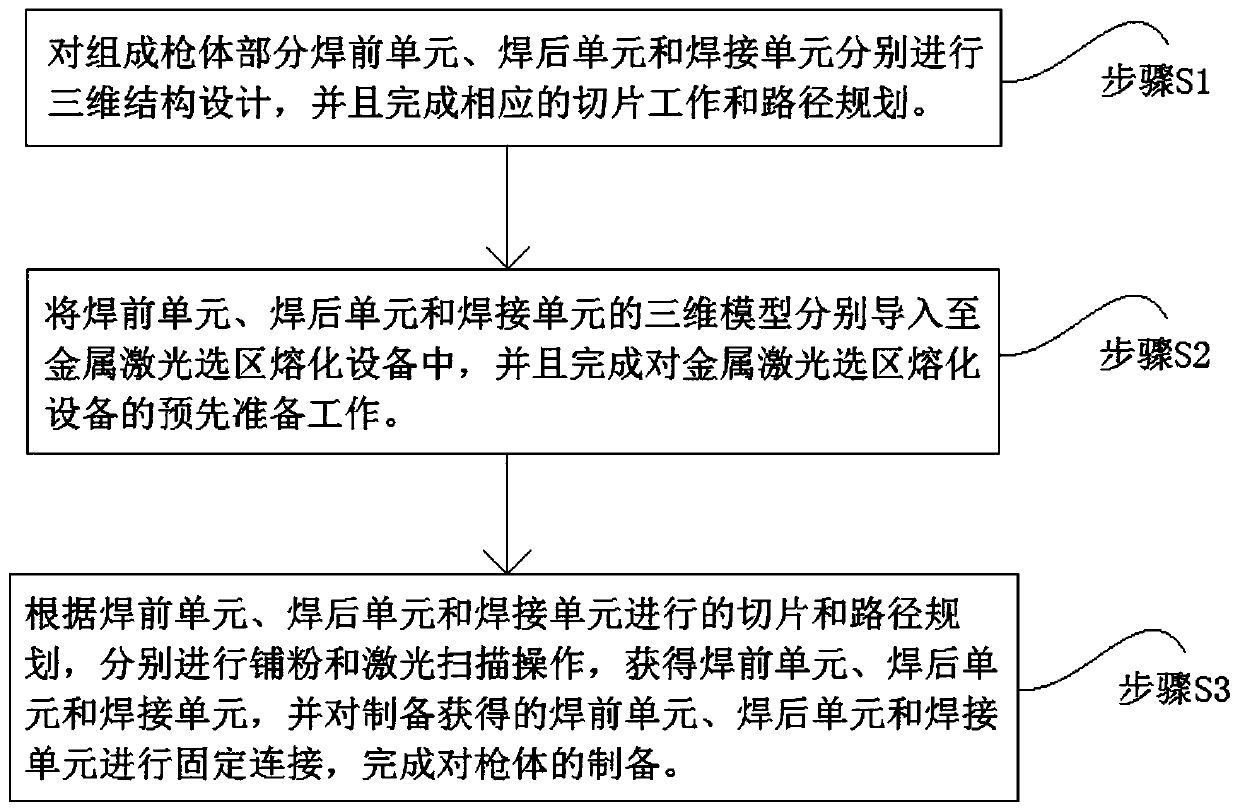

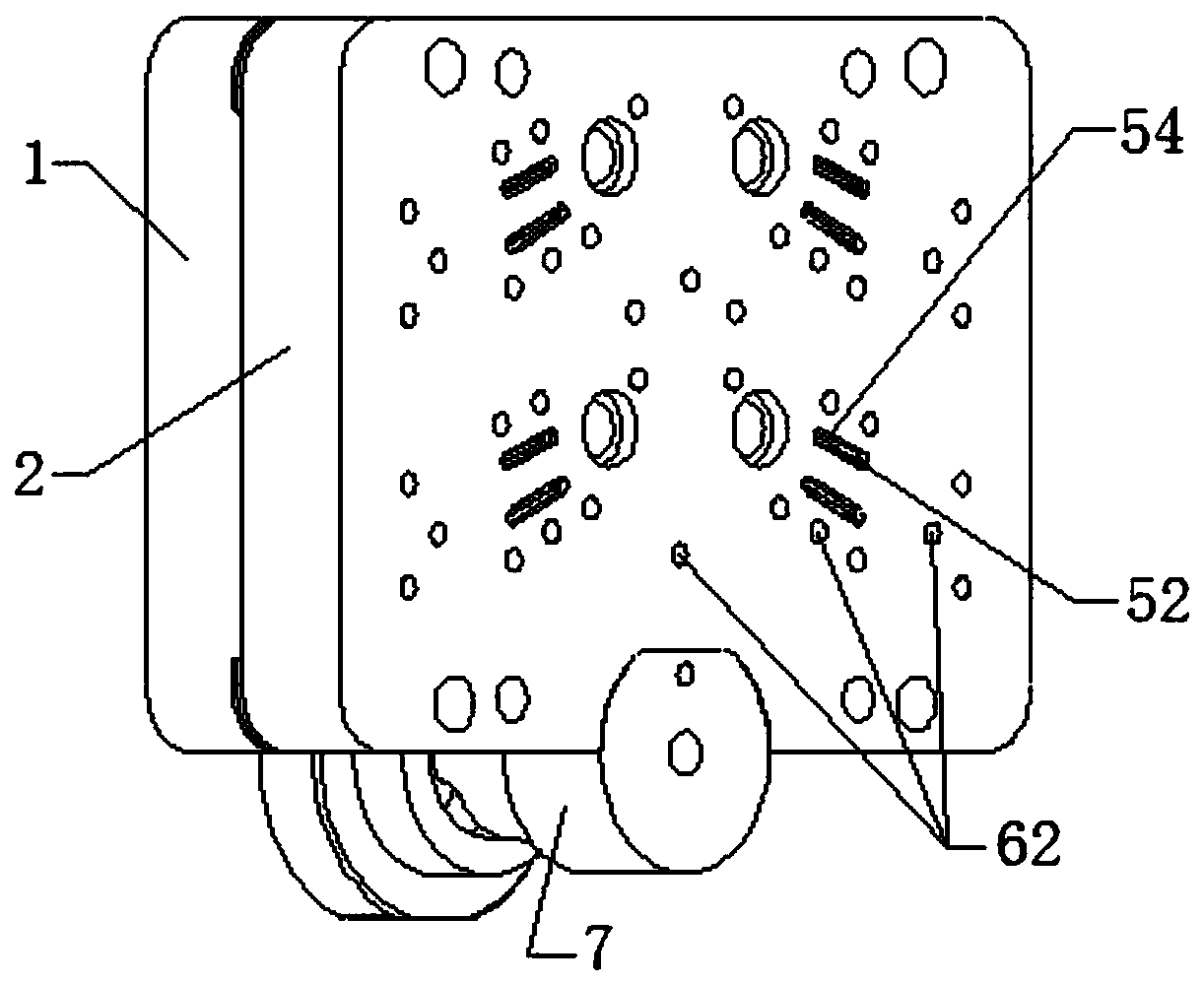

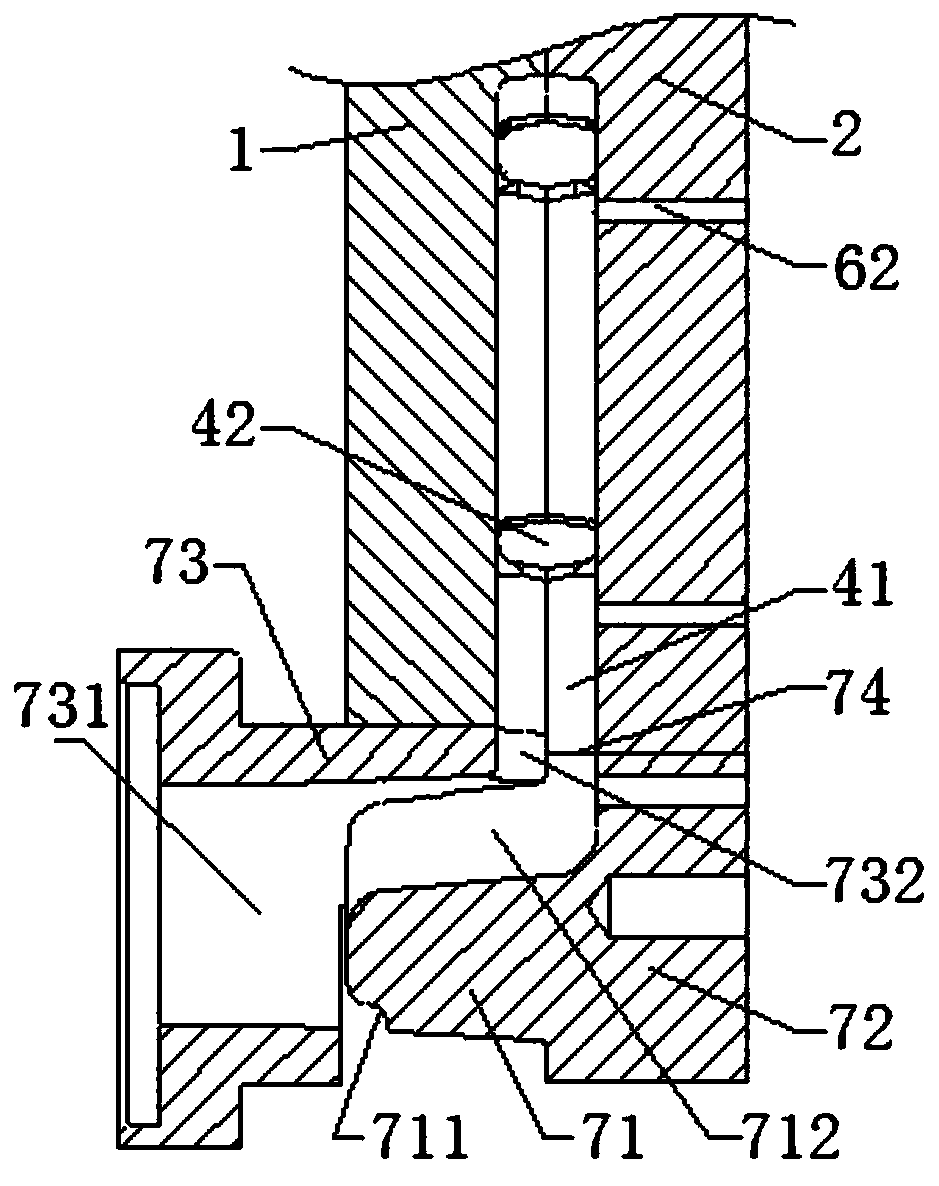

Narrow-gap welding gun and preparation method thereof

ActiveCN110328439APrevent getting involvedSolve the problem of getting caught in the welding areaElectrode supporting devicesIncreasing energy efficiencyAcute angleShielding gas

The invention belongs to the technical field of narrow gap welding. In order to solve the problem that when a conventional narrow-gap welding gun is adopted for narrow gap welding operation, the quality of a welded joint is low due to the fact that the protective gas is prone to generating eddy currents, and air is involved, a narrow-gap welding gun is provided. The narrow-gap welding gun comprises a gun body of a flat plate structure, and the gun body comprises a pre-welding unit, a welding unit and a post-welding unit, wherein the pre-welding unit is provided with a first protective gas channel and a second protective gas channel; the welding channel is provided with a wire feeding channel and a nozzle; the post-welding unit is provided with a third protective gas channel; an outlet of the first protective gas channel is arranged in the pre-welding direction, and an acute angle is formed between the outlet and the vertical direction; an outlet of the second protective gas channel isarranged in the post-welding direction, and an acute angle is formed between the outlet and the vertical direction; and an outlet of the third protective gas channel is arranged in the welded seam direction. Through the narrow-gap welding gun, the situation that the air is involved in a welding area by the protective gas can be effectively avoided, and the quality of a welded joint is ensured.

Owner:YANGJIANG PURUIDE ADDITIVE MFG RES INST CO LTD +2

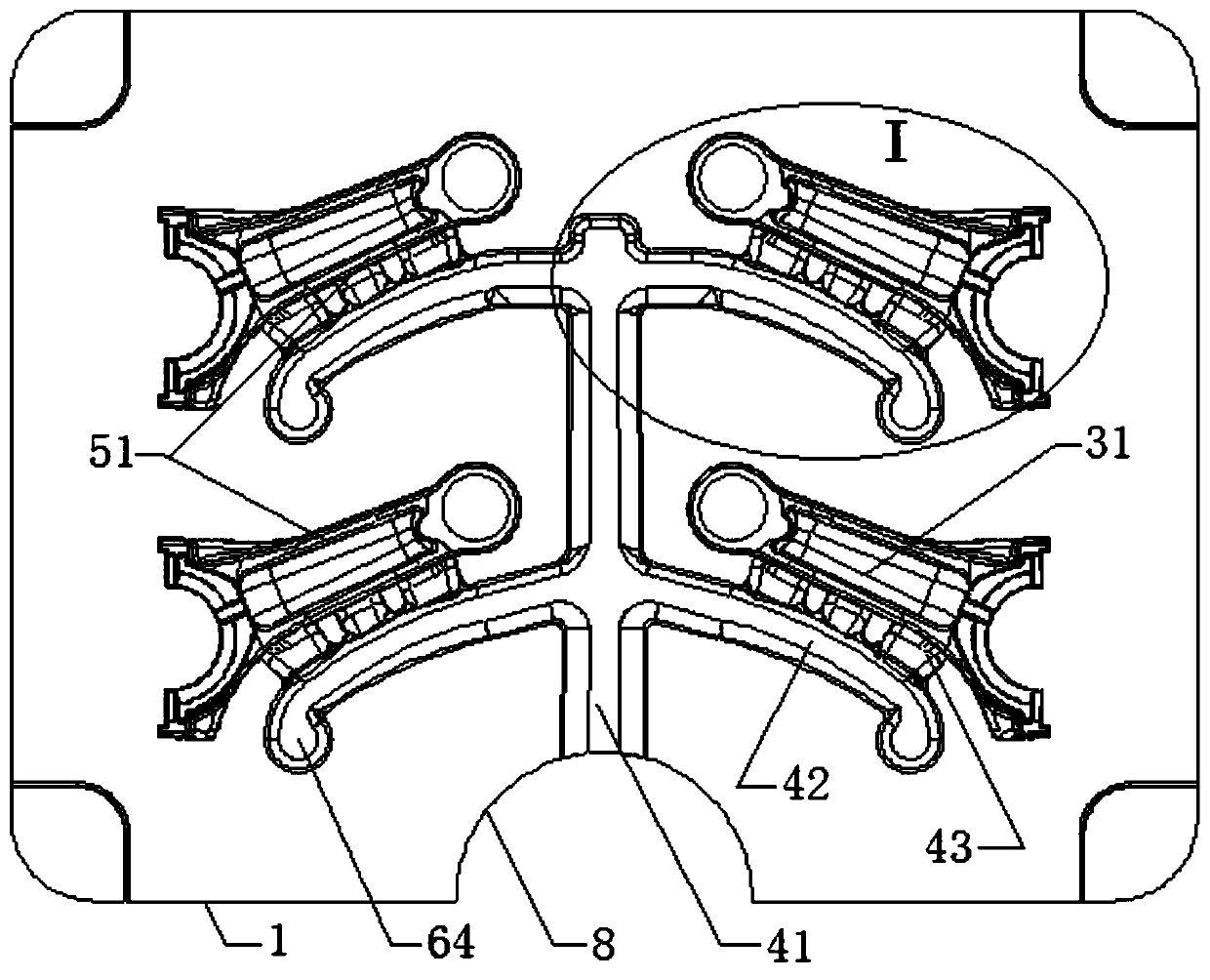

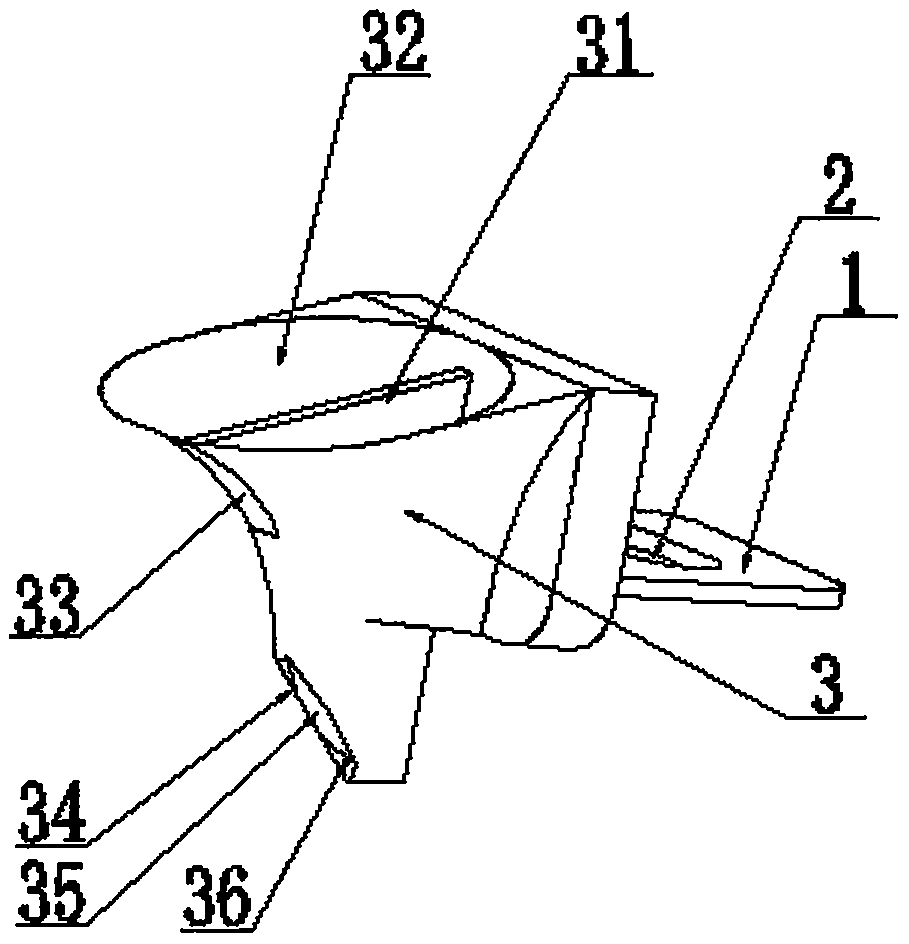

Die casting mold with connecting rod body cavity liquid inlet multi-flow channel structure

The invention provides a die casting mold with a connecting rod body cavity liquid inlet multi-flow channel structure. The die casting mold with the connecting rod body cavity liquid inlet multi-flowchannel structure comprises a fixed mold core and a movable mold core; the fixed mold core and the movable mold core surround to form a melt flow channel and multiple connecting rod body cavities inside; the melt flow channel comprises a primary main flow channel and multiple secondary main flow channels; each two of the multiple secondary main flow channels are symmetrically arranged on the two sides of the primary main flow channel; the primary main flow channel and the multiple secondary main flow channels are correspondingly distributed in the vertical direction and the transverse direction; the multiple connecting rod body cavities are correspondingly arranged on one sides of the multiple secondary main flow channels in a one-to-one corresponding manner; the extending directions of the connecting rod body cavities and the secondary main flow channels are as same as each other; multiple sub pouring flow channels are arranged between a rod body molding cavity of each connecting rodbody cavity and the secondary main flow channels; during die casting of the connecting rods, an aluminium alloy melt enters the connecting rod body cavities via multiple sub pouring flow channels; andtherefore, the melt filling speeds of the connecting rod body cavities are effectively increased. According to the die casting mold with the connecting rod body cavity liquid inlet multi-flow channelstructure, multiple aluminium alloy connecting rods can be simultaneously produced through die casting, it can be guaranteed that the melt is full of the connecting rod body cavities, and the qualification rate of connecting rod finished products can be increased.

Owner:重庆环鹰机械有限公司

Weaving and yarn selection method for woven fabrics, and woven fabric knitting method

ActiveCN108977991AAffect qualityAvoid substandard qualityWoven fabricsPulp and paper industryYarn strength

The invention relates to a weaving and yarn selection method for woven fabrics, and the method comprises the steps: classifying the warp yarns and / weft yarns required by the weaving of the woven fabric according to the colors, and obtaining the consumption ratio of the yarns of all colors in the warp yarns and / weft yarns; obtaining the yarn strength adjustment coefficient of the yarns of the corresponding color in the corresponding yarns according to the consumption ratio of the yarns of the color in the warp yarns and / weft yarns when the consumption ratio of the yarns of each color in the warp yarns and / weft yarns is not greater than 50%; adjusting the yarns of one color or multiple colors in the corresponding yarns at the same time, and controlling the total consumption ratio of the yarns to be adjusted in the corresponding yarns not to be greater than 50% during the adjustment of the yarn strength of the yarns of various colors; and selecting the yarns of each color in the warp yarns and / weft yarns according to the determined yarn strength. The woven fabric prepared through the yarns selected via the method can meet the general strength standard of the woven fabrics, and the yarn cost can be properly reduced.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Anti-yarn-winding device

ActiveCN106567167AAvoid substandard qualityReduce manufacturing costDrafting machinesYarnEngineering

The invention discloses an anti-yarn-winding device comprising a main horn-shaped horn mouth body; a separation board arranged inside the main horn-shaped horn mouth body divides the main horn-shaped horn mouth body into two parts; and a leading-in end is arranged above the main horn-shaped horn mouth body and a leading-out end is arranged below the main horn-shaped horn mouth body. A vertical yarn slot is formed in the top front end of the front side of the main horn-shaped horn mouth body, wherein the length of the yarn slot is the half of the overall length of the main horn-shaped horn mouth body. An inclined cutting surface is processed at the leading-out end; the separation board extends to the three-quarter part from the middle of the inside of the main horn-shaped horn mouth body from top to bottom and forms, together with the inclined cutting surface, an observation port. Using the anti-yarn-winding device, a phenomenon that a rough yarn is broken in a yarn slot because of twisting spinning due to winding of the rough yarn at the leading-out end can be avoided. With the reserved observation port, the feed-in situation of the yarn at the observation port can be observed through the observation port and thus the quality situation of the yarn can be determined preliminarily in advance according to the yarn parallel situation based on observation, so that the production cost can be reduced.

Owner:PINGYUAN HENGFENG TEXTILE TECH CO LTD

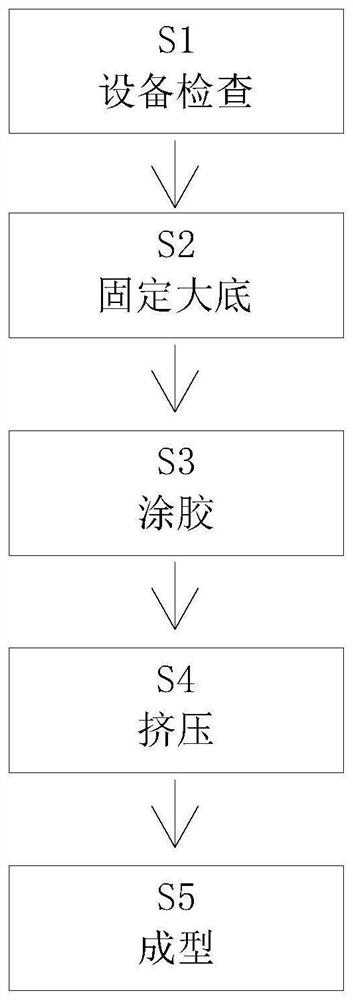

Sneaker producing and manufacturing process

InactiveCN112773054AImprove manufacturing efficiencyQuality is not affectedSolesHeelsGear driveGear wheel

The invention provides a sneaker producing and manufacturing process, the sneaker producing and manufacturing process adopts the following equipment for production, the equipment comprises I-shaped frames, conveying devices and an assembling device, the lower ends of the I-shaped frames are connected with the existing ground, the I-shaped frames are arranged in a bilateral symmetry mode, the conveying devices are arranged between the I-shaped frames which are right opposite in the left-right direction, and the assembling device is arranged above the conveying devices. According to the invention, through mutual cooperation of a first motor, a rotating shaft, a fixed shaft and an incomplete gear, a first gear drives a conveyor belt to do intermittent circulating motion, so that the function of intermittent assembly line operation can be realized; therefore, the production and manufacturing efficiency of sneakers is improved, and the quality of the sneakers is not affected.

Owner:文成

Waste recovery device for stainless steel shot production

ActiveCN114178537ARealize the effect of centralized recyclingAvoid substandard qualityPipeWaste material

The invention belongs to the technical field of stainless steel shot production equipment, and particularly relates to a waste recovery device for stainless steel shot production, which comprises a protective shell, a bearing plate is fixed in the protective shell, a guide plate is fixed in the bearing plate, and a blanking pipe is fixed in the guide plate. A recycling pipe is fixed between the guide plate and the bearing plate, a mounting frame is fixed to the bottom end of the protective shell, a recycling hole connected with the recycling pipe is formed in the mounting frame, and a back suction shell is fixed to the top of the protective shell. Equipment is installed between atomization equipment and cooling equipment, so that molten metal cannot be splashed when atomized and exploded into powder, the scattered powder is pulled through negative pressure, the effect of centralized recovery of waste is achieved, meanwhile, rising airflow is discharged in a discharging pipe, the powder cannot fall off from the discharging pipe, and the powder is prevented from falling off from the discharging pipe. Therefore, unqualified quality caused by the fact that the surfaces of the finished steel shots are contaminated with powder is effectively prevented.

Owner:无锡锋速钢丸有限公司

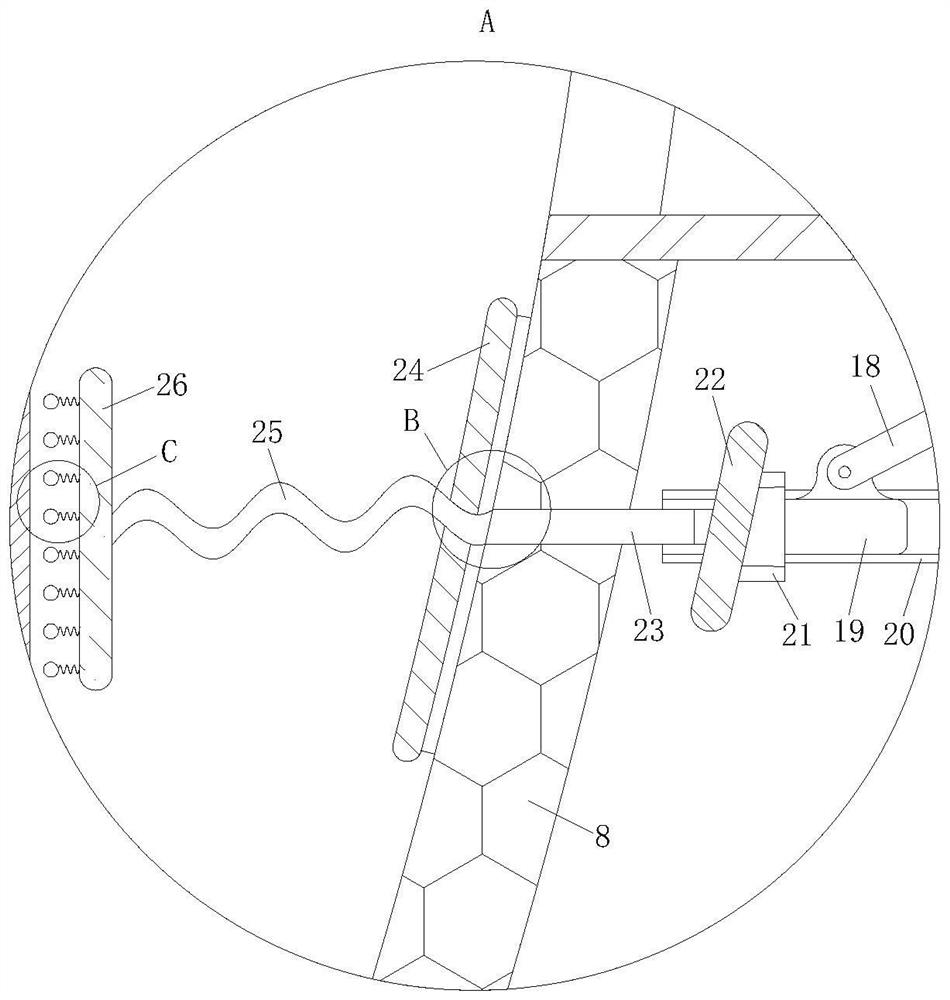

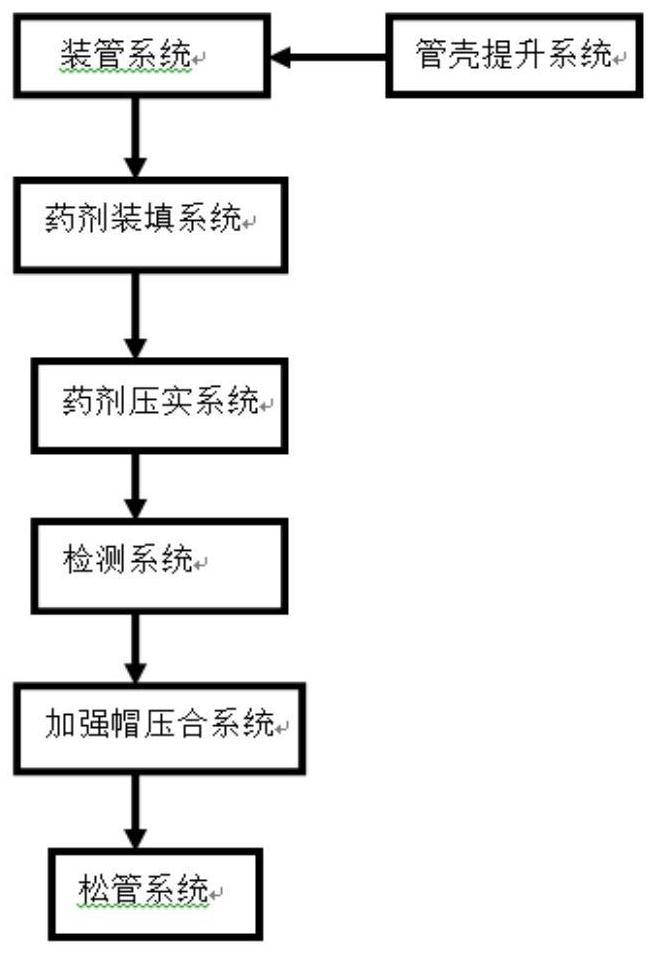

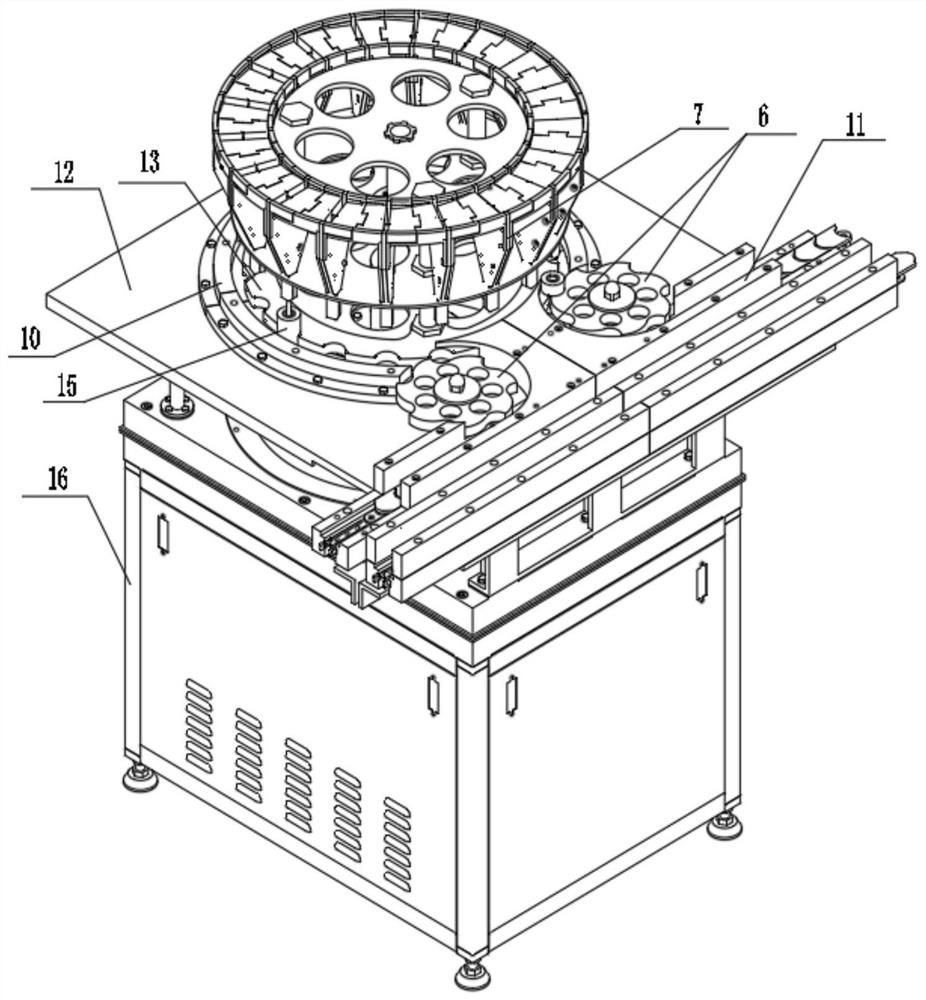

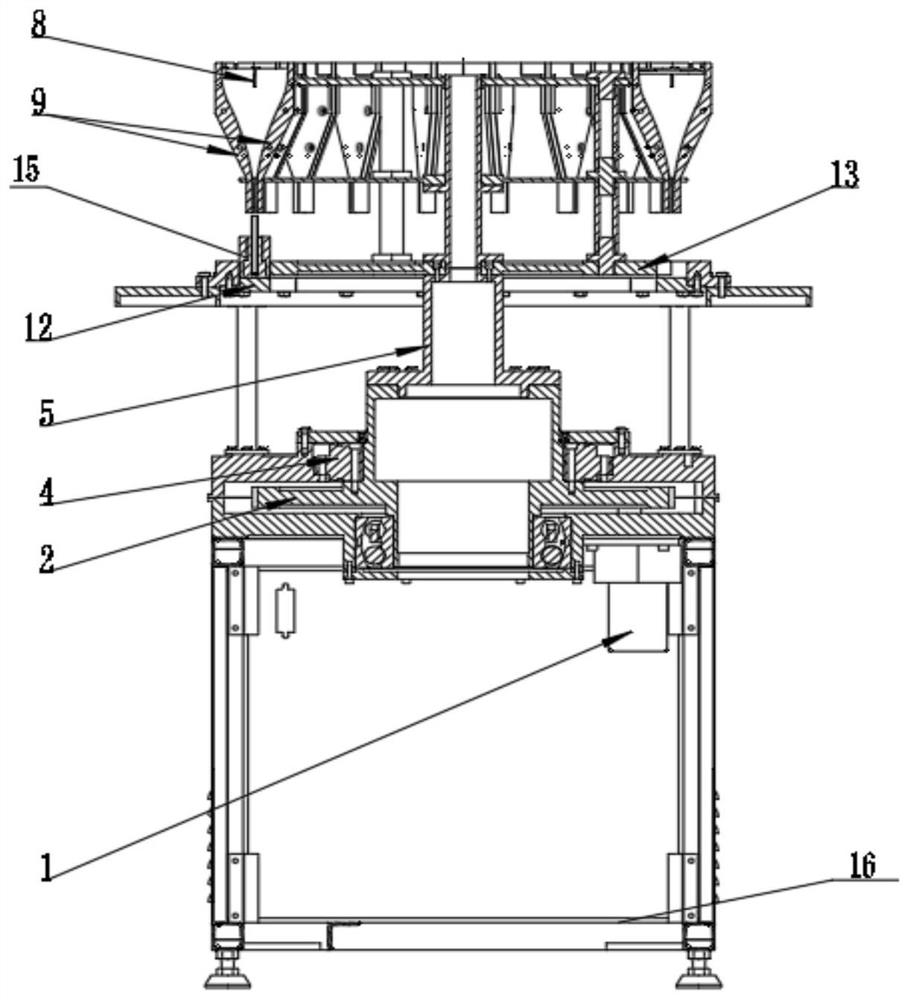

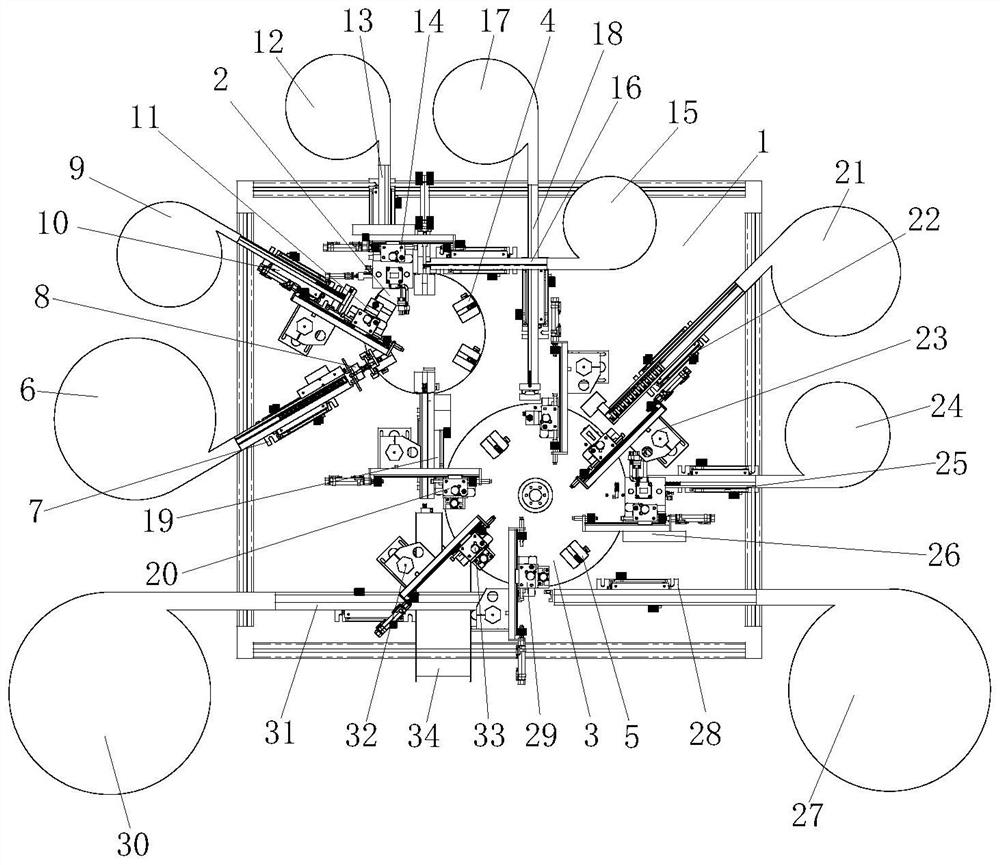

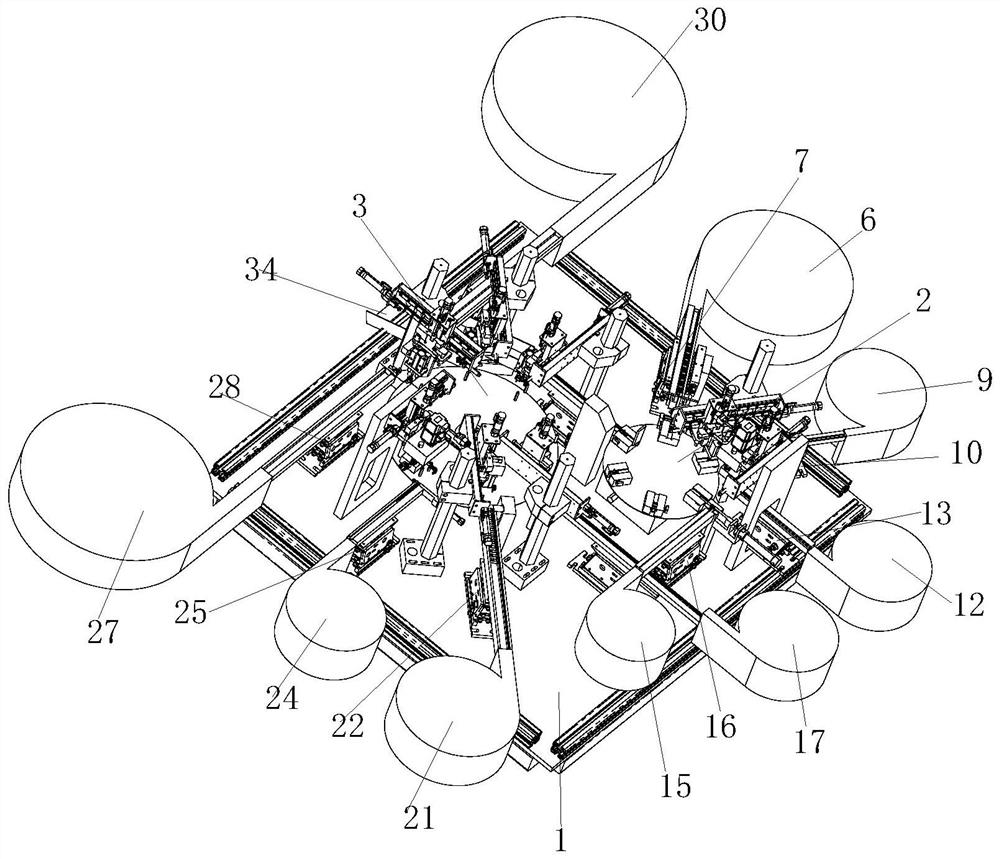

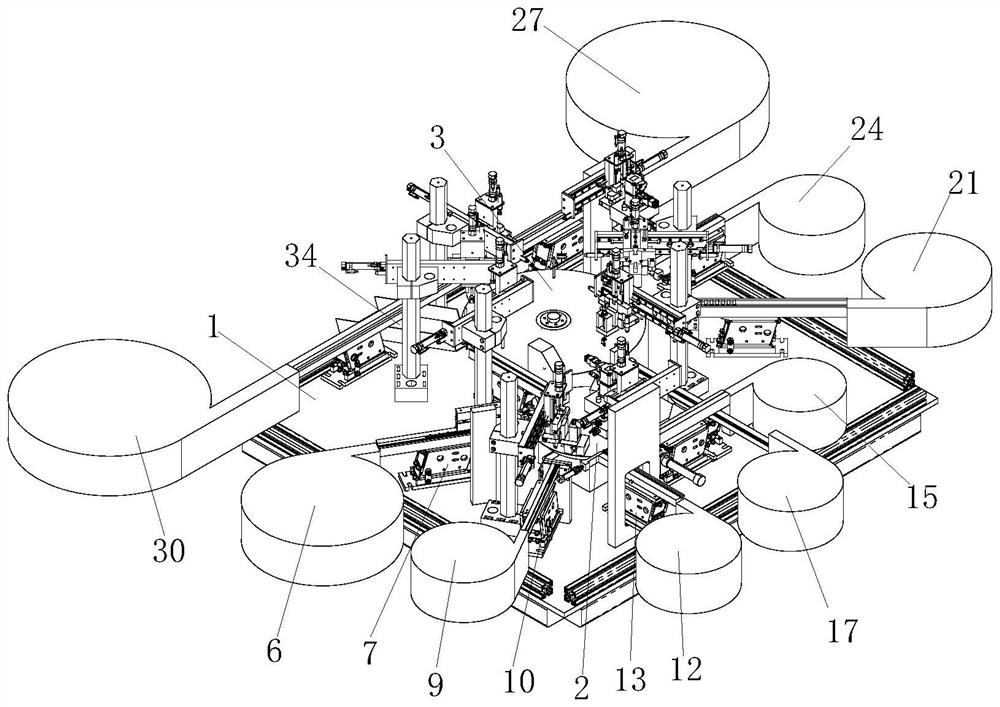

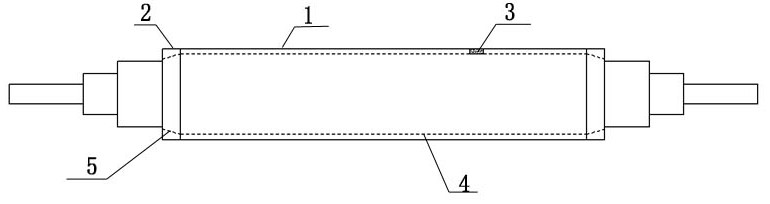

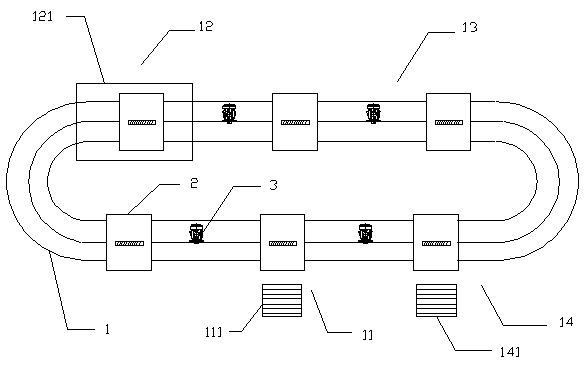

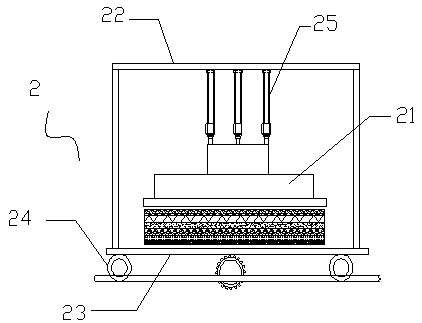

Full-automatic production line for disc single detonators

The invention discloses a full-automatic production line for disc single detonators. The production line sequentially comprises a detonator shell lifting system, a detonator loading system, an agent loading system, a detection system, an agent compaction system, a reinforcing cap pressing system and a detonator loosening system. The detonator shell lifting system is a calandria lifting machine; the detonator discharging end of the calandria lifting machine corresponds to the detonator feeding end of the detonator loading system; the detonator loading system, the agent loading system, the detection system, the agent compaction system, the reinforcing cap pressing system and the detonator loosening system realize transportation of the single detonators among all procedures through chain plate transmission equipment, and guide blocks are arranged on the two sides of the chain plate transmission equipment; the detonator loading system, the agent loading system, the detection system, the agent compacting system, the reinforcing cap pressing system and the detonator loosening system are all arranged above a mold operation platform; the mold operation platform is fixed on a rack; and a transmission system used for driving all the systems to operate is arranged in the rack. In the whole production process of the detonators, the number of manual contact procedures is small, safety is high, and production efficiency is high.

Owner:YAHUA GROUP MIANYANG INDAL

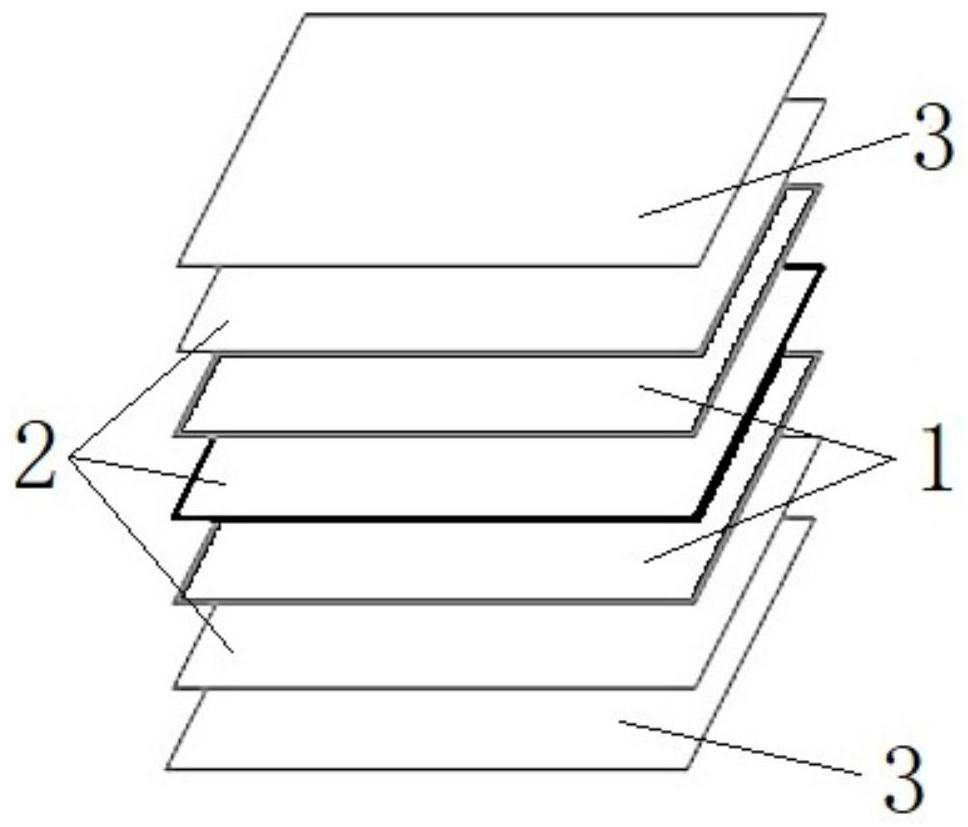

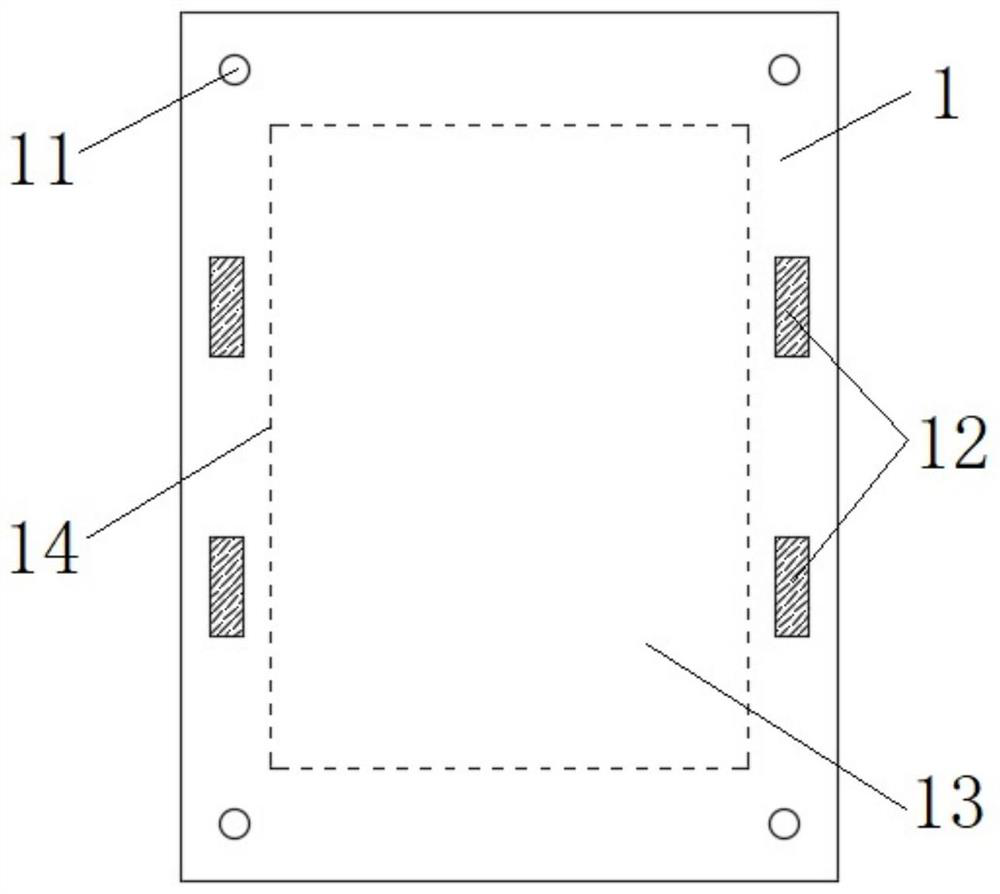

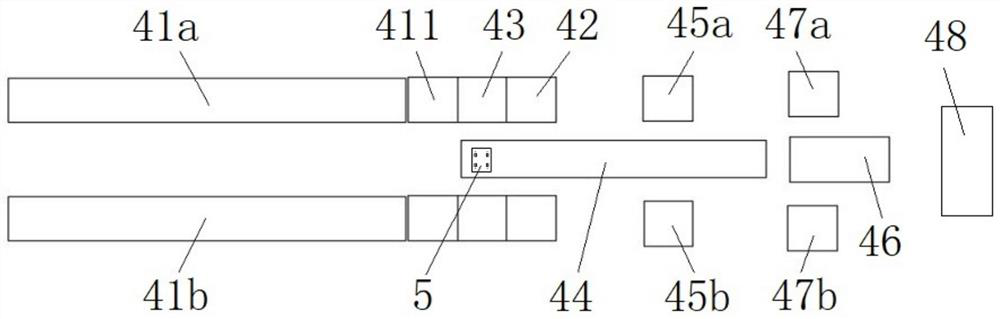

Novel PCB base material structure and PCB lamination manufacturing method using same

PendingCN112040638AAvoid substandard qualityImprove automationPrinted circuit detailsMultilayer circuit manufactureMechanical engineeringPrinted circuit board

The invention belongs to the technical field of printed circuit board manufacturing, and relates to a novel PCB base material structure and a PCB lamination manufacturing method using the same. The novel PCB base material structure comprises a rectangular base material, the base material is provided with a circuit part located in the middle and a plurality of alignment holes located outside the circuit part and arranged in a penetrating mode, and a fusion block is further arranged on the edge, located outside the circuit part, of the base material. The method comprises the steps of (1) preprocessing, (2) browning, (3) pre-stacking, (4) fusing, (5) stacking and (6) hot pressing. The fusion block is additionally arranged on the base material, so that the dielectric layer is combined with theedge of the base material during fusion positioning, the problem of unqualified quality caused by internal deformation is avoided, automatic operation is better facilitated, and the labor cost is greatly saved.

Owner:PLOTECH TECH KUNSHAN CO LTD

Thermal-insulation fireproof cement composite board and manufacturing process thereof

PendingCN113650153AWell laidGuaranteed embeddingAuxillary shaping apparatusHeat proofingManufacturing technologyCement composites

The invention discloses a thermal-insulation fireproof cement composite board and a manufacturing process thereof. The manufacturing process comprises the following steps of step A, manufacturing a mold; B, placing the mold; C, using manufacturing equipment for manufacturing a lower fabric layer with a lower mesh layer; D, placing a core material; E, manufacturing an upper fabric layer with an upper surface layer by using manufacturing equipment; F, stacking and standing; and G, demolding a finished product. Through the arrangement of the manufacturing equipment, gridding cloth can be conveniently laid, clamping connection between the gridding cloth and a laying roller is prevented, meanwhile, the gridding cloth can be conveniently embedded into cement mortar, the uneven wrinkle phenomenon of the laid gridding cloth is prevented, the heat preservation effect of the gridding cloth is guaranteed, meanwhile, the gridding cloth is conveniently cut, the cut gridding cloth is fixed, the phenomena of shaking and displacement of the laid gridding cloth during cutting are prevented, and then the laying effect of the gridding cloth is guaranteed.

Owner:BEIJING ZHONGXING NINGHAO NEW BUILDING MATERIALS CO LTD

Method for improving evaporation efficiency in production process of tomato sauce

InactiveCN107890080AAvoid substandard qualityFast concentrationFood thermal treatmentSprayerEvaporation

The invention discloses a method for improving evaporation efficiency in the production process of tomato sauce. The method comprises storage, cleaning, selection, crushing, preheating, refining, concentration, sterilizing and cooling, aseptic bag packaging, steel barrel inspection and loading. In the concentration process, a vacuum continuous three-effect four-stage evaporator composed of a heating system, a vacuum system and a condensate suction system is used and 360-degree cold water sprayers are arranged in juice and steam outlets at the top of the three-effect evaporator. Through a steaming method of the vacuum continuous three-effect four-stage evaporator, the vacuum degree of the three-effect evaporator is improved and juice and steam flowing rates are improved. Through use of a salt-sugar mixture, the concentration of the external solution of the tomato cells is higher than that of the internal solution so that the precipitation of water in the tomato cells is accelerated, theevaporation efficiency is improved, a tomato juice concentration rate is accelerated and the processing efficiency of tomato sauce is improved.

Owner:GANSU WESTSUN FOOD

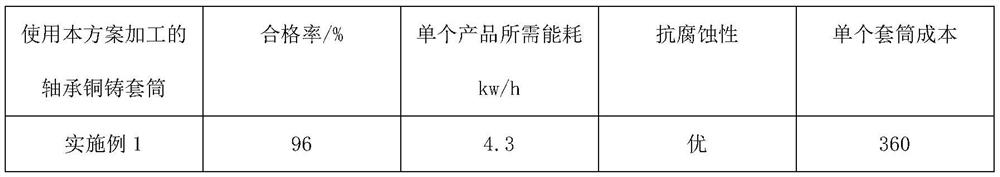

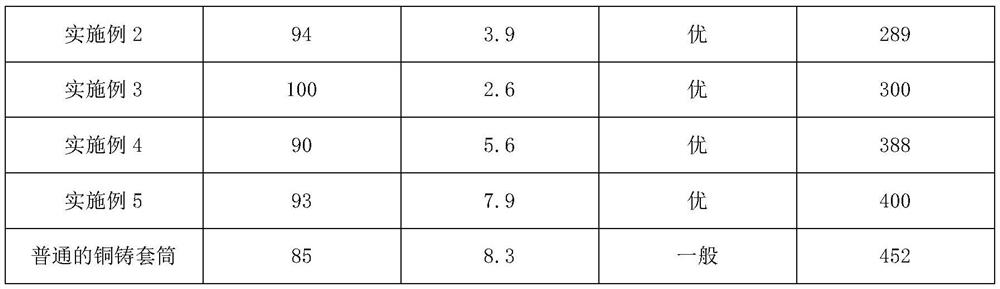

Production process for copper casting sleeve of bearing

The invention discloses a production process for a copper casting sleeve of a bearing. The production process comprises the following steps: S1, blank detection: carrying out sorting, surface crack eddy current flaw detection and ultrasonic internal defect detection on a copper material by steel bar nondestructive detection equipment, automatically spraying paint and marking on a steel bar part which does not meet detection requirements, and carrying out scrap treatment on a defect part; and S2, roughly boring an inner hole, namely fixing the qualified copper material on a lathe, and forming ahole in the qualified copper material by using a special inner hole boring cutter. According to the method, the blank is detected, so that the disqualification of the quality of the produced copper casting sleeve caused by the defects of the blank is avoided; and the strength of the copper cast sleeve is further improved by carrying out heat treatment on the processed semi-finished coarse material. According to the production process for the copper casting sleeve of the bearing, the copper cast sleeve is easier to process, and a processing procedure of the copper cast sleeve is simplified.

Owner:嘉善县联诚机械有限公司

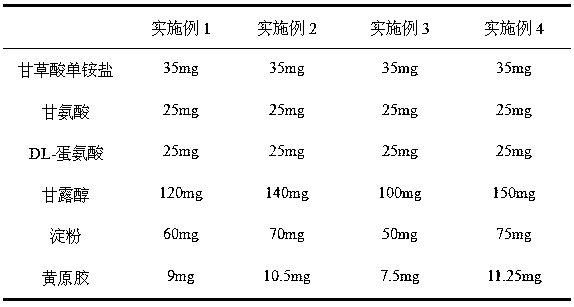

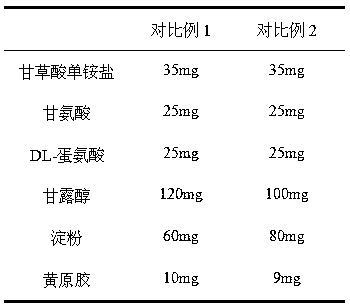

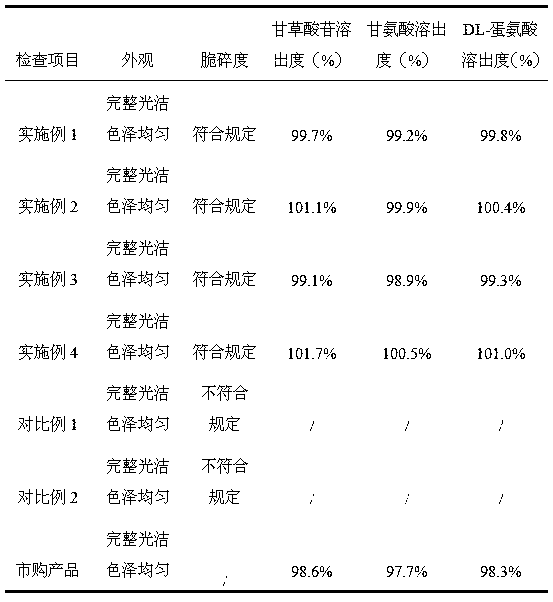

A kind of compound glycyrrhizin tablet and preparation method thereof

ActiveCN106692086BAvoid substandard qualityMask bitternessOrganic active ingredientsDispersion deliveryFiller ExcipientDL-methionine

The invention discloses compound glycyrrhizin tablets. The compound glycyrrhizin tablets are prepared from a main drug raw material comprising glycyrrhizic acid ammonium salt, glycine and DL-methionine and an auxiliary material comprising a filling agent and a disintegrating agent. The mass ratio of the main drug raw material to the auxiliary material is 1:(1.7-2.8). The filling agent is prepared by evenly mixing mannitol and starch in a mass ratio of 2:1, and the disintegrating agent is xanthan gum. The invention further discloses a preparation method of the compound glycyrrhizin tablets. The method sequentially comprises the steps of grinding, screening, mixing and tabletting, and then the compound glycyrrhizin tablets are prepared. Due to mannitol in the auxiliary material, the situation that the drug quality is unqualified caused by moisture absorption of glycyrrhizic glycoside can be avoided, and the sweetness of mannitol can mask the bitterness of the tablets; by matching with the starch and xanthan gum in a certain ratio, the raw materials of the tablets are good in fluidity and pressing-ability; the technology is simple, energy conservation and environment protection are achieved, and the production cost is low.

Owner:LEPU PHARMACEUTICAL CO LTD

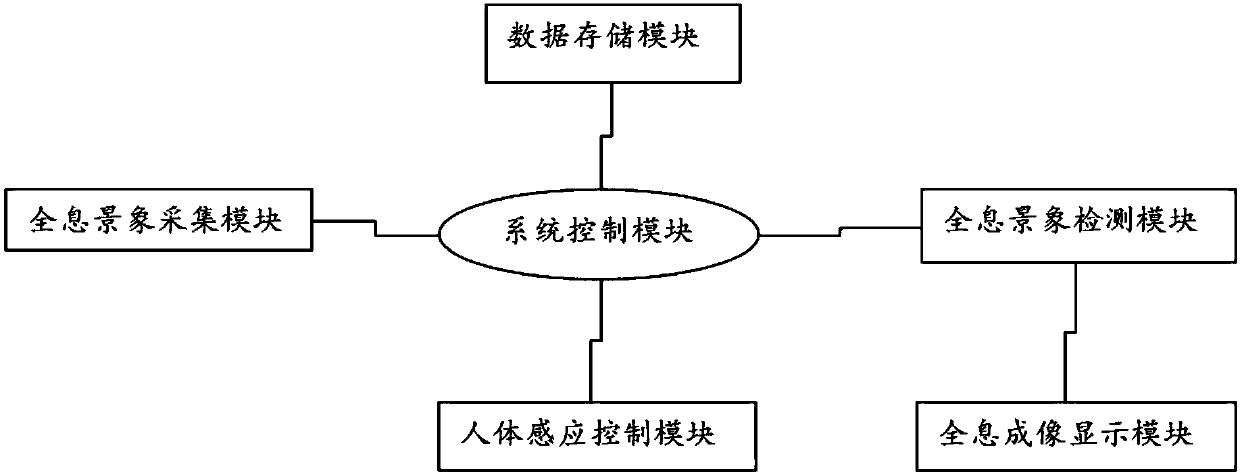

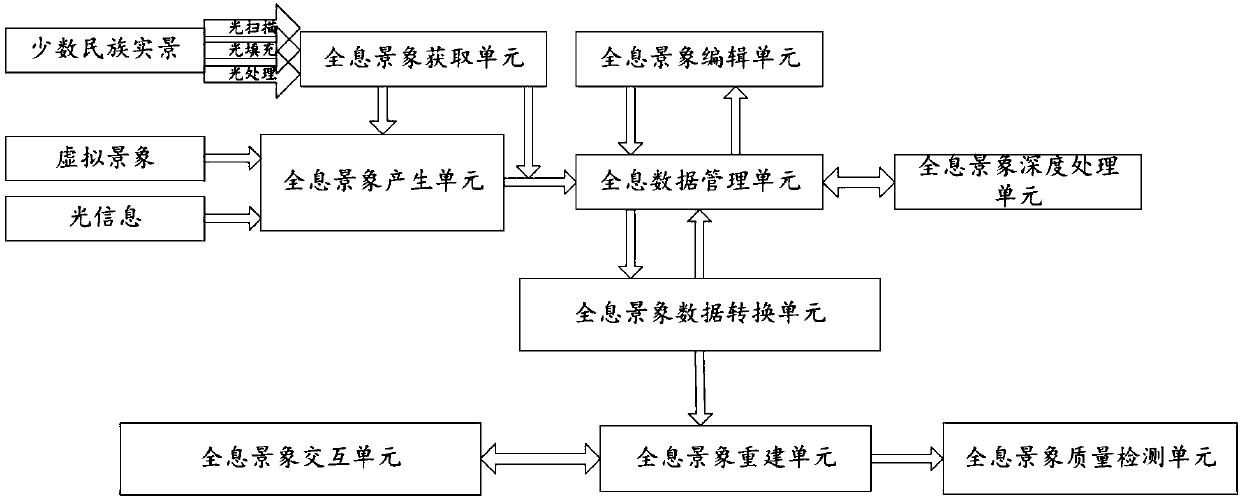

Somatosensory type library resource database system and method

InactiveCN107609100AIncrease diversityComprehensiveImage data processingSpecial data processing applicationsHuman bodyLibrary science

The invention discloses a somatosensory type library resource database system and method, and aims at the problem of an existing library that the three-dimensional storage of rare resources can not bestored so as to lose a great quantity of rare resources along with time. A holographic image is generated, holographic image data is obtained, human body induction control information is obtained bylight and is fused to the holographic image, and the holographic image data is called according to human body induction, and a target holographic image is reconstructed, detected and generated according to the holographic image data. By use of the method, an advanced holographic technology is imported to realize the storage diversification and generalization of library information storage, meanwhile, the brand-new storage way and control way of the library can be realized, the experience of a user is improved, and the problem in the prior art that a great quantity of precious resources are lost along with time since the library can not realize the three-dimensional storage of the precious resources is solved. The method is suitable for the field of intelligent libraries.

Owner:叙永县图书馆

A multi-strand twisting machine

ActiveCN111945264BAvoid substandard qualityHang evenlyTextiles and paperTextile technologyClassical mechanics

The invention relates to the technical field of textiles, and more specifically relates to a multi-strand twisting machine, which can evenly arrange a plurality of thin threads for twisting operations. Including suspension automatic telescopic mechanism, twisting follow-up tensioning mechanism, tensioning drive mechanism, limit wetting mechanism, guiding immersion mechanism and wire reel placement follow-up mechanism, the moving sleeve is driven by the moving cylinder to slide on the horizontal rotating rod, Make the moving bushing drive multiple arc-shaped telescopic hooks to protrude from multiple auxiliary limit rollers to hang multiple strands of thin wire, and at the same time make the suspension of thin wire more uniform and avoid twisting during the twisting process The thickness of the final thick thread is not uniform enough to avoid uneven strength of the twisted thick thread.

Owner:TAIZHOU LAI & KE INTELLIGENT TECH CO LTD

Rewinding device for stripping base cloth

PendingCN114803612APrevent deviationAvoid substandard qualityDrying gas arrangementsArticle deliveryBrakeElectric machinery

The invention discloses a rewinding device for stripping base cloth, and relates to the technical field of rewinding equipment.The rewinding device comprises a main body, an air drying device is arranged at the upper end of the main body, a guide roller is arranged above the air drying device, a winding device is arranged at the front end of the guide roller, and a deviation rectifying device is arranged on one side of the guide roller; a controller is arranged on the other side of the guide roller, and a steel wheel is arranged above the guide roller. Under the combined action of a mounting block, a slot, a vertical comparison plate, a fixed plate, a deviation rectifying module, a lead screw, a polish rod, a power source, a connecting block and a sensor, the deviation rectifying device can prevent the position of base cloth from deviating during stripping, can play a deviation rectifying role on the base cloth, prevents the produced base cloth from being unqualified, and guarantees the quality of the base cloth. The sensor senses and detects whether the base cloth is laterally deviated or not in real time, under the combined action of the bottom plate, the motor, the brake mechanism, the bearing, the winding roller, the supporting frame and the supporting shaft rolling wheel, the base cloth can be rapidly wound, and the phenomenon that the base cloth is wound in the winding process can be prevented.

Owner:FUJIAN HUAXIA SYNTHETIC LEATHER CO LTD

Tooling and method for bogie sub-frame inspection

ActiveCN109060366BAvoid substandard qualitySolve the quality failureVehicle testingBogieIndustrial engineering

The invention, which belongs to the technical field of vehicle quality detecting, provides a bogie sub-frame detecting tool and a method thereof. The detecting tool comprises a supporting bottom plateprovided with two supporting units I and two supporting units II. The detection method includes: four adapters are arranged on four supporting platforms correspondingly in a sub frame; a support unitIII is supported at the middle part for supporting a sub-frame U-shaped end. Whether the four adapters match the four supporting platforms completely is determined to determine whether the sub-frameforming product is qualified. The supporting units I are fixed on the support bottom plate; an adjustment mechanism for adjusting the distance and angles between the two supporting units I and the twosupporting units II is arranged between the two supporting units II and the support bottom plate so as to simulate the actual state of the sub-frame unit during the bogie forming and application processes. The production quality of the sub-frame unit is guaranteed; a problem that the basic measurement method can not measure the related data is solved; a problem that the product is disqualified because of error accumulation of the traditional measurement method is solved; and the work efficiency and economic benefits are improved.

Owner:CRRC SHIJIAZHUANG CO LTD

Constructional engineering concrete conveying device

InactiveCN112211408AReduce viscosityEasy to useAlarmsBuilding material handlingArchitectural engineeringStructural engineering

The invention relates to the technical field of constructional engineering equipment, in particular to a constructional engineering concrete conveying device. The conveying device comprises a shell body, a conveying belt is slidably connected to the interior of the shell body, a bearing table is fixedly connected to the bottom end of the inner surface of the shell body, a fixed plate is fixedly connected to the interior of the shell body and is located below the conveying belt, a guiding ball is fixedly connected to the upper surface of the fixed plate, and fixed frames are fixedly connected to the lower surface of the fixed plate and are located on two sides of the bearing table. Due to the fact that protruding blocks are arranged on the outer surface of a rotating shaft, when a roller rotates on the outer surface of the rotating shaft, intermittent pressure is generated on air bags on a pressing plate, water in the air bags is discharged due to the fact that the air bags bear pressure, the water is sprayed to caked concrete through a water pipe, the viscosity of the caked concrete is reduced, normal use of the concrete is guaranteed, and the situation that the caked concrete andnormal concrete are mixed together to be poured so the quality of poured concrete blanks is unqualified is avoided.

Owner:何的花

Threaded obliquely-arranged ribbed steel tube concrete column and design method thereof

PendingCN112376800ADoes not affect the pouring processAvoid substandard qualityStrutsBridge structural detailsArchitectural engineeringUltimate tensile strength

The invention relates to a threaded obliquely-arranged ribbed steel tube concrete column and a design method thereof. The threaded obliquely-arranged ribbed steel tube concrete column comprises a ribbed steel tube and concrete, the ribbed steel tube comprises a steel tube and a plurality of ribs fixed on the steel tube, the multiple ribs are fixed on the steel tube in a spiral ascending mode, andthe vertical distance between the adjacent ribs is 0.15-0.3 m. The design method comprises the following steps that the size and shape of the steel tube for engineering are determined, and the steel tube is manufactured; the ribs are produced according to the shape and the size of the steel tube, as for the circular steel tube, the length of the ribs is 20% of the diameter of the circular steel tube, and as for the rectangular steel tube, the length of the ribs is 20% of length of the rectangular short edges, and the width of the ribs is 50% of the length of the ribs; and the produced ribs arewelded to the inner wall of the steel tube in a spiral ascending mode. The problems that coarse aggregate is accumulated at the lower part due to too fast sinking of the coarse aggregate at the maintenance stage after concrete pouring is completed, the concrete segregation phenomenon is caused, consequently, the compactness of the concrete is affected, the strength of the concrete is reduced andthe steel tube concrete column cannot exert excellent performance are solved.

Owner:HEBEI UNIV OF TECH

Automatic assembly equipment for plastic parts

PendingCN113977263AAvoid substandard qualityLow costAssembly machinesMetal working apparatusEngineeringAutonomation

The invention belongs to the technical field of plastic part assembling equipment, and particularly relates to automatic assembly equipment for plastic parts, which comprises a base, a first divider, a second divider, a first assembling assembly and a second assembling assembly. The first divider is fixedly connected to the top of the base; the second divider is fixedly connected to the top of the base; the first assembling assembly comprises a first vibration disc, a first straight vibration feeder, a first air cylinder, a second assembling mechanism, a third assembling mechanism and a fourth assembling mechanism; the first vibration disc is arranged at the top of the base; the first straight vibration feeder is fixedly connected to the top of the base; the first air cylinder is fixedly connected to the top of the base; the second assembling mechanism is arranged at the top of the base; the third assembling mechanism is arranged at the top of the base; and all assembling work of the plastic part is completed through cooperative work of the first assembling assembly and the second assembling assembly, manual intervention in the working procedures is avoided, automation of the assembling process is achieved, and the assembling efficiency is improved.

Owner:TAIZHOU UNIV

Surface crack repairing and nondestructive detection method for levelling roller

InactiveCN113547281AReduce waiting rollAvoid substandard qualityOptically investigating flaws/contaminationMaterial magnetic variablesStructural engineeringMechanical engineering

The invention relates to the field of levelling roller detection and repairing, and discloses a surface crack repairing and nondestructive detection method for a levelling roller. The method comprises the following steps of: detecting whether cracks exist in the middle of the surface of the levelling roller or not through eddy current flaw detection, and if so, repairing the cracks in the middle of the surface of the levelling roller through a slotting method; and detecting whether cracks exist on the two sides of the surface of the levelling roller or not through dye penetrant inspection, and if so, repairing the cracks on the two sides of the surface of the levelling roller through a large chamfering method. The method disclosed by the invention can effectively detect and identify defects such as roller surface microcracks for modification, avoids quality inconsistency caused by machine feeding, efficiently and completely realizes levelling roller repairing and detection control, and reduces roller waiting of levelling rollers.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

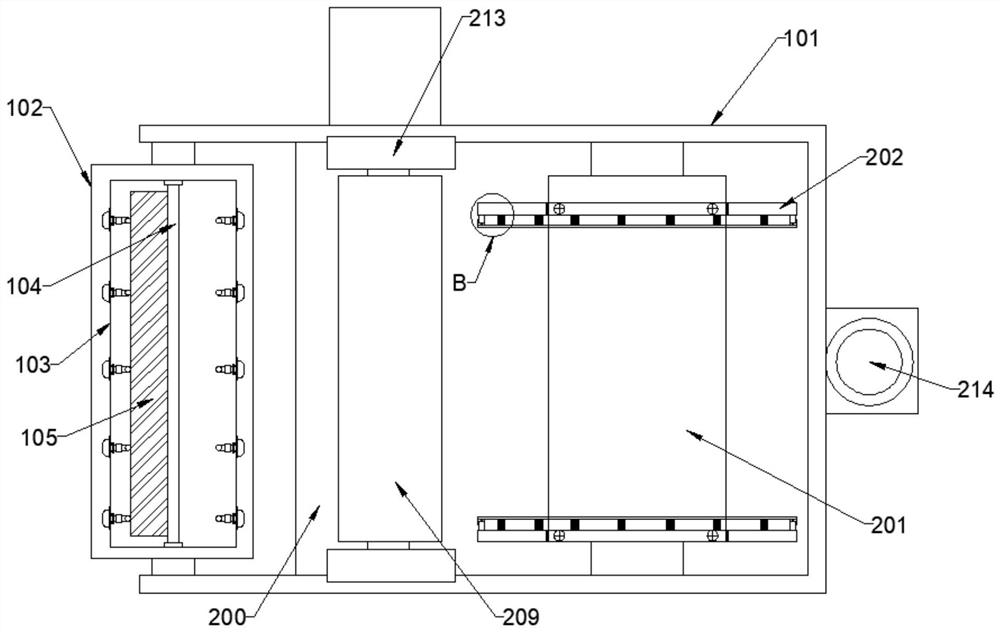

A New Type of Automatic Marble Composite Panel Manufacturing System

ActiveCN106401123BIncrease productivityAvoid substandard qualityCovering/liningsLamination ancillary operationsAssembly lineEngineering

The invention relates to a novel automatic manufacture system for marble composite plates. The novel automatic manufacture system is initiatively characterized by comprising a guide rail, pressing frame devices and driving mechanisms, wherein a glue applying area, a drying area, a cooling area and a plate unloading area are sequentially divided on the guide rail; the pressing frame devices move along each area of the guide rail circularly under the driving of the driving mechanisms; a glue applying device is arranged on one side of the glue applying area of the guide rail; a plate unloading device is arranged on one side of the plate unloading area of the guide rail; a passing-through-type drying box is arranged on the drying area of the guide rail; a close-loop-type rail structure is arranged, and the pressing frame devices move along the direction of the guide rail circularly through chains and gear pairs driven by a motor, so that assembly-line production and high automation of production of the marble composite pressing plates are realized; and production efficiency of the marble composite pressing plates is improved.

Owner:致尊建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com